Page 1

INSTALLATION AND

OPERATION MANUAL

HEEGM XX CL

HIGH EFFICIENCY

RADIANT CHAR-BROILER

Français . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 17

FOR YOUR SAFETY:

DO NOT STORE OR USE GASOLINE

OR OTHER FLAMMABLE VAPORS OR

LIQUIDS IN THE VICINITY OF

THIS OR ANY OTHER

APPLIANCE

PLEASE READ ALL SECTIONS OF THIS MANUAL

AND RETAIN FOR FUTURE REFERENCE.

THIS PRODUCT HAS BEEN CERTIFIED AS

COMMERCIAL COOKING EQUIPMENT AND

MUST BE INSTALLED BY PROFESSIONAL

PERSONNEL AS SPECIFIED.

WARNING:

IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE

CAN CAUSE PROPERTY DAMAGE, INJURY,

OR DEATH. READ THE INSTALLATION,

OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR

SERVICING THIS EQUIPMENT

Users are cautioned that maintenance and repairs must be performed by a Garland authorized service agent

using genuine Garland replacement parts. Garland will have no obligation with respect to any product that has been

improperly installed, adjusted, operated or not maintained in accordance with national and local codes or installation

instructions provided with the product, or any product that has its serial number defaced, obliterated or removed,

or which has been modified or repaired using unauthorized parts or by unauthorized service agents.

For a list of authorized service agents, please refer to the Garland web site at http://www.garland-group.com.

The information contained herein, (including design and parts specifications), may be superseded and is subject

to change without notice.

IN THE COMMONWEALTH OF MASSACHUSETTS

THIS PRODUCT MUST BE INSTALLED BY A

LICENSED PLUMBER OR GAS FITTER.

For Your Safety:

In a clear and observable location, post

instructions to be followed if a user smells

gas. This information shall be obtained by

consulting your local gas supplier.

GARLAND COMMERCIAL RANGES, LTD.

1177 Kamato Road, Mississauga, Ontario L4W 1X4

CANADA

Phone: 905-624-0260

Fax: 905-624-5669

Part # 4530868 (04/25/12) © 2012 Garland Commercial Ranges Ltd..

General Inquiries 1-905-624-0260

USA Sales, Parts and Service 1-800-424-2411

Canadian Sales 1-888-442-7526

Canada or USA Parts/S ervice 1-800-427-6668

Page 2

IMPORTANT INFORMATION

WARNING:

This product contains chemicals known to the state of California to cause cancer and/or birth defects

or other reproductive harm. Installation and servicing of this product could expose you to airborne

particles of glass wool/ceramic fibers. Inhalation of airborne particles of glass wool/ceramic fibers

is known to the state of California to cause cancer. Operation of this product could expose you to

carbon monoxide if not adjusted properly. Inhalation of carbon monoxide is known to the state of

California to cause birth defects or other reproductive harm.

Keep appliance area free and clear of combustibles.

Part # 4530868 (04/25/12)Page 2

Page 3

TABLE OF CONTENTS

IMPORTANT INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

DIMENSIONS AND SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

PRE INSTALLATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Damage check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Rating Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Positioning and Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Optional Stand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Air Supply and Ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Electrical Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Gas Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Start Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

USE AND CARE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Optional Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

CLEANING AND MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Cleaning During Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Daily Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Weekly/Periodic Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Service and Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Part # 4530868 (04/25/12) Page 3

Page 4

DIMENSIONS AND SPECIFICATIONS

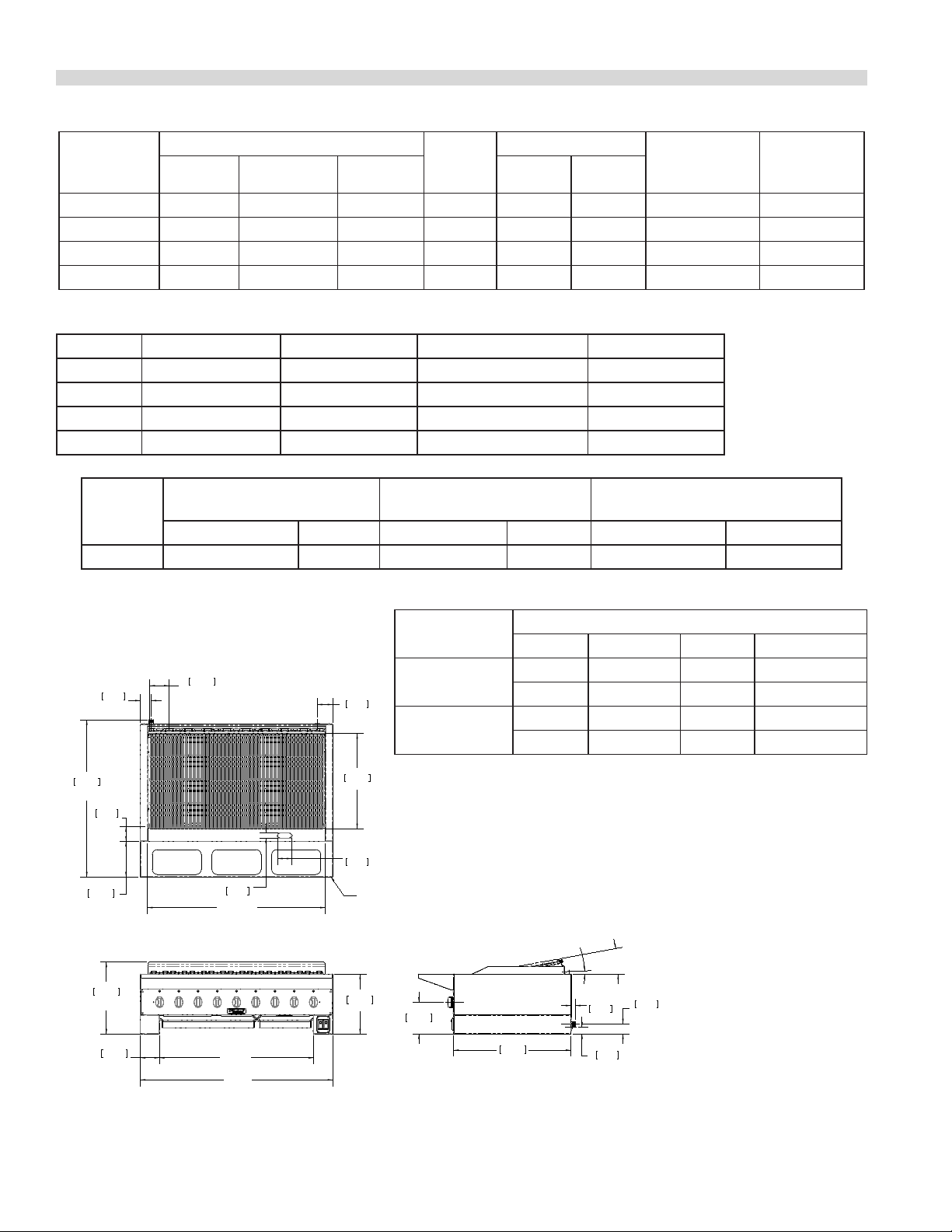

Model #

Shipping Dimensions: In. (mm)

Width Depth Height

No. Of

Burners

Total BTU*

Natural Propane

Shipping

Weight Lbs/Kg

Shipping

Size CuFT/

Cu/m

HEEGM24CL 45/1143 45/1143 25-1/2/648 4 58,000 52,000 280/127 29.9/0.846

HEEGM36CL 45/1143 45/1143 25-1/2/648 6 87,000 78,000 420/191 29.9/0.846

HEEGM48CL 65/1651 45/1143 25-1/2/648 9 130,500 117,000 254/560 43.2/1.223

HEEGM60CL 65/1651 45/1143 25-1/2/648 11 159,500 143,000 700/318 43.2/1.223

TOTAL BTU BASED ON MANIFOLD OPERATING PRESSURE SPECIFIED IN TABLE BELOW AND APPLY TO INSTALLATIONS UP TO

2000 FT (610m).

Model COOK WIDTH "C" LEG PITCH "D" OVERALL WIDTH "E" GREASE TRAY

24" 19-7/8in (506mm) 14-1/4in (362mm) 23-1/2in (597mm) SINGLE

36" 29-7/8in (760mm) 24-1/4in (616mm) 33-1/2in (851mm) SINGLE

48" 43-7/8in (1115mm) 36-1/4in (972mm) 47-1/2in (1207mm) DUAL

60" 53-7/8in (1369mm 48-1/4in (1222mm) 57-1/2in (1461mm) DUAL

Models

Manifold Operating Pressure

w.c.(Mbar)

Manifold Supply Pressure

w.c.(Mbar)

Clearance to non-

combustible material

Natural Gas Propane Natural Gas Propane Rear (in/mm) Sides (in/mm)

All Models 4.5(11.2) 10.0(25.0) 7.0(17.4) 11.0(27.5) 0/0 0/0

*GAS INLET PIPE IS 3/4" NPT ON ALL MODELS

38-13/16in

986mm

OVERALL

DEPTH

8-13/16in

RAIL DEPTH

4.-3/4in

2-3/4in

68mm

3/4" NPT

GAS INLET

3-5/8in

93mm

TROUGH

DEPTH

224mm

**OPTIONAL FAJITA RACK REQUIRES THE REMOVAL OF 2 STANDARD GRATES

STANDARD GRATE AVAILABLE IN ONE-SIDED OR TWO-SIDED STYLES

17-7/16in

451mm

OVERALL

HEIGHT

4.-11/16in

119mm

LEG WIDTH

TYP

121mm

STANDARD

GRATE WIDTH**

1-1/8in

30mm

COOK WIDTH

"C"

LEG PITCH

"D"

OVERALL

WIDTH

"E"

HEEGM48CL SHOWN

3-7/8in

97mm

ELECTRICAL

23-7/16in

596mm

COOK DEPTH

3-1/2in

89mm

RAIL FITS 1/3 PANS

14-13/16in

376mm

COOK HEIGHT

Model

HEEGM24&36CL

HEEGM48&60CL

Voltage Frequency Current Cord

120 50-60 Hz 0.10 A NEMA 5-15P

220-240 50-60 Hz 0.05 A NOT SUPPLIED

120 50-60 Hz 0.22 A NEMA 5-15P

220-240 50-60 Hz 0.11 A NOT SUPPLIED

ELECTRICAL REQUIREMENTS

*WIRING DIAGRAMS PROVIDED WITH EACH UNIT

2.2°

STANDARD

7-7/8in

199mm

VALVE HEIGHT

28-15/16in

735mm

LEG DEPTH

GRATE POSITION

2ND GRATE

1-1/8in

28mm

1-11/16in

43mm

ELECTRICAL

10.4°

POSITION

2-1/2in

63mm

3/4" NPT

GAS INLET

Part # 4530868 (04/25/12)Page 4

Page 5

SPECIFICATIONS

High Eciency HEEGM Radiant Charbroiler

HEEGM24CL, HEEGM36CL, HEEGM48CL & HEEGM60CL

HEGM36CL

HEGM48CL

Standard Features :

• All stainless steel construction.

• Front rail with cut outs to hold 1/3 size food pans (pans not included).

• Heavy duty reversible cast iron grates with wide edge on one side and ne edge on the other.

• Two grate positions to choose from: the standard position, with a slight 2° slope to the front or the second position, with a

10° slope to the front and more distance between the product and the burner.

• Large capacity, removable grease trays.

• Energy ecient cast iron burners.

• Complete system ON/OFF power switch(es), which ignites burners and shuts them down. HEEGM24CL & 36CL models

have one switch and HEEGM48CL & 60CL have two switches.

• Each burner outputs 14,500 BTU for natural gas & 13,000 BTU for propane gas, and is individually controlled by a manual

high-low valve.

• 9 ft power cord with NEMA 5-15P plug for standard 120V models.

• Wire brush and scraper combination tool included for cleaning grates.

• ¾” gas regulator for applicable gas type.

Optional Features :

• Heavy duty single sided cast iron grate, in lieu of standard reversible grate N/C.

• Fajita pan grate designed specically for holding/warming fajita pans, in lieu of two reversible or single sided grates N/C.

• 240V models supplied without a cord, available for export and/or non-CE countries.

• Stands are available, see HEMST specication sheet.

Note: To comply with NSF requirements, the unit may need to be sealed with silicone to the non-combustible mounting

surface.

Specications: :

Shall be Garland High Eciency (HE) Charbroiler, Model HEEGMCL with total BTU/hr rating when used with natural gas. All

stainless steel construction with front rail that holds 1/3 size food pans. Available in 24” (600mm) [HEEGM24CL], 36” (900mm)

[HEEGM36CL], 48” (1200mm) [HEEGM48CL] and 58” (1500mm) [HEEGM60CL] widths.

Part # 4530868 (04/25/12) Page 5

Page 6

PRE INSTALLATION

TRAY SLIDES

FORKS

IT IS STRONGLY RECOMMENDED THAT INSTALLATION,

MAINTENANCE AND REPAIRS BE DONE BY AN AUTHORIZED

SERVICE AGENCY. FOR A LIST OF AUTHORIZED SERVICE

AGENTS, REFER TO THE GARLAND WEB SITE AT http://www.

garland-group.com

Introduction

Garland manufactures the HEEGM series broiler in several

sizes. While service and customer operation may vary

from size to size, installation is similar for each. All units are

shipped fully assembled, except for the radiants and top

grates, which are packaged in separate boxes. Each unit

is tested, adjusted and inspected at the factory prior to

shipment.

Damage Check

After unpacking the unit, be sure to carefully inspect the unit

for visible and/or concealed damage. Report any damage

immediately to your carrier to le the appropriate freight

claims.

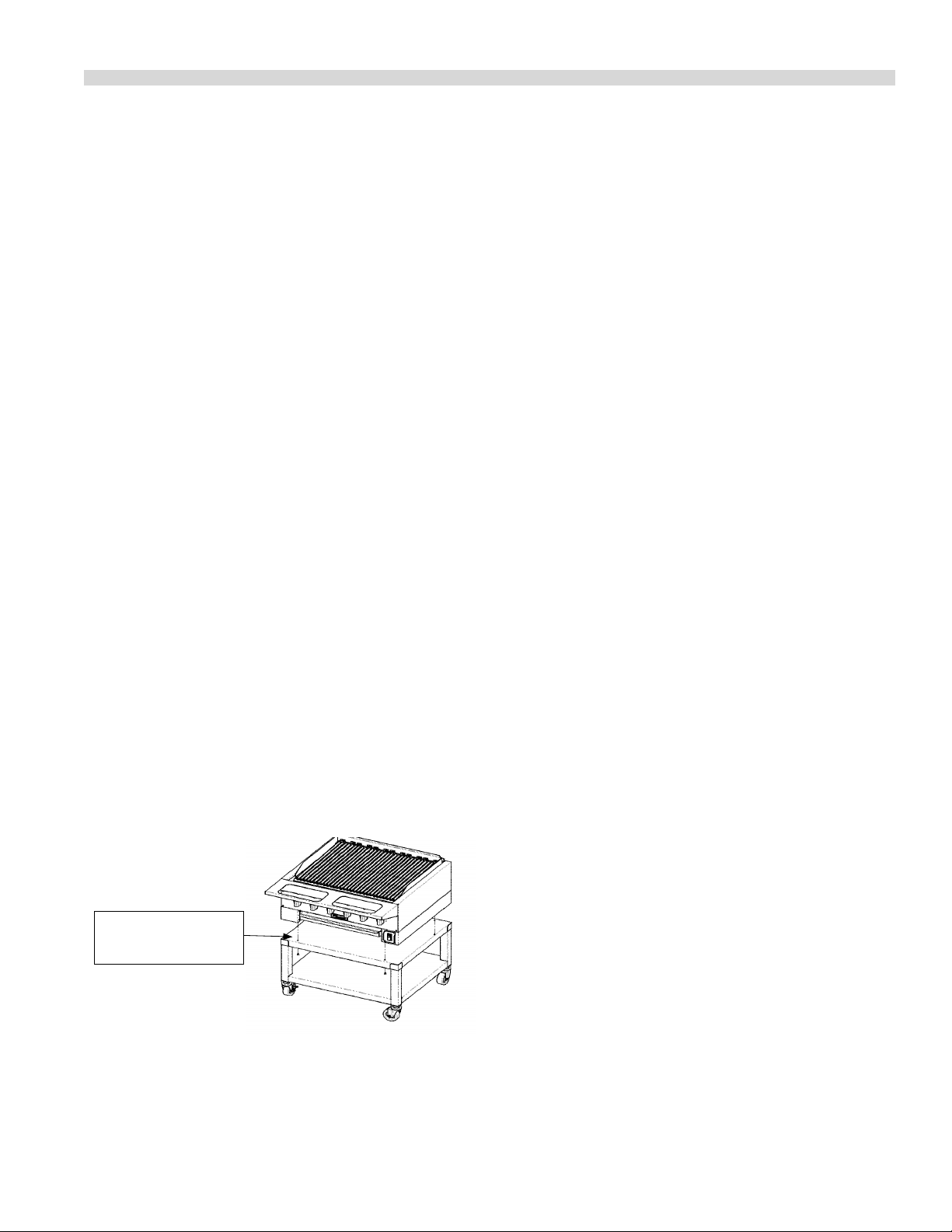

Rating Plate

The rating plate can be found on the inside face of the left

leg. The grease drawer may need to be removed in order

to read the information. If service or replacement parts

are needed, refer to the model number (including prex &

sux letters/numbers) and serial number on the rating plate

when contacting the factory or authorized service agency.

These numbers ensure proper unit identication and aid in

providing faster and more accurate service.

The rating plate contains other important information critical

to the proper installation of the unit. It species the gas type;

gas pressure; voltage and clearance requirements for the

appliance.

INSTALLATION

THIS PRODUCT IS NOT AUTHORIZED FOR HOME OR

RESIDENTIAL USE. GARLAND WILL NOT PROVIDE SERVICE,

WARRANTY, MAINTENANCE OR SUPPORT OF ANY KIND

OTHER THAN IN COMMERCIAL APPLICATIONS.

General

In the United States, installation of this appliance must

conform to the National Fuel Gas Code ANSI Z223.1, or latest

edition, NFPA No.54-latest edition/or local code to assure

safe and ecient operation.

In Canada, installation of this appliance must comply with

CSA B149.1 and local codes.

In other countries, installation must be carried out by

a competent person, in accordance with the relevant

regulations; codes of practice and the related publications of

the country of destination.

If you have any questions regarding the installation of this

unit, contact the Garland Service Department at (800) 4276668 or online at http://www.garland-group.com

Positioning and Setup

1. Carefully remove the unit from the crate base. Some

form of mechanical assistance may be required to lift and

position the broiler. With the grease drawers removed,

the unit is designed to be lifted with a pallet or lift jack as

shown in the image below.

DO NOT LIFT BY GREASE DRAWER SLIDES. CARE SHOULD BE

TAKEN TO AVOID THE LEFT, RIGHT AND/OR CENTER GREASE

DRAWER SLIDES WHEN POSITIONING LIFTING EQUIPMENT.

Part # 4530868 (04/25/12)Page 6

Page 7

INSTALLATION Continued

DRIVE SCREWS U P

THROUGH STAND AND

INTO UNIT LEG CHANNELS

(ONE PER CORNE R)

2. The unit is designed to sit ush on a counter, stand or

refrigerated base. Leveling of the unit is done through

adjustment of the stand casters, refrigerated base legs/

casters or using shims for countertop installation.

IT IS IMPERATIVE THAT THE UNIT IS PROPERLY LEVELED

DURING INSTALLATION TO ENSURE OPTIMAL PERFORMANCE

OF THE PRODUCT.

3. To comply with NSF requirements, the unit should be

sealed to the mounting surface with silicone. If possible,

apply silicone to the underside of both leg channels

and then put the unit in place on the mounting surface.

Otherwise, apply silicone to the surface rst and then put

the unit on the surface, placing the leg channels on the

pre-applied silicone. Avoid sealing lower stainless steel

panels to the surface, as these may need to be removed

for service.

4. Position the appliance in an area that is free and clear of

all combustibles. This unit is for use in non-combustible

locations only.

5. For service, this unit may need to be accessed from the

side. An adequate service clearance should be provided

in front of the unit to enable the unit to be brought

forward for access to serviceable components. Keep this

in mind when determining the installation location.

Optional Stand

Air Supply and Ventilation

VENTILATION REQUIREMENTS MAY BE SUBJECT TO LOCAL

BUILDING AND FIRE CODES. CONSULT LOCAL AUTHORITIES

HAVING JURISDICTION.

1. For any commercial cooking appliance, means must

be provided to exhaust combustion waste products to

the outside of the building. This is especially important

for broilers, since they generate substantial amounts of

smoke when in operation.

2. A properly designed ventilating canopy should be used

for this appliance, which extends at least 6” (152mm)

beyond each side of the appliance (except against the

wall if the canopy is a wall installation) and is equipped

with lters and drip troughs.

3. Air movement should be checked during installation.

There must be adequate air intake into the building

to compensate for the amount of air removed by the

ventilation system. Without a proper balance, abnormal

atmospheric pressure will occur, aecting burner and

appliance performance. If air movement is a concern,

adjustments should be made to correct the problem by a

qualied technician.

HAVING DIFFICULTY OPENING DOORS THAT EXIT THE

BUILDING, IS AN INDICATION THAT THE BUILDING HAS A

PROBLEM WITH AIR MOVEMENT.

STANDS SPECIFICALLY DESIGNED TO ACCOMMODATE

THESE UNITS ARE AVAILABLE FOR PURCHASE. USE THE

APPROPRIATE STAND FOR THE SIZE OF UNIT. FOR YOUR

SAFETY, BE SURE TO SECURE THE UNIT TO THE STAND WITH 4

SCREWS, AS SHOWN BELOW.

STAND ASSEMBLY INSTRUCTIONS ARE PROVIDED WITH EACH

STAND.

4. Do not permit fans to blow directly at the appliance and

avoid opening windows behind or beside the appliance.

This can create air cross-currents and/or excessive drafts

that interfere with the operation of the unit.

Electrical Connection

DISCONNECT THE POWER SUPPLY BEFORE SERVICING.

1. Standard units are supplied with a Nema 5-15P power

cord with appropriate strain relief. This will require a

suitable 120V 15Amp 60Hz outlet in close proximity to

the appliance. Consult a certied electrician if you have

concern about the suitability of the outlet.

DO NOT USE AN EXTENSION CORD TO CONNECT THIS UNIT

TO A POWER SUPPLY. DO NOT USE THIS APPLIANCE IF THE

POWER CORD IS DAMAGED. DO NOT ATTEMPT TO REPAIR A

DAMAGED POWER CORD. TAKE CARE NOT TO EXPOSE THE

POWER CORD TO HEAT OR SHARP EDGES.

2. Units supplied without a cord are intended for use with a

220-240V (LINE TO LINE) single phase power supply. The

appliance must be tted with an appropriate power cord

Part # 4530868 (04/25/12) Page 7

Page 8

INSTALLATION Continued

and strain relief, and connected to the appropriate power

supply by a certied electrician in accordance with local

codes.

Gas Connection

ENSURE THE GAS METER AND GAS PIPING ARE SIZED

CORRECTLY FOR THE AMOUNT OF GAS FLOW AND PRESSURE

THAT WILL BE NEEDED TO RUN ALL APPLIANCES IN THE

KITCHEN. UNDERSIZED GAS PIPING INTO THE KITCHEN

MAY AFFECT THE PERFORMANCE OF THIS AND/OR OTHER

EQUIPMENT. IF IN DOUBT, CONSULT YOUR LOCAL GAS

AUTHORITY.

A MANUAL OR AUTOMATIC ISOLATION VALVE MUST BE

INSTALLED ON THE GAS SUPPLY TO THE KITCHEN FOR

ACCESS IN THE EVENT OF AN EMERGENCY. THE MANUAL

VALVE OR AUTOMATIC VALVE ACCESS POINT SHOULD BE

READILY ACCESSIBLE AND LOCATED EITHER OUTSIDE THE

KITCHEN OR CLOSE TO AN EXIT. POST THE FOLLOWING

NOTICE AT THE MANUAL VALVE OR AUTOMATIC VALVE

ACCESS POINT:

“ALL DOWNSTREAM BURNER AND PILOT VALVES MUST

BE TURNED OFF PRIOR TO RESTORING THE GAS SUPPLY.

AFTER AN EXTENDED SHUT OFF, PURGE BEFORE

RESTORING GAS.”

1. A manual gas shut-o valve must be installed in the gas

supply line ahead of the appliance for safety and ease

of future service. The shut-o valve should be located

such that it can be reached quickly in the event of an

emergency. The shut-o valve is normally supplied by the

installer.

3. A certied exible gas hose and quick disconnect

assembly with suitable strain relief is recommended for

connection from the gas supply line to the unit. This will

allow the unit to be moved for future service.

FLEXIBLE HOSES & QUICK DISCONNECT DEVICES MUST

COMPLY WITH ALL LOCAL AUTHORITIES AND CODES.

IN NORTH AMERICA THIS INCLUDES ANSI Z21.69/CSA

6.16, ADDENDA Z21.69B-2006/CSA 6.16B-2006 (OR

LATEST EDITION) AND ANSI Z21.41/CSA 6.9, ADDENDA

Z21.41A-2005/CSA 6.16A-2005 (OR LATEST EDITION).

4. Only connect this unit to the type of gas shown on the

rating plate. Operating this unit with the wrong gas type

can result in abnormal performance, property damage,

injury or death.

5. Ensure that any new piping, joints and connections have

been made in a clean manner, so that dirt, threading

chips and/or other foreign matter will not clog pilots,

valves and/or controls. If necessary, purge new piping

prior to connecting the appliance. Use pipe sealant that

is certied for use with liqueed petroleum, for new joints

and/or connections, where sealant is required.

6. When pressure testing the gas supply piping to a

maximum of ½ psi (14” WC, 3.45 KPa), the appliance must

be isolated from the supply line by closing the manual

shut-o valve.

7. To ensure optimal operation of this unit, it is

recommended that the dynamic gas supply pressure into

the appliance regulator is a minimum of 1” WC higher than

the pressure stated on the rating plate.

2. This unit is shipped with a gas pressure regulator. It must

be installed at the appliance prior to connecting the

equipment to the gas line. Each appliance must have its

own pressure regulator. Be sure to install the regulator

according to the gas ow direction and verify that the

pressure marking corresponds with the gas type. Failure

to install a regulator will void the equipment warranty.

PRIOR TO CONNECTING THE REGULATOR, CHECK THE GAS

SUPPLY LINE PRESSURE. THE REGULATOR SUPPLIED WITH

THE UNIT IS RATED FOR A MAXIMUM OF ½ PSI (14” WC). IF

THE GAS SUPPLY LINE PRESSURE EXCEEDS THIS MAXIMUM,

A STEP DOWN REGULATOR WILL BE REQUIRED AND MUST BE

INSTALLED IN ACCORDANCE WITH LOCAL CODES.

THE RED AIR-VENT CAP IS PART OF THE REGULATOR AND

SHOULD NOT BE REMOVED, UNLESS LOCAL CODES REQUIRE

EXTERNAL VENTING. IF EXTERNAL VENTING IS REQUIRED,

INSTALL IN ACCORDANCE WITH LOCAL CODES.

Start Up

1. Inside the unit, ensure the burners are in the correct

position and the shields hanging under the burners have

not rotated out of position during transit.

2. Install cast radiants over each burner and place the

cooking grates in position on the unit.

3. Ensure the gas supply to the appliance is open and the

unit is connected to the power supply. Activating the one

or two power switches on the right leg operates the unit.

4. Check all gas connections for leaks using a soap solution.

Do not use an open ame to check for leaks. Be sure to

inspect connections outside and inside the unit (ie: valves,

manifold ttings and connections in the left leg channel)

to make certain all connections are gas tight after

shipping.

5. Verify the unit is running at the pressure stated on the

rating plate as follows:

Part # 4530868 (04/25/12)Page 8

Page 9

INSTALLATION Continued

FOR HEEGM24 & 36 SIZE UNITS

• Connect a manometer to the test spigot on the

manifold.

• Turn on the unit and adjust the burners so that they are

all set to high.

• If necessary, adjust the pressure so that the reading

on the manometer matches the pressure value stated

on the rating plate. To adjust the pressure, access and

rotate the pressure adjustment screw on the regulator

installed at the appliance.

FOR HEEGM48 & 60 SIZE UNITS

• Connect a manometer to the test spigot on the LEFT

manifold.

USE AND CARE

• Turn on the LEFT side of the unit only (by activating the

left switch) and adjust the burners so that they are all

set to high.

• If necessary, adjust the pressure so that the reading

on the manometer matches the pressure value stated

on the rating plate. To adjust the pressure, access and

rotate the pressure adjustment screw on the regulator

installed at the appliance.

6. Inspect the ame of each burner to determine whether

adjustments to the burner air shutter are necessary.

Adjustments are made by loosening the air shutter screw;

rotating the shutter and re-tightening the screw. If the

tips of the ame appear too yellow, the shutter should be

turned to allow MORE air to enter the burner cavity. If the

ames appear to be lifting o the burner ports, the shutter

should be turned to allow LESS air to enter the burner

cavity.

Operation

IF FOR ANY REASON YOU SMELL GAS, BEFORE, DURING OR

AFTER OPERATION, TURN THE POWER OFF AND CLOSE THE

MANUAL SHUT-OFF VALVE TO THE APPLIANCE. CONTACT

AN AUTHORIZED SERVICE AGENT FOR SERVICE BEFORE

ATTEMPTING TO RESTORE GAS SUPPLY. FOR A LIST OF

AUTHORIZED SERVICE AGENTS, REFER TO THE GARLAND WEB

SITE AT http://www.garland-group.com

1. To turn on and use this appliance, the operator simply

needs to turn on the power switch(es).

FOR STANDARD 120 VOLT UNITS:

2. Models HEEGM-24CL and HEEGM-36CL have one power

switch on the lower right side of the unit. Once pushed

to the “ON” position, gas is supplied to all the burners. At

the same time a spark is supplied to each burner to ignite

the gas. Sparking will continue until a ame has been

established at all burners.

3. Models HEEGM-48CL and HEEGM-60CL have two power

switches on the lower right side of the unit. Once pushed

to the “ON” position, they operate in the same manner as

the single switch above, except they allow the operator to

run the left and right side of the broiler independently as

shown below:

• HEEGM-48CL: The left switch operates burners 1 to 4

on the left side of the unit. The right switch operates

burners 5 to 9 on the right side of the unit. The entire

unit runs when both switches are used.

• HEEGM-60CL: The left switch operates burners 1 to 6

on the left side of the unit. The right switch operates

burners 7 to 11 on the right side of the unit. The entire

unit runs when both switches are used.

FOR OPTIONAL 220-240 VOLT UNITS, THE MAIN

POWER SWITCH NEEDS TO BE TURNED ON BEFORE

THE FUNCTIONALITY OF THE SWITCHES DESCRIBED IN

2 & 3 APPLY. REFER TO IMAGES BELOW FOR A VISUAL

COMPARISON BETWEEN THE STANDARD 120 AND OPTIONAL

220-240V MODELS.

Part # 4530868 (04/25/12) Page 9

Page 10

120V SINGLE SWITCH

120V DOUBLE SWITCH

220-240V SINGLE SWITCH

220-240V DOUBLE SWITCH

$

BURNERS

ON/OFF

LEFT SIDE

BURNERS

ON/OFF

RIGHT SIDE

BURNERS

ON/OFF

MAIN

POWER

BURNERS

ON/OFF

MAIN

POWER

RIGHT SIDE

BURNERS

ON/OFF

LEFT SIDE

BURNERS

ON/OFF

USE AND CARE Continued

4. Once the desired power switch(es) have been turned to

the “ON” position, the burners should ignite quickly. If

sparking continues and/or a burner does not light, shut

down power to the unit by turning the switch(es) to

the “OFF” position and wait 5 minutes before repeating

ignition. If ignition fails repeatedly, shut down power to

the unit and contact a qualied service technician.

5. It is recommended that the unit run for approximately 30

minutes on start up to reach the desired temperature.

6. For temperature adjustment, each burner has a control

knob which will adjust the height of the ame from a high

to a low position.

7. To shut o the unit, the operator simply needs to turn o

the power switch(es). When shutting down for longer

periods of time, it is best to also close the manual shut-o

valve to the unit.

8. The cooking grates can be installed in 2 positions, to

provide exibility when preparing dierent types of food.

To install the cooking grates in the standard position,

the rear feet on the grates should be placed through the

square cutouts on the rear wall of the broiler. To install the

cooking grates in the elevated position, the groove in the

feet of the grates should be placed on the top edge of the

rear wall of the broiler. Grates must be manually moved

from one position to another; and therefore, should be

moved when the grates are cool.

Part # 4530868 (04/25/12)Page 10

Page 11

USE AND CARE Continued

FOR STANDARD GRATE

POSITION, GRATE FEET SIT

IN CUTOUTS OF REAR WALL

FOR 2nd GRATE POSITION,

GRATE FEET SIT ON EDGE

OF REAR WALL

THE SIDE SHIELDS MUST ALWAYS BE IN PLACE WHEN

OPERATING THIS UNIT. THE SIDE SHIELDS PREVENT THE

COOKING GRATES FROM SLIDING OFF THE SIDE OF THE UNIT,

WHEN THEY ARE PLACED IN THE ELEVATED POSITION.

Warnings

To ensure consistent and dependable performance of this

appliance, the following are recommended:

• Do not use an extension cord to connect this unit to a

power supply. Do not use this appliance if the power cord

is damaged. Do not attempt to repair a damaged power

cord. Take care not to expose the power cord to heat (ie:

under grease tray, near ue or grate support etc) and be

careful not to damage the cord by pinching under unit or

rubbing on sharp edges.

• Do not lift unit by the front rail or apply excessive force to

the rail to move the unit. Under no circumstances should

the front rail be used as a step or standing platform (ie: to

access light bulbs or grease bucket in ventilation hood).

Doing so may result in serious injury and/or death; and

may cause damage to your broiler and/or property.

• This appliance generates signicant amounts of heat

and the operator should take caution when touching

accessible surfaces that are likely to get hot. Surfaces

close to the cooking surface including the side panels,

side shields, front rail, grease tray handle and valve panel

may get hot enough to burn skin.

• Use of foil in the grease tray is not recommended.

However, if foil is being used, it must be kept tight to the

tray so that it does not obstruct the ow of air into and

around the unit, particularly between the grease tray and

the valve panel.

• It is important that the grease trays are emptied on a

regular basis. Flare ups in the grease tray are possible with

this type of appliance and excessive amounts of grease

in the tray can lead to a sustained are up or re, which

can be dangerous and result in personal and/or property

damage.

• Do not operate the broiler without the grease drawers in

place and ensure they are always fully pushed in. Failing

to do so may result in grease and/or debris spilling onto

the counter, stand and/or refrigerated base top.

• Do not attempt to service this appliance unless you are a

qualied service technician. This appliance is connected

to live electrical power. Disconnect power before

attempting to clean/remove accessible metal panels.

• Without proper cleaning & maintenance, this appliance

will accumulate oil and grease. This may result in reduced

performance, excessive are ups and/or re. It is the

user’s responsibility to prevent the hazards of grease

accumulation by cleaning & maintaining their appliance

on a regular basis. Garland will not be responsible for

performance reductions and/or res resulting from

misuse and/or poor cleaning & maintenance habits.

• If this appliance experiences abnormal are ups and/

or sustained re in any area other than the combustion

chamber (ie: the grease tray, behind the valve panel or in

the leg channel), the unit must be shut down immediately

and should not be used until it has been serviced by a

qualied technician and deemed safe to operate.

Optional Equipment

As an option, your appliance may have been supplied with

a special top grate designed to hold and heat fajita pans.

This appliance is certied to use only one of these fajita pan

grates at a time. Installing multiple fajita pan grates on one

appliance is prohibited and could void your warranty.

• Do not operate the broiler without the side shields in

Part # 4530868 (04/25/12) Page 11

place as it may adversely aect the performance of

the unit and/or allow heat to migrate to neighboring

equipment/property causing damage. The shields also

prevent the cooking grates from sliding o the side of the

unit when they are placed in the elevated position.

The fajita pan grate has been designed to accommodate

only one fajita pan per slot, in either the vertical or horizontal

position, as shown in the image below. Placing multiple

fajita pans in one slot and/or placing fajita pans at on this

grate or the standard grate may cause damage to the broiler

and could void your warranty.

Page 12

USE AND CARE Continued

BRUSH SIDE - FOR

GENERAL CLEANING

SCRAPER SIDE - FITS

CONTOURS OF GRATES

CLEANING AND MAINTENANCE

THE FAJITA PAN GRATE IS INSTALLED ON THE UNIT IN THE

SAME MANNER AS THE STANDARD GRATE IN THE STANDARD

POSTION. FEET ON THE REAR OF THE FAJITA GRATE SIT IN

THE SQUARE CUTOUTS ON THE REAR WALL.

THIS APPLIANCE WILL PERFORM OPTIMALLY AND LAST

LONGER IF IT IS PROPERLY MAINTAINED. FOLLOWING A

CLEANING SCHEDULE AND HAVING THE UNIT CHECKED

PERIODICALLY BY AN AUTHORIZED SERVICE AGENT ARE

STRONGLY RECOMMENDED. FOR A LIST OF AUTHORIZED

SERVICE AGENTS, REFER TO THE GARLAND WEB SITE AT

http://www.garland-group.com

General

This appliance has been supplied with a combination brush/

scraper tool for cleaning your cooking grates. The scraper

side of the tool has stainless steel teeth, designed specically

to t the contours of the cooking grate and will clean hard to

remove debris. The brush side of the tool has stainless steel

wire bristles which can be used to remove ner debris and

for general cleaning.

• This appliance is connected to live electrical power.

Disconnect power before attempting to clean/remove

accessible metal panels.

• Do not spray or pour water on the unit to clean. This

appliance has several electronic components behind

access panels that can be damaged or become unsafe if

exposed to water. This unit should only be cleaned by

wiping down with a damp cloth.

• Do not attempt to clean the grates by burning o grease/

debris. The cooking grates on this unit are shielded

from open ame by the radiants. Attempting to burn

o grease/debris will likely have the opposite eect and

cause the grease/debris to stick even more.

• When cleaning cast iron components such as the cooking

grates; radiants; and burners, do not handle these

components roughly. Dropping them on the oor or in

the sink may cause them to crack and/or break.

• Cast iron components are susceptible to cracking/

breaking if they are thermally shocked. Do not expose

hot cooking grates, radiants; and/or burners to cold

water. These components must be allowed to properly

cool before they are washed with water.

Warnings

• Never place a sheet pan or other large obstruction over

the grates when the broiler is hot. Covering the grates

and running the broiler as a method of cleaning is

prohibited. Doing so, may cause damage to your broiler

and/or property; endanger the safety of others; and void

your warranty.

• Do not use steel wool, abrasive cloths, cleaners or

powders to clean stainless steel. Do not use a metal

scraper, knife or other tool to scrape stainless steel. Doing

so may cause irreparable scratches on the stainless steel

material.

Cleaning During Operations

1. It is important to clean the grates periodically during

daily operations, using the tool provided or any other

cleaning tool of preference. Cleaning the grates as

needed throughout the day will limit the eects of grease

Part # 4530868 (04/25/12)Page 12

Page 13

CLEANING AND MAINTENANCE Continued

accumulation, which include excess smoke; are ups;

res and sub-par product.

2. The grease trough and chute should be kept clean during

daily operations to prevent grease from accumulating

near the cook surface. If necessary, stagnant grease and/

or food particles should be directed to the grease chute

using a standard 3” wide turner. If necessary, this turner

can also be used to push items/grease in the grease

chute down into the grease drawer.

3. The grease drawer(s) should be emptied periodically

during daily operations. Every environment diers,

so the frequency of this action will vary depending on

amount and type of product being cooked. Keeping the

amount of grease in the drawer to a minimum greatly

reduces the chance of are ups and sustained re.

Daily Cleaning

1. Scrape and/or brush the cooking grates using the tool

provided or any other cleaning tool of preference while

the grates are still warm. Once the grates have cooled,

remove them from the unit and wash them in a hot soapy

solution. Dry the grates immediately after washing and

lightly season with non-toxic oil (liquid vegetable oil or

spray) before re-installing on the unit. Properly drying

and seasoning the grates will prevent them from rusting.

DO NOT SEASON GRATES WHILE THEY ARE ON THE

APPLIANCE. SEASONING GRATES OVER AN OPEN FLAME

MAY RESULT IN DANGEROUS FLARE UPS AND/OR A FLASH

FIRE.

1. Once the unit has cooled, remove the side shields from

the unit by sliding them up and then o the shoulder

bolts. Clean the side shields with a hot soapy solution

and/or a food safe liquid cleaner designed to clean

stainless steel.

2. Remove the burners and hanging shields from the unit as

follows:

• Remove the pins at the rear of the burner

• Lift the burner peg up and out of the bracket at the rear

• Slide the burner back and o the orice

• Angle the front of the burner down and then remove

from unit

The burners on the far left and right of the unit should be

removed last

WHEN REMOVING BURNERS FROM THE UNIT, TAKE CARE NOT

TO MOVE AND/OR BEND THE IGNITION PROBES. MOVING

OR BENDING THE PROBES CAN CRACK THE CERAMIC

INSULATING MATERIAL, ALTER THE SPARK GAP OR MISALIGN

WITH BURNER LIGHTING PORTS WHICH MAY RENDER THE

UNIT INOPERABLE.

Clean the burners and their hanging shields in a hot soapy

solution, paying attention to ensure that all burner ports

are free and clear of debris. Pay particular attention to the

small lighting holes at the front of the burner. These holes

must remain clear to ensure the appliance ignites and

functions properly.

2. Wire brush the radiants clean using the tool provided or

any other cleaning tool of preference. Once the radiants

have cooled, remove them from the unit and wash them

in a hot soapy solution.

3. Scrape the grease trough and chute, directing any

grease/debris into the grease drawer (s). Empty the

grease drawer(s), scraping out stubborn grease/debris.

Wash the grease drawer(s) in a hot soapy solution.

4. Once the unit has cooled, accessible stainless steel panels

should be cleaned with a hot soapy solution and/or a

food safe liquid cleaner designed to clean stainless steel.

Never spray or pour water on the unit to clean. Always

disconnect electrical power before cleaning accessible

panels.

Weekly/Periodic Cleaning

In addition to the daily cleaning tasks outlined above, the

following should be done weekly/periodically:

Part # 4530868 (04/25/12) Page 13

ENSURE THE POWER SUPPLY IS DISCONNECTED BEFORE

PROCEEDING.

3. With all the components removed from the cooking

chamber, wipe down the interior with a hot soapy

solution taking care to avoid the ignition probes. With the

cooking chamber cleaned, components can be put back

in.

WHEN PUTTING THE BURNERS BACK IN THE UNIT, TAKE

CARE NOT TO MOVE AND/OR BEND THE IGNITION PROBES.

BURNERS ON THE FAR LEFT & RIGHT SIDE OF THE UNIT MUST

BE PUT IN FIRST. ENSURE THE PINS AT THE REAR ARE REINSTALLED TO SECURE THE BURNERS IN PLACE.

4. Once the unit has been returned to its original state,

verify that the burners ignite correctly. Slight front to

back adjustments may be required to ensure quick and

accurate lighting after cleaning.

Page 14

CLEANING AND MAINTENANCE Continued

Maintenance

Any maintenance involving the disassembly of components

should be performed by a qualied service technician as

part of a regular kitchen maintenance program. Periodic

inspections should be done to check temperatures, verify

performance and make any adjustments as necessary. In

addition, cleaning behind non-accessible panels; such as the

front panel and/or leg panels, should also be done during

regular maintenance.

Service and Parts

If for any reason this appliance requires service, contact your

local authorized Garland service agency. All repairs must be

performed by a qualied technician, using genuine Garland

replacement parts or risk negating the warranty. For a list

of Authorized Service Agents, to view a Genuine Parts list

for your appliance and/or to contact the Garland Service

Department, visit the Garland web site at: http://www.

garland-group.com or call (800) 427-6668.

Refer to the rating plate when calling for service. It contains

the model number and serial number for your appliance.

Properly identifying the appliance will help the factory or

your local service agent provide faster and more accurate

service. The rating plate can be found on the inside face of

the left leg. The grease drawer may need to be removed in

order to read the information

Part # 4530868 (04/25/12)Page 14

Page 15

Part # 4530868 (04/25/12) Page 15

Page 16

Page 17

Pièce nº # 4530868 (04/25/12)Page 16

Page 18

Pièce nº # 4530868 (04/25/12) Page 15

Page 19

Pièce nº # 4530868 (04/25/12)Page 14

pouvoir lire les informations.

Il est possible que l'on doive retirer le tiroir à graisse pour

signalétique se trouve sur la face intérieure du pied avant.

local à orir un service plus rapide et plus précis. La plaque

correcte de l'appareil aidera l'usine et l'agent de service

et le numéro de série de votre appareil. Une identication

département de service. Elle contient le numéro de modèle

Consulter la plaque signalétique pour appeler le

group.com ou appelez le (800) 427-6668.

Web Garland à l'adresse suivante : http://www.garlandcontacter le département de service Garland, visitez le site

la liste des pièces d'origine de votre appareil et/ou pour

obtenir la liste des agents de service agréés, pour acher

d'origine Garland sous peine d'annuler la garantie. Pour

par un technicien qualié, utilisant des pièces de rechange

Garland. Toutes les réparations doivent être eectuées

réparations, contacter l'agence de service agréée locale

Si, pour une raison quelconque, cet appareil a besoin de

Réparations et pièces de rechange

eectué lors de l'entretien régulier.

avant et/ou les panneaux des pieds, doit également être

derrière les panneaux non accessibles, comme le panneau

eectuer les réglages nécessaires. De plus, un nettoyage

pour vérier les températures, et les performances et pour

cuisine. Des inspections périodiques doivent être eectuées

le cadre d'un programme régulier de maintenance de la

doit être eectué par un technicien de service qualié dans

Tout entretien impliquant le démontage des composants

Entretien

après le nettoyage.

nécessaires pour assurer un allumage rapide et précis

petits ajustements d'avant en arrière peuvent être

vérier que les brûleurs s'allument correctement. De

4. Une fois que l'unité a été remise dans son état d'origine,

REMONTÉES POUR MAINTENIR LE BRÛLEUR EN PLACE.

PREMIER. S'ASSURER QUE LES GOUPILLES À L'ARRIÈRE SONT

ET À DROITE DE L'UNITÉ DOIVENT ÊTRES INSTALLÉS EN

D'ALLUMAGE. LES BRÛLEURS COMPLÈTEMENT À GAUCHE

ATTENTION À NE PAS DÉPLACER NI PLIER LES SONDES

EN REMETTANT LES BRÛLEURS DANS L'UNITÉ, FAIRE

remettre les composants en place

La chambre de cuisson étant nettoyée, il est possible de

chaude en faisant attention à éviter les sondes d'allumage.

cuisson, essuyer l'intérieur avec de l'eau savonneuse

3. Tous les composants étant retirés de la chambre de

ENTRETIEN ET NETTOYAGE

Page 20

DÉBRANCHÉE AVANT DE CONTINUER.

S'ASSURER QUE L'ALIMENTATION ÉLECTRIQUE EST

fonctionne correctement.

trous doivent rester dégagés pour que l'unité s'allume et

aux petits trous d'allumage à l'avant du brûleur. Ces

bouchés par des débris. Faire particulièrement attention

s'assurer que tous les orices des brûleurs ne sont pas

une solution savonneuse chaude, en faisant attention à

Nettoyer les brûleurs et leurs écrans suspendus dans

RENDRE L'UNITÉ INUTILISABLE.

LES ORIFICES D'ALLUMAGE DES BRÛLEURS, CE QUI PEUT

L'ÉCLATEUR À ÉTINCELLES OU MODIFIER L'ALIGNEMENT AVEC

LE MATÉRIAU ISOLANT EN CÉRAMIQUE, ENDOMMAGER

FAIT DE DÉPLACER OU PLIER LES SONDES PEUT FISSURER

À NE PAS DÉPLACER NI PLIER LES SONDES D'ALLUMAGE. LE

EN RETIRANT LES BRÛLEURS DE L'UNITÉ, FAIRE ATTENTION

doivent être retirés en dernier.

Les brûleurs complètement à gauche et à droite de l'unité

l'unité

• Incliner l'avant du brûleur vers le bas et le retirer de

• Faire glisser le brûleur vers l'arrière et hors de l'orice.

support à l'arrière

• Soulever la cheville du brûleur vers le haut et hors du

• Retirer les goupilles à l'arrière du brûleur.

procédant comme suit :

2. Retirer les brûleurs et les écrans suspendus de l'unité en

alimentaires et conçu pour nettoyer l'acier inoxydable.

un produit nettoyant liquide compatible avec les produits

écrans latéraux avec de l'eau savonneuse chaude et/ou

dégageant ensuite des boulons épaulés. Nettoyer les

de l'unité en les faisant glisser vers le haut et en les

1. Une fois que l'unité a refroidi, retirer les écrans latéraux

semaine/périodiquement :

dessus, les tâches suivantes devront être eectuées chaque

En plus des tâches de nettoyage quotidiennes indiquées ci-

Nettoyage hebdomadaire/périodique

accessibles.

l'alimentation électrique avant de nettoyer les panneaux

de l'eau sur l'unité pour la nettoyer. Toujours débrancher

nettoyer l'acier inoxydable. Ne pas pulvériser ni verser

compatible avec les produits alimentaires et conçu pour

savonneuse chaude et/ou un produit nettoyant liquide

en acier inoxydable doivent être nettoyés avec de l'eau

4. Une fois que l'unité a refroidi, les panneaux accessibles

Pièce nº # 4530868 (04/25/12) Page 13

savonneuse chaude.

débris attachés. Laver le(s) tiroir(s) à graisse dans l'eau

Vider le(s) tiroir(s) à graisse en grattant la graisse/les

la graisse et les débris dans le(s) tiroir(s) à graisse.

3. 3. Gratter la gouttière à graisse et la rigole, en dirigeant

savonneuse chaude

ont refroidi, les retirer de l'unité et les laver dans de l'eau

de nettoyage si vous préférez. Une fois que les radiants

2. Brosser les radiants avec l'outil fourni ou un autre outil

DANGEREUSES ET/OU UN FEU ÉCLAIR.

D'UNE FLAMME NUE PEUT CAUSER DES INFLAMMATIONS

SUR L'APPAREIL. L'APPRÊTAGE DES GRILLES AU-DESSUS

NE PAS APPRÊTER LES GRILLES PENDANT QU'ELLES SONT

empêcheront de rouiller.

Un séchage et un apprêtage corrects des grilles les

pulvérisée) avant de les remettre en place sur l'unité.

avec de l'huile non toxique (huile végétale liquide ou

grilles après les avoir lavées et les apprêter légèrement

de l'eau savonneuse chaude. Sécher immédiatement les

les grilles ont refroidi, les retirer de l'unité et les laver dans

pendant que les grilles sont encore tièdes. Une fois que

fourni ou n'importe quel autre outil de nettoyage

1. Gratter et/ou brosser les grilles de cuisson avec l'outil

Nettoyage quotidien

d'inammations et de feu.

le tiroir au minimum, on réduit grandement les risques

de produit cuit. En maintenant la quantité de graisse dans

cette action variera en fonction de la quantité et du type

Chaque environnement est diérent et la fréquence de

périodiquement pendant les opérations quotidiennes.

3. Il est nécessaire de vider le(s) tiroir(s) à graisse

dans le tiroir à graisse.

pousser les débris/la graisse dans la rigole à graisse puis

Si nécessaire, cette spatule peut aussi être utilisée pour

graisse en utilisant une spatule standard de 3 po de large.

particules d'aliments devront être dirigées vers la rigole à

de cuisson. Si nécessaire, la graisse stagnante et/ou les

empêcher la graisse de s'accumuler près de la surface

propres pendant les opérations quotidiennes pour

2. La gouttière à graisse et la rigole doivent être maintenues

produits.

l'excès de fumée, les inammations, les feux et souslimitera les eets de l'accumulation de graisse, à savoir

nettoyage des grilles si nécessaire pendant la journée

fourni ou tout autre outil de nettoyage si on préfère. Le

pendant l'utilisation quotidienne, en utilisant l'outil

1. Il est important de nettoyer périodiquement les grilles

Nettoyage pendant le fonctionnement

ENTRETIEN ET NETTOYAGE suite

Page 21

Pièce nº # 4530868 (04/25/12)Page 12

sécurité des autres et annuler la garantie.

l'acier inoxydable.

inoxydable. Cela peut causer des rayures irréparables sur

de couteau ou tout autre outil pour gratter l'acier

l'acier inoxydable. Ne pas utiliser de grattoir métallique,

ou de produits de nettoyage abrasifs pour nettoyer

• Ne pas utiliser de laine d’acier, de tissus, de poudres

causer d'autres dommages matériels, mettre en danger la

pour le nettoyage. Cela peut endommager le gril et/ou

interdit de couvrir les grilles et de faire fonctionner le gril

de cuisine sur les grilles quand le gril est chaud. Il est

• Ne jamais placer de plateau ou d'autres grands ustensiles

Avertissements

correctement avant de les laver à l'eau.

brûleurs chauds. On doit laisser refroidir ces composants

EddKz''EZ>

NdZK^^ʹWKhZhE

l'eau froide les grilles de cuisson, les radiants et/ou les

se casser en cas de choc thermique. Ne pas exposer à

• Les composants en fonte sont susceptibles de se ssurer/

ssures et/ou les casser.

laisser tomber sur le sol ou dans l'évier peut causer des

>'Z/>>

^ΖWdhyKEdKhZ^

Nd'ZddK/Zʹ

manipuler ces composants avec brutalité. Le fait de les

les grilles de cuisson, les radiants et les brûleurs, ne pas

• Lors du nettoyage des composants en fonte comme

débris.

l'eet inverse et de faire coller encore plus la graisse et les

fait d'essayer de brûler la graisse/les débris risque d'avoir

sont protégées des ammes nues par les radiants. Le

graisses/débris. Les grilles de cuisson de cette unité

• Ne pas essayer de nettoyer les grilles en brûlant les

en l'essuyant avec un chion humide.

débris plus petits et pour un nettoyage général.

ls en acier inoxydable et peut être utilisé pour éliminer les

débris diciles à retirer. Le côté brosse de l'outil est doté de

s'adapter aux contours de la grille de cuisson et nettoyer les

dents en acier inoxydable spécialement conçues pour

grilles de cuisson. Le côté grattoir de l'outil comporte des

métallique et un grattoir combinés pour le nettoyage des

Cet appareil a été livré avec un outil comportant une brosse

Généralités

exposés à l'eau. Cette unité doit seulement être nettoyée

être endommagés ou devenir dangereux s'ils sont

électroniques derrière les panneaux d'accès qui peuvent

nettoyer. Cet appareil comporte plusieurs composants

• Ne pas pulvériser ni verser de l'eau sur l'unité pour la

L’ADRESSE http://www.garland-group.com

SERVICE AGRÉÉS, CONSULTER LE SITE WEB DE GARLAND À

SERVICE AGRÉÉ. POUR OBTENIR UNE LISTE DES AGENTS DE

VÉRIFIER L'UNITÉ PÉRIODIQUEMENT PAR UN AGENT DE

DE SUIVRE UN CALENDRIER DE NETTOYAGE ET DE FAIRE

nettoyer/déposer les panneaux métalliques accessibles.

tension. Débrancher l'alimentation avant d'essayer de

• Cet appareil est relié à une alimentation électrique sous

CORRECTEMENT. IL EST FORTEMENT RECOMMANDÉ

ET DURERA PLUS LONGTEMPS S'IL EST ENTRETENU

CET APPAREIL FONCTIONNERA DE FAÇON OPTIMALE

ENTRETIEN ET NETTOYAGE

PAROI ARRIÈRE.

FAJITAS SONT POSÉS DANS LES DÉCOUPES CARRÉES DE LA

POSITION STANDARD. LES PIEDS À L'ARRIÈRE DE LA GRILLE À

L'UNITÉ DE LA MÊME FAÇON QUE LA GRILLE STANDARD EN

LA GRILLE POUR POÊLES À FAJITAS EST INSTALLÉE SUR

endommager le gril et pourrait annuler la garantie.

poêles à fajitas à plat sur cette grille ou la grille standard peut

plusieurs poêles à fajitas dans une fente et/ou de placer les

comme illustré sur l'image ci-dessous. Le fait de placer

poêle à fajitas par fente, en position verticale ou horizontale,

La grille pour poêles à fajitas a été conçue pour accueillir une

cela pourrait annuler la garantie.

UTILISATION ET ENTRETIEN suite

Page 22

Pièce nº # 4530868 (04/25/12) Page 11

plusieurs grilles pour poêles à fajitas sur un seul appareil et

grilles pour poêles à fajitas à la fois. Il est interdit d'installer

fajitas. Cet appareil est certié pour utiliser une seule de ces

grille spéciale conçue pour accueillir et chauer les poêles à

En option, votre appareil a peut-être été livré avec une

Équipement optionnel

qualié et jugée sûre à l'utilisation

être utilisée avant d'avoir été réparée par un technicien

l'unité doit être arrêtée immédiatement et ne doit pas

le panneau des robinets ou dans la gouttière du pied),

combustion (p. ex. dans le plateau à graisse, derrière

dans n'importe quel endroit autre que la chambre de

• En cas d'inammations anormales et/ou de feu soutenu

de mauvaises habitudes de nettoyage et d'entretien.

et/ou des incendies résultant d'un mauvais usage et/ou

n'est pas responsable des réductions des performances

et en entretenant l'appareil de façon régulière. Garland

d'éviter les risques d'accumulation de graisse en nettoyant

un feu soutenu. Il est de la responsabilité de l'utilisateur

dégradation des performances, des inammations et/ou

accumulera l'huile et la graisse. Cela peut causer une

• Sans nettoyage et entretien corrects, cet appareil

panneaux métalliques accessibles.

l'alimentation avant d'essayer de nettoyer/déposer les

une alimentation électrique sous tension. Débrancher

un technicien de service qualié. Cet appareil est relié à

• Ne pas essayer de réparer cet appareil si l'on n'est pas

socle et/ou le dessus de la base réfrigérée.

déversement de graisse et/ou débris sur le comptoir, le

manquement à cette instruction peut causer un

et vérier qu'ils sont toujours bien enfoncés. Tout

• Ne pas utiliser le gril sans les tiroirs à graisse en place

des blessures et/ou dommages matériels.

ou un feu soutenu, qui peuvent être dangereux et causer

graisse dans le plateau peut entraîner une inammation

feu avec ce type d'appareil et une quantité excessive de

régulièrement. Les plateaux à graisse risque de prendre

• Il est important que les plateaux à graisse soient vidés

permettre à la chaleur de migrer vers l'équipement /les

car cela peut nuire aux performances de l'unité et/ou

• Ne pas utiliser le gril sans les écrans latéraux en place,

peau.

robinets peuvent être susamment chauds pour brûler la

avant, la poignée du plateau à graisse et le panneau des

compris les panneaux latéraux, les écrans latéraux, le rail

chaudes. Les surfaces proches de la surface de cuisson, y

surfaces accessibles qui sont susceptibles de devenir très

et l'opérateur doit faire attention lorsqu'il touche des

• Cet appareil génère d'importantes quantités de chaleur

le gril et/ou entraîner d'autres dommages matériels.

des blessures graves, voire mortelles et peut endommager

à graisse de la hotte de ventilation). Cela risque de causer

marchepied (p. ex. pour accéder aux ampoules ou au bac

cas le rail avant ne doit être utilisé comme marche ou

force excessive sur le rail pour déplacer l'unité. En aucun

• Ne pas soulever l'unité par le rail avant ni exercer de

frottant contre des bords coupants.

endommager le cordon en le pinçant sous l'unité en

de fumées ou du support des grilles, etc.) et à ne pas

chaleur (p. ex. sous le plateau à graisse, près du conduit

attention à ne pas exposer le cordon d'alimentation à la

de réparer un cordon d'alimentation endommagé. Faire

cordon d'alimentation est endommagé. Ne pas essayer

à une prise de courant. Ne pas utiliser cet appareil si le

• NE pas utiliser de rallonge pour connecter cette unité

il est recommandé de suivre les instructions suivantes :

Pour obtenir des résultats réguliers et ables de cet appareil,

Avertissements

POSITION ÉLEVÉE.

SUR LE CÔTÉ DE L'UNITÉ QUAND ELLES SONT PLACÉES EN

LATÉRAUX EMPÊCHENT LES GRILLES DE CUISSON DE GLISSER

LORS DE L'UTILISATION DE CETTE UNITÉ. LES ÉCRANS

LES ÉCRANS LATÉRAUX DOIVENT TOUJOURS ÊTRE EN PLACE

graisse et le panneau des robinets.

vers et autour de l'unité, en particulier entre le plateau à

plateau de façon à ne pas obstruer la circulation de l'air

de papier d'aluminium, il doit être maintenu contre le

dans le plateau à graisse. Cependant, en cas d'utilisation

• Il n'est pas recommandé d'utiliser du papier d'aluminium

élevée.

sur le côté de l'unité quand elles sont placées en position

empêchent également les grilles de cuisson de glisser

matériaux voisins, causant des dommages. Les écrans

KhW^>WZK/ZZ/Z

'Z/>>^ZWK^EdE^>^

^'Z/>>^>^W/^^

WKhZ>WK^/d/KE^dEZ

KZ>WZK/ZZ/Z

'Z/>>^ZWK^Ed^hZ>

'Z/>>^>^W/^^

WKhZ>ϮĞWK^/d/KE^

UTILISATION ET ENTRETIEN suite

Page 23

Pièce nº # 4530868 (04/25/12)Page 10

Ψ

k

ZZd

DZ,

WZ/E/W>

/EdZZhWd

doivent être déplacées quand elles sont froides.

manuellement d'une position à l'autre et, par conséquent,

paroi arrière du gril. Les grilles peuvent être déplacées

des grilles doit être placée sur le bord supérieur de la

cuisson dans la position élevée, la rainure dans les pieds

de la paroi arrière du gril. Pour installer les grilles de

arrière des grilles doivent être placés dans les découpes

les grilles de cuisson dans la position standard, les pieds

préparation de types diérents d'aliments. Pour installer

deux positions pour donner plus de exibilité lors de la

8. Les grilles de cuisson peuvent être installées dans

le robinet d'arrêt manuel de l'unité.

longue période de temps, il vaut mieux fermer également

interrupteur(s) en position d'arrêt. En cas d'arrêt pour une

7. Pour arrêter l'unité, il sut à l'opérateur de mettre le ou les

amme de haute à basse.

d'un bouton de commande qui réglera la hauteur de la

6. Pour le réglage de température, chaque brûleur est doté

température souhaitée.

environ 30 minutes au démarrage pour atteindre la

5. Il est recommandé de faire fonctionner l'unité pendant

contacter un technicien de service qualié.

à plusieurs reprises, couper l'alimentation de l'unité et

avant de recommencer l'allumage. Si l'allumage échoue

interrupteur(s) en position « OFF » et attendre 5 minutes

pas, couper l'alimentation de l'unité en mettant le ou les

les étincelles continuent et/ou si un brûleur ne s'allume

« ON », les brûleurs devraient s'allumer rapidement. Si

4. Une fois le ou les interrupteur(s) souhaité(s) en position

ZZd

DZ,

WZ/E/W>

/EdZZhWd

>>hD^d/Ed^

ZK/d

Zk>hZ^

>>hD^d/Ed^

'h,

Zk>hZ^

d/Ed^

>>hD^

Zk>hZ^

ϮϮϬͲϮϰϬs/EdZZhWdhZ^/DW> ϮϮϬͲϮϰϬs/EdZZhWdhZKh>

d/Ed^

>>hD^

>>hD^d/Ed^

ZK/d

Zk>hZ^

>>hD^d/Ed^

'h,

Z

>hZ^

Zk>hZ^

ϭϮϬsͲ/EdZZhWdhZ^/DW> ϭϮϬsͲ/EdZZhWdhZKh>

UTILISATION ET ENTRETIEN suite

Page 24

Pièce nº # 4530868 (04/25/12) Page 9

STANDARD ET LES MODÈLES 220-240 V EN OPTION.

UNE COMPARAISON VISUELLE ENTRE LES MODÈLES 120 V

POINTS 2 ET 3. CONSULTER LES IMAGES CI-DESSOUS POUR

POUVOIR UTILISER LES INTERRUPTEURS COMME DÉCRIT AUX

L'INTERRUPTEUR PRINCIPAL DOIT ÊTRE ACTIONNÉ AVANT DE

POUR LES UNITÉS 220-240 VOLTS EN OPTION,

interrupteurs sont utilisés.

l'unité. Toute l'unité fonctionne quand les deux

droit actionne les brûleurs 7 à 11 du côté droit de

brûleurs 1 à 6 du côté gauche de l'unité. L'interrupteur

• HEEGM-60CL : L'interrupteur gauche actionne les

sont utilisés.

Toute l'unité fonctionne quand les deux interrupteurs

droit actionne les brûleurs 5 à 9 du côté droit de l'unité.

brûleurs 1 à 4 du côté gauche de l'unité. L'interrupteur

• HEEGM-48CL : L'interrupteur gauche actionne les

comme illustré ci-dessous :

indépendamment le côté gauche et le côté droit du gril

sauf qu'ils permettent à l'opérateur de faire fonctionner

de la même façon que l'interrupteur unique ci-dessus,

Une fois enfoncés en position « ON », ils fonctionnent

interrupteurs électriques du côté inférieur droit de l'unité.

3. Les modèles HEEGM-48CL et HEEGM-60CL ont deux

soient allumés.

étincelles continuent jusqu'à ce que tous les brûleurs

brûleur reçoit une étincelle pour allumer le gaz. Les

brûleurs sont alimentés en gaz. En même temps, chaque

Une fois qu'on l'a enfoncé en position « ON », tous les

interrupteur électrique du côté inférieur droit de l'unité.

2. Les modèles HEEGM-24CL et HEEGM-36CL ont un

POUR LES UNITÉS 120 VOLTS STANDARD :

interrupteurs) électrique(s).

simplement besoin d'actionner l'interrupteur (ou les

1. Pour allumer et utiliser cet appareil, l'opérateur a

GARLAND À L’ADRESSE http://www.garland-group.com

AGENTS DE SERVICE AGRÉÉS, CONSULTER LE SITE WEB DE

L'ALIMENTATION EN GAZ. POUR OBTENIR UNE LISTE DES

D'ENTRETIEN AGRÉÉ AVANT D'ESSAYER DE RÉTABLIR

D'ARRÊT MANUEL DE L'APPAREIL. CONTACTER UN AGENT

L'ALIMENTATION ÉLECTRIQUE ET FERMER LE ROBINET

GAZ AVANT, PENDANT OU APRÈS L'UTILISATION, COUPER

SI, POUR UNE RAISON QUELCONQUE, VOUS SENTEZ LE

Fonctionnement

entrer dans la cavité du brûleur.

du brûleur, tourner l'obturateur pour laisser MOINS d'air

brûleur. Si les ammes semblent se détacher des orices

l'obturateur pour laisser PLUS d'air entrer dans la cavité du

les pointes de la amme semblent trop jaunes, tourner

d'air, en tournant l'obturateur et en resserrant la vis. Si

réglages se font en desserrant la vis de l'obturateur

nécessaire de régler l'obturateur d'air du brûleur. Les

6. Inspecter la amme de chaque brûleur pour voir s'il est

sur le régulateur installé sur l'appareil.

ajuster la pression, tourner la vis de réglage de pression

de pression indiquée sur la plaque signalétique. Pour

l'indication sur le manomètre corresponde à la valeur

• Si nécessaire, régler la pression de façon à ce que

brûleurs au maximum.

actionnant l'interrupteur de gauche) et régler les

• Allumer le côté GAUCHE de l'unité seulement (en

sur le collecteur GAUCHE.

• • Brancher un manomètre au point d’essai de pression

POUR LES UNITÉS HEEGM DE 48 ET 60 PO

sur le régulateur installé sur l'appareil.

ajuster la pression, tourner la vis de réglage de pression

de pression indiquée sur la plaque signalétique. Pour

UTILISATION ET ENTRETIEN

l'indication sur le manomètre corresponde à la valeur

• Si nécessaire, régler la pression de façon à ce que

tous au maximum.

• Allumer l'unité et régler les brûleurs an qu'ils soient

le collecteur.

Brancher un manomètre au point d’essai de pression sur

• Connect a manometer to the test spigot on the •

POUR LES UNITÉS HEEGM DE 24 ET 36 PO

plaque signalétique de la façon suivante.

5. Vérier que l'unité fonctionne à la pression indiquée sur la

transport.

raccords ne comportent pas de fuites de gaz après le

gouttière du pied gauche) pour s'assurer que tous les

raccordements du collecteur et connexions dans la

à l'extérieur et à l'intérieur de l'unité (c.-à-d. robinets,

la présence de fuites! Bien inspecter tous les raccords

savonneuse. Ne pas utiliser de amme nue pour vérier

4. Vérier les fuites de gaz sur les raccords avec une solution

sur le pied droit place l'unité sous tension.

L'activation du ou des deux interrupteur(s) électrique(s)

ouverte et que l'unité est reliée à l'alimentation électrique.

3. S'assurer que l'alimentation en gaz de l'appareil est

INSTALLATION suite

Page 25

Pièce nº # 4530868 (04/25/12)Page 8

en place les grilles de cuisson sur l'unité.

2. Installer les radiants en fonte sur chaque brûleur et mettre

toujours en place.

brûleurs n'ont pas tourné pendant le transport et sont

la position correcte et que les écrans suspendus sous les

1. À l'intérieur de l'unité, s'assurer que les brûleurs sont dans

Démarrage

pression indiquée sur la plaque signalétique.

l'appareil soit au minimum de 1 po CE supérieure à la

d'alimentation en gaz dans le régulateur de pression de

unité, il est recommandé que la pression dynamique

7. Pour assurer un fonctionnement optimal de cette

d'alimentation en fermant le robinet d'arrêt manuel.

po CE, 3,45 KPa), l'appareil doit être isolé du système

d'alimentation jusqu'à un maximum de ½ lb/po² (14

6. Lors de tout essai de pression des canalisations

utilisation avec du gaz de pétrole liquéé.

utiliser un produit d'étanchéité homologué pour une

raccords, là où du produit d'étanchéité est nécessaire,

de brancher l'appareil. Pour les nouveaux joints et/ou

Si nécessaire, purger les nouvelles canalisations avant

bouchent pas les veilleuses, robinets et/ou commandes.

copeaux de letage et/ou tout autre corps étranger ne

ont été installés de façon propre, an que les saletés,

5. S'assurer que les nouveaux tuyaux, joints et raccords

CONFORMÉMENT AUX CODES LOCAUX.

RÉDUCTEUR SERA NÉCESSAIRE ET DEVRA ÊTRE INSTALLÉ

DÉPASSE CETTE VALEUR MAXIMALE, UN RÉGULATEUR

CE). SI LA PRESSION DE LA CONDUITE D'ALIMENTATION

UNE PRESSION NOMINALE MAXIMUM DE ½ LB/PO² (14 PO

RÉGULATEUR FOURNI AVEC L'UNITÉ EST CONÇU POUR

PRESSION DE LA CONDUITE D'ALIMENTATION EN GAZ. LE

AVANT DE BRANCHER LE RÉGULATEUR, VÉRIFIER LA

annulera la garantie sur l’équipement.

correspond au type de gaz. L’absence de régulateur

de débit du gaz et à vérier que le marquage de pression

à installer le régulateur de pression en fonction du sens

avoir son propre régulateur de pression. Faire attention

l’équipement à la conduite de gaz. Chaque appareil doit

gaz. Il doit être installé sur l’appareil avant de brancher

2. L’appareil est expédié avec un régulateur de pression du

l'installateur.

d'urgence. Le robinet d'arrêt est normalement fourni par

devra être placé de façon à être facilement atteint en cas

pour faciliter les réparations ultérieures. Le robinet d'arrêt

d’alimentation en amont de l’appareil pour la sécurité et

1. Un robinet d'arrêt du gaz doit être installé sur la conduite

PURGER AVANT DE RÉTABLIR L'ALIMENTATION. »

L'ALIMENTATION EN GAZ. APRÈS UN ARRÊT PROLONGÉ,

EN AVAL DOIVENT ÊTRE FERMÉS AVANT DE RÉTABLIR

« TOUS LES ROBINETS DES BRÛLEURS ET VEILLEUSES

voire mortelles.

anormales, des dommages matériels et des blessures,

un autre type de gaz peut entraîner des performances

sur la plaque signalétique. L'utilisation de cette unité avec

4. Branchez cette unité uniquement au type de gaz indiqué

2005 (OU DERNIÈRE ÉDITION).

ANSI Z21.41/CSA 6.9, ADDENDA Z21.41A-2005/CSA 6.16AZ21.69B-2006/CSA 6.16B-2006 (OU DERNIÈRE ÉDITION) ET

COMPREND LES NORMES ANSI Z21.69/CSA 6.16, ADDENDA

ET CODES LOCAUX. EN AMÉRIQUE DU NORD, CELA

RAPIDE DOIVENT ÊTRE CONFORMES AUX AUTORITÉS

LES TUYAUX SOUPLES ET RACCORDS À DÉBRANCHEMENT

en cas de réparation.

d'alimentation à l'unité. Cela permettra de déplacer l'unité

convenable sont recommandés pour raccorder la conduite

débranchement rapide avec réducteur de tension

3. Un tuyau de gaz souple certié et un raccord à

L'INSTALLER CONFORMÉMENT AUX CODES LOCAUX.

SI UNE VENTILATION VERS L'EXTÉRIEUR EST NÉCESSAIRE,

LOCAUX EXIGENT UNE VENTILATION VERS L'EXTÉRIEUR.

ET NE DOIT PAS ÊTRE RETIRÉ À MOINS QUE LES CODES

LE BOUCHON DE VENTILATION FAIT PARTIE DU RÉGULATEUR

AUTOMATIQUE :

SUIVANT PRÈS DU POINT D'ACCÈS AU ROBINET MANUEL OU

DE LA CUISINE OU PRÈS D'UNE SORTIE. AFFICHER L'AVIS

DOIT ÊTRE FACILEMENT ACCESSIBLE ET SITUÉ À L'EXTÉRIEUR

POINT D'ACCÈS AU ROBINET MANUEL OU AUTOMATIQUE

CUISINE POUR POUVOIR Y ACCÉDER EN CAS D'URGENCE. LE

DOIT ÊTRE INSTALLÉ SUR L'ALIMENTATION EN GAZ DE LA

UN ROBINET D'ISOLEMENT MANUEL OU AUTOMATIQUE

CONSULTER LE FOURNISSEUR LOCAL DE GAZ.

DE CET ÉQUIPEMENT ET/OU DES AUTRES. EN CAS DE DOUTE,

DIMENSIONNÉES PEUVENT AFFECTER LE FONCTIONNEMENT

APPAREILS DE LA CUISINE. DES TUYAUTERIES DE GAZ SOUS-

GAZ NÉCESSAIRES POUR FAIRE FONCTIONNER TOUS LES

DE DIAMÈTRE ADAPTÉ POUR LE DÉBIT ET LA PRESSION DE

VÉRIFIER QUE LE COMPTEUR À GAZ ET LA TUYAUTERIE SONT

Connexion du gaz

électricien certié conformément aux codes locaux.

connecté à une alimentation électrique appropriée par un

d'alimentation approprié avec réducteur de tension et être

(PHASE À PHASE). L'appareil doit être équipé d'un cordon

utilisées avec une alimentation 220-240 V monophasée

2. Les unités livrées sans cordon sont destinées à être

INSTALLATION suite

Page 26

Pièce nº # 4530868 (04/25/12) Page 7

COUPANTES.

CORDON D'ALIMENTATION À LA CHALEUR OU À DES ARÊTES

ENDOMMAGÉ. FAIRE ATTENTION À NE PAS EXPOSER LE

NE PAS ESSAYER DE RÉPARER UN CORDON D'ALIMENTATION

APPAREIL SI LE CORDON D'ALIMENTATION EST ENDOMMAGÉ.

UNITÉ À UNE PRISE DE COURANT. NE PAS UTILISER CET

NE PAS UTILISER DE RALLONGE POUR CONNECTER CETTE

électricien certié en cas de doute sur la prise de courant

à proximité immédiate de l'appareil. Consulter un

approprié. Il faudra une prise 120 V 15 A 60 Hz appropriée

d'alimentation Nema 5-15P avec un réducteur de tension

1. Les unités standard sont fournies avec un cordon

RÉPARATION

DÉBRANCHER L'ALIMENTATION ÉLECTRIQUE AVANT TOUTE

Raccordement électrique

de l'unité

tirage d'air excessif pouvant perturber le fonctionnement

de l'appareil. Cela peut créer des courants d'air et/ou un

et ne pas laisser de fenêtres ouvertes derrière ou à côté

4. Ne pas diriger les ventilateurs directement sur l'appareil

LE BÂTIMENT.

QU'IL EXISTE UN PROBLÈME DE CIRCULATION D'AIR DANS

DONNANT À L'EXTÉRIEUR DU BÂTIMENT, CELA INDIQUE

SI L'ON A DES DIFFICULTÉS À OUVRIR LES PORTES

corriger le problème.

qualié doit faire les ajustements nécessaires pour

En cas de problème de circulation d'air, un technicien

aectera le fonctionnement des brûleurs et de l'appareil.

adapté, la pression atmosphérique sera anormale et

évacuée par le système de ventilation. Sans un équilibre

dans le bâtiment an de compenser la quantité d'air

l'installation. Une entrée d'air adaptée doit être prévue

3. La circulation de l'air doit être vériée pendant

ltres et gouttières d'écoulement.

contre le mur si la hotte est xée au mur) et équipée de

pouces (152 mm) de chaque côté de l’appareil (sauf

correctement conçue, se prolongeant d'au moins six

2. Pour cet appareil , on doit utiliser une hotte de ventilation

quantités importantes de fumée quand ils sont utilisés.

particulièrement important pour les grils qui génèrent des

de combustion à l'extérieur du bâtiment. Cela est

est nécessaire de prévoir une évacuation des produits

1. Pour tout appareil de cuisson de type professionnel, il

FOURNIES AVEC CHAQUE SOCLE.

LES INSTRUCTIONS DE MONTAGE DES SOCLES SONT

>ΖhE/d;hEW^K/EͿ

'Khdd/Z^^W/^

>^K>dE^>^

s/^^Z>^s/^dZsZ^

SOCLE AVEC 4 VIS, COMME ILLUSTRÉ CI-DESSOUS.

DES UTILISATEURS, NE PAS OUBLIER DE FIXER L'UNITÉ AU

APPROPRIÉ POUR LA TAILLE DE L'UNITÉ. POUR LA SÉCURITÉ

SONT DISPONIBLES À L'ACHAT. UTILISER LE SOCLE

DES SOCLES SPÉCIALEMENT CONÇUS POUR CES UNITÉS

Socle en option

pour décider de l'emplacement d'installation.

d'accéder aux composants à réparer. Tenir compte de cela

pouvoir déplacer susamment l'unité vers l'avant an

les réparations doit être prévu à l'avant de l'unité pour

à l'unité par le côté. Un dégagement adéquat pour

5. Pour les réparations, il est possible que l'on doive accéder

uniquement dans des endroits incombustibles.

matière combustible. Cette unité doit être installée

4. Positionner l'appareil dans un endroit éloigné de toute

doive les déposer en cas de réparation.

inférieurs en acier inoxydable, car il est possible que l'on

mastic silicone préappliqué. Éviter de coller les panneaux

plan de travail en plaçant les gouttières des pieds sur le

silicone sur le plan de travail, puis poser l'unité sur le

sur la surface de montage. Sinon, appliquer du mastic

deux gouttières des pieds, puis mettre l'unité en place

appliquer du mastic silicone sur la partie inférieure des

la surface de montage avec du mastic silicone. Si possible,

3. Pour satisfaire aux exigences NSF, l'unité doit être collée à

FAÇON OPTIMALE.

NIVEAU LORS DE L'INSTALLATION POUR FONCTIONNER DE

IL EST IMPÉRATIF QUE L'UNITÉ SOIT CORRECTEMENT MISE DE

CONSULTER LES AUTORITÉS LOCALES AYANT JURIDICTION.

CODES LOCAUX DE LA CONSTRUCTION ET DES INCENDIES.

LES BESOINS EN VENTILATION PEUVENT ÊTRE SOUMIS AUX

pour une installation dans un plan de travail.

roulettes de la base réfrigérée ou en utilisant des cales

de niveau en réglant les roulettes du socle, les pieds/

travail, un socle ou une base réfrigérée. On met l'unité

Alimentation en air et ventilation

2. L'unité est conçue pour être encastrée dans un plan de

INSTALLATION suite

Page 27

Pièce nº # 4530868 (04/25/12)Page 6

^d/ZK/Z^

'>/^^/Z^

LORS DU POSITIONNEMENT DE L'ÉQUIPEMENT DE LEVAGE.

GAUCHE, DROITE ET/OU CENTRALE DES TIROIRS À GRAISSE

GRAISSE. FAIRE ATTENTION À ÉVITER LES GLISSIÈRES

NE PAS SOULEVER PAR LES GLISSIÈRES DES TIROIRS À

&KhZ,^

transpalette comme illustré sur l'image ci-dessous.

être levée avec un chariot élévateur à fourches ou un