Garland ICO-E-10 Installation Manual

INSTALLATION AND

OPERATION MANUAL

SUNFIRE ELECTRIC

CONVECTION OVENS MODELS:

ICO-E-10M & ICO-E-20M

FOR YOUR SAFETY:

DO NOT STORE OR USE GASOLINE

OR OTHER FLAMMABLE VAPORS OR

LIQUIDS IN THE VICINITY OF

THIS OR ANY OTHER

APPLIANCE

PLEASE READ ALL SECTIONS OF THIS MANUAL

AND RETAIN FOR FUTURE REFERENCE.

THIS PRODUCT HAS BEEN CERTIFIED AS

COMMERCIAL COOKING EQUIPMENT AND

MUST BE INSTALLED BY PROFESSIONAL

PERSONNEL AS SPECIFIED.

WARNING:

IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE

CAN CAUSE PROPERTY DAMAGE, INJURY,

OR DEATH. READ THE INSTALLATION,

OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR

SERVICING THIS EQUIPMENT

INSTALLATION AND ELECTRICAL CONNECTION

MUST COMPLY WITH CURRENT CODES:

IN CANADA - THE CANADIAN ELECTRICAL

CODE PART 1 AND / OR LOCAL CODES.

IN USA – THE NATIONAL ELECTRICAL CODE

ANSI / NFPA – CURRENT EDITION.

ENSURE ELECTRICAL SUPPLY CONFORMS WITH

ELECTRICAL CHARACTERISTICS SHOWN ON

THE RATING PLATE.

Users are cautioned that maintenance and repairs must be performed by a Garland authorized service agent

using genuine Garland replacement parts. Garland will have no obligation with respect to any product that has been

improperly installed, adjusted, operated or not maintained in accordance with national and local codes or installation

instructions provided with the product, or any product that has its serial number defaced, obliterated or removed,

or which has been modified or repaired using unauthorized parts or by unauthorized service agents.

For a list of authorized service agents, please refer to the Garland web site at http://www.garland-group.com.

The information contained herein, (including design and parts specifications), may be superseded and is subject

to change without notice.

Manufactured by

Cleveland Range

1333 East 179th Street, Cleveland, Ohio 44110

USA

GARLAND COMMERCIAL RANGES, LTD.

1177 Kamato Road, Mississauga, Ontario L4W 1X4

CANADA

Phone: 905-624-0260

Fax: 905-624-5669

Part # 4520415 (07/12/11) © 2005 Garland Commercial Industries, Inc.

Part # 4520415 (07/12/11) Page 1

IMPORTANT INFORMATION

WARNING:

This product contains chemicals known to the state of California to cause cancer and/or birth defects

or other reproductive harm. Installation and servicing of this product could expose you to airborne

particles of glass wool/ceramic fibers. Inhalation of airborne particles of glass wool/ceramic fibers

is known to the state of California to cause cancer.

Keep appliance area free and clear of combustibles.

Part # 4520415 (07/12/11)Page 2

TABLE OF CONTENTS

IMPORTANT INFORMATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

DIMENSIONS AND SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Rating Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Installation Of Legs, Stand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Assembly Instructions For Open Base . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Assembly Instructions for Legs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Assembly Instructions For Double Deck Casters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Stacking Of Ovens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Cable Entrance and Connection Point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

OPERATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Explanation Of Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Operation Of Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Automatic Cool Down Feature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Shut Down Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Energy Conservation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

PERFORMANCE RECOMMENDATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

PROBLEMS/SOLUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

COOKING GUIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

CLEANING AND MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Break in Period . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Exterior Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Interior Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Motor Care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Part # 4520415 (07/12/11) Page 3

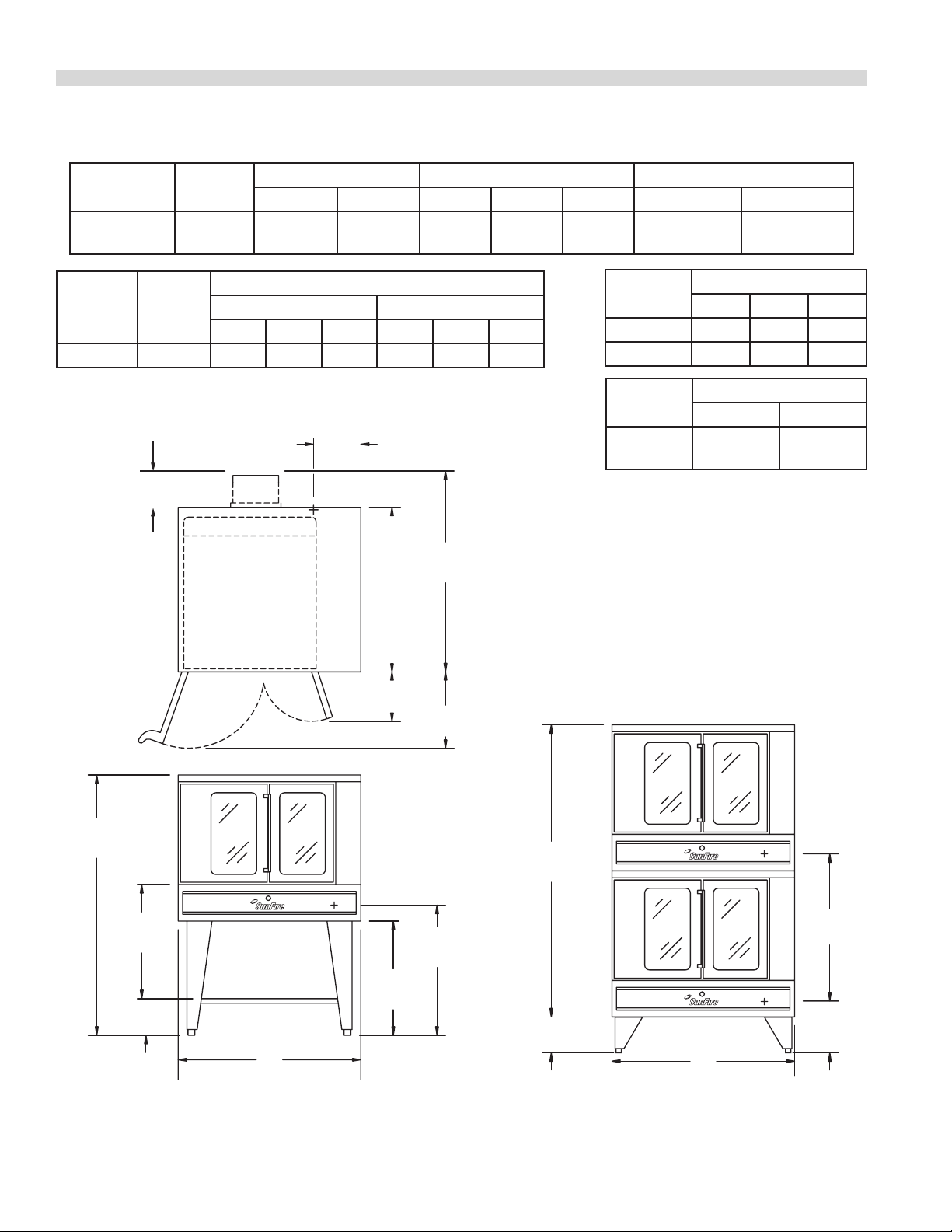

DIMENSIONS AND SPECIFICATIONS

C

Width Depth

40"

(1016mm)

Model

ICO-E-10M 11.0 32 32 28 28 28 24

Not convertible to single-phase

*

Double deck models require individual power supply connections.

Total kW

8-1/2"

(216mm)

44-1/2"

(1130mm)

Load

ICO-E-10 ICO-E-20 Height Depth Width Sides Rear

(1524mm)

208V / 3Ø* 240V / 3Ø*

X Y Z X Y Z

Height Oven Interior Dimensions Combustible Wall Clearance

60"

Nominal Amperes Per Line

L

72"

(1829mm)

10-1/4"

(260mm)

CABLE ENTRANCE

36"

(914mm)

20-1/2"

(520mm)

44-1/2"

(1130mm)

(723mm)

28-1/2"

29"

(736mm)

Model

ICO-E-10M 550 250 58.0

ICO-E-20M 1100 495 114.0

Model

ICO-E-10M

• These appliances are intended for

commercial use by professionally trained

personnel.

• It is the responsibility of the installer to

ensure that installation complies with all

national and local codes.

6"

(152mm)

Shipping Information

Lbs. Kg Cube

Entry Clearances

Crated Uncrated

47"

(1194mm)

6"

(152mm)

32-1/2"

(826mm)

60"

(1524mm)

(762mm)

(152mm)

30"

6"

10-7/8"

(276mm)

CABLE

ENTRANCE

(711mm)

40"

(1016mm)

SINGLE OVEN DOUBLE OVENS

16-7/8"

(429mm)

64"

(1626mm)

31-1/2"

(800mm)

28"

8"

(203mm)

40"

(1016mm)

C

L

32"

(813mm)

C

L

11-1/2"

(292mm)

Part # 4520415 (07/12/11)Page 4

INTRODUCTION

Please read all sections of this manual. This product must be

installed by professional personnel as specied. Garland/U.S.

Range products are not approved or authorized for home or

residential use, but are intended for commercial applications

only. Garland / U.S. Range will not provide service,

warranty, maintenance or support of any kind other than in

commercial applications.

Like any other ne precision built appliance your oven

should be given regular care and maintenance. Periodic

inspections by your dealer or a qualied service agency are

recommended. We suggest installation, maintenance and

repairs should be performed by your local authorized service

agency listed in your information manual pamphlet, or

you may contact Garland/U.S. Range directly using contact

information listed on the front of this manual. Factory

specied replacement parts must be used to maintain listing.

Use of “Generic” Replacement parts may create a hazard and

will void listing.

Rating Plate

In the event you have questions concerning this installation,

use, care or service of this or any other Garland/US Range

(Sunre) product, contact our Product Service Department.

When corresponding with the factory or your local

authorized service agency regarding service or parts, be sure

to refer to the particular unit by the correct model number

(including prex and sux letters and numbers) and the

serial or code number. The rating plate axed to the unit

contains this information. The rating plate is located behind

the combustion chamber front panel.

INSTALLATION

Clearances

COMBUSTIBLE WALL

CLEARANCE

Side 6” (152mm)

Rear 6” (152mm)

Location

Proper placement of the oven will ensure operator

convenience and satisfactory performance. Adequate

clearance must be provided for servicing, ventilation and

proper operation. The oven must be kept free and clear of

combustible material.

Part # 4520415 (07/12/11) Page 5

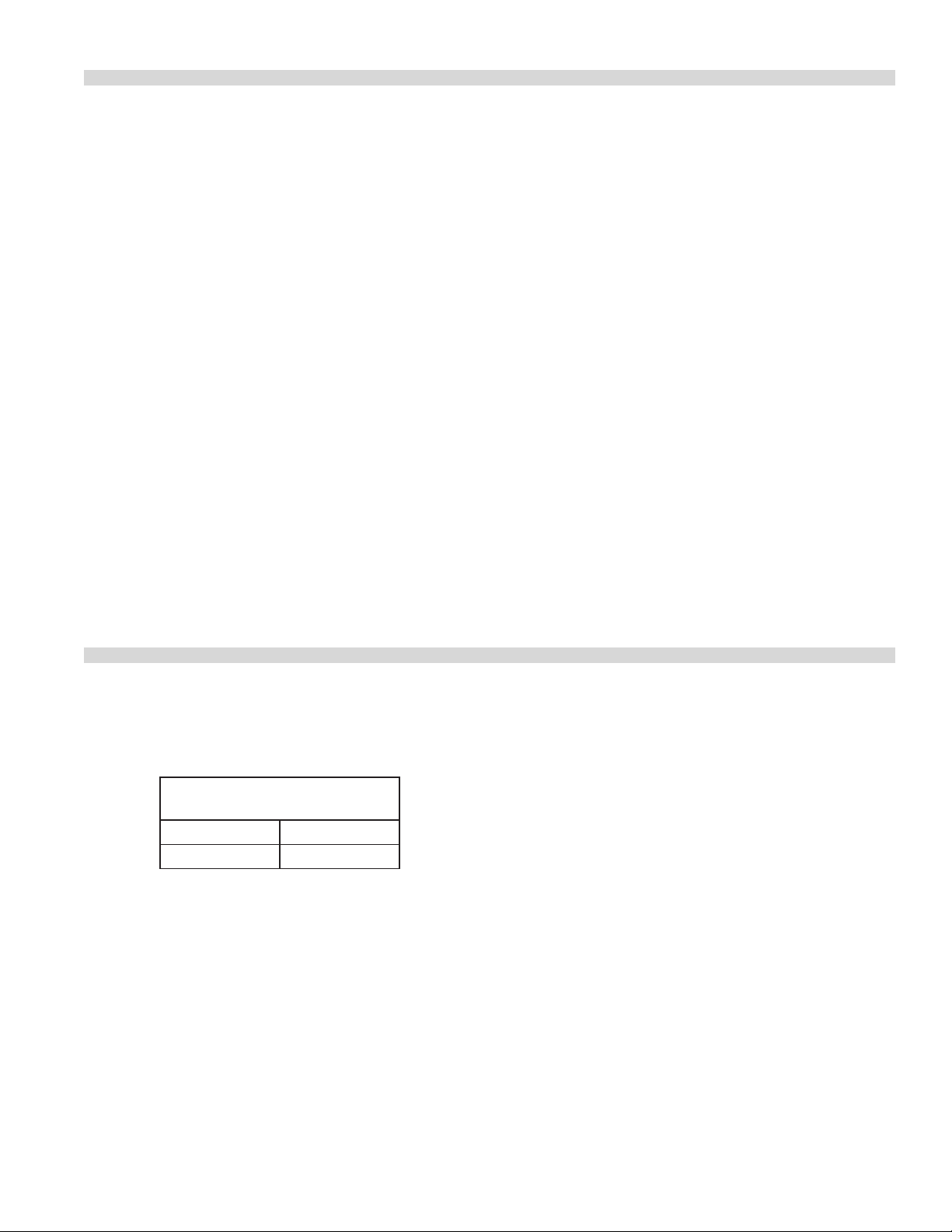

INSTALLATION Continued

Installation Of Legs, Stand

Verify that all parts are present before beginning assembly.

Tools required for Assembly

1. 9/16” Wrench

2. 3/8” Wrench

3. 1” Wrench

4. Phillips Head Screw Driver

5. Hammer (Foot Version Only)

Diagram of unit shown on left side

Assembly Instructions For Open Base

1. Raise the unit or lay it on its left side.

2. For foot versions take a hammer and lightly tap a square

foot insert (2) into each leg.

3. For caster versions attach a caster pad assembly (5) to the

bottom of each leg. Position caster pad (5) and drill four

11/64 diameter holes in the leg and fasten the caster pad

to the leg with #10 Phillips head sheet metal screws.

4. For caster versions screw the heavy duty caster with

brakes (4) into the front legs and the heavy duty casters

without brakes (3) into the rear legs.

1

5

2

1

1

2 3

1

2

2

5

5

4

3

6

5

9

7

9

10

10

REF

4

10

7

6

10

9

9

Part # 4520415 (07/12/11)Page 6

INSTALLATION Continued

Parts List

ITEM # QTY DESCRIPTION

1 4 Legs

2 4 Square Foot Inserts (Foot Version Only)

3 2 Heavy Duty Casters W/O Brakes (Caster Version Only)

4 2 Heavy Duty Casters W/Brakes (Caster Version Only)

5 4 Caster Pad Assembly (Caster Version Only)

6 2 Open Stand Upper Support (Open Base Versions Only)

7 2 Rack Guides (Open Base Version Only)

8 1 Open Stand Lower Rack Support

9 4 Rack Support Clips (Top)

10 4 Rack Support Clips (Bottom)

1 Bag of Hardware

12 3/8”-16 x 3/4” Bolts

12 3/8” Flat Washers

16 10-24 x 3/4” Hex Head Machine Screws

16 # 10 Split Ring Lock Washers

16 # 10-24 Hex Nuts

28 # 10 x 3/4” Truss Heat Sheet Metal Screws

5. Attach each leg (1) with three 3/8” bolts and at washers.

6. Mount right and left open stand rack support (6) to the

front and rear legs using #10 Phillips head sheet metal

screws.

7. Mount the four rack clips (9) to the upper rack supports

(6) with 10-24 bolts, nuts and lock washers. If the holes at

the edge of the rack clip (9) are used it will accommodate

18” x 26” pans, if the holes in the center of the rack clip (9)

are used it will accommodate oven racks.

8. Mount the open stand lower rack support (8) to the legs

using #10 Phillips head sheet metal screws.

9. Place the rack guides (7) on the rack clips (9). Attach the

bottom of each rack guide (7) to the lower rack support

(8) with two rack clips (10) with 10-24 nuts, bolts and lock

washers.

10. Make sure all bolts and screws are tight.

11. Stand the unit up.

12. Move the unit into its desired location.

13. Level the oven using a 1” wrench to adjust the feet or the

casters.

Assembly Instructions for Legs

1. Raise the unit or lay on its left side.

2. For foot versions take a hammer and lightly tap a square

foot insert (2) into each leg.

3. For caster versions attach a caster pad assembly (5) to the

bottom of each leg. Position caster pad (5) and drill four

11/64” diameter holes in the leg and fasten the caster pad

to the leg with #10 Phillips head sheet metal screws.

4. For caster versions screw the heavy duty casters with

brakes (4) into the front legs and the heavy duty casters

without brakes (3) into the rear legs, ( single deck only).

5. Attach each leg (1) with three 3/8” bolts and at washers.

6. Make sure all bolts and screws are tight.

7. Stand the unit up.

8. Move the unit to desired location.

Part # 4520415 (07/12/11) Page 7

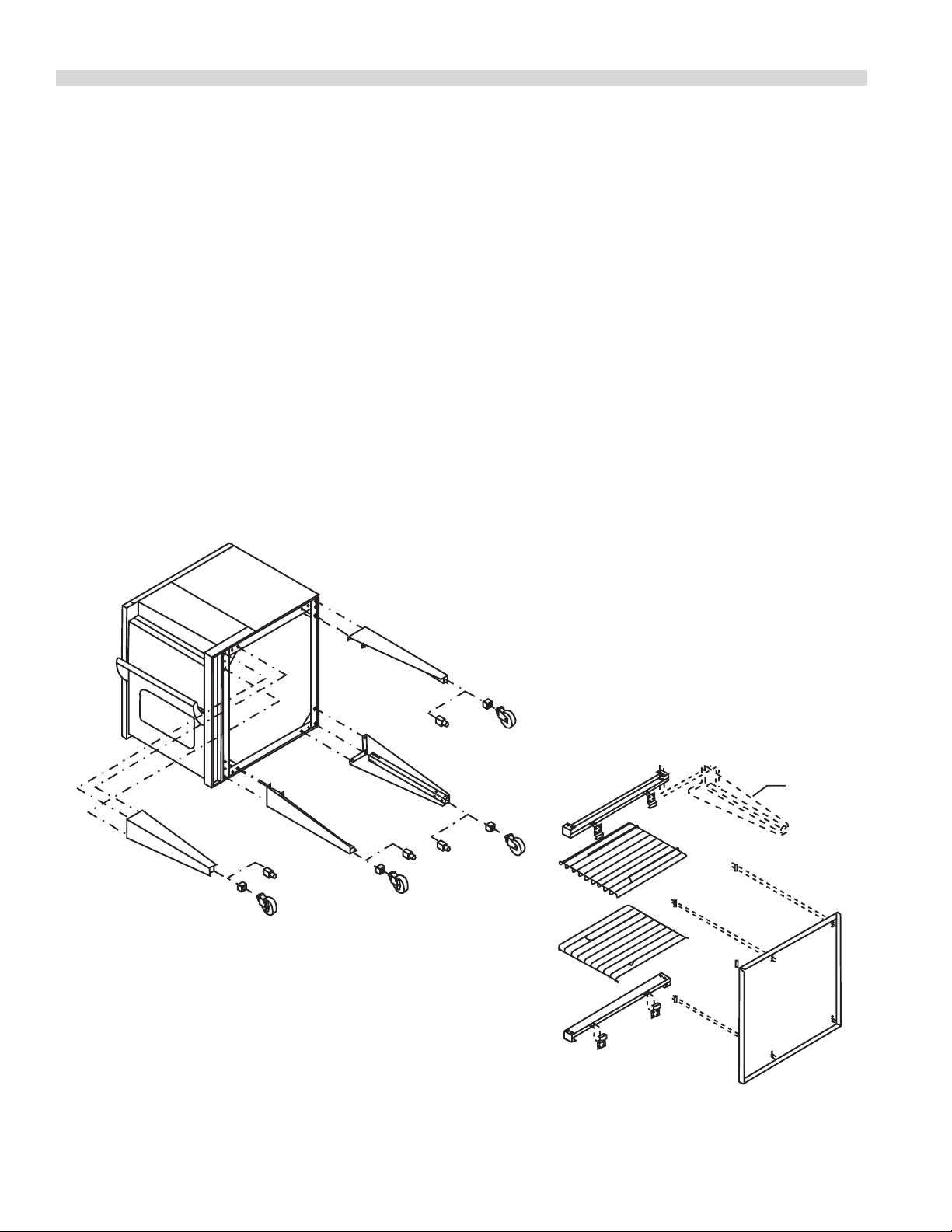

INSTALLATION Continued

9. Level the oven using a 1” wrench and adjust the feet or

the casters.

NOTE: Ovens supplied with casters must be installed with an

approved restraining device

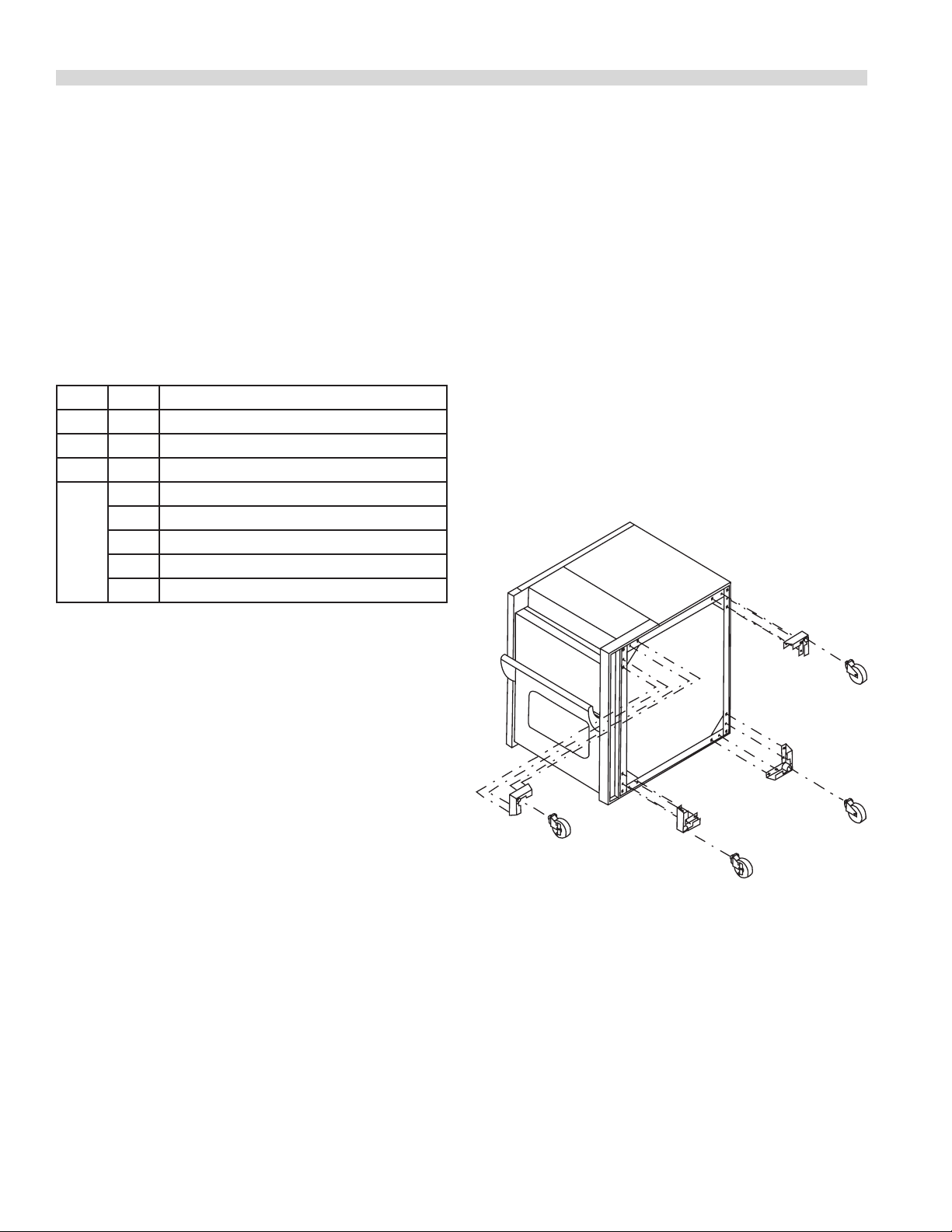

Assembly Instructions For

Double Deck Casters

Verify all parts are present before beginning assembly.

Parts List

ITEM QTY DESCRIPTION

1 4 Caster Pads Assembly

2 2 Heavy Duty Caster W/O Brake

3 2 Heavy Duty Caster W/Brake

1 Bag Of Hardware

8 3/8”-16” x 3/4” Bolts

8 3/8” Flat Washer

8 1/4” Hex Type B Sheet Metal Screws

8 Split Ring Lock Washers

Assembly

1. Raise the unit or lay it on its left side.

2. Attach each caster pad (1) with two 3/8” bolts and at

washers and two 1/4” hex type “B” sheet metal screws and

lock washers.

3. Screw the heavy duty casters with brakes (2) into the

front caster pads and the heavy duty casters without

brakes (3) into the rear caste pads.

4. Make sure all bolts and screws are tight.

5. Stand the unit up.

6. Move the unit to its desired location.

7. Level the oven using a 1” wrench to adjust the casters.

Tools required for assembly

1. 9/16” wrench

2. 3/8” wrench

3. 1” wrench

1

3

1

1

2

1

3

2

Part # 4520415 (07/12/11)Page 8

INSTALLATION Continued

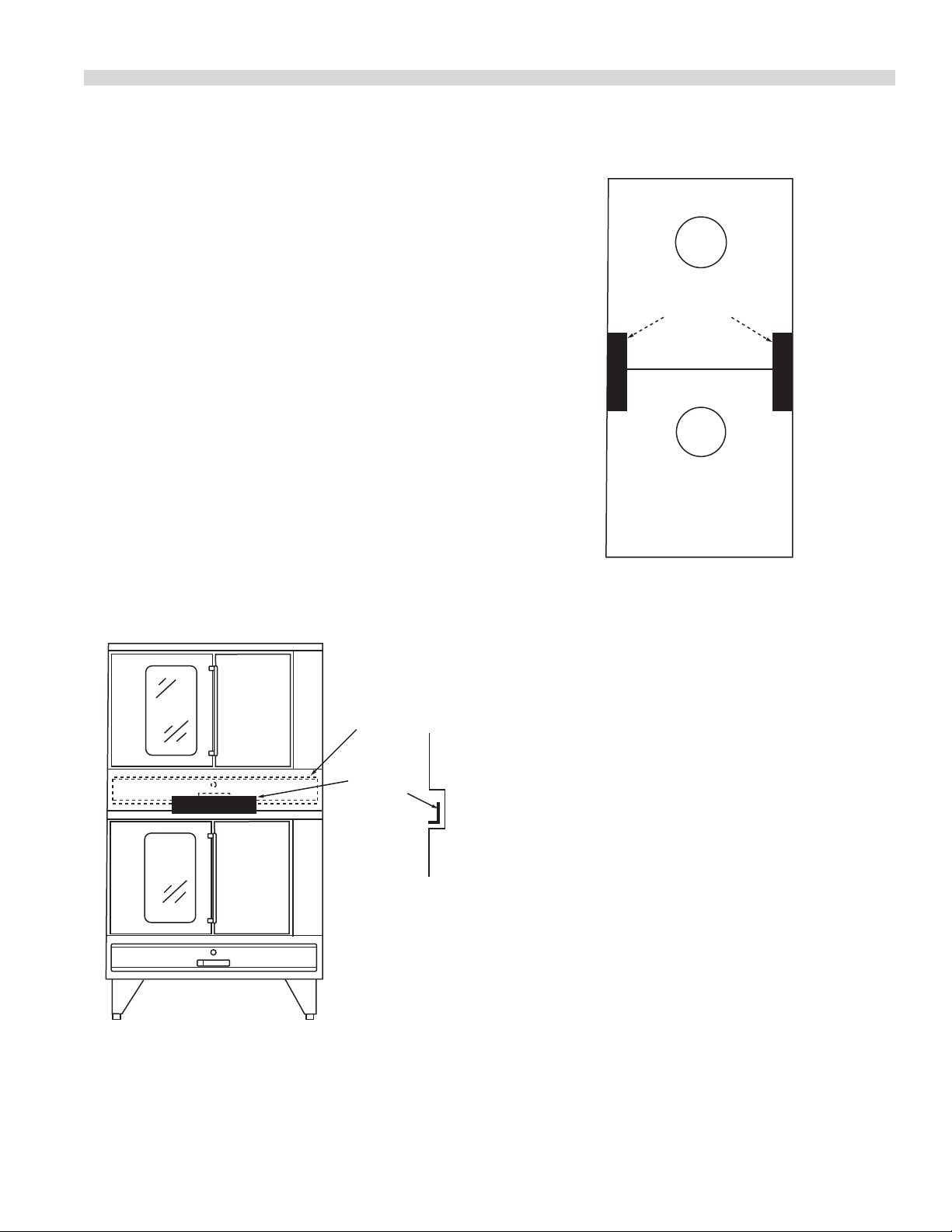

Stacking Of Ovens

Remove the lower front shroud from the unit that is to be the

top deck. To remove-open the oven doors and remove four

(4) #10 sheet metal screws located in front of the lower door

seal. Open the ip-down door on the lower front shroud and

remove one Phillips screw from each inner side (left & right),

pull the lower front shroud forward and remove.

Install the double deck legs or casters on the oven that is to

be the lower deck See leg/caster installation instructions on

previous pages.

Raise the oven that is to be the top deck and place on tope

of the lower deck. Match and align the body sides and rear

of the units using one mounting bracket, match and attach

to the two holes in the bottom deck main top and the two

holes in the top deck frame, (exposed by the removal of the

lower front shroud.)

Rear View of Ovens

Mounting Brackets

Fasten the rear of the two ovens together by removing the

bottom sheet metal screw from the left and right body sides

of the top deck. Remove the top sheet metal screw from

the left and right body sides of the bottom deck. Secure

mounting plate to each side. See Illustrations.

Lower Front

Shroud

Angle

Mounting

Bracket

Side View

w/Front Shroud

Removed

Electrical Connections

Before attempting the electrical connection, the rating

plate should be checked to ensure that the unit’s electrical

characteristics and supply electric characteristics agree.

Installation of the wiring must be made in accordance with

U.L. 197 Commercial Electric Cooking Appliance Standards,

Local and/or National Electrical Code, ANSI/NFPA 70-1990.

1. Switch panel size

2. Overload protection

3. Wire type

4. Wire size

5. Temperature limitations of the wires

6. Method of connection ( Cable, Conduit ect.)

Part # 4520415 (07/12/11) Page 9

INSTALLATION Continued

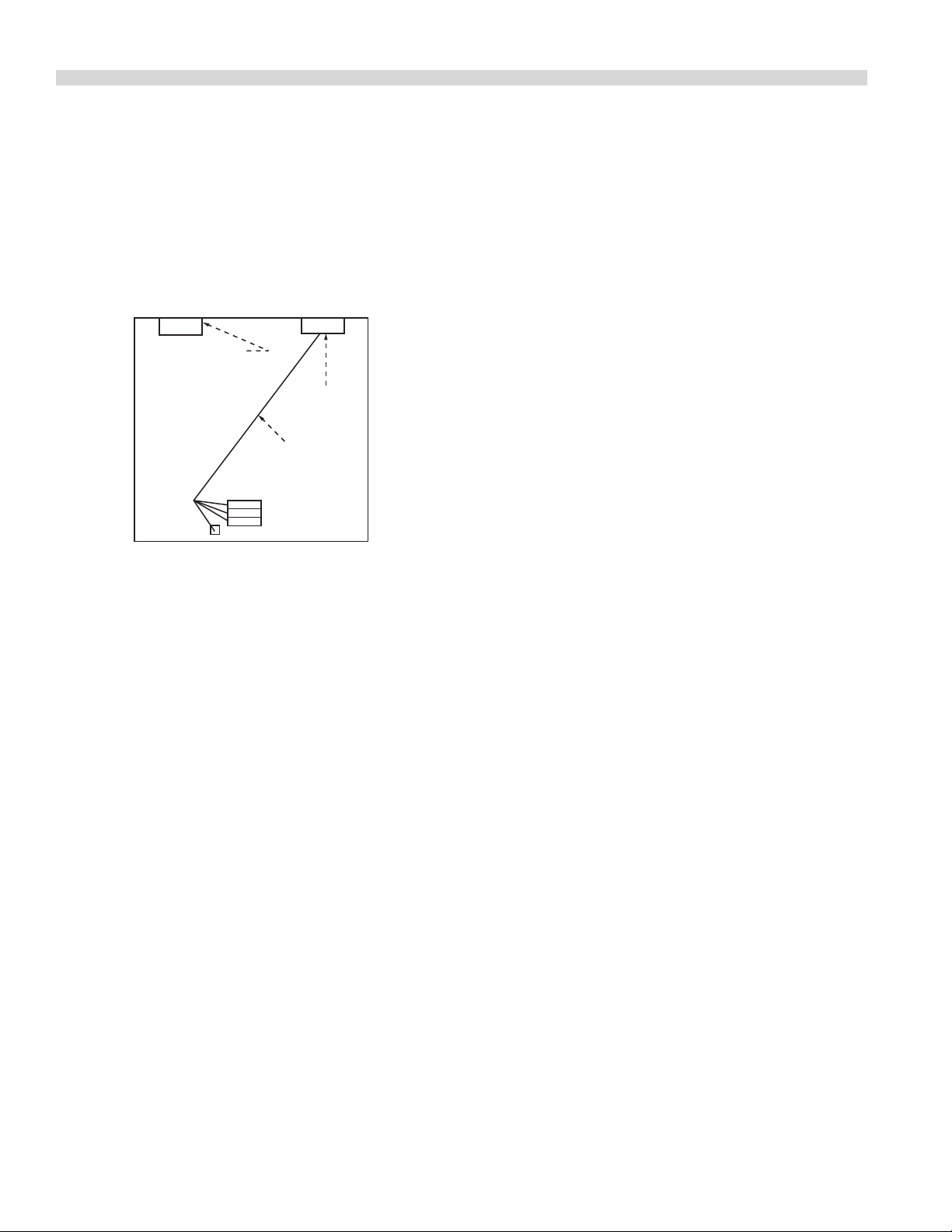

Cable Entrance and Connection Point

The service line enters though the rear of the unit and is

connected to the terminal block (Located behind the “ip

down” access door) as indicated in the diagram When

stacking ovens (see diagram), double deck models require

individual power supply connections.

Optional Cable

Exit/Entrance

for Double Deck

Ovens

GRN

Top view of the main deck of double deck ovens or one

single deck oven.

Cable

Entrance

Power

Supply

Terminal

Block

Commissioning

Input voltage and phasing must match the unit’s voltage and

phasing. A wiring diagram is attached to the main back of

each oven. Visually check all electrical connections. Energize

electrical service to the units. The electric oven is only

available in 3 phase, service and unit voltage must agree.

Unit rating plate is located behind the combustion chamber

front panel.

Ventilation

WARNING Inadequate ventilation may result in the high

ambient temperature at the rear of the oven. Excessive

ambient temperature can cause tripping of the blower motor

terminal overload protection device. This condition must be

corrected immediately to avoid damage to the blower motor.

Part # 4520415 (07/12/11)Page 10

Loading...

Loading...