Garland MIR34L, IR36-280L, IR-280WL, IR36-380CL, IR60-280L Installation & Operating Manual

...Page 1

INSTALLATION, OPERATING

& SERVICE INSTRUCTIONS

FOR GARLAND INFRA-RED SALAMANDER

BROILERS AND INFRA-RED CHEESE MELTERS

WARNING:

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER

FLAMMABLE VAPORS OR LIQUIDS IN THE

VICINITY OF THIS OR ANY OTHER APPLIANCE.

PLEASE READ ALL SECTIONS OF THIS MANUAL AND RETAIN FOR FUTURE REFERENCE.

THIS PRODUCT HAS BEEN CERTIFIED AS COMMERCIAL COOKING EQUIPMENT AND MUST BE INSTALLED

BY PROFESSIONAL PERSONNEL AS SPECIFIED.

IN THE COMMONWEALTH OF MASSACHUSETTS THIS PRODUCT MUST BE INSTALLED BY A LICENSED

PLUMBER OR GAS FITTER. APPROVAL NUMBER: G-1-07-05-28

IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE CAN

CAUSE PROPERTY DAMAGE, INJURY OR DEATH.

READ THE INSTALLATION, OPERATION AND

MAINTENANCE INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR SERVICING

THIS EQUIPMENT.

For Your Safety:

Post in a prominent location, instructions to be followed in the event the user smells gas. is information shall be

obtained by consulting your local gas supplier.

Users are cautioned that maintenance and repairs must be performed by a Garland authorized service agent using genuine

Garland replacement parts. Garland will have no obligation with respect to any product that has been improperly installed,

adjusted, operated or not maintained in accordance with national and local codes or installation instructions provided

with the product, or any product that has its serial number defaced, obliterated or removed, or which has been modified

or repaired using unauthorized parts or by unauthorized service agents. For a list of authorized service agents, please refer

to the Garland web site at http://www.garland-group.com. e information contained herein, (including design and parts

specifications), may be superseded and is subject to change without notice.

Continuous product improvement is a Garland policy, therefore design and specifications are subject to change without notice.

GARLAND COMMERCIAL INDUSTRIES

185 East South Street

Freeland, Pennsylvania 18224

Phone: (570) 636-1000

Fax: (570) 636-3903

Part # 1382669 (07/05) Page 1

Part # 1382669 (07/05) © 2005 Garland Commercial Industries, Inc.

GARLAND COMMERCIAL RANGES,

LTD.

1177 Kamato Road, Mississauga, Ontario L4W 1X4

CANADA

Phone: 905-624-0260

Fax: 905-624-5669

Enodis UK LTD.

Swallowfield Way, Hayes, Middlesex UB3 1DQ ENGLAND

Telephone: 081-561-0433

Fax: 081-848-0041

Page 2

INTRODUCTION

WARNING:

is product contains chemicals known to the State of California to cause birth defects or other reproductive

harm. Operation of this product could expose you to carbon monoxide if not adjusted properly. Inhalation of

carbon monoxide is known to the State of California to cause birth defects or other reproductive harm.

Keep appliance area free and clear from combustibles

Units included in this manual are:

Salamander Models: MIR34L, IR36-280L,IR-280WL,

IR36-380CL, IR60-280L

Cheese Melter Models: GCM-2C, GCM-3C, GCM-6C,

GCM24-280G, CM36-280,

GCM72-280, MCM34

Part # 1382669 (07/05)Page 2

Page 3

TABLE OF CONTENTS

Introduction . . . . . . . . . . . . . . . . . . . . . . . . 2

Dimensions And Specifications,

Model MIR 34L . . . . . . . . . . . . . . . . . . . . . 4

Dimensions And Specifications,

Model IR-280L Series . . . . . . . . . . . . . . . . . 5

Dimensions And Specifications,

Cheese Melter . . . . . . . . . . . . . . . . . . . . . . . 6

General Information . . . . . . . . . . . . . . . . . . 7

Salamander Performance and Construction . . . . 7

Cheese Melter Performance and Construction . . 7

Rating Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Installation . . . . . . . . . . . . . . . . . . . . . . . . . 8

National Code Requirements . . . . . . . . . . . . . . . 8

Operation . . . . . . . . . . . . . . . . . . . . . . . . . 12

Pilot Lighting Instructions . . . . . . . . . . . . . . . . 12

Main Burner Operation . . . . . . . . . . . . . . . . . . 12

Burn off Period . . . . . . . . . . . . . . . . . . . . . . . . . 12

Energy Conservation . . . . . . . . . . . . . . . . . . . . 12

Shut Down Instructions . . . . . . . . . . . . . . . . . . 12

Main Burner Adjustments . . . . . . . . . . . . . . . . 12

Maintenance And Cleaning . . . . . . . . . . . 13

Daily . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Monthly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Exterior Cleaning . . . . . . . . . . . . . . . . . . . . . . . 13

Gas Connections . . . . . . . . . . . . . . . . . . . . . . . . 8

Pressure Regulators in Battery Installations. . . . . 8

Installation of Salamander to a Range. . . . . . . . . 9

Assembly Instructions Salamander/Cheese Melters

M-Series Salamanders/Cheese Melters . . . . . . . 9

Models IR60-280L, GCM60-280 . . . . . . . . . . 10

Models IR48-280L IR72-280L, GCM48-280,

GCM72-280 . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Models IR48-280L or GCM48-280 Mounting to

48” Range with one Full Size Oven . . . . . . . . . 10

Wall Mounted Salamanders, Cheese Melters or

Counter Mounted Salamander or

Cheese Melters . . . . . . . . . . . . . . . . . . . . . . . . . 11

Ventilation and Air Supply . . . . . . . . . . . . . . . . 11

Clearances: . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Part # 1382669 (07/05) Page 3

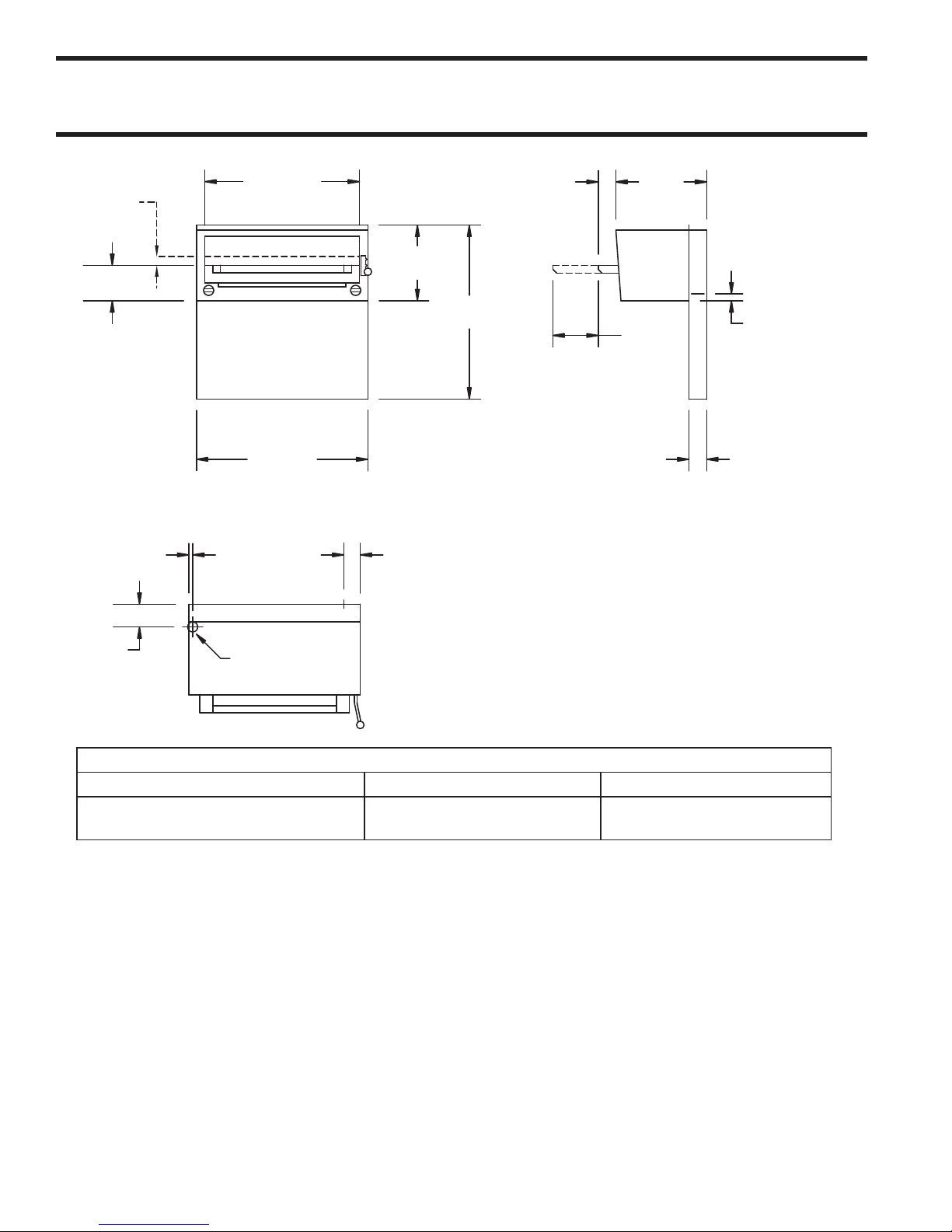

Page 4

DIMENSIONS AND SPECIFICATIONS, MODEL MIR 34L

3-1/2"

[89mm]

18"

[457mm]

3-1/2"

[89mm]

9”

[229mm]

1-3/8"

[35mm]

REARGAS

INLETON

”W"&"C"

MODELS

¾"

[19mm]

4-1/2"

[114mm]

3-1/4"

[83mm]

REARGAS

INLETON

"W"&"C

MODELS

1/2"N.P.T.

[13mm]

TOPGAS

INLET

34"

[864mm]

15"

[381mm]

7"

[178mm]

1-3/4"

[44mm]

34-1/2"

[876mm]

30-11/16"

[779mm]

INSTALLATION NOTES

Combustible Wall Clearances ¹ Entry Clearances Operating Pressure

Sides: 6" (152mm)

Back: 6" (152mm)

¹NOTE: Installation clearance reductions are applicable only where local codes permit.

Crated: 39 3/4" (997mm)

Uncrated: 34-3/4" (870)

Natural: 6" WC (15mbar)

Propane: 11" WC (28mbar)

Data applies only to North America

Commercial cooking equipment requires an adequate ventilation system. For additional information, refer

to the National Fire Protection Association's standard NFPA96. (for North American only)

Gas input ratings shown here are for installations up to 2,000 ft. (610m) above sea level.

Specify altitudes over 2,000 ft.

Please specify gas type when ordering.

Part # 1382669 (07/05)Page 4

Page 5

DIMENSIONS AND SPECIFICATIONS, MODEL IR-280L SERIES

4-1/2"

1-3/4"

[44mm]

3-1/2"

[89mm]

1-3/8"

[35mm]

OPTIONAL

REAR

GAS

INLET

3-1/4"

[83mm]

OPTIONAL

REAR

GAS

INLET

1/2"N.P.T.

[83mm]

TOP

GAS

INLET

18"

[457mm]

1-3/4"

[45mm]

9"

[229mm]

34"

[864mm]

15"

[381mm]

15"

[381mm]

30"

[762mm]

36"

[914mm]

Model Width

IR36-280L 36" (914mm) H286 200/91 29" (737mm) 21" (533mm)

IR48-280L

IR60-280L

IR72-280L

(36" broiler + 12"/305mm flue riser w/shelf)

(36" broiler + 24"/610mm flue riser w/shelf)

(36" broiler + 36"/914mm flue riser w/shelf)

48"(1219mm)

60" (1524mm)

72" (1829mm)

Use With H280

Series Model

H288 230/105 29" (737mm) 21" (533mm)

H284 & H287 260/118 29" (737mm) 21" (533mm)

H289 280/127 29" (737mm) 21" (533mm)

Shipping Wt.

Lbs./Kgs.

Entry Clearances: In (mm)

Crated Uncrated

Note Salamander Broiler on Left Side. Right Side Optional

Operating Pressure Installation Clearances Total Input Orifice

Natural Propane Sides Rear

6"WC (15mbar) 11"WC (28mbar) 6"(152mm) 6"(152mm) #48F #55F

40,000 BTU/HR (11.7Kw)

NAT PRO

Gas input ratings shown for installations up to

2000 ft., (610m), above sea level.

Please specify altitudes over 2000 ft.

For use on noncombustible floors

Commercial cooking equipment requires an

adequate ventilation system. For additional

information, refer to the National Fire Protection

Association's standard NFPA96.

This product is not approved for residential use.

Part # 1382669 (07/05) Page 5

Page 6

DIMENSIONS AND SPECIFICATIONS, CHEESE MELTER

20"

[508mm]

17-3/8"

[441mm]

31-1/4"

[794mm]

8-3/8”

[213mm]

5-13/32"

[137mm]

3-1/2"

[89mm]

15-1/2"

[394mm]

37-3/8"

[949mm]

37-3/8"

[949mm]

15-1/2"

[394mm]

3-1/2"

[89mm]

2-1/4"

[57mm]

19"

[483mm]

2"

[51mm]

34"

[864mm]

1/2"N.P.T.[13mm]

TOPGASINLET

19"

483mm]

1/2"N.P.T.

[13mm]

TOPGAS

INLET

2-1/4"

[57mm]

2"

[51mm]

24"

[610mm]

17-3/8"

[441mm]

20"

[508mm]

5-13/32

[137mm]

8-3/8"

[213mm]

21-1/4"

[540mm]

Model Width Depth Height

GCM 24-280 24" (610,mm) 19" (483mm) 37-1/4" (946mm)

GCM 36-280 36" (314mm) 19" (483mm) 37-1/4" (946mm)

MCM 34 34" (864mm) 19" (483mm) 37-1/4" (946mm) 24"(610mm 20"(508mm)

Note: Data applies only to North America

Operating Pressure Installation Clearances Input: Natural and Propane Orifice

Natural Propane Sides Rear

6" WC (15 mbar) 11" WC (28 mbar) 6" (152mm) 6" (152mm)

NOTE: Installation clearance reductions are applicable

Model Shipping Wt. (Lbs./Kg)

GCM 34 180/82

GCM 36-280 180/82

GCM 60-280 220/100

GCM 72-280 240/109

only where local codes permit

Commercial cooking equipment requires an adequate

ventilation system. For additional information, refer to the

National Fire Protection Association's standard NFPA96.

Gas input ratings shown for installations up to 2000 ft.,

(610m), above sea level. Please specify altitudes over

2000 ft.

Please specify gas type when ordering.

This product is not approved for residential use

Entry Clearances: All Models

Crated Uncrated

15,000 BTU/Hr (4.39 Kw) per Burner

30,000 BTU/Hr (8.79 Kw) Total

Nat #50F

Pro #57F

Part # 1382669 (07/05)Page 6

Page 7

GENERAL INFORMATION

e range-mounted, gas Infra-Red Salamander Broiler

and Infra-Red Cheese Melter is designed as M Series

and H/P Series Models for perfect match and fit.

e range-mounted, gas Infra-Red Cheese Melter Broiler

is designed as Series and H/P Series Models for

perfect match and fit. Ideal for preparing melted cheese

dishes, casseroles, au gratin dishes, soufflés, Mexican

food and other ethnic foods.

Garland/U.S. Range products are not approved or

authorized for home or residential use, but are intended

for commercial applications only. Garland / U.S. Range

will not provide service, warranty, maintenance or support

of any kind other than in commercial applications.

Salamander Performance and Construction

Two Hi-Low gas valves provide individual control of the

() atmospheric-type , BUT gas infra-red burners

for the Salamander. “LO” position is adjustable for most

field gas pressure situations. Fast preheat and uniform

production is provided by the high-efficiency, infrared burners. Unique atmospheric design eliminates the

need for fans and filters. Heat is directed downward to

the large - square inch plus – heavy duty broiling

rack. Rack is easily removed from spring balanced rack

assembly. Rack assembly rolls out for ease of loading and

unloading. Rack assembly raises and lowers with positive

locking in three positions. Full-width grease deflector

attached to the underside of the rack assembly channels

hot drippings to a large capacity drain pan even when

rack assembly is rolled out. e rack assembly and drain

pan are easily removed for cleaning. e MIRL is ”

wide and is supported by heavy-formed brackets with

stainless steel back-splash. Front and sides of salamander

are stainless steel.

IR- is ” wide, supported by heavy-formed

brackets. Salamander front & back-splash is stainless

steel with black baked enamel sides.

IR-L has a finished width of ” which includes

a ” wide shelf. Salamander front and back-splash is

stainless steel with black baked enamel sides.

Cheese Melter

Performance and Construction

Twenty-four inch wide model has a single atmospheric

type, , BTU gas infra-red burner. irty-four and

thirty six inch wide models each have two () atmospheric

type, , BTU has infra-red burners. Burners are

individually controlled by three () position three ()

heat valves (HI, LO, OFF). Fast preheat and uniform

production is provided by the high-efficiency, infra-red

burners. Unique atmospheric design eliminates the need

for fans and filters. Heat is directed downward to the

large heavy chrome-plated rack. Sturdy chrome-plated

rack guides support the rack, which is adjustable to three

() positions. Rack and rack guides are easily removed

for cleaning.

H/P Series and Series range mounted cheese melters

are securely supported by heavy formed brackets.

H/P Series and Series cheese melters are standard

with stainless steel fronts. Backsplash and remainder of

exterior are finished in black baked enamel. Pressure

regulator is standard.

Rating Plate

When corresponding with the factory or your local

authorized factory service center regarding service

problems or replacement parts, be sure to refer to the

particular unit by the correct model number (including

the prefix and suffix letters and numbers) and the

warranty serial number. e rating plate affixed to the

unit contains this information.

We suggest installation, maintenance and repairs should

be performed by your local authorized service agency

listed in your information manual pamphlet.

In the event you have any questions concerning the

installation, use, care or service of the product, write or

call our Product Service Department.

is product has been certified as commercial cooking

equipment and must be installed by professional

personnel as specified.

Part # 1382669 (07/05) Page 7

Page 8

INSTALLATION

National Code Requirements

e importance of the proper installation of Commercial

Gas Cooking Equipment cannot be over stressed. Proper

performance of the equipment is dependent, in great

part, on the compliance of the installation with the

manufacturer’s specifications. Installation must conform

to local codes or, in the absence of local codes, with

the National Fuel code, ANSI Z., Natural Gas

Installation Code, CAN/GCA-B. or the Propane

Installation Code, CAN/CGA-B., as applicable.

Gas Connections

Before assembly and connection, check gas supply.

A. e type of gas for which the unit is equipped is

stamped on the data plate located on the lower front

frame, simply remove the drip pan for easy access.

Connect a unit stamped “NAT” only to natural

gas; connect those stamped “PRO” only to propane

gas.

B. If it is a new installation, have gas authorities

check meter size and piping to assure that the unit

is supplied with sufficient amount of gas pressure

required to operate the unit.

C. If it is additional equipment or replacement have

a qualified gas technician check the gas pressure

to make certain that existing gas facilities (meter

piping, etc.) will deliver the BTU’s of gas required

at the unit with no more than ½” water column

pressure drop. When checking pressure, be certain

that other equipment on the same gas line is on at

full rate.

NOTE: When checking pressure, be sure that all

other equipment on the same gas line is on. A pressure

regulator is supplied with Garland Infra-Red Broilers.

Regulator is preset at deliver gas at pressure shown on

the rating plate.

D. e appliance and its individual shut off (supplied

by others) must be disconnected from the gas supply

piping system during any pressure testing of that

system at pressures in excess of ½” psi (3.45 kPa).

E. e appliance must be isolated from the gas supply

piping system by closing its individual manual shut

off valve (supplied by others) during any pressure

testing of the gas supply piping system at test

pressures equal to or less than ½ psi (3.45 kPa).

F. Gas supply connection is made in back lower left

hand corner of unit. A readily accessible approved

type of hand valve should be installed on each

supply line. Test for leaks – DO NOT USE ANY

OPEN FLAME.

G. A pressure tap plug is supplied with the units and it

is installed on the manifold. e drip pan must be

removed to use the pressure tap. e gas pressure

must be checked when the unit is installed, to insure

that the unit gas pressure is the same as specified on

the rating plate. If necessary, pressure adjustments

must be made at the pressure regulator, supplied on

each Infra-Red Broiler.

NOTE: the pressure regulator is located at the top rear

of the salamander.

H. If it is completely new installation, have gas lines,

meter size piping and piping installed and checked

by a qualified gas technician.

I. Make certain that the new piping, joints and

connections have been made in a clean manner and

have been purged, so that the piping compound,

chips, etc, will not clog pilots, valves and/or

controls. Use pipe joint sealant that is resistant to

liquefied petroleum gas.

WARNING Check gas connections for leaks. Use a

soap solution or similar means. DO NOT USE AN

OPEN FLAME!

Note: is appliance is not recommended for residential

installation.

Pressure Regulators in Battery Installations

1. Must have a maximum regulation capacity for the

total connected load.

Part # 1382669 (07/05)Page 8

Page 9

INSTALLATION Continued

Upright

Burner Box

Side

1/4" x 3/4"

Type "B"

Washer Hex Head SMS

4 Req'd

~

1

"X"

"X"

2

8

4

3

6

7

5

GARL

AN

D

2. e pressure regulator(s) installed must be listed by

a nationally recognized agency.

3. e pressure regulator(s) must have a pressure

adjustment range to allow adjustment to the

manifold pressure on the appliance rating plate.

4. Unless the manifold pressure on all connected

appliances is the same, a separate regulator must

be supplied for each appliance(s) having different

manifold pressures.

5. Gas supply lines may be connected at right, left or

both ends of a battery or at the tee connections on

spreader plates. If five (5) or more units are placed

in a battery, more that one (1) supply line should

be used. A readily accessible, approved type of

hand shut off valve (supplied by others) should be

installed on each supply line.

CAUTION: Local codes may require that the pressure

regulator be externally vented. is is to be supplied by

others.

Assembly Instructions

Salamander/Cheese Melters

M-Series Salamanders/Cheese Melters

1. Remove front panel #5 by removing two (2) sheet

metal screws from under side of salamander/cheese

melter and pushing front panel downward.

2. With back panel #4 still attached to the left #2 and

right #3 uprights drop uprights into the rectangular

cutouts at the rear of the range

3. Fasten uprights #2 and #3 to the range #1 with four

(4) 5/16” -18 bolts and flat washers #6 and #7.

4. If unit is in a battery line up, fasten adjacent units

together at hole marked “X” with ¼” -20 bolts, nuts

and washers.

5. Install front panel #5 previously removed. Attach

front panel #5 to salamander/cheese melter with

two (2) sheet metal screws

Installation of Salamander to a Range

Model IR-L. GCM-. GCM-

1. e back of the range must be easily accessible

2. Position the salamander on rear of the range slipping

uprights into burner box sides.

3. Securely fasten using hardware shown.

Part # 1382669 (07/05) Page 9

Page 10

INSTALLATION Continued

Upright

Burner Box

Back

Stabilizer

Bracket

Mounting

Bracket

Mounting

Bracket

Top

Bottom

Upright

Burner

Box Side

Stabilizer

Bracket

1/4" x 3/4"

Type "B" Washer

Hex Head (8 Req'd

)

# 10 x 3/4"

Phillips Truss

Head

1/4" 20 x 3/4" Hex

Head Self Tapping

Screws (2 ea. Side)

&

1/4 x 2/4 Washer

(2 ea. Side)

End Support Bracket

Center Support

Use Existing # 10 Sheet Metal Screws

From Back Flange

Back Flange

Rear View

Remove Oven Flue for H/P288 Double Ovens Only

Models IR60-280L, GCM60-280

1. Back of range must be easily accessible.

2. Fasten mounting bracket to burner box back as

shown using four (4) of #10 x ½” type “A” truss

head SMS, Phillips.

3. Position salamander on rear of range slipping

uprights into burner box sides and mounting

bracket.

4. Make sure front panel is in front of stabilizer

bracket.

5. Securely fasten using hardware shown.

Models IR48-280L or GCM48-280 Mounting

to 48” Range with one Full Size Oven

Models IR48-280L IR72-280L,

GCM48-280, GCM72-280

1. Back of range must be easily accessible.

2. Position salamander on rear of range slipping

uprights into burner box sides.

3. Make sure front panel is in front of stabilizer bracket

on 72” range.

1. Back of range must be easily accessible.

2. If mounting to a double oven, remove oven flue

from left side looking at rear of unit.

3. Place salamander in place and fasten securely, using

hardware shown.

4. Re-install oven flue

4. Securely fasten hardware shown.

Part # 1382669 (07/05)Page 10

Page 11

INSTALLATION Continued

Wall Mounted Salamanders, Cheese Melters

or Counter Mounted Salamander or

Cheese Melters

1. Clearance from combustible construction must be

six inches (6’) minimum at rear and six inches (6”)

minimum at sides.

Each gas appliance shall be located with respect to

building construction and other equipment so as

to permit access to the appliance. Such access and

clearance my be necessary for service and cleaning.

2. All models ending with suffix “C” must be fastened

to the counter top.

3. All models ending with suffix “W” are mounted to

a vertical surface using the mounting kit as shown

below. e salamanders are shipped with the wall

mounting kit already attached to the appliance.

4. Provisions for gas connections, bottom or rear,

should be taken into consideration at time of

installation.

Ventilation and Air Supply

Proper ventilation is highly important for good operation.

e ideal method of ventilation a Salamander Broiler is

the use of a properly designed canopy hood which should

extend six inches (”) beyond all sides of the appliance

and six () feet six () inches from the floor.

A strong exhaust fan will create a vacuum in the room,

for an exhaust system to work properly, replacement air

must enter the room in which the vent is located. the

amount of air which is exhausted must equal the amount

entering, (make-up air).

All gas burners and pilots need sufficient air to operate

and large objects should not be placed in front or on top

of the broiler which would obstruct the air flow through

the front of the broiler.

FOR YOUR SAFETY never place any type of object

on top of the salamander broiler or cheese melters. e

top of the broiler will exceed º F. It could cause

severe burns or fire and obstruct ventilation

Clearances:

From Combustible material ” sides and rear. A clearance

of .” to non combustible construction as sides & rear

is acceptable, for the Salamander, e Cheese melter is

not suitable for installation on a combustible floor.

Part # 1382669 (07/05) Page 11

Page 12

OPERATION

Pilot Lighting Instructions

1. e in-line service shut-off valve should be in the

“ON” position.

2. With a lighted taper you can now light in the pilots

which are located at the rear of the main burner.

3. Pilot flame should be approximately 7/8” long for

proper ignition of the burners. e pilot adjustment

valve can be located by sliding the drip tray forward.

Adjustment valves are located on the manifold pipe

which runs horizontal across the back of the unit,

behind the drip tray, one is at the left rear and the

other at the right rear.

To adjust the pilot light, turn the brass screw

counter-clock-wise to increase the pilot flame, and

clock-wise to decrease the pilot flame.

NOTE: No more than /” pilot flame length should

be required. Too high a setting will cause the fame to

lift off or will create excessive carboning. Do not adjust

the pilot flame lower than /” long because this can

cause delayed ignition at the burner. e delayed ignition

could cause the burner tiles to crack; in that case the

burner would have to be replaced.

Main Burner Operation

Turn main burner knob to the “MAX” position

immediately check ignition.

Burn off Period

Many parts used in the manufacturing of commercial

equipment have a thin, protective coating of machine

oil. is oil should be burned off before the equipment

is used for food preparation.

After all start-up and safety checks have been completed,

turn burner valve to the “MAX” position. Smoke (a

bluish haze) will be produced. is process can take

several hours and can be completed over a few days

Energy Conservation

Do not waste energy by leaving controls at high

temperature settings during idle periods. Lower settings

will keep broiler warm and ready for next use period.

Reset burner valve knob as required for heavy load

periods

Shut Down Instructions

Turn main burner valve knobs to the “OFF” position.

If the unit is to be shut down for an extended period of

time, close the manual in-line service valve off, (manual

in-line service valve is not factory supplied).

FOR YOUR SAFETY never place any type of object on

top of the salamander broiler or cheese melters. e top

of the broiler will exceed º F. It could cause severe

burns and/or fire and also will obstruct ventilation.

CAUTION Should ignition fail after five seconds, turn

valve off and wait five minutes before trying again.

Pilot gas is not interrupted automatically. It is the

responsibility of the operator to check the ignition of

burners immediately after the burner valve has been

turned on.

When ignition has been accomplished, a blue flame will

cover the surface of the ceramics for - seconds. e

haze will disappear and the burner rod will glow red.

After the burners have operated for several minutes turn

the valve to “MIN.” e burner rods will no longer glow

red and the flame travels back and forth on the face of

the burner ceramics.

Main Burner Adjustments

All Salamanders are provided with a fixed burner orifices

to provide , BTU/HR at the “MAX” setting on

propane gas supplied at .” W/C. All Cheese Melters

are provided with a fixed burner orifices to provide

, BTU/HR at the “MAX” setting on natural gas

supplied at a .” W/C pressure and , BTU/HR

at the “MAX” setting on propane gas supplied at .”

W/C.

e “MIN” setting is adjustable and should be set as

follows:

1. Set the burner valve knob to “MIN” setting and

remove the knob.

Part # 1382669 (07/05)Page 12

Page 13

OPERATION Continued

2. Insert a thin bladed screwdriver into the valve stem

to engage the slot inside the stem. Turn clockwise

to decrease the rate and counter-clockwise to

increase.

Proper adjustment is attained at the point where the

burner rods no longer glow and the flame travels back

and forth on the face of the ceramics.

MAINTENANCE AND CLEANING

A program of proper cleaning techniques will aid in

continued trouble free operation of this or any quality

equipment

Daily

Grid racks should be wiped daily while still warm,

using a heavy cloth or other grease absorbing material

to remove grease and burnt food before they burn into

the grid. Remove burnt materials, such as carbonized

grease or food, with a stiff wire brush. DO NOT USE

ANY TYPE OF STEEL WOOL. Small particles may

be left on the grid surface and get into food products.

Grid racks should be washed thoroughly using a wire

brush and a hot, mild detergent or soap solution. Rinse

with clear, warm water.

Monthly

is adjustment has been factory pre-set, however, with

changing pressures this adjustment and pilot adjustment

may need to be re-done after installation.

is is not considered a manufacturing defect and is

not warrantable.

Exterior Cleaning

Establish a regular schedule. Any spills should be wiped

off immediately.

1. Wipe exposed, clean-able surface when cool with

a mild detergent and hot water. Stubborn residue

spots may be removed with a light weight nonmetallic scouring pad. Dry thoroughly with a clean

cloth.

2. Stainless steel should be cleaned using a mild

detergent, a soft cloth and hot water. If it is necessary

to use a non-metallic scouring pad, always rub in

the direction of the grain in the metal to prevent

scratching. Use a water based stainless steel cleaner

(such as Drackett Twinkle), if you want a high

shine.

Lubricate valves and bearings as required. Due to the

usual location of the broiler that is mounted above a

range with open tops, the heat from the open top will

cause the lubrication grease inside the valves to dry out.

When you notice that the valve is becoming harder to

turn it is then time to have them greased. We suggest

an Authorized Service Agent who is familiar with the

appliance and working with natural and propane gas,

to perform this type of work.

Part # 1382669 (07/05) Page 13

Page 14

NOTES

Part # 1382669 (07/05)Page 14

Page 15

NOTES

Part # 1382669 (07/05) Page 15

Page 16

Loading...

Loading...