Page 1

INSTALLATION AND

OPERATION MANUAL

HEEG “CL”

HIGH EFFICIENCY

RADIANT CHAR-BROILER

FOR YOUR SAFETY:

DO NOT STORE OR USE GASOLINE

OR OTHER FLAMMABLE VAPORS OR

LIQUIDS IN THE VICINITY OF

THIS OR ANY OTHER

APPLIANCE

WARNING:

IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE

CAN CAUSE PROPERTY DAMAGE, INJURY,

OR DEATH. READ THE INSTALLATION,

OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR

SERVICING THIS EQUIPMENT

PLEASE READ ALL SECTIONS OF THIS MANUAL

AND RETAIN FOR FUTURE REFERENCE.

THIS PRODUCT HAS BEEN CERTIFIED AS

COMMERCIAL COOKING EQUIPMENT AND

MUST BE INSTALLED BY PROFESSIONAL

PERSONNEL AS SPECIFIED.

IN THE COMMONWEALTH OF MASSACHUSETTS

THIS PRODUCT MUST BE INSTALLED BY A

LICENSED PLUMBER OR GAS FITTER.

For Your Safety:

Post in a prominent location, instructions to be

followed in the event the user smells gas. This

information shall be obtained by consulting

your local gas supplier.

Users are cautioned that maintenance and repairs must be performed by a Garland authorized service agent

using genuine Garland replacement parts. Garland will have no obligation with respect to any product that has been

improperly installed, adjusted, operated or not maintained in accordance with national and local codes or installation

instructions provided with the product, or any product that has its serial number defaced, obliterated or removed,

or which has been modified or repaired using unauthorized parts or by unauthorized service agents.

For a list of authorized service agents, please refer to the Garland web site at http://www.garland-group.com.

The information contained herein, (including design and parts specifications), may be superseded and is subject

to change without notice.

GARLAND COMMERCIAL INDUSTRIES, LCC

185 East South Street

Freeland, Pennsylvania 18224

Phone: (570) 636-1000

Fax: (570) 636-3903

Part # 4526671 (10/02/09) © 2009 Garland Commercial Industries, LCC.

GARLAND COMMERCIAL RANGES, LTD.

1177 Kamato Road, Mississauga, Ontario L4W 1X4

CANADA

Phone: 905-624-0260

Fax: 905-624-5669

Page 2

IMPORTANT INFORMATION

WARNING:

This product contains chemicals known to the state of california to cause cancer and/or birth defects

or other reproductive harm. Installation and servicing of this product could expose you to airborne

particles of glass wool/ceramic fibers. Inhalation of airborne particles of glass wool/ceramic fibers

is known to the state of california to cause cancer. Operation of this product could expose you to

carbon monoxide if not adjusted properly. Inhalation of carbon monoxide is known to the state of

california to cause birth defects or other reproductive harm.

Keep appliance area free and clear of combustibles.

Part # 4526671 (10/02/09)Page 2

Page 3

TABLE OF CONTENTS

IMPORTANT INFORMATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

DIMENSIONS AND SPECIFICATIONS CL MODELS . . . . . . . . . . . . . . . . . . . . . . 4

INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Rating Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

General Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Stand Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Positioning and Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Air Supply and Ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Gas Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Manual Shut-O Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Pressure Regulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Rigid Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Flexible Couplings & Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Final Gas Connection Review . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Start Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Shut Down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Final Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

CLEANING AND MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Daily . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Periodic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Cleaning Stainless Steel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

SERVICE AND PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Part # 4526671 (10/02/09) Page 3

Page 4

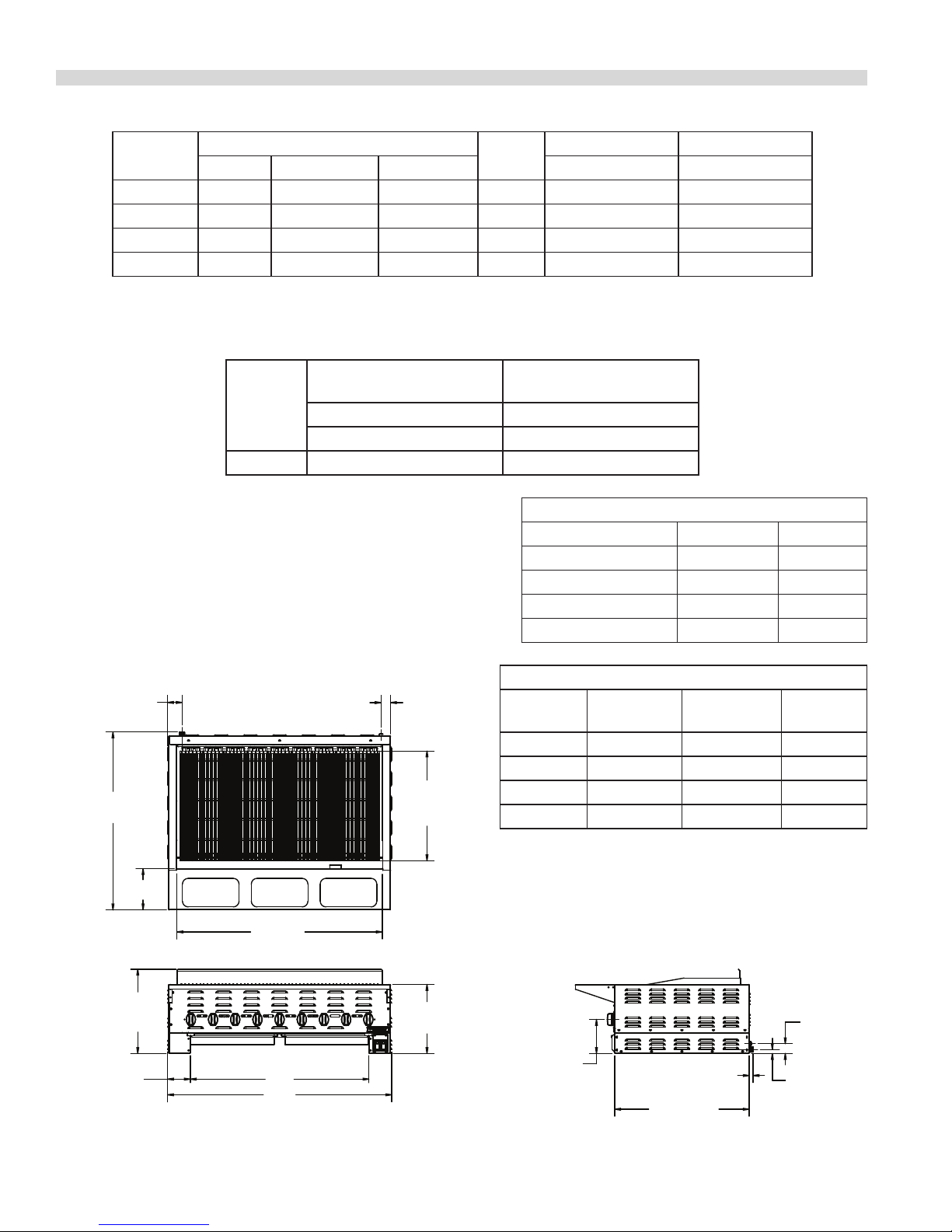

DIMENSIONS AND SPECIFICATIONS CL MODELS

HEEG-48CL BROILER SHOWN

GAS INLET

Model #

Dimensions: In. (mm)

Width Depth Height Natural Weight Lbs/Kg

No. Of

Burners

HEEG-24CL 24 (610) 38-1/16 (967) 18-1/16 (458) 4 54,000 338/153

HEEG-36CL 34 (864) 38-1/16 (967) 18-1/16( 458) 6 81,000 391/177

HEEG-48CL 48 (1219) 38-1/16(967) 18-1/16 (458) 9 121,500 505/229

HEEG-60CL 58 (1473) 38-1/16 (967) 18-1/16 (458) 11 148,500

* Manifold operating pressure as per table shown below

Gas Manifold 3/4" NPT on all models

Gas Input ratings shown here are for installations up to 2000 ft. (610m)

Manifold Operating

Pressure

Models

Natural Gas Natural Gas

"w.c.(Mbar) "w.c.(Mbar)

All Models 4.5 (11.2) 7.0(17.4)

Garland/U.S. Range products are not approved or authorized

for home or residential use, but are intended for commercial

applications only. Garland / U.S. Range will not provide service,

warranty, maintenance, or support of any kind other than in

commercial applications.

Many local codes exist and it is the responsibility of the

owner and installer to comply with those codes.

Total BTU* Shipping

620/281

Minimum Supply Pressure

Depth Measurements all models In (mm)

Front Rail Option Over All "A" Rail "B"

With/ 1/3 Pan Cutouts 38-1/16 (967) 8-7/8 (225)

With/1/9 Pan Cutouts 35-5/8 (905) 6-3/8 (162)

Std. Rail (No Cutouts) 34-5/8 (879) 5-3/8 (137)

Stub Rail (No Cutouts) 31-3/4 (806) 2-1/2 (64)

3-1/8"

[79mm]

3/4" NPT

GAS INLET

"A"

"B"

"C"

18-1/16"

[458mm]

4-7/8"

[123mm] "D"

"E"

2"

[51mm]

ELECTRICAL

23-1/2"

[596mm]

14-3/4"

[375mm]

Width Measurements In (mm)

Model

Broiler Grid

"C"

"D"

Over All

"E"

HEEG-24CL 20 (507) 14-1/4 (362) 24 (610)

HEEG-36CL 30 (761) 24-1/4 (616) 34 (864)

HEEG-48CL 44 (1117) 36-1/4 (972) 48 (1219)

HEEG-60CL 54 (1371) 48-1/4 (1226) 58 (1473)

Electrical : 120V, 60 Hz

Provided with NEMA 5-15P Power Cord Supply

NOTE: Wiring Diagram is located in right side of broiler’s

leg section.

2-1/16"

[53mm]

ELECTRICAL

7-1/8"

[185mm]

7/8"[22mm]

28-13/16"

[732mm]

13/16"

[21mm]

3/4"

Part # 4526671 (10/02/09)Page 4

Page 5

INTRODUCTION

Garland manufactures the HE Series char-broiler with widths

ranging from 24” (610mm) to 58” (1473mm). While service

and customer operation may vary from model to model,

installation is similar throughout the line.

All units are shipped completely assembled, with top grates

and radiants banded to skid in separate boxes, any loose

parts are secured in place with masking tape or tie cords,

and the pressure regulators packed inside the unit. All units

are adjusted, tested, and inspected at the factory prior to

shipment.

IMPORTANT: After uncrating, immediately check the

equipment for visible signs of shipping damage. If such

damage has occurred, do not refuse shipment, but contact

the shipper and le the appropriate freight claims.

There are two metal guide shipping brackets used to help

prevent the unit from sliding in the shipping crate. It is not

necessary to remove these brackets but if desired they are

located on the inside center support leg channels. Each

guide bracket is attached with two sheet metal screws. To

remove the brackets, rst remove the grease trays for easier

access and then loosen the screws. Once the screws are

loosen the brackets will slide o. Finally tighten the screws

back into the unit and replace the grease trays.

Rating Plate

The rating plate is attached to the front left inside broiler

channel leg support.

Information on this plate includes the model and serial

numbers. When communicating with the factory about a

unit or requesting special parts or information, this data is

essential for proper identication. Other information on this

plate is the BTU/hr input to the burners, outlet gas pressure

in inches WC, and whether oriced for natural or propane

gas.

In the event you have any questions concerning the

installation, use, care or service of the product, write or call

our Product Service Department.

WARNING: All Garland Char-Broilers must be connected only

to the type of gas identied on the rating plate!

INSTALLATION

General Installation

In European countries, installation must be carried out by

a competent person and in accordance with the relevant

regulations, codes of practice and the related publications of

the country of destination.

In the United States, the installation must conform to the

National Fuel Gas Code ANSI Z223.1, or latest edition, NFPA

No.54-latest edition/or local code to assure safe and ecient

operation. In Canada, the installation must comply with CSA

B149.1 and local codes.

CAUTION: This appliance is not recommended for residential

installation.

1. The type of gas for which the unit is equipped is stamped

on the rating plate. Connect a unit stamped “NAT” only to

natural gas; connect one stamped “PRO” only to propane

gas.

2. A manual gas shut-o valve must be installed in the gas

supply line ahead of the appliance for safety and for ease

of future service.

3. A gas pressure regulator must be installed at the appliance

prior to connecting the equipment to the gas line. This unit

is shipped with a regulator. Failure to install a regulator will

void the equipment warranty.

4. When mounting onto counter or optional HEST stand seal

the broiler to the at surface with silicone. A NSF code

requirement in many areas.

Part # 4526671 (10/02/09) Page 5

Page 6

INSTALLATION Continued

Stand Dimensions

Dimensions

Model

Number

HEST-24 24"(610mm) 39/18

HEST-36 34"(864mm) 55/25

HEST-48 48"(1219mm) 69/31

HEST-60 58"(1473mm) 77/35

1-7/8"

[48mm]

A (Width)

STOPS

29-5/16"

[746mm]

SIDE VIEW

A

Shipping

Weight

lb/kg

NONCOMBUSTIBLE

CONSTRUCTION

Rear 0”

Sides 0”

Positioning and Setup

Some form of mechanical assistance will be required to

position these broilers, as the smallest weighs 338 lbs

(153 kg) and the larger sizes weigh 620 lbs (281kg). A pallet

or lift jack will also make leveling easier, as these units are

designed to sit ush on a counter, do not have adjustable

legs or feet, and leveling is with shims and repeated tting.

Inside the unit, the char-broilers use cast tubular burners

with cast iron radiants, which are secured to the burner

hangers to stop vibration and damage during shipping Once

free, double-check that the burners are positioned squarely

in the notches of the back burner holder. If they are out of

position, the burner will not work properly.

Air Supply and Ventilation

The area around the appliance must be kept clear to avoid

any obstruction to the ow of combustion and ventilation

air, as well as, for ease of maintenance and service.

2"

[51mm]

SQUARE

TUBING LEGS

6"

[152mm]

FRONT VIEW

21"

[533mm]

Clearances

HE Series

The appliance area must be kept free and clear of all

combustibles. Adequate clearance must be provided for air

openings into the combustion chamber and for proper air

supply.

These units are design-certied for the following

installations:

1. Intended for other than household use.

2. For use in non-combustible locations only.

Means must be provided for any commercial, heavy-duty

cooking appliance to exhaust combustion waste products

to the outside of the building. This is doubly important for

open grate broilers, since the design promotes grease and fat

dripping through onto hot radiants sending smoke back up

onto the product as seasoning. This smoke then continues

either up to the ceiling or to an exhaust hood. Garland

Char-Broilers must be under a vent hood! Filters and drip

troughs should be part of any industrial hood, but consult

local codes before constructing and installing a hood.

Air movement should be checked during installation,

strong exhaust fans in the hood or in the overall system can

produce a vacuum in the room and/or cause air drafts. Either

of which can interfere with the burner performance and be

dicult to diagnose. If burner problems persist, make-up air

openings or baes may have to be provided in the room.

Any adjustments to air movement should be performed or

inspected by a qualied technical installer. Maintain and do

not block the appliances designed air openings.

Part # 4526671 (10/02/09)Page 6

Page 7

INSTALLATION Continued

Gas Connection

NOTE: The gas supply (service) line must be the same size or

greater than the inlet line of the appliance. Garland CharBroilers use a 3/4” NPT inlet. Sealant on all pipe joints must be

resistive to LP gas.

The appliance and its individual shut-o valve must be

disconnected from the gas supply piping system during any

pressure testing of that system at test pressures in excess of

1/2 psi (3.45 kPa).

The appliance must be isolated from the gas supply piping

system by closing its individual manual shut-o valve during

any pressure testing of the gas supply piping system at test

pressures equal to or less than 1/2 psi (3.45 kPa).

Manual Shut-O Valve

The Manual Shut-O Valve is supplied by the installer, it must

be installed in the gas service line ahead of the appliance

and regulator in the gas stream and in a position where it can

be reached quickly in the event of an emergency.

Pressure Regulator

Regulators can be adjusted in the eld, but it is

recommended that they not be tampered with unless that

part is known to be out of adjustment or serious pressure

uctuations are found to exist and can be solved no other

way. Any adjustments to regulators must be made by

qualied service personnel with the proper test equipment.

If a vent line from the gas appliance pressure regulator is

used, it should be installed to the outdoors in accordance

with local codes.

In North America in the absence of local codes, in accordance

with the National Fuel code, ANSI Z223.1, Natural Gas

Installation Code, CAN/CGA-B149.1 or the Propane

Installation Code, CAN/CGA-B149.2, as applicable.

WARNING: Failure to install a pressure regulator will void the

equipment warranty!

Rigid Connections

Double-check any installer-supplied intake pipes visually

and clear any dirt particles, threading chips, or other foreign

matter before installing in a service line. Those particles will

clog orices when gas pressure is applied.

All heavy-duty, commercial cooking equipment must have

a pressure regulator in the incoming service line for safe and

ecient operation, since service pressure may uctuate with

local demand. The manual shut-o valve is normally supplied

by the installer, but pressure regulators are shipped from

Garland with every Char-Broiler.

Regulators are pre-set at the factory according to the

customer’s ordering instructions. It is important to check and

adjust regulator to manifold operating pressure as per rating

plate.

Prior to connecting the regulator, check the incoming line

pressure, as these regulators can withstand a maximum

pressure of 1/2 psi (14” WC). If the Line pressure is beyond

this limit, a step-down regulator will be required. Doublecheck the arrow forged onto the bottom of the regulator

body which shows gas ow directions; it should point

downstream to the appliance. The red air-vent cap is part of

the regulator and should not be removed unless local codes

require external venting.

Flexible Couplings & Connectors

If the unit is to be installed with exible couplings and/or

quick disconnect ttings, for an appliance equipped with

stand and casters, the installation shall be made with a heavy

duty design-certied commercial exible connector or at

least 3/4” NPT (with suitable strain relief) in compliance with

all local authorities and codes.

In North America connection must be in compliance with the

Standard for Connectors for Moveable Gas Appliances, ANSI

Z21.69/CSA 6.16, Addenda Z21.69B-2006/CSA 6.16B-2006 (or

latest edition), and a quick-disconnect device that complies

with the Standard for Quick Disconnects for Use with Gas

Fuel, ANSI Z21.41/CSA 6.9, Addenda Z21.41A-2005/CSA

6.16A-2005 (or latest edition), and adequate means must be

provided to limit the movement of the appliance without

depending on the connector and the quick-disconnect

device or its associated piping to limit the appliance

movement and the location(s) where the restraining means

may be attached to the appliance shall be specied.

Part # 4526671 (10/02/09) Page 7

Page 8

INSTALLATION Continued

Further, if the unit is to be installed on a non-combustible

surface that is equipped with casters, means must be

provided to limit the movement of the unit with casters.

Final Gas Connection Review

Check all gas connections for leaks using a soapy solution

before lighting any pilots! DO NOT USE AN OPEN FLAME

TO CHECK FOR LEAKS! Putting an open ame beside a new

connection is not only dangerous, but will often miss small

leaks that a soapy solution would nd.

All Garland appliances are adjusted and tested before

leaving the factory, eectively matching them to sea

level conditions. Adjustments and calibrations to assure

proper operation may be necessary on installation to meet

local conditions, low gas pressure, dierences in altitude,

variations in gas characteristics, to correct possible problems

caused by rough handling or vibration during shipment, and

are to be performed only by qualied service personnel.

These adjustments are the responsibility of the customer,

installer and/or dealer and are not covered by the Garland

warranty.

All burners are equipped with continuous electronic spark

electrodes to insure ame is on at all times during operation.

Continuous sparking is intended to remain energized until

power is manually switched o.

WARNING: All connections must be sealed with a joint

compound suitable for LP gas, and all connections must be

tested with a soapy solution before lighting any pilots!

For daily start up:

1. Models HEEG-24CL and HEEG-36CL have one power

switch. Once pushed to the “ON” position an igniter

supplies a continuous spark to the burners igniting the

gas to all burners simultaneously. At the same time the

power switch opens up the gas ow to burners.

2. Models HEEG-48CL and HEEG-60CL have two power

switches which operate in the same manner as the

single switch above. Each switch operates separately

allowing the operator to run two sections of the broiler

independently. On the HEEG-48CL the switch on the far

left operates burners 1 to 5. The power switch on the

right will operate burners 6 to 9. On the HEEG-60CL the

left switch controls burners 1 to 6 and the right switch

controls burners 7 to 11.

3. If burners do not ignite, shutdown power to the unit,

and wait 5 minutes before repeating ignition. If repeated

ignition fails, shutdown power to the unit and contact a

service person.

Shut Down

1. For shutting down overnight, on all models turn the

power switch(es) to the “OFF” position.

2. When shutting down for longer periods, turn the power

switch(es) to the “OFF” position and turn the manual

supply shut o valve to the “OFF” position.

Final Preparation

Start Up

Before initial lighting or if unit does not operate at all check

to see if:

1. Main gas supply shut o to appliance is open.

2. Electric power supply power and cord Nema 5-15P has

been plug into an appropriate 120V 15Amp 60Hz outlet.

New units are wiped clean with solvent at the factory to

remove any visible signs of dirt, oil, grease, etc., remaining

from the manufacturing process. They should be washed

with hot, soapy water to remove any solvent or oil residue or

installation dust or debris before using for food preparation.

Part # 4526671 (10/02/09)Page 8

Page 9

CLEANING AND MAINTENANCE

Any piece of equipment works better and lasts longer when

maintained properly and kept clean. Cooking equipment is

no exception. Your Garland Char-Broiler must be kept clean

during the working day and thoroughly cleaned at the end

of each day.

WARNING: If gas odors are detected, the gas supply must

be turned “OFF” at the main shut-o valve and the local gas

company or authorized service agency contacted for service.

NOTE: A wire brush is supplied with your broiler for cleaning

your rack. The solid stainless steel tooth side of the brush is

for hard to remove debris and the reverse wire bristles side is

for ner materials.

Daily

NOTE: Never Place A Sheet Pan Or Other Large Obstruction

Over The Grates When Broiler Is Hot.

1. Remove the broiler grates. Wire brush them clean of

any encrusted materials and wash in hot, soapy water. A

common cleaning practice is to turn grates upside-down

to burn o encrusted material. Do not do this with the

radiant char-broiler! The ame from the burner is shielded

by a cast iron radiant, with the result that heat not ame

reaches the grate. It is likely that cooked-on-matter will

cook in even deeper rather than burn o.

2. Remove the radiants and wire brush them clean, then

wash in hot soapy water. A rule of thumb is that if the

grates are becoming encrusted, so are the radiants.

3. Spills should be wiped as they occur. At the end of the

day drip tray pans should be washed in hot soapy water,

replacing the trays once cleaned. DO NOT operate the

broiler with out the drip trays.

Periodic

Your Garland Char-Broiler should be checked and adjusted

periodically by qualied service personnel as part of a regular

kitchen maintenance program.

Cleaning Stainless Steel

All stainless steel body parts should be wiped regularly with

hot, soapy water during the day, and with a liquid cleaner

designed for this material at the end of each day. Do not

use steel wool, abrasive cloths, cleaners, or powders! If it

is necessary to scrape stainless steel to remove encrusted

materials, soak the encrusted area with wet cloths to loosen

the material, then use a wood or nylon scraper. Do not use

a metal knife, spatula, or any other metal tools to scrape

stainless steel. Scratches are almost impossible to remove.

SERVICE AND PARTS

Installation, maintenance and repairs should be performed

by your local authorized Garland service agency listed in

your information manual pamphlet.

Garland/U.S. Range products are not approved or authorized

for home or residential use, but are intended for commercial

applications only. Garland / U.S. Range will not provide

service, warranty, maintenance or support of any kind other

than in commercial applications.

Part # 4526671 (10/02/09) Page 9

Page 10

WIRING DIAGRAMS

WHITE

-

JS

SIZE

B

APP.

DR. CK.

2009

06/03

DOC DATE DR APP

2166

PCO-

BLACK

GREEN

BLACK

34

#4

See Note 2

33

32

31

#12#2 #3

GREEN

GND

BLACK

1

3

BLUE

24

L1N

BLACK

20 19

BLUE

3

20

CHANGE DESCRIPTION

RELEASED ITEM

SYM

REV

0 -

*** CAD PRODUCED DRAWING - DO NOT REVISE MANUALLY ***

BLUE

1

2009 GARLAND COMMERCIAL INDUSTRIES

C

THESE DRAWINGS AND SPECIFICATIONS ARE THE PROPERTY OF GARLAND COMMERCIAL INDUSTRIES

5

SW1

n/a

SCALE FACTOR

18224

FREELAND

PENNSYLVANIA

AND SHALL NOT BE COPIED OR REPRODUCED WITHOUT THEIR WRITTEN PERMISSION.

6

(EXCEPT AS NOTED)

TOLERANCE IN INCHES

(ANGULAR ± .5°)

DR. BY

DATE

(FLAT .XXX ± .015)(FORM .XXX ± .031)

DESCRIPTION

FILE NAMEMODEL(S)

WIRE DIAGRAM,

HEE(E/G) BROILER,

4525617-1

24CL

HEE(E/G)

24" , 120VAC

ORANGE (TYP)

USE WITH WIRE PKG 4525624-11 -

USE WAGO (773-104) F580 4 WIRE PUSH-IN (GCR #F580 GCI# 4525593)2 -

NOTES: UNLESS OTHERWISE SPECIFIED

3

4

49

47

48

1

50

IGNITION MODULE

IGNITION MODULE

I

BLACK

0

ON

OFF

See Note 2

POWER SWITCH

BOTTOM VIEW

72

71

BLACK

BLUE

See Note 2

BLACK

82

86

BLUE

83

87

BLACK

BLUE

TO

SOLENOID VALVE

SOL2

SOL1

SOLENOID VALVE

USE FROM

SERIAL No.

Part # 4526671 (10/02/09)Page 10

Page 11

WIRING DIAGRAMS Continued

-

JS

SIZE

B

APP.

DR. CK.

03/23

DOC DATE DR APP

2166 2009

PCO-

WHITE

BLACK

GREEN

BLACK

35

36

#5

#6

32

33

34

#4

31

#1

#2 #3

GREEN

GND

BLACK

1

3

BLUE

24

L1N

BLACK

20 19

BLUE

20

CHANGE DESCRIPTION

RELEASED ITEM0 -

SYM

REV

2009 GARLAND COMMERCIAL INDUSTRIES

C

THESE DRAWINGS AND SPECIFICATIONS ARE THE PROPERTY OF GARLAND COMMERCIAL INDUSTRIES

*** CAD PRODUCED DRAWING - DO NOT REVISE MANUALLY ***

n/a

SCALE FACTOR

18224

FREELAND

PENNSYLVANIA

AND SHALL NOT BE COPIED OR REPRODUCED WITHOUT THEIR WRITTEN PERMISSION.

BLUE

5

SW1

1

(EXCEPT AS NOTED)

TOLERANCE IN INCHES

6

(ANGULAR ± .5°)

DR. BY

DATE

(FLAT .XXX ± .015)(FORM .XXX ± .031)

DESCRIPTION

WIRE DIAGRAM,

FILE NAMEMODEL(S)

4525618-1

HEE(E/G)

36" , 120VAC

HEE(E/G) BROILER,

36CL

ORANGE (TYP)

USE WAGO (773-104) F580 4 WIRE PUSH-IN (GCR #F580 GCI# 4525593)2 -

1 - USE WITH WIRE PKG 4525625-1

NOTES: UNLESS OTHERWISE SPECIFIED

1

6

54

46

45

47

2 3

48

49

50

IGNITION MODULE

I

BLACK

0

ON

OFF

See Note 2

POWER SWITCH

BOTTOM VIEW

74

73

BLACK

BLUE

See Note 2

SOL2

BLACK

86

87

SOL1

BLACK

TO

SOLENOID VALVE

USE FROM

SERIAL No.

83

BLUE

SOLENOID VALVE

82

BLUE

Part # 4526671 (10/02/09) Page 11

Page 12

WIRING DIAGRAMS Continued

DO NOT CONNECT

INPUT AT UNUSED

51

GREEN

GROUND UNUSED TERMINALS

BLACK (TYP)

65

TERMINALS

#5

#6

6

ORANGE

(TYP)

63

64

#4

54

46

GREEN

-

62

61

#1

#2 #3

24

GND

2 3

L1N

21

22

1

IGNITION MODULE 2

WHITE

BLACK

GREEN

03/23PCO-

DOC DATE DR APP

2166 2009

1

3

SIZE

SCALE FACTOR

FREELAND

PENNSYLVANIA

B

18224

n/a

(ANGULAR ± .5°)

(EXCEPT AS NOTED)

(FLAT .XXX ± .015)(FORM .XXX ± .031)

APP.

DR. CK.

FILE NAMEMODEL(S)

DR. BY

DATE

4525619-1

48CL,

HEE(E/G)

CHANGE DESCRIPTION

DESCRIPTION

TOLERANCE IN INCHES

WIRE DIAGRAM,

17

HEE(E/G) BROILER

48", 120VAC

BLACK

21

SYM

REV

18

2009 GARLAND COMMERCIAL INDUSTRIES

C

THESE DRAWINGS AND SPECIFICATIONS ARE THE PROPERTY OF GARLAND COMMERCIAL INDUSTRIES

AND SHALL NOT BE COPIED OR REPRODUCED WITHOUT THEIR WRITTEN PERMISSION.

*** CAD PRODUCED DRAWING - DO NOT REVISE MANUALLY ***

80

5

50

47

34

BLACK (TYP)

49

48

0 RELEASED- MC

BLUE

BLUE

GREEN

23

23

32

33

31

GND

L1N

#4

#12#2 #3

BLACK

19

22

20

78

BLUE

See Note 2

6

79

3

BLACK

BLACK

See Note 2

BLUE

NOTES: UNLESS OTHERWISE SPECIFIED

(GCR #F580 GCI# 4525593)

2 - USE WAGO (773-104) F580 4 WIRE PUSH-IN

1 - USE WITH WIRE PKG 4525626-1

3

4

ORANGE

(TYP)

43

42

See Note 2

82

BLUE

(SOL 1, IGNITION MODULE 1)

(SOL 2, IGNITION MODULE 2)

3 - (4) BURNERS ON LEFT MANIFOLD

4 - (5) BURNERS ON RIGHT MANIFOLD

1

IGNITION MODULE 1

1

45

44

BLACK

BLUE

78

BLUE

84

88

SOL1A

SOLENOID VALVE

See Note 2

79

BLACK

89

BLACK

85

86

BLUE

SOL1B

82

BLUE

BLACK

83

SOL2A

BLACK

80

See Note 2

87

BLACK

BLUE

SOL2B

SW2 (RIGHT)

18

13

BLACK

BLACK

SW1 (LEFT)

POWER SWITCH

BLUE

17

13

6

I

0

ON

OFF

TO

USE FROM

SERIAL No.

Part # 4526671 (10/02/09)Page 12

Page 13

WIRING DIAGRAMS Continued

DO NOT CONNECT

INPUT AT UNUSED

51

GREEN

GROUND UNUSED TERMINALS

BLACK (TYP)

65

TERMINALS

#6

6

ORANGE

(TYP)

BLACK (TYP)

36

#6

#5

54

46

n/a

(ANGULAR ± .5°)

(EXCEPT AS NOTED)

(FLAT .XXX ± .015)(FORM .XXX ± .031)

APP.

DR. CK.

FILE NAMEMODEL(S)

DR. BY

DATE

4525620-1

60CL,

HEE(E/G)

GREEN

62

63

64

#4

61

#1

#2 #3

24

GND

2 3

L1N

1

21

22

IGNITION MODULE 2

WHITE

BLACK

GREEN

JS -RELEASED ITEM0 -

07/20

DOC DATE DR APP

2166 2009

PCO-

1

3

SIZE

SCALE FACTOR

FREELAND

PENNSYLVANIA

B

18224

CHANGE DESCRIPTION

DESCRIPTION

TOLERANCE IN INCHES

WIRE DIAGRAM,

17

60", 120VAC

HEE(E/G) BROILER,

BLACK

21

SYM

REV

18

2009 GARLAND COMMERCIAL INDUSTRIES

C

THESE DRAWINGS AND SPECIFICATIONS ARE THE PROPERTY OF GARLAND COMMERCIAL INDUSTRIES

AND SHALL NOT BE COPIED OR REPRODUCED WITHOUT THEIR WRITTEN PERMISSION.

*** CAD PRODUCED DRAWING - DO NOT REVISE MANUALLY ***

80

5

50

47

33

35

34

#5

#4

49

48

BLUE

BLACK

BLUE

GREEN

23

32

#2 #3

23

31

GND

#1

L1N

BLACK

19

22

20

78

BLUE

See Note 2

6

BLACK

79

3

See Note 2

BLUE

6

40

ORANGE

(TYP)

NOTES: UNLESS OTHERWISE SPECIFIED

2 - USE WAGO (773-104) F580 4 WIRE PUSH-IN

1 - USE WITH WIRE PKG 4525627-1

54

41

42

See Note 2

82

BLUE

(GCR #F580 GCI# 4525593)

3 - (6) BURNERS ON LEFT MANIFOLD SOL 1, IGNITION MODULE 1)

4 - (5) BURNERS ON RIGHT MANIFOLD (SOL 2, IGNITION MODULE 2)

1

1

2 3

44

43

BLUE

78

BLUE

84

45

SOLENOID VALVE

IGNITION MODULE 1

BLACK

88

85

BLUE

SOL1A

BLACK

BLACK

80

See Note 2

See Note 2

79

89

BLACK

SOL1B

82

BLUE

BLACK

87

86

BLACK

BLUE

83

SOL2A

SOL2B

SW2 (RIGHT)

18

13

BLACK

BLACK

SW1 (LEFT)

POWER SWITCH

BLUE

17

13

6

I

0

ON

OFF

TO

USE FROM

SERIAL No.

Part # 4526671 (10/02/09) Page 13

Page 14

Part # 4526671 (10/02/09)Page 14

Page 15

Part # 4526671 (10/02/09) Page 15

Page 16

Loading...

Loading...