Page 1

INSTALLATION AND

OPERATION MANUAL

MASTER SERIES

INFRA-RED

SALAMANDER BROILER

M/MS/MST (SRC, SR16)

Français . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 12

FOR YOUR SAFETY:

DO NOT STORE OR USE GASOLINE

OR OTHER FLAMMABLE VAPORS OR

LIQUIDS IN THE VICINITY OF

THIS OR ANY OTHER

APPLIANCE

WARNING:

IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE

CAN CAUSE PROPERTY DAMAGE, INJURY,

OR DEATH. READ THE INSTALLATION,

OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR

SERVICING THIS EQUIPMENT

Users are cautioned that maintenance and repairs must be performed by a Garland authorized service agent

using genuine Garland replacement parts. Garland will have no obligation with respect to any product that has been

improperly installed, adjusted, operated or not maintained in accordance with national and local codes or installation

instructions provided with the product, or any product that has its serial number defaced, obliterated or removed,

or which has been modified or repaired using unauthorized parts or by unauthorized service agents.

For a list of authorized service agents, please refer to the Garland web site at http://www.garland-group.com.

The information contained herein, (including design and parts specifications), may be superseded and is subject

to change without notice.

PLEASE READ ALL SECTIONS OF THIS MANUAL

AND RETAIN FOR FUTURE REFERENCE.

THIS PRODUCT HAS BEEN CERTIFIED AS

COMMERCIAL COOKING EQUIPMENT AND

MUST BE INSTALLED BY PROFESSIONAL

PERSONNEL AS SPECIFIED.

IN THE COMMONWEALTH OF MASSACHUSETTS

THIS PRODUCT MUST BE INSTALLED BY A

LICENSED PLUMBER OR GAS FITTER. APPROVAL

NUMBER: G-1-07-05-28

For Your Safety:

Post in a prominent location, instructions to be

followed in the event the user smells gas. This

information shall be obtained by consulting

your local gas supplier.

Garland Commercial Ranges, Ltd.

1177 Kamato Road, Mississauga, Ontario L4W 1X4 CANADA

Phone: 905-624-0260

Fax: 905-624-5669

Part # 1382684 Rev. 02 (11 Feb 2014)

General Inquires 1-95-624-0260

USA Sales, Parts and Service 1-800-424-2411

Canadian Sales 1-888-442-4526

Canada or USA Parts/Service 1-800-427-6668

Page 2

IMPORTANT INFORMATION

WARNING:

This product contains chemicals known to the state of California to cause cancer and/or birth defects

or other reproductive harm. Installation and servicing of this product could expose you to airborne

particles of glass wool/ceramic fibers. Inhalation of airborne particles of glass wool/ceramic fibers

is known to the state of California to cause cancer. Operation of this product could expose you to

carbon monoxide if not adjusted properly. Inhalation of carbon monoxide is known to the state of

California to cause birth defects or other reproductive harm.

Keep appliance area free and clear of combustibles.

For Australia “TO BE INSTALLED BY AN AUTHORISED PERSON IN ACCORDANCE WITH AS5601,

LOCAL AUTHORITY AND APPLICABLE LOCAL STATUTORY REGULATIONS AND MANUFACTURER’S

INSTRUCTIONS”

Part # 1382684 Rev. 02 (11 Feb 2014)Page 2

Page 3

TABLE OF CONTENTS

IMPORTANT INFORMATION. . . . . . . . . . . . . 2

DIMENSIONS AND SPECIFICATIONS . . . . . 4

Su x De nitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . 5

Product application . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Rating Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

INSTALLATION. . . . . . . . . . . . . . . . . . . . . . . . . 6

Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Installation Instructions for

Range Mount Salamander . . . . . . . . . . . . . . . . . . . . 6

Wall Mounted Salamanders . . . . . . . . . . . . . . . . . . 6

Statutory Regulations . . . . . . . . . . . . . . . . . . . . . . . . 6

Gas Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

OPERATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

M, MS Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Pilot Lighting Instructions. . . . . . . . . . . . . . . . . 8

Main Burner Operation . . . . . . . . . . . . . . . . . . . 8

Shut Down. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

MST Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Operating Controls . . . . . . . . . . . . . . . . . . . . . . . 8

Lighting Instructions . . . . . . . . . . . . . . . . . . . . . 8

Shut Down. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

All Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Burner Ignition . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Main burner Adjustments. . . . . . . . . . . . . . . . . 9

Burn o Period . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Operating Suggestions . . . . . . . . . . . . . . . . . . . 9

Energy Conservation . . . . . . . . . . . . . . . . . . . . . 9

Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . 9

Ventilation and Air Supply . . . . . . . . . . . . . . . . . . . . 7

Testing And Adjustments . . . . . . . . . . . . . . . . . . . . . 7

MAINTENANCE AND CLEANING. . . . . . . . 10

Daily . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Monthly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Exterior Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Stainless Steel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

SERVICING. . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

SAFETY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Part # 1382684 Rev. 02 (11 Feb 2014) Page 3

Page 4

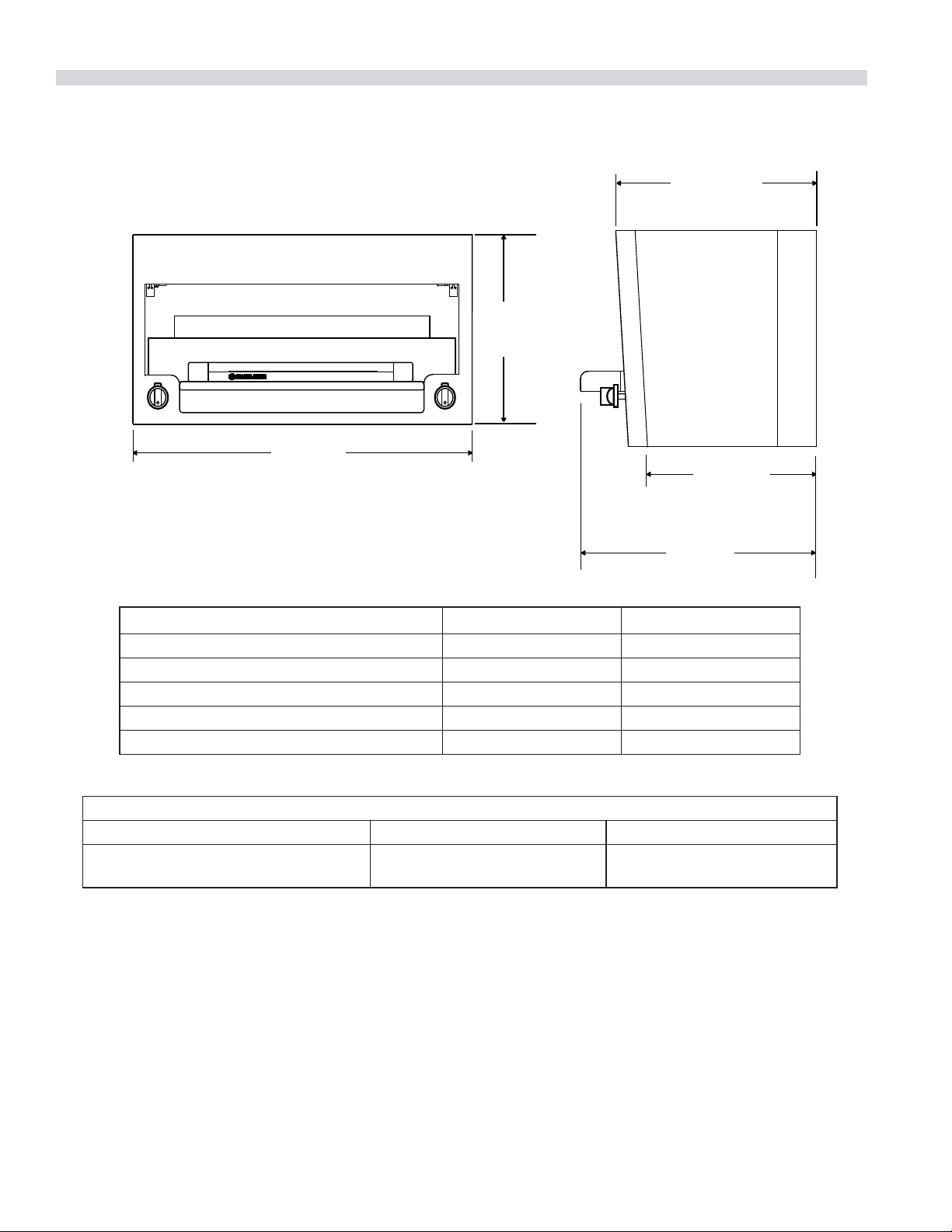

DIMENSIONS AND SPECIFICATIONS

16 5/16"

[414mm]

34"

[864mm]

17 61/64"

[456mm]

16 13/16"

[427mm]

20 1/4"

[514mm]

PRODUCT MSR16 MRSC

Width: In(mm) 34(864) 34(864)

Depth: In(mm) 20-1/4(514) 20-1/4(514

Height: In(mm) 35-5/8(965) 17(432)

INPUT:BTU/hr(kw)(Natural Gas) 28,000 (8.20) 28,000 (8.20)

Shipping Wt:(LB/KG) 170/78 135/61

INSTALLATION NOTES

Combustible Wall Clearances ¹ Entry Clearances Operating Pressure

Sides: 0"

Back: 0"

¹ For instillations in non-combustible locations only.

NOTE: Data applies only to North America

Gas input ratings shown here are for installations up to 2,000 ft. (610m) above seal level. Specify altitudes over 2,000 ft.

Commercial cooking equipment requires an adequate ventilation system. For additional information, refer to the

National Fire Protection Association's standard NFPA96. “Vapor Removal from Cooking equipment”

(for North American only)

Please specify gas type when ordering.

Crated: 26-3/4" (680mm)

Uncrated: 21" (533mm)

Natural: 6" WC (15mbar)

Propane: 11" WC (28mbar)

Part # 1382684 Rev. 02 (11 Feb 2014)Page 4

Page 5

DIMENSIONS AND SPECIFICATIONS continued

GAS TYPE

MODEL NUMBER

(M,MS,MST)(SRC, SR16) 47F 14,000 1.1mm 13,000

Australia Only Nominal Gas Consumption & Injector Sizes

MODEL NUMBER

Ori ce Input (MJ/Hr)

(MST)(SRC, SR16) 2.4mm 21.0 1.0 1.4mm 21.0 2.5

Natural Gas Propane

Su x De nitions

M/MS/MST SRC, SR16-280, SR16

Natural Gas Propane

Ori ce Input (BTU/Hr) Ori ce Input (BTU/Hr)

GAS TYPE

Gas Pressure

(kPa)

Ori ce Input (MJ/Hr)

SRC - Counter Top Version

SR16-280 - Restaurant Range Mount Version

SR16 - Heavy Duty Range Mount Version

Gas Pressure

(kPa)

*MSTSRC and MSTSR16 models are “CE” approved.

INTRODUCTION

IMPORTANT: Read these instructions carefully before

attempting to operate the appliance.

Garland/U.S. Range products are not approved or authorized

for home or residential use, but are intended for commercial

applications only. Garland / U.S. Range will not provide

service, warranty, maintenance or support of any kind other

than in commercial applications.

Your new equipment must be installed and adjusted by a

competent person in accordance with the law. Failure to

install appliances correctly could lead to prosecution. It is

in your own interests and that of safety to ensure that the

law is complied with. Your Garland dealer is well quali ed to

provide this service.

Like any other ne precision built piece of equipment, it

should be given regular care and maintenance. Periodic

inspections by your dealer or a quali ed service company are

recommended to check temperatures, burner adjustments

and ensure moving parts are operative. Wherever possible

avoid overheating idle equipment, as this is the primary

cause for increased service cost.

“Regular Maintenance Ensures Peak Performance.”

Base Model Number

Product application

The Garland infra-red salamander o ers broiling for a wide

variety of products such as steak, lobster, sh, onion soup,

casseroles, garlic bread and hamburgers. The oven- re infrared design provides for quick preheat and e cient, uniform

production. The tilting rack feature allows for an easy view

broiling.

Rating Plate

The rating plate is located behind the drip tray. In the event

you have any questions concerning the installation, use

care or service of this or any other Garland product, write or

call our Product Service Department. When corresponding

with the factory or your equipment dealer regarding

service problems or replacement parts, be sure to refer to

the particular unit by the correct model number (including

pre x and su x letters and numbers) and the serial or code

number. The rating plate a xed to the unit contains this

information.

For proper operation, the Fuel information on the data plate

of you new equipment must match your fuel supply.

Part # 1382684 Rev. 02 (11 Feb 2014) Page 5

Page 6

INSTALLATION

Clearances

Models (M, MS, MST)(SRC, SR16) are for installation in noncombustible locations only with zero (0”) sides and rear

clearance.

NOTE: Adequate clearance must be provided for servicing

and proper operation.

Location

Counter salamanders should be installed on a rm, smooth

and level base designed to withstand the weight of the fully

laden appliance. Any openings in the wall behind or beside

the appliance must be sealed.

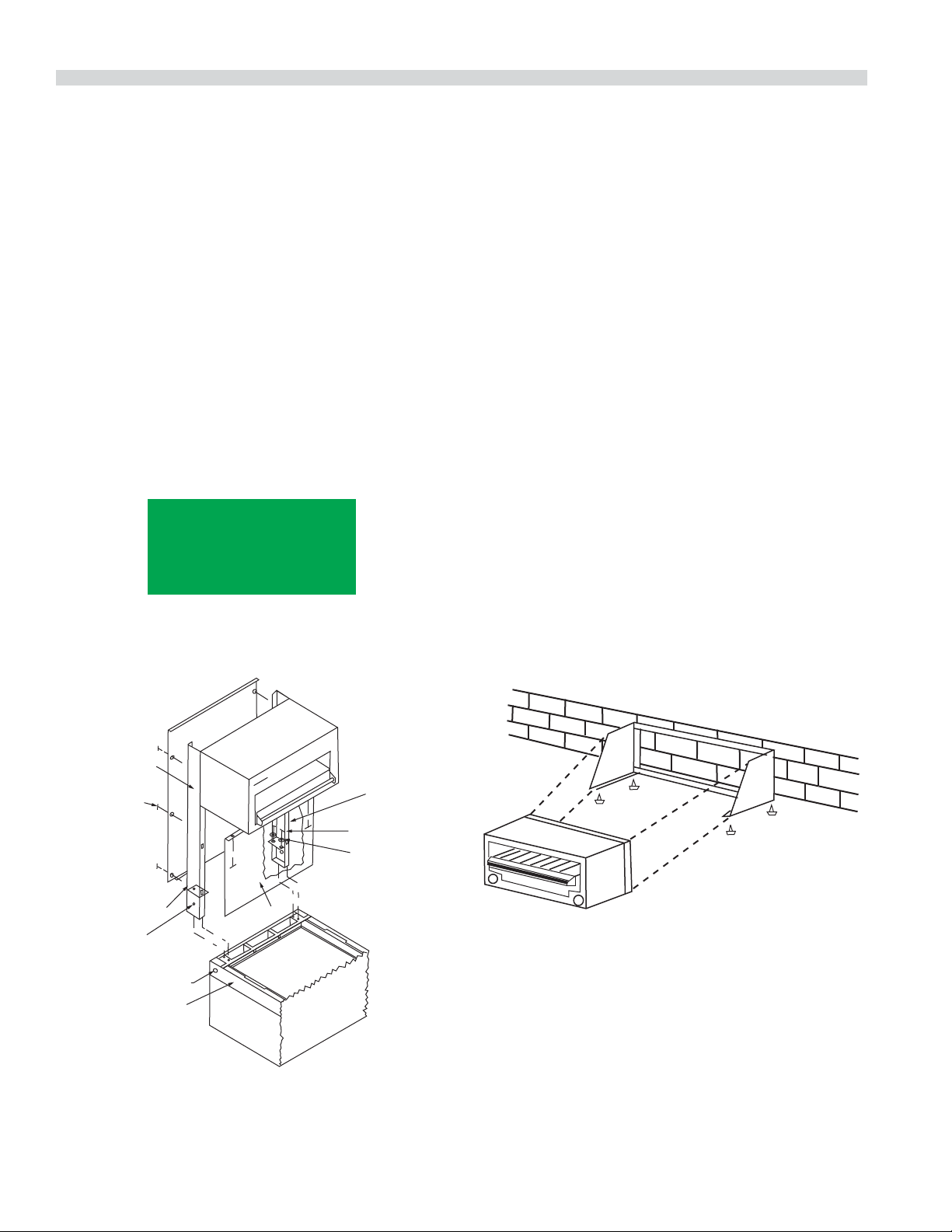

Installation Instructions for

Range Mount Salamander

SAFETY

FIRST

USE PROPER

LIFTING TECHNIQUES

1. Remove the front panel (5) by removing two (2), sheet

metal screws from the underside of the salamander.

2. With the back panel, (4), still attached to the uprights

(2&3) drop the uprights into the rectangular openings at

the rear of the range (1).

3. Fasten the uprights, (2 & 3) to the range with four, (4),

5/16” x 18 bolts and at washers. (6&7)

4. If the range is in a battery line-up, fasten units together

at the hole marked “X” with 1/4” x 20 bolts, nuts and

washers.

5. Reattach the front panel (5) to the salamander with sheet

metal screws previously removed.

Wall Mounted Salamanders

1. Each gas appliance must be located with respect to

building construction and other equipment so as to

permit access to the appliance, Such access and clearance

may be necessary for servicing and cleaning.

2. Salamanders intended for wall mounting are shipped

with the mounting kit already attached.

3. Provisions for gas connections, bottom or rear should be

taken into consideration.

"X"

4

8

2

D

N

RLA

A

G

5

3

6

7

Statutory Regulations

"X"

1

~

When checking gas pressure be sure that all other

equipment on the same gas line is on. A pressure regulator is

supplied as standard equipment with Garland salamanders.

Installation must conform to the National Fuel Gas Code ANSI

Z223.1 or latest edition and/or local code to assure safe and

e cient operation.

Part # 1382684 Rev. 02 (11 Feb 2014)Page 6

Page 7

INSTALLATION continued

In Canada, the installation must comply with

CAN/CGA-B149.1 Natural Gas Installation Code or CAN/CGAB149.2 Propane Gas Installation Code, and local codes where

applicable.

NOTE: The appliance must be isolated from the gas supply

piping system by closing it individual manual shut-o (not

supplied by the manufacturer) during any testing of the gas

supply piping system at test pressures equal to or less than

1/2 PSIG (3.45 kPa).

Gas Supply

Danger

Turn O Gas

Supplies When

Installing or

Servicing Unit.

Before assembly and connection check the gas supply.

1. The type of gas for which the unit is equipped is stamped

on the data plate located behind the drip tray. Connect

a unit stamped “NAT” only to natural gas; connect those

stamped “PRO” only to propane gas.

2. If it is a new installation have the gas authorities check

the meter size and piping to assure that the unit is

supplied with su cient amount of gas pressure required

to operate the unit.

3. If it is an additional or replacement equipment have the

gas authorities check the pressure to make certain that

the existing meter and piping will supply fuel to the unit

with not more than 1/2” water column pressure drop.

WARNING: Check gas connections for leaks. Use a soap

solution or similar means. DO NOT USE AN OPEN FLAME.

Ventilation and Air Supply

Proper ventilation is highly important for good operation.

The ideal method of ventilation for a Salamander broiler is

the use of a properly designed canopy hood, which should

extend six (6”, 152 mm) beyond all sides of the appliance and

six (6) feet six (6) inches (1981 mm) from the oor.

A strong exhaust fan will create a vacuum in the room. For an

exhaust system to work properly, replacement air must enter

the room in which the vent is located. The amount of air that

is exhausted must equal the amount entering, (make-up air).

All gas burners and pilots need su cient air to operate and

large objects should not be placed in front or on the top of

the broiler, which would obstruct the air ow though, the

front of the broiler.

For your safety NEVER place any type of object on top of

the salamander broiler or cheese meters. The top of the

broiler will exceed 1000°F. It could cause severe burns or

re and obstruct ventilation.

Testing And Adjustments

All ttings and pipe connections must be tested for leaks.

Use approved gas leak detectors, soap solution or equivalent,

checking over and around the ttings and pipe connections.

DO NOT USE A FLAME! Accessibility to all gas lines and

ttings require that valve panel(s), lower front panel(s) be

removed. It may be necessary to remove or at least raise and

secure top grates. All parts removed (including fasteners)

should be stored safely for re-use.

Testing

1. Be sure all valves are in the “OFF” position

2. Turn on the main gas supply valve. Light all top section

pilots.

3. Leak test all valves and ttings as described in the

procedure above. Correct any leaks as required and

recheck.

NOTE: This appliance is not recommended for residential

installation.

Part # 1382684 Rev. 02 (11 Feb 2014) Page 7

4. Shut o all gas valves.

All units are tested and adjusted at the factory. However,

burners and pilots should be checked at installation and

adjusted if necessary.

Page 8

OPERATION

NOTE: Ensure the gas supply to the appliance is turned “ON”.

During the initial ignition cycle, air must be purged from the

gas line and thus it may take one to two minutes for the pilot

burner to ignite.

M,MS Models

Pilot Lighting Instructions

1. The in-line service shut-o valve should be in the “ON”

position.

2. With a lighted taper light the pilots which are located at

the rear of the main burner.

3. The pilot ame should be approximately 7/8”

(22 mm) long for proper ignition of the burners. The

pilot adjustment valve is located by sliding the drip

tray forward. The adjustment valves are located on the

manifold pipe, which runs horizontally across the back of

the unit, behind the drip tray, one is at the left rear and

the other is at the right rear.

4. To adjust the pilot light, turn the brass screw counterclockwise to increase the pilot ame, and clockwise to

decrease the ame.

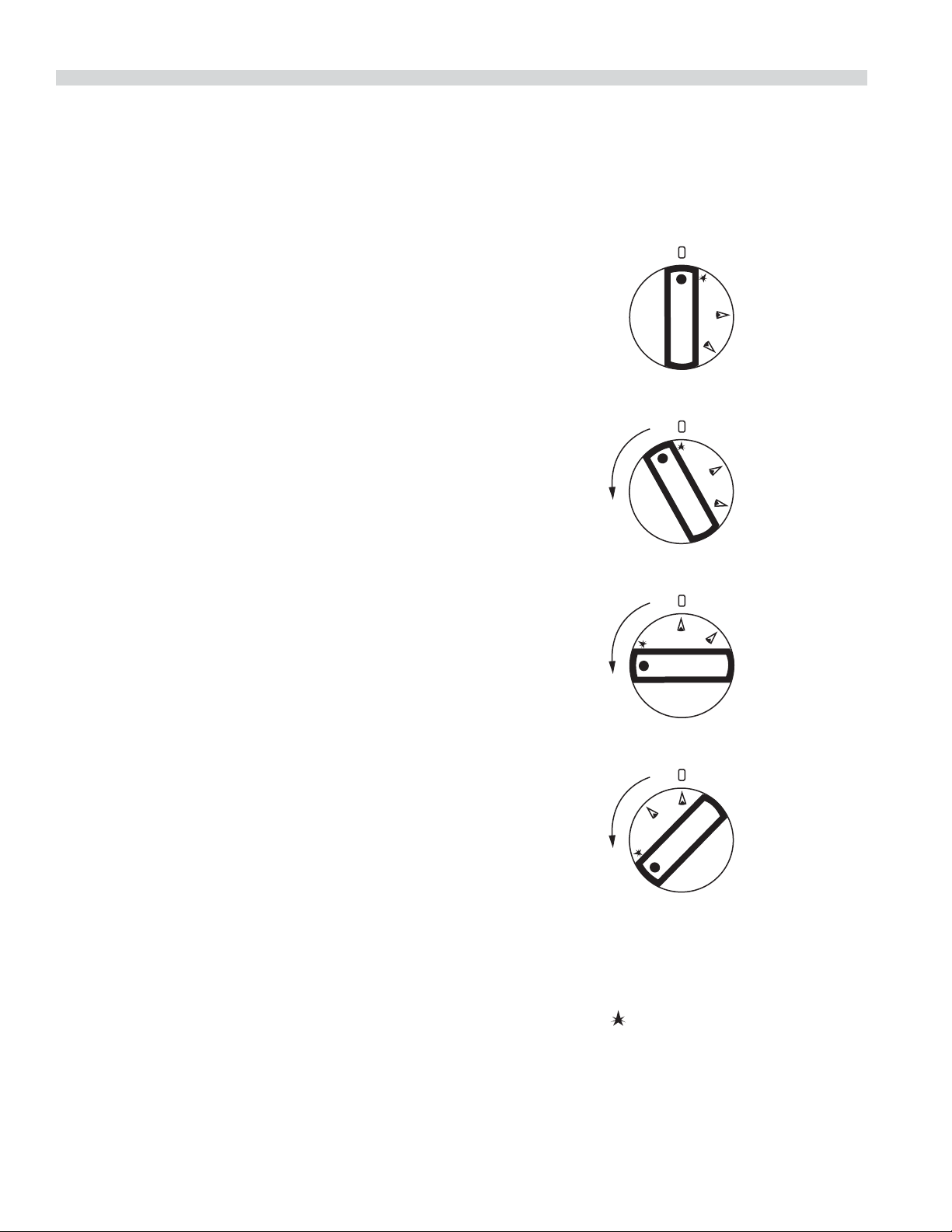

MST Models

Operating Controls

OFF

IGNITION

NOTE: No more than 7/8” (22 mm) pilot ame length should

be required. Too high a setting will cause the ame to lift o

or will create excessive carboning. Do not adjust the pilot

ame lower than 7/8” (22mm) long because this can cause

delayed ignition at the burner. The delayed ignition could

cause the burner tiles to crack, in that case the burner would

have to be replaced.

Main Burner Operation

1. Turn the main burner to the “MAX” position.

2. Immediately check ignition of the burner.

CAUTION: Should ignition fail after ve (5) seconds, turn the

valve o and wait ve (5) minutes before trying again. The

pilot gas is not interrupted automatically, it is the responsibility

of the operator to check the ignition of the burners

immediately after the burner valve has been turned on.

Shut Down

1. Turn all valves to the “OFF” position by rotating the knob

clockwise 1/4 turn.

2. If the unit is to be shut down for an extended period of

time close the inline gas valve.

MAX

MIN

Lighting Instructions

1. Push in the tap and turn it counter-clockwise to the

Ignition Position “ ”

2. Holding the tap fully in, light the pilot with a match or

taper.

Part # 1382684 Rev. 02 (11 Feb 2014)Page 8

Page 9

OPERATION continued

3. When the pilot is lit, continue to hold the tap fully in for

20 seconds, then release it. IF the pilot goes out, wait for

ve (5) minutes, and then repeat from step 1.

4. When the pilot is established, push the tap in again and

turn it counter-clockwise to the full ame position “ ”

thus lighting the main burner.

5. For low ame or simmer, push the tap in and turn it

counter-clockwise to the low ame “ ” position.

6. To shut the burner o , turn the dial to the “ ” symbol and

the safety device will disengage within 60 seconds.

Shut Down

1. Turn all valves to the “OFF” position by rotating the knob

clockwise 1/4 turn.

2. If the unit is to be shut down for an extended period of

time, close the inline gas valve.

All Models

Burner Ignition

When ignition has been accomplished, a blue ame will

cover the surface of the ceramics for 10-15 seconds. This haze

will disappear and the burner rod will glow red. After the

burners have operated for several minutes turn the valve to

“MIN”. The burner rods will no longer glow red and the ame

travels back and forth on the face of the burner ceramics.

Main burner Adjustments

This adjustment has been factory pre-set however, with

changing pressures this adjustment and pilot adjustment

may need re-done after installation. This is not considered a

manufacturing defect and is not warrantable.

Burn o Period

Many parts used in the manufacturing of commercial

equipment have a thin protective coating of machine oil. This

oil should be burned o before the equipment is used for

food preparation.

After all start-up and safety checks have been completed,

turn the burner valve to the “MAX” position. A Smoke (a

bluish haze) will be produced. This process can take several

hours and can be completed over a few days.

Operating Suggestions

1. Clean the racks as soon as possible after cooking with

tomato or vinegar based products that have a high acid

content. These foods can cause pitting of the rack surface.

2. Allow the salamander to preheat before adding product.

3. Drain and clean the drip tray frequently. Excessive oil

drain o in the pan can cause spillover.

Energy Conservation

Do not waste energy by leaving controls at high temperature

settings during idle periods. Lower setting will keep broiler

warm and ready got the next use period. Reset burner valve

knob as required for heavy load periods.

All Salamander are provided with a xed burner ori ce to

provide 20,000 BTU/Hr at the “MAX” setting on natural gas

supplied at 6.0” W/C pressure and 20,000 BTU/Hr at the “MAX”

setting on propane gas supplied at 10.0” W/C.

The “MIN” setting is adjustable and should be set as follows:

1. Set the burner valve knob to “MIN”.

2. Insert a thin bladed screwdriver into the valve stem

to engage the slot inside the stem. Turn Clockwise to

decrease the rate and counter clock-wise to increase.

Proper adjustment is attained at the point where the burner

rods no longer glow and the ame travels back and forth on

the face of the ceramics.

Part # 1382684 Rev. 02 (11 Feb 2014) Page 9

Safety Precautions

It is the responsibility of the supervisor or equivalent

person to ensure that users of this equipment wear suitable

protective clothing and to draw attention to the fact that

some parts will by necessity become very hot and will cause

burns if touched accidentally.

For your safety never place any type of object on top of the

salamander broiler. The top of the broiler will exceed 1000°F.

It could cause severe burns and/or le and also obstruct

ventilation.

Page 10

MAINTENANCE AND CLEANING

A program of proper cleaning techniques will aid in

continued trouble free operation of this or any quality

equipment.

Daily

1. Remove and clean grid rack. Grid racks should be wiped

clean while still warm, using a heavy cloth or other grease

absorbing material to remove grease and burnt food

before they burn into the grid. Remove burnt materials,

such as carbonized grease or food, with a sti wire brush.

DO NOT USE ANY TYPE OF STEEL WOOL. Small particles

of steel may be left on the grid surface and get into food

products. Grid racks should be washed thoroughly using

a wire brush and a hot, mild detergent or soap solution.

Rinse with clear, warm water.

2. With the rack removed clean the interior of the unit with

a damp cloth.

3. Clean out the grease container.

Monthly

Lubricate valves and bearings as required. Due to the usual

location of the broiler which is mounted above a range

with open tops, the heat from the open top will cause the

lubrication grease inside the valves to dry out. When you

notice that the valves are becoming harder to turn, it is

then time to have them greased. We suggest an authorized

service agent who is familiar with the appliance and working

with natural and propane gas, perform this type of work.

Exterior Cleaning

Establish a regular schedule. Any spills should be wiped o

immediately.

Wipe exposed, cleanable surface when cool with a mild

detergent and hot water. Stubborn residue spots may be

removed with a lightweight non-metallic scouring pad. Dry

thoroughly with a clean cloth.

Stainless Steel

Stainless steel should be cleaned using a mild detergent,

a soft cloth and hot water. If it is necessary to use a nonmetallic scouring pad, always rub in the direction of the

grain in the metal to prevent scratching. Use a water based

stainless steel cleaner (such as Drackett Twinkle), if you

want a high shine. Wash a small area at a time and rinse the

washed area with a clean sponge dipped into a disinfectant

and wipe dry with a soft cloth before it can dry.

Use only stainless steel, wood or plastic tools to scrape

o heavy deposits of grease or oil. Do not use ordinary

steel scrapers or knives, as particles of iron may become

embedded and rust. NEVER USE STEEL WOOL.

Part # 1382684 Rev. 02 (11 Feb 2014)Page 10

Page 11

SERVICING

To ensure e cient and safe operation of the appliance it

is recommended that servicing be carried out at regular

interval, the frequency of which will vary, depending on the

SAFETY

It is essential that the instructions in this booklet are strictly

followed for the safe and economical operation of the

equipment. If it is known or suspected that a fault exists on

the appliance then it must not be used until the fault has

been recti ed by a competent person.

installation. Servicing must be carried out by competent

persons in accordance with the law.

Part # 1382684 Rev. 02 (11 Feb 2014) Page 11

Page 12

INSTRUCTIONS

D’INSTALLATION ET

D’UTILISATION

SALAMANDRES À

INFRAROUGE SÉRIE MASTER

MODÈLES M/MS/MST (SRC, SR16)

POUR VOTRE SÉCURITÉ:

NE PAS STOCKER NI UTILISER D’ESSENCE OU

D’AUTRES VAPEURS OU LIQUIDES

INFLAMMABLES À PROXIMITÉ DE CET

APPAREIL OU DE TOUT AUTRE APPAREIL

AVERTISSEMENT:

UNE INSTALLATION, DES RÉGLAGES, DES

MODIFICATIONS, DES RÉPARATIONS OU UN

ENTRETIEN MAL FAITS PEUVENT CAUSER

DES DOMMAGES MATÉRIELS, DES

BLESSURES OU LA MORT. LIRE

SOIGNEUSEMENT LES INSTRUCTIONS

D’INSTALLATION, D’UTILISATION ET

D’ENTRETIEN AVANT D’INSTALLER OU DE

RÉPARER L’ÉQUIPEMENT

LIRE TOUTES LES SECTIONS DU PRÉSENT

MANUEL ET LE CONSERVER POUR S’Y

REPORTER ULTÉRIEUREMENT.

CE PRODUIT A ÉTÉ HOMOLOGUÉ EN TANT

QU’ÉQUIPEMENT PROFESSIONNEL DE CUISSON ET

DOIT ÊTRE INSTALLÉ PAR DU PERSONNEL

PROFESSIONNEL TEL QUE SPÉCIFIÉ.

DANS L’ÉTAT DU MASSACHUSETTS, CE PRODUIT

DOIT ÊTRE INSTALLÉ PAR UN PLOMBIER OU UN

MONTEUR D’INSTALLATION AU GAZ CERTIFIÉ.

NOMBRE D’APPROBATION : G-1-07-05-28

Pour votre sécurité:

Placer dans un endroit bien en vue les

instructions à suivre en cas d’odeur de gaz

détectée par l’utilisateur. Cette information peut

être obtenue auprès du fournisseur de gaz local.

L’attention des utilisateurs est attirée sur le fait que l’entretien et les réparations doivent être effectués par un agent

d’entretien autorisé par Garland utilisant des pièces de rechange d’origine Garland. Garland n’aura aucune obligation

en ce qui concerne n’importe quel produit mal installé, réglé, utilisé ou qui n’aurait pas été entretenu conformément

aux codes nationaux et locaux ou aux instructions d’installation fournies avec le produit ou n’importe quel produit

dont le numéro de série aurait été mutilé, oblitéré ou supprimé ou qui aurait été modifié ou réparé avec des pièces

non autorisées ou par des agents d’entretien non autorisés. Pour obtenir la liste des agents de service autorisés,

consulter le site web de Garland à : http://www.garland-group.com. Les renseignements contenus dans le présent

document (y compris la conception et les spécifications des pièces) peuvent être remplacés ou modifiés sans préavis.

GARLAND COMMERCIAL RANGES, LTD.

1177 Kamato Road, Mississauga, Ontario L4W 1X4

CANADA

Téléphone: 905-624-0260

Télécopieur: 905-624-5669

Piéce nº 1382684 Rev. 2 (11 Feb 2014)Page 12

Page 13

INFORMATIONS IMPORTANTES

AVERTISSEMENT:

Ce produit contient des produits chimiques reconnus par l’état de Californie comme causant

le cancer et/ou des malformations congénitales ou d’autres problèmes de reproduction.

L’installation et l’entretien de ce produit peut vous exposer aux poussières de laine de verre/

fibres céramiques. L’inhalation de ces particules de laine de verre ou de fibres céramiques

est reconnue par l’état de Californie comme causant le cancer. L’utilisation de ce produit

peut vous exposer au monoxyde de carbone en cas de mauvais réglage. L’inhalation de

monoxyde de carbone est reconnue par l’état de Californie comme pouvant causer des

malformations congénitales ou d’autres problèmes reproductifs.

Maintenir les abords de l’appareil dégagés et ne pas y

stocker de produits combustibles.

Piéce nº 1382684 Rev. 2 (11 Feb 2014) Page 13

Page 14

TABLE DES MATIÈRES

INFORMATIONS IMPORTANTES . . . . . . . . 13

DIMENSIONS ET SPÉCIFICATIONS . . . . . . 15

Australie Seulement nominale Consommation

de Gaz & injecteur Tailles . . . . . . . . . . . . . . . . . . . .16

Dé nitions des su xes . . . . . . . . . . . . . . . . . . . . . . 16

INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . 16

INSTALLATION. . . . . . . . . . . . . . . . . . . . . . . . 17

Dégagements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Emplacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Instructions D’installation D’une Salamandre

Montée Sur Cuisinière. . . . . . . . . . . . . . . . . . . . . . . 17

Salamandres à Montage Mural. . . . . . . . . . . . . . . 17

Réglementation Légale . . . . . . . . . . . . . . . . . . . . .17

Alimentation En Gaz . . . . . . . . . . . . . . . . . . . . . . . . 18

FONCTIONNEMENT . . . . . . . . . . . . . . . . . . . 19

Modèles M, MS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Instructions D’allumage des Veilleuses. . . . 19

Fonctionnement du Brûleur Principal . . . . 19

Arrêt. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Modèles MST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Commandes . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Instructions D’allumage. . . . . . . . . . . . . . . . . . 19

Arrêt. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Tous Les Modèles . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Allumage Des Brûleurs . . . . . . . . . . . . . . . . . . 20

Réglages du Brûleur Principal . . . . . . . . . . . . 20

Période de Brûlage . . . . . . . . . . . . . . . . . . . . . . 20

Suggestions D’utilisation. . . . . . . . . . . . . . . . . 20

Économies D’énergie . . . . . . . . . . . . . . . . . . . . 20

Ventilation Et Alimentation En Air. . . . . . . . . . . .18

Essais Et Réglages . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Précautions De Sécurité . . . . . . . . . . . . . . . . . 20

ENTRETIEN ET NETTOYAGE . . . . . . . . . . . . 21

Chaque Jour . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Chaque Mois . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Nettoyage Extérieur. . . . . . . . . . . . . . . . . . . . . . . . .21

RÉPARATION. . . . . . . . . . . . . . . . . . . . . . . . . . 22

SÉCURITÉ. . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Piéce nº 1382684 Rev. 2 (11 Feb 2014)Page 14

Page 15

DIMENSIONS ET SPÉCIFICATIONS

34"

[864mm]

17 61/64"

[456mm]

16 5/16"

[414mm]

16 13/16"

[427mm]

PRODUIT MSR16 MRSC

Largeur : Po (mm) 34(864) 34(864)

Profondeur : Po (mm) 20-1/4(514) 20-1/4(514

Hauteur : Po (mm) 35-5/8(965) 17(432)

DÉBIT CALORIFIQUE : BTU/h (kw) (Gaz naturel) 28,000 (8.20) 28,000 (8.20)

Pds d’expédition : (LB/KG) 170/78 135/61

NOTES D’INSTALLATION

Dégagements Par Rapport Aux

Murs Combustibles ¹

Côtés : 0 po

Arrière : 0 po

¹ Pour installation dans des emplacements incombustibles uniquement.

REMARQUE: Données applicables à l’Amérique du Nord uniquement

Dégagements

D’entrée

En caisse : 26 -3/4 po (680 mm

Déballé : 21 po (533 mm)

20 1/4"

[514mm]

Pression de

Fonctionnement

Gaz naturel : 6 po CE (15 mbar)

Propane : 11 po CE (28 mbar)

Les débits calori ques du gaz indiqués ici s’appliquent à des altitudes inférieures à 2 000 pi (610 m) au-dessus du

niveau de la mer. Prière de spéci er les altitudes supérieures à 2 000 pieds.

Les équipements de cuisson commerciaux ont besoin d’un système de ventilation adéquat. Pour plus de

renseignements, consulter la norme de la National Fire Protection Association NFPA96. « Vapor Removal from Cooking

equipment » (pour l’Amérique du Nord seulement)

Spéci er le type de gaz lors de la commande.

Piéce nº 1382684 Rev. 2 (11 Feb 2014) Page 15

Page 16

DIMENSIONS ET SPÉCIFICATIONS suite

TYPE DE GAZ

Gaz Naturel Propane

NUMÉRO DE MODÈLE

Ori ce

(M,MS,MST)(SRC, SR16) 47F 14,000 1.1mm 13,000

Australie Seulement nominale Consommation de Gaz & injecteur Tailles

Gaz Naturel Propane

NUMÉRO DE MODÈLE

Ori ce

(MST)(SRC, SR16) 2.4mm 21.0 1.0 1.4mm 21.0 2.5

Débit

Calori que

(MJ/Hr)

Dé nitions des su xes

Débit

Calori que

(BTU/Hr)

TYPE DE GAZ

pression de

gaz(kPa)

Ori ce

Ori ce

Calori que

(BTU/Hr)

Débit

Calori que

(MJ/Hr)

Débit

pression de

gaz(kPa)

Les modèles MSTSRC et MSTSR16 sont approuvés “ CE “

INTRODUCTION

IMPORTANT : Lire soigneusement les instructions suivantes

avant d’essayer d’utiliser l’appareil.

Les produits Garland/U.S. Range ne sont pas agréés ni autorisés

pour une utilisation personnelle ou résidentielle, mais sont

destinés à des applications commerciales seulement. Garland

/ U.S. Range n’o re pas de services de réparation, garantie,

entretien ou soutien de n’importe quelle sorte pour des

applications autres que commerciales.

Cet équipement neuf doit être installé et réglé par une

personne compétente, conformément à la loi. Le fait de ne

pas installer correctement des appareils électriques pourrait

entraîner des poursuites. Il est de votre propre intérêt et

sécurité de vous assurer que la loi est respectée. Votre

concessionnaire Garland est quali é pour vous fournir ce

service.

Comme tout autre équipement fabriqué avec précision, il devra

être nettoyé et entretenu de façon régulière. Des inspections

périodiques par le concessionnaire ou une entreprise

d’entretien quali ée sont recommandées pour véri er les

températures, les réglages des brûleurs et s’assurer que les

pièces mobiles fonctionnement correctement. Dans la mesure

du possible, éviter de surchau er l’équipement inutilisé, car

cela représente la principale cause de coûts de réparation.

« Un entretien régulier assure des performances optimales. »

Application Des Produits

La salamandre à infrarouge Garland permet de rôtir toute

une gamme de produits tels que steak, homard, poisson,

soupe à l’oignon, plats en cocotte, pain grillé à l’ail et

hamburgers. La conception à infrarouge au-dessus du feu

assure un préchau age rapide et un chau age e cace et

uniforme. La fonction d’inclinaison des grilles permet de voir

facilement l’état des aliments.

Plaque Signalétique

La plaque signalétique est située sous le bac récepteur

amovible. En cas de questions concernant l’installation,

l’utilisation, l’entretien ou la réparation du produit, écrire ou

communiquer avec le département de service des produits.

Pour correspondre avec l’usine ou le centre de service agréé

local concernant des problèmes de service ou des pièces de

rechange, bien faire référence à l’appareil avec le numéro de

modèle correct (comprenant les lettres et chi res du pré xe

et du su xe) et le numéro de série de garantie. La plaque

signalétique xée à l’appareil contient ces renseignements.

Pour que l’appareil fonctionne correctement, les

informations relatives au combustible de la plaque

signalétique de votre nouvel appareil doivent correspondre

à votre alimentation en combustible.

Piéce nº 1382684 Rev. 2 (11 Feb 2014)Page 16

Page 17

INSTALLATION

Dégagements

Les modèles (M, MS, MST) (SRC, SR16) doivent être installés

dans des emplacements incombustibles seulement avec un

dégagement nul (0”) sur les côtés et à l’arrière.

REMARQUE : Un dégagement su sant doit être prévu pour

l’entretien et l’utilisation.

Emplacement

Les salamandres pour plan de travail doivent être installées

sur une surface solide, lisse et de niveau, conçue pour

résister au poids de l’appareil complètement chargé. Toutes

les ouvertures dans le mur derrière ou à côté de l’appareil

doivent être bouchées.

Instructions D’installation D’une Salamandre

Montée Sur Cuisinière.

la sécurité

d'abord

1. Retirer le panneau avant (5) en dévissant les deux (2) vis

Parker de la partie inférieure de la salamandre.

2. Le panneau arrière (4) étant toujours xé aux montants

(2 et 3), faire descendre les montants dans les ouvertures

rectangulaires à l’arrière de la cuisinière (1).

3. Fixer les montants (2 et 3) à la cuisinière avec quatre (4)

boulons de 5/16 po x 18 et rondelles plates. 6/7

4. Si la cuisinière est installée en batterie, xer ensemble les

unités au trou marqué d’un «X» avec des boulons ¼ po x

20, des écrous et des rondelles.

5. Re xer le panneau avant (5) à la salamandre avec les vis

Parker retirées précédemment.

Salamandres à Montage Mural.

1. Chaque appareil doit être placé en fonction de la

conception du bâtiment et des autres appareils de

manière à en garantir l’accès et en permettre le nettoyage

et l’entretien.

2. Les salamandres prévues pour un montage mural sont

expédiées avec le kit de montage déjà xé.

utiliser des techniques

de levage appropriées

4

8

2

"X"

"X"

1

D

N

LA

R

A

G

5

~

3. Au moment de l’installation, il faut tenir compte des

raccords de gaz prévus en bas ou à l’arrière.

3

6

7

Réglementation Légale

Lors de la véri cation de la pression du gaz, s’assurer que

tous les appareils installés sur la même canalisation sont

allumés. Il n’y a pas de régulateur de pression fourni avec les

équipement standard des salamadres Garland. L’installation

doit être conforme au National Fuel Gas Code ANSI Z 223.1

ou la dernière édition et/ou au code local pour assurer une

fonctionnement sécuritaire et e cace.

Piéce nº 1382684 Rev. 2 (11 Feb 2014) Page 17

Page 18

INSTALLATION suite

Au Canada, l’installation doit être conforme au Code

d’Installation du Gaz Naturel CAN/CGA-149.2 au Code

d’Installation du Propane CAN/CGA B149.2 et aux codes

locaux le cas échéant.

REMARQUE : L’appareil doit être isolé de la canalisation

d’alimentation en gaz en fermant son robinet d’arrêt

individuel (non fourni avec l’appareil), pendant tout essai

du système de canalisations d’alimentation en gaz à des

pressions d’essai égales ou supérieures à ½ PSIG (3,45 kPa).

Alimentation En Gaz

Danger

Couper

l'alimentation

en gaz lors de

l'installation ou

l'Unité des

services

Avant de procéder au montage et à la connexion, véri er

l’alimentation en gaz.

1. Le type de gaz pour lequel l’appareil est équipé est

estampillé sur la plaque signalétique se trouvant derrière

le panneau avant inférieur. Les appareils estampillés

«NAT» doit uniquement être connectés au gaz naturel,

ceux estampillés «PRO» doivent l’être uniquement au

propane.

2. S’il s’agit d’une nouvelle installation, demander à la

compagnie de gaz locale de véri er la taille du compteur

et de la canalisation pour s’assurer que l’appareil peut

être alimenté avec la pression de gaz nécessaire à son

fonctionnement.

3. S’il s’agit d’un équipement de remplacement ou

additionnel, demander à la compagnie locale de gaz de

véri er la pression a n de s’assurer que le compteur et la

canalisation existants alimenteront l’appareil avec une

chute éventuelle de pression ne dépassant pas ½ po de

colonne d’eau.

AVERTISSEMENT: Véri er la présence de fuites sur les

connexions de gaz. Utiliser une solution savonneuse ou une

méthode similaire. NE PAS UTILISER DE FLAMME NUE!

REMARQUE : Cet appareil n’est pas recommandé pour une

installation résidentielle.

Ventilation Et Alimentation En Air.

Une ventilation correcte est extrêmement importante pour

un bon fonctionnement. La méthode idéale de ventilation

pour une salamandre est une hotte correctement conçue,

se prolongeant de six pouces (152 mm) de tous les côtés de

l’appareil et située à six pieds six pouces (1 981 mm) du sol.

Une forte aspiration risque de créer une dépression dans

la pièce. Pour qu’un système d’évacuation fonctionne

correctement, de l’air de remplacement doit entrer dans la

pièce d’où l’air est évacué. La quantité d’air évacuée doit être

égale celle entrant dans la pièce (air d’appoint).

Les brûleurs à gaz et les veilleuses ont besoin de

su samment d’air pour fonctionner et on ne doit pas placer

d’objets encombrants devant ou au-dessus de la salamandre

qui pourraient empêcher l’air d’entrer à l’avant de la

salamandre.

POUR VOTRE SÉCURITÉ, ne jamais placer d’objets sur le

dessus de la salamandre. La température au-dessus de

la salamandre dépasse 1 000° F (538° C). Cela pourrait

causer des brûlures graves et/ou un incendie et aussi

obstruer la ventilation

Essais Et Réglages

Tous les raccords et connexions de tuyaux doivent être

testés pour détecter les fuites éventuelles. Utiliser des

détecteurs de fuites approuvés, de l’eau savonneuse ou des

produits équivalents, appliqués sur et autour des raccords et

connexions de tuyaux. NE PAS UTILISER DE FLAMME ! Pour

accéder à toutes les canalisations de gaz et aux raccords il

est nécessaire de retirer le(s) panneau(x) des robinets, le(s)

panneau(x) inférieur(s) avant et les grilles du four. Il peut être

nécessaire de retirer ou au moins de soulever et de supporter

correctement les grils, les plaques de cuisson et grilles

supérieures. Toutes les pièces retirées (y compris les moyens

de xation) doivent être soigneusement rangées pour les

réutiliser ensuite.

Essais

1. Véri er que tous les robinets et thermostats sont en

position «OFF».

2. Ouvrir le robinet principal d’alimentation en gaz. Allumer

toutes les veilleuses de la section haute.

3. Véri er la présence de fuites aux robinets et raccords,

comme décrit dans la procédure ci-dessus. Réparer les

fuites si nécessaire et véri er de nouveau.

4. Fermer tous les robinets de gaz.

Tous les appareils sont testés et réglés en usine. Cependant,

les brûleurs et les veilleuses doivent être véri és au moment

de l’installation et réglés si nécessaire.

Piéce nº 1382684 Rev. 2 (11 Feb 2014)Page 18

Page 19

FONCTIONNEMENT

REMARQUE: Véri er que l’alimentation en gaz de l’appareil

est activée. Pendant le cycle d’allumage initial, il est

nécessaire de purger l’air de la conduite de gaz et cela

peut prendre une à deux minutes avant que la veilleuse

ne s’allume.

Modèles M, MS

Instructions D’allumage des Veilleuses

1. Le robinet d’arrêt en ligne doit être en position

d’ouverture.

2. Avec une mèche allumée, il est maintenant possible

d’allumer les veilleuses qui sont situées à l’arrière du

brûleur principal.

Remarque: Les veilleuses doivent être toutes

fonctionnelles et être véri ées par un technicien gazier

agréé avant d’utiliser l’unité.

3. Pour allumer correctement les brûleurs, la amme des

veilleuses doit avoir une longueur d’environ 7/8 po. On

trouve le robinet de réglage de veilleuse en faisant glisser

le bac récepteur vers l’avant. Les robinets de réglage se

trouve sur le tube collecteur, qui passe à l’horizontale à

l’arrière de l’appareil, derrière le bac récepteur; l’un se

trouve à l’arrière gauche et l’autre à l’arrière droite.

4. Pour régler la veilleuse, tourner la vis en laiton dans le

sens inverse des aiguilles d’une montre pour augmenter

la amme de la veilleuse et dans le sens des aiguilles

d’une montre pour la diminuer.

Arrêt

1. Placer tous les robinets en position de fermeture en

tournant le bouton d’¼ de tour dans le sens des aiguilles

d’une montre.

2. Si la cuisinière doit être arrêtée pour une période de

temps prolongée, fermer le robinet de gaz de la conduite.

Modèles MST

Commandes

ÉTEINT

ALLUMAGE

Remarque: La longueur de amme des veilleuses ne

devrait pas dépasser 7/8 po. Si la amme est réglée trop

haut, elle décolle des veilleuses ou crée des dépôts de

carbone excessifs. Ne pas régler la amme des veilleuses

plus bas que 7/8 po car cela peut retarder l’allumage du

brûleur. L’allumage retardé pourrait causer des ssures

dans les blocs de brûleur qui, dans ce cas, devraient

être remplacés.

Fonctionnement du Brûleur Principal

1. Tourner le bouton du brûleur principal en position «MAX»

2. Véri er immédiatement l’allumage.

ATTENTION: Si l’allumage ne se fait pas après cinq

secondes, fermer le robinet et attendre cinq minutes avant

d’essayer de nouveau. Le gaz des veilleuses n’est pas coupé

automatiquement. Il incombe à l’opérateur de véri er

l’allumage des brûleurs immédiatement après que le robinet

des brûleurs a été ouvert.

Piéce nº 1382684 Rev. 2 (11 Feb 2014) Page 19

Instructions D’allumage

1. Enfoncer le robinet et le tourner dans le sens inverse des

aiguilles d’une montre jusqu’à la position d’allumage “ ”.

2. En maintenant le robinet enfoncé, allumer la veilleuse

avec une allumette ou une mèche.

3. Une fois la veilleuse allumée, continuer de maintenir le

robinet complètement enfoncé pendant 20 secondes,

MAX

MIN

Page 20

FONCTIONNEMENT suite

puis le relâcher. Si la veilleuse s’éteint, attendre cinq (5)

minutes et recommencer à partir de l’étape 1.

4. Quand la veilleuse est bien allumée, appuyer de nouveau

sur le robinet et le tourner complètement dans le sens

contraire des aiguilles d’une montre jusqu’à la position

“ ” pour allumer le brûleur principal.

5. Pour obtenir une amme basse ou pour mijoter, appuyer

sur le bouton du robinet et le tourner dans le sens

contraire des aiguilles d’une montre jusqu’à la position de

amme basse “ ”.

6. Pour éteindre le brûleur, tourner le cadran à la position

“ ” et le dispositif de sécurité se désengagera dans un

délai de 60 secondes.

Arrêt

1. Placer tous les robinets en position de fermeture en

tournant le bouton d’¼ de tour dans le sens des aiguilles

d’une montre.

2. Si la cuisinière doit être arrêtée pour une période de

temps prolongée, fermer le robinet de gaz de la conduite.

Tous Les Modèles

rougeoient plus et quand la amme va et vient à la surface

de la céramique du brûleur.

Ce réglage a été e ectué en usine; cependant, avec les

changements de pression, ce réglage et celui des veilleuses

peut avoir besoin d’être refait après l’installation. Cela n’est

pas considéré comme un défaut de fabrication et n’est

pas garanti.

Période de Brûlage

Beaucoup de pièces utilisées dans la fabrication de

l’équipement commercial sont recouvertes d’une ne couche

protectrice d’huile mouvement. L’huile doit être brûlée avant

d’utiliser l’équipement pour la préparation des aliments.

Une fois toutes les véri cations de démarrage et de sécurité

terminées, tourner le robinet du brûleur en position «MAX». Il

se produit de la fumée (brouillard bleuâtre). Cette procédure

peut prendre plusieurs heures et peut s’étaler sur

quelques jours.

Suggestions D’utilisation

1. Nettoyer les grilles dès que possible après avoir cuit des

aliments très acides à base de tomate ou de vinaigre. Ces

aliments peuvent causer des piqûres sur la surface du gril.

Allumage Des Brûleurs

Quand l’allumage se fait, une amme bleue couvre la surface

de la céramique pendant 10 à 15 secondes. Cette amme

disparaît et la tige du brûleur devient rouge. Une fois que les

brûleurs ont fonctionné pendant plusieurs minutes, tourner

le robinet sur «MIN». Les tiges de brûleurs cessent d’être

rouges et la amme va et vient à la surface de la céramique

du brûleur.

Réglages du Brûleur Principal

Toutes les salamandres à fromage sont livrée avec des

ori ces de brûleur xes assurant un débit calori que de 20

000 Btu/h sur réglage «MAX» avec du gaz naturel sous une

pression de 6,0 po C.E. et 20 000 Btu/h sur réglage «MAX»

avec du propane sous une pression de 10.0 po C.E.

Le réglage «MIN» peut être modi é en procédant de la

façon suivante:

1. Régler le bouton du robinet du brûleur sur « MIN ».

2. Insérer un petit tournevis plat dans la tige du robinet

pour tourner la fente à l’intérieur de la tige. Tourner dans

le sens des aiguilles d’une montre pour diminuer le débit

de gaz et dans le sens inverse pour l’augmenter.

Le réglage est correct quand les tiges de brûleur ne

2. Laisser la salamandre préchau er avant d’ajouter le

produit.

3. Vider et nettoyer le bac récepteur fréquemment. Un

excès d’huile se vidant dans le bac peut causer un

débordement.

Économies D’énergie

Ne pas gaspiller l’énergie en laissant les commandes sur

les réglages de haute température pendant les périodes

d’inactivité. Des réglages moins élevés garderont la

salamandre à fromage chaude et prête pour la période

d’utilisation suivante. Remettre le bouton du robinet de

brûleur au réglage requis pour les périodes de forte charge.

Précautions De Sécurité

Il est de la responsabilité du superviseur ou d’une personne

équivalente de s’assurer que les utilisateurs de cet

équipement portent des vêtements de protection adaptés

et d’attirer leur attention sur le fait que certaines pièces

deviennent très chaudes par nécessité et causeront des

brûlures si on les touche.

Pour votre sécurité, ne jamais placer d’objets sur le dessus

de la salamandre. La température en haut de la salamandre

dépasse 1 000ºF. Cela pourrait causer des brûlures graves et/

ou un incendie et aussi obstruer la ventilation.

Piéce nº 1382684 Rev. 2 (11 Feb 2014)Page 20

Page 21

ENTRETIEN ET NETTOYAGE

Un programme de méthodes de nettoyage adaptées

contribuera à un fonctionnement continu sans problème de

cet équipement ou de tout autre équipement de qualité.

Chaque Jour

1. Retirer et nettoyer soigneusement la crémaillère de

grille. La crémaillère de grille doit être essuyée chaque

jour pendant qu’elle est encore chaude, avec un torchon

épais ou un autre matériau absorbant la graisse a n

d’éliminer la graisse et les aliments brûlés avant qu’ils ne

brûlent dans la grille. Éliminer les produits brûlés comme

la graisse ou les aliments carbonisés avec une brosse

métallique dure. NE PAS UTILISER DE LAINE D’ACIER.

Des petites particules peuvent être laissées sur la

surface de la grille et risquent pénétrer dans les produits

alimentaires. La crémaillère de grille doit être lavée

soigneusement avec une brosse métallique et une

solution très chaude de détergent doux ou de savon.

Rincer à l’eau claire chaude.

2. La crémaillère étant retirée, nettoyer l’intérieur de

l’appareil avec un chi on humide.

3. Nettoyer le contenant à graisse.

de lubri cation à l’intérieur des robinets. Quand on remarque

que le robinet devient plus dur à tourner, il est alors temps

de le faire lubri er. Nous suggérons de faire exécuter ce type

de travail par un agent de service agréé connaissant bien

l’appareil et ainsi que le gaz naturel et le propane.

Nettoyage Extérieur

Établir un calendrier régulier. Les déversements devront être

essuyés immédiatement.

Essuyer la surface nettoyable exposée quand elle est froide

avec de l’eau chaude et un détergent doux. Les résidus

rebelles peuvent être éliminés avec un tampon à récurer

non métallique. Bien essuyer avec un chi on propre. Laver

une petite surface à la fois, rincer la surface lavée avec une

éponge trempée dans un produit désinfectant et sécher avec

un chi on doux propre avant que la surface ait séché.

Utiliser uniquement des outils en acier inoxydable, en bois

ou en plastique pour gratter les dépôts épais de graisse et

d’huile. Ne pas utiliser de grattoirs ou couteaux en acier

ordinaire, étant donné que des particules de fer risquent de

s’incruster dans le métal et de rouiller. NE JAMAIS UTILISER

DE LAINE D’ACIER.

Chaque Mois

Lubri er les robinets et roulements si nécessaire. À cause de

l’emplacement habituel de la salamandre qui est montée

au-dessus d’une cuisinière avec des plaques ouvertes, la

chaleur provenant des plaques ouvertes fait sécher la graisse

Piéce nº 1382684 Rev. 2 (11 Feb 2014) Page 21

Page 22

RÉPARATION

Pour assurer une longue durée de vie et une utilisation

sécuritaire de l’appareil, il est recommandé d’e ectuer un

entretien à intervalles réguliers, dont la fréquence variera

SÉCURITÉ

Il est essentiel de suivre à la lettre les instructions

contenues dans le présent livret pour un fonctionnement

sûr et économique de cet équipement. Si l’on sait ou si

l’on suppose que l’appareil présente un défaut, il ne doit

pas être utilisé avant que le défaut ne soit recti é par une

personne compétente.

en fonction des conditions d’installation. Les réparations

doivent être e ectuées par des personnes compétentes

selon la réglementation.

Piéce nº 1382684 Rev. 2 (11 Feb 2014)Page 22

Page 23

Piéce nº 1382684 Rev. 2 (11 Feb 2014) Page 23

Page 24

Installation, Operation Manual

MASTER INFRA-RED SALAMANDER BROILER M/MS/MST (SRC, SR16)

Garland Commercial Ranges

http://www.garland-group.com

Loading...

Loading...