Page 1

INSTALLATION AND

OPERATION MANUAL

GARLAND

S18-F AND S18-SF SERIES

RESTAURANT FRYERS

NRTL/C

FOR YOUR SAFETY:

DO NOT STORE OR USE GASOLINE

OR OTHER FLAMMABLE VAPORS OR

LIQUIDS IN THE VICINITY OF

THIS OR ANY OTHER

APPLIANCE

PLEASE READ ALL SECTIONS OF THIS MANUAL

AND RETAIN FOR FUTURE REFERENCE.

THIS PRODUCT HAS BEEN CERTIFIED AS

COMMERCIAL COOKING EQUIPMENT AND

MUST BE INSTALLED BY PROFESSIONAL

PERSONNEL AS SPECIFIED.

WARNING:

IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE

CAN CAUSE PROPERTY DAMAGE, INJURY,

OR DEATH. READ THE INSTALLATION,

OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR

SERVICING THIS EQUIPMENT

INSTALLATION AND ELECTRICAL CONNECTION

MUST COMPLY WITH CURRENT CODES:

IN CANADA - THE CANADIAN ELECTRICAL

CODE PART 1 AND / OR LOCAL CODES.

IN USA – THE NATIONAL ELECTRICAL CODE

ANSI / NFPA – CURRENT EDITION.

ENSURE ELECTRICAL SUPPLY CONFORMS WITH

ELECTRICAL CHARACTERISTICS SHOWN ON

THE RATING PLATE.

Users are cautioned that maintenance and repairs must be performed by a Garland authorized service agent

using genuine Garland replacement parts. Garland will have no obligation with respect to any product that has been

improperly installed, adjusted, operated or not maintained in accordance with national and local codes or installation

instructions provided with the product, or any product that has its serial number defaced, obliterated or removed,

or which has been modified or repaired using unauthorized parts or by unauthorized service agents.

For a list of authorized service agents, please refer to the Garland web site at http://www.garland-group.com.

The information contained herein, (including design and parts specifications), may be superseded and is subject

to change without notice.

GARLAND COMMERCIAL INDUSTRIES

185 East South Street

Freeland, Pennsylvania 18224

Phone: (570) 636-1000

Fax: (570) 636-3903

GARLAND COMMERCIAL RANGES, LTD.

1177 Kamato Road, Mississauga, Ontario L4W 1X4

CANADA

Phone: 905-624-0260

Fax: 905-624-5669

Part # P157 Rev 2 (01/06/10) © 2004 Garland Commercial Industries, Inc.

Part # P157 Rev 2(01/06/10) Page 1

Page 2

IMPORTANT INFORMATION

WARNING:

This product contains chemicals known to the state of California to cause cancer and/or birth defects

or other reproductive harm. Installation and servicing of this product could expose you to airborne

particles of glass wool/ceramic fibers. Inhalation of airborne particles of glass wool/ceramic fibers

is known to the state of California to cause cancer.

Part # P157 Rev 2 (01/06/10)Page 2

Page 3

TABLE OF CONTENTS

IMPORTANT INFORMATION..........................................2

DIMENSIONS AND SPECIFICATIONS ..................................4

Exterior Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

INTRODUCTION.....................................................5

General Information .............................................................5

Safety ...........................................................................5

Rating Plate ......................................................................5

Product Information .............................................................6

INSTALLATION......................................................6

Unpacking .......................................................................6

Siting ............................................................................6

Clearances .......................................................................7

Appliances Equipped With Legs ..................................................7

Appliances Equipped With Casters ................................................7

Ventilation .......................................................................7

Electrical Supply .................................................................7

Single and Three Phase Connection ...............................................7

Commissioning ..................................................................7

Preparation Before Use ...........................................................8

OPERATION.........................................................8

Filling the Tank. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Operating Instructions ...........................................................8

High Temperature Cuto/Reset ...................................................8

Operating Controls. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Operation Safety .................................................................9

Suggestions for Quality Fried Products ............................................9

MAINTENANCE AND CLEANING.....................................10

Frying Compound ..............................................................10

Stainless Steel ..................................................................10

Enamelled / Painted Surfaces ....................................................10

Thermostat Calibration ..........................................................10

Servicing .......................................................................11

Precautions .....................................................................11

Part # P157 Rev 2(01/06/10) Page 3

Page 4

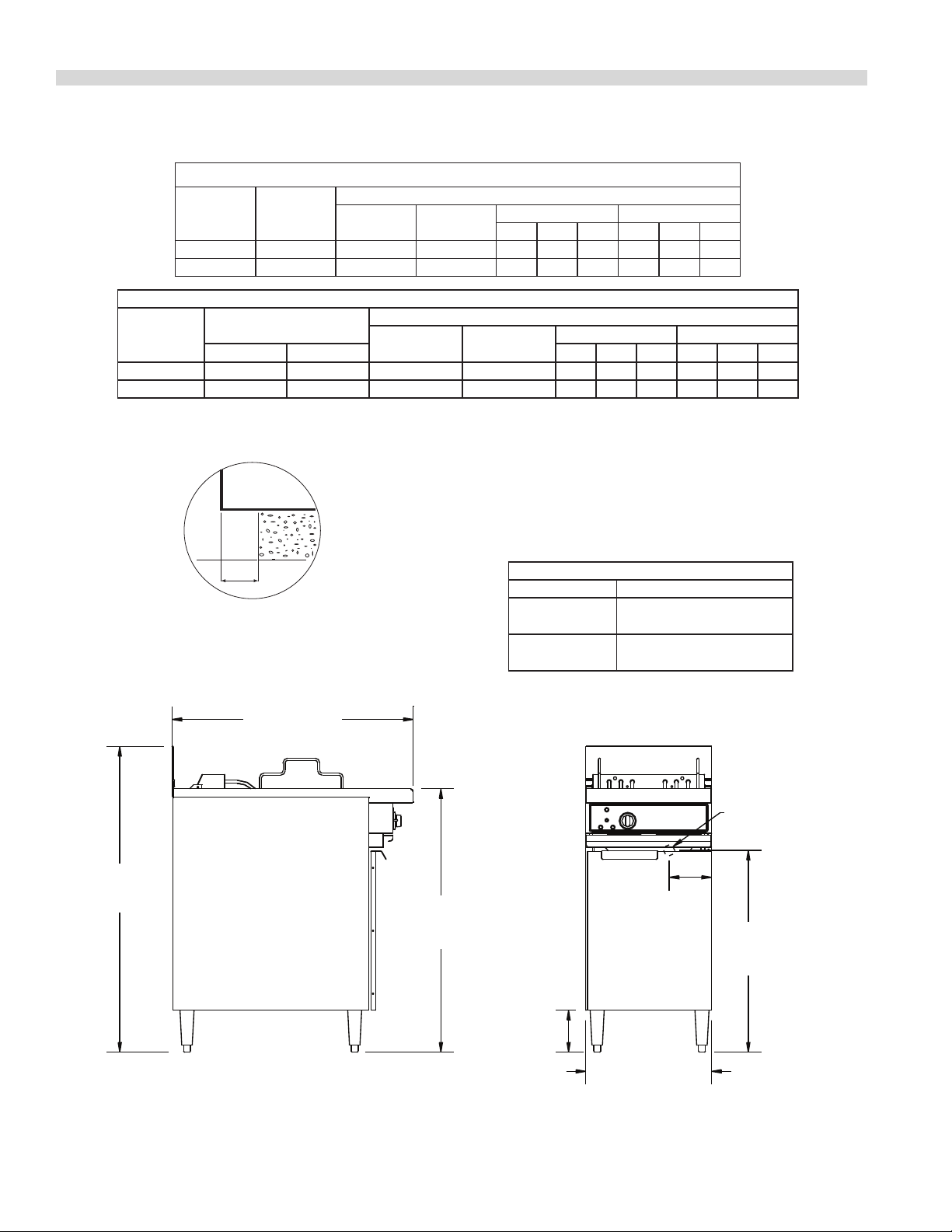

DIMENSIONS AND SPECIFICATIONS

North American (60 cycle) Electrical Loading:

Model

S18F 12 58 50 34 34 34 28.9 28.9 28.9

S18SF 16 77 66.7 49 38 49 41.8 41.8 32.5

Model

220/380V 240/415V XYZXYZ

S18F 10.1 12 46.2 50 15.4 15.4 15.4 16.7 16.7 16.7

S18SF 13.4 16 61.1 66.7 17.2 26.7 17.2 18.8 29.2 18.8

Total

kW

Total kW

208v/1Ø 240V/1Ø

Export (50 cycle) Electrical Loading:

220/380V/ 1Ø240/415V/ 1Ø220/380/3Ø 240/415V/3Ø

Nominal Amperes Per Line

Nominal Amperes Per Line

208V/3Ø 240V/3Ø

XYZXYZ

DAIS Installation:

FRYER

MAX

2-/12"

[64mm]

Frying area is 13” (330mm) wide x 15-1/2” (394mm) deep.

34-1/2"

[877mm]

43-3/4"

[1111mm]

37-3/4"

[959mm]

Installation Clearances:

Clearance to combustible surfaces

Sides: 1” (25mm) Rear: 1-1/2” (38mm)

NOTE: Many local codes exist, and it is the

responsibility of the Owner and the Installer to comply

with those codes.

Production Capacity (per hour)

Model French Fries

S18F

S18SF

Frozen to Done

50 lbs. /23kg

Frozen to Done

60 lbs./ 27kg

REAR

ELECTRICAL

CONNECTION

6"

[152mm]

28-7/8"

[733mm]

6"

[152mm]

18"

[457mm]

Frying area is 13" (330mm) wide x 15-1/2" (394mm) deep

Part # P157 Rev 2 (01/06/10)Page 4

Page 5

DIMENSIONS AND SPECIFICATIONS continued

Exterior Dimensions

Model Height* Width Depth Weight

S18-(F,SF) 37-3/4” (959mm) 18” (457mm) 34-1/2” (876mm) 140Lb/64Kg

* Height from front rail to oor

NOTE: Height Dimensions specied with 6” (152mm) legs.

INTRODUCTION

You have purchased the nest Commercial cooking

Equipment available. Like any ne precision built piece of

equipment it should be given regular care and maintenance.

The following instructions should be read carefully as the

manufacturer can not be held responsible for any damage

to property or persons caused by incorrect installation or

operation of the equipment.

General Information

1. Check the crate for possible damage sustained during

transit. Carefully remove the unit from the crate and

again check for damage. Any damage to the unit must be

reported to the carrier immediately.

2. Any protective material covering stainless steel parts

must be removed.

3. All fryers are shipped from the factory with legs or casters

tted unless specially ordered without.

4. The type of voltage supply that the equipment was

manufactured for at the factory is noted on the data plate

and on the packaging. This type of supply must be used.

5. Do not remove permanently axed labels, warnings

or data plates from the appliance, for this may void

approvals and creates a safety hazard.

Safety

A qualied person must make the installation of these

products in accordance with the local codes of the country of

destination.

Always follow these safety precautions when operating the

fryer.

The unit must only be operated by qualied persons. DO

NOT operate without reading this manual.

DO NOT operate the product unless it has been properly

installed and earthed.

DO NOT operate the product unless all service and access

panels are in place and fastened properly.

DO NOT attempt to repair or replace any part of this product

unless all main power supplies have been disconnected.

WARNING: to avoid serious personal injury: Use extreme

caution in setting up, operating and cleaning this product to

avoid coming in contact with hot surfaces or hot oil. Suitable

protective clothing should be worn to prevent the risk of

burns.

NOTE all warning labels and markings on the product,

which call attention to further dangers and necessary

precautions.

WARNING: this appliance must not be cleaned with a

water jet.

This manual pertains to fryers. The reader/operator must

interpret its contents to applicable needs. If there is any

question of interpretation of any of the literature pertaining

to Garland fryers, please contact your Authorized Service

Agency or our Customer Service Department at the phone

number listed on the front of this manual.

Part # P157 Rev 2(01/06/10) Page 5

Rating Plate

For proper operation, the information on the data plate of

your new equipment must match your electrical supply.

The data plate is readily accessible, located on the inside of

the cabinet door. It contains all of the pertinent information

required by the installer.

Page 6

INTRODUCTION continued

When corresponding with the factory or your equipment

dealer regarding service problems or replacement parts,

be sure to refer to the particular unit by the correct model

number, including prex and sux letters and numbers and

serial number. The rating plate axed to the unit contains

this information.

INSTALLATION

The Garland S18 series deep fat fryer complies with the

standards CSA C22.2 No. 109 – latest edition, the UL197 –

latest edition and the NSF#4 – latest edition. The installation

& connection of this appliance must comply with current

codes. In Canada – the Canadian Electric Code Part 1 and in

the USA – The National Electrical Code.

Product Information

The deep fat fryer is one of the more versatile products in

today’s kitchen. Its ability to cook a variety of products in

large quantities makes it the most common & economical

choice. The Garland restaurant series fryer is designed to be

installed free standing or in battery with Garland S, SS, SU680

series ranges.

Cooking larger quantities of food can be done more

eciently than small quantities. Product is cooked directly in

the oil using the lift out wire baskets supplied.

Unpacking

1. Carefully remove the unit from the crate. All packing

material must be removed from the unit. The protective

material covering the stainless steel must be removed

immediately after the unit is installed.

Your new equipment must be installed and adjusted by

a competent person as required by the local electrical

authorities. Failure to install appliances correctly could lead

to prosecution. It is in your own interests and that of safety to

ensure that the law is complied with.

Your Garland Dealer is well qualied to provide this service.

Periodic inspections by your dealer or a qualied service

company are recommended to check temperatures and to

ensure moving parts are operative. Wherever possible avoid

overheating idle equipment, as this is the primary cause for

increased service cost.

2. Do not remove permanently axed labels, warnings

or data plates from the appliance, for this may void

approvals and creates a safety hazard.

Siting

The fryer should be installed on a rm smooth and level oor

designed to withstand the weight of the appliance and any

ancillary equipment. (Refer to dimensions and specications

section for weights). Once in position check that the

equipment is level, the fryer must be level front to back, side

to side and diagonally. This leveling must be done with the

unit under the hood and in it’s normal operational position.

Adjust if necessary.

If the fryer is to be dais or cove mounted, the base on which

it is to be set should be level. If it is not, the fryer must be

shimmed to level.

Part # P157 Rev 2 (01/06/10)Page 6

Page 7

INSTALLATION continued

Clearances

The space in which the appliance is to be sited must include

the minimum installation clearances to combustible surfaces

as indicated in the following table.

CLEARANCE TO COMBUSTIBLE MATERIAL

Location All Models

Top *

Left Hand Side 1” (25mm)

Right Hand Side 1” (25mm)

Rear 1.5” (38mm)

Type of Floor or Base Combustible

* NOTE Equipment must be installed

under a ventilation canopy

Adequate clearance must be provided for servicing,

ventilation & proper operation. The product must be kept

free from combustible material.

Appliances Equipped With Legs

All Fryers are shipped from the factory with legs installed

unless otherwise specied. When the fryer is specied for

dais or cove mounting it is shipped less legs. Legs must be

adjusted to a minimum height of 6” (152mm) in order to

comply with NSF standards.

Appliances Equipped With Casters

1. The front casters on the unit are equipped with brakes to

limit the movement of the fryer without depending on

the electrical connection.

2. A restraint can be attached to the unit near the electrical

connection. If the restraint is disconnected be sure to

reconnect it after the fryer has been returned to its

original installed position.

Any ventilation system will break down if improperly

maintained. The duct system, the hood, and the lters must

be cleaned on a regular bases and kept clean.

Electrical Supply

CAUTION: Prior to installation check the electrical supply

to ensure input voltage and phase match the equipment

voltage rating and phase. See data plate located inside of the

cabinet door.

The supply entrance is located at the rear. The supply

terminal block is accessible from the front. The electrical

supply must be adequate for the voltage, phase & current

marked on the rating plate.

NOTE: A means of disconnection from the supply having

a contact separation of at least 3 mm in all poles must be

incorporated in the xed wiring.

This equipment is intended to be installed with xed

permanent wiring

WARNING: This appliance must be earthed.

Single and Three Phase Connection

Unless otherwise noted all fryers are shipped from the

factory for three phase connection. A wiring diagram is

attached to the rear of each fryer. Visually check all the

electrical connections. The fryer is wired at the factory

as specied on the order. If it is necessary to change the

phasing, refer to the wiring diagram.

Commissioning

Ensure all circuit breakers located in the lower compartment

are set to the ‘ON’ (1) position.

1. Ensure that all controls are in the o position and turn on

the main electrical supply.

Ventilation

The area in which the appliance is installed must be

adequately ventilated to provide air for removal of steam,

heat generated by the appliance, etc. These products are

intended to be installed under a ventilation hood. The use

of a mechanical extract system should be considered and

conform to local codes.

Proper operation of exhaust fans (proper speed, rotation and

adjustment) is essential. In addition a make-up air system

(HVAC) for the kitchen to supply fresh air is recommended.

Part # P157 Rev 2(01/06/10) Page 7

2. Operate the fryer in accordance with the operating

instructions.

3. Check that the product functions correctly and that the

voltage supply to the unit does not drop by more than

5% when all sections are operated simultaneously.

When the operation has been check, hand the instructions to

the user or purchaser for retention and instruct them in the

ecient and safe operation of the appliance.

Page 8

INSTALLATION continued

Preparation Before Use

After the fryer has been properly installed and checked for

operation, it will be necessary to clean the protective coating

from the tank as follows:

1. Turn the power service disconnect switch o.

2. Remove baskets from the fry tank.

3. Lift the element handle until the heating elements are in

full raised position.

OPERATION

Filling the Tank

4. Lift the tank out of the fryer for cleaning. If a special fry

tank cleaner is used, carefully follow the manufacture’s

instructions for use. A soap, vinegar or baking soda

solution may be used for cleaning the tank. Rinse the tank

thoroughly with clean, hot water and dry completely.

5. Replace the tank in the fryer. If the tank has the optional

drain valve, make sure that this valve is tightly closed.

6. With the circuit breakers and toggle switch on the fryer

in the “OFF” position, turn on the power at the service

disconnect box.

Operating Instructions

Once the tank and elements have been cleaned the tank can

be lled with oil.

1. If Liquid frying compound is used, ll the tank to the ‘Full’

mark stamped on the inside of the tank. Do not over ll

the tank.

2. If hydrogenated or solid frying compound is used,

measure 30 lbs (13.6 kg). Pack the compound rmly

around the heating unit. The elements must be

completely covered with compound. Start the fryer

and set the thermostat to 250°F (121°C). Operate at this

temperature until the compound is completely melted.

Operating at higher temperatures can scorch the frying

compound.

3. For optimum frying compound life, it has been

recommended by the manufactures of the compound

limit the maximum operating temperature to 375°F

(190°C) on S18F models and 350°F (177°C) on S18SF

models.

The S18 series fryers are equipped with a temperature

limiting safety system. To start the fryer operating:

1. Turn the thermostat to the “OFF” position.

2. Lift the toggle switch to the start position (momentarily

up).

3. Release the switch. It will return to the run position. The

green indicator lamp should be illuminated.

4. Turn the thermostat dial to the desired temperature.

High Temperature Cuto/Reset

Your Garland Fryer is equipped with a protective secondary

thermostat. If the operating thermostat fails to control

the temperature, the secondary (Hi-Limit) thermostat will

take over. It will cut o power to the heating elements if

the frying compound reaches a temperature greater than

430°F (221°C). The system cannot be reset until the frying

compound drops in temperature by approximately 50°F

(28°C). Repeating the starting procedure can reset the

system.

Part # P157 Rev 2 (01/06/10)Page 8

Page 9

OPERATION continued

D

If this condition occurs, it could indicate that the operating

thermostat has become damaged. A qualied service

technician should check the fryer. Continued operation

of the fryer in this condition will deteriorate the frying

compound and degrade the product quality.

Operating Controls

Control Panel, Symbols and Indicators

OVER TEMPERATURE

(HIGH LIMIT) SYMBOL

AND INDICATOR - RE

ON

START

POWER

SWITCH

Thermostat Dial

Degrees F

0

0

3

0

1

0

3

0

0

2

0

5

2

F

˚

3

7

5

3

5

0

3

0

0

Operation Safety

It is the responsibility of the supervisor or equivalent

person to ensure that users of this equipment wear suitable

protective clothing and to draw attention to the fact that

some parts will be necessity, become very hot and will cause

burns if touched accidentally.

Suggestions for Quality Fried Products

Thermostat Dial

Degrees C

OFF

POWER SYMBOL

AND INDICATOR

GREEN

5

9

0

2

1

HEATING SYMBOL AND

INDICATOR - AMBER

C

˚

1

9

0

1

7

5

1

5

0

Clean equipment is vital to the quality of fried foods. Fresh

uncontaminated frying compounds produce better fried

foods.

1. Taste the frying compound once a day. Your patrons do,

when they eat the product.

2. Filter the frying compound daily. Use a proper lter and

cone or a lter system.

3. Drain or dry foods before frying. Excessive moisture and

water breaks down frying compound.

4. Do not salt or otherwise season food over the fryer.

This practice contaminates the frying compound and

accelerates its deterioration.

5. Do not shake breaded items over the fryer.

6. Keep the fry tank covered when not in use. This will

prevent air from oxidizing the frying compound and will

keep impurities out.

Part # P157 Rev 2(01/06/10) Page 9

Page 10

OPERATION continued

7. Watch for the signs of shortening break down. An

unusual darkening of the shortening or smoking are the

rst signs of break down. Foaming, objectionable change

in avour of the product and fuming also indicate a break

down of the frying compound.

MAINTENANCE AND CLEANING

NOTE: This Appliance is not Protected against Water Jets. Do

not Clean with Water Jets.

Frying Compound

It is important to keep the cooking oil clean. The frequency

of change depends on the amount of use and the type of

products cooked.

Stainless Steel

Stainless steel should be cleaned using a mild detergent,

a soft cloth and hot water. If it is necessary to use a nonmetallic scouring pad, always rub in the direction of the grain

in the metal to prevent scratching. Wash a small area at a

time and rinse the washed area with a clean sponge dipped

into a disinfectant and wipe dry with a soft clean cloth before

it can dry.

Use only stainless steel, wood or plastic tools to scrape

o heavy deposits of grease or oil. Do not use ordinary

steel scrapers or knives, as particles of iron may become

embedded and rust.

NEVER USE STEEL WOOL.

Enamelled / Painted Surfaces

Establish a regular cleaning schedule. Any spills should be

wiped o immediately. The unit should be allowed to cool

down before cleaning any exterior surfaces. Wipe exposed

surfaces when cool with mild detergent and hot water.

Stubborn residue spots may be removed with scouring pad.

Dry thoroughly with a clean cloth.

8. Set the thermostat to 200°F (93°C) during idle periods. This

will conserve energy and extend frying compound life.

Thermostat Calibration

WARNING: Turn o the electrical mains before commencing

any service work.

It is normal for an electromechanical thermostat to cycle

with a 45° F - 50°F (25°C - 28°C). When checking calibration,

allow the thermostat to cycle a minimum of two times.

1. Place the thermocouple of the test instrument in the

center of the tank 1” (25mm) below the oil surface.

2. Turn the thermostat dial to 325° F (163° C). In order to

allow the oil temperature to stabilize, the control must be

allowed to cycle twice before taking a test reading.

3. Check the temperature reading just when the control

cycles “OFF” as indicated by the cycle pilot lamp. If the

temperature does not read within 15°F (8°C) of the dial

setting, recalibrate as follows:

4. Carefully remove the thermostat dial, not disturbing the

dial setting.

5. Hold the thermostat shaft steady and with a small at

blade screw driver, turn the calibration screw located

inside the shaft clockwise to decrease the temperature

and counter clock wise to increase the temperature.

NOTE: Each 1/4 turn of the screwdriver will create a

change of approximately 35° F (20° C).

6. Replace the thermostat dial and repeat steps 1 through 3

to verify that correct adjustment has been made.

Part # P157 Rev 2 (01/06/10)Page 10

Page 11

MAINTENANCE AND CLEANING continued

Servicing

To ensure ecient and safe operation of the appliance it

is recommended that servicing is carried out at regular

intervals, the frequency of which will vary, depending on the

installation conditions and usage. Usually once per year is

adequate.

Competent persons in accordance with the law must carry

out servicing.

Precautions

It is essential that the instructions in this booklet be strictly

followed for the safe and economical operation of the

equipment. If it is known or suspected that a fault exists on

the appliance then it must not be used until a competent

person has rectied the fault.

Part # P157 Rev 2(01/06/10) Page 11

Page 12

Page 13

Page 14

une personne compétente.

devez pas l’utiliser tant que celle-ci n’a pas été corrigée par

soupçonnez que l’appareil présente une défaillance, vous ne

sécuritaire et économique de l’équipement. Si vous savez ou

soient strictement suivies a n d’assurer le fonctionnement

IIl est essentiel que les instructions de la présente brochure

Sécurité

entretien selon les dispositions de la loi.

Seules des personnes compétentes peuvent e ectuer cet

entretien annuel est généralement su sant.

fonction des conditions d’installation et d’utilisation. Un

à intervalles périodiques, selon une fréquence qui sera

de l’appareil, on recommande d’en e ectuer l’entretien

Pour assurer le fonctionnement e cace et sécuritaire

Pièce n° P157 Rev 2(01/06/10) Page 11

du bassin, à 1 po (25 mm) sous la surface de l’huile.

1. Placer le thermocouple de l’instrument d’essai au centre

au moins deux fois.

Pour véri er l’étalonnage, laisser le thermostat se déclencher

déclenche à une température de 45° F - 50°F (25°C - 28°C).

Il est normal qu’un thermostat électromécanique se

commencer les travaux de réparation.

AVERTISSEMENT : Couper l’alimentation électrique avant de

Étalonnage Du Thermostat

chi on propre.

être éliminés avec un tampon à récurer. Bien essuyer avec un

chaude et un détergent doux. Les résidus rebelles peuvent

les surfaces exposées quand elles sont froides avec de l’eau

l’appareil avant de nettoyer les surfaces extérieures. Essuyer

devront être essuyés immédiatement. Laisser refroidir

Établir un calendrier de nettoyage régulier. Les déversements

Surfaces Émaillées/Peintes

Entretien

étapes 1 à 3 pour véri er que le réglage est correct.

6. Remettre en place le cadran du thermostat et répéter les

25°F(14°C).

1/4 de tour de la vis modi e la température d’environ

pour augmenter la température. REMARQUE : Chaque

ou dans le sens contraire des aiguilles d’une montre

des aiguilles d’une montre pour diminuer la température

plat la vis d’étalonnage à l’intérieur de l’axe dans le sens

5. En immobilisant l’axe, tourner avec un petit tournevis

modi er le réglage du cadran.

4. Retirer soigneusement le cadran du thermostat, sans

réétalonner comme suit :

di ère de plus de 15°F (8°C) de la température du cadran,

par le témoin de chau age. Si la température indiquée

commande ferme l’élément chau ant comme indiqué

3. Véri er l’indication de température juste avant que la

lecture d’essai.

commande se déclencher deux fois avant de faire une

la température de l’huile se stabiliser, il faut laisser la

2. Tourner le thermostat sur 325° F (163° C). A n de laisser

NE JAMAIS UTILISER DE LAINE D’ACIER.

de s’incruster dans les surfaces et rouiller.

couteaux en acier ordinaire, car des particules de fer risquent

de graisses ou d’huiles. Ne pas utiliser de grattoirs ni de

ou en plastique pour gratter si nécessaire les résidus tenaces

Utiliser uniquement des outils en acier inoxydable, en bois

avec un chi on doux propre avant que la surface ait séché.

une éponge trempée dans un produit désinfectant et sécher

Laver une petite surface à la fois, rincer la surface lavée avec

toujours dans le sens du grain a n d’éviter de rayer le métal.

d’utiliser un tampon à récurer non métallique, frotter

doux, un chi on et de l’eau chaude. S’il est nécessaire

L’acier inoxydable devra être nettoyé avec un détergent

Acier Inoxydable

et du type de produit cuit.

fréquence des changements dépend de la quantité utilisée

Il est important de maintenir l’huile de cuisson propre. La

Produit À Friture

d’eau. Ne pas nettoyer avec un jet d’eau.

REMARQUE : Cet appareil n’est pas protégé contre les jets

ENTRETIEN ET NETTOYAGE

Page 15

Pièce n° P157 Rev 2 (01/06/10)Page 10

brûlures si on les touche.

deviennent très chaudes par nécessité et causeront des

et d’attirer leur attention sur le fait que certaines pièces

équipement portent des vêtements de protection adaptés

durée de vie du produit à friture.

d’inactivité. Cela économisera l’énergie et prolongera la

8. Régler le thermostat à 200°F (93°C) pendant les périodes

équivalente de s’assurer que les utilisateurs de cet

Il est de la responsabilité du superviseur ou d’une personne

Sécurité De Fonctionnement

également une décomposition du produit à friture.

inacceptable du produit et un encrassement indiquent

La formation de mousse, un changement de saveur

0

de la fumée sont les premiers signes de décomposition.

friture. Un assombrissement inhabituel du produit ou

7. Observer les signes de décomposition du produit à

les impuretés de tomber dedans.

utilisé. Cela empêchera l’air d’oxyder le produit à friture et

0

3

0

5

3

5

7

3

2

5

0

2

0

0

6. Maintenir le bassin de friture couvert quand il n’est pas

3

0

1

0

friteuse.

˚

F

3

0

0

5. Ne pas secouer les produits panés au-dessus de la

accélère sa détérioration.

friteuse. Cette pratique contamine le produit à friture et

4. Ne pas saler ni assaisonner les aliments au-dessus de la

Degrés F

Cadran Du Thermostat

friture.

Un excès d’humidité et d’eau décompose le produit à

3. Laisser s’égoutter ou sécher les aliments avant de les frire.

un cône ou un système de ltration adaptés.

2. Filtrer chaque jour le produit à friture. Utiliser un ltre et

font, quand ils mangent l’aliment frit.

5

7

1

0

9

1

0

5

1

1

2

0

9

5

1. Goûter le produit à friture une fois par jour. Les clients le

˚

donne de meilleurs produits frits.

C

des aliments frits. Un produit à friture frais et non contaminé

Il est essentiel que l’équipement soit propre pour la qualité

Degrés C

Suggestion Pour Des Aliments Frits De Qualité

Cadran Du Thermostat

UTILISATION suite

Page 16

N

AMBRE

A

DE CHAUFFAGE –

SYMBOLE ET TÉMOIN

ÉTEINT

Pièce n° P157 Rev 2(01/06/10) Page 9

répétant la procédure de démarrage.

à environ 50°F (28°C). On peut réenclencher le système en

avant que la température du produit à friture ne descende

à 430°F (221°C). Le système ne peut pas être réenclenché

si le produit à friture atteint une température supérieure

coupera l’alimentation électrique des éléments chau ants

thermostat secondaire (à maximum,) prendra la relève. Il

fonctionnement ne contrôle pas la température, le

secondaire de protection. Si le thermostat de

Cette friteuse Garland est équipée d’un thermostat

De Température Élevée

Coupure/Réenclenchement En Cas

4. Tourner le thermostat sur la température souhaitée

fonctionnement. Le témoin vert devrait être allumé.

TÉMOIN D'ALIMENTATION - VERT

SYMBOLE ET

3 Relâcher l’interrupteur. Il revient en position de

démarrage (action momentanée sur le haut).

2. Soulever l’interrupteur à bascule en position de

1. Tourner le thermostat en position «OFF».

marche la friteuse :

sécurité de limitation de la température. Pour mettre en

Les friteuses série S18 sont équipées d’un système de

Instructions D’utilisation

D'ALIMENTATIO

INTERRUPTEUR

DÉMARRAGE

(À MAXIMUM)

EXCESSIVE

TEMPÉRATURE

(ROUGE) DE

TÉMOIN

SYMBOLE ET

LLUMÉ

Panneau De Commande, Symboles Et Témoins

Commandes

frits.

produit à friture et de la qualité des produits alimentaires

d’utiliser la friteuse dans cet état causera la détérioration du

service quali é de véri er la friteuse. Le fait de continuer

service est endommagé. Demander à un technicien de

Dans ce cas, cela pourrait indiquer que le thermostat de

modèles S18F et à 350°F (177°C) sur les modèles S18SF.

maximale d’utilisation du produit à 375°F (190°C) sur les

fabricants recommandent de limiter la température

3. Pour une durée de vie optimale du produit à friture, les

élevée peut faire brûler le produit.

friture soit complètement fondu. Une température plus

la friteuse à cette température jusqu’à ce que le produit à

la friteuse et régler le thermostat à 250°F (121°C). Utiliser

complètement couverts par le produit à friture. Allumer

des éléments chau ants. Les éléments doivent être

solide, mesurer 30 livres (13,6 kg). Tasser le produit autour

2. En cas d’utilisation de produit à friture hydrogéné ou

du bassin. Ne pas trop remplir le bassin.

bassin jusqu’à la marque «Full» estampée sur l’intérieur

1. En cas d’utilisation de produit à friture liquide, remplir le

nettoyés, on peut remplir d’huile le bassin.

Une fois que le bassin et les éléments chau ants ont été

Remplissage Du Bassin

UTILISATION

Page 17

Pièce n° P157 Rev 2 (01/06/10)Page 8

utilisation e cace et sécuritaire des appareils.

à l’acheteur pour qu’il le conserve et s’en serve pour une

commandes en position d’arrêt. Laisser le présent manuel

Une fois le fonctionnement véri é, tourner toutes les

simultanément.

de plus de 5 % quand toutes les sections sont activées

électrique.

friteuse en position «OFF», brancher l’alimentation

6. Avec les disjoncteurs et l’interrupteur à bascule de la

est bien fermé.

un robinet de vidange en option, véri er que le robinet

5. Remettre en place le bassin dans la friteuse. Si le bassin a

parfaitement.

le bassin avec de l’eau chaude propre et sécher

de soude pour nettoyer le bassin. Rincer soigneusement

utiliser une solution de savon, vinaigre ou bicarbonate

de friture, suivre les instructions du fabricant. On peut

d’utilisation d’un produit spécial de nettoyage du bassin

4. Lever le bassin hors de la friteuse pour le nettoyer. En cas

levée.

éléments chau ants soient en position complètement

3. Soulever la poignée des éléments jusqu’à ce que les

l’alimentation électrique de chaque appareil ne chute pas

3. Véri er que l’appareil fonctionne correctement et que

2. Activer l’appareil conformément aux instructions.

d’arrêt et mettre l’appareil sous tension.

1 S’assurer que toutes les commandes sont en position

inférieur sont réglés en position ON (1).

Véri er que tous les disjoncteurs situés dans le compartiment

Mise En Service

modi er le phasage, se reporter au schéma de câblage.

usine comme spéci é sur la commande. S’il est nécessaire de

toutes les connexions électriques. La friteuse est câblée en

est xé à l’arrière de chaque friteuse. Véri er visuellement

l’usine pour une connexion triphasée. Un schéma de câblage

Sauf indication contraire, toutes les friteuses sont livrées de

Connexion Mono Et Triphasée

2. Retirer les paniers du bassin de friture.

AVERTISSEMENT : Cet appareil doit être relié à la terre.

1. Débrancher l’alimentation électrique.

câblage xe permanent.

revêtement de protection du bassin de la façon suivante :

véri ée pour être utilisée, il sera nécessaire de nettoyer le

Une fois que la friteuse a été correctement installée et

Préparation Avant Utilisation

Cet équipement est prévu pour une installation avec un

tous les pôles doit être intégré au câblage xe.

une séparation des contacts d’au moins 3 mm (0,12 po) pour

REMARQUE : Un moyen de coupure de l’alimentation avec

INSTALLATION suite

Page 18

signalétique pour la tension, les phases et l’intensité.

électrique doit correspondre aux indications de la plaque

d’alimentation est accessible depuis l’avant. L’alimentation

L’entrée d’alimentation est située à l’arrière. Le bornier

meuble.

la plaque signalétique située à l’intérieur de la porte du

correspondent aux caractéristiques de l’équipement. Voir

électrique pour s’assurer que la tension d’entrée et les phases

ATTENTION : Avant l’installation, véri er l’alimentation

Alimentation Électrique

doivent être nettoyés régulièrement et maintenus propres.

entretenu. Le système de conduits, la hotte et les ltres

Tout système de ventilation tombera en panne s’il est mal

pour alimenter la cuisine en air frais.

est recommandé d’avoir un système d’air d’appoint (CVAC)

(vitesse, rotation et réglage corrects) est essentiel. En plus, il

Un bon fonctionnement des ventilateurs d’extraction

d’extraction mécanique conforme aux codes locaux.

de ventilation. On doit envisager d’utiliser un système

etc. Ces produits doivent être installés sous une hotte

combustion, l’évacuation des produits de combustion,

ventilé a n de permettre l’admission d’air pour la

L’endroit où l’appareil est installé doit être convenablement

Ventilation

position d’installation d’origine.

oublier de le rebrancher après avoir remis le four dans sa

de l’entrée du gaz. Si le dispositif est débranché, ne pas

2. Le dispositif de retenue peut être xé à l’appareil près

aucun e ort sur les connexions électriques.

pour limiter le déplacement de frituese sans exercer

1. Les roulettes avant de l’appareil seront équipées de freins

Appareils Équipés De Roulettes

(152 mm) pour respecter les normes NSF.

Les pieds doivent ajustés à une hauteur minimale de 6 po

montée sur une estrade, elle est expédiée sans les pieds.

d’usine avec des pieds installés. Quand la friteuse doit être

Sauf indication contraire, toutes les friteuses sont expédiées

Pièce n° P157 Rev 2(01/06/10) Page 7

des matériaux combustibles.

ventilation et l’utilisation. L’appareil doit être tenu à l’écart

Un dégagement su sant doit être prévu pour l’entretien, la

hotte de ventilation.

* REMARQUE : L’équipement doit être installé sous une

Type De Plancher Ou Base Combustible

Arrière 1.5 Po (38mm)

Côté Droit 1 Po (25mm)

Côté Gauche 1 Po (25mm)

Haut *

Emplacement Tous Les Modèles

AUX MATÉRIAUX COMBUSTIBLES

DÉGAGEMENT PAR RAPPORT

suivant.

surfaces combustibles, comme indiqué dans le tableau

comprendre les dégagements minimum par rapport aux

L’espace dans lequel l’appareil doit être installé doit

Dégagements

pas le cas, la friteuse doit être mise de niveau avec des cales.

laquelle elle doit être placée doit être de niveau. Si ce n’est

Si la friteuse doit être montée sur une estrade, la base sur

fonctionnement normale. Ajuster si nécessaire.

avec l’appareil sous la hotte et dans sa position de

en diagonale. Cette mise de niveau doit être e ectuée

être de niveau entre l’avant et l’arrière, entre les côtés et

est en place, véri er qu’il est de niveau; la friteuse doit

et spéci cations pour les poids). Une fois que l’appareil

l’équipement annexe. (Consulter la section Dimensions

niveau, conçu pour résister au poids de l’appareil et de

La friteuse doit être installée sur un sol solide, lisse et de

Implantation

annuler les agréments et créer un danger.

signalétiques xée de façon permanente car cela peut

2. Ne pas retirer les étiquettes, avertissements ou plaques

retirés aussitôt après l’installation de l’appareil.

protection des surfaces en acier inoxydable doivent être

emballant doit être retiré de l’appareil. Les matériaux de

1. Sortir avec précaution l’appareil du carton. Le matériau

Appareils Équipés De Pieds

Déballage

INSTALLATION suite

Page 19

Pièce n° P157 Rev 2 (01/06/10)Page 6

loi est respectée.

est de votre propre intérêt et sécurité de vous assurer que la

des appareils électriques pourrait entraîner des poursuites. Il

électriques locales. Le fait de ne pas installer correctement

représente la principale cause de coûts de réparation.

éviter de surchau er l’équipement inutilisé, car cela

pièces mobiles fonctionnement correctement. Si possible,

véri er les températures et les réglages et s’assurer que les

agence d’entretien quali ée sont recommandées pour

inspections périodiques par le concessionnaire ou une

sont parfaitement quali és pour fournir ce service. Des

Votre concessionnaire ou agence de service agréée Garland

personne compétente, conformément à la loi des autorités

Cet équipement neuf doit être installé et réglé par une

Electrical Code.

électrique canadien, partie 1 et aux É—U. – le National

être conformes aux codes en vigueur. Au Canada - le Code

L’installation et le branchement de cet appareil doivent

nº 109 – dernière édition et UL 197 – dernière édition.

La série Garland E22 est conforme aux normes CSA C22.2

INSTALLATION

signalétique xée à l’appareil contient ces renseignements.

du su xe) et le numéro de série de garantie. La plaque

correct (comprenant les lettres et chi res du pré xe et

bien faire référence à l’appareil avec le numéro de modèle

des problèmes de réparation ou des pièces de rechange,

avec l’usine ou le centre de service agréé local concernant

département de service des produits. Pour correspondre

autre produit Garland, écrire ou communiquer avec le

l’entretien ou la réparation de ce produit ou de tout

En cas de questions concernant l’installation, l’utilisation,

métallique relevables fournis.

directement dans l’huile en utilisant les paniers en l

d’aliments que de petites quantités Le produit est cuit

On peut cuire plus e cacement de grandes quantités

SU680 de Garland.

seule ou en batterie avec les cuisinières des séries S, SS et

série Restaurant de Garland est conçue pour être installée

l’appareil le plus répandu et le plus économique. La friteuse

toute une gamme de produits en grandes quantités, c’est

trouve dans les cuisines actuelles. Grâce à sa capacité à cuire

La friteuse est un des appareils les plus polyvalents que l’on

Information Sur Le Produit

informations nécessaires requises par l’installateur.

à l’intérieur de la porte du meuble. Elle contient toutes les

électrique. La plaque signalétique est d’accès facile et située

nouvel appareil doivent correspondre à votre alimentation

informations notées sur la plaque signalétique de votre

Pour que l’appareil fonctionne correctement, les

Plaque Signalétique

avec un jet d’eau.

AVERTISSEMENT : Ces appareils ne doivent pas être nettoyés

précautions nécessaires.

l’appareil, qui attirent l’attention sur les autres dangers et

NOTER : les étiquettes et marques d’avertissement sur

INTRODUCTION suite

Page 20

brûlures.

ou utiliser des ustensiles appropriés pour éviter les risques de

chaudes. Porter des vêtements de protection convenables

de cet appareil, à éviter tout contact avec les surfaces

attention, lors de l’installation, de l’utilisation et du nettoyage

AVERTISSEMENT : Pour éviter les blessures, faire très

alimentations électriques.

partie de ces appareils avant d’avoir débranché toutes les

NE PAS essayer de réparer ou de remplacer n’importe quelle

d’accès ne sont pas en place et xés correctement.

NE PAS utiliser l’appareil si les panneaux d’entretien et

et relié à la terre.

NE PAS utiliser l’appareil s’il n’a pas été correctement installé

quali ée. NE PAS utiliser sans avoir lu le présent manuel.

Ces unités ne doivent être utilisées que par une personne

utiliser ces friteuses.

Toujours suivre les précautions de sécurité suivantes pour

destination.

quali ée conformément aux codes locaux du pays de

L’installation de ces produits doit être faite par une personne

Pièce n° P157 Rev 2(01/06/10) Page 5

annuler les agréments et créer un danger.

signalétiques xée de façon permanente car cela peut

5. Ne pas retirer les étiquettes, avertissements ou plaques

d’alimentation.

plaque signalétique et l’emballage On doit utiliser ce type

l’équipement a été fabriqué en usine est indiqué sur la

4. Le type d’alimentation électrique pour lequel

commande.

ou roulettes installés, sauf indication contraire dans la

3. Toutes les friteuses sont expédiées d’usine avec des pieds

inoxydable doit être retiré.

2. Le matériau de protection couvrant les pièces en acier

transporteur.

Tout dommage doit être immédiatement signalé au

de la caisse et véri er encore la présence de dommages.

transport. Sortir avec précaution l’appareil du carton ou

1 Véri er si la caisse/le carton a été endommagé pendant le

Informations Générales

du présent manuel.

clientèle au numéro de téléphone gurant sur la couverture

contactez votre agence de service agréée ou notre service à

besoins. En cas de problèmes d’interprétation de documents,

opérateur doit interpréter son contenu en fonction de ses

Le présent manuel concerne les friteuses. Le lecteur/

Sécurité

équipement.

causés par une mauvaise installation ou utilisation de cet

pour responsable de dommages matériels ou corporels

instructions suivantes car le fabricant ne peut pas être tenu

de façon régulière. Il est nécessaire de lire attentivement les

fabriqué avec précision, il devra être nettoyé et entretenu

de cuisson au monde. Comme tout autre équipement

Vous venez d’acheter le meilleur équipement commercial

INTRODUCTION

REMARQUE : Dimensions de hauteur avec pieds de 6 po (152 mm).

* Hauteur du rail au plancher

S18-(F,SF) 37-3/4 Po (959mm) 18 Po (457mm) 34-1/2 PO (876mm) 140Lb/64Kg

Modèle Hauteur* Largeur Profondeur Poids

Dimensions Extérieures

DIMENSIONS ET SPÉCIFICATIONS suite

Page 21

[733mm]

28-7/8"

ARRIÈRE

ÉLECTRIQUE

CONNEXION

Pièce n° P157 Rev 2 (01/06/10)Page 4

La surface de friture est de 13 po (330 mm) de large x 15-1/2 po (394 mm) de profondeur.

[457mm]

18"

[152mm]

6"

[959mm]

[152mm]

6"

37-3/4"

[1111mm]

43-3/4"

[877mm]

34-1/2"

60 lbs./ 27kg

Congelées À Cuites

50 lbs. /23kg

Congelées À Cuites

S18SF

S18F

Modèle Frites

Capacité De Production (Par Heure)

respecter ces codes.

de la responsabilité du propriétaire et de l’installateur de

REMARQUE : Il existe de nombreux codes locaux et il est

Côtés : 1 po (25 mm) Arrière : 1-1/2 po (38 mm).

Dégagement par rapport aux surfaces combustibles.

Dégagements D’installation :

1Ø

220/380/3Ø 240/415V/3Ø

240/415V/

Intensité Nominale Par Ligne

1Ø

220/380V/

Charge Électrique Export (50 Cycles) :

2-/12"

MAX

FRITEUSE

Total kW

[64mm]

INSTALLATION SUR ESTRADE :

S18SF 13.4 16 61.1 66.7 17.2 26.7 17.2 18.8 29.2 18.8

S18F 10.1 12 46.2 50 15.4 15.4 15.4 16.7 16.7 16.7

220/380V 240/415V XYZXYZ

Modèle

po (394 mm) de profondeur.

La surface de friture est de 13 po (330 mm) de large x 15-1/2

S18SF 16 77 66.7 49 38 49 41.8 41.8 32.5

S18F 12 58 50 34 34 34 28.9 28.9 28.9

XYZXYZ

208V/3Ø 240V/3Ø

Intensité Nominale Par Ligne

208v/1Ø 240V/1Ø

kW

Total

Charge Électrique Nord-Américaine (60 Cycles) :

Modèle

DIMENSIONS ET SPÉCIFICATIONS

Page 22

Pièce n° P157 Rev 2(01/06/10) Page 3

Sécurité . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Entretien . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Étalonnage Du Thermostat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Surfaces Émaillées/Peintes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Acier Inoxydable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Produit À Friture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

ENTRETIEN ET NETTOYAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Suggestion Pour Des Aliments Frits De Qualité . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Sécurité De Fonctionnement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Commandes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Coupure/Réenclenchement En Cas De Température Élevée . . . . . . . . . . . . . . . . . . . . . . . .9

Instructions D’utilisation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Remplissage Du Bassin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

UTILISATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Préparation Avant Utilisation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Mise En Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Connexion Mono Et Triphasée . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Alimentation Électrique . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Appareils Équipés De Roulettes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Appareils Équipés De Pieds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Dégagements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Implantation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Déballage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

INSTALLATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Information Sur Le Produit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Plaque Signalétique . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Sécurité . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Informations Générales . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Dimensions Extérieures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

DIMENSIONS ET SPÉCIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

INFORMATIONS IMPORTANTES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

TABLE DES MATIÈRES

Page 23

Pièce n° P157 Rev 2 (01/06/10)Page 2

AVERTISSEMENT :

Californie comme causant le cancer.

L’inhalation de ces particules de laine de verre ou de fibres céramiques est reconnue par l’état de

et l’entretien de ce produit peut vous exposer aux poussières de laine de verre/fibres céramiques.

cancer et/ou des malformations congénitales ou d’autres problèmes de reproduction. L’installation

Ce produit contient des produits chimiques reconnus par l’état de Californie comme causant le

INFORMATIONS IMPORTANTES

Page 24

Pièce n° P157 Rev 2(01/06/10) Page 1

Pièce n° P157 Rev 2 (01/06/10) © 2004 Garland Commercial Industries, Inc.

Télécopieur : 905-624-5669

Téléphone : 905-624-0260

CANADA

1177 Kamato Road, Mississauga, Ontario L4W 1X4

GARLAND COMMERCIAL RANGES, LTD.

FIGURANT SUR LA PLAQUE SIGNALÉTIQUE.

CONFORME AUX CARACTÉRISTIQUES ÉLECTRIQUES

VÉRIFIER QUE L’ALIMENTATION ÉLECTRIQUE EST

NFPA – ÉDITION EN VIGUEUR.

AUX É.-U. – LE NATIONAL ELECTRICAL CODE ANSI /

L’ÉLECTRICITÉ, PARTIE 1 ET/OU LES CODES LOCAUX.

VIGUEUR :AU CANADA – LE CODE CANADIEN DE

DEVRONT ÊTRE CONFORMES AUX CODES EN

L’INSTALLATION ET LES CONNEXIONS ÉLECTRIQUES

SIONNEL TEL QUE SPÉCIFIÉ.

DOIT ÊTRE INSTALLÉ PAR DU PERSONNEL PROFESQU’ÉQUIPEMENT PROFESSIONNEL DE CUISSON ET

CE PRODUIT A ÉTÉ HOMOLOGUÉ EN TANT

MENT.

ET LE CONSERVER POUR S’Y REPORTER ULTÉRIEURELIRE TOUTES LES SECTIONS DU PRÉSENT MANUEL

Télécopieur : (570) 636-3903

Téléphone : (570) 636-1000

Freeland, Pennsylvanie 18224

185 East South Street

GARLAND COMMERCIAL INDUSTRIES, LLC

être modifiées à tout moment et sans préavis.

Les informations contenues dans le présent manuel (y compris les spécifications de conception et des pièces) peuvent

obtenir une liste des agences de service agréées, contacter le site web de Garland à l’adresse www.garland-group.com.

modifié, abîmé, effacé ou supprimé ou pour tout produit modifié ou réparé par des agents de service non autorisés. Pour

et locaux, ni les instructions d’installation fournies avec le produit ou pour tout produit dont le numéro de série a été

responsabilité pour les produits incorrectement installés, réglés, utilisés ou entretenus sans respecter les codes nationaux

par une entreprise de service agréée Garland utilisant des pièces de rechange d’origine Garland. Garland décline toute

Nous attirons l’attention des utilisateurs sur le fait que l’entretien et les réparations doivent être exécutés uniquement

RÉPARER L’ÉQUIPEMENT.

D’ENTRETIEN AVANT D’INSTALLER OU DE

D’INSTALLATION, D’UTILISATION ET

SOIGNEUSEMENT LES INSTRUCTIONS

DES BLESSURES OU LA MORT. LIRE

CAUSER DES DOMMAGES MATÉRIELS,

OU UN ENTRETIEN MAL FAITS PEUVENT

MODIFICATIONS, DES RÉPARATIONS

UNE INSTALLATION, DES RÉGLAGES, DES

AVERTISSEMENT :

APPAREIL OU DE TOUT AUTRE APPAREIL.

INFLAMMABLES À PROXIMITÉ DE CET

OU D’AUTRES VAPEURS OU LIQUIDES

NE PAS STOCKER NI UTILISER D’ESSENCE

POUR VOTRE SÉCURITÉ :

NRTL/C

FRITEUSES DE RESTAURANT

SÉRIE S18-F ET S18-SF

GARLAND

ET D’UTILISATION

MANUEL D’INSTALLATION

Loading...

Loading...