Garland GI-MO/DU 7000, GI-MO/DU 14000, GI-MO/DU 10000, GI-MO/QU 14000, GI-MO/QU 20000 Installation, Operation And Maintenance Manual

...

Induction Designer Series

Module-Line Built-In Models

Installation, Operation and Maintenance Manual

models

GI-MO/DU 7000

GI-MO/DU 10000

GI-MO/DU 14000

GI-MO/QU 14000

GI-MO/QU 20000

GI-MO/QU 21000

GI-MO/QU 24000

GI-MO/QU 28000

Original Instructions

Part Number 4532415 Rev 5 12/15

READ THIS MANUAL

Warning

n

Read this manual thoroughly before installing,

operating, or performing maintenance on the

equipment. Failure to follow instructions in this manual

can cause property damage, injury or death.

This manual must always be available for reference at

the place of operation.

This manual is intended for kitchen consultants, cabinet

designers, fabricators, installers, owners and operators of

our appliances.

Owners, consultants, fabricators and designers:

In order for the induction appliance to function safely

and normally, you must read and understand all

specific and critical requirements when designing the

location and the counter for the appliance.

Installers, operators and staff:

For your safety and safety of the others, you must

observe all safety instructions during installation,

operation and maintenance of the equipment.

Should you require technical assistance, call your factory

authorized service agent or distributor. Always have your

model and serial number available when you call.

Your Factory Authorized Service Agent

ABOUT THIS MANUAL

Throughout this manual, the induction appliance model

indicated on the cover page is referred to as appliance,

induction appliance or equipment.

A period (.) is used in this manual as the decimal separator.

Original measurements are in metrics. Measurements in

imperial are provided for reference.

Not ALL models, options and accessories are available in all

geographical regions. Please consult your local equipment

supplier for the availability of the specific products in your

region.

INSPECT THE SHIPMENT

Thoroughly inspect the equipment upon delivery.

Immediately report to the delivery carrier, any damage that

occurred during transportation and request for a written

inspection report from a claim inspector.

Your shipment might include small packages of fasteners

or silicone strips for installation. Keep all packages.

KEEP THE PACKING SLIP

The packing slip attached to the shipment contains

detailed information on all components. Keep the packing

slip for reference.

Service Agent Telephone Number

Your Local Equipment Supplier

Supplier Telephone Number

Model Number

Serial Number

Date of Installation

Safety Notices

Safety Notices

DEFINITIONS

DANGER

Indicates a hazardous situation that, if not avoided, will

result in death or serious injury. This applies to the most

extreme situations.

Warning

n

Indicates a hazardous situation that, if not avoided,

could result in death or serious injury.

Caution

,

Indicates a hazardous situation that, if not avoided,

could result in minor or moderate injury.

Notice

Indicates information considered important, and is used

to address practices not related to physical injury. For

example, messages relating to property damage.

NOTE: Indicates useful, extra information about the

procedure you are performing.

Reference: ANZI Z535.6-2011

SAFETY SYMBOLS AND WARNINGS ON THE APPLIANCE

This symbol alerts you to a hazardous situation

that WILL or COULD cause serious bodily harm

or death. Be alert and implement relevant safety

precautions.

DANGER - HIGH VOLTAGE

This dangerous voltage warning symbol

indicates a risk of electric shock and hazards

from dangerous voltage.

Electromagnetic Field

Warning

RISK OF FIRE OR ELECTRIC SHOCK! DO NOT OPEN!

To reduce the risk of fire or electric shock, do not remove or

open cover. No user serviceable parts inside.

Refer servicing to qualified personnel.

CAUTION ATTENTION

DISCONNECT FROM SUPPLY CIRCUIT BEFORE OPENING

DISCLAIMERS

DANGER

Disregarding any safety instructions may cause harm to

people, the surroundings, and the equipment. Garland

is not responsible for any damages or personal injury

caused by failure to observe any safety requirements.

Risks involved when disregarding safety precautions

include, but not limiting to:

• Death or injury caused by electric shock.

• Burn injury caused by contacting overheated cooking

surface, cookware, or oil and grease.

• Damage to the equipment caused by using

unsuitable cookware.

DANGER

Do not install or operate equipment and/or accessories

that have been misused, abused, neglected, damaged,

or altered from that of original manufactured

specifications.

DANGER

Contact the manufacturer if you intend to make any

changes on the equipment. For safety reasons, always

use genuine parts and accessories approved by the

manufacturer or authorized representative. Refer to the

warranty documents for your equipment.

DANGER

Owners and operators are cautioned that maintenance

and repairs must be performed by an authorized service

agent using only genuine replacement parts. The

manufacturer will have no obligation with respect to any

product that has been improperly installed, adjusted,

operated or not maintained in accordance with national

and local codes and/or installation instructions provided

with the product or any product that has its serial

number defaced, obliterated or removed, and/or which

has been modified or repaired using unauthorized parts

or by unauthorized service agents.

DANGER

Improper installation, adjustment, alteration, service,

or maintenance of this appliance or installation of

a damaged appliance can result in DEATH, INJURY,

EQUIPMENT DAMAGE, and void the warranty.

DANGER

All utility connections and fixtures must be maintained

in accordance with local and national codes.

Part Number 4532415 Rev 5 12/15 3

Safety Notices

Warning

n

Do not store or use gasoline or other flammable vapors

or liquids in the vicinity of this or any other appliance.

Never use flammable oil soaked cloths or combustible

cleaning solutions for cleaning.

Warning

n

This appliance is not intended for use by persons

(including children) with reduced physical, sensory or

mental capabilities, or lack of experience and knowledge,

unless they have been given supervision concerning

use of the appliance by a person responsible for their

safety. Do not allow children to play with this appliance.

Warning

n

This product contains chemicals known to the State

of California to cause cancer and/or birth defects or

other reproductive harm. Operation, installation, and

servicing of this product could expose you to airborne

particles of glass-wool or ceramic fibers, crystalline

silica, and/or carbon monoxide. Inhalation of airborne

particles of glass-wool or ceramic fibers is known to the

State of California to cause cancer. Inhalation of carbon

monoxide is known to the State of California to cause

birth defects or other reproductive harm.

your area.

CORRECT DISPOSAL OF THIS PRODUCT

This marking shown on the product

indicates that the product should not be

disposed as household waste or regular

commercial waste. Instead it shall be

handed over to the applicable collection

point for the recycling of electrical and electronic

equipment. By ensuring this product is disposed correctly,

you will help prevent potential harm to the environment

or human health, which could otherwise be caused by

inappropriate waste handling of this product.

For more detailed information regarding recycling of the

product, please contact your local city office or your waste

disposal service.

DANGER

Induction appliances, sent for disposal, can be brought

back into operation and their use must be avoided.

NOTE: The appliance is built with common electrical,

electromechanical and electronic parts. No batteries are

used.

NOTE: The owner and operator are responsible for the

proper and safe disposal of the appliance.

Warning

n

Authorized Service Representatives are obligated to

follow industry standard safety procedures, including,

but not limited to, local/national regulations for

disconnection / lock out / tag out procedures for all

utilities including electric, gas, water and steam.

Notice

This appliance is not approved or authorized for home

or residential use, but is intended for commercial

applications only. The manufacturer and/or authorized

representative will not provide service, warranty,

maintenance or support of any kind other than in

commercial applications.

Notice

Routine adjustments and maintenance procedures

outlined in this manual are not covered by the warranty.

NOTE: Proper installation, care and maintenance are

essential for maximum performance and trouble-free

operation of your equipment. Visit our website

www.mtwkitchencare.com for manual updates,

translations, or contact information for service agents in

4 Part Number 4532415 Rev 5 12/15

Safety Notices

Table of Contents

Section 1

General Information

Section 2

Installation

Table of Contents

Definitions.................................................................................................................................................3

Safety symbols and Warnings on the Appliance ........................................................................3

Disclaimers ................................................................................................................................................3

Correct Disposal of This Product .......................................................................................................4

Description of Product .......................................................................................................7

Application .........................................................................................................................7

Compliances .......................................................................................................................7

Components and Features ................................................................................................8

Serial Plate Location ..........................................................................................................9

Model Number ....................................................................................................................9

Marketing Identifier ........................................................................................................... 9

Serial Number ................................................................................................................... 10

Accessories ........................................................................................................................10

Important Installation Safety and Electrical Requirements ................................................. 11

Installation safety—Disclaimer ...................................................................................................... 12

Installation Safety—Clearance and Ventilation ........................................................................ 12

Installation Safety—Electrical ......................................................................................................... 12

Personal Protection ............................................................................................................................13

Exploded View of a Typical Installation ..........................................................................14

Planning for Installation ..................................................................................................15

Cabinet Requirements .....................................................................................................15

Typical Applications .........................................................................................................17

Specifications ...................................................................................................................21

Component charts and connection diagrams .......................................................................... 21

Dimensions: induction generator IN/MO 7000, IN/MO 10000, IN/MO 7000FL ............. 21

Dimensions: induction generator IN/MO 14000FL ................................................................. 22

Dimensions: Control Unit ................................................................................................................. 23

Dimensions: Mounting Frames ...................................................................................................... 24

Cut-Out Dimensions: Counter-top ................................................................................................ 27

Cut-out Dimensions: Holes and Studs for Control / Operation unit ................................. 27

Installation Clearance ........................................................................................................................ 28

Installation distance between components .............................................................................. 28

Electrical Specifications..................................................................................................................... 29

Electrical Cables ................................................................................................................................... 30

Operating Conditions ........................................................................................................................ 30

Orientation of Coil Carrier, Glass and Frame for Installation ................................................31

Installation Instructions ..................................................................................................32

Installing the Induction Generator ............................................................................................... 32

Installing the Control Unit ................................................................................................................32

Installing the Operation Unit (Power Switch) ...........................................................................32

Installing The Mounting Frame, Glass and Coil Carrier .......................................................... 33

Electrical Installation .......................................................................................................................... 37

Function Test .................................................................................................................... 38

5

Part Number 4532415 Rev 5 12/15

Section 3

Operation

Section 4

Maintenance

Table of Contents (continued)

Installation Appendix B: Power Supply Cable Wiring Diagrams ..................................44

Wiring Diagram: Module-Line and Built-In Dual Cook-Top, 208V, 400V. ......................... 44

Wiring Diagram: MO/QU 14kW/20kW, Round coils. 208V, 400V.........................................45

Wiring Diagram: MO/QU, 21kW/24kW, Flat+Round coils. 208V, 400V. ............................46

Wiring Diagram: MO/QU, 28kW, Flat coils. 208V, 400V. ..........................................................47

Installation Appendix A: Component Charts and Connection Diagrams ....................39

Chart 1, Module-Line Round Coil Dual Models ........................................................................ 39

Chart 2, Module-Line Round Coil Quad Models ...................................................................... 40

Chart 3, Module-Line Full Coil Dual Models .............................................................................. 41

Chart 4, Module-Line FULL Coil Quad Models .......................................................................... 42

Chart 5, Module-Line Round+FULL Coil Quad Models ......................................................... 43

Operation Safety—Disclaimer ........................................................................................................ 48

Operation Safety—Personal Protection ...................................................................................... 48

Important Rules—Operation and Maintenance ............................................................ 50

Types of Induction Coil In Your Equipment ....................................................................51

Proper Induction Cookware ............................................................................................51

Condition ...............................................................................................................................................51

Round bottom Wok pans.................................................................................................................. 51

Material ................................................................................................................................................... 52

BOIL TEST: Testing the Performance of Cookware ................................................................... 52

Size of Pan .............................................................................................................................................. 52

Placing Pan On A Cook Zone ...........................................................................................53

Power Control ...................................................................................................................55

Power Level Settings .......................................................................................................................... 55

Automatic Pan Detection, No Pan No Heat ....................................................................56

Indicator Lamp Signals ....................................................................................................56

When Appliance Is Idle.....................................................................................................56

Maintenance Safety—Disclaimer .................................................................................................. 57

Dangerous Electrical Voltage .......................................................................................................... 57

Maintenance Safety—Cleaning ..................................................................................................... 57

Personal Protection ............................................................................................................................58

Daily Cleaning and Maintenance ....................................................................................59

Glass Cleaning ...................................................................................................................................... 59

Stainless Steel case ............................................................................................................................. 59

Visual Inspection of Silicone Seal .................................................................................................. 59

Weekly Cleaning and Maintenance ................................................................................59

Air intake filters .................................................................................................................................... 59

Yearly Maintenance ..........................................................................................................59

Section 5

Troubleshooting

Dangerous Electrical Voltage .......................................................................................................... 60

Common Problems ...........................................................................................................60

Symptoms .........................................................................................................................60

Boil Test ............................................................................................................................. 60

Troubleshooting Without Error Code / Flash Code ........................................................61

Troubleshooting — Error Code / Flash Code ..................................................................61

Wearable Parts List ...........................................................................................................63

6 Part Number 4532415 Rev 5 12/15

Section 1

General Information

Description of Product

Built with a robust construction, our induction appliances

are compact and powerful with the revolutionary RTCS®

or RTCSmp® Technology (Realtime Temperature Control

System).

The RTCS®/RTCSmp® Technology monitors continuously in

realtime, the energy supply, temperature of the cook zone,

and the state of the components such as the induction coil.

This monitoring system ensures the most efficient energy

transfer, as well as maximizes safety:

• Safety functions such as Pan Detection and Boil Dry

Protection are therefore guaranteed.

• The appliance generates power only when a pan is in

contact with the cook zone surface.

• When a malfunction occurs, the integrated fault

diagnostic system reports the malfunction instantly.

The unique RTCSmp® Module-Line are engineered for

building the most flexible kitchen operation. The ModuleLine Family offers a wide selection of cooking surfaces: dual

or quad cook zones with round, full or a combination of

round and full induction coils. In addition, griddle, braising

pan, and wok cooking options are also available.

The components are compact and low profile. The

induction generator can be installed up to 3 meters or 10

feet away from the cooking surface or away from the high

heat area of the island suite. All power and communication

connections can be connected conveniently through plug

connections.

Application

The RTCS®/RTCSmp® induction appliances are designed to

be incorporated into a custom-built counter or an island

suite. See section 2 Installation.

You can use your appliance for many applications

throughout the day, such as cooking, warming up,

keeping warm, flambéing and roasting of food. All these

applications are possible because:

• Temperature control is instantaneous and precise.

Instant energy transmission from inverter coil to the

bottom of cookware, allows for fast startup time.

• High power is possible for braising application and

quick sauté.

• High power also means you can heat up a large

stockpot quickly (3.5kW coil or above).

• Cooking surface fitted with full coils: Several large or

small pans can be placed on one cook zone at the same

time. A small pot engages only 3.5kW power and a large

pot engages the full 7.0kW power.

• Cooking surface fitted with round coils: One pan is used

for each cook zone.

Compliances

• North American models:

ETL recognized* in compliance with UL 197, CSA C22.2

No.109, NSF-4. Complies with FCC part 18, ICES-001

*See section 2 Installation.

• CE models comply with the latest European Norms:

EN 60335-1, EN 60335-2-36, EN 62233 (EMC/EMV)

Part Number 4532415 Rev 5 12/15 7

General Information Section 1

Components and Features

1. Coil Carrier Sheet (Induction Coil and Sensor

Assemblies)

Multiple versions available:

round coil (RU) or full coil (FL) in single, dual, quad, or

combined RU+FL configurations.

1.2

1.1

1.4

1.3

1.1 Cable connectors for coil and sensor cables.

1.2 Induction coil and sensor assembly.

1.3 Full coil (FL): Rectangular in shape. Each cook-zone

consists of two coils. More than one pan can be placed

on a single cook zone at the same time.

1.4 Round coil (RU): Round coils have higher power

density. Each cook zone consists of one coil. Only one

pan can be placed on a single cook zone.

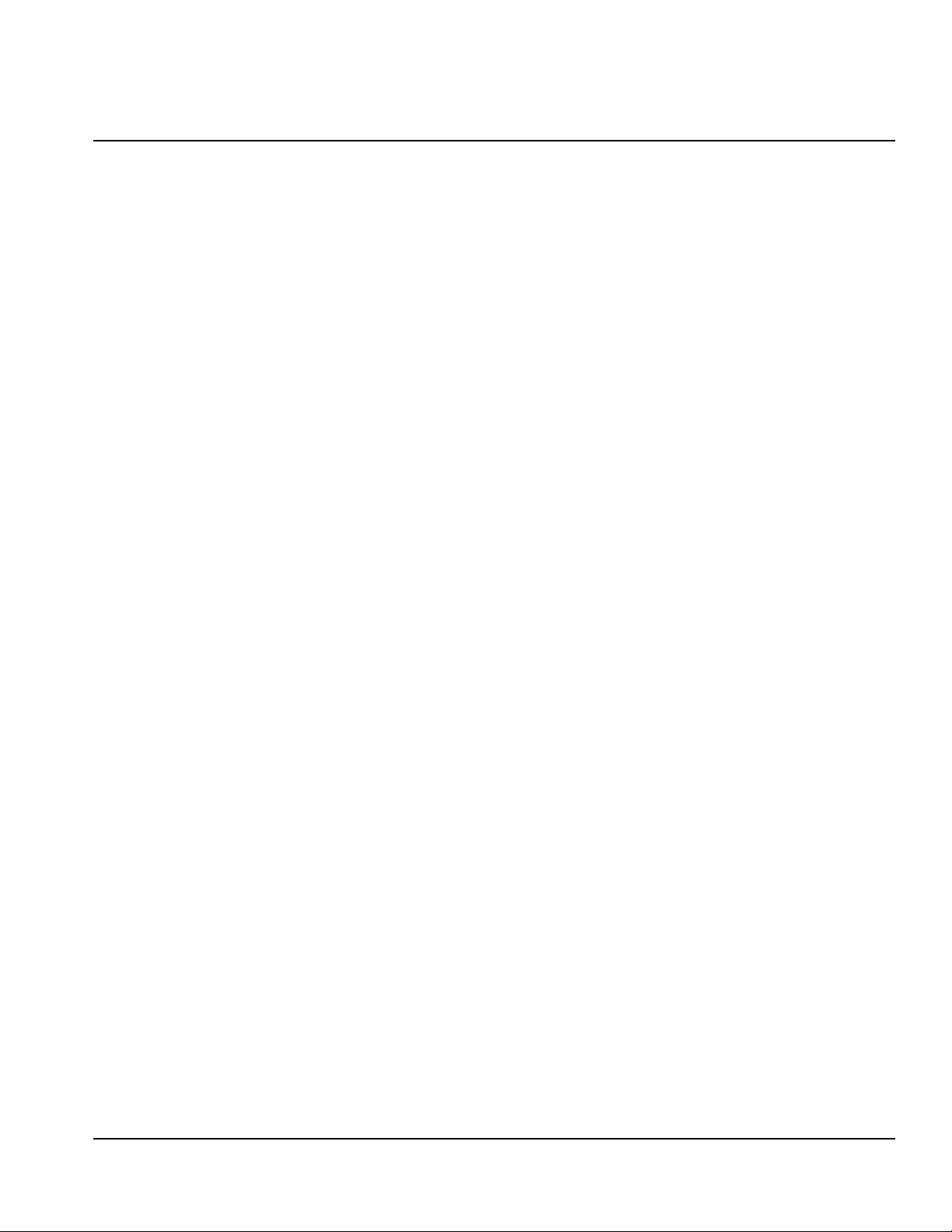

4. Operating Unit

4.3

4.14.2

4.1 Rotary power switch, allows for continuously variable

power adjustment. Dial is marked 0 to 12 power levels.

4.2 Indicator lamp

4.3 1-meter [39.4”] long cable, to connect to the Control

Unit.

5. Control unit

• Communication and diagnostic hub for the

induction equipment.

• Mounting brackets are provided.

• 2 versions available:

IN/MO7000/10000, IN/MO7000/14000

5.2

2. Ceran® Glass-Top

• 6mm thick. 5 sizes available:

• Dual: 360x360x6mm; 650x375x6mm;

720x360x6mm

• Quad: 650x650x6mm; 720x720x6mm

• Included: silicone gaskets (not shown) for

installation.

• Glass-top pattern matches the corresponding coil

version underneath: Round coil (2.1, below) or full

coil (2.2, below).

2.1 2.2

3. Installation Frame

• Installation frame is provided to mount both the

coil carrier sheet and glass-top.

• 5 sizes available.

5.1

5.1 Cable connectors.

5.2 Service interface, provides service technician a wireless

connection to diagnose problems.

6. Induction generator

• 4 versions available: IN/MO7000FL, IN/MO14000FL,

IN/MO7000, IN/MO10000

6.3

6.2

6.1

6.1 Cable connectors.

6.2 Fresh air intake.

6.3 Hot air exhaust vent. Refer to the dimensional drawing.

6.4 Power supply connection.

Power supply cable is NOT INCLUDED.

6.4

8 Part Number 4532415 Rev 5 12/15

Section 1 General Information

Serial Plate Location

7. Cable Kit

• Cable kit voltage versions: 208V or 400V

• Standard, 2.5-meter cable kit, includes:

• Coil Cable, 2.5-meter [98”]

• CAN/BUS RJ-45 Cable, 3-meter [118”]

• Sensor Cable, 1-meter [39”]

• Fan Cable is included where applicable.

• Options, 4-meter cable kit, includes:

• Coil Cable, 4-meter [157.5”]

• CAN/BUS RJ-45 Cable, 5-meter [197”]

• Sensor Cable, 1-meter [39”]

• Fan Cable is included where applicable.

• Option, 6-meter cable kit, includes:

• Coil Cable, 6-meter [236.2”]

• CAN/BUS RJ-45 Cable, 7-meter [276.6”]

• Sensor Cable, 1-meter [39”]

• Fan Cable is included where applicable.

• There are different cable kits for Round coil (RU)

components and Full coil (FL) components.

• RU cable kit descriptions: IN/MO7000/10000-

360 or IN/MO7000/10000

• FL cable kit descriptions: IN/MO7000FL-360 or

IN/MO14000

The serial plate specifies the model number, serial number,

and electrical specifications of the appliance.

See illustration below for location.

Model Number

The model number is located on the serial plate.

NOTE: The model number on the serial plate is the model

number of the induction generator.

This manual covers the following models:

IN/MO 7000 IN/MO 7000FL

IN/MO 10000 IN/MO 14000FL

READING THE MODEL NUMBER

Example:

1 Product Series 1 IN = Built-In Line

2 Product Series 2 MO = Module Line

3 Power (Watt) 7000, 10000

4 Type of Induction Coil Standard, Round Coil

IN/MO 7000

2

1

3

IN/MO 7000FL

2

1

FL = Full Coil (Rectangular)

3 4

Marketing Identifier

Marketing identifier is used when specifying the product

on specification sheet and other marketing literature. This

product is identified as:

Dual Models Quad Models

MO/DU 7000-360/650/720 MO/QU 14000-650/720

MO/DU 10000-360/650/720 MO/QU 20000-650/720

MO/DU 7000-360FL MO/QU 21000-720

MO/DU 14000-360/650/720FL MO/QU 24000-720

MO/QU 28000-650/720FL

READING THE MARKETING IDENTIFIER

Example:

1 Product Series MO = Module Line

2 Multi-Zone DU = Dual Cook Zones

3 Power (Watt) 7000, 10000, 14000, 20000,

4 Glass Size, length (mm) 360, 650, 720

5 Type of Induction Coil Standard, Round Coil

MO/DU 7000-650FL

2

1

3 4

QU = Quad Cook Zones

21000, 28000

FL = Full Coil (Rectangular)

5

Part Number 4532415 Rev 5 12/15 9

General Information Section 1

Serial Number Accessories

The serial number is located on the serial plate.

READING THE SERIAL NUMBER

Example:

1 Type of induction appliance:

2 Last two(2) or three(3) digits of the appliance article number

3 A sequential number:

4 Month of manufacture: 01, 02, 03, 04, ...

5 Year of manufacture: 2014 (14), 2015 (15), ...

BA01 . 00014 . 1214

2

1

BA = Base Line Series (Counter-Top Cook-Top)

IN = Built-In Series

WO = Counter Wok Series

MO = Module Line Series

HO = Hold Line Series

GR = Griddle Line Series

or part number that can be found on the invoice or the

packing slip.

• A 4-digit sequence number indicates that the

appliance is not RTCS® nor RTCSmp®.

• A 5-digit sequence number indicates that the

appliance is either a RTCS® or RTCSmp® appliance.

• A RTCSmp® appliance is marked as such on the serial

plate.

3 4 5

Induction cooking equipment requires Induction Ready

pans to operate. Consult your equipment supplier for a list

of our pan selection and prices.

10 Part Number 4532415 Rev 5 12/15

Section 2

Installation

IMPORTANT INSTALLATION SAFETY AND ELECTRICAL REQUIREMENTS

Warning

n

Safety and Electrical Requirements

This appliance component requires additional features and components to comply with appliance and electrical

standards.

It is the responsibility of the customer and installer to interpret and comply with all applicable national and

regional health codes, safety and electrical standards in your jurisdiction.

This product requires the addition of:

• A suitable non-flammable electrical enclosure; a means to conceal and protect components and wiring.

• Grounding and bonding to the enclosure.

• An appliance rating plate that includes end manufacturer information.

• Investigation by local electrical authority. Warning, caution labels and other markings required by electrical

and safety standards could be provided by local authority.

Depending on the application and configuration of this product(s), consider the addition of:

• Field supply connection terminals (terminal block).

• Branch circuit protection (breakers).

• Fans, ventilation or cooling systems and controls.

Warning

n

The induction appliance is designed to be installed into a custom built counter or an island suite.

The appliance includes a number of components that have to be installed separately. Customers are responsible for

providing proper installation mounting for the components.

Read ALL SECTIONS carefully, comply with all requirements listed and ensure inspection is done by qualified personnel.

Part Number 4532415 Rev 5 12/15 11

Installation Section 2

INSTALLATION SAFETYDISCLAIMER

DANGER

Installation must be carried out by registered installation

contractors only.

The contractors are responsible for interpreting all

instructions correctly and performing the installation

in compliance with all applicable national and local

regulations.

The warning signs and serial plates on the equipment

must strictly be followed.

Warning

n

This equipment is intended for indoor use only. Do not

install or operate this equipment in outdoor areas.

Warning

n

To avoid instability, the installation area must be capable

of supporting the combined weight of the equipment

and food product. The equipment must be level side to

side and front to back.

Caution

,

Consultants, fabricators and designers must consult their

counter-top suppliers when designing an appropriate

support structure and clearance for the counter-top and

the installation.

Notice

Induction equipment that is not installed correctly will

have warranty voided.

INSTALLATION SAFETYCLEARANCE AND

VENTILATION

DANGER

Risk of Fire or Shock or Equipment Failure

All minimum clearances must be maintained. Air intake

vents and exhaust vents must not be blocked or be

restricted by the installation.

Caution

,

This equipment must only be operated under an

approved ventilation system in accordance with all

applicable national and local regulations. Exceptions

may apply.

Notice

The maximum ambient temperature for the

induction appliance to operate must not exceed

40°C [104°F].

Failure to provide adequate ventilation will cause

the appliance to overheat, to reduce power, or to

shutdown.

NOTE: Always maintain enough space between and

around the equipment for maintenance and service.

INSTALLATION SAFETYELECTRICAL

DANGER

All electrical connections must be carried out by a

certified electrical contractor, who is responsible for

the correct rating and installation of the appliance. The

contractor has to comply with all legal safety regulations

and all applicable national and local electrical codes.

Warning

n

Markings and warning labels mounted directly on the

equipment must be observed at all times and kept in a

fully legible condition.

Warning

n

This equipment must be positioned so that the plug is

accessible unless other means for disconnection from

the power supply, such as circuit breaker or disconnect

switch, is provided.

Warning

n

CE Induction Appliance only: If ground fault current

protective switches are used, they must be provided

with selective activation and designed for a minimum

fault current of 30mA.

Notice

Ensure the supply voltage and the line current match

the specifications given on the serial plate affixed to the

appliance. Wrong voltage will damage the appliance. A

stable power supply must be provided.

Notice

Always refer to the serial plate on the appliance to verify

the electrical data. When the data listed on the serial

plate is different than that listed in this manual, contact

the manufacturer or the authorized representative.

12 Part Number 4532415 Rev 5 12/15

Section 2 Installation

Notice

All cables must be routed, protected and tension free.

PERSONAL PROTECTION

DANGER

All utilities (gas, electric, water and steam) must be

OFF to all equipment and locked out of operation

according to national/regional, as well as company

approved practices during installation, maintenance

and servicing. Always allow appliance to cool.

DANGER

Use appropriate safety equipment during installation,

maintenance and servicing.

DANGER

Never stand, sit, or lean on the equipment! They are

not designed to hold the weight of an adult, and may

collapse or tip if misused in this manner.

DANGER

To avoid cardiac pacemaker malfunction, consult your

physician or pacemaker manufacture about effects of

electromagnetic field on your pacemaker.

Warning

n

Markings and warning labels mounted directly on the

equipment must be observed at all times and kept in a

fully legible condition.

Warning

n

Risk of burns from high temperatures. You may get burnt

if you touch any of the parts during operation. Surfaces

close to the cooking area including side panels may get

hot enough to burn skin. Use extreme caution to avoid

coming in contact with hot surfaces or hot grease. Wear

personal protective equipment.

Caution

,

Use caution when handling metal surface edges of all

equipment.

Part Number 4532415 Rev 5 12/15 13

Installation Section 2

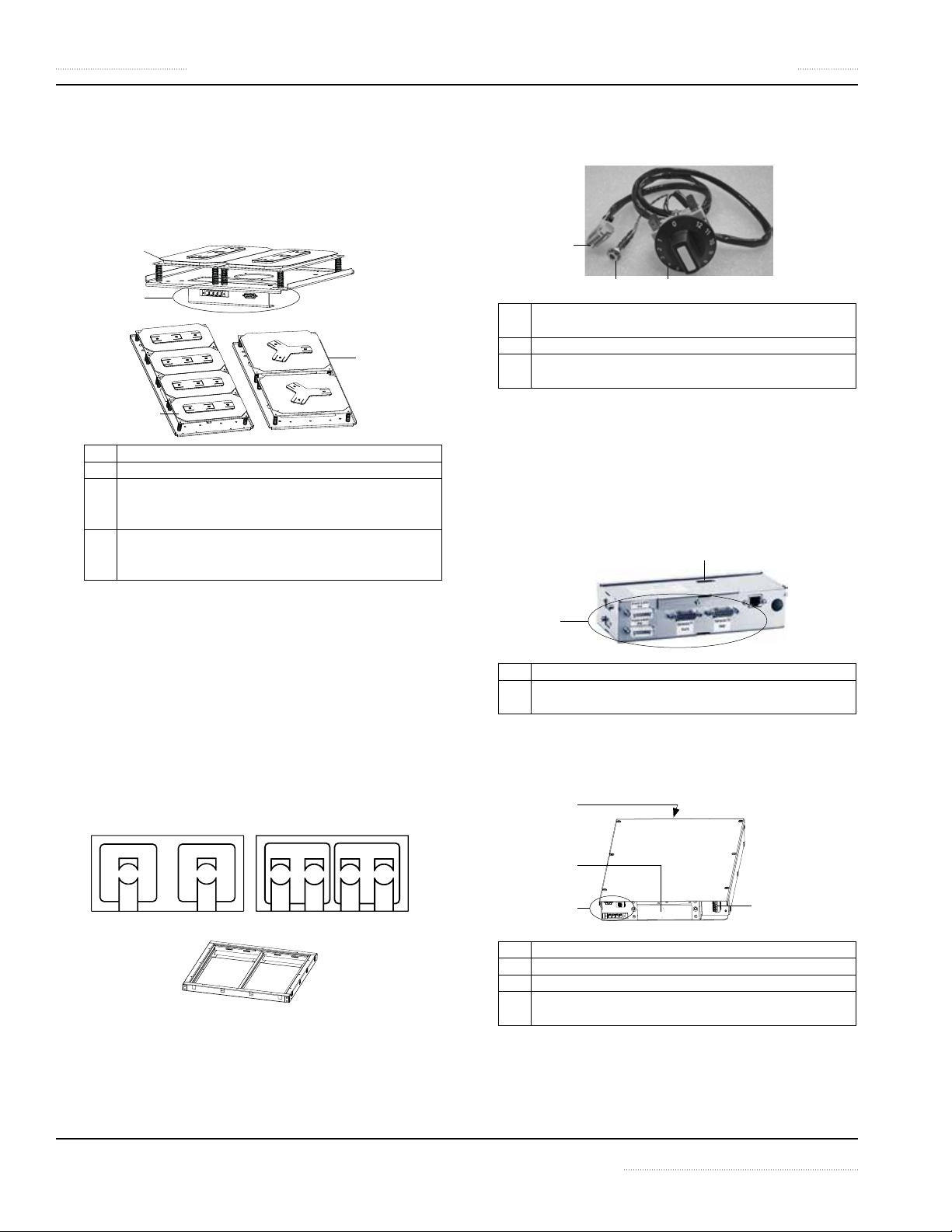

1

5

2

3

4

6

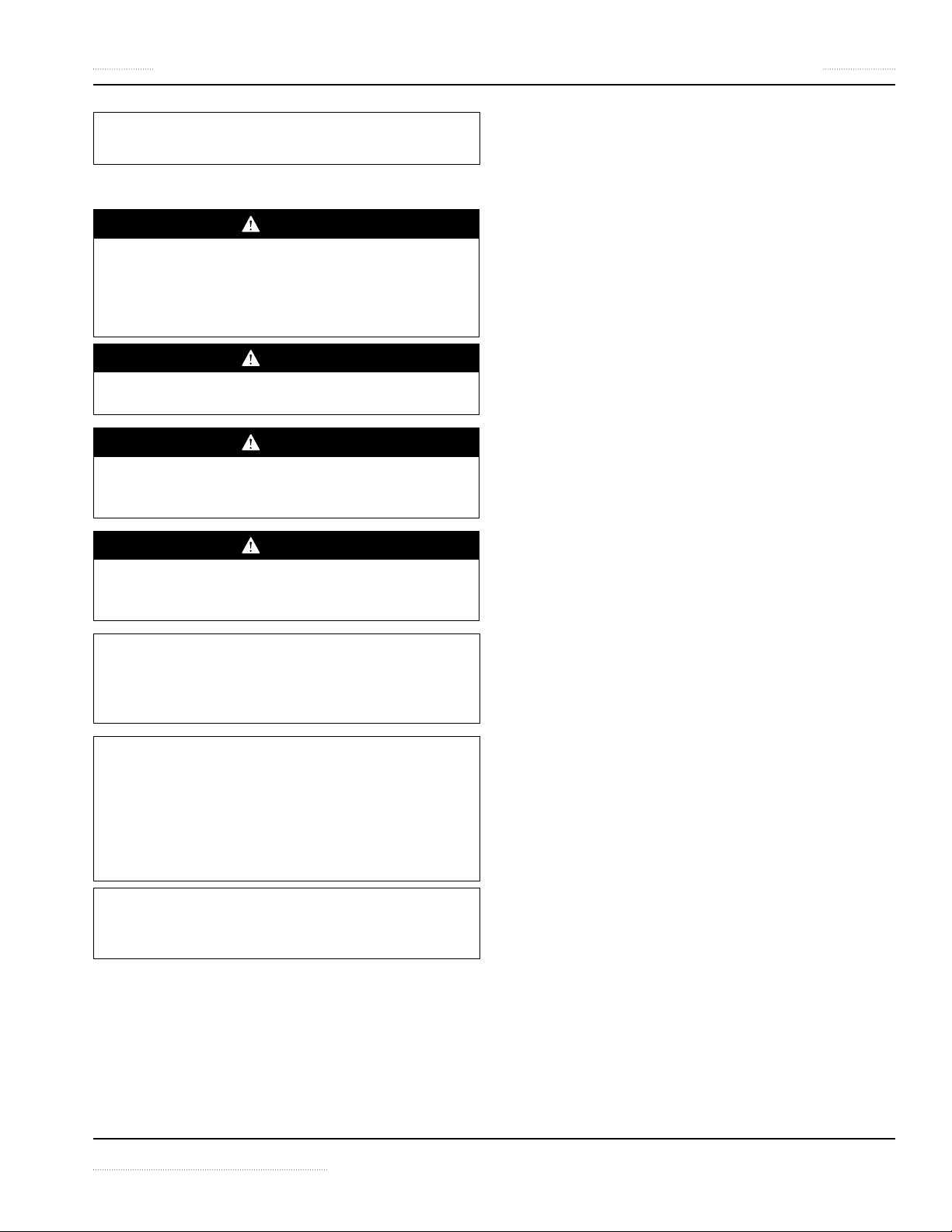

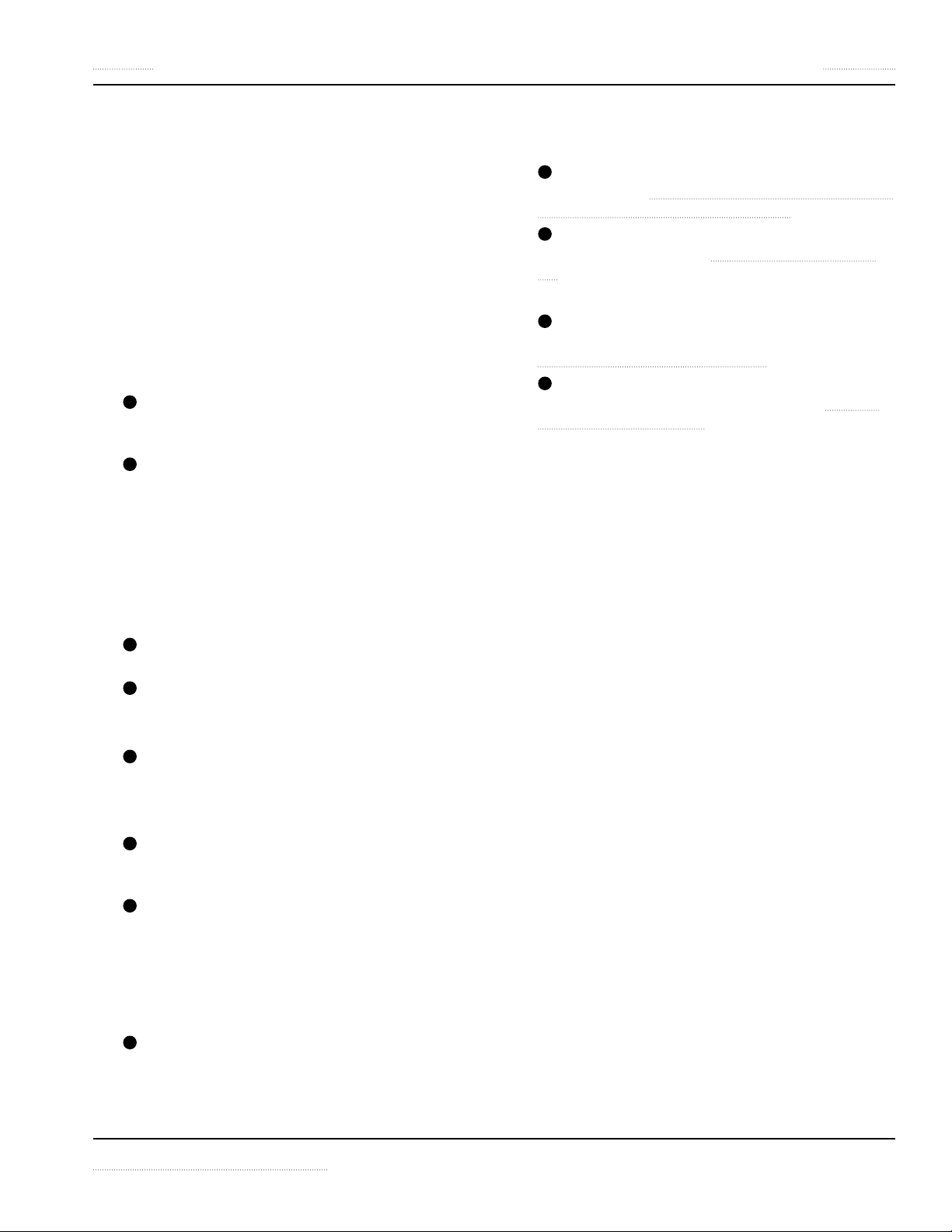

Exploded View of a Typical Installation

Shown below, model MO/QU. For a complete list of components, see the components chart for your specific model. Tube of

silicone sealant (part number 70000015) shown for installation is not provided.

Glass cooktop

1

Mounting Frame (for typical installation on 1.5 - 3mm [16 - 10 gauge] thick counter-tops]

2

Coil Carrier Sheets (Induction Coil and Sensor Assembly)

3

Induction Generator

4

Control Unit

5

Operating Unit

6

14 Part Number 4532415 Rev 5 12/15

Section 2 Installation

Planning for Installation

The induction appliance is designed to be installed

into a custom built counter or an island suite. You

1

must plan ahead for the location, ventilation and

electrical requirements for the induction appliance.

See sections:

• Electrical safety at the beginning of this chapter.

• Cabinet Requirements on page 15

• Specifications on page 21

At the design stage, it is important to consult your

electrical contractor to ensure your cabinet design

2

and installation will meet all applicable electrical and

safety codes. See sections:

• Electrical safety at the beginning of this chapter.

• Electrical Specifications on page 29

• Electrical Installation on page 37

Your custom built counter or island suite must have

proper support structure for the countertop,

3

the appliance and cooking vessels. The support

structure will depend on the installation method,

the countertop material and thickness. See sections:

• Typical Applications on page 17

We recommend consulting a mechanical

contractor to advise on the structure, ventilation

4

methods and the overall design. See sections:

• Cabinet Requirements on page 15

• Typical Applications on page 17

• Specifications on page 21

The equipment includes a number of components

that have to be installed separately. Ensure

5

you understand the clearance requirements and

installation methods. See sections:

• Exploded View of a Typical Installation on page

14

• Specifications on page 21

• Installation Instructions on page 32

An exploded view of a typical installation is provided.

It is very important to seal all installation gaps with

6

silicone sealant to prevent water ingress.

• Exploded View of a Typical Installation on page

14

• Installation Instructions on page 32

Cabinet Requirements

Read and understand all installation

safety instructions at the beginning of

Section 2 Installation.

PLACE THE INDUCTION APPLIANCE AWAY FROM

1

HEAT AND MOISTURE

• Similar to other electronic equipment, induction

equipment is sensitive to moisture and high heat.

Recommendations

• Do not position the air intake vent near steam or

heat exhaust of another appliance.

• Never place your induction equipment next to

any grease generating, heat generating or steam

emitting equipment, such as oven, deep fryer,

pasta cooker, steamer and water bath.

• Never install or place your induction equipment

near or on a hot surface.

• Isolate and protect the electronic equipment and

wiring with a separate compartment. Install heat

shield such as an insulated wall or air gap.

PROVIDE ADEQUATE VENTILATION AND MANAGE

2

AIRFLOW

• Maximum ambient temperature for the

induction appliance to operate must not exceed

40°C [104°F].

• Minimum opening for fresh air supply required per

induction generator: total sum of 6500mm2 [10.08

square inches].

• Opening for exhaust should be at least as big as

the intake vent. Minimum, a total sum of 6500mm

[10.08 square inches] per induction generator.

• Fresh air intake and hot exhaust vents must not be

blocked or restricted by the installation.

• Ensure the appliance does not pull in hot ambient

air or steam from another appliance.

• The intake air and exhaust air must not mix. Hot

exhaust must not be pulled back into the appliance

through the fresh air intake opening.

• Air intake filter, custom built or provided, must be

easily accessible for weekly inspection or cleaning.

Recommendations

• Install fresh air filter on the cabinet.

• Install louvered opening or ventilation gaps to aid

air movement and to allow hot exhaust to escape.

• Depending on the air path and the amount of

natural air movement, install ventilation fan on the

2

Part Number 4532415 Rev 5 12/15 15

Installation Section 2

cabinet to pull quickly hot exhaust away from the

electronic equipment. As an alternative, provide a

separate exhaust air plenum.

NOTE: In a situation that when ventilation fan

cannot be installed on the cabinet, you must provide

ventilation gaps with size of minimum 323 square

centimeters [50 square inches] per dual built-in

appliance.

NOTE: Additional air filters, ventilation fans, cooling

controls, and air ducts are the responsibility of the

customer and installer.

PREVENT WATER INGRESS

3

• Any ingress of water will damage the electronic

equipment.

Recommendations

• Consider cleaning method and how it might

impact your cabinet design.

• All mating surfaces and installation gaps between

the countertop and the appliance must be bonded

and sealed properly with silicone.

• Design and construct ventilation gaps in such a

ways that they would prevent water ingress.

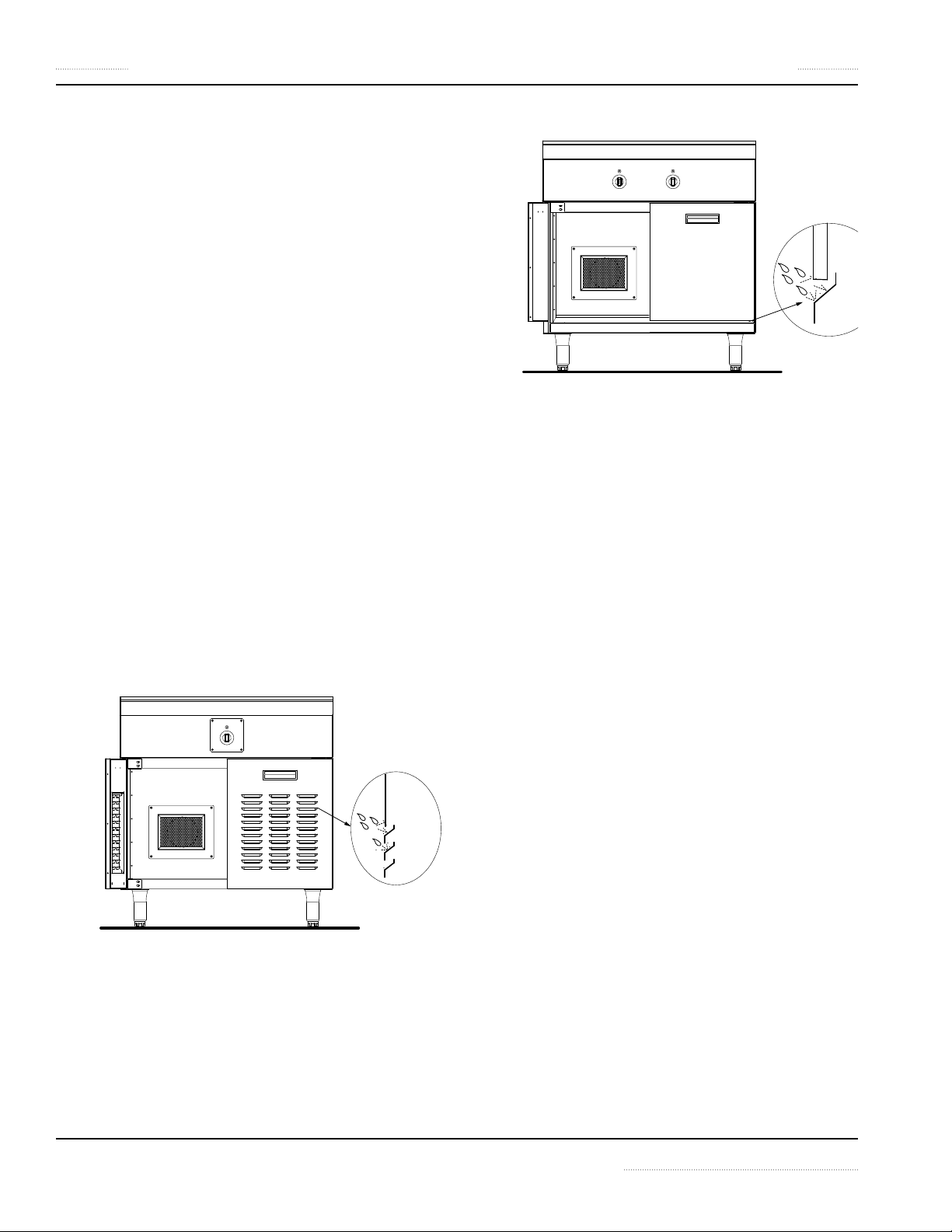

Examples below shown that bent flanges are

created behind louvered openings (Example 1)

or ventilation gaps (Example2) to deflect water

splashes.

Example 1.

Example 2.

ELIMINATE FIRE HAZARDS

4

• Comply with all ventilation and installation

clearances.

• Keep the appliance away from combustible

materials, vapors or liquids.

• Final cabinet construction and installation must

comply with all applicable national and local

electrical and safety codes.

PROVIDE SAFE DISCONNECT FROM POWER

5

SUPPLY

• The appliance is intended to be permanently

connected to fixed wiring. Other means for

disconnection from power supply, such as circuit

breaker or disconnect switch, must be accessible.

Consult your local authorities or your electrical

contractor for details.

PROVIDE SERVICE CLEARANCE

6

• Provide enough space and service access for

technicians to perform maintenance and service.

16 Part Number 4532415 Rev 5 12/15

Section 2 Installation

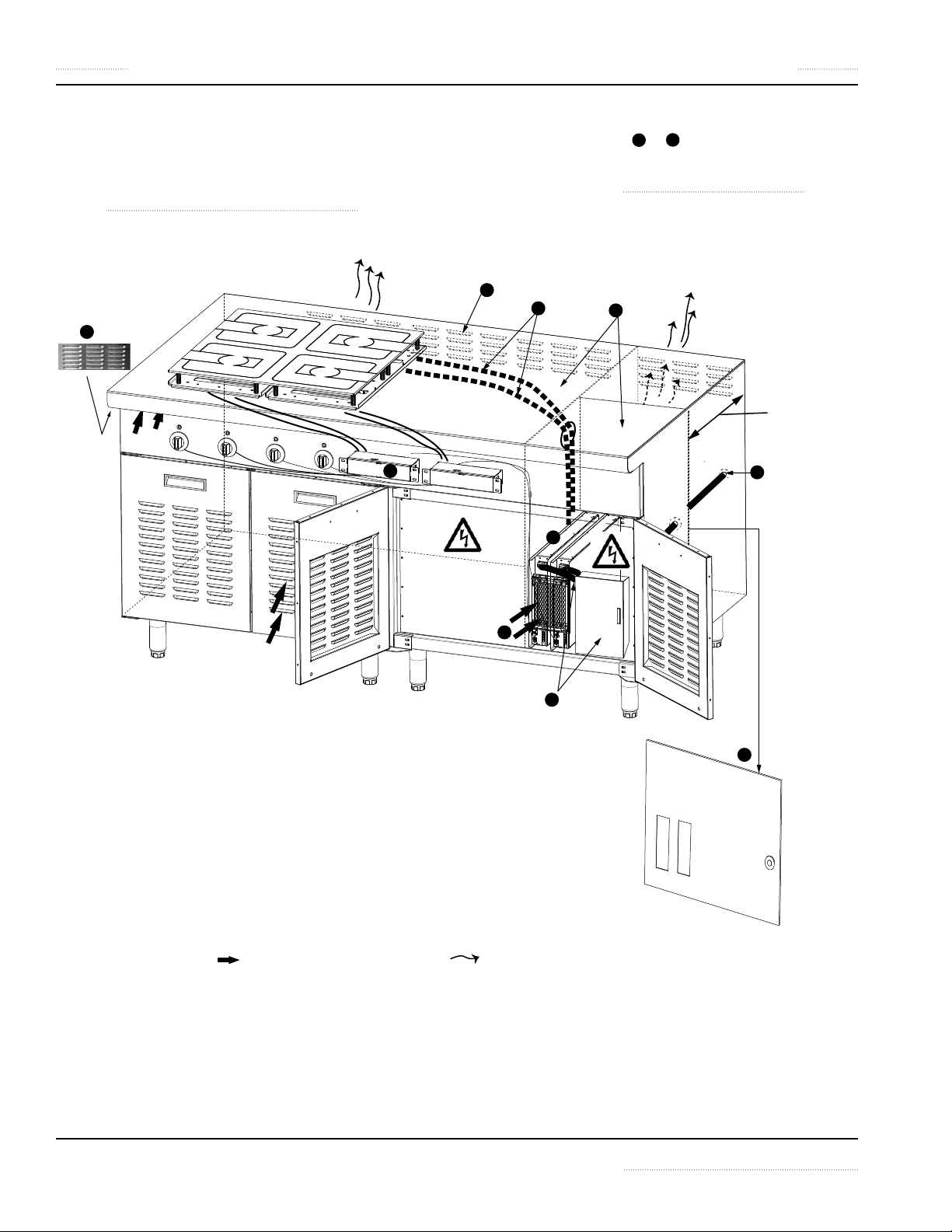

Typical Applications

In this section you will find examples of the most common

installations for the induction appliance.

A quad model is shown in the illustrations as an example.

When multiple appliances are installed into the same

counter, special attention must be paid to the ventilation

and electrical requirements. Use the list of features below as

your design guideline to ensure a proper cabinet is used for

the application and installation.

IMPORTANT DESIGN FEATURES

Install the Induction Generator in a separate

compartment away from heat and moisture. Ensure to

have adequate ventilation:

1

The air intake vent is located at the front and the

intake air is filtered by an air filter mounted on the

cabinet.

2

The exhaust vent is located at the back of the

generator. Consider to create a baffle to prevent the

exhaust air from mixing with the fresh intake air. As an

alternative, create an exhaust air plenum.

In each of the application example, a baffle is placed

behind the generator and the exhaust is vented into

a separate channel or chamber and then outside the

cabinet. Distance between the exhaust openings and

any obstruction is minimum 40mm [1.57”].

3

Louvered openings of ventilation fan allow exhaust

to escape.

4

Louvered openings or ventilation gap facilitate

proper air-flow.

Safe electrical environment:

5

An enclosed compartment protects the electronic

appliance and wiring from the environment.

Personnel are also protected from the electronics and

the electrical cables.

6

It is important that the coil cables are routed

separately from other communication and power

cables.

7

The appliance is intended to be permanently

connected to fixed wiring. Other means for

disconnection from power supply, such as circuit

breaker or disconnect switch, must be accessible.

NOTE: National and local electrical codes dictate the

electrical requirements. Consult your local authorities

or your electrical contractor for details.

8

Supply inlet / conduit opening shown.

Flexible configuration:

9

The control unit can be installed in multiple

orientations. See Cut-out Dimensions: Holes and Studs

for Control / Operation unit on page 27

10

The generator can be installed up to 3-meter [10fee] from the cooktop. See Electrical Cables on page

30.

Water-tight environment:

11

Mating surfaces between the appliance and

coutertop are sealed with silicone (not shown, see

Installation Instructions on page 32).

12

Design and construct ventilation gaps that

could prevent water ingress (not shown, see Cabinet

Requirements on page 15).

Part Number 4532415 Rev 5 12/15 17

Installation Section 2

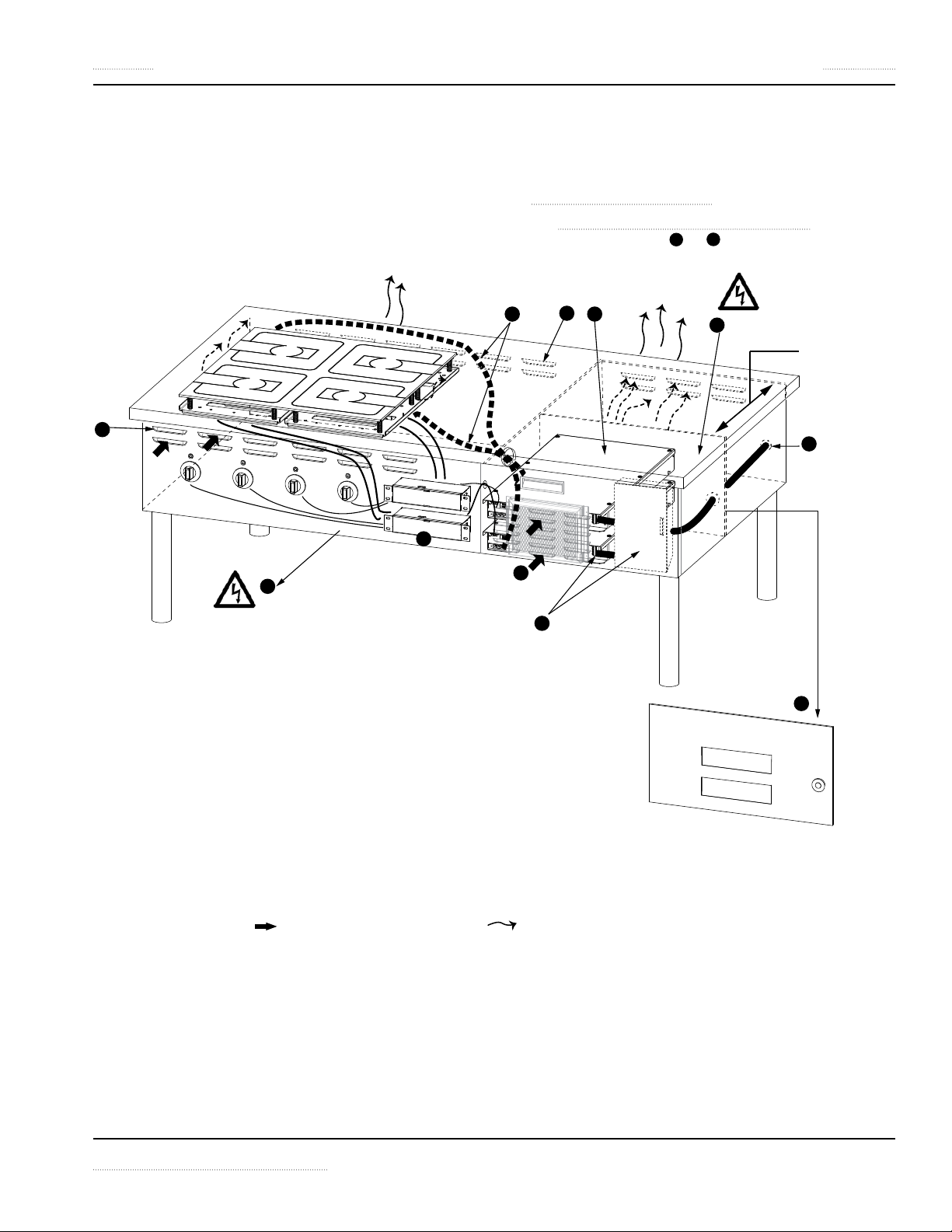

9

1

5

2

3

4

6

7

8

10

APPLICATION EXAMPLE 1

• The equipment is built into a large, enclosed

compartment. There is ample of space for installation

and service.

descriptions of items 1 to 10 in illustration.

• For minimum fresh air intake and exhaust openings for

each generator, see Electrical Cables on page 30

• See Important Design Features on page 17 for the

min.

40mm [1.57”]

Indicates the direction of airflow for fresh air. Indicates the direction of airflow for exhaust air.

Application Example 1: Equipment Built Into A Large Compartment.

18 Part Number 4532415 Rev 5 12/15

Section 2 Installation

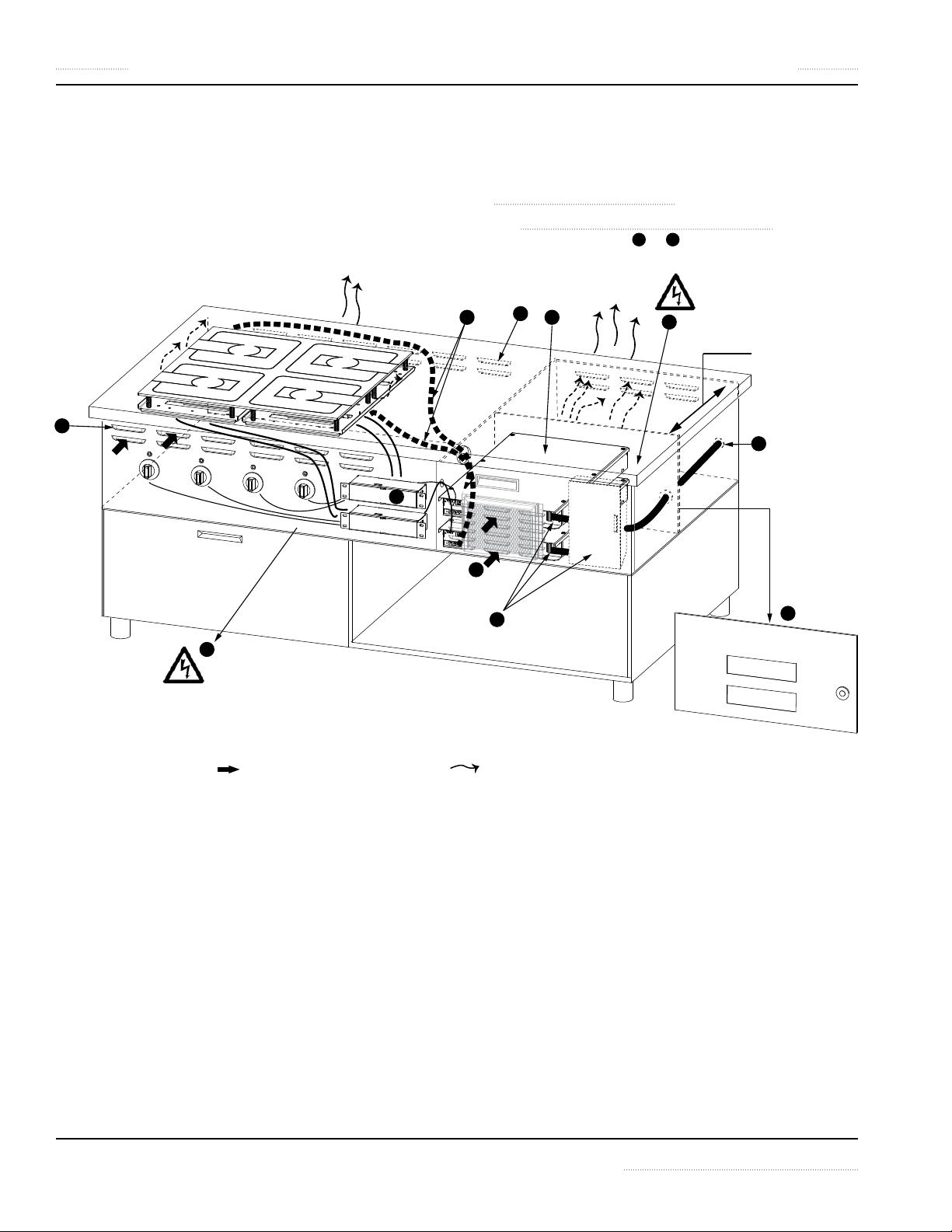

7

9

4

2

6

1

5

3

8

10

5

APPLICATION EXAMPLE 2

• The equipment is built into a small, enclosed

compartment of a counter with an open base. The

compact profile of the appliance is ideal for a front of

house cooking station.

• The generators are enclosed in a small electrical

compartment. It is important to ensure that there

is adequate ventilation to maintain an operating

temperature of below 40°C [104°F]. For minimum fresh

air intake and exhaust openings for each generator, see

Electrical Cables on page 30

• See Important Design Features on page 17 for the

descriptions of items 1 to 10 in illustration.

min.

40mm [1.57”]

Indicates the direction of airflow for fresh air. Indicates the direction of airflow for exhaust air.

Application Example 2: Equipment Built Into A Counter With An Open Base.

Part Number 4532415 Rev 5 12/15 19

Installation Section 2

7

9

4

2

6

1

5

3

8

10

5

APPLICATION EXAMPLE 3

• This is an application of a low profile design, combined

with additional functionalities such as cold or dry

storage base. The induction appliance and wiring are

isolated and protected in the upper compartment.

• The generators are enclosed in a small electrical

compartment. It is important to ensure that there

is adequate ventilation to maintain an operating

temperature of below 40°C [104°F]. For minimum fresh

air intake and exhaust openings for each generator, see

Electrical Cables on page 30

• See Important Design Features on page 17 for the

descriptions of items 1 to 8 in illustration.

min.

40mm [1.57”]

Application Example 4: Equipment Built Into A Counter With Other Built-In Functionalities.

Indicates the direction of airflow for fresh air. Indicates the direction of airflow for exhaust air.

20 Part Number 4532415 Rev 5 12/15

Loading...

Loading...