Garland GIU2.5 BI, GIU5.0 BI, GIU3.5 BI, GIU3.5DUAL BI, GIWOK3.5 BI Installation And Operation Manual

...

INSTALLATION AND

S

A

N

I

T

A

T

I

O

N

L

I

S

D

CM

OPERATION MANUAL

GARLAND INDUCTION SINGLE, DUAL AND WOK BUILT IN

UNITS, MODELS: GIU2.5 BI, GIU3.5 BI, GIU5.0 BI, GIU3.5

DUAL BI, GIU5.0 DUAL BI, GIWOK3.5 BI & GIWOK5.0 BI

86037

C

PLEASE READ ALL SECTIONS OF THIS MANUAL

FOR YOUR SAFETY:

DO NOT STORE OR USE GASOLINE

OR OTHER FLAMMABLE VAPORS OR

LIQUIDS IN THE VICINITY OF

THIS OR ANY OTHER

APPLIANCE

WARNING:

IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE

CAN CAUSE PROPERTY DAMAGE, INJURY,

OR DEATH. READ THE INSTALLATION,

OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR

SERVICING THIS EQUIPMENT

Users are cautioned that maintenance and repairs must be performed by a Garland authorized service agent

using genuine Garland replacement parts. Garland will have no obligation with respect to any product that has been

improperly installed, adjusted, operated or not maintained in accordance with national and local codes or installation

instructions provided with the product, or any product that has its serial number defaced, obliterated or removed,

or which has been modified or repaired using unauthorized parts or by unauthorized service agents.

For a list of authorized service agents, please refer to the Garland web site at http://www.garland-group.com.

The information contained herein, (including design and parts specifications), may be superseded and is subject

to change without notice.

AND RETAIN FOR FUTURE REFERENCE.

THIS PRODUCT HAS BEEN CERTIFIED AS

COMMERCIAL COOKING EQUIPMENT AND

MUST BE INSTALLED BY PROFESSIONAL

PERSONNEL AS SPECIFIED.

INSTALLATION AND ELECTRICAL CONNECTION

MUST COMPLY WITH CURRENT CODES:

IN CANADA - THE CANADIAN ELECTRICAL

CODE PART 1 AND / OR LOCAL CODES.

IN USA – THE NATIONAL ELECTRICAL CODE

ANSI / NFPA – CURRENT EDITION.

CONFORMS TO UL-197 & NSF-4 CERTIFIED TO

CAN/CSA C22.2NO. 109 VDE EN60335-2-38.

GARLAND COMMERCIAL INDUSTRIES

185 East South Street

Freeland, Pennsylvania 18224

Phone: (570) 636-1000

Fax: (570) 636-3903

Part # 4520895 (01/31/08) © 2004 Garland Commercial Industries, Inc.

Part # 4529895 (01/31/08) Page 1

GARLAND COMMERCIAL RANGES, LTD.

1177 Kamato Road, Mississauga, Ontario L4W 1X4

CANADA

Phone: 905-624-0260

Fax: 905-624-5669

Enodis UK LTD.

Swalloweld Way, Hayes, Middlesex UB3 1DQ ENGLAND

Telephone: 081-561-0433

Fax: 081-848-0041

Part # 4520895 (01/31/08)Page 2

Part # 4529895 (01/31/08) Page 3

TABLE OF CONTENTS

DIMENSIONS AND SPECIFICATIONS,

GIU 2.5 BI..............................4

DIMENSIONS AND SPECIFICATIONS,

GIU 3.5/5.0 BI ..........................5

DIMENSIONS AND SPECIFICATIONS,

GIU 3.5/5.0 BI DUAL ....................6

DIMENSIONS AND SPECIFICATIONS,

GI 3.5/5.0 BI WOK ......................7

Operation And Control .......................8

Operation Conditions ........................8

Plug Descriptions ............................8

INTRODUCTION........................8

Application ..................................8

Purpose of induction cookers. . . . . . . . . . . . . . . . . 8

Description of products ......................8

INSTALLATION.........................9

Requirements of Installation ..................9

Installation Ambience ........................9

Electrical Connections .......................9

Cut Out .....................................10

Fresh Air Intake Installation .................10

Unit Installation .............................10

Remote Control Installation .................11

For Units Used Up To October 2001 ...... 11

For Units Used From October 2001.......12

OPERATION...........................13

Function Test ...............................13

Heating ....................................13

Control Knob ...............................13

Simmer Control .............................13

SAFETY CONCERNS ...................14

Description Of Danger Signs ................14

Safety Conscious Work ......................14

Cooking Process ............................14

Comfort ....................................14

Pan Detection ..............................14

Control Of The Heating Area. . . . . . . . . . . . . . . . . 14

Out Of Operation ...........................14

Operator/Operating Personnel Safety

Information .................................15

Unauthorized Reconstruction And

Use Of Spare Parts ..........................15

TROUBLE SHOOTING..................16

Error Messages .............................16

Trouble Shooting Guide .....................16

CLEANING AND SERVICING ............18

Cleaning ....................................18

Support ....................................18

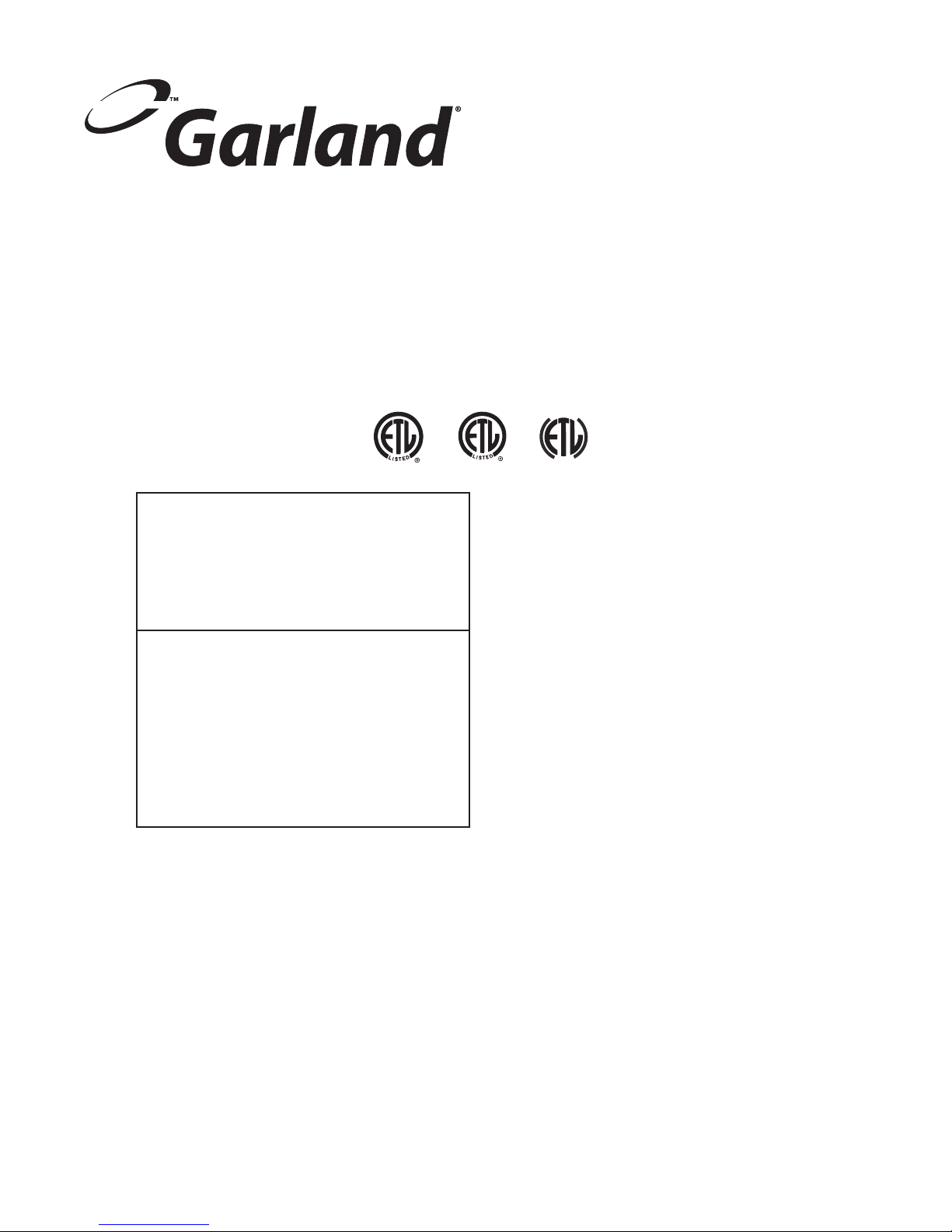

11 1/4" (285mm)

3"(76mm)

Exhaust

103/8"(260mm)

CeranGlass

DIMENSIONS AND SPECIFICATIONS, GIU 2.5 BI

4.09"

[104mm]

4.09"

[104mm]

4.72"

[120mm]

4.72"

[120mm]

0"

0.55"

[14mm]

0.75"

[19mm]

1.73"

[44mm]

4.17"

[106mm]

4.72"

[120mm]

3.66"

[93mm]

REMOTE

5 1/8"

(130mm)

Cable

6' Corded Plug

(208/240 Volt,

60 Cycle Units Only)

Fresh Air

4 3/8" (111mm)

10 7/8" (275mm)

For

Controls

Required Cut-Out Of Work Top

12 1/4"

(310mm)

MODEL

GIU-2.5 BI

12 1/4" (310mm)

Plug Congurations:

Electrical

Chararactericts

208V/60Hz/1Ø

240V/60 Hz/1Ø

11 1/2" (292mm) x 11 1/2" (292mm)

Plug

Model Watts 208/60/1 208/60/3 240/60/1 230/50/1 400/50/3 440/60/3

GUI-2.5 BI 2500 12 amp N/A 9 amp 10 amp N/A N/A

Note: Above remote control used from October 2001, for

remote switch used up to October 2001 see “Remote Control

Installation”.

Electrical Loading:

Part # 4520895 (01/31/08)Page 4

Part # 4529895 (01/31/08) Page 5

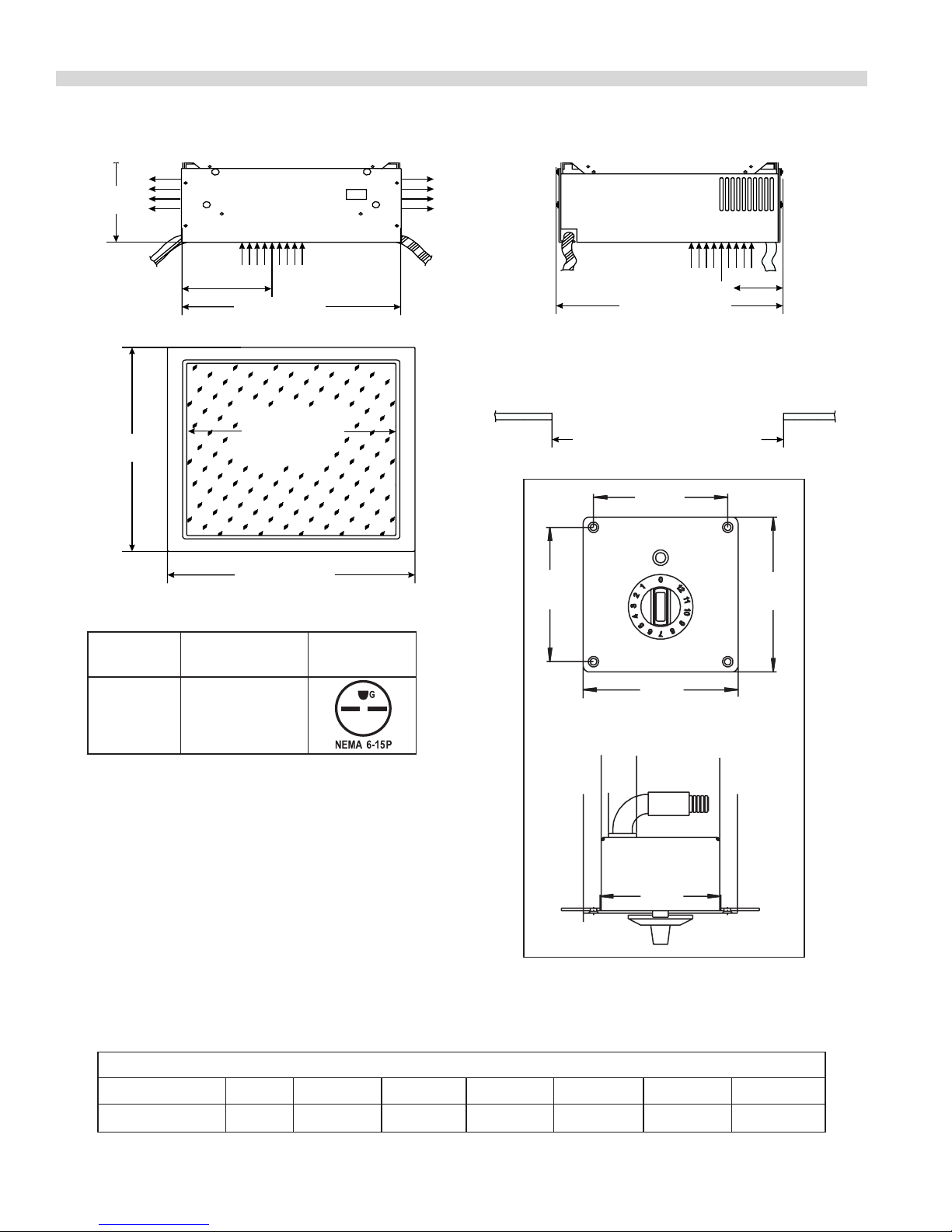

DIMENSIONS AND SPECIFICATIONS, GIU 3.5/5.0 BI

6 1/8"

(155mm)

Exhaust

6' Cord & Plug

(208/240 Volt

60 Cycle Units Only)

15 1/8"

(384mm)

Plug Congurations:

MODEL

GIU-3.5 BI

6"

(153mm)

13 1/8" (333mm)

12 5/8" (320mm)

(384mm)

Electrical

Chararactericts

208V/60Hz/1Ø

240V/60 Hz/1Ø

Fresh Air

CeranGlass

15 1/8"

Plug

Cable

For

Controls

4.09"

[104mm]

6 3/8"

(163mm)

13 1/2" (343mm)

The Required Cut-Out Of The Work Top:

14" (356mm) x 14" (356mm)

4.09"

[104mm]

4.72"

[120mm]

4.72"

[120mm]

0.55"

0"

1.73"

[14mm]

0.75"

[19mm]

[44mm]

4.17"

[106mm]

4.72"

[120mm]

GIU-5.0 BI 208V/60HZ/3Ø

Model Watts 208/60/1 208/60/3 240/60/1 230/50/1 400/50/3 440/60/3

GUI-3.5 BI 3500 16 amp N/A 14 amp 15 amp N/A N/A

GUI-5.0 BI 5000 N/A 14 amp N/A N/A 8 amp 7 amp

Note: Above remote control used from October 2001, for

remote switch used upto October 2001 see “Remote Control

Installation”.

Electrical Loading:

REMOTE

3.66"

[93mm]

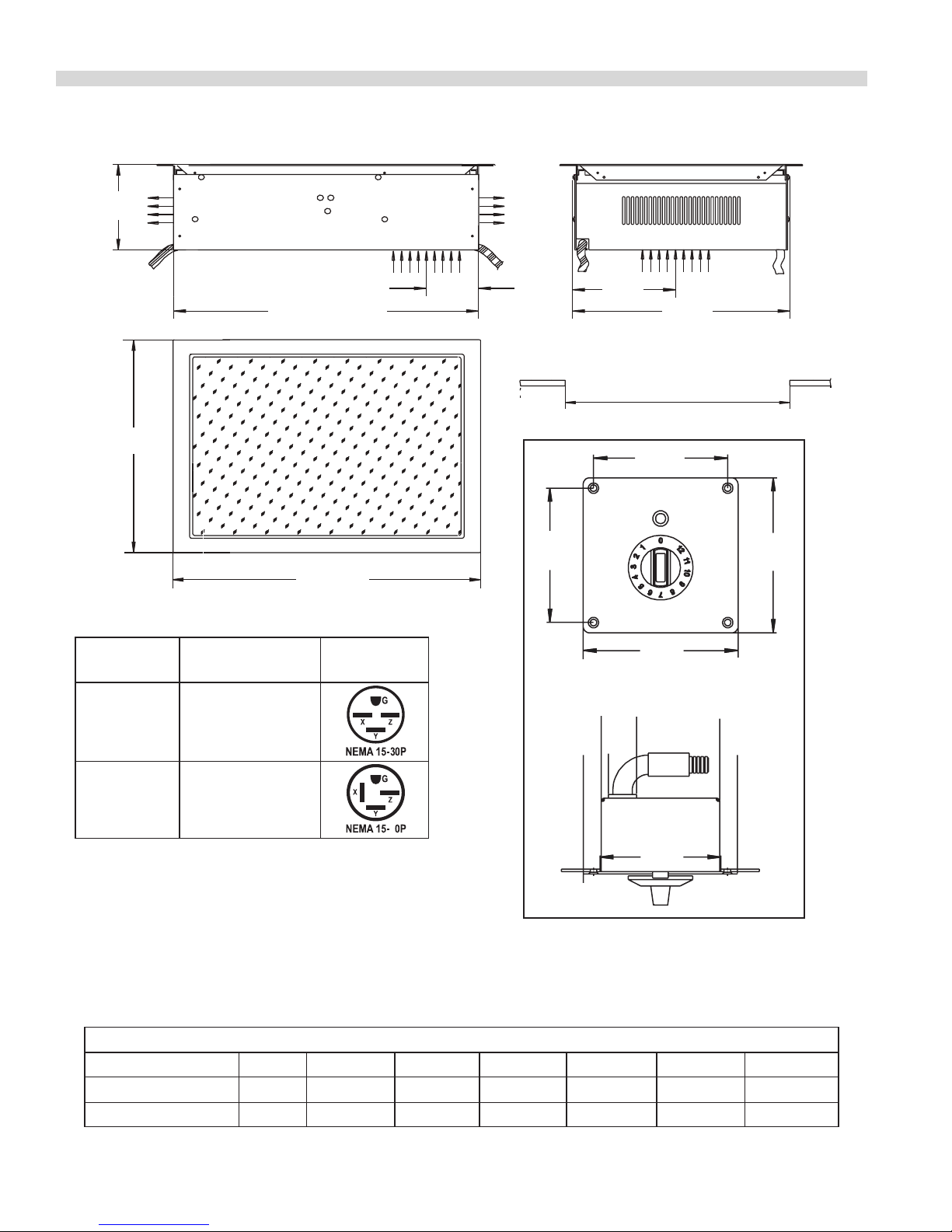

DIMENSIONS AND SPECIFICATIONS, GIU 3.5/5.0 BI DUAL

4.09"

[104mm]

4.09"

[104mm]

4.72"

[120mm]

4.72"

[120mm]

0"

0.55"

[14mm]

0.75"

[19mm]

1.73"

[44mm]

4.17"

[106mm]

4.72"

[120mm]

3.66"

[93mm]

REMOTE

5-3/8"

(137mm)

6-Foot Cord

& Plug

(208/240Volt,

60 Cycle

Units Only)

15"

(380mm)

23-3/8" (594mm)

(645mm)

Plug Congurations:

25-3/8"

Intake

3-3/8"

(86mm)

Exhaust

Control

Cable

6-3/8"

(163mm)

Intake

13-1/2"

(343mm)

The Required Cut-Out Of The Work Top:

14" (356mm) x 24" (610mm)

MODEL

GIU-3.5 Dual

BI

GIU-5.0 Dual

BI

Electrical

Chararactericts

208V/60Hz/3Ø

208V/60HZ/3Ø

Plug

5

Note: Above remote control used from October 2001, for

remote switch used up to October 2001 see “Remote Control

Installation”.

Electrical Loading:

Model Watts 208/60/1 208/60/3 240/60/1 230/50/1 400/50/3 440/60/3

GIU-3.5 DUAL BI 7000 N/A 20 amp N/A N/A 10 amp 9 amp

GIU-5.0 DUAL BI 10,000 N/A 28 amp N/A N/A 15 amp 13 amp

Part # 4520895 (01/31/08)Page 6

Part # 4529895 (01/31/08) Page 7

DIMENSIONS AND SPECIFICATIONS, GI 3.5/5.0 BI WOK

4.09"

[104mm]

4.09"

[104mm]

4.72"

[120mm]

4.72"

[120mm]

0"

0.55"

[14mm]

0.75"

[19mm]

1.73"

[44mm]

4.17"

[106mm]

4.72"

[120mm]

3.66"

[93mm]

REMOTE

83/8"

(213mm)

6’ CordandPlug

(208/240Volt

60CycleUnitsOnly)

151/8"

(384mm)

6"

(152mm)

FRESHAIR

131/8"

(333mm)

117/8"

(300mm)

151/8"

(384mm)

1/16"

EXHAUST

Cable

for

Controls

141/4"

(361mm)

63/8"

(163mm)

14 1/2" (368mm) x 14 1/2" (368mm)

135/8"

(344mm)

Required Cut-Out of WorkTop

Plug Congurations:

Model

Electrical

Characteristics

Plug

GIWOK-3.5BI208V/60Hz/1Ø

240V/60Hz/1Ø

GIWOK-5.5

BI

208V/60Hz/1Ø

Note: Above remote control used from October 2001, for

remote switch used up to October 2001 see “Remote Control

Installation”.

Electrical Loading:

Model Watts 208/60/1 208/60/3 240/60/1 230/50/1 400/50/3 440/60/3

GIWOK-3.5 BI 3500 16 amp N/A 14 amp 15 amp N/A N/A

GIWOK-5.0 BI 5000 N/A 14 amp N/A N/A 8 amp 7 amp

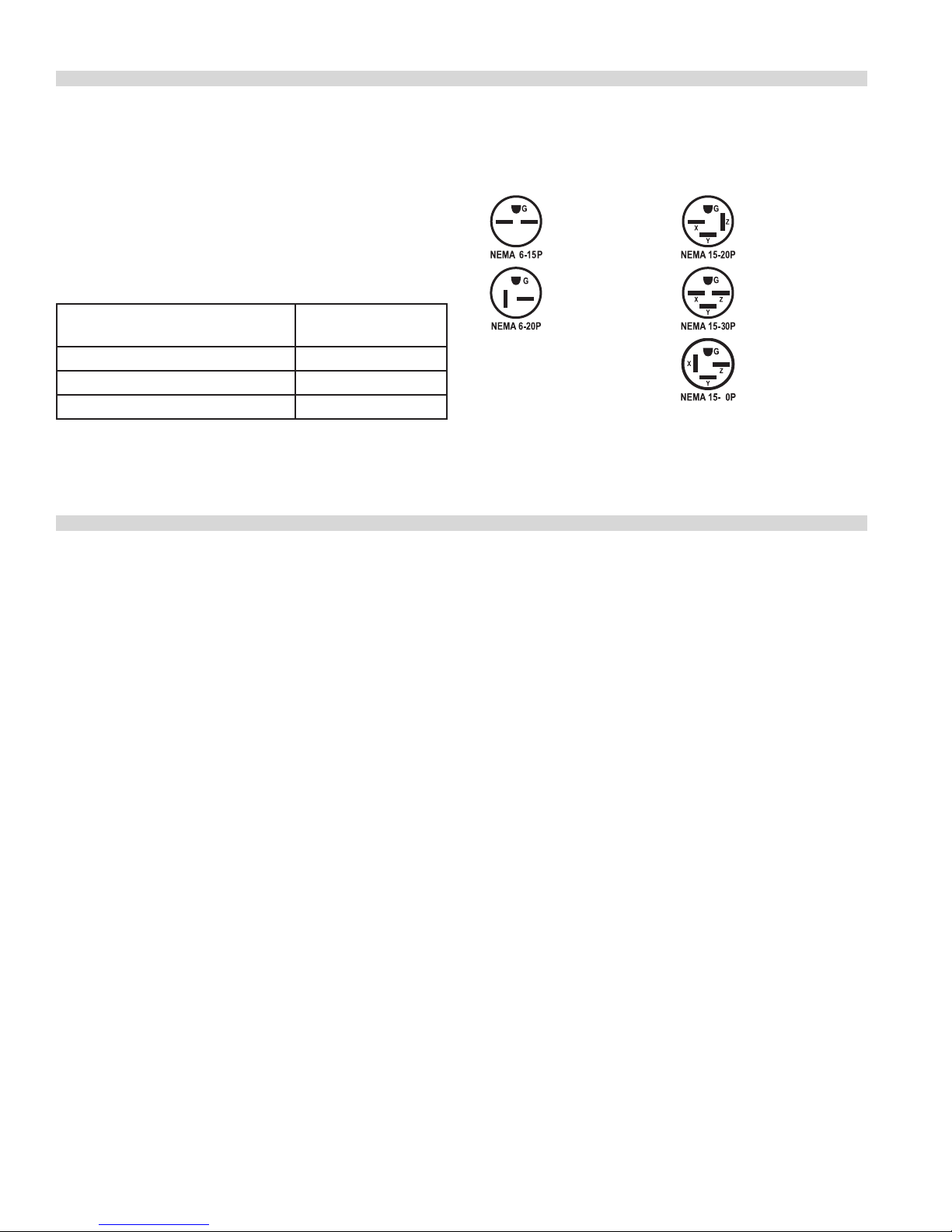

DIMENSIONS AND SPECIFICATIONS, Continued

Operation And Control

Lamp operation 24V DC/max. 40mA (Green)

Output regulator - Potentiometer 10k Ohm

Operation Conditions

Max. Tolerance Of The Nominal

Supply Voltage

Supply Frequency 50/60 Hz

Protection Class 1P 43

Minimal Diameter Of The Pan 5” (127mm)

+6/-10%

INTRODUCTION

Application

Plug Descriptions

208/240 volt,

single phase, 15

amp

208/240 volt,

single phase, 20

amp

Description of products

208 volt,

3 phase,

20 amp

208 volt,

3 phase,

30 amp

208 volt,

3 phase,

50 amp.

5

The following instructions contain information, which

is fundamentally important and must be taken into

account during assembly, operation and maintenance.

They must therefore read very carefully before installation

and operation by the responsible specialist sta and the

operator(s). They must always be available for consultation at

the place of operation.

Purpose of induction cookers

The Garland induction unit cookers are especially suitable

as cookers in the kitchen and for the preparation of meals

on the table. A cooker can be used for cooking, warming up,

keeping warm, ambéing, roasting, etc. The cookers are to

be used only with pans made of material which is suitable for

induction. There are specic manufacturers who sell special

types of pots and pans for induction cooking.

NOTE: For Wok models, only use supplied pans or “Spring of

Switzerland” wok pans. Other pans may not have the same

shape as the ceramic wok bowl, causing overheating and

cracking of the ceramic.

DO NOT use induction cookers to heat up any other

metallic objects other than pots and pans provided for it.

We manufacture several basic types of induction cookers

with various performances and measurements. All are

built to last; they are also compact and powerful with a

revolutionary technology in a complete case of stainless

steel. All of our accessories are designed to coordinate with

the induction units and since each unit is equipped with

continuous control, they allow ecient cooking.

Features include:

• Simple operation with rotary switch

• Compact powerful electronics enable at construction and

safe operation

• A maximum of safety thanks to multiple safety functions

• Short cooking time

• Electronic checking

• Compact measurement – light weight

• Meets all current standards: VDE EN 60335-1/-2/36, CEconforming

• UL197; CAN/CSA/C22.2 No., 109, NSF 4-1996

Part # 4520895 (01/31/08)Page 8

Part # 4529895 (01/31/08) Page 9

INSTALLATION

Requirements of Installation

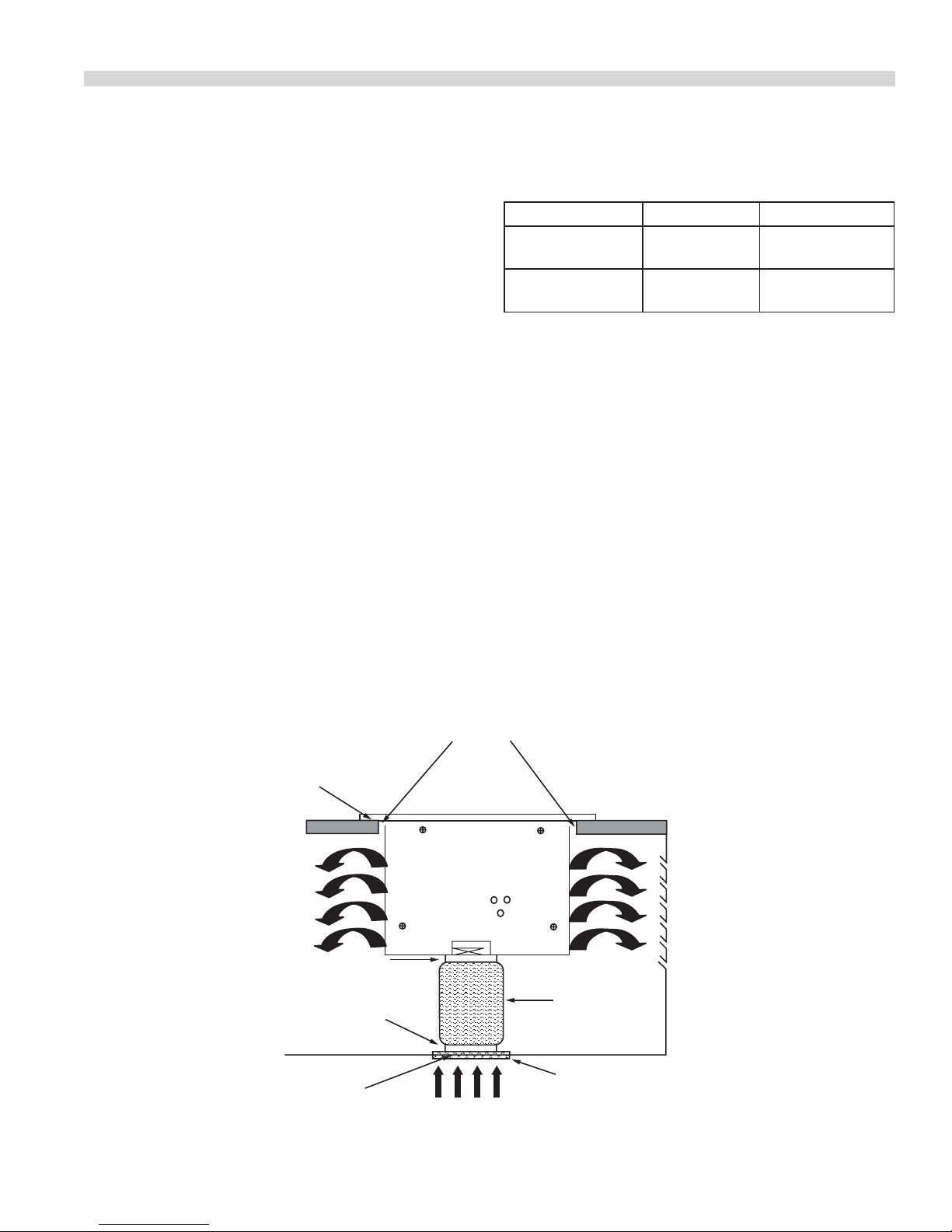

The underside and sides of the induction unit must be

absolutely clear of obstructions to provide for adequate

cooling air to enter and exhaust. Cooling air enters from the

bottom of the unit and is discharged either from the sides

(single or wok units) or from the rear (double units). An

air intake kit is provided to ensure adequate cooling air is

brought to the unit. A minimum of 30 sq inch opening must

be provided for the heated air to be discharged into the

room.

1 Make Sure that the induction unit does not take in hot

ambient air (concerns units standing side by side, or one

behind the other, or standing near a frying pan or oven).

2. The induction unit must not be placed near or on a hot

surface.

3. Make sure that the induction unit does not take in grease

laden air which is produced by other applications (deep

fat fryer, grill, frying pan). In which case you must use an

air an air duct (available as an accessory).

4. The air intake temperature must be under 104°F (40°).

5. The operating sta has to make sure that the installation,

support and inspection is done by qualied personnel.

Installation Ambience

CONDITIONS STORAGE FUNCTION

Max. Ambient

Temperature

Max. Relative

Humidity Of Air

> -4°F (-20ºC) to

158°F (70ºC)

> -10% to 90% > 30% to 90%

> 41ºF (5ºC) to

104ºF (40ºC)

Electrical Connections

Turn the control knob to the OFF-position before connecting

the cooker to the voltage supply.

The operator has to insure that all installation, maintenance

and inspection work is carried out by authorized and

qualied personnel.

1. Check and ensure that the supply voltage matches the

voltage given on the specication plate.

2. The electrical connections must satisfy local house

installation regulations. The valid national and local

regulations must be observed.

3. The cooker is provided with a cord and plug (60 cycle

units only).

Cut Out Opening

Silicone

Louvered

Air Exhaust

Opening

(By Installer)

Sleeve with hose clip:

mounted on bottom of unit

Sleeve with hose clip:

mounted to cabinet

Air Intake Housing

See Fig. # 1

Fresh Air Supply

Aluminum air duct

(Max 96" (8'))

mounted on collars

with hose clamps

Removable grease lter and air

intake housing mounted on

cabinet

INSTALLATION Continued

Cut Out

The size of the cut out required will vary depending on

the model of the unit. (See cut-out dimensions for the

various unit in the dimensions and specications sections).

Make sure there is enough depth below the top surface

to accommodate the depth of the unit and the air intake

connection. Apply silicone to the top of the table and press

the unit frame onto the silicone, allowing for a complete

watertight seal between the unit and the table.

Fresh Air Intake Installation

The built-in induction units require a cooling air intake to

operate eectively. The air intake housing is mounted to

the cabinet, and is tted with a removable stainless steel

grease lter that can be cleaned in a dishwasher. Install the

air intake housing and connect it to the induction unit with

the aluminum air duct. Maximum length of this air inlet is

to be 96” (8’). Make sure the cabinet is also equipped with

a louvered air exhaust having a size of no less than 30 sq

inches (50 sq inches for dual units) for the hot air to escape

(by installer). Failure to provide adequate ventilation for the

unit will result in the unit overheating, nuisance shut down

and potential failure of the unit.

Figure 1.

Figure 1 Continued

4 HOLES

CUTOUT

9.125" x 7"

[231.8mm x 177.8mm]

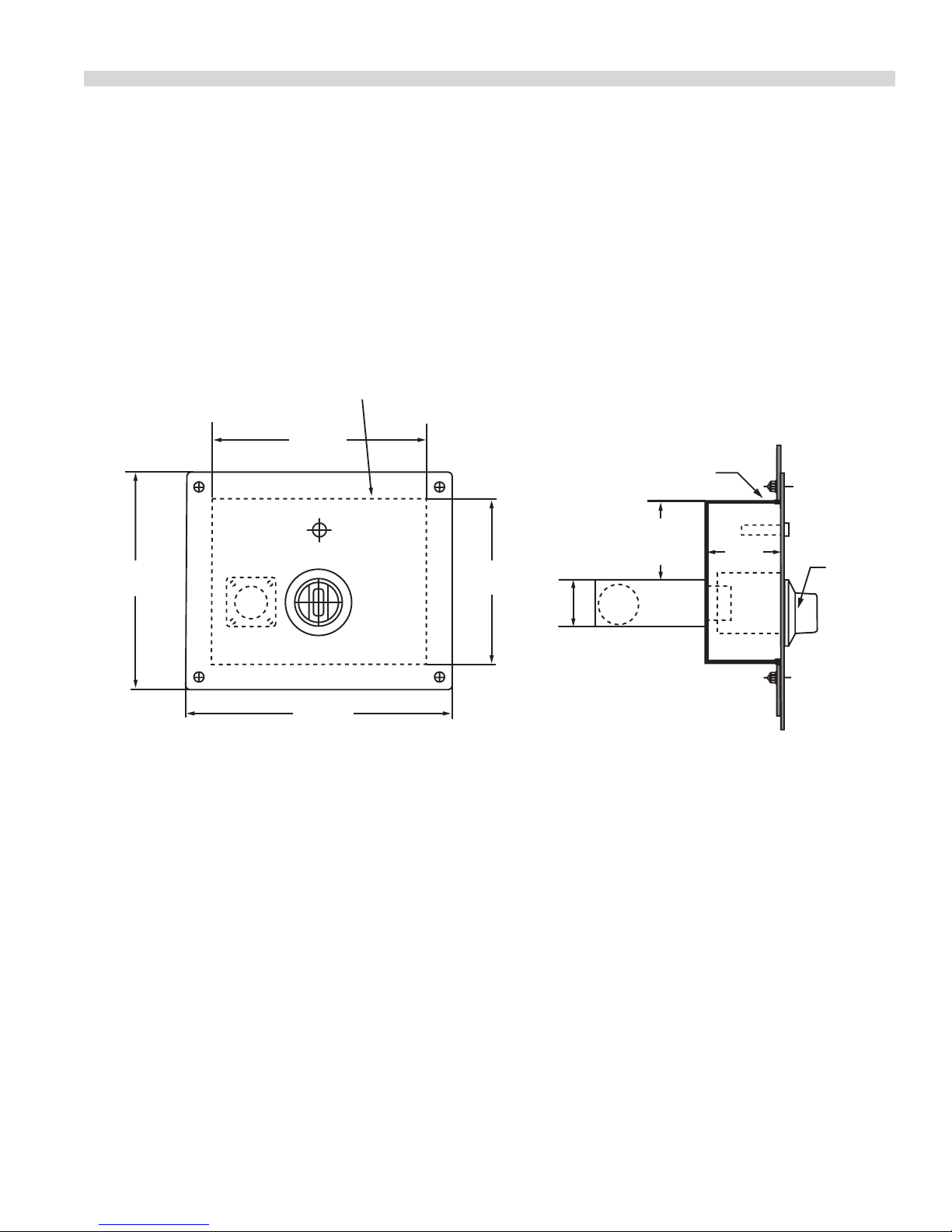

Unit Installation

Check and ensure, that the supply voltage matches the

voltage given on the specication plate.

The cooker must be installed so that it is level and that the

top of the unit has been sealed to the counter. Install the air

intake kit to the bottom of the unit, and ensure that there is a

minimum of 30 sq inch opening to allow the heated air from

the cooling fan to be discharged into the room.

TOP VIEW

11" [279.4mm]

10 3/16" [258.8mm]

8 3/16"

[208 mm]

9"

[288.6 mm]

FRONT VIEW

5/32"

[4mm]

4 Holes

Part # 4520895 (01/31/08)Page 10

Part # 4529895 (01/31/08) Page 11

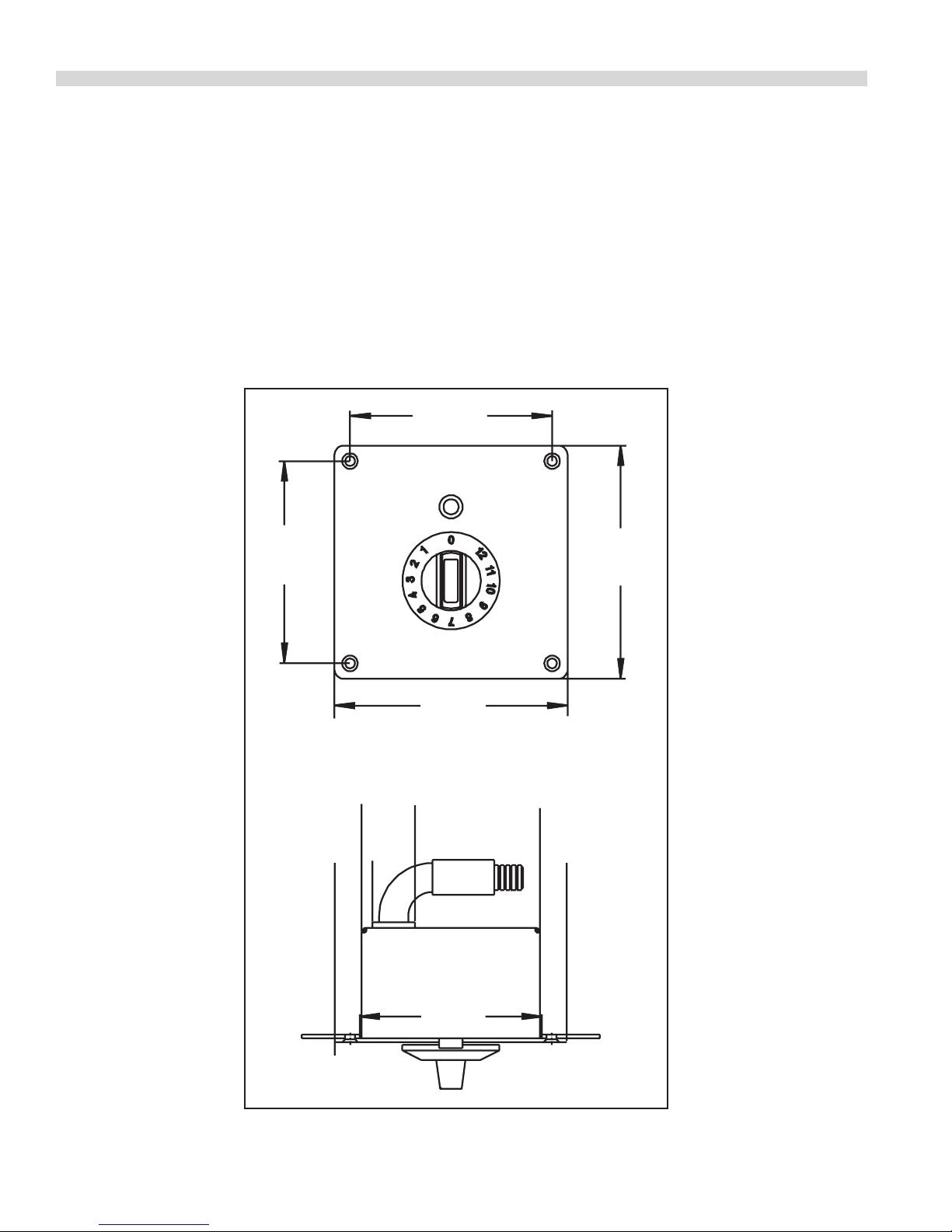

INSTALLATION Continued

Remote Control Installation

Install the remote mounted controls at the front of the unit in

a convenient location, and connect to the unit (2 controls are

provided for the dual hob model).

Figure 2

Cut-Out For

Control Box

6 1/2"

[165 mm]

6 3/8"

[162mm]

[127mm]

For Units Used Up To October

Up to serial # IN16.0044.101 (See Fig 2).

Edge

Protection

5"

1 3/8"

[35mm]

Cable

2 3/8"

[60 mm]

2 1/4"

[57mm]

Control

Knob

7 7/8"

[200mm]

4.09"

[104mm]

4.09"

[104mm]

4.72"

[120mm]

4.72"

[120mm]

0"

0.55"

[14mm]

0.75"

[19mm]

1.73"

[44mm]

4.17"

[106mm]

4.72"

[120mm]

3.66"

[93mm]

REMOTE

INSTALLATION Continued

For Units Used From October

From serial # IN16.0045.1001

The remote rotary control is mounted on a plate measuring

4.72” (120mm) high x 4.72” (120mm) wide that is mounted to

the front of a fabricated cabinet (supplied by others) with 4

screws. The Cut-out opening for the control is 3.40” (86mm)

high x 3.40” (86mm) wide.

Part # 4520895 (01/31/08)Page 12

Loading...

Loading...