Garland M100XR Owner’s Manual

Master Series

Infra-Red & Ceramic Broilers

Installation, Operation and Maintenance Manual

models

M60XR

M60XRC

M60XS

M60XT

M100XR

M100XRC

M100XS

M100XT

M110XM

Original Instructions

Part # 4515576 Rev 2 (01/15/16)

IMPORTANT INFORMATION

WARNING:

This product contains chemicals known to the state of California to cause cancer and/or birth defects

or other reproductive harm. Installation and servicing of this product could expose you to airborne

particles of glass wool/ceramic fibers. Inhalation of airborne particles of glass wool/ceramic fibers

is known to the state of California to cause cancer. Operation of this product could expose you to

carbon monoxide if not adjusted properly. Inhalation of carbon monoxide is known to the state of

California to cause birth defects or other reproductive harm.

Keep appliance area free and clear of combustibles.

FOR YOUR SAFETY:

DO NOT STORE OR USE GASOLINE

OR OTHER FLAMMABLE VAPORS OR

LIQUIDS IN THE VICINITY OF

THIS OR ANY OTHER

APPLIANCE

WARNING:

IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE

CAN CAUSE PROPERTY DAMAGE, INJURY,

OR DEATH. READ THE INSTALLATION,

OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR

SERVICING THIS EQUIPMENT

Users are cautioned that maintenance and repairs must be performed by a Garland authorized service agent

using genuine Garland replacement parts. Garland will have no obligation with respect to any product that has been

improperly installed, adjusted, operated or not maintained in accordance with national and local codes or installation

instructions provided with the product, or any product that has its serial number defaced, obliterated or removed,

or which has been modified or repaired using unauthorized parts or by unauthorized service agents.

For a list of authorized service agents, please refer to the Garland web site at http://www.garland-group.com.

The information contained herein, (including design and parts specifications), may be superseded and is subject

to change without notice.

PLEASE READ ALL SECTIONS OF THIS MANUAL

AND RETAIN FOR FUTURE REFERENCE.

THIS PRODUCT HAS BEEN CERTIFIED AS

COMMERCIAL COOKING EQUIPMENT AND

MUST BE INSTALLED BY PROFESSIONAL

PERSONNEL AS SPECIFIED.

IN THE COMMONWEALTH OF MASSACHUSETTS

THIS PRODUCT MUST BE INSTALLED BY A

LICENSED PLUMBER OR GAS FITTER.

For Your Safety:

Post in a prominent location, instructions to be

followed in the event the user smells gas. This

information shall be obtained by consulting

your local gas supplier.

Part # 4515576 Rev 2 (01/15/16)Page 2

TABLE OF CONTENTS

IMPORTANT INFORMATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Technical Speci cations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Electrical Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Individual Burner Input Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Model Designations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

STATUTORY REGULATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

INSTALLATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Siting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Ventilation Air . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Gas Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Electrical Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Installation Notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Installing Ceramic Radiants (model M60XR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Appliances Equipped With Casters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Appliances Equipped With Legs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Testing & Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

FDO Heavy Duty Oven control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

OPERATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Broiler Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Cast Iron Burner With Ceramic Tile - M60X . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Infra-Red Burners -M100XM, M110XM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Ovens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Standard Ovens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Convection Ovens (RC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

PRODUCT APPLICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Broiler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Convection Ovens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

CARE & CLEANING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Stainless Steel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Oven Interior (Porcelain Enamel) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Broiler Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

General Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

M110XM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

M100X (R/RC/S/TM). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Instructions For Removal Of Grid Rack &

Grid Rack Frame. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

WIRING DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Part # 4515576 Rev 2 (01/15/16) Page 3

SPECIFICATIONS

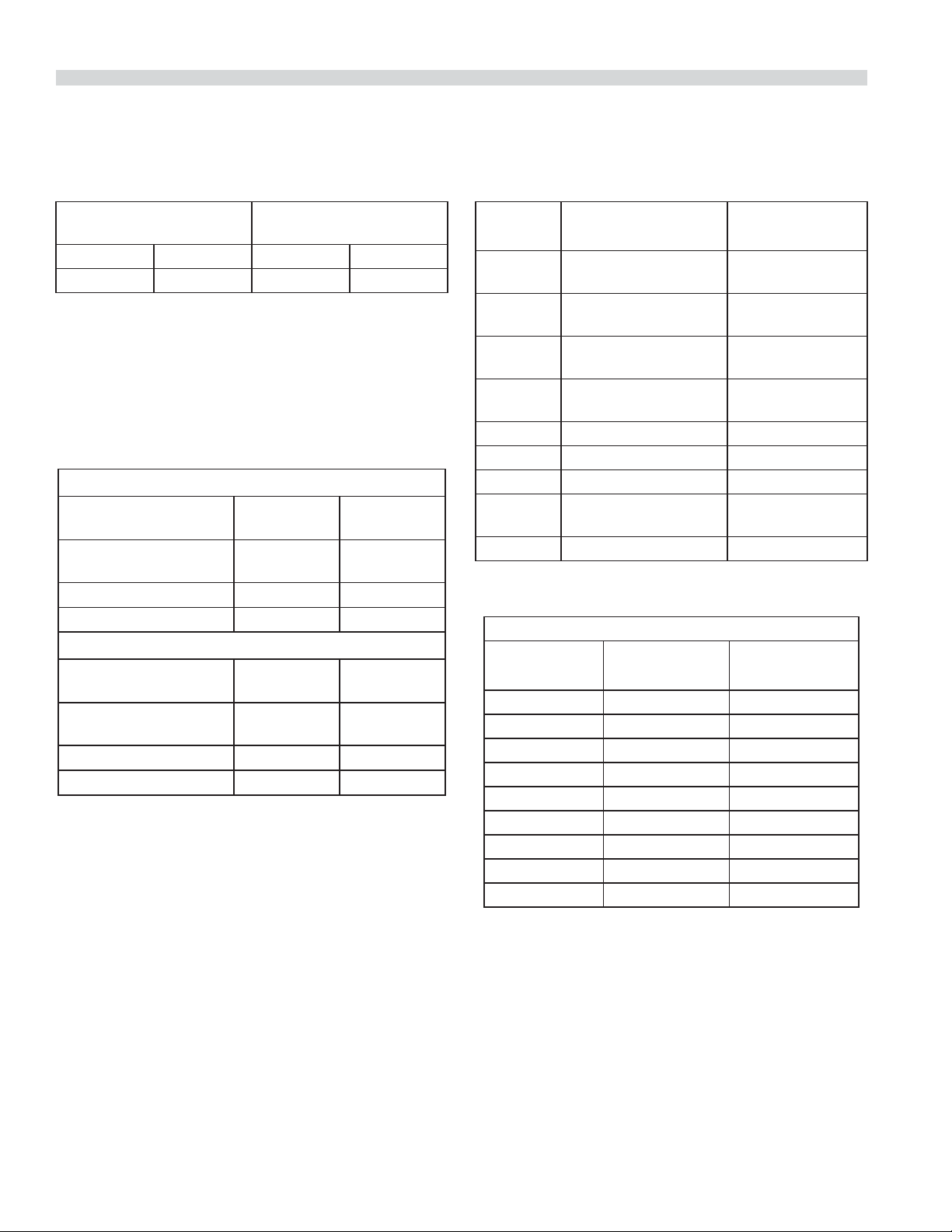

Technical Speci cations

MINIMUM SUPPLY

PRESSURE

Natural Gas: 7” w.c. Natural Gas: 6” w.c.

Propane: 11” w.c. Propane: 10” w.c.

MANIFOLD

OPERATING PRESSURE

Electrical Supply

120V 60Hz, 1A – Infra-Red Burner Models.

120V 60Hz, 4.4A - Models with Infra-Red Burners and a

Convection Oven Base.

Individual Burner Input Ratings

Natural Gas

Burner

Cast Iron Burner With

Ceramic Tile

Infra-Red 70,000 # 50

Oven 40,000 # 33

Burner

Cast Iron Burner With

Ceramic Tile

Infra-Red 70,000 # 56

Oven 35,000 # 50

Input BTU/Hr

per Section

80,000 # 35

Propane

Input BTU/Hr

per Section

80,000 # 48

Ori ce Size

DMS

Ori ce Size

DMS

Model Designations

Model

Number

M60XR Cast Iron Burner With

M60XRC Cast Iron Burner With

M60XS Cast Iron Burner With

M60XT Cast Iron Burner With

M100XR Infra-Red Standard Oven

M100XRC Infra-Red Convection Oven

M100XS Infra-Red Storage

M100XT Infra-Red Counter Top or

M110XM Infra-Red —

Broiler Burner Base

Standard Oven

Ceramic Tile

Convection Oven

Ceramic Tile

Storage

Ceramic Tile

Counter Top or

Ceramic Tile

Modular Stand

Modular Stand

Clearances

INSTALLATION CLEARANCES

Model Number Sides Rear

M60XR 6” (152mm) 6” (152mm)

M60XRC 6” (152mm) 6” (152mm)

M60XS 6” (152mm) 6” (152mm)

M60XT 6” (152mm) 6” (152mm)

M100XR 6” (152mm) 6” (152mm)

M100XRC 6” (152mm) 6” (152mm)

M100XS 6” (152mm) 6” (152mm)

M100XT 6” (152mm) 6” (152mm)

M110XM 6” (152mm) 6” (152mm)

Part # 4515576 Rev 2 (01/15/16)Page 4

GENERAL INFORMATION

1. Check crate for possible damage sustained during transit.

Carefully remove unit from crate and again check for

damage. Any damage to the appliance must be reported

to the carrier immediately.

2. The wires for retaining the burners and other packing

material must be removed from units. Any protective

material covering stainless steel parts must also be

removed.

3. All equipment is shipped from the factory with legs

tted, unless otherwise speci ed. Where the range is to

be mounted on a dais or cove base, it is shipped without

legs. Legs must be tted to the oven where it is installed

on a combustible oor.

STATUTORY REGULATIONS

4. The type of gas and supply pressure that the equipment

was set-up for at the factory is noted on the data plate

and on the packaging. This type of gas supply must be

used.

5. Garland/U.S. Range products are not approved or

authorized for home or residential use, but are intended

for commercial applications only. Garland / U.S. Range

will not provide service, warranty, maintenance

or support of any kind other than in commercial

applications.

6. Do not remove permanently a xed labels, warnings or

data plates from the appliance, for this may invalidate the

manufacturer’s warranty.

The installation of this appliance must be carried out by

a competent person and in accordance with the relevant

regulations, codes of practice and the related publications of

the country and destination.

The installation must conform to the National Fuel Gas Code

ANSI Z223.1-latest edition, NFPA No. 54 – latest edition and

National Electrical Code ANSI/NFPA 70-latest edition and/or

local code to assure safe and e cient operation. In Canada,

the installation must comply with CSA B149.1 and local

codes where applicable.

In Canada, electrical connections must comply with

applicable sections of the Canadian Electrical Code, C22.1 latest edition.

Part # 4515576 Rev 2 (01/15/16) Page 5

INSTALLATION

Siting

The oor on which the appliance is to be sited must be

capable of adequately supporting the weight of the

appliance and any ancillary equipment.

Units with ovens must be tted with legs if installed on a

combustible oor.

Ventilation Air

The following notes are intended to give general guidance.

For detailed recommendations, refer to the applicable

code(s) in the country of destination.

Proper ventilation is highly essential for optimum

performance. The ideal method of ventilating open-top

equipment is the use of a properly designed canopy which

should extend six inches (152mm), beyond all sides of the

appliance(s) and six feet, six inches (1981mm) above the

oor.

A strong exhaust will create a vacuum in the room. For an

exhaust vent to work properly, replacement air must enter

the room. The amount of air that enters must be equal to the

amount exhausted.

All gas burners and pilots need su cient air to operate. Large

objects should not be placed in front of the appliance(s) that

would obstruct the ow of air into the front.

At locations where the manual isolation valve is tted or

the automatic system can be reset, a notice MUST be tted

stating:

“ALL DOWNSTREAM BURNER AND PILOT VALVES MUST

BE TURNED OFF PRIOR TO ATTEMPTING TO RESTORE THE

SUPPLY. AFTER EXTENDED SHUT OFF, PURGE BEFORE

RESTORING GAS SUPPLY.”

Electrical Connection

(Models with Infra-Red Burners and/or Convection Oven

Bases)

IMPORTANT – This appliance must be electrically grounded

in accordance with local codes.

Installation Notices

Before assembly and connection check gas supply.

A. The type of gas for which the unit is equipped is stamped

on the data plate located behind the lower front panel.

Connect a unit stamped “NAT” only to natural gas;

connect one stamped “PRO” only to propane gas.

B. If it is a new installation have the gas authorities check

the meter size and piping to assure that the unit is

supplied with the necessary amount of gas pressure

required for operation.

Gas Connection

The local gas authority should be consulted at the

installation planning stage in order to establish the

availability of an adequate supply of gas and to ensure

that the meter is adequate for the required ow rate. The

pipe work from the meter to the appliances must be of an

appropriate size.

All xed (non-mobile) appliances MUST be tted with a

manual gas-cock upstream of the appliance to provide a

means of isolation for servicing or cleaning purposes. A

union or similar means of disconnection must be provided

between the gas-cock and the appliance.

A manually operable valve must be tted to the gas supply

to the kitchen to enable it to be isolated in an emergency.

Wherever practical, this shall be located either outside the

kitchen or near to an exit in a readily accessible position.

Where it is not practical to do this, an automatic isolation

valve system shall be tted which can be operated from a

readily accessible position near to the exit.

C. If it is additional or replacement equipment have the

gas authorities check the pressure to make certain that

existing meter and piping will supply fuel to the unit with

no more than 1/2” water column pressure drop.

D. Legs must be tted to the oven where it is installed on a

combustible oor.

E. When installed without legs on a non-combustible curb

or plateform, the front of the unit should extend at least 3

inches or 76 mm such that the air vent is not blocked.

NOTE: When checking gas pressure be sure that all other

equipment on the same gas line is on.

The appliance and its individual shut-o valve must be

disconnected from the gas supply piping system during any

pressure testing of that system with pressures in excess of

1/2 PSIG (3.45kPa).

Adequate clearance must be provided for servicing and

proper operation.

THIS APPLIANCE IS NOT RECOMMENDED FOR RESIDENTIAL

INSTALLATION.

Part # 4515576 Rev 2 (01/15/16)Page 6

INSTALLATION Continued

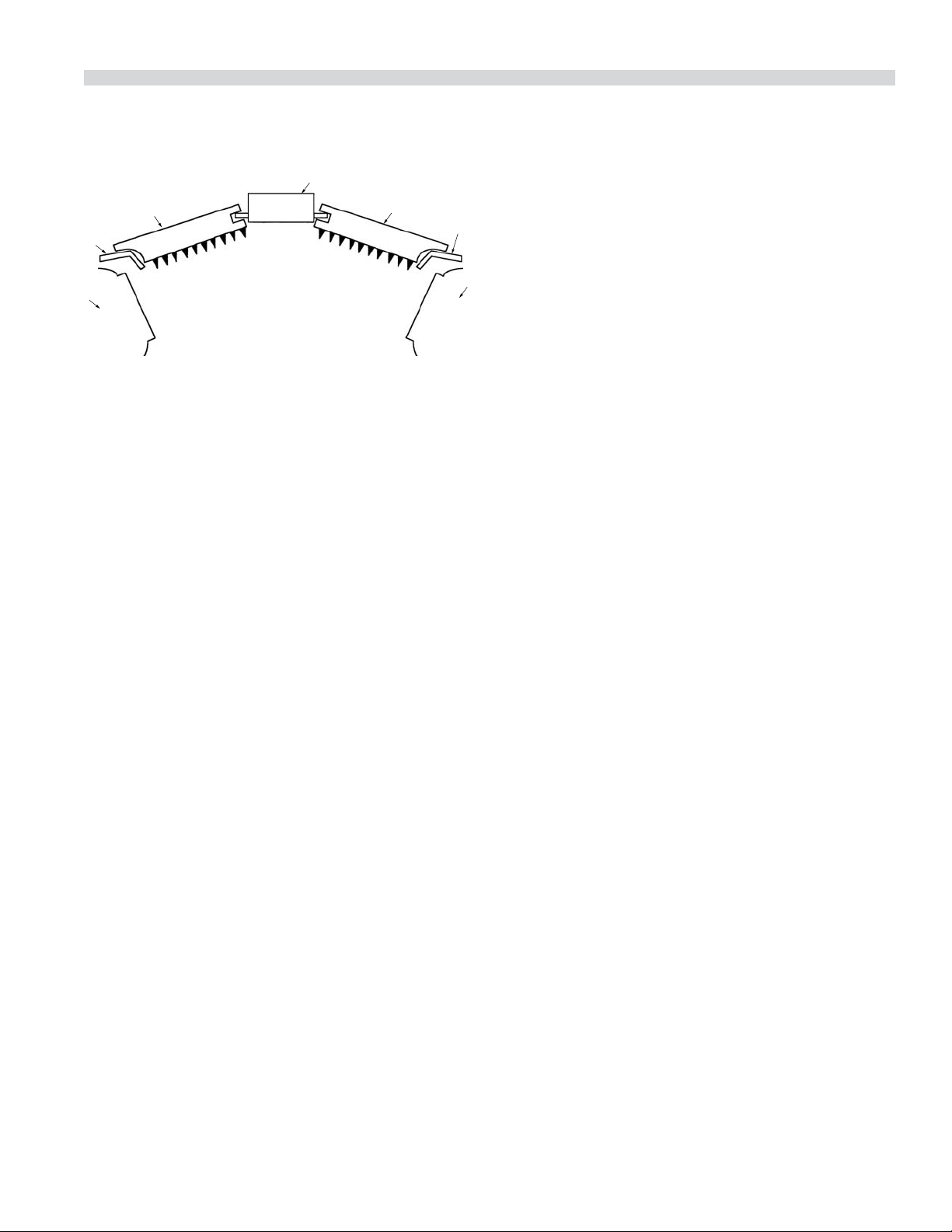

Installing Ceramic Radiants (model M60XR)

i

ii

iii

iv

View: Looking into the front of broiler section.

i. Center Support ii. Ceramic Radiants iii. Side Support Rails iv. Burners

1. Pull forward the broiler rack of the ceramic broiler

section. Lift out rack insert and remove grease deflector

pan beneath rack assembly by raising it off the shoulder

bolts at the rear of the rack front plate.

2. Lower rack raising mechanism to its lowest position and

tie or wire the raising arm in place to avoid premature

release of the raising mechanism.

3. Start with the left side. Projections of the ceramic

radiants, will be down and the groove of the ceramic

radiants will be toward the center of the unit (See

sketch). Tilt the ceramic radiant to permit it to clear both

the side support and the center support and raise the

radiant above these 2 supports. Fit the groove of the

ceramic radiant into the flange of the center support

and lower its outer edge to rest on the top of the side

support. Slide this ceramic radiant to the rear and

repeat this with the two remaining ceramic radiants

overlapping.

4. Installation of the ceramic radiants on the right side is

similar to that as described above, except that you will

start from the front and work toward the rear. It may be

necessary to tilt the adjacent ceramic radiant upward

slightly to permit the interlocking of the final ceramic

radiants.

5. When all radiants have been installed, slide them as far

as possible to provide for proper flue movement.

ii

iii

2. The front casters on the appliance are equipped with

brakes to limit the movement of the appliance without

placing any strain on the connector or quick-disconnect

device or its associated piping.

3. Please be aware that the required restraint is attached to

a bracket (which is located on the rear caster closest to

iv

the gas connection) and if disconnection of the restraint

is necessary, be sure to reconnect the device after the

appliance has been returned to its original position.

Appliances Equipped With Legs

1. Raise the front of the appliance an block. Do not lay the

appliance on its back.

2. Position leg insert in leg retainer opening and tap upward

until the insert seats at the collar ange.

3. Repeat leg insert installation for the other legs and adjust

all four legs to the same height.

4. Legs can be further adjusted to level the appliance and to

compensate for uneven ooring.

Testing & Adjustment

All ttings and pipe connections must be tested for

leaks. Use approved gas leak detectors, soap solution or

equivalent, checking over and around all the ttings and

pipe connections. DO NOT USE A FLAME! Accessibility to

all gas lines and ttings require that valve panel(s), lower

front panel(s), and/or oven rack(s) be removed. It may be

necessary to remove, or at least raise and securely prop

griddles, hot top, and/or top grates. All parts removed,

(including fasteners), should be stored safely for reinstallation.

1. Be sure that all valves and thermostats are in the “OFF”

position.

2. Turn on the main gas supply valve. Light all broiler pilots.

3. Leak test all valves and ttings as described at the

beginning of this section. Correct any leaks as required

and recheck.

Appliances Equipped With Casters

1. The installation shall be made with a connector that

complies with the Standard for Connectors for Moveable

Gas Appliances, ANSI Z21.69/CSA 6.16, Addenda

Z21.69B-2006/CSA 6.16B-2006 (or latest edition), and a

4. Light the oven pilot.

5. If the range is equipped with an oven on/o valve

separate from the thermostat, turn this valve on. If

the oven thermostat dial has an “OFF” position the

thermostat is its own on/o valve.

quick-disconnect device that complies with the Standard

for Quick Disconnects for Use with Gas Fuel, ANSI Z21.41/

CSA 6.9, Addenda Z21.41A-2005/CSA 6.16A-2005 (or

latest edition).

6. In either case, now set the thermostat to 500°F (260°C).

Leak test all valves and ttings as described at the

beginning of this section. Correct any leaks as required

and recheck.

Part # 4515576 Rev 2 (01/15/16) Page 7

INSTALLATION Continued

7. Shut o all valves and set thermostat dials to “OFF” or

lowest position.

All units are tested and adjusted at the factory, however,

burners and pilots should be checked upon installation and

adjusted if necessary.

CAUTION: Gas will ow to the top section burners even

if the broiler section pilots are not lit. Gas will not be

interrupted. It is the responsibility of the operator to

con rm the proper ignition of each burner as it is turned

on. Should ignition fail to occur 5 seconds after turning

a burner on, turn the burner o , wait 5 minutes, and try

again.

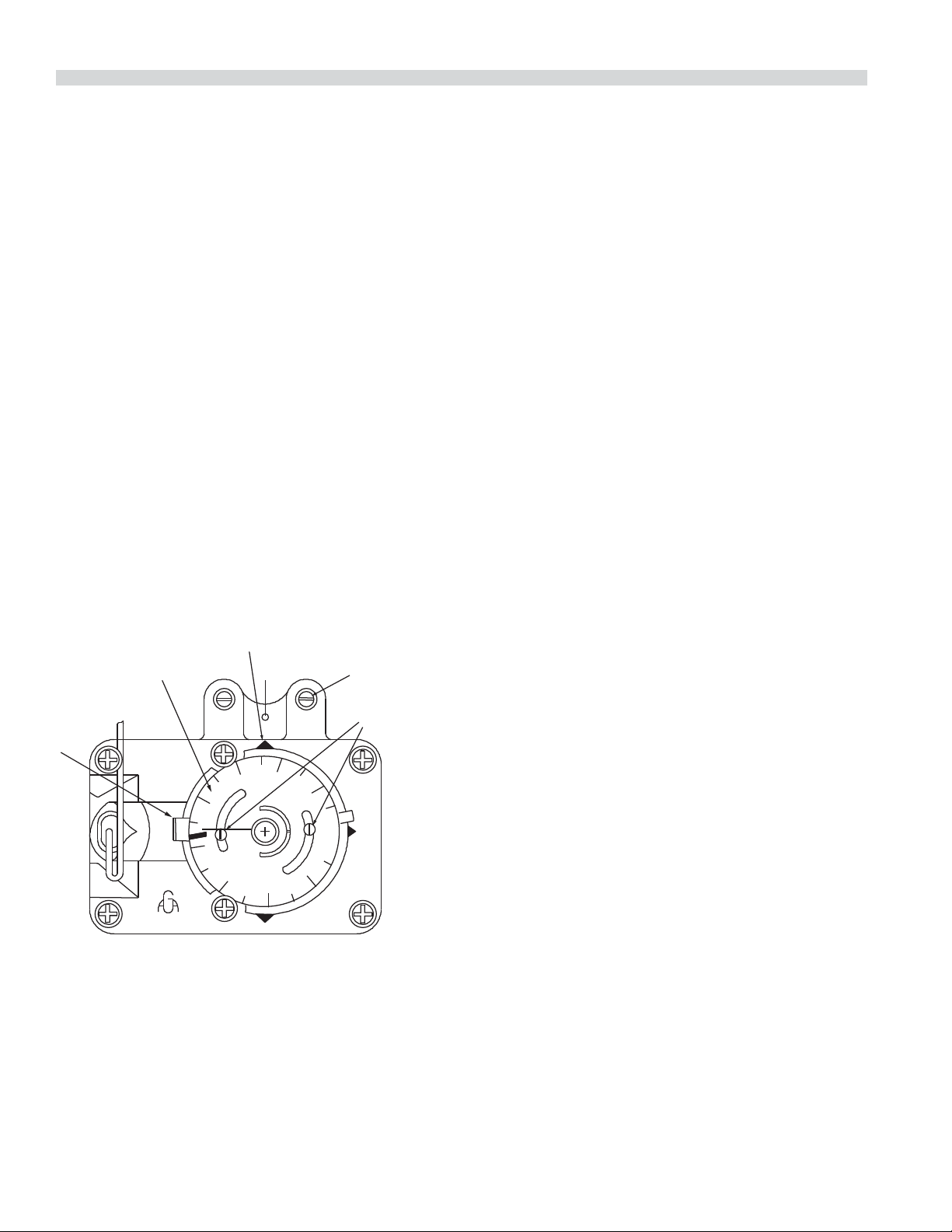

FDO Heavy Duty Oven control

The model FDO oven thermostat is a precision-made

instrument, carefully set at the factory to accurately control

oven temperatures from 150° to 500°F, (66° to 260°C). All

adjustments are accessible from the front of the appliance

after moving the dial. To remove the dial, grasp the outer

edges and pull straight out.

By-Pass Adjustment

The Robertshaw FDO snap/throttle thermostat requires that

the by-pass ame be properly adjusted. To adjust proceed as

follows:

Calibration

Plate

Dial

Stop

MODEL

FDO

Indicator Mark

0

5

4

0

0

4

0

5

3

0

0

3

0

5

2

By-pass Flame

Adjuster

Calibration

Lock Screws

5

0

0

5

5

0

1

5

0

3

0

0

clockwise to decrease, or counter-clockwise to increase

the ame on the burner to the lowest possible stable

ame. When properly adjusted, the by-pass ames will

cover the entire length of the burner.

Calibration Instructions

Field calibration is seldom necessary and should not

be resorted to unless experience with cooking results

undoubtedly indicate that the control is not maintaining

the temperature for which the dial is set. To check oven

temperatures when calibrating, use only a reliable mercury

thermometer, or preferably an oven pyrometer. To check

calibration, proceed as follows:

1. Place the thermocouple of the test instrument or reliable

mercury thermometer in the center of the oven.

2. Turn the oven temperature control knob to 400°F, (204°C),

and allow the oven to cycle at least three times.

3. Continue to monitor the oven temperature, recording

the readings at 5 minute intervals until three successive

readings are within 5°F, (2°C), of each other.

If the temperature does not read within 15°F, (8°C), of the dial

setting, recalibrate as follows.

1. Remove the oven temperature control dial, making sure

the setting is not disturbed.

2. Hold the calibration plate, (located directly behind the

control dial), and loosen the two calibration lock screws

until the plate can be rotated independently of the

control.

3. Turn the calibration plate until the temperature indicated

on the plate corresponds with the reading on the test

instrument. Hold the plate in place and tighten the

screws rmly.

4. Repeat step 3 in the previous section, checking the

temperature to ensure the adjustment has been made

properly.

5. Replace the temperature control dial.

1. Ensure pilot ame is lit and adjusted.

2. Turn oven temperature control to 200°F, (93°C), and allow

the oven to heat for three minutes.

3. Turn, the oven temperature control to the lowest

position, then turn slowly counter-clockwise until the

audible “click” is heard.

4. Making sure the oven temperature control dial is not

disturbed, turn the by-pass ame adjusting screw

NOTE: If adjustment of the calibration plate is prevented by

the position of the lock screws, the screws can be moved to

other holes that have been tapped for them.

Part # 4515576 Rev 2 (01/15/16)Page 8

OPERATION

Broiler Section

Cast Iron Burner With Ceramic Tile - MX

Initial Operation:

When all gas connections have been inspected, proceed as

follows to put the unit into operation:

1. Open gas service valve located in your supply line.

2. With a lighted taper, light the broiler pilots located at the

front of the unit. There is one pilot per burner.

3. Pilot adjustment valves can be found on the manifold,

behind the control panel. The valves may be accessed

through holes in the control panel.

4. The pilot ame should be adjusted to provide a ame

7/8”(22mm) to 1”(25mm) in length.

Operation:

1. Turn the broiler valve to HIGH.

2. Immediately check ignition of the burners.

These special burners operate in a manner similar to that

of a conventional gas burner except that the radiation

surfaces consist of a series of ceramic blocks each containing

numerous small gas ports. These ceramic blocks are

connected utilizing a special compound that also seals all

seams of the radiating surface. The gas ame appears as a

red glow covering the entire ceramic surface.

A special wire mesh has been provided as an outside

surface beneath the ceramics to further increase the burner

e ciency. This mesh will provide for additional infra-red

energy.

Initial Operation:

1. Connect electrical supply.

2. Open gas service valve located in your supply line.

3. With a lighted taper, light the broiler pilots located at the

front of the unit. There is one pilot per pair of burners.

4. Pilot adjustment valves can be found on the manifold,

behind the control panel. The valves may be accessed

through holes in the control panel.

3. When ignition has been accomplished a blue ame will

cover the length of the burner.

4. Flames will ow upward over ceramic radiant bricks and

will glow red.

Shut-Down:

1. Turn all valves to the “OFF” position.

2. If the unit is to be shut down for an extended period of

time, close the in-line gas valve.

Infra-Red Burners -MXM, MXM

The GARLAND® Infra-Red Broiler is a direct radiant heavy

duty gas broiler utilizing four (4) extremely e cient gas

burners in each broiling section. The infra-red burners

provide for high speed broiling with rapid searing of product

so that natural juices and avor will be sealed in.

5. The pilots should be adjusted so that ame extends 1/2”

to 3/4” (12mm to 25mm) beyond the pilot shield.

Operation:

1. Switch on (1) the main power switch.

2. Turn the broiler valve to HIGH.

3. Immediately check ignition of the burners.

4. When ignition has been accomplished a blue ame will

cover the surface of the ceramics for 10-15 seconds.

5. The haze will disappear and the ceramics will glow red.

Shut-Down:

1. Turn all valves to the “OFF” position.

2. Switch o (0) the main power switch.

3. If the unit is to be shut down for an extended period of

time, close the in-line gas valve.

Part # 4515576 Rev 2 (01/15/16) Page 9

OPERATION Continued

CAUTION: Should burner ignition fail within 5 seconds,

turn the burner valve o and repeat steps 1 through 5. If

ignition continues to fail, consult your factory authorized

service agency.

Ovens

Standard Ovens

Lighting:

1. Push in the main / pilot gas valve and turn it counterclockwise to the IGNITION position.

2. Lower the front kick panel.

3. Holding the oven gas valve fully in, press the red piezo

igniter button several times.

4. When the pilot burner is lit, continue holding in the oven

gas valve for 20 seconds, then release it. If the pilot goes

out, wait ve minutes and try again.

5. When the pilot ame is established, push the gas

valve in again and turn it counter-clockwise to the full

ON position, then set the thermostat to the desired

temperature.

Shut-Down:

1. Turn all valves to the OFF position and the safety device

will disengage within 60 seconds.

2. If the unit is to be shut down for an extended time, close

the in-line gas valve.

Re-lighting:

Convection Ovens (RC)

Lighting:

Same as standard oven.

Start-Up:

1. Activate the power switch to COOK position.

2. Turn oven valve ON.

3. Turn thermostat to desired setting.

Cool Down:

1. Turn thermostat and oven valve OFF.

2. Open door.

3. Activate power to the COOL DOWN position.

The motor on your range convection oven is maintenance

free since it is constructed with self-lubricating sealed ball

bearings. It is designed to provide durable service when

treated with ordinary care. We have a few suggestions to

follow on the care of your motor.

A When the motor is operating, it cools itself internally by

air entering the rear of the motor case, provided proper

clearance has been allowed.

B. Since the blower wheel is in the oven cavity it is at the

same temperature as the oven. If the motor is stopped

while the oven is hot, the heat from the blower wheel is

conducted down the shaft and into the armature of the

motor. This action could shorten the motor life.

1. Turn all gas valves o .

2. Wait ve minutes.

3 Follow procedure under “Lighting” at left.

C. We recommend, at the end of the bake or roasting

period, when the oven will be idle for any period of time

or before shutting down completely, that the doors be

left open, and by use of the cool down position on the fan

switch, the fan continues to run for at least 20 minutes.

Note: The convection oven motor should never be turned

“OFF” during cooking or when the oven is “HOT”.

Part # 4515576 Rev 2 (01/15/16)Page 10

Loading...

Loading...