Page 1

INSTALLATION AND

SERVICING MANUAL

GARLAND

S18-F AND S18-FS SERIES

RESTAURANT FRYERS

NRTL/C

FOR YOUR SAFETY:

DO NOT STORE OR USE GASOLINE

OR OTHER FLAMMABLE VAPORS OR

LIQUIDS IN THE VICINITY OF

THIS OR ANY OTHER

APPLIANCE

PLEASE READ ALL SECTIONS OF THIS MANUAL

AND RETAIN FOR FUTURE REFERENCE.

THIS PRODUCT HAS BEEN CERTIFIED AS

COMMERCIAL COOKING EQUIPMENT AND

MUST BE INSTALLED BY PROFESSIONAL

PERSONNEL AS SPECIFIED.

WARNING:

IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE

CAN CAUSE PROPERTY DAMAGE, INJURY,

OR DEATH. READ THE INSTALLATION,

OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR

SERVICING THIS EQUIPMENT

INSTALLATION AND ELECTRICAL CONNECTION

MUST COMPLY WITH CURRENT CODES:

IN CANADA - THE CANADIAN ELECTRICAL

CODE PART 1 AND / OR LOCAL CODES.

IN USA – THE NATIONAL ELECTRICAL CODE

ANSI / NFPA – CURRENT EDITION.

ENSURE ELECTRICAL SUPPLY CONFORMS WITH

ELECTRICAL CHARACTERISTICS SHOWN ON

THE RATING PLATE.

Users are cautioned that maintenance and repairs must be performed by a Garland authorized service agent

using genuine Garland replacement parts. Garland will have no obligation with respect to any product that has been

improperly installed, adjusted, operated or not maintained in accordance with national and local codes or installation

instructions provided with the product, or any product that has its serial number defaced, obliterated or removed,

or which has been modified or repaired using unauthorized parts or by unauthorized service agents.

For a list of authorized service agents, please refer to the Garland web site at http://www.garland-group.com.

The information contained herein, (including design and parts specifications), may be superseded and is subject

to change without notice.

GARLAND COMMERCIAL INDUSTRIES

185 East South Street

Freeland, Pennsylvania 18224

Phone: (570) 636-1000

Fax: (570) 636-3903

GARLAND COMMERCIAL RANGES, LTD.

1177 Kamato Road, Mississauga, Ontario L4W 1X4

CANADA

Phone: 905-624-0260

Fax: 905-624-5669

Part # P156 Rev 1 (12/03/09) © 2004 Garland Commercial Industries, Inc.

Part # P156 Rev 1 (12/03/09) Page 1

Page 2

IMPORTANT INFORMATION

WARNING:

This product contains chemicals known to the state of California to cause cancer and/or birth defects

or other reproductive harm. Installation and servicing of this product could expose you to airborne

particles of glass wool/ceramic fibers. Inhalation of airborne particles of glass wool/ceramic fibers

is known to the state of California to cause cancer.

Part # P156 Rev 1 (12/03/09)Page 2

Page 3

TABLE OF CONTENTS

IMPORTANT INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

DIMENSIONS AND SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Exterior Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Siting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Rating Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Appliances Equipped With Legs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Appliances Equipped With Casters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Electrical Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Single and Three Phase Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

MAINTENANCE AND CLEANING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Thermostat Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

REPLACEMENT OF PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Thermostat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Indicator Lamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Heating Elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

FAULT FINDING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

APPENDIX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Wiring diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Part # P156 Rev 1 (12/03/09) Page 3

Page 4

DIMENSIONS AND SPECIFICATIONS

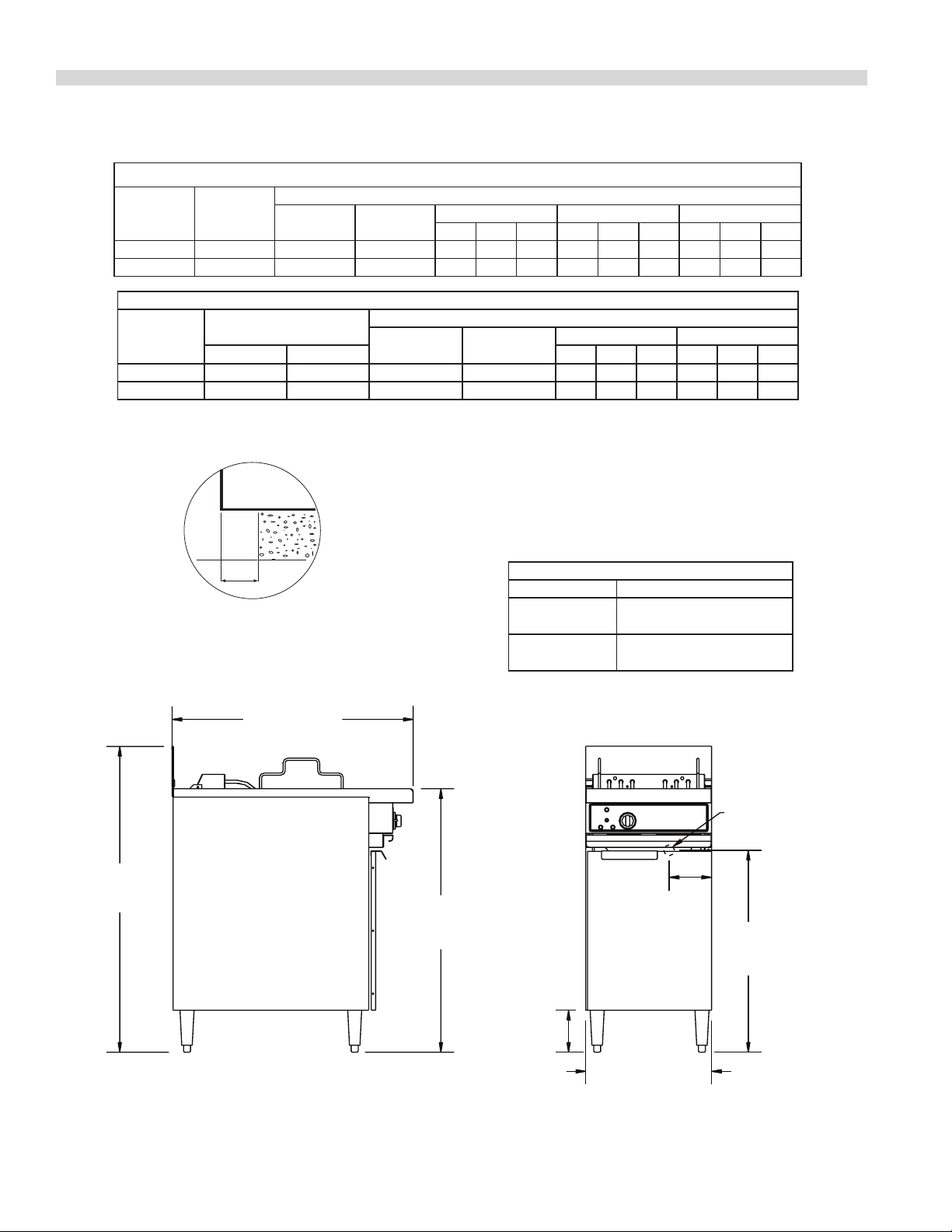

North American (60 cycle) Electrical Loading:

Model

S18F 12 58 50 34 34 34 28.9 28.9 28.9 15 15 15

S18SF 16 77 66.7 49 38 49 41.8 41.8 32.5 21 17 21

Model

S18F 10.1 12 46.2 50 15.4 15.4 15.4 16.7 16.7 16.7

S18SF 13.4 16 61.1 66.7 17.2 26.7 17.2 18.8 29.2 18.8

Total

kW

220/380V 240/415V X Y Z X Y Z

208v/1Ø 240V/1Ø

Export (50 cycle) Electrical Loading:

Total kW

220/380V/ 1Ø240/415V/ 1Ø220/380/3Ø 240/415V/3Ø

Nominal Amperes Per Line

208V/3Ø 240V/3Ø 480V/3Ø

X Y Z X Y Z X Y Z

Nominal Amperes Per Line

DAIS Installation:

FRYER

MAX

2-/12"

[64mm]

Frying area is 13” (330mm) wide x 15-1/2” (394mm) deep.

34-1/2"

[877mm]

43-3/4"

[1111mm]

37-3/4"

[959mm]

Installation Clearances:

Clearance to combustible surfaces

Sides: 1” (25mm) Rear: 1-1/2” (38mm)

NOTE: Many local codes exist, and it is the

responsibility of the Owner and the Installer to comply

with those codes.

Production Capacity (per hour)

Model French Fries

S18F

S18SF

Frozen to Done

50 lbs. /23kg

Frozen to Done

60 lbs./ 27kg

REAR

ELECTRICAL

CONNECTION

6"

[152mm]

28-7/8"

[733mm]

6"

[152mm]

18"

[457mm]

Frying area is 13" (330mm) wide x 15-1/2" (394mm) deep

Part # P156 Rev 1 (12/03/09)Page 4

Page 5

DIMENSIONS AND SPECIFICATIONS continued

Exterior Dimensions

Model Height* Width Depth Weight

S18-(F,SF) 37-3/4” (959mm) 18” (457mm) 34-1/2” (876mm) 140Lb/64Kg

* Height from front rail to oor

NOTE: Height Dimensions specied with 6” (152mm) legs.

INTRODUCTION

The following instructions should be read carefully as the

manufacturer can not be held responsible for any damage

to property or persons caused by incorrect installation or

operation of the equipment.

General Information

1. Check the crate for possible damage sustained during

transit. Carefully remove the unit from the crate and

again check for damage. Any damage to the unit must be

reported to the carrier immediately.

2. Any protective material covering stainless steel parts

must be removed.

3. All fryers are shipped from the factory with legs or casters

tted unless specially ordered without.

4. The type of voltage supply that the equipment was

manufactured for at the factory is noted on the data plate

and on the packaging. This type of supply must be used.

5. Do not remove permanently axed labels, warnings

or data plates from the appliance, for this may void

approvals and creates a safety hazard.

Safety

This manual pertains to fryers. The reader/operator must

interpret its contents to applicable needs. If there is any

question of interpretation of any of the literature pertaining

to Garland fryers, please contact your Authorized Service

Agency or our Customer Service Department at the phone

number listed on the front of this manual.

A qualied person must make the installation of these

products in accordance with the local codes of the country of

destination.

Always follow these safety precautions when operating the

fryer.

The unit must only be operated by qualied persons. DO

NOT operate without reading this manual.

DO NOT operate the product unless it has been properly

installed and earthed.

DO NOT operate the product unless all service and access

panels are in place and fastened properly.

DO NOT attempt to repair or replace any part of this product

unless all main power supplies have been disconnected.

WARNING: to avoid serious personal injury:

Use extreme caution in setting up, operating and cleaning

this product to avoid coming in contact with hot surfaces

or hot oil. Suitable protective clothing should be worn to

prevent the risk of burns.

NOTE all warning labels and markings on the product,

which call attention to further dangers and necessary

precautions.

WARNING: this appliance must not be cleaned with a water

jet.

Part # P156 Rev 1 (12/03/09) Page 5

Page 6

INTRODUCTION continued

Rating Plate

For proper operation, the information on the data plate of

the new equipment must match the electrical supply. The

data plate is readily accessible, located on the inside of the

cabinet door. It contains all of the pertinent information

required by the installer.

INSTALLATION

The Garland S18 series deep fat fryer complies with the

standards CSA C22.2 No. 109 – latest edition, the UL197 –

latest edition and the NSF#4 – latest edition. The installation

& connection of this appliance must comply with current

codes. In Canada – the Canadian Electric Code Part 1 and in

the USA – The National Electrical Code.

This equipment must be installed and adjusted by a

competent person as required by the local electrical

authorities. Failure to install appliances correctly could lead

to prosecution. It is in your own interests and that of safety to

ensure that the law is complied with.

Unpacking

1. Carefully remove the unit from the crate. All packing

material must be removed from the unit. The protective

material covering the stainless steel must be removed

immediately after the unit is installed.

2. Do not remove permanently axed labels, warnings

or data plates from the appliance, for this may void

approvals and creates a safety hazard.

Clearances

The space in which the appliance is to be sited must include

the minimum installation clearances to combustible surfaces

as indicated in the following table.

When corresponding with the factory or equipment dealer

regarding service problems or replacement parts, be sure

to refer to the particular unit by the correct model number,

including prex and sux letters and numbers and serial

number. The rating plate axed to the unit contains this

information.

CLEARANCE TO COMBUSTIBLE MATERIAL

Location All Models

Top *

Left Hand Side 1” (25mm)

Right Hand Side 1” (25mm)

Rear 1.5” (38mm)

Type of Floor or Base Combustible

* NOTE Equipment must be installed under a

ventilation canopy

Adequate clearance must be provided for servicing,

ventilation & proper operation. The product must be kept

free from combustible material.

Siting

The fryer should be installed on a rm smooth and level oor

designed to withstand the weight of the appliance and any

ancillary equipment. (Refer to dimensions and specications

section for weights). Once in position check that the

equipment is level, the fryer must be level front to back, side

to side and diagonally. This leveling must be done with the

unit under the hood and in it’s normal operational position.

Adjust if necessary.

If the fryer is to be dais or cove mounted, the base on which

it is to be set should be level. If it is not, the fryer must be

shimmed to level.

Part # P156 Rev 1 (12/03/09)Page 6

Page 7

INSTALLATION continued

Appliances Equipped With Legs

All Fryers are shipped from the factory with legs installed

unless otherwise specied. When the fryer is specied for

dais or cove mounting it is shipped less legs. Legs must be

adjusted to a minimum height of 6” (152mm) in order to

comply with NSF standards.

Appliances Equipped With Casters

1. The front casters on the unit are equipped with brakes to

limit the movement of the fryer without depending on

the electrical connection.

2. A restraint can be attached to the unit near the electrical

connection. If the restraint is disconnected be sure to

reconnect it after the fryer has been returned to its

original installed position.

Ventilation

The area in which the appliance is installed must be

adequately ventilated to provide air for removal of steam,

heat generated by the appliance, etc. These products are

intended to be installed under a ventilation hood. The use

of a mechanical extract system should be considered and

conform to local codes.

Proper operation of exhaust fans (proper speed, rotation and

adjustment) is essential. In addition a make-up air system

(HVAC) for the kitchen to supply fresh air is recommended.

Any ventilation system will break down if improperly

maintained. The duct system, the hood, and the lters must

be cleaned on a regular bases and kept clean.

The supply entrance is located at the rear. The supply

terminal block is accessible from the front. The electrical

supply must be adequate for the voltage, phase & current

marked on the rating plate.

NOTE: A means of disconnection from the supply having

a contact separation of at least 3 mm in all poles must be

incorporated in the xed wiring.

This equipment is intended to be installed with xed

permanent wiring.

WARNING: This appliance must be earthed.

Single and Three Phase Connection

Unless otherwise noted all fryers are shipped from the

factory for three phase connection. A wiring diagram is

attached to the rear of each fryer. Visually check all the

electrical connections. The fryer is wired at the factory

as specied on the order. If it is necessary to change the

phasing, refer to the wiring diagram.

NOTE: SF 3 phase loads are unbalanced, see Appendix, rating

plate or consult factory for more details.

Commissioning

Ensure all circuit breakers located in the lower compartment

are set to the ‘ON’ (1) position.

1. Ensure that all controls are in the o position and turn on

the main electrical supply.

2. Operate the fryer in accordance with the operating

instructions in the operating manual.

Electrical Supply

CAUTION: Prior to installation check the electrical supply

to ensure input voltage and phase match the equipment

voltage rating and phase. See data plate located inside of the

cabinet door.

Part # P156 Rev 1 (12/03/09) Page 7

3. Check that the product functions correctly and that the

voltage supply to the unit does not drop by more than

5% when all sections are operated simultaneously.

When the operation has been check, hand the operating

manual to the user or purchaser for retention and instruct

them in the ecient and safe operation of the appliance.

Page 8

MAINTENANCE AND CLEANING

Regular servicing by a competent person is recommended to

ensure the continued safe and ecient performance of the

appliance.

Thermostat Calibration

WARNING: Turn o the electrical mains before commencing

any service work.

It is normal for an electromechanical thermostat to cycle

with a 45° F - 50°F (25°C - 28°C). When checking calibration,

allow the thermostat to cycle a minimum of two times.

1. Place the thermocouple of the test instrument in the

center of the tank 1” (25mm) below the oil surface.

2. Turn the thermostat dial to 325° F (163° C). In order to

allow the oil temperature to stabilize, the control must be

allowed to cycle twice before taking a test reading.

REPLACEMENT OF PARTS

3. Check the temperature reading just when the control

cycles “OFF” as indicated by the cycle pilot lamp. If the

temperature does not read within 15°F (8°C) of the dial

setting, recalibrate as follows:

4. Carefully remove the thermostat dial, not disturbing the

dial setting.

5. Hold the thermostat shaft steady and with a small at

blade screw driver, turn the calibration screw located

inside the shaft clockwise to decrease the temperature

and counter clock wise to increase the temperature.

NOTE: Each 1/4 turn of the screwdriver will create a

change of approximately 35° F (20° C).

6. Replace the thermostat dial and repeat steps 1 through 3

to verify that correct adjustment has been made.

WARNING: Turn o the electrical mains before commencing

any servicing work.

Thermostat

1. Remove the screws securing the front panel to the front

rail and drop the panel.

2. Disconnect the wires from the taps on the thermostat.

3. Remove the dial from the thermostat and the screws

securing the thermostat body to the control panel

4. Remove the wires from the thermostat terminals. Be sure

to note which wire connects to which terminal on the

thermostat.

5. Remove the thermostat sense bulb. Note the path of the

capillary and install the new one in the same manner.

6. Replace the faulty thermostat and reassemble in the

reverse order.

Indicator Lamps

1. Remove the screws securing the front panel to the front

rail and drop the panel.

2. Disconnect the supply wires to the lamp body and

remove the faulty lamp.

3. Reassemble in the reverse order.

Heating Elements

1. Tilt rotating element head up and remove the element

terminal cover.

2. Disconnect the supply wires to the element.

3. Remove the sealing connectors.

4. Reassemble in the reverse order replacing the sealing

connectors.

Part # P156 Rev 1 (12/03/09)Page 8

Page 9

FAULT FINDING

FRYER DIAGNOSTICS

PROBLEM POSSIBLE CAUSE SOLUTION

Power indicator is on.

Heating indicator comes on.

Fryer recovering or heating unevenly.

Red indicator light is on.

Fryer is not heating.

Fryer will not start - green indicator

does not come on.

Red indicator light is not on.

Oil temperature too hot or too cold. Thermostat is out of calibration. Calibrate or replace thermostat.

One or more circuit breakers are o. Switch circuit breakers to the “ON”

position.

One or more elements are defective. Replace Elements.

High temperature limit is tripped Operating thermostat may be defective

- Replace.

Operating contractor may be defective

- Replace

Power switch is defective Replace Power Switch

Safety Contactor is defective Replace Contactor.

Auxiliary contacts on the thermostat

are defective.

Replace operating thermostat.

Part # P156 Rev 1 (12/03/09) Page 9

Page 10

APPENDIX

Wiring diagrams

Part # P156 Rev 1 (12/03/09)Page 10

Page 11

TH1

GREEN

RED

AMBER

4kW/4.5kW

4kW/7.0kW

4kW/4.5kW

K

S1-2

K2

Z

1 PHASE

4

X

Y

3

5

G

1

Z

3 PHASE

4

2

X

Y

6

5

3

G

1

TH2

S1-1

2

6

MISSISSAUGA, ONTARIO, CANADA

4

GARLAND COMMERCIAL RANGES LIMITED

454443424140

30A

S18F, SF (208/240 VAC)

X

Z

Y

SCHEMATIC DIAGRAM

F=30A

SF=40A

6 35 2

20

22

30A

1

23

TH2

HIGH LIMIT

COM NO NC

30

19

13

1817

41

12

45

K

CONTACTOR

REGULATING

15

19

43

11

26

20

17

21

TH1

THERMOSTAT

200°-375° F

:

MODEL

28

21

12

16

15

13

10

24

AMBER, HEATING

16

42

44

F=4.0kW F=4.0kW F=4.0kW

SF=4.5kW SF=7.0kW SF=4.5kW

22

14

40

K2

29

27

11

LIMIT CONTACTOR

18

14

24

10

GREEN, POWER ON

25

28

30

2926

S

SWITCH

CIRCUIT 1

TOP

RED, t>LIMIT

CIRCUIT 2

25

23

3013800

:

DWG

Part # P156 Rev 1 (12/03/09) Page 11

Page 12

N

L3

TH1

GREEN

AMBER

4kW/4.5kW

4kW/4.5kW

RED

4kW/7.0kW

K

K2

S1-2

1 PHASE

7

L2

3

E

L1

N

L3

2

3 PHASE

1

L2

2

3

E

L1

1

6

4

TH2

S1-1

N

L3

L1

L2

SCHEMATIC DIAGRAM

5

4

4241

29

26

40

27

TH2

HIGH LIMIT

COM NO NC

28

6

5

7

3

MISSISSAUGA, ONTARIO, CANADA

GARLAND COMMERCIAL RANGES LIMITED

S18F, SF (220/380, 240/415 VAC)

:

30A

30A

F=30A

SF=40A

2

1

MODEL

710

4

30

10

11

K

CONTACTOR

REGULATING

16

15

14

17

6

18

18

22

25

TH1

THERMOSTAT

19

200°-375° F

17

13

11

24

512

40

15

16

41

F=4.0kW F=4.0kW F=4.0kW

SF=4.5kW SF=7.0kW SF=4.5kW

42

26

23

22

K2

LIMIT CONTACTOR

14

19

20

AMBER, HEATING

GREEN, POWER ON

28

2325

S

SWITCH

CIRCUIT 1

TOP

RED, t>LIMIT

CIRCUIT 2

20

27

3013801

:

21

DWG

Part # P156 Rev 1 (12/03/09)Page 12

Page 13

TH1

GREEN

RED

K2

4kW/4.5kW

4kW/7.0kW

4kW/4.5kW

AMBER

K

S1-2

Z

1 PHASE

4

2

TH2

X

Y

3

5

G

1

6

Z

3 PHASE

2

4

X

Y

1

5

3

G

6

S1-1

MISSISSAUGA, ONTARIO, CANADA

GARLAND COMMERCIAL RANGES LIMITED

27

32

H4

H2

33

X

Z

Y

SCHEMATIC DIAGRAM

H3

H

31

X

33

X2 X3

X4

S18F, SF (380, 480 VAC)

:

29

20

MODEL

22

23

TH2

HIGH LIMIT

COM NO NC

30

19

13

1817

5

31

20

4

2

K

CONTACTOR

REGULATING

15

19

11

26

17

21

TH1

THERMOSTAT

200°-375° F

28

21

16

15

13

10

AMBER, HEATING

16

6

18

3

F=4.0kW F=4.0kW F=4.0kW

SF=4.5kW SF=7.0kW SF=4.5kW

22

14

1

K2

32

27

11

LIMIT CONTACTOR

14

10

GREEN, POWER ON

25

28

30

2926

S

SWITCH

CIRCUIT 1

TOP

RED, t>LIMIT

CIRCUIT 2

25

23

3013802

:

DWG

Part # P156 Rev 1 (12/03/09) Page 13

Page 14

TH1

GREEN

RED

K2

4kW/4.5kW

4kW/7.0kW

4kW/4.5kW

AMBER

K

S1-2

Z

1 PHASE

4

2

TH2

X

Y

3

5

G

1

6

Z

3 PHASE

2

4

X

Y

1

5

3

G

6

S1-1

MISSISSAUGA, ONTARIO, CANADA

GARLAND COMMERCIAL RANGES LIMITED

27

32

H2

33

X

Z

Y

SCHEMATIC DIAGRAM

H3

H

31

X

H4

33

X2 X3

X4

S18F, SF (380, 480 VAC)

:

29

20

MODEL

22

23

TH2

HIGH LIMIT

COM NO NC

30

19

13

1817

5

31

20

4

2

K

CONTACTOR

REGULATING

15

19

11

26

17

21

TH1

THERMOSTAT

200°-375° F

28

21

16

15

13

10

AMBER, HEATING

16

6

18

3

F=4.0kW F=4.0kW F=4.0kW

SF=4.5kW SF=7.0kW SF=4.5kW

22

14

1

K2

32

27

11

LIMIT CONTACTOR

14

10

GREEN, POWER ON

25

28

30

2926

S

SWITCH

CIRCUIT 1

TOP

RED, t>LIMIT

CIRCUIT 2

25

23

3013802

:

DWG

Part # P156 Rev 1 (12/03/09)Page 14

Page 15

Part # P156 Rev 1 (12/03/09) Page 15

Page 16

Loading...

Loading...