Garland GIR36 Installation Manual

INSTALLATION AND

OPERATION MANUAL

GARLAND G SERIES INFRA-RED

SALAMANDER BROILERS

Français . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 17

Españo. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Página 33

DO NOT OBSTRUCT THE FLOW OF COMBUSTION

FOR YOUR SAFETY:

DO NOT STORE OR USE GASOLINE

OR OTHER FLAMMABLE VAPORS OR

LIQUIDS IN THE VICINITY OF

THIS OR ANY OTHER

APPLIANCE

WARNING:

IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE

CAN CAUSE PROPERTY DAMAGE, INJURY,

OR DEATH. READ THE INSTALLATION,

OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR

SERVICING THIS EQUIPMENT

AND VENTILATION AIR TO THIS APPLIANCE

PLEASE READ ALL SECTIONS OF THIS MANUAL

AND RETAIN FOR FUTURE REFERENCE.

THIS PRODUCT HAS BEEN CERTIFIED AS

COMMERCIAL COOKING EQUIPMENT AND MUST

BE INSTALLED BY PROFESSIONAL

PERSONNEL AS SPECIFIED.

IN THE COMMONWEALTH OF MASSACHUSETTS

THIS PRODUCT MUST BE INSTALLED BY A

LICENSED PLUMBER OR GAS FITTER.

For Your Safety:

Post in a prominent location, instructions to be

followed in the event the user smells gas. This

information shall be obtained by consulting your

local gas supplier.

Users are cautioned that maintenance and repairs must be performed by a Garland authorized service agent using genuine

Garland replacement parts. Garland will have no obligation with respect to any product that has been improperly installed,

adjusted, operated or not maintained in accordance with national and local codes or installation instructions provided

with the product, or any product that has its serial number defaced, obliterated or removed, or which has been modified

or repaired using unauthorized parts or by unauthorized service agents. For a list of authorized service agents, please refer

to the Garland web site at http://www.garland-group.com. The information contained herein, (including design and parts

specifications), may be superseded and is subject to change without notice.

GARLAND COMMERCIAL RANGES, LTD.

1177 Kamato Road, Mississauga, Ontario, CANADA L4W 1X4

905-624-0260 | fax 905-624-5669 | www.garland-group.com

phone

Part # 4523916 Rev 2 (05/05/14) © 2007 Garland Commercial Ranges, Ltd.

Part # 4523916 Rev 2 (05/05/14)

USA Sales, Parts and Service 1-800-424-2411

Canadian Sales 1-888-442-7526

Canada or USA Parts/Service 1-800-427-6668

International Sales and Service www.ManitowocFoodservice.com

IMPORTANT INFORMATION

WARNING:

This product contains chemicals known to the state of california to cause cancer and/or birth defects

or other reproductive harm. Installation and servicing of this product could expose you to airborne

particles of glass wool/ceramic fibers. Inhalation of airborne particles of glass wool/ceramic fibers

is known to the state of california to cause cancer. Operation of this product could expose you to

carbon monoxide if not adjusted properly. Inhalation of carbon monoxide is known to the state of

california to cause birth defects or other reproductive harm.

Keep appliance area free and clear of combustibles.

Part # 4523916 Rev 2 (05/05/14)Page 2

TABLE OF CONTENTS

IMPORTANT INFORMATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Uncrating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Rating Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

DIMENSIONS AND SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Salamander Performance and Construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

INSTALLATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

National Code Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Gas Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Optional Inter-Connect Kit

Installation Of A Salamander To A Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Model GIR36 – 36” Ranges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Model GIR48 – 48” Ranges. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Model GIR60 – 60” Ranges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Wall Or Counter Mounted Salamanders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Model GIR36C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Ventilation and Air Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

(Models GIR36, GIR48 & GIR60) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

OPERATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Pilot Lighting Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Main Burner Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Burn o Period. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Energy Conservation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Shut Down Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Main Burner Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

MAINTENANCE AND CLEANING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Daily . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Monthly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Exterior Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Part # 4523916 Rev 2 (05/05/14) Page 3

INTRODUCTION

Units included in this manual are:

Salamander Models: GIR36C, GIR36, GIR48, GIR60

All units are shipped completely assembled with the

pressure regulator packed inside the unit drip tray. Units are

inspected at the factory prior to shipment.

The appliance should be given regular care and

maintenance. Periodic inspections by your dealer or a

quali ed service agency are recommended.

This product has been certi ed as commercial cooking

equipment and must be installed by professional personnel

as speci ed.

Uncrating

Check the crate for possible damage during transit. Carefully

remove the unit from the crate and again check for damage.

If damage has occurred, report it to the carrier immediately.

Shipping wire, or ties for retaining the packaging material

must be removed from the units, as well as any protective

material covering stainless steel.

DO NOT remove any permanently a xed label warnings or

the rating plate from the appliance, as this may invalidate the

manufacturer’s warranty.

The type of gas and supply pressure that the equipment was

set-up for at the factory are indicated on the rating plate and

packaging. The type of gas and pressure speci ed must be

supplied to the unit.

Rating Plate

The rating plate is a xed to the Salamander front panel and

is located underneath the removable drip tray.

When corresponding with the factory or your local

authorized factory service center regarding service problems

or replacement parts, be sure to refer to the particular unit

by the correct model number (including the pre x and su x

letters and numbers) and the warranty serial number. The

rating plate contains this information.

The rating plate also contains the gas type and supply

pressure, as well as listing the input rating of all burners.

In the event you have any questions concerning the

installation, use, care or service of the product, write or call

our Product Service Department.

Page 4

Part # 4523916 Rev 2 (05/05/14)

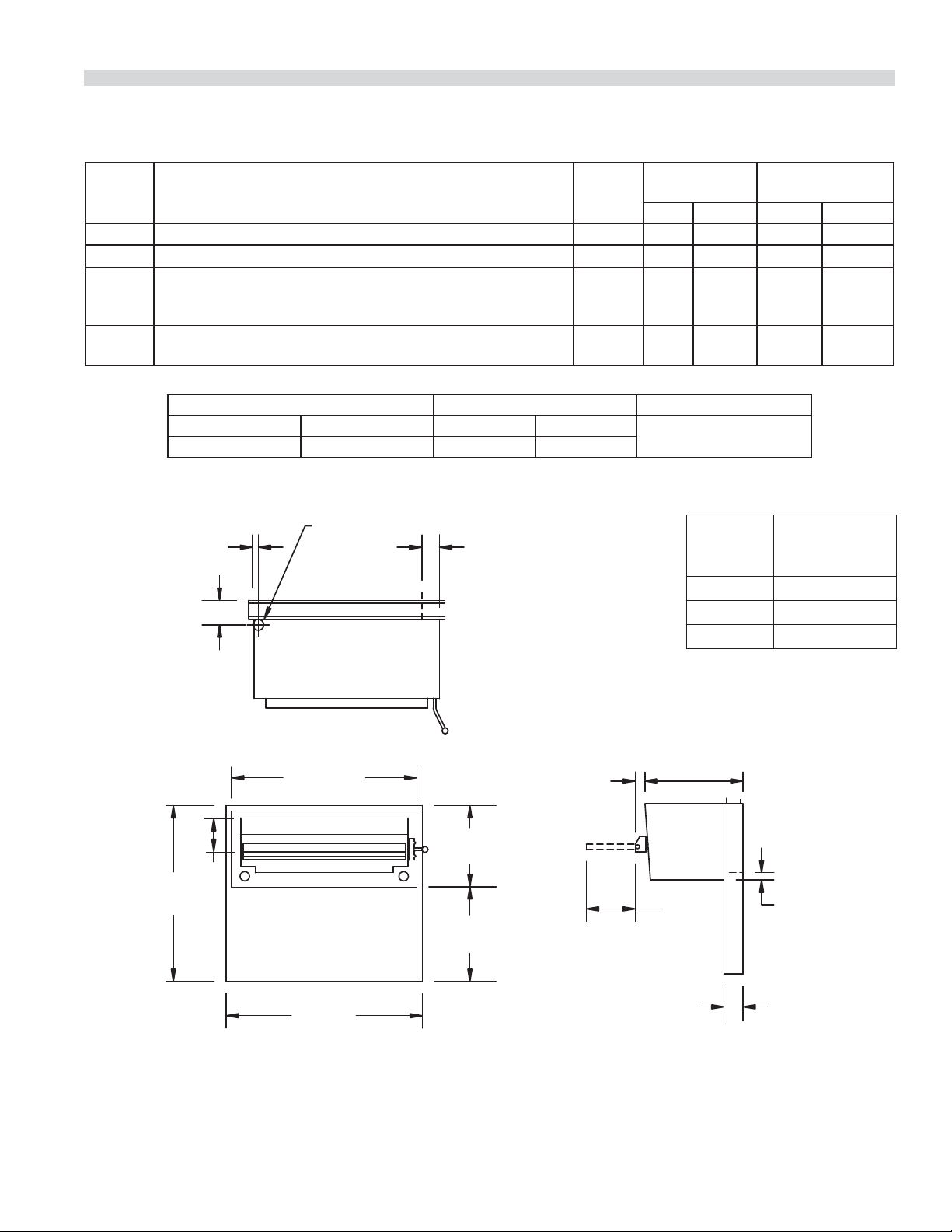

DIMENSIONS AND SPECIFICATIONS

Use With

Model Width

GIR36C 34" (864mm) N/A 21 170/77 29(737) 21(533)

GIR36 35-1/2" (900mm) G36

47-1/4"(1200mm)

GIR48

GIR60*

* Note Salamander Broiler on Left Side. Right Side Optional

6"WC (15mbar) 10"WC (25mbar) 6"(152mm) 6"(152mm)

Gas input ratings shown for installations up to 2000 ft., (610m), above sea level. Please specify altitudes over 2000 ft.

Please specify gas type when ordering.

[22mm]

[70mm]

(35-1/2" /900mm center mounted broiler

with 47-1/4"/1200mm ue riser)

59" (1500mm)

(35-1/2" /900mm broiler + 24"/600mm ue riser w/shelf)

Operating Pressure Installation Clearances Total Input

Natural Propane Sides Rear

7/8"

2-3/4"

1/2" N.P.T

TOP GAS

INLET*

3-1/4"

[83mm]

OPTIONAL

REAR

GAS INLET

*Note: TOP GAS INLET

pipe extension adds 4"

(258mm) to overall height.

G Series

Model

G48

G60

Shipping

Information

Cu Ft lbs/Kg Crated Uncrated

38.2

60.6

60.6

40,000 BTU/HR (11.7Kw)

200/91 29(737) 21(533))

230/105 29(737) 21(533)

260/118 29(737) 21(533)

Rack

Position

3 Highest 2-3/4" (70mm)

2 Middle 3-1/2" (87mm)

1 Lowest 4-3/8" (111mm)

Entry Clearances:

In (mm)

Opening Height

to Cook Surface

(A)

16-5/8" [422mm]

[GIR36, 48, 60]

18" [457mm]

34"

[864mm]

15"

[381mm]

A

34-1/4"

[870mm]

19"

[483mm]

35-1/2"

[900mm]

Garland/US Range products are not approved or authorized for home or residential use, but are intended for commercial

applications only. Garland/US Range will not provide service, warranty, maintenance or support of any kind other than in

commercial applications.

1-3/4"

[45mm]

[GIR36C]

9"

[229mm]

2-1/8"

[54mm]

1-3/8"

[35mm]

OPTIONAL

REAR

GAS

INLET

Part # 4523916 Rev 2 (05/05/14)

Page 5

GENERAL INFORMATION

The range-mounted, gas Infra-Red Salamander Broiler is

designed for a perfect match and t to the Garland G Series

Range.

Garland products are not approved or authorized for

home or residential use, but are intended for commercial

applications only. Garland will not provide service,

warranty, maintenance or support of any kind other than in

commercial applications.

Salamander Performance and Construction

Two Hi-Low gas valves provide individual control of the two

(2) atmospheric-type 20,000 BTU/Hr gas infra-red burners for

the Salamander.

The“LO” position is adjustable for most eld gas pressure

situations. Fast preheat and uniform production is provided

by the high-e ciency, infra-red burners.

The unique atmospheric design eliminates the need for

fans and lters. Heat is directed downward to the large -380

square inch plus – heavy duty broiling rack.

The rack is easily removed from the spring balanced rack

assembly. The rack assembly rolls out for ease of loading and

unloading and, raises and lowers with positive locking in

three positions. The full-width grease de ector attached to

the underside of the rack assembly channels hot drippings

to a large capacity drip tray even when the rack assembly

is rolled out. The rack assembly and drip pan are easily

removed for cleaning.

Models GIR36 and GIR48 salamanders are 36” (900mm)

and 48” (1200 mm) wide respectively and are supported by

heavy-formed brackets to mount to the range.

Model GIR60 mounts to a 60” (1500mm) wide G Series range

and includes a 24” (600mm) wide shelf.

Model GIR36C is a counter unit and comes equipped with

4” (102mm) stainless steel legs, it may be mounted to a wall

with an optional wall mounting kit.

All salamander models have a stainless steel top and sides.

Stainless steel bottoms and heat shields are standard on

range match models, optional on model GIR36C.

INSTALLATION

This product has been certi ed as commercial cooking

equipment and must be installed by professional personnel

as speci ed. THIS APPLIANCE IS NOT RECOMMENDED FOR

RESIDENTIAL INSTALLATION.

We suggest installation, maintenance and repairs be

preformed by your local Garland/US Range authorized

service agency.

National Code Requirements

The importance of the proper installation of Commercial

Gas Cooking Equipment cannot be over stressed. Proper

performance of the equipment is dependent, in great part,

on the compliance of the installation with the manufacturer’s

speci cations. Installation must conform to local codes

or, in the absence of local codes, with the National Fuel

Gas Code, NFPA54 / ANSI Z223.1 or latest edition, Natural

Gas Installation Code, CAN/GCA-B149.1 or the Propane

Installation Code, CAN/CGA-B149.2 or latest editions, as

applicable.

Page 6

Part # 4523916 Rev 2 (05/05/14)

INSTALLATION Continued

Gas Connections

Danger

Turn O Gas

Supplies When

Installing or

Servicing Unit.

All xed (non mobile) appliances MUST be tted with a

manual gas cock upstream of the appliance to provide a

means of isolation for servicing or cleaning purposes. A

union or similar means of disconnection must be provided

between the gas cock and the appliance.

A manually operable valve must be tted to the gas supply

to the kitchen to enable it to be isolated in an emergency.

Whenever practical, this shall be located either outside the

kitchen of near an exit in a readily accessible position.

Where it is not practical to do this, an automatic isolation

valve system shall be tted which can be operated from a

readily accessible position or near to the exit.

At locations where the manual isolation valve is tted or

the automatic system can be reset, a notice MUST be tted

stating:

“ALL DOWNSTREAM BURNER AND PILOT VALVES MUST

BE TURNED OFF PRIOR TO ATTEMPTING TO RESTORE THE

SUPPLY. AFTER EXTENDED SHUT OFF, PURGE BEFORE

RESTORING GAS.”

Before assembly and connection, check gas supply.

A. The type of gas for which the unit is equipped is stamped

on the rating plate located on the lower front panel

simply remove the drip tray for easy access. Connect a

unit stamped “NAT” only to natural gas; connect those

stamped “PRO” only to propane gas.

B. If it is additional equipment or a replacement have a

quali ed gas technician check the gas pressure to make

certain that existing gas facilities (meter piping, etc.)

will supply gas to the unit with no more than 1/2” water

column pressure drop.

NOTE: When checking pressure, be sure that all other

equipment on the same gas line is on. A pressure regulator

is supplied with Garland Infra-Red Broilers. The regulator

is preset to deliver gas at the pressure shown on the rating

plate.

C. The appliance and its individual shut o (supplied by

others) must be disconnected from the gas supply piping

system during any pressure testing of that system at

pressures in excess of 1/2” psi (3.45 kPa).

D. The appliance must be isolated from the gas supply

piping system by closing its individual manual shut o

valve (supplied by others) during any pressure testing of

the gas supply piping system at test pressures equal to or

less than ½ psi (3.45 kPa).

E. The gas supply connection is made either at the top left

rear or lower rear right corner, depending on how the

unit was ordered. A readily accessible approved type of

hand valve should be installed on each supply line. Test

for leaks – DO NOT USE ANY OPEN FLAME.

F. A pressure tap plug is supplied with the units and it is

installed on the manifold. The drip tray must be removed

to use the pressure tap. The gas pressure must be

checked when the unit is installed, to insure that the unit

gas pressure is the same as speci ed on the rating plate.

If necessary, pressure adjustments must be made at the

supplied pressure regulator.

NOTE: the pressure regulator is located at the top left rear or

bottom right rear of the salamander.

G. If it is a completely new installation, have a quali ed gas

technician check meter size and piping to ensure that

the unit is supplied with a su cient amount of gas at the

speci ed pressure for unit operation.

H. Make certain that the new piping, joints and connections

have been made in a clean manner and have been

purged, so that the piping compound, chips, etc, will not

clog pilots, valves and/or controls. Use pipe joint sealant

that is resistant to lique ed petroleum gas.

WARNING Check gas connections for leaks. Use a soap

solution or similar means. DO NOT USE AN OPEN FLAME!

Part # 4523916 Rev 2 (05/05/14) Page 7

INSTALLATION Continued

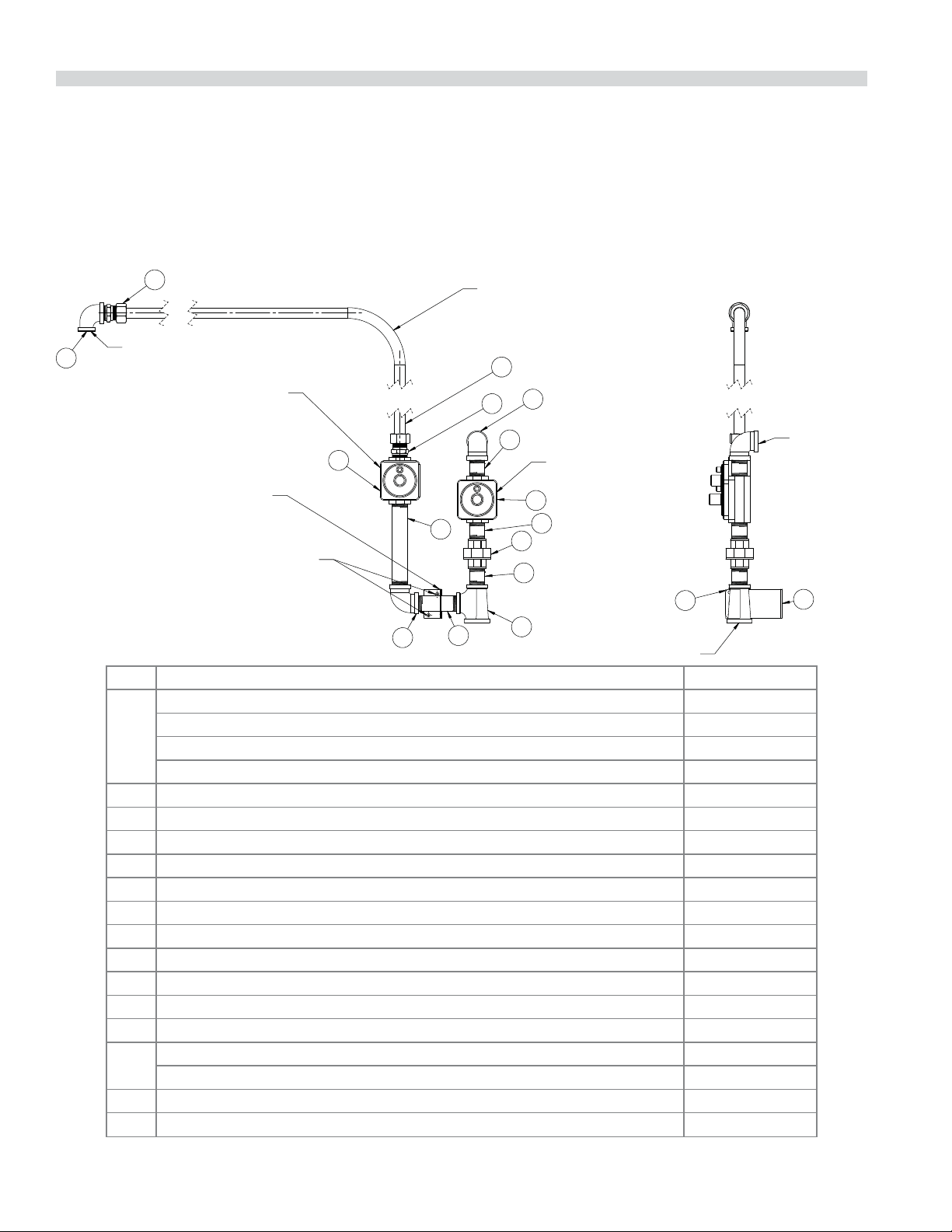

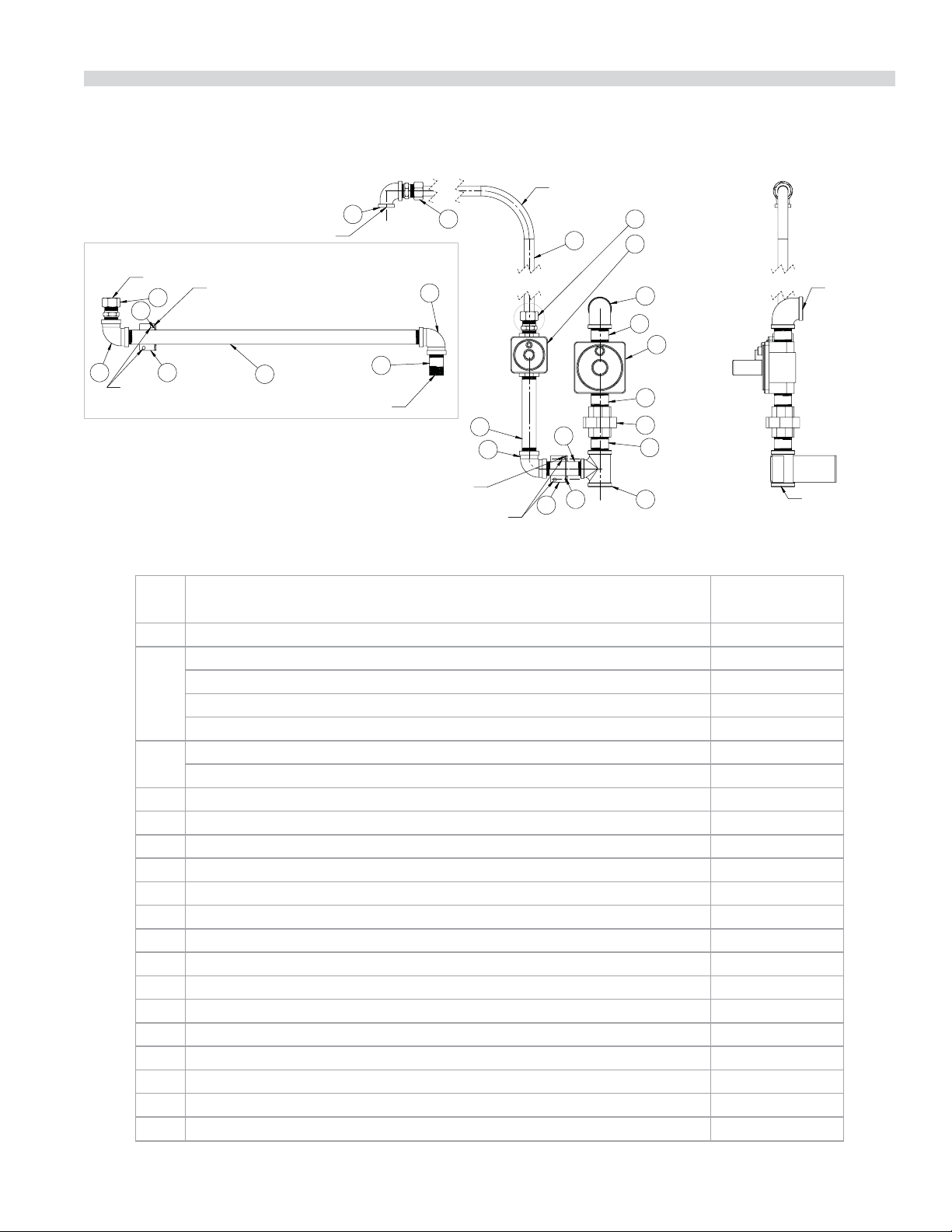

Optional Inter-Connect Kit (Models GIR36, GIR48 & GIR60)

The gas supply of the range mounted salamanders may be inter-connected with the supply of the range, so both units

are supplied from a single gas connection. The supply gas piping should be a minimum of 1” (25mm) diameter to ensure

enough gas capacity is available at the speci ed pressure to supply the total combined input rating of both appliances. The

components comprising the optional inter-connect kit are shown below.

Optional Interconnect Gas Kit #4531606 - Version 1, Connecting to a 36in Range

5

TO INLET OF SALAMANDER/

8

CHEESEMELTER MANIFOLD

REGULATOR - 6.0"w.c. NATURAL GAS

OR 10.0"w.c. PROPANE GAS

(SUPPLIED WITH SALAMANDER/

CHEESEMELTER)

CUT TUBING (ITEM 15 - 4531608) TO SIZE AS REQUIRED

TO SUIT SALAMANDER/CHEESEMELTER TOP OR REAR

MANIFOLD INLET CONNECTION

15

SUPPLIED WITH RANGE

3

5

SUPPLIED WITH RANGE

2

ATTACH SUPPORT CLAMP (ITEM 7 - 2640800)

TO SUPPORT BRACKET ( ITEM 6 - 2640700)

WITH (2)#10-24 SELF-TAPPING SCREWS (ITEM 12

F32 - NOT SHOWN) PROVIDED.

MARK HOLE LOCATIONS AND MOUNT

SUPPORT BRACKET (ITEM 6 - 2640700) TO RANGE

BACK WITH (2)#10-16 TEKS SELF-DRILL/TAP

SCREWS (ITEM 11 - F67 - NOT SHOWN) PROVIDED.

13

9

3

14

REGULATOR - 4.5" w.c. NATURAL GAS

OR 10.0" w.c. PROPANE GAS

(SUPPLIED WITH RANGE)

1

2

4

2

10

7

1" NPT GAS SUPPLY

CONNECTION

ITEM DESCRIPTION QUANTITY 36”

4.5” W.C 3/4”NPT, Regulator Natural Gas, supplied with Range 1

3/4” ISO 7-1, Regulator Natural Gas, supplied with Range 1

1

10” W.C 3/4”NPT, Regulator Propane Gas, supplied with Range 1

3/4” ISO 7-1, Regulator Propane Gas, supplied with Range 1

2 Nipple, 3/4” NPT x 1/2” (one supplied with range) 3

3 Elbow, 90deg, 3/4” NPT (one supplied with range) 2

4 Union, 3/4” NPT 2

5 3/4”CC x 3/4” NPT Straight Fitting 2

6 Bracket, Pipe Support 1

7 Clamp, Pipe Support Bracket 1

8 Reducing Elbow, 90deg, 3/4” NPT x 1/2” NPT 1

9 Nipple, 3/4” NPT x 6.5” 1

10 Reducing Tee, 3/4” NPT x 3/4” NPT x 1” 1

11 Screw, #10-16 x 1/2” Hex, Washer Head, Teks Self-Drill/Tap (not shown) 2

12 Screw, #10-24 x 1/2” Pan Head, Self-Tap, Type F (not shown) 2

6” W.C 3/4” NPT, Regulator Natural Gas, supplied with Salamander/Cheesemelter 1

13

10” W.C 3/4” NPT, Regulator Propane Gas, supplied with Salamander/Cheesemelter 1

14 Nipple, 3/4” NPT x 3.5” 1

15 Tubing 3/4” 1

TO INLET OF RANGE

MANIFOLD

6

Page 8

Part # 4523916 Rev 2 (05/05/14)

INSTALLATION Continued

Optional Interconnect Gas Kit #4531606 - Version 2, Connecting to a 48in or 60in Range

NOTE: CUT TUBING (ITEM 18 - 4531608) TO SIZE AS REQUIRED

TO SUIT SALAMANDER/CHEESEMELTER TOP OR REAR

MANIFOLD INLET CONNECTION

18

15

10

9

17

3

7

4

REGULATOR - 4.5"w.c.

NATURAL GAS OR 10.0"w.c.

PROPANE GAS (SUPPLIED

WITH RANGE)

4

8

4

11

TO INLET OF SALAMANDER/

CHEESEMELTER MANIFOLD

FOR LEFT-MOUNTED SALAMANDER/CHEESEMELTER

SUBSTITUTE COMPONENTS SHOWN FOR ITEM 17 CIRCLED IN ADJACENT VIEW

TO INTER-CONNECT TUBING ( ITEM 18 - 4531608)

17

10

6

MARK HOLE LOCATIONS AND MOUNT

SUPPORT BRACKET (ITEM 9 - 4531602 ) TO RANGE

BACK WITH (2) #10-16 TEKS SELF-DRILL/TAP

SCREWS (ITEM 14 - F67 - NOT SHOWN) PROVIDED.

ATTACH SUPPORT CLAMP (ITEM 10 - 2640800)

TO SUPPORT BRACKET (ITEM 9 - 4531602)

WITH (2) #10-24 SELF-TAPPING SCREWS (ITEM 1

F32 - NOT SHOWN) PROVIDED

9

12

TO OUTLET OF SALAMANDER/

CHEESEMELTER REGULATOR

16

13

ATTACH SUPPORT CLAMP (ITEM 10 - 2640800)

TO SUPPORT BRACKET (ITEM 9 - 4531602)

WITH (2) #10-24 SELF-TAPPING SCREWS (ITEM 1

F32 - NOT SHOWN) PROVIDED

MARK HOLE LOCATIONS AND MOUNT

SUPPORT BRACKET (ITEM 9 - 4531602) TO

BACK WITH (2) #10-16 TEKS SELF-DRILL/TAP

SCREWS (ITEM 14 - F67 - NOT SHOWN) PROVIDED.

17

6

5

6

REGULATOR - 6.0"w.c.

NATURAL GAS OR 10.0"w.c.

PROPANE GAS (SUPPLIED

WITH SALAMANDER/CHEESEMELTER)

SUPPLIED WITH

RANGE

SUPPLIED WITH

RANGE

2

TO INLET OF RANGE

MANIFOLD

1" NPT GAS SUPPLY

CONNECTION

ITEM DESCRIPTION

QUANTITY

48” / 60”

1 Screw, #10-24 x 1/2” Pan Head, Self-Tap, Type F (not shown) 4

4.5” W.C 1”NPT, Regulator Natural Gas, supplied with Range 1

1” ISO 7-1, Regulator Natural Gas, supplied with Range 1

2

10” W.C 1”NPT, Regulator Propane Gas, supplied with Range 1

1” ISO 7-1, Regulator Propane Gas, supplied with Range 1

6” W.C 3/4” NPT, Regulator Natural Gas, supplied with Salamander/Cheesemelter 1

3

10” W.C 3/4” NPT, Regulator Propane Gas, supplied with Salamander/Cheesemelter 1

4 Nipple, 1” NPT x 2” (one supplied with range) 3

5 Nipple, 3/4” NPT x 6.5” 1

6 Elbow, 90deg, 3/4” NPT 3

7 Elbow, 90deg, 1” NPT (supplied with range) 1

8 Union, 1” NPT 1

9 Bracket, Pipe Support 48/60 2

10 Clamp, Pipe Support Bracket 2

11 Reducing Tee, 1” NPT x 1” NPT x 3/4” 1

12 Nipple, 3/4” NPT x 22.75” 1

13 Nipple, 3/4” NPT x 2” 1

14 Screw, #10-16 x 1/2” Hex, Washer Head, Teks Self-Drill/Tap (not shown) 4

15 Nipple, 3/4” NPT x 3.5” 1

16 Reducing Elbow, 90deg, 3/4” NPT x 1/2” NPT 1

17 3/4”CC x 3/4” NPT Straight Fitting 2

18 Tubing 3/4” 1

Part # 4523916 Rev 2 (05/05/14) Page 9

INSTALLATION Continued

LIFTING TECHNIQUES

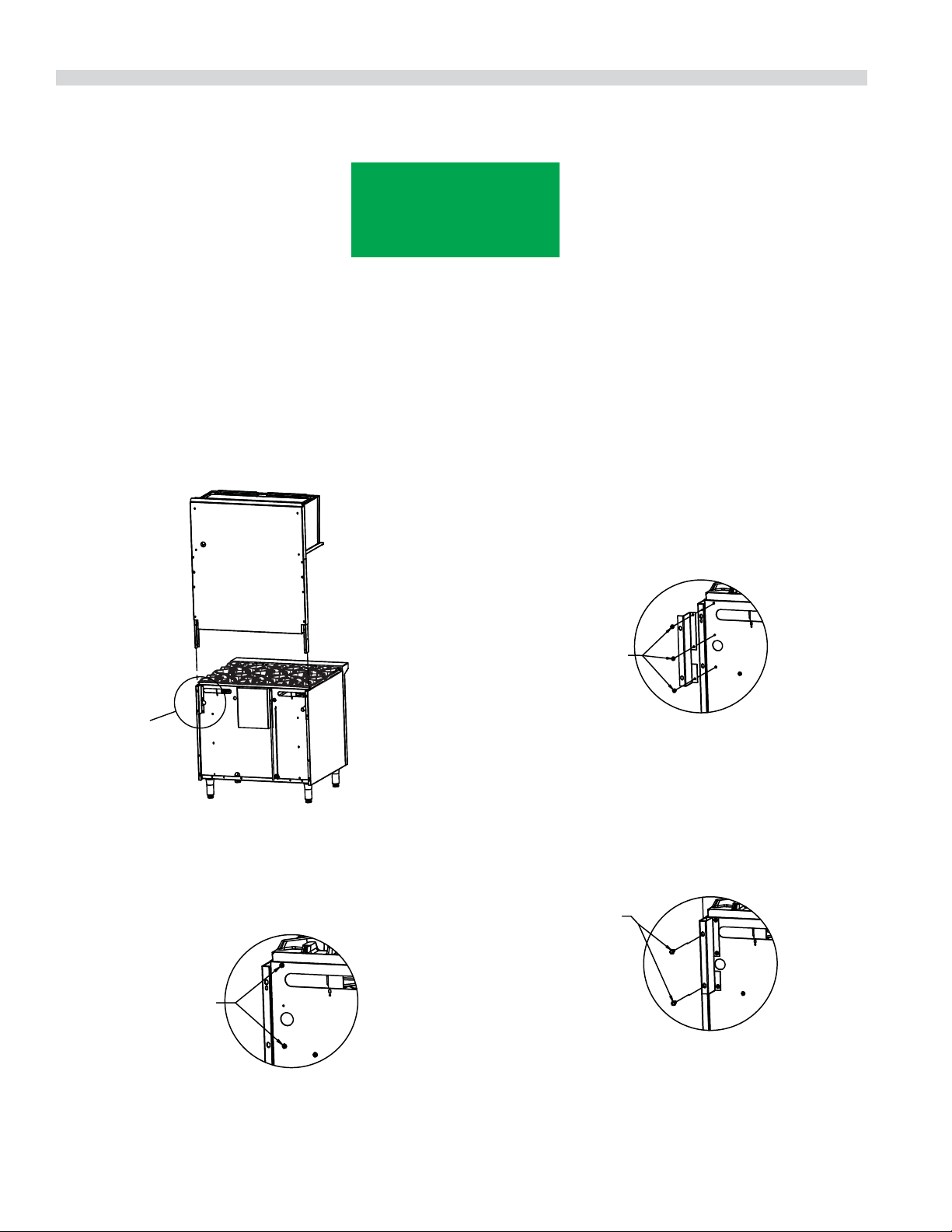

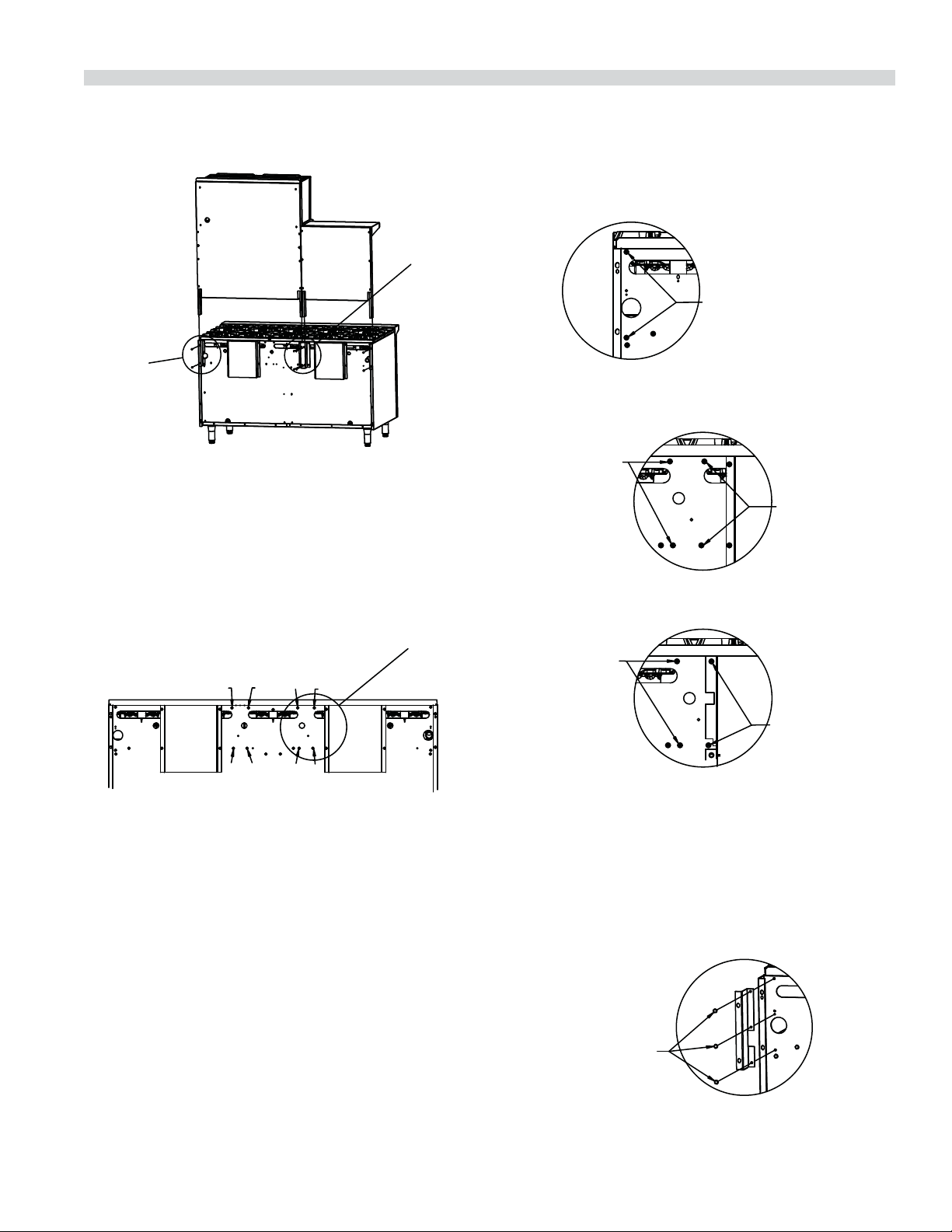

Installation Of A Salamander To A Range

NOTE: The back of the range must be easily accessible.

Model GIR – ” Ranges

SAFETY

FIRST

USE PROPER

2. Install the left and right support brackets (part # 4523226

and 4523227) by re-inserting the 2 screws removed in

step 1 and one additional screw (on both sides of the

range).

DETAIL

I

36" RANGE

Figure 1 – With area detail de ned for 36 inch range.

1. Remove screws from back of oven (on both sides of

range) as shown:

REMOVE

2 SCREWS

(BOTH SIDES)

DETAIL I

INSERTED

SCREWS

DETAIL I

3. Slide the salamander down into the support brackets

installed in step 2, see gure 1.

4. Once the salamander is in place, fasten it to the unit on

both sides of the range with the provided #14B x 5/8 hex

washer head tapping screws.

PROVIDED

#14B x 5/8 HEX

WASHER HEAD

TAPPING SCREWS

DETAIL I

Page 10

Part # 4523916 Rev 2 (05/05/14)

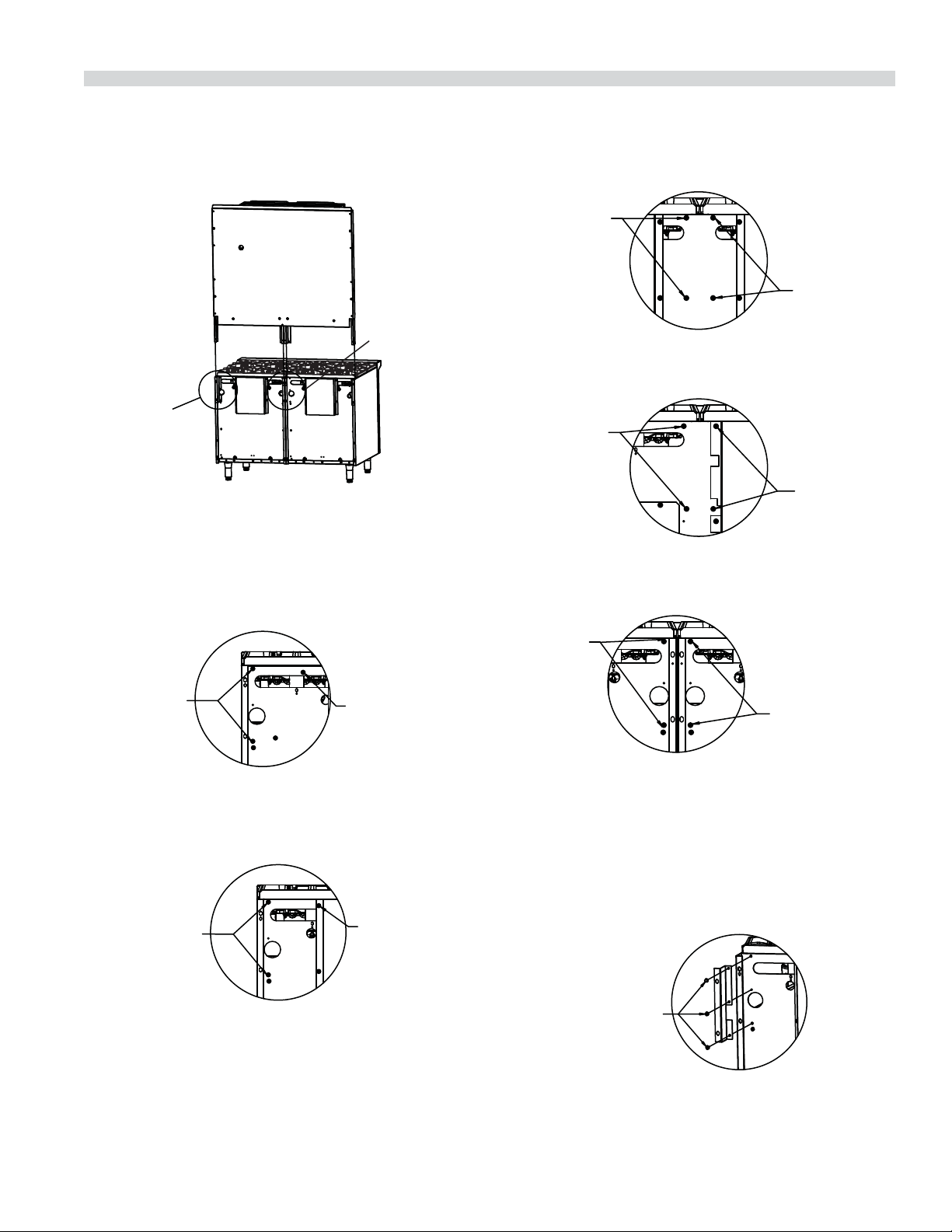

INSTALLATION Continued

Model GIR – ” Ranges

DETAIL

II

DETAIL

I

48" RANGE

Figure 2 – With area detail de ned for 48 inch ranges.

1. Remove screws (a total of 10) from back of oven on both

sides of the range (detail I) and center (detail II) as shown

for each range model:

REMOVE

2 SCREWS

WITH STANDARD OVEN AND STORAGE

REMOVE

2 SCREWS

(IF REQUIRED)

WITH CONVECTION O

REMOVE

2 SCREWS

REMOVE

2 SCREWS

DETAIL II 48" RANGES

REMOVE

2 SCREWS

IF REQUIRED

DETAIL II 48" RANGES

VEN AND STORAGE

REMOVE

2 SCREWS

BOTH SIDES

DETAIL I

48" RANGES WITH

STANDARD OR CONVECTION OVENS

AND STORAGE

REMOVE

2 SCREWS

(BOTH SIDES)

DETAIL I

FOR 48" RANGES

WITH 2 SPACE SAVER OVENS

REMOVE

1 SCREW

(BOTH SIDES)

REMOVE

1 SCREW

(BOTH SIDES)

REMOVE

2 SCREWS

DETAIL II

FOR 48" RANGES

WITH 2 SPACE SAVER OVENS

2. For all 48” ranges install the left and right support

brackets (part # 4523226 and 4523227) by re-inserting

the 2 screws removed in step 1 and one additional screw

(on both sides of the range).

INSERTED

SCREWS

DETAIL I

ALL 48" RANGES

Part # 4523916 Rev 2 (05/05/14)

Page 11

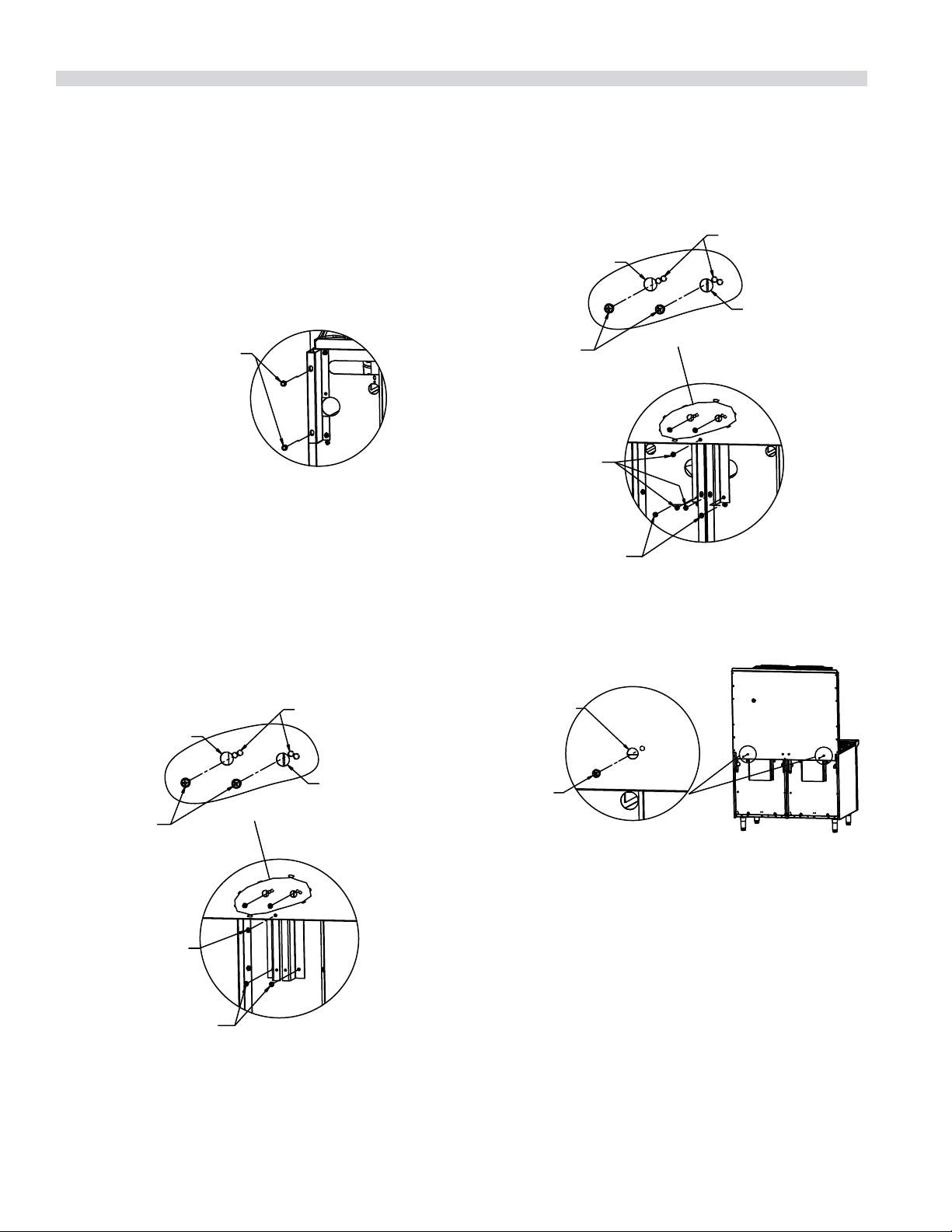

INSTALLATION Continued

3. Slide the salamander down into the support brackets

installed in step 2, see gure 2. NOTE: On ranges with

space saver ovens, the center post must slide into the

center channels built into the back of the unit.

4. Once the salamander is in place, fasten it to the unit on

both sides of the range with the provided #14B x 5/8 hex

washer head tapping screws.

PROVIDED

#14B x 5/8 HEX

WASHER HEAD

TAPPING SCREWS

DETAIL I

ALL 48" RANGES

5. For center support, (detail II) re-insert screws removed in

step 1 or provided sheet metal screws as shown in detail

II and III, inserting screws for detail III through clearance

in back panel.

FOR 48" RANGES WITH

STANDARD OR CONVECTION OVENS

AND STORAGE

INNER

CLEARANCE

SCREWS

REMOVED

IN STEP 1

HOLE

DETAIL III

HOLES

CLEARANCE

HOLE

FOR 48" RANGES WITH

2 SPACE SAVER OVENS

INNER

CLEARANCE

HOLE

SCREWS

REMOVED

IN STEP 1

3 PROVIDED

SHEET METAL

SCREWS

2 SCREWS

REMOVED

IN STEP 1

6. Re-insert screws removed in step 1 though clearance hole

in back panel as shown:

CLEARANCE

HOLE

REMOVED

SCREW

DETAIL IV

ALL 48" RANGES

DETAIL III

HOLES

CLEARANCE

HOLE

DETAIL II

PROVIDED

SHEET METAL

SCREW

2 SCREWS

REMOVED

IN STEP 1

DETAIL II

Part # 4523916 Rev 2 (05/05/14)Page 12

INSTALLATION Continued

Model GIR – ” Ranges

DETAIL

I

1. Remove screws from back of oven on both sides of the

range (detail I) and center (detail II) as shown:

DETAIL

II

REMOVE

2 SCREWS

FROM BOTH SIDES

DETAIL I

ALL 60" MODELS

60" RANGE

Figure 3 – With area detail de ned for 60 inch range.

NOTE: Instructions are for mounting the salamander on the

right side, for mounting on the left side follow the same

directions except use references 1, 2, 3, & 4 (to the left of

detail II see below) in lieu of A, B, C, D for detail II in the

following steps.

DETAIL

II

1 2

34

A B

C D

REMOVE

2 SCREWS

IF REQUIRED

REMOVE

2 SCREWS

IF REQUIRED

WITH CONVECTION OVEN

2. Install the left and right support brackets (part # 4523226

and 4523227) using the 2 screws removed in step 1

(detail I) and one additional screw on both sides of the

range, and center support bracket (part # 4523282) with

the four screws removed in step 1 (detail II).

A

C D

DETAIL II

FOR 60" RANGES

WITH STANDARD OVEN

ABB

C D

DETAIL II

FOR 60" RANGES

REMOVE

2 SCREWS

IF REQUIRED

REMOVE

2 SCREWS

IF REQUIRED

Part # 4523916 Rev 2 (05/05/14)

INSERTED

SCREWS

DETAIL I

ALL 60" MODELS

Page 13

INSTALLATION Continued

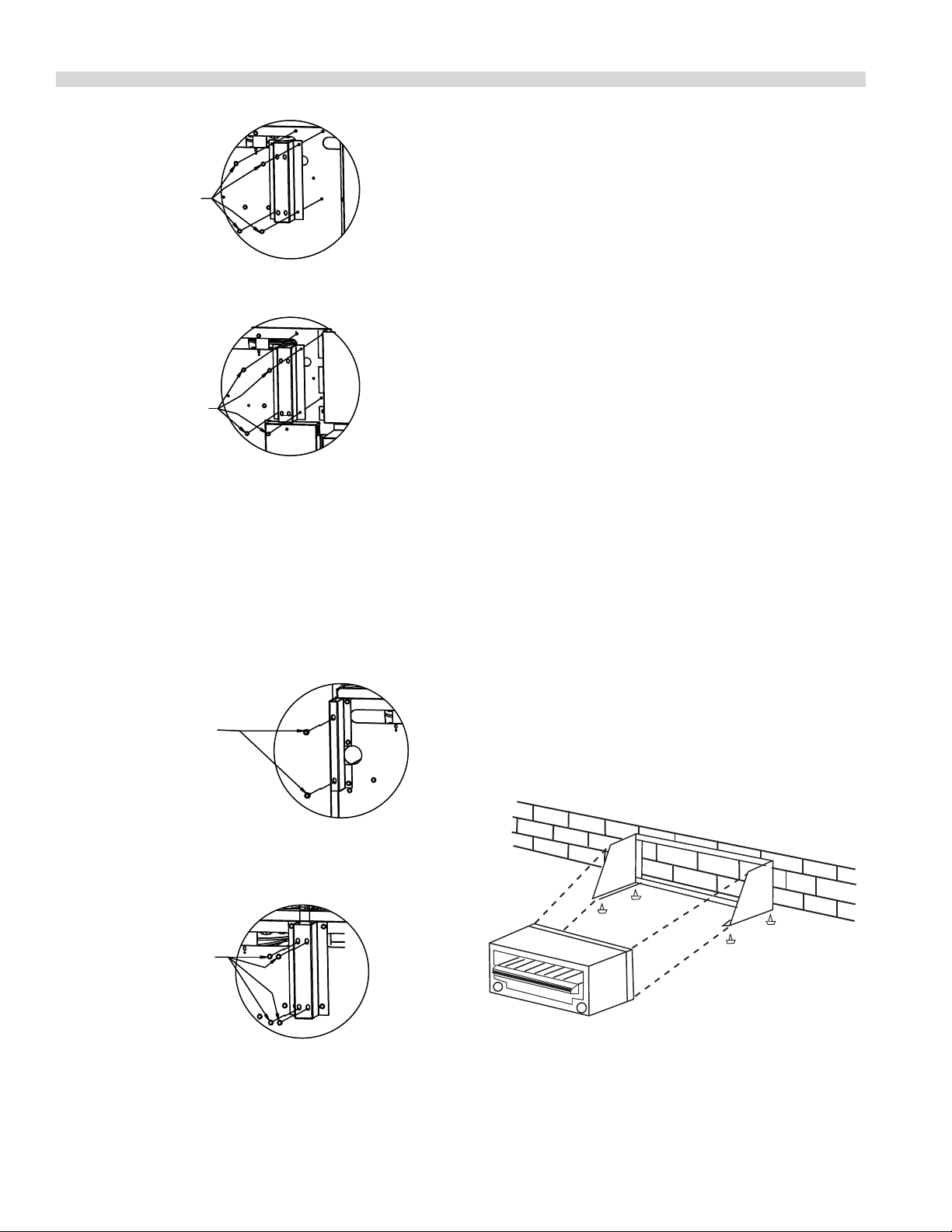

Wall Or Counter Mounted Salamanders

Model GIRC

4 INSERTED

SCREWS

DETAIL II

FOR 60" RANGES

WITH STANDARD OVEN

4 INSERTED

SCREWS

DETAIL II

FOR 60" RANGES

WITH CONVECTION OVEN

3. Slide the salamander down into the support brackets

installed in step 2, see gure 3.

4. Once the salamander is in place, fasten it to the unit on

both sides of the range with the provided #14B x 5/8 hex

washer head tapping screws (detail I) and the center to the

support bracket using 4 of the provided screws (detail II).

PROVIDED

#14B x 5/8 HEX

WASHER HEAD

TAPPING SCREWS

1. Clearance from combustible construction must be six

inches (6”, 152mm) minimum at the rear and six inches

(6”, 152mm) minimum at both sides.

The appliance shall be located with respect to building

construction and other equipment so as to permit access

to the appliance. Such access and clearance may be

necessary for service and cleaning.

2. Counter models are furnished with 4” (102mm) legs.

Level the unit with a carpenter’s level and make minor

adjustments with the threaded leg feet. Ensure that the

counter top can support the weight of the appliance

prior to installation and is comprised of non-combustible

material.

3. Provisions for gas connections, top or rear, should be

taken into consideration at time of installation.

4. If the unit is to be mounted on a non-combustible wall

contact the local authorities for local codes.

5. Position, level, and mark location of the assembled wall

mount kit.

6. Drill wall (locating studs if necessary) to accept suitable

fastening devices.

7. Drill the angle iron bars of the wall mounting kit to match

those drilled in the wall.

8. Install wall mounting kit to wall.

9. Install and secure broiler with bolts supplied.

Page 14

DETAIL I

ALL 60" RANGES

4 PROVIDED

SCREWS

DETAIL II

ALL 60" RANGES

Part # 4523916 Rev 2 (05/05/14)

INSTALLATION Continued

Ventilation and Air Supply

Proper ventilation is highly important for good operation.

The ideal method of ventilation for a Salamander Broiler is

the use of a properly designed canopy hood which should

extend six inches (6”, 152mm) beyond all sides of the

appliance and six (6) feet six (6) inches (1981mm)from the

oor.

A strong exhaust fan will create a vacuum in the room. For

an exhaust system to work properly, replacement air must

enter the room in which the vent is located. The amount

of air which is exhausted must equal the amount entering,

(make-up air).

All gas burners and pilots need su cient air to operate and

large objects should not be placed in front or on top of the

broiler which would obstruct the air ow through the front of

the broiler.

The following notes are intended to give general guidance.

For detailed recommendations, refer to the applicable

code(s) in the country of destination.

NOTE 1: The room containing the appliance is required to

have a permanent air vent. The minimum e ective area of

the vent is related to the maximum rated heat input of the

appliance and shall be 4.5 cm² per kW (2.04 X 10-4 in² per

BTU/H) in excess of 7 kW. (23,900 BTU/H).

NOTE 2: Air vents should be of such a size to compensate for

the e ects of any extract fan in the premises.

FOR YOUR SAFETY never place any type of object on top of

the salamander broiler. The top of the broiler will exceed

1000° F (538° C). It could cause severe burns and/or re

and also will obstruct ventilation.

Clearances

Clearance must be 6” (152mm) at the sides and rear from

combustible material. A clearance of 0.0” to noncombustible

construction at the sides & rear is acceptable, for the

Salamander.

This appliance is for use on non-combustible oors/counters

only.

OPERATION

Pilot Lighting Instructions

1. The in-line service shut-o valve should be in the “ON”

position.

2. With a lighted taper you can now light the pilots which

are located at the rear of the main burner.

3. The Pilot ame should be approximately 7/8” long for

proper ignition of the burners. The pilot adjustment

valve can be located by sliding the drip tray forward.

Adjustment valves are located on the manifold pipe

which runs horizontally across the back of the unit,

behind the drip tray. One valve is at the left rear and the

other at the right rear.

To adjust the pilot light, turn the brass screw counter-

clock-wise to increase the pilot ame, and clock-wise to

decrease the pilot ame.

NOTE: No more than 7/8” pilot ame length should be

required. Too high a setting will cause the ame to lift o or

will create excessive carbon deposits. Do not adjust the pilot

ame lower than 7/8” long because this can cause delayed

ignition at the burner. The delayed ignition could cause the

burner tiles to crack; in that case the burner would have to be

replaced.

Main Burner Operation

Turn main burner knob to the “MAX” position and

immediately check ignition.

CAUTION Should ignition fail after ve seconds, turn valve

o and wait ve minutes before trying again. Pilot gas is

not interrupted automatically. It is the responsibility of the

operator to check the ignition of burners immediately after

the burner valve has been turned on.

When ignition has been accomplished, a blue ame will

cover the surface of the ceramics for 10-15 seconds. The haze

will disappear and the burner rod will glow red. After the

burners have operated for several minutes turn the valve to

“MIN.” The burner rods will no longer glow red and the ame

travels back and forth on the face of the burner ceramics.

Burn o Period

Many parts used in the manufacturing of commercial

equipment have a thin, protective coating of machine oil.

This oil should be burned o before the equipment is used

for food preparation.

After all start-up and safety checks have been completed,

turn burner valve to the “MAX” position. Smoke (a bluish

haze) will be produced. This process can take several hours

and can be completed over a few days.

Part # 4523916 Rev 2 (05/05/14) Page 15

OPERATION Continued

Energy Conservation

Do not waste energy by leaving controls at high temperature

settings during idle periods. Lower settings will keep broiler

warm and ready for next use period. Reset burner valve knob

as required for heavy load periods.

Shut Down Instructions

Turn main burner valve knobs to the “OFF” position. If the

unit is to be shut down for an extended period of time, close

the manual in-line service valve (manual in-line service valve

is not factory supplied).

FOR YOUR SAFETY never place any type of object on top of

the salamander broiler. The top of the broiler will exceed

1000° F. It could cause severe burns and/or re and also

will obstruct ventilation.

Main Burner Adjustments

All salamanders are provided with xed burner ori ces to

provide 20,000 BTU/HR at the “MAX” setting on Natural

Gas supplied at 6.0” WC (15 Mbar) pressure or propane gas

supplied at 10.0” WC (25 Mbars) pressure.

The “MIN” setting is adjustable and should be set as follows:

1. Set the burner valve knob to “MIN” setting and remove

the knob.

2. Insert a thin bladed screwdriver into the valve stem

to engage the slot inside the stem. Turn clockwise to

decrease the rate and counter-clockwise to increase.

Proper adjustment is attained at the point where the burner

rods no longer glow and the ame travels back and forth on

the face of the ceramics.

This adjustment has been factory pre-set, however, with

changing pressures this adjustment and pilot adjustment

may need to be re-done after installation.

This is not considered a manufacturing defect and is not

warrantable.

NOTE : Burner adjustments should only be done by an

authorized service technician.

MAINTENANCE AND CLEANING

WARNING if gas odors are detected, the gas supply must

be turned “OFF” at the main shut-o valve and the local gas

company or authorized service agency contacted for service.

A program of proper cleaning techniques will aid in

continued trouble free operation of this or any quality

equipment.

Daily

The broiling rack should be wiped daily while still warm,

using a heavy cloth or other grease absorbing material to

remove grease and burnt food before they burn into the

grid. Remove burnt materials, such as carbonized grease

or food, with a sti wire brush. DO NOT USE ANY TYPE OF

STEEL WOOL. Small particles may be left on the rack surface

and get into food products. The rack should be washed

thoroughly using a wire brush and a hot, mild detergent or

soap solution. Rinse with clear, warm water.

Monthly

Lubricate valves and bearings as required. Due to the

usual location of the broiler that is mounted above a range

with open tops, the heat from the open top will cause the

lubrication grease inside the valves to dry out. When you

notice that the valve is becoming harder to turn it is then

time to have them greased. We suggest an Authorized

Service Agent who is familiar with the appliance and working

with natural and propane gas, to perform this type of work.

Exterior Cleaning

Establish a regular schedule. Any spills should be wiped o

immediately.

1. Wipe exposed, cleanable surface when cool with a mild

detergent and hot water. Stubborn residue spots may be

removed with a light weight non-metallic scouring pad.

Dry thoroughly with a clean cloth.

2. Stainless steel should be cleaned using a mild detergent,

a soft cloth and hot water. If it is necessary to use a nonmetallic scouring pad, always rub in the direction of the

grain in the metal to prevent scratching. Use a water

based stainless steel cleaner (such as Drackett Twinkle), if

you want a high shine.

Part # 4523916 Rev 2 (05/05/14)Page 16

Loading...

Loading...