Page 1

INSTALLATION AND

OPERATION MANUAL

GARLAND GF SENTRY SERIES

GAS RESTAURANT RANGES

All 24, 36, 48, & 60-inch wide models.

Français . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 21

Españo. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Página 43

FOR YOUR SAFETY:

DO NOT STORE OR USE GASOLINE

OR OTHER FLAMMABLE VAPORS OR

LIQUIDS IN THE VICINITY OF

THIS OR ANY OTHER

APPLIANCE

WARNING:

IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE

CAN CAUSE PROPERTY DAMAGE, INJURY,

OR DEATH. READ THE INSTALLATION,

OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR

SERVICING THIS EQUIPMENT

Users are cautioned that maintenance and repairs must be performed by a Garland authorized service agent using

genuine Garland replacement parts. Garland will have no obligation with respect to any product that has been

improperly installed, adjusted, operated or not maintained in accordance with national and local codes or installation

instructions provided with the product, or any product that has its serial number defaced, obliterated or removed, or

which has been modified or repaired using unauthorized parts or by unauthorized service agents. For a list of authorized

service agents, please refer to the Garland web site at http://www.garland-group.com. The information contained

herein, (including design and parts specifications), may be superseded and is subject to change without notice.

PLEASE READ ALL SECTIONS OF THIS MANUAL

AND RETAIN FOR FUTURE REFERENCE.

THIS PRODUCT HAS BEEN CERTIFIED AS

COMMERCIAL COOKING EQUIPMENT AND

MUST BE INSTALLED BY PROFESSIONAL

PERSONNEL AS SPECIFIED.

IN THE COMMONWEALTH OF MASSACHUSETTS

THIS PRODUCT MUST BE INSTALLED BY A

LICENSED PLUMBER OR GAS FITTER.

For Your Safety:

Post in a prominent location, instructions to be

followed in the event the user smells gas. This

information shall be obtained by consulting

your local gas supplier.

Garland Commercial Ranges, Ltd.

1177 Kamato Road, Mississauga, Ontario L4W 1X4 CANADA

Phone: 905-624-0260

Fax: 905-624-5669

Part # 4525587 Rev 4 (29 April 14)

General Inquires 1-95-624-0260

USA Sales, Parts and Service 1-800-424-2411

Canadian Sales 1-888-442-4526

Canada or USA Parts/Service 1-800-427-6668

Page 2

IMPORTANT INFORMATION

WARNING:

This product contains chemicals known to the State of California to cause cancer and/or birth defects or other reproductive harm. Installation and servicing of this product could expose you to airborne particles of glass wool/ceramic fibers. Inhalation of airborne particles of glass wool/ceramic

fibers is known to the State of California to cause cancer. Operation of this product could expose

you to carbon monoxide if not adjusted properly. Inhalation of carbon monoxide is known to the

State of California to cause birth defects or other reproductive harm.

Keep appliance area free and clear of combustibles.

Part # 4525587 Rev 4 (29 April 14)Page 2

Page 3

TABLE OF CONTENTS

IMPORTANT INFORMATION. . . . . . . . . . . . . 2

DIMENSIONS AND SPECIFICATIONS . . . . . 4

Base Model Designations & Total Input Rates . . 5

Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Gas Pressure & Individual Burner Input Rates . . 6

North America . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

CE & General Export . . . . . . . . . . . . . . . . . . . . . . 6

Reduced Input Rates . . . . . . . . . . . . . . . . . . . . . 6

Note: Manifold pressure is to measured at the

test spigot located on the 3/4” gas manifold

pipe.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Australia . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Gas Inlet Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

CE Approved Gas Categories . . . . . . . . . . . . . . . . . 7

INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . 8

Final Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Optional Interconnect Gas Kit . . . . . . . . . . . . . . . 12

TESTING AND ADJUSTMENT . . . . . . . . . . . 13

Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

OPERATION. . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Flame Failure Technology . . . . . . . . . . . . . . . . . . . 14

How Flame Failure Technology Works . . . . . . . .14

Burner Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Open Top burners . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Hot Tops and Front-Fired Target Tops . . . . . . . . 15

Ovens (Standard) . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Convection Ovens . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Thermostat Controlled Griddles . . . . . . . . . . . . . 17

Griddle/Broiler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Rating Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

INSTALLATION. . . . . . . . . . . . . . . . . . . . . . . . . 9

Siting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Appliances Equipped With Casters . . . . . . . . . . . . 9

Appliances Equipped With Legs . . . . . . . . . . . . . . 9

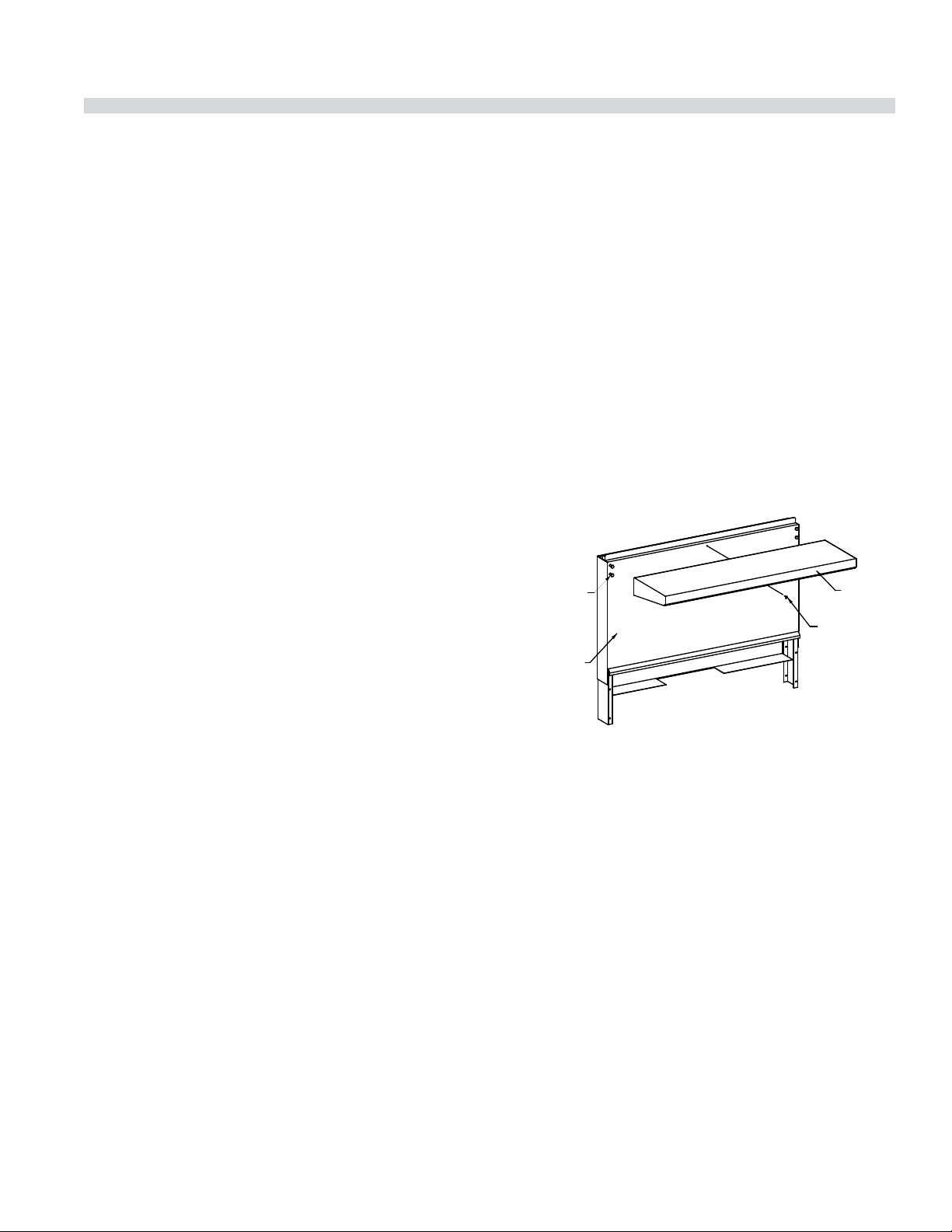

Installing Shelf To Backguard . . . . . . . . . . . . . . . . . 9

Backguard With High Shelf Or Salamander

Mounting Instructions . . . . . . . . . . . . . . . . . . . . . . .9

Ventilation Air . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Statutory Regulations . . . . . . . . . . . . . . . . . . . . . . . 11

Australia Speci c Clause . . . . . . . . . . . . . . . . . . . . . 11

Electrical Connection Settings

(Where Applicable) . . . . . . . . . . . . . . . . . . . . . . . . . 11

Gas Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Range Shut down . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

PRODUCT APPLICATION INFORMATION 18

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Open Burners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Hot Tops. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

MAINTENANCE AND CLEANING. . . . . . . .19

Seasoning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Griddle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Cast Iron top Grates . . . . . . . . . . . . . . . . . . . . . 19

Stainless Steel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Oven Interior (Porcelain Enamel) . . . . . . . . . . . . . 19

Open Top Burners . . . . . . . . . . . . . . . . . . . . . . . . . .19

Cast Iron Top & Grates . . . . . . . . . . . . . . . . . . . . . . .20

Hot Tops and Front-Fired Target Hot Tops . . . .20

Griddle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Part # 4525587 Rev 4 (29 April 14) Page 3

Page 4

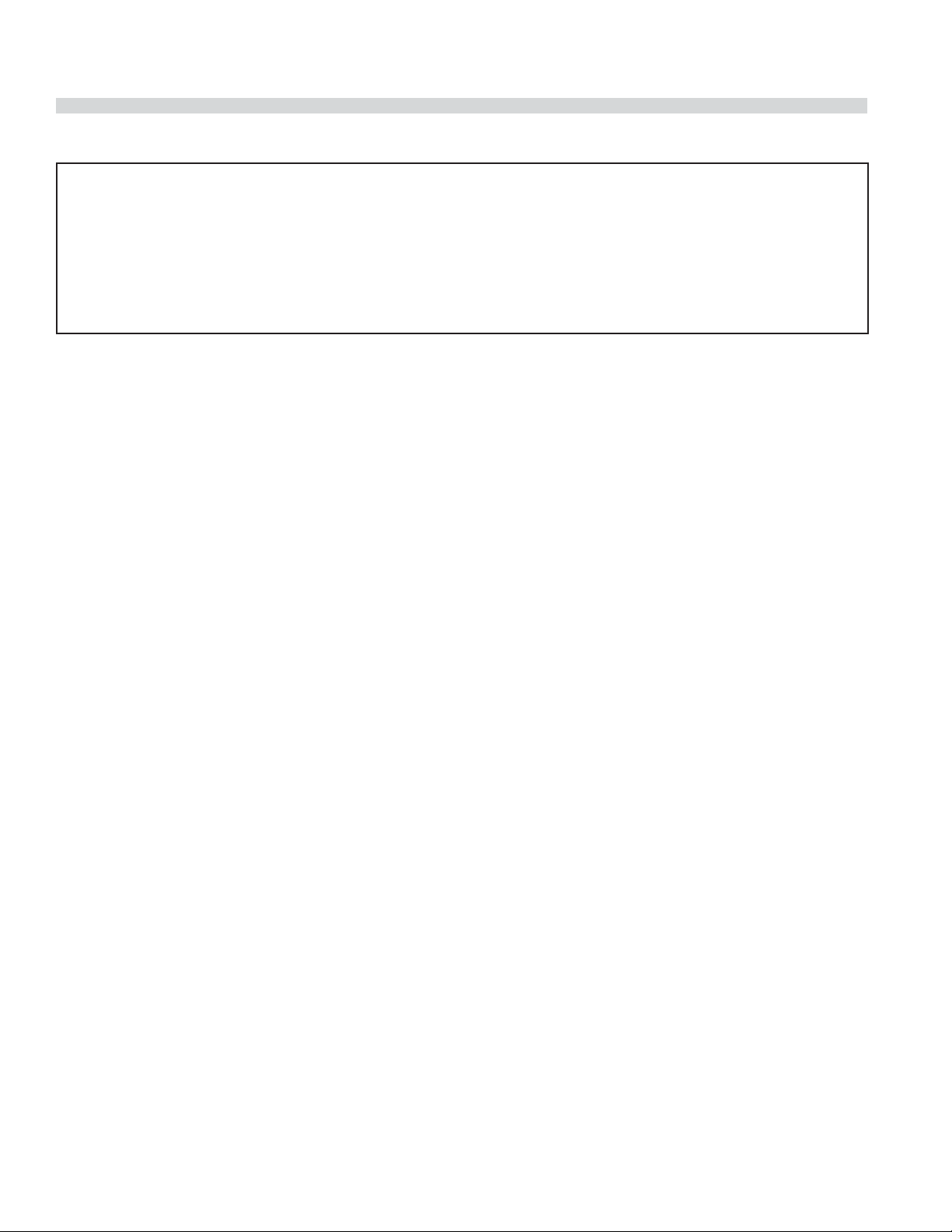

DIMENSIONS AND SPECIFICATIONS

Top View

Model widths vary depending on model series.

(See Chart on left)

ELECTRICAL PLUG

(WHERE APPICALBE)

3-1/2"

[89mm]

27-1/4"

[692mm]34-1/2"

[876mm]

2-1/4"

[57mm]

5"

[127mm]

Series Width

GF24 600mm (23-5/8”)*

GF36 900mm (35-2/2”)* Shown

GF48 1200mm (47-1/4”)

GF60 1500mm (59-1/2”)

*Range base or modular top

Modular Top Models GF24-_T or GF36-_T Side View

9-3/8" [238mm]

15-5/8"

[396mm]

GF Series Side View

(Showing convection base where applicable).

12-1/8"

[307mm]

18-3/8"

[466mm]

39-3/8"

[1000mm]

LOW PROFILE

BACKGUARD

13-7/8"

[352mm]

ADD WHEN

DOOR OPEN

31-1/8"

[791mm]

3-7/8" [98mm]

CONVECTION OVEN

[1290mm]

STD BACKGUARD

W/HIGH SHELF

(OPTIONAL)

ADD FOR

51"

GF Series 60” Raised Griddle/Broiler Side View

12-1/8"

[307mm]

CLEARANCE FROM TOP OF GRIDDLE PLATE

TO OPTIONAL HIGH SHELF 14-3/4" [374mm]

CLEARANCE FROM TOP OF GRATE

TO OPTIONAL HIGH SHELF 18-3/8" [466mm]

1"

[25mm]

GAS

INLET

[1041mm]

LOW PROFILE

BACKGUARD

13-7/8"

[352mm]

ADD WHEN

DOOR OPEN

31-1/8"

[791mm]

3-7/8" [98mm]

CONVECTION OVEN

51"

[1296mm]

STD BACKGUARD

W/HIGH SHELF

41"

ADD FOR

Part # 4525587 Rev 4 (29 April 14)Page 4

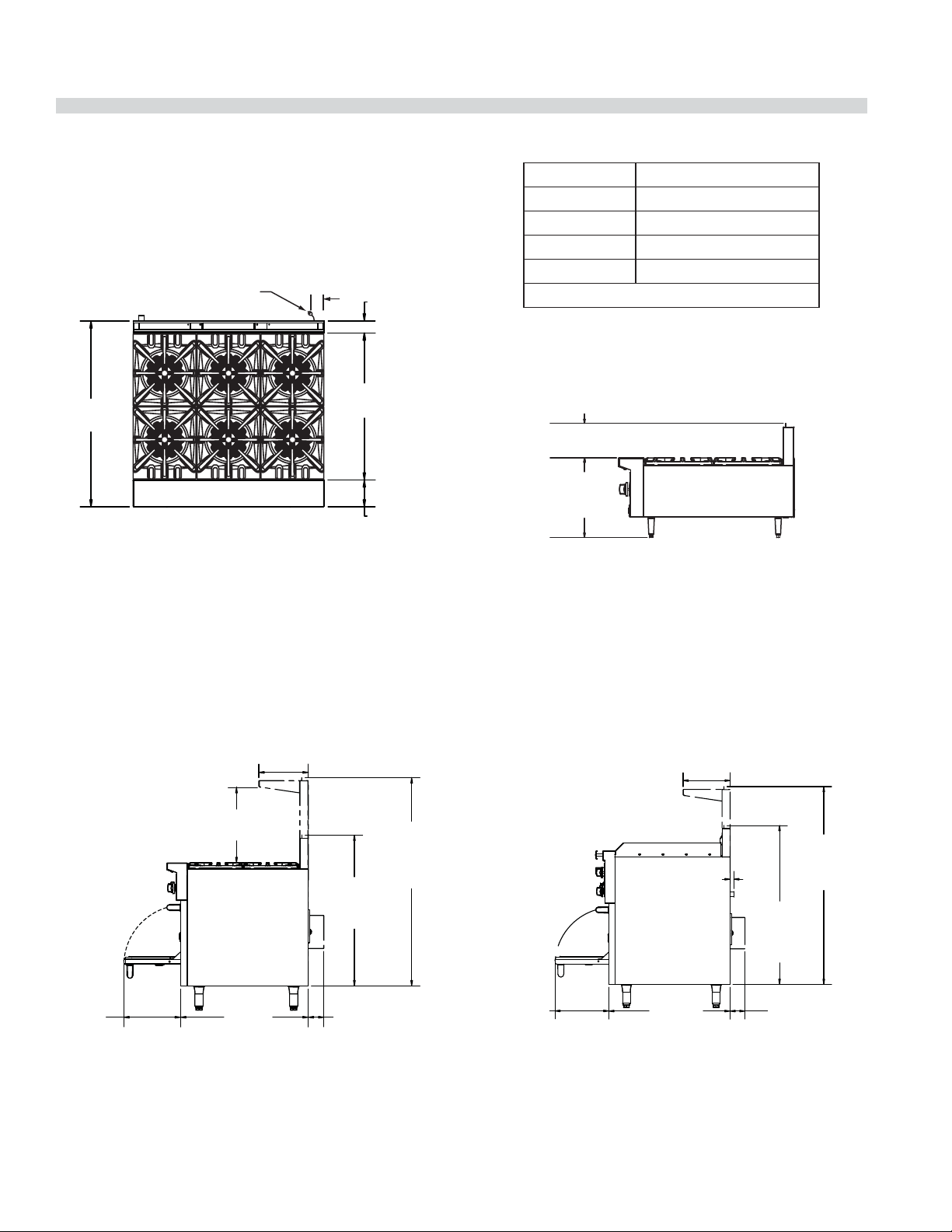

Page 5

DIMENSIONS AND SPECIFICATIONS continued

Base Model Designations & Total Input Rates

Input

Natural Gas Propane Gas

Model #* Description

BTU/Hr

GF/GFE24-4L 24” (600mm) nominal size unit, 4 open burners, space saver oven 136,000 41.50 132,000 39.70

GF24-T 24” (600mm) nominal size unit, 4 open burners, modular top 104,000 30.40 104,000 30.40

GF/GFE36-6R 36” (900mm) nominal size unit, 6 open burners, standard oven 194,000 56.70 188,000 54.90

GFE36-6C 36” (900mm) nominal size unit, 6 open burners, convection oven 194,000 56.70 188,000 54.90

GF36-T 36” (900mm) nominal size unit, 6 open burners, modular top 156,000 45.60 156.000 45.60

GF/GFE36-TTR

GFE36-TTC

GF/GFE48-LL

GF/GFE60-10RR

GFE60-10RC

GFE60-10CC

GF/GFE60-6R24RR

GFE60-6R24RC

GFE60-6R24CC

GF/GFE60-6R24RS

GFE60-6R24CS

*Models beginning with GFE pre x have electric spark ignition systems for pilots.

Rates are for installations up to 2000’ (610m) above sea level

Each 12”(305mm) Hot Top section is 5.3kW, replacing 2 Open Burners (7.6kW each)

36” (900mm) nominal size unit, 2 Front- red Target Hot Top

sections, standard oven

36” (900mm) nominal size unit, 2 Front- red Target Hot Top

sections, convection oven

48” (1200mm) nominal size unit, 8 open burners,

2 space saver ovens

60” (1500mm) nominal size unit, 10 open burners,

2 standard ovens

60” (1500mm) nominal size unit, 10 open burners, 1 standard &

1 convection oven

60” (1500mm) nominal size unit, 10 open burners,

2 convection ovens

60” (1500mm) nominal size unit, 6 open burner, 24” (610mm),

raised griddle/broiler, 2 standard ovens

60” (1500mm) nominal size unit, 6 open burner, 24” (610mm),

raised griddle/broiler, 1 standard & 1 convection oven

60” (1500mm) nominal size unit, 6 open burner, 24” (610mm),

raised griddle/broiler, 2 convection ovens

60” (1500mm) nominal size unit, 6 open burner, 24” (610mm),

raised griddle/broiler, 1 standard oven & 1 storage section

60” (1500mm) nominal size unit, 6 open burner, 24” (610mm),

raised griddle/broiler, 1 convection oven & 1 storage section

100,000 29.10 94,000 25.50

100,000 29.10 94,000 25.50

272,000 79.60 264,000 77.20

336,000 98.20 324,000 94.60

336,000 98.20 324,000 94.60

336,000 98.20 324,000 94.60

265,000 76.80 253,000 73.20

265,000 76.80 253,000 73.20

265,000 76.80 253,000 73.20

227,000 65.70 221,000 63.90

227,000 65.70 221,000 63.90

CE

Rating kWBTU/Hr

CE

Rating

kW

Clearances

Clearances Applicable For All Models Except Where Noted

Surface Sides Range Sides Modular Top Rear

Combustible Wall Minimum 14” (356mm) 6” (152mm) 6” (152mm)

Non-Combustible Wall Minimum 0” 0” 0”

Part # 4525587 Rev 4 (29 April 14) Page 5

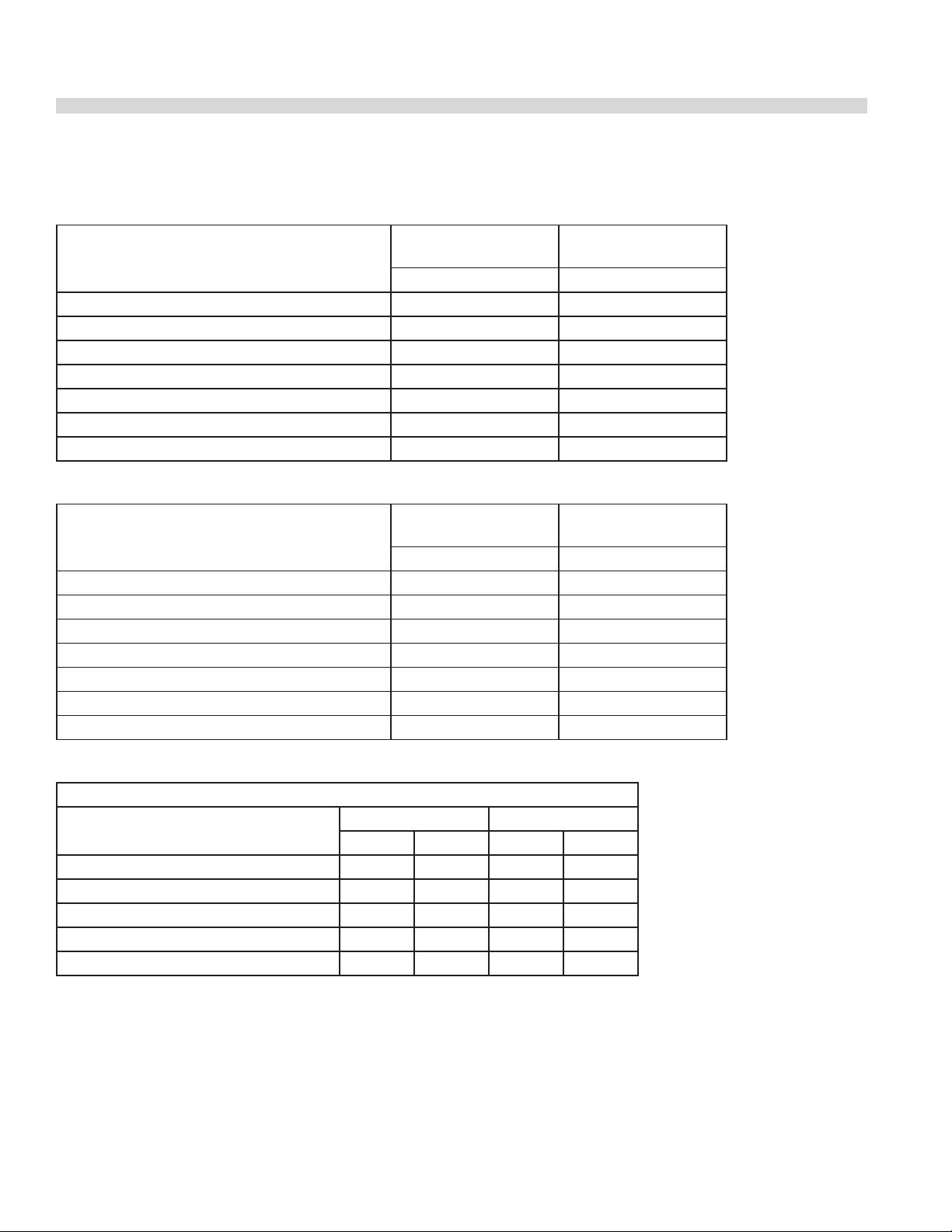

Page 6

DIMENSIONS AND SPECIFICATIONS continued

Gas Pressure & Individual Burner Input Rates

North America

Nat.,

Garland GF Series

Open Top (Flame Failure) 26,000 26,000

Target Top 36” models only, per section 3@10,333 3@10,333

Hot Top FF (in lieu of 2 Open Top Burners) 18,000 18,000

Griddle (in lieu of 2 Open Top Burners)(Tstat) 18,000 18,000

Raised Griddle Broiler (3 burners) 3 @11,000 3 @11,000

26” Oven Burner (H-Cast)(Standard or Convection) 38,000 32,000

Space Saver Oven (H-Cast) 32,000 28,000

4.5” wc Manifold

BTU/h BTU/h

LPG,

10” wc Manifold

CE & General Export

Nat. (G20),

Garland GF Series

Open Top (Flame Failure) 7.6 7.6

Hot Top FF (in lieu of 2 Open Top Burners) 5.3 5.0

Target Top “36” models, only per section 3@3.0 3@2.7

Griddle (in lieu of 2 Open Top Burners)(Tstat) 5.3 5.3

Raised Griddle Broiler (3 burners) 3 @ 3.0 3 @ 3.0

26” Oven Burner (H-Cast)(Standard or Convection) 11.1 9.3

Space Saver Oven (H-Cast) 9.4 8.2

11.2 mbar Manifold

kW kW

LPG (G31),

24.9 mbar Manifold

Reduced Input Rates

Approximate input ratings for adjustable top burners set at LOW:

Garland GF Series

Open Top Burner (Flame Failure) 2.0 0.21 4.2 0.17

Hot Top (Flame Failure) 2.75 0.29 4.9 0.20

Griddle (Tstat) 3.0 0.32 2.0 0.08

Raised Griddle Broiler (Total Of 3 Burners) 3.0 0.32 5.9 0.24

Target Top 2.7 0.28 4.0 0.16

NAT(G20) LPG(G31)

kW m

3

/h kW m3/h

Note: Manifold pressure is to measured at the test spigot located on the /” gas manifold pipe.

Part # 4525587 Rev 4 (29 April 14)Page 6

Page 7

DIMENSIONS AND SPECIFICATIONS continued

Australia

Garland GF Series

Nat., 1.0kPa Manifold LPG, 2.49 kPa Manifold

MJ/H Injector MJ/H Injector

Open Top (Flame Failure) 30.6 37 (2.64mm) 28.49 53 (1.51mm)

Hot Top FF (in lieu of 2 Open Top Burners) 19.0 47 (1.99mm) 18.15 1.2mm

Front Fired Hot Top (Target Top) 36.5 52(1.61mm) 36.5 1.0mm

Griddle (in lieu of 2 Open Top Burners)(Tstat) 19.0 47 (1.99mm) 18.15 1.2mm

Raised Griddle Broiler (3 burners) 30.0 47 (1.99mm) 34.82 61 (0.99 mm)

26” Oven Burner (H-Cast)(Standard) 40.09 30 (3.26mm) 33.76 50 (1.78mm)

26” Oven Burner (H-Cast) (Convection) 40.09 30 (3.26mm) 32.18 51 (1.7mm)

Space Saver Oven (H-Cast) 33.7 33 (2.87mm) 27.96 52 (1.61mm)

Gas Inlet Size

Model Width Connection

23-5/8” (600mm) &

35-1/2” (900mm)

47-1/4” (1200mm) &

59-1/2” (1500mm)

3/4” NPT

Rear Gas Connection

1” NPT

Rear Gas Connection

Connection CE Models

(ISO7-1)

3/4” (19.1mm) BSPT

1” (25.4 mm) BSPT

CE Approved Gas Categories

Country Gas Category Gas Type Pressure (mbar)

AT, CH, CY, CZ, DK, EE, ES, FI, GB, GR, HR, IE, IT,

LT, LV, NO, PT, RO, SE, SI, SK, TR

BE, CH, CZ, ES, FR, GB, GR, HR, IE, IT, LU, PL, PT I

AT, BE, CH, CZ, DE, ES, FR, GB, HU, NL I

CH, CZ, ES, GB, GR, HR, IE, IT, PT II

CH, CZ, ES, GB, II

I

2H

3P

3P

2H3P

2H3P

G20 20

G31 37

G31 50

G20 20

G31 37

G20 20

G31 50

Part # 4525587 Rev 4 (29 April 14) Page 7

Page 8

INTRODUCTION

1. Check crate for possible damage sustained during transit.

Carefully remove unit from crate and again check for

damage. Any damage to the appliance must be reported

to the carrier immediately.

2. The wires for retaining packing material must be

removed from units. Any protective material covering

stainless steel parts must also be removed.

3. All equipment is supplied with 6” (152mm) legs unless

speci ed to be dais for cove base mounting, casters

or deck mount anged feet. Units 48” (1200mm) and

60” (1500mm) wide have legs factory mounted. Base

mounting is required when range is being installed on a

combustible oor.

4. The type of gas and supply pressure that the equipment

was set-up for at the factory is noted on the rating plate

and on the packaging. This type of gas supply must be

used.

5. Do not remove permanently a xed labels, warnings or

rating plates from the appliance, for this may invalidate

the manufacturer’s warranty.

Rating Plate

All burner input rates are shown on the rating plate, which is

located behind the lower front drop down panel under the

oven door.

Safety Information

Warning: Accessible parts may become hot during use.

Young children should be kept away.

This appliance is for professional use and should only be

used by quali ed personnel

This appliance is not intended for use by persons (including

children) with reduced physical, sensory or mental

capabilities, or lack of experience and knowledge, unless

they have been given supervision or instruction concerning

use of the appliance by a person responsible for their safety.

Part # 4525587 Rev 4 (29 April 14)Page 8

Page 9

INSTALLATION

This product has been certi ed as commercial cooking

equipment and must be installed by professional personnel

as speci ed. THIS APPLIANCE IS NOT RECOMMENDED FOR

RESIDENTIAL INSTALLATION.

Garland suggest installation, maintenance and repairs

should be performed by your local Garland/US Range

authorized service agency, when ever possible.

Siting

The oor on which the appliance is to be sited must

be capable of adequately supporting the weight of

the appliance and any ancillary equipment. Units with

ovens must be tted with legs or casters if installed on a

combustible oor. Adequate clearance must be provided for

servicing and proper operation.

Appliances Equipped With Casters

1. The installation shall be made with a connector that

complies with the Standard for Connectors for Moveable

Gas Appliances, ANSI Z21.69/CSA 6.16, Addenda

Z21.69B-2006/CSA 6.16B-2006 (or latest edition), and a

quick-disconnect device that complies with the Standard

for Quick Disconnects for Use with Gas Fuel, ANSI Z21.41/

CSA 6.9, Addenda Z21.41A-2005/CSA 6.16A-2005

(or latest edition).

2. The front casters of the appliance are equipped with

brakes to limit the movement of the appliance without

placing any strain on the connector or quick disconnect

device or its associated piping.

3. Please be aware that required restraint is attached to a

cut out hole in side panel, and if disconnection of the

restraint is necessary, be sure to reconnect the device

after the appliance has been returned to its original

position.

Appliances Equipped With Legs

1. Raise the front of the appliance and block. Do not lay the

appliance on its back.

Installing Shelf To Backguard

Note: Shelf may be installed before or after installing the

backguard to the range.

1. Loosen 4 bolts on the front of the backguard

approximately 1/4” (6mm).

2. Align the 4 slotted holes on the back of the shelf with the

4 bolts on the backguard.

3. Slide the shelf downward until the 4 bolts are engaged in

the slotted portion of the keyhole.

4. Tighten the 4 bolts to secure the shelf.

5. On 60” units only, install a sheet metal screw though the

hole in the underside of the shelf into the backguard and

tighten.

MOUNTING

BOLTS

BACKGUARD

SHELF

SHEETMETAL

SCREW

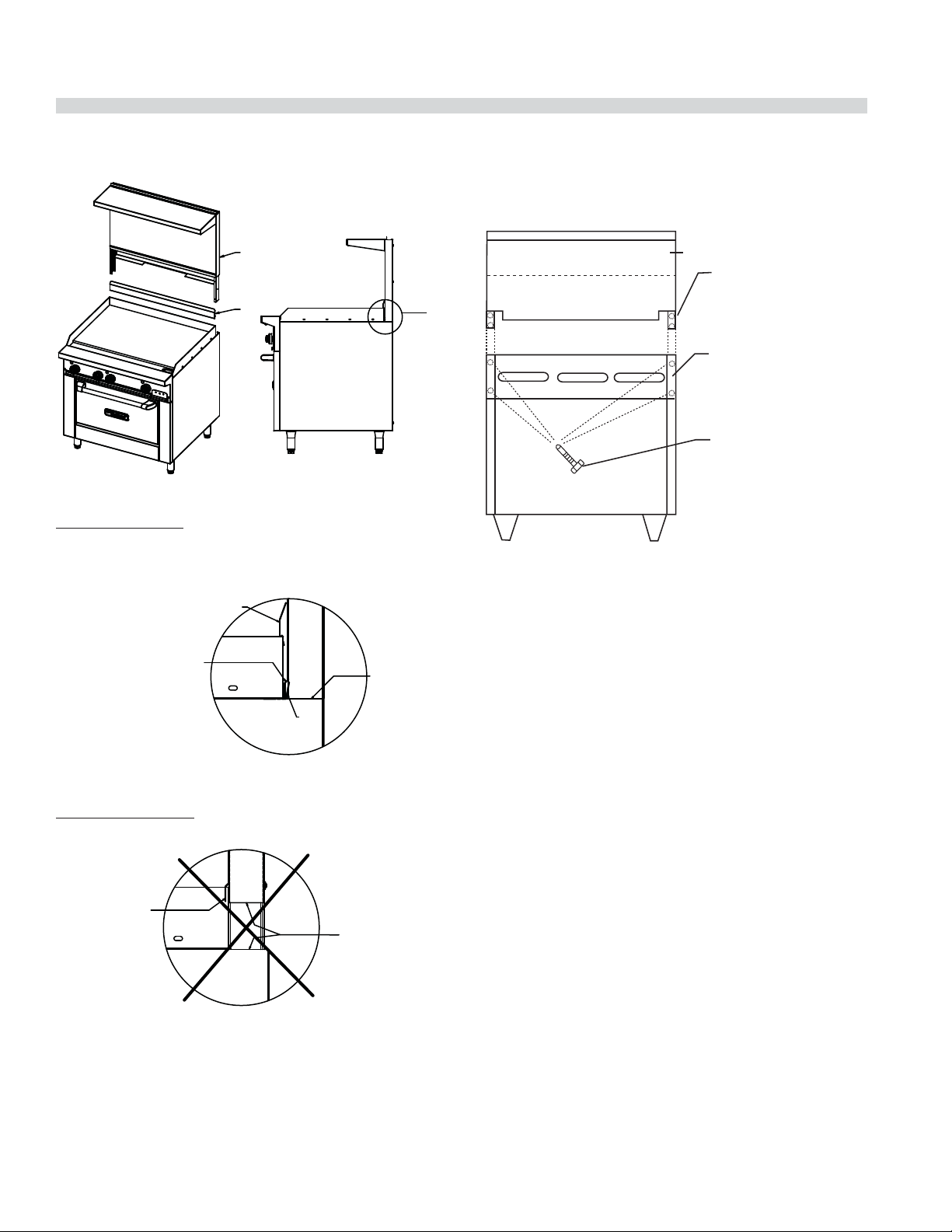

Backguard With High Shelf Or Salamander

Mounting Instructions

1. Rear of the range must be easily accessible.

2. Please refer to the installation instructions included with

the salamander for further instructions on these units.

3. Place the backguard or high shelf on the rear of the

range, slipping the support brackets into the openings in

the main body sides.

2. Legs are threaded to be easily screwed into the holes

provided on the bottom of the range.

3. Once legs have been attached and secured they can

be adjusted to level the appliance and compensate for

uneven ooring.

Part # 4525587 Rev 4 (29 April 14) Page 9

4. For ranges with griddles, care must be taken when

mounting the backguard or high shelf. The front panel

of the stainless steel backguard or high shelf has an

extruding lip at the bottom. This lip must NOT go over

the griddle back splash, if it does the backguard will not

t properly and the range will not ue properly. Refer to

illustration for proper installation.

Page 10

INSTALLATION Continued

BACKGUARD

5. Securely fasten the support brackets to the burner box

sides with (4sheet metal screws provided).

SPLASH

GUARD

Correct Installation

CLIP GRIDDLE SPLASH GUARD

ONTO BACK FLANGE OF GRIDDLE

(SHIPPED ON TOP OF GRIDDLE)

BACKGUARD LIP GOES

BEHIND BACK FLANGE

OF GRIDDLE & OVER

ANGLE FLANGE

Incorrect Installation

BACKGUARD

LIP ON BACK

FLANGE

OF GRIDDLE

ANGLE

FLANGE

FLUSH WITH

SIDE PANEL

NOT FLUSH

WITH

SIDE PANEL

DETAIL

AREA

Upright

Main Body

Side

Sheet Metal

Screws (4 Req'd)

Ventilation Air

The following notes are intended to give general guidance.

For detailed recommendations, refer to the applicable

code(s) in the country of destination. These appliances shall

be installed in a room with su cient ventilation to prevent

the occurrence of hazardous concentrations of combustion

by-products.

The room containing the appliance is required to have a

permanent vent. The minimum e ective area of the vent is

related to the maximum rated heat input of the appliance

and shall be 4.5 cm2 per kW in excess of 7 kW.

Proper ventilation is critical for optimum performance. The

ideal method of ventilating open-top equipment is the use

of a properly designed canopy that should extend six inches

(152 mm), beyond all sides of the appliance(s) and six feet, six

inches (1981mm) above the oor.

Air vents should be of such a size as to compensate for the

e ects of any extract fan in the premises. A strong exhaust

will create a vacuum in the room. For an exhaust vent to work

properly, replacement air must be equal to the amount of air

exhausted. An imbalance between exhaust and replacement

air can cause degradation in the appliance’s performance.

All gas burners and pilots need su cient air to operate. Large

objects should not be placed in front of the appliance(s) that

would obstruct the ow of air into the front.

Part # 4525587 Rev 4 (29 April 14)Page 10

Page 11

INSTALLATION Continued

Statutory Regulations

In European countries, installation must be carried out by

a competent person and in accordance with the relevant

regulations, codes of practice and the related publications of

the country of destination.

In the United States, the installation must conform to the

National Fuel Gas Code ANSI Z223.1, or latest edition, NFPA

No.54 - latest edition/or local code to assure safe and e cient

operation. In Canada, the installation must comply with CSA

B149.1 and local codes.

Australia Speci c Clause

This appliance must be installed in accordance with the

manufacturer’s instructions, local gas tting regulations

and requirements of AS 5601 installation code. All burner

adjustments and setting should be made by a quali ed gas

technician.

Electrical Connection Settings

(Where Applicable)

IMPORTANT- This appliance must be electrically grounded in

accordance with local codes, or in the absence of local codes

with the National Electrical Code.

220/240 Volt Convection Oven Models

When the appliance is ordered and equipped for 220/240

volt operation, the supply line must be connected to the

wiring terminations located inside the terminal box at the

rear of the appliance.

For ease of attaching the supply line, there is a removable

cover on the terminal box.

Permanent connection to the electrical service must comply

with local codes, or in the absence of local codes, with the

national electrical code.

All xed (non-mobile) appliances MUST be tted with an

accessible upstream gas shut o valve as a means of isolating

the appliance for emergency shut o and for servicing. A

union or similar means of disconnection must be provided

between the gas-cock and the appliance.

A manually operable valve must be tted to the gas supply

to the kitchen to enable it to be isolated in an emergency.

Wherever practical, this shall be located either outside the

kitchen or near to an exit in a readily accessible position.

Where it is not practical to do this, an automatic isolation

valve system shall be tted which can be operated from a

readily accessible position near to the exit.

In locations where the manual isolation valve is tted or the

automatic system can be reset this notice MUST be posted:

“ALL DOWNSTREAM BURNER AND PILOT VALVES MUST

BE TURNED OFF PRIOR TO ATTEMPTING TO RESTORE THE

SUPPLY. AFTER EXTENDED SHUT OFF, PURGE BEFORE

RESTORING GAS.”

Installation Notes

Before assembly and connection, check gas supply.

A. The type of gas for which the unit is equipped is stamped

on the rating plate located behind the lower front

panel. Connect a unit stamped “NAT” only to natural gas;

connect one stamped “PRO” only to propane gas.

B. If it is a new installation have the gas authorities check

meter size and piping to assure that the unit is supplied

with the necessary amount of gas pressure required to

operate the unit.

C. If it is additional or replacement equipment have the gas

authorities check pressure to make certain that existing

meter and piping will supply fuel to the unit with no

more than 0.15 Kpa pressure drop.

Gas Connection

The local gas authority should be consulted at the

installation planning stage in order to establish the

availability of an adequate supply of gas and to ensure

that the meter is adequate for the required ow rate. The

pipe work from the meter to the appliance must be an

appropriate size.

Part # 4525587 Rev 4 (29 April 14) Page 11

D. Make certain new piping and connections have been

made in a clean manner and have been purged so that

piping compound, chips, etc. will not clog pilots, valves or

burners. Use pipe joint compound approved for natural

and lique ed petroleum gases.

NOTE: Gas pressure should be checked when the unit is

installed with all other equipment on the same line turned

on. The operating manifold gas pressure must be the same

as that speci ed on the rating plate. If necessary, pressure

adjustment may be made at the pressure regulator supplied

with the appliance.

Page 12

INSTALLATION Continued

The appliance pressure regulator provided by the factory

is pre-set to the correct manifold pressure. The manifold

pressure may require veri cation and adjustment at the

installation. Allow at least one burner to be ignited and

operating while checking manifold pressure at the test

spigot located on the appliance manifold, and adjust the

appliance pressure regulator accordingly.

The appliance and its individual shut-o valve must be

disconnected from the gas supply piping system during any

pressure testing of that system where pressures are in excess

of 1/2 PSIG (3.45kPa.)

5

TO INLET OF SALAMANDER/

8

CHEESEMELTER MANIFOLD

REGULATOR - 6.0"w.c. NATURAL GAS

OR 10.0"w.c. PROPANE GAS

(SUPPLIED WITH SALAMANDER/

CHEESEMELTER)

Final Preparation

NOTE: Your new range has a plastic coating to help protect

the nish from scratches during shipping. This protective

plastic lm should be peeled o prior to starting the range.

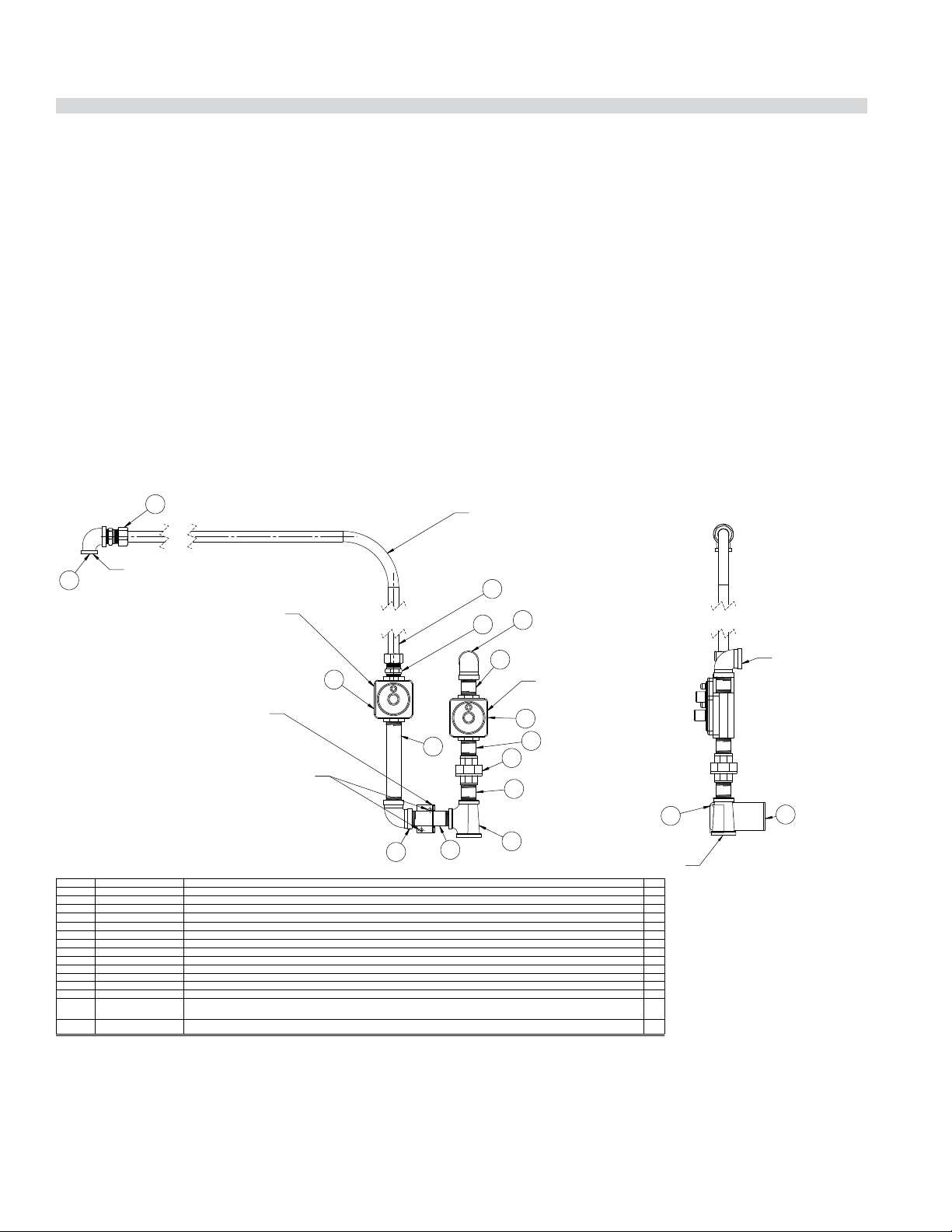

Optional Interconnect Gas Kit

To interconnect range mount salamanders with range

The GF series Garland range can be equipped with a range

mount gas salamander. Salamanders can be plumbed

independently or be interconnected with the range. See

Drawing for various options for mounting onto a 36”

(900mm) a 48” (1200mm) or a 60” (1500mm) range.

CUT TUBING (ITEM 15 - 4531608) TO SIZE AS REQUIRED

TO SUIT SALAMANDER/CHEESEMELTER TOP OR REAR

MANIFOLD INLET CONNECTION

15

SUPPLIED WITH RANGE

3

5

15 4531608

14

13

2127503/2127500

12

11

10

9

8

7

6 2640700

5 3013000

4

3

2

NAT: 2127502/4525047

1

PRO: 2127500/4525048

ITEM NO.

PART NUMBER

ATTACH SUPPORT CLAMP (ITEM 7 - 2640800)

TO SUPPORT BRACKET ( ITEM 6 - 2640700)

WITH (2)#10-24 SELF-TAPPING SCREWS (ITEM 12

F32 - NOT SHOWN) PROVIDED.

MARK HOLE LOCATIONS AND MOUNT

SUPPORT BRACKET (ITEM 6 - 2640700) TO RANGE

BACK WITH (2)#10-16 TEKS SELF-DRILL/TAP

SCREWS (ITEM 11 - F67 - NOT SHOWN) PROVIDED.

G01738-11

F32

F67

G03716-1

G01738-5

G01474-9

2640800

G01963-1

G01474-5

G01738-14

6.0"wc 3/4"NPT REG. NATURAL GAS/10"wc 3/4" NPT REG. PROPANE GAS - SUPPLIED WITH SALAMANDER/CHEESEMELTER

4.5"wc 3/4"NPT/3/4" ISO 7-1 REG. NATURAL GAS OR 10"wc 3/4"NPT/3/4" ISO 7-1 REG. PROPANE GAS - SUPPLIED W/RANGE

SUPPLIED WITH RANGE

2

13

9

3

3/4" X 51" X 33" TUBING

3/4" NPT X 3.5" PIPE NIPPLE

SCREW-10-24X1/2" PAN HD SELF-TAP TYPE F (NOT SHOWN)

SCREW - #10-16 X 1/2" HEX WASHER HEAD TEKS SELF DRILL/TAP (NOT SHOWN)

3/4" NPT X 3/4" NPT X 1" NPT REDUCING TEE

3/4" NPT X 6.5" PIPE NIPPLE

3/4" NPT X 1/2" NPT 90 DEG. REDUCING ELBOW

PIPE SUPPORT BRACKET CLAMP

PIPE SUPPORT BRACKET

3/4" CC X 3/4" NPT STRAIGHT FITTING

90 DEGREE ELBOW 3/4" NPT (ONE SUPPLIED WITH RANGE)

3/4" NPT X 2IN PIPE NIPPLE (ONE SUPPLIED WITH RANGE)

3/4" NPT PIPE UNION

DESCRIPTION

14

REGULATOR - 4.5" w.c. NATURAL GAS

OR 10.0" w.c. PROPANE GAS

(SUPPLIED WITH RANGE)

1

2

4

2

10

7

1" NPT GAS SUPPLY

CONNECTION

1

1

1

2

2

1

1

1

1

1

2

1

2

3

1

QTY

TO INLET OF RANGE

MANIFOLD

6

Optional Interconnect Gas Kit

36in (900mm) G/U/X

Part # 4531606

Part # 4525587 Rev 4 (29 April 14)Page 12

Page 13

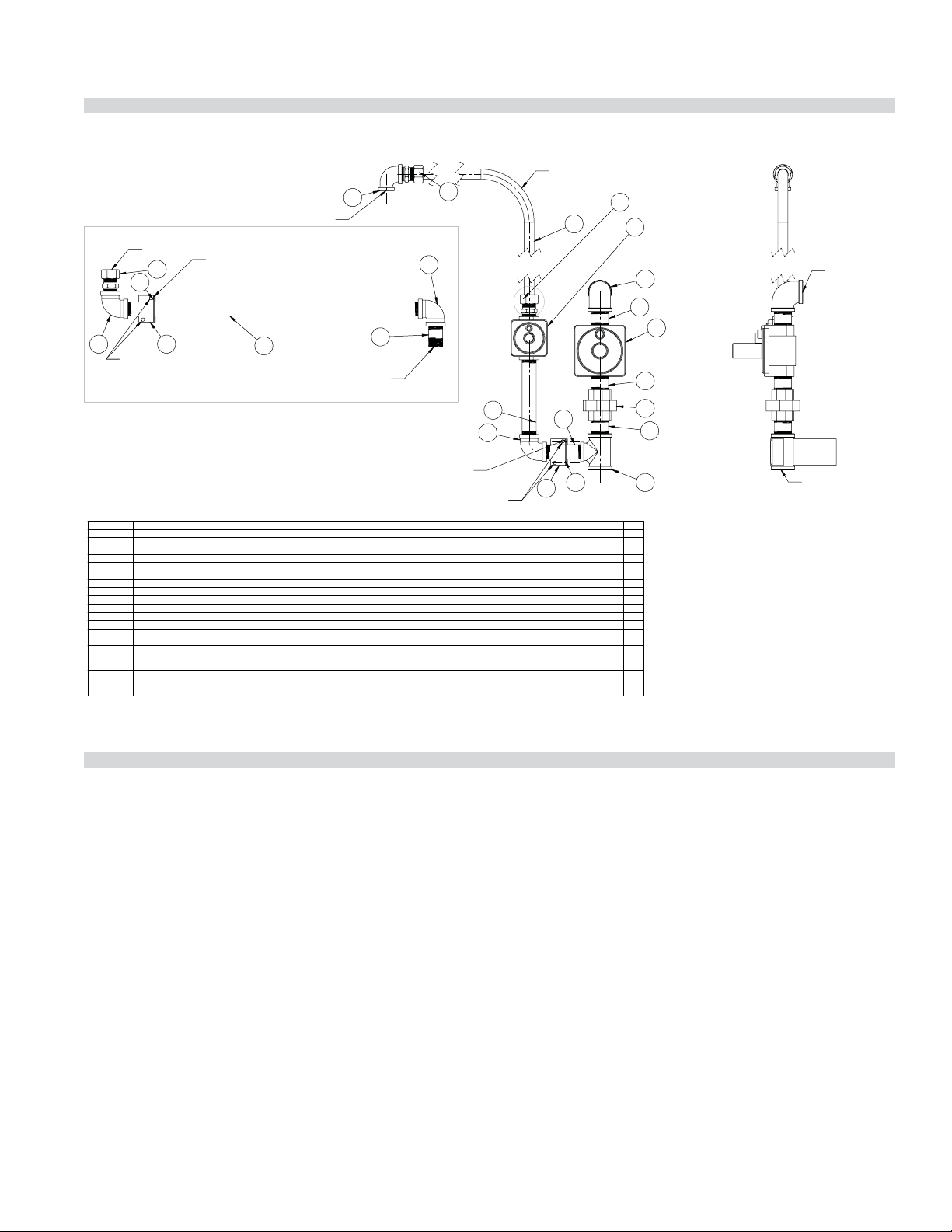

INSTALLATION Continued

TO INLET OF SALAMANDER/

CHEESEMELTER MANIFOLD

FOR LEFT-MOUNTED SALAMANDER/CHEESEMELTER

SUBSTITUTE COMPONENTS SHOWN FOR ITEM 17 CIRCLED IN ADJACENT VIEW

6

TO INTER-CONNECT TUBING ( ITEM 18 - 4531608)

17

10

MARK HOLE LOCATIONS AND MOUNT

SUPPORT BRACKET (ITEM 9 - 4531602 ) TO RANGE

BACK WITH (2) #10-16 TEKS SELF-DRILL/TAP

SCREWS (ITEM 14 - F67 - NOT SHOWN) PROVIDED.

ATTACH SUPPORT CLAMP (ITEM 10 - 2640800)

TO SUPPORT BRACKET (ITEM 9 - 4531602)

WITH (2) #10-24 SELF-TAPPING SCREWS (ITEM 1

F32 - NOT SHOWN) PROVIDED

9

12

TO OUTLET OF SALAMANDER/

CHEESEMELTER REGULATOR

16

13

NOTE: CUT TUBING (ITEM 18 - 4531608) TO SIZE AS REQUIRED

TO SUIT SALAMANDER/CHEESEMELTER TOP OR REAR

17

6

MANIFOLD INLET CONNECTION

17

18

3

REGULATOR - 6.0"w.c.

NATURAL GAS OR 10.0"w.c.

PROPANE GAS (SUPPLIED

WITH SALAMANDER/CHEESEMELTER)

SUPPLIED WITH

7

RANGE

SUPPLIED WITH

4

RANGE

2

REGULATOR - 4.5"w.c.

NATURAL GAS OR 10.0"w.c.

PROPANE GAS (SUPPLIED

WITH RANGE)

4

TO INLET OF RANGE

MANIFOLD

ATTACH SUPPORT CLAMP (ITEM 10 - 2640800)

TO SUPPORT BRACKET (ITEM 9 - 4531602)

WITH (2) #10-24 SELF-TAPPING SCREWS (ITEM 1

F32 - NOT SHOWN) PROVIDED

MARK HOLE LOCATIONS AND MOUNT

SUPPORT BRACKET (ITEM 9 - 4531602) TO

BACK WITH (2) #10-16 TEKS SELF-DRILL/TAP

SCREWS (ITEM 14 - F67 - NOT SHOWN) PROVIDED.

18 4531608

17 3013000

16

15

14

13

12

11 3012800

10 2640800

9 4531602

8 4530189

7

6

5

4

3

NAT: 4522421/4525049

2

PRO: 4522422/4525050

1

ITEM NO.

G01474-9

G01738-11

F67

G01738-14

G01738-16

076029-171

G01474-5

G01738-5

076029-204

2127503/2127500

F32

PART NUMBER

SCREW - #10-16 X 1/2" HEX WASHER HEAD TEKS SELF-DRILL/TAP (NOT SHOWN)

4.5"wc 3/4"NPT REG. NATURAL GAS/10"wc 3/4"NPT REG. PROPANE GAS - PROVIDED WITH SALAMANDER/CHEESEMELTER

4.5" wc 1" NPT/ 1" ISO 7-1 REG. NATURAL GAS OR 10"wc 1"NPT/1" ISO 7-1 REG. PROPANE GAS - PROVIDED WITH RANGE

SCREW - #10-24 X 1/2" PAN HD SELF-TAP TYPE F (NOT SHOWN)

3/4" X 51" X 33" TUBING

3/4" CC X 3/4" NPT STRAIGHT FITTING

3/4" NPT X 1/2" NPT 90 DEG. REDUCING ELBOW

3/4" NPT X 3.5" PIPE NIPPLE

3/4" NPT X 2.000 PIPE NIPPLE

3/4" NPT X 22.750 PIPE NIPPLE

1" NPT X1" NPT X 3/4" NPT REDUCING TEE

PIPE SUPPORT BRACKET CLAMP

PIPE SUPPORT BRACKET 48/60

1" NPT 90 DEGREE ELBOW(SUPPLIED WITH RANGE)

1" NPT X 2" PIPE NIPPLE (ONE SUPPLIED WITH RANGE)

1" NPT PIPE UNION

90 DEGREE ELBOW 3/4" NPT

3/4" NPT X 6.5" PIPE NIPPLE

DESCRIPTION

TESTING AND ADJUSTMENT

Testing

All ttings and pipe connections must be tested for

leaks. Use approved gas leak detectors, soap solution or

equivalent, checking over and around all the ttings and

pipe connections. DO NOT USE A FLAME! Accessibility to

all gas lines and ttings require that valve panel(s) lower

front panel(s), and/or oven rack(s) be removed. It may be

necessary to remove, or at least raise and securely prop

griddle(s), hot top(s), and/or top grate(s). All parts removed,

(including fasteners), should be stored safely for reinstallation.

1. Be sure that all valves and thermostats are in the “OFF”

position.

5

6

15

10

9

8

4

11

1

2

1

1

4

1

1

1

2

QTY

2

1

1

3

1

3

1

1

4

Optional Interconnect Gas Kit

48in (1200mm) & 60in (1500mm) G/U/X

Part # 4531606

1" NPT GAS SUPPLY

CONNECTION

2. Turn on the main gas supply valve. Light all top section

pilots.

3. Leak test all valves and ttings as described at the

beginning of this section. Correct any leaks as required

and recheck.

4. Light the oven pilot.

5. Set the oven thermostat to maximum. Leak test all valves

and ttings as described at the beginning of this section.

Correct any leaks as required and recheck.

6. Shut o all valves and set thermostat dials to “OFF” or

lowest position. All units are tested and adjusted at the

factory, however, burners and pilots should be checked

upon installation and adjusted if necessary.

Part # 4525587 Rev 4 (29 April 14) Page 13

Page 14

OPERATION

Flame Failure Technology

The Garland GF series gas range has total ame failure (also

referred to as ame safety) technology. It is a simple system

that monitors the existence of a gas ame. It can be used on

most gas appliances and will turn o the gas supply to any

burner using the system when a pilot ignition ame is not

present.

Flame failure systems have been available for many years

and it is the “CE” agency standard accepted for European gas

appliance approvals. In North America this technology is

gaining greater acceptance and various levels of government

are making it mandatory in schools and other government

institutions.

How Flame Failure Technology Works

For gas restaurant ranges, there are three principles at

work in a ame failure system, they are a safety valve, the

thermocouple and the pilot.

Safety Valve

The SIT control used on the new Garland series of restaurant

ranges operates both as the mechanism to control the

oven temperature (thermostat) and the safety valve for the

ame failure system. This valve contains a magnet which

when electrically charged, will hold a check valve in an open

state allowing for gas to ow through the valve as required

by either the pilot or main burner. The magnet is charged

through an electrical signal sent from the thermocouple

when a ame is present. When no ame is present, no signal

is sent and the magnet releases closing the check valve.

Because no gas can ow through the valve if the pilot is not

burning, no gas can build up, decreasing the risks a of any

safety conditions.

magnet in the safety valve releases to close o the supply

gas.

Pilot

The pilot provides the ame that the thermocouple uses to

generate millivolts. When all three of the above components

are placed together a Flame Failure system is created.

The above principles apply no matter what section of the

range is using ame failure technology. When operating

open top burners or hot tops the hi-lo valve also acts as a

safety valve in the system. The same SIT thermostat as in the

oven section of the range is used on at griddle models.

Burner Operation

Caution: In the event that a binding or malfunctioning

valve, or thermostat control is observed DO NOT light the

pilots or continue operation until an authorized service

technician has inspected the appliance. Failure to do so

may result in injury.

Open Top burners

Lighting

1. Push in the valve knob, and turn it counter clockwise to

the ignition “” position.

2. While holding the valve knob fully in, light the pilot

burner with a match or BBQ ignition device.

Note: On ranges equipped with electric spark igniters, press

the igniter button and check that the pilot lights. Should

burner ignition fail within 4 seconds, turn the burner valve

o and repeat steps 1 through 2. If ignition continues to fail,

consult the factory authorized service agency.

Thermocouple

The thermocouple is positioned so that the tip of the

thermocouple comes into contact with the pilot ame

when lit. When exposed to a ame, a properly functioning

thermocouple produces a small electrical signal measured

in millivolts. This signal is transferred through the electrical

wire connecting the thermocouple to the safety valve in

the SIT control, and to the magnet inside the valve thereby

energizing it. Again, when the magnet is energized, it is able

to hold a check valve in an open state allowing gas to ow

through the valve to the burner(s) and pilot(s). If the pilot

goes out then the generation of millivolts stops and the

3. When the pilot is lit continue to hold the valve knob fully

in for at least 30 seconds, then release it. If the pilot goes

out, wait for (5), minutes, then repeat from step 1.

4. When the pilot remains lit, push the valve in again and

turn it counter-clockwise to the desired ame setting

position, lighting the burner.

Part # 4525587 Rev 4 (29 April 14)Page 14

Page 15

OPERATION Continued

Shut Down

1. To turn the burner o and still have the pilot remain on,

turn the dial to the ignition “ ” position.

2. To turn the burner and pilot o , turn the dial to the

circular “OFF” symbol. The safety device will disengage

within 60 seconds.

Hot Tops and Front-Fired Target Tops

Lighting

1. Push in the valve knob, and turn it counter clockwise to

the ignition “ ” position.

2. While holding the valve knob fully in, press the igniter

button and observe if the pilot lights. If it does not light,

repeatedly depress the igniter button until it does.

Note: On ranges equipped with electric spark igniters, press

the igniter button and check if the pilot lights. Should burner

ignition fail within 4 seconds, turn the burner valve o and

repeat steps 1 through 2. If ignition continues to fail, consult

the factory authorized service agency.

Ovens (Standard)

Lighting

1. Lower front kick panel below oven door, raise oven

hearth bottom for easy access to oven pilot.

2. Turn oven control knob ( gure 1) to “ ” position and

then push in to engage the ow of gas through the safety

device to the pilot.

Figure 1

3. When the pilot is lit continue to hold the valve knob fully

in for at least 30 seconds, then release it. If the pilot goes

out, wait for (5), minutes, then repeat from step 1.

4. When the pilot remains lit, push the valve in again and

turn it counter-clockwise to the desired ame setting

position, lighting the burner.

5. For low ame or simmer push in the valve knob and turn

it counter-clockwise to the low ame position.

6. Surface plates are capable of reaching very high

temperatures, solid hot tops 380C(716F) front - red

target tops 585C(1085F).

Shut Down

1. To turn the burner o and still have the pilot remain on,

turn the dial to the ignition “ ” position.

2. To turn the burner and pilot o , turn the dial to the

circular “OFF” symbol. The safety device will disengage

within 60 seconds.

3. While holding knob in, light pilot with a match/BBQ

lighter or use the spark ignition (if provided) to spark

ignite pilot.

4. Continue to hold knob in for 15 seconds after ignition,

then release. Pilot should remain lit.

5. If pilot burner fails to light or does not stay lit, wait 5

minutes and repeat steps 2 through 4.

6. Replace hearth or close kick panel, then turn oven

thermostat to desired cooking temperature.

7. To shut down main burner turn control knob ( gure 1) to

“ ” position.

Warning: Use caution when opening the oven door while it

is in use. Hot air or steam may cause injury.

Shut Down

If pilot shut down is required push in oven thermostat knob

and turn to “ ” symbol. The system will disengage with in 60

seconds.

Part # 4525587 Rev 4 (29 April 14) Page 15

Page 16

OPERATION Continued

Convection Ovens

The forced air range oven consists of a food preparation

chamber completely sealed from the combustion area.

This eliminates the possibility of contamination from ue

products and permits an e cient method of circulating the

heated air within the cooking chamber.

During the cooking process in a conventional oven, a vapor

barrier and a layer of “cool” air covers the exposed area of

the product. In a forced air oven, the fan pushes the heated

air over and around the product, sweeping away the vapor

barrier and cool air, permitting faster heat penetration. This

action permits the use of lower temperatures and shorter

cooking times.

The rule of thumb for determining the cooking temperature

is to reduce the set temperature by approximately

80°F, (28°C), from that which you would set in a conventional

oven. The product should be checked at a point midway in

the time required in a conventional oven.

Lighting

1. Lower front kick panel below oven door.

Cool down

1. Turn the oven valve knob to the “ ” position this will

prevent the main oven burner from cycling on. ( gure 1).

2. Turn the thermostat to its lowest setting.

3. Open the oven door.

Warning: Use caution when opening the oven door while it

is in use. Hot air or steam may cause injury.

4. Set the power switch to the “COOL DOWN” position.

5. Once the oven has cooled turn the power switch to o

and close the oven door.

Shut Down

1. If pilot shut down is required push in oven thermostat

knob turn to “ ” symbol. The system will disengage with

in 60 seconds.

2. Power switch should be in the o position.

Operating Suggestions

2. Push and hold in oven thermostat control valve knob

( gure 1) and turn it counter clockwise to the ignition

position “ ”.

3. While holding knob fully in depress the red igniter button

and observe that the pilot ame is lit. If it does not light,

repeatedly depress the igniter button until it does.

Note: On ranges equipped with electric spark igniters, press

the igniter button and check if the pilot lights. Should burner

ignition fail within 4 seconds, turn the burner valve o and

repeat steps 1 through 2. If ignition continues to fail, consult

the factory authorized service agency.

4. When the pilot is lit, continue to hold the valve knob fully

in for 15 seconds, then release it. If the pilot goes out, wait

for ve (5) minutes, then repeat steps 2 to 4.

Start Up

1. Set the power switch to the “COOK” position.

2. Turn the thermostat to the desired setting.

The motor in your range convection oven is maintenance

free since it is constructed with self-lubricating sealed ball

bearings. It is designed to provide durable service when

treated with ordinary care. We have a few suggestions to

follow for the care of your motor.

A. When the motor is operating, it cools itself internally by

air entering the rear of the motor case, provided proper

clearance has been allowed.

B. Since the blower wheel is in the oven cavity it is at the

same temperature as the oven. If the motor is stopped

while the oven is hot, the heat from the blower wheel is

conducted down the shaft and into the armature of the

motor. This action could shorten motor life.

C. We recommend, at the end of the bake or roasting

period, when the oven will be idle for any period of time

or before shutting down completely, that the doors

be left open, and by use of the cool-down position on

the fan switch, the fan continues to run for at least 20

minutes. The “FAN” should never be turned “OFF” when

the oven section is in use.

Part # 4525587 Rev 4 (29 April 14)Page 16

Page 17

OPERATION Continued

D. All convection oven model units have a controllable

moisture vent. The vent control is a sliding cover inside

the oven cavity. Sliding the vent from left to right will

increase or decrease the amount moisture inside the

oven during cooking. Dryness or moisture of the nished

product will dictate the setting of the vent. To speed up

pre-heat time close the vent during preheat.

Thermostat Controlled Griddles

See griddle seasoning before use.

1. For general thermostat griddle lighting instructions

please refer to the section entitled “OVEN (STANDARD)”

above. (Steps 2 though 7)

2. Pilots should be lit though the front panel with an extend

match or long BBQ lighter. If necessary the front panel of

the range can be removed to allow the griddle plates to

be raised at the front, block securely.

3. Light pilots located at the front left side of each burner

4. The sensing bulbs must be fully inserted into their

individual holders, which are located on the underside

of the griddle. To check griddle burner ame set the

thermostat to its maximum setting and then return to

pilot.

5. If the griddle has been raised to light the pilots, lower

carefully into position, being very careful not to leave any

part of the capillary tube in the burner compartment.

Replace the front panel of the range.

6. Surface temperature of solid griddle top is capable of

reaching at least 265C (509 F).

Griddle/Broiler

See griddle seasoning before use.

Lighting

1 Push in the valve knob, and turn it counter clockwise to

the ignition “ ” position.

2 While holding the valve knob fully in, press the igniter

button and check if the pilot lights. If it does not,

repeatedly depress the igniter button until it does.

Note: On ranges equipped with electric spark igniters, press

the igniter button and check that the pilot lights. Should

burner ignition fail within 4 seconds, turn the burner valve

o and repeat steps 1 through 2. If ignition continues to fail,

consult the factory authorized service agency.

3. When the pilot is lit continue to hold the valve knob fully

in for at least 30 seconds, then release it. If the pilot goes

out, wait for (5), minutes, then repeat from step 1.

4. When the pilot remains lit, push the valve in again and

turn it counter-clockwise to the desired ame setting

position, lighting the burner.

5. For low ame or simmer push in the valve knob and turn

it counter-clockwise to the low ame position.

6. Surface Temperature of solid griddle top is capable of

reaching at least 380C (716 F).

Shut Down

1. To turn the burner o and still have the pilot remain on,

turn the dial to the ignition “ ” position.

Caution: Only authorized service

technicians should be removing thermostat

control knobs. In the event the thermostat

temperature knob has been removed, the set

screw must line up with the hole on the

thermostat control dial.

Part # 4525587 Rev 4 (29 April 14) Page 17

2. To turn the burner and pilot o , turn the dial to the

circular “OFF” symbol. The safety device will disengage

within 60 seconds.

Range Shut down

1. Turn all valves to the “OFF” position.

2. If the unit is to be shut down for an extended period of

time, close the in-line gas valve.

Page 18

PRODUCT APPLICATION INFORMATION

General

The range is the workhorse of the kitchen because of its

versatility. Most frequently used in small applications, such as

cafes, schools, church kitchens, rehouses, and small nursing

homes where demands are less taxing. As a general rule of

thumb, one four to six burner range with a hot top will be

adequate for a restaurant seating 30 to 35.

The top of the range is designed for exibility and the

preparation of numerous medium volume types of products.

It may be equipped with two, or even three di erent types

of tops and burners, depending on the menu needs. An

operation that cooks to order, or uses the range primarily

as back-up will nd that open burners will suit most of their

needs.

Preparation of soups, stocks, or sauces is done on a hot top

where slow, even cooking is desirable.

Heating larger quantities of food can be done more

e ciently than heating small quantities. Pots and pans

should be covered whenever possible to reduce energy

consumption.

High acid sauces, such as tomato should be cooked in

stainless steel rather than aluminum to avoid chemical

reaction. Light colored sauces such as Alfredo may be

discolored by the use of aluminum, especially if stirred with

a metal spoon or whip. Saltwater shell sh may pit aluminum

pots if they are frequently used for this purpose.

Use appropriately sized pots and pans to t each burner. Do

not allow pots to overhang plate rail.

NOTE: Many parts of the commercial range are raw steel.

Hot tops, griddles, springs, door hooks etc., can react with

moisture forming rust. This occurrence is normal and not

considered a defect. Clean with a stainless steel or ber pad.

A light coating of cooking oil may be applied.

CAUTION: DO NOT SPRAY AEROSOLS IN THE VICINITY OF THIS

APPLIANCE WHILE IT IS IN OPERATION.

Open Burners

The most traditional uses of open burners are sautéing, pan

frying, and small stock pot work. Short-term cooking is the

most e cient use for the open burner. Pans should cover

as much of the grate as possible to minimize heat loss. The

maximum stock pot size to be used on an open burner is

12 inches, (305mm), diameter. Use a pan size large enough

to contact all of the grate supports (minimum 6 “, 150mm).

Open burners should be turned o when not in use to

conserve energy. Leaving a ame burning is of no advantage

since the heat is instantaneous.

Hot Tops

Use of the solid hot tops is recommended where long-term

stock pot cooking is required for soups, sauces or stock. Pots

can be placed anywhere on the hot tops. Recommended

pre-heat time is 30 minutes. This will ensure that the casting

is thoroughly saturated with heat. Pots have should at

bottoms for maximum surface contact. Warped or dented

pots will not transfer heat evenly, wasting energy and

resulting uneven cooking patterns. During slow periods, it is

advisable to lower the burner setting to conserve energy.

Crumb Trays

In the event of a grease re in the crumb tray, call a service

technician to inspect for possible damage to components.

Do not continue to operate unit until inspected by

authorized service agent.

Part # 4525587 Rev 4 (29 April 14)Page 18

Page 19

MAINTENANCE AND CLEANING

Seasoning

Griddle

A. Remove all factory applied protective material by

washing with hot water, mild detergent or soap solution.

B. Apply a thin coat of cooking oil to the griddle surface,

about one ounce per square foot of griddle surface.

Spread over the entire griddle surface with a cloth to

create a thin lm. Wipe o any excess oil with a cloth.

C. Light all burners, set at the lowest possible setting. Some

discoloration will occur when heat is applied to steel.

D. Heat the griddle slowly for 15 to 20 minutes. Then wipe

away oil. Repeat the procedure 2 to 3 times until the

griddle has a slick, mirror like nish.

IMPORTANT: Do not set to a high position (on valve control)

or 450° (on thermostat control) during “break-in” period.

NOTE: Steel griddle surface will tone (blue discoloration)

from heat. This toning will not diminish function or operation

and it is not a defect.

The griddle will not require reseasoning if it is used properly.

If the griddle is over heated and product begins to stick to

the surface it may be necessary to repeat the seasoning

process again. If the griddle is cleaned with soap and water it

will be necessary to reseason the griddle surface.

Cast Iron top Grates

First, remove the cast iron top grates from the range. Wash

the cast iron top grates thoroughly with a mild soap and

warm water. Dry the cast-iron top grates thoroughly with a

clean cloth. Immediately after drying, season the top grates

lightly with a non-toxic oil, (Liquid vegetable oil or Pam spray

oil) WARNING; DO NOT SEASON THE TOP GRATES WHILE ON

THE RANGE TOP! Seasoning grates on the range top over an

open ame could cause a ash re. After seasoning, replace

the top grates onto the range. Turn all the range top sections

“ON LOW”. Allow the top sections to burn in this manner

for at least 20 minutes before using pots or pans on the top

grates. SEASONING OF THE TOP GRATES WILL BE REQUIRED

WHENEVER THEY HAVE BEEN CLEANED. FAILURE TO SEASON

GRATES WILL CAUSE RUSTING.

Stainless Steel

Rinse the washed area with a clean sponge dipped in a

sanitizing solution and wipe dry with a soft clean cloth

before it can dry.

Use a paste (of water and a mild scouring powder) if you

have to, but never rub against the grain. All stainless steel has

been polished in one direction. Rub with the polish lines to

preserve the original nish. Then thoroughly rinse as before.

To prevent ngerprints there are several stainless steel

polishes on the market that leave an oily or waxy lm. Do not

use on surfaces that will be in contact with food.

Stainless steel may discolor if overheated. These stains can

usually be removed by vigorous rubbing with a scouring

powder paste.

Use only stainless steel, wood or plastic tools if necessary

to scrape o heavy deposits of grease and oil. Do not use

ordinary steel scrapers or knives, as particles of the iron may

become imbedded and rust. NEVER USE STEEL WOOL.

Either a typical bleach solution or hot water can be used to

sanitize stainless steel.

Oven Interior (Porcelain Enamel)

NOTE: Disconnect line cord (if applicable) from power supply

before cleaning or servicing.

1. Before cleaning oven interior, remove all oven racks

and guides (if “RC” base). Oven racks and guides can be

cleaned with a mild soap and warm water or run through

dish washer.

2. The porcelain interior can be cleaned with oven cleaners

such as “Easy O , or “Dow Oven Cleaner”.

Follow product manufacturer’s instructions for proper use.

Open Top Burners

Cleaning of the range top burner is a simple procedure, and,

if done at regular intervals will prolong the life of the range

and ensure good ame characteristics.

1. The most common problem with open burner ranges is

spillage. Once the burner ports are partially plugged with

food, the air-to-gas mixture is disturbed and results in an

ine cient burner.

For routine cleaning, wash with a hot water and detergent

solution. Wash just a small area at a time or the water will

evaporate leaving the chemicals behind causing streaking.

Part # 4525587 Rev 4 (29 April 14) Page 19

2. Wipe any spills as they occur.

3. Grids and trays should be removed daily, washed, rinsed

and dried thoroughly.

Page 20

MAINTENANCE AND CLEANING Continued

4. Use a wire brush to clean the ports of the burners. Ignite

and check for clogged holes.

5. If any clogged holes are apparent, the burner should be

lifted out and brushed inside and out with a small Venturi

brush. Each port on the burner itself should be cleaned

with a properly sized wire or thumb drill. Wash with soap

and hot water if grease is observed on the burners. Dry

thoroughly.

6. When reinstalling the open top burner head be sure

the burner ports are lined up correctly to the pilot. On

the cast burner head there is a raised indicator arrow to

ensure the burner is installed correctly.

RAISED ARROW INDICATOR

PILOT

hot water. Dry thoroughly. In damp climates, wipe down with

a light coating of oil to prevent rusting. Avoid excessive use

of water as this could damage the surface and the controls

below.

CAUTION: Do not use water on top plates while they are hot

or Do not use ice to cool plates.

NOTE: Hot top and front- red target hot top surface will

“tone” (blue/brown discoloration) from heat. This toning will

not diminish function or operation and is not a defect.

Griddle

To produce evenly cooked, browned griddle products, keep

griddle free from carbonized grease. Carbonized grease on

the surface hinders the transfer of heat from the griddle

surface to food product. This results in uneven browning

and loss of cooking e ciency, and worst of all, carbonized

grease tends to cling to grilled foods, giving them a highly

unsatisfactory and unappetizing appearance. To keep the

griddle clean and operating at peak performance, follow

these simple instructions:

A. AFTER EACH USE clean griddle thoroughly with a grill

scraper or spatula. Wipe o any excess debris left from

cooking process.

7. If an abnormal ame appears around the edges, it is

usually a sign of grease or dirt in the throat of the burner.

Remove the burner venturi (main body that the burner

heads sit on) to access the air shutter opening. Remove

grease and dirt from the air shutter area carefully. Do

not adjust the shutter setting. The air shutter allows the

proper amount of air to mix with the ow of gas coming

in from your valve/thermostat ori ce and should not be

adjusted unless by a licensed gas tter technician.

Cast Iron Top & Grates

Cast iron top and grate(s) can be cleaned with mild soap

and warm water. For baked on material, a wire brush can be

used. Dry thoroughly. Lightly coat with vegetable oil to help

prevent rust from forming.

Hot Tops and Front-Fired Target Hot Tops

While the surface is still slightly warm, wipe down with a

clean burlap cloth. Burnt on spillage should be scraped o . If

necessary, remove the plate and wash in a sink with soap and

B. ONCE A DAY clean griddle surface with a grill brick and

grill pad. Remove grease container and clean thoroughly,

in the same manner as any ordinary cooking utensil.

C. ONCE A WEEK clean griddle surface thoroughly. If

necessary, use a grill stone or grill pad over the griddle

surface. Rub with grain of the metal while still warm.

A detergent may be used on the plate surface to help

clean it, but care must be taken to be sure it is thoroughly

removed. After removal of detergent, the surface of the

plate should be covered with a thin lm of oil to prevent

rusting. To remove discolorations, use a non-abrasive

cleaner. Before re-using, the griddle must be reseasoned.

Keep griddle drain tube to grease container clear at all

times.

CAUTION This griddle plate is steel, but the surface is

relatively soft and can be scored or dented by careless use of

a spatula.

Be careful not to dent, scratch, or gouge the plate surface.

This will cause food to stick in those areas. Also, note, since

this is a steel griddle if a light coating of oil is not always

present rust will develop on exposed and uncoated areas.

Part # 4525587 Rev 4 (29 April 14)Page 20

Page 21

INSTRUCTIONS

D’INSTALLATION ET

D’UTILISATION

SÉRIE GARLAND GF

SENTRY CUSINIÈRES DE

RESTAURANT À GAZ

POUR VOTRE SÉCURITÉ:

NE PAS STOCKER NI UTILISER D’ESSENCE

OU D’AUTRES VAPEURS OU LIQUIDES

INFLAMMABLES À PROXIMITÉ DE CET

APPAREIL OU DE TOUT AUTRE APPAREIL

AVERTISSEMENT

UNE INSTALLATION, DES RÉGLAGES, DES

MODIFICATIONS, DES RÉPARATIONS

OU UN ENTRETIEN MAL FAITS PEUVENT

CAUSER DES DOMMAGES MATÉRIELS,

DES BLESSURES OU LA MORT. LIRE

SOIGNEUSEMENT LES INSTRUCTIONS

D’INSTALLATION, D’UTILISATION ET

D’ENTRETIEN AVANT D’INSTALLER OU DE

RÉPARER L’ÉQUIPEMENT.

Tous des 24, 36, 48, et 60 pouce les modèles larges.

LIRE TOUTES LES SECTIONS DU PRÉSENT

MANUEL ET LE CONSERVER POUR S’Y REPORTER

ULTÉRIEUREMENT.

CE PRODUIT A ÉTÉ HOMOLOGUÉ EN TANT

QU’ÉQUIPEMENT PROFESSIONNEL DE CUISSON

ET DOIT ÊTRE INSTALLÉ PAR DU PERSONNEL

PROFESSIONNEL TEL QUE SPÉCIFIÉ.

DANS L’ÉTAT DU MASSACHUSETTS, CE PRODUIT

DOIT ÊTRE INSTALLÉ PAR UN PLOMBIER OU UN

MONTEUR D’INSTALLATION AU GAZ.

Pour votre sécurité

Placer dans un endroit bien en vue les

instructions à suivre en cas d’odeur de gaz

détectée par l’utilisateur. Cette information peut

être obtenue auprès du fournisseur de gaz local

.

L’attention des utilisateurs est attirée sur le fait que l’entretien et les réparations doivent être e ectués par un agent

d’entretien autorisé par Garland utilisant des pièces de rechange d’origine Garland. Garland n’aura aucune obligation

en ce qui concerne n’importe quel produit mal installé, réglé, utilisé ou qui n’aurait pas été entretenu conformément aux

codes nationaux et locaux ou aux instructions d’installation fournies avec le produit ou n’importe quel produit dont le

numéro de série aurait été mutilé, oblitéré ou supprimé ou qui aurait été modi é ou réparé avec des pièces non autorisées

ou par des agents d’entretien non autorisés. Pour obtenir la liste des agents de service autorisés, consulter le site web

de Garland à : http://www.garland-group.com. Les renseignements contenus dans le présent document (y compris la

conception et les spéci cations des pièces) peuvent être remplacés ou modi és sans préavis.

Garland Commercial Ranges, Ltd.

1177 Kamato Road, Mississauga, Ontario L4W 1X4 CANADA

Phone: 905-624-0260

Fax: 905-624-5669

Pièce nº 4525587 Rev 4 (29 Apr 14) Page 21

General Inquires 1-95-624-0260

USA Sales, Parts and Service 1-800-424-2411

Canadian Sales 1-888-442-4526

Canada or USA Parts/Service 1-800-427-6668

Page 22

INFORMATIONS IMPORTANTES

AVERTISSEMENT

Ce produit contient des produits chimiques reconnus par l’état de Californie comme causant

le cancer et/ou des malformations congénitales ou d’autres problèmes de reproduction.

L’installation et l’entretien de ce produit peut vous exposer aux poussières de laine de

verre/fibres céramiques. L’inhalation de ces particules de laine de verre ou de fibres céramiques

est reconnue par l’état de Californie comme causant le cancer. L’utilisation de ce produit peut vous

exposer au monoxyde de carbone en cas de mauvais réglage. L’inhalation de monoxyde de carbone

est reconnue par l’état de Californie comme pouvant causer des malformations congénitales ou

d’autres problèmes reproductifs.

Maintenir les abords de l’appareil

dégagés et ne pas y stocker de produits combustibles

Pièce nº 4525587 Rev 4 (29 Apr 14)Page 22

Page 23

TABLE DES MATIÈRES

INFORMATIONS IMPORTANTES . . . . . . . .22

DIMENSIONS ET SPÉCIFICATIONS . . . . . . 24

Désignations Des Modèles De Base Et Débits

Calori ques Totaux . . . . . . . . . . . . . . . . . . . . . . . . .25

Dégagements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Pression du Gaz et Débits Calori ques des

Brûleurs Individuels . . . . . . . . . . . . . . . . . . . . . . . . . 26

Amérique du Nord . . . . . . . . . . . . . . . . . . . . . . 26

CE Et Export Général . . . . . . . . . . . . . . . . . . . . 26

Taux réduits d’entrée . . . . . . . . . . . . . . . . . . . . 27

Remarque : La pression du collecteur doit

être mesurée au bout uni d’essai situé sur le

tube du collecteur de gaz de ¾ po.. . . . . . . 27

Australie . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Dimension d’entrée du gaz . . . . . . . . . . . . . . . . . .27

Catégories de Gaz Agréées CE . . . . . . . . . . . . . . .27

INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . .28

Plaque Signalétique . . . . . . . . . . . . . . . . . . . . . . . .28

Informations de Sécurité . . . . . . . . . . . . . . . . . . . . 28

Kit d’interconnexion au Gaz en Option

N° 4523975 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

ESSAIS ET RÉGLAGES. . . . . . . . . . . . . . . . . . 34

Essais . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

UTILISATION. . . . . . . . . . . . . . . . . . . . . . . . . . 35

Technologie à Détecteur de Flamme . . . . . . . . 35

Comment Fonctionne la Technique

de Détection de Flamme . . . . . . . . . . . . . . . . . . . .35

Brûleurs de Plaque Ouverte . . . . . . . . . . . . . . . . .35

Fours (standard) . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Fours à Convection . . . . . . . . . . . . . . . . . . . . . . . . .37

Grils à Thermostat . . . . . . . . . . . . . . . . . . . . . . . . . .38

Gril/Rôtissoire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Arrêt de la Cuisinière . . . . . . . . . . . . . . . . . . . . . . . .39

INFORMATIONS D’APPLICATION DES

PRODUITS . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Généralités . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Brûleurs Ouverts . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

INSTALLATION. . . . . . . . . . . . . . . . . . . . . . . .29

Implantation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Appareils Équipés de Roulettes . . . . . . . . . . . . . 29

Installation de l’étagère sur le dosseret . . . . . . .29

Instructions de Montage de Dosseret Avec

Étagère Haute ou de Salamandre . . . . . . . . . . . .30

Air de Ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Clause Spéci que à L’australie . . . . . . . . . . . . . . .31

Connexions Électriques (Le Cas Échéant) . . . . .31

Connexion du Gaz . . . . . . . . . . . . . . . . . . . . . . . . . .31

Préparation Finale . . . . . . . . . . . . . . . . . . . . . . . . . .32

Pièce nº 4525587 Rev 4 (29 Apr 14) Page 23

ENTRETIEN ET NETTOYAGE . . . . . . . . . . . .40

Apprêtage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Gril . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Grilles Supérieures en Fonte . . . . . . . . . . . . . 40

Acier Inoxydable . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Plaques de Cuisson . . . . . . . . . . . . . . . . . . . . . . . . .40

Intérieur du Four (Émail Vitri é) . . . . . . . . . . . . . . 41

Brûleurs de Plaque Ouverte . . . . . . . . . . . . . . . . . 41

Plaques et Grilles en Fonte . . . . . . . . . . . . . . . . . . 41

Plaques de cuisson et plaques de cuisson

chau ées par l’avant à chaleur ciblée . . . . . . . . 41

Nettoyage du Gril . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Page 24

DIMENSIONS ET SPÉCIFICATIONS

Vue de dessus

Les largeurs des modèles varient en fonction de la série du

modèle. (Voir tableau à gauche)

FICHE ÉLECTRIQUE

(LE CAS ÉCHÉANT)

3-1/2"

[89mm]

2-1/4"

[57mm]

27-1/4"

[692mm]34-1/2"

[876mm]

5"

[127mm]

Série Largeur

GF24 600mm (23-5/8 Po)*

GF36 900mm (35-1/2 Po)* Illustré

GF48 1 200mm (47-1/4 Po)

GF60 1 500mm (59-1/2 Po)

*Base de la cuisinière ou plaque

de cuisson modulairep

Modèles à Plaque de Cuisson Modulaire GF24-_T

ou GF36-_T Vue de Côté

9-3/8" [238mm]

15-5/8"

[396mm]

Vue de côté de la série GF

(Montrant la base de convection le cas échéant).

12-1/8"

[307mm]

18-3/8"

[466mm]

39-3/8"

[1000mm]

DOSSERET À

PROFIL BAS

13-7/8"

[352mm]

AJOUTER

AVEC

LA PORTE

OUVERTE

31-1/8"

[791mm]

3-7/8" [98mm]

AJOUTER POUR

FOUR À CONVECTION

51"

[1290mm]

DOSSERET STD

AVEC

ÉTAGÈRE HAUTE

(EN OPTION)

GF Série 60” Vue Latérale du Gril/de la Rôtissoire Surélevés

12-1/8"

DÉGAGEMENT ENTRE LE HAUT DE LA

PLAQUE DU GRIL ET L’ÉTAGÈRE HAUTE

EN OPTION 14-3/4" [374mm]

DÉGAGEMENT ENTRE LE DESSUS DE LA

GRILLE ET L’ÉTAGÈRE HAUTE

EN OPTION 18-3/8" [466mm]

13-7/8"

[352mm]

AJOUTER

AVEC

LA PORTE

OUVERTE

[307mm]

31-1/8"

[791mm]

1"

[25mm]

ENTRÉE

DU GAZ

41"

[1041mm]

DOSSERET

À PROFIL BAS

3-7/8" [98mm]

AJOUTER POUR

FOUR À CONVECTION

51"

[1296mm]

DOSSERET STD

AVEC ÉTAGÈRE

HAUTE

Pièce nº 4525587 Rev 4 (29 Apr 14)Page 24

Page 25

DIMENSIONS ET SPÉCIFICATIONS suite

Désignations Des Modèles De Base Et Débits Calori ques Totaux

Model #* Description

BTU/H

GF/GFE24-4L

GF24-T

GF/GFE36-6R

GFE36-6C

GF36-T

GF/GFE36-TTR

GFE36-TTC

GF/GFE48-LL

GF/GFE60-10RR

GFE60-10RC

GFE60-10CC

GF/GFE60-6R24RR

GFE60-6R24RC

GFE60-6R24CC

GF/GFE60-6R24RS

Unité de 24 po (600 mm) de taille nominale,

4 brûleurs ouverts, four économiseur d’espace

Unité de 24 po (600 mm) de taille nominale,

4 brûleurs ouverts, plaque de cuisson modulaire

Unité de 36 po (900 mm) de taille nominale,

6 brûleurs ouverts, four standard

Unité de 36 po (900 mm) de taille nominale,

6 brûleurs ouverts, four à convection

Unité de 36 po (900 mm) de taille nominale,

6 brûleurs ouverts, plaque de cuisson modulaire

Unité de 36 po (900 mm) de taille nominale, 2 sections

de plaque de cuisson chau ée par l’avant à chaleur

ciblée, four standard

Unité de 36 po (900 mm) de taille nominale, 2 sections

de plaque de cuisson chau ée par l’avant à chaleur

ciblée, four à convection

Unité de 48 po (1200 mm) de taille nominale,

8 brûleurs ouverts, 2 fours économiseur d’espace

Unité de 60 po (1500 mm) de taille nominale,

10 brûleurs ouverts, 2 fours standard

Unité de 60 po (1500 mm) de taille nominale,

10 brûleurs ouverts, 1 four standard, 1 four à convection

Unité de 60 po (1500 mm) de taille nominale,

10 brûleurs ouverts, 2 fours à convection

Unité de 60 po (1500 mm) de taille nominale,

6 brûleurs ouverts, 24 po (610 mm),

gril/rôtissoire surélevé ,2 fours standard

Unité de 60 po (1500 mm) de taille nominale, 6 brûleurs

ouverts, 24 po (610 mm), gril/rôtissoire surélevé, 1 four

standard, 1 four à convection

Unité de 60 po (1500 mm) de taille nominale, 6 brûleurs

ouverts,24 po (610 mm), gril/rôtissoire surélevé, 2 fours

à convection

Unité de 60 po (1500 mm) de taille nominale, 6 brûleurs

ouverts, 24 po (610 mm), gril/rôtissoire surélevé ,1 four

standard, 1 base de rangement

136,000

104,000

194,000

194,000

156,000

100,000

100,000

272,000

336,000

336,000

336,000

265,000

265,000

265,000

227,000

Débit

Gaz Naturel Gaz Propane

CE

Estimation kWBTU/H

41.50

30.40

56.70

56.70

45.60

29.1

29.1

79.60

98.20

98.20

98.20

76.80

76.80

76.80

65.70

132,000

104,000

188,000

188,000

156.000

94,000

94,000

264,000

324,000

324,000

324,000

253,000

253,000

253,000

221,000

CE

Estimation

kW

39.70

30.40

54.90

54.90

45.60

25.5

25.5

77.20

94.60

94.60

94.60

73.20

73.20

73.20

63.90

Pièce nº 4525587 Rev 4 (29 Apr 14) Page 25

Page 26

DIMENSIONS ET SPÉCIFICATIONS suite

Unité de 60 po (1500 mm) de taille nominale, 6 brûleurs

GFE60-6R24CS

* Les modèles commençant par le pré xe GFE ont des systèmes d’allumage par étincelles électriques pour les veilleuses.

Débits calori ques pour installations jusqu’à 2 000 pi (610 m) au-dessus du niveau de la mer.

Chaque 12” (305mm) La section Plaque de Cuisson est 5.3kW, remplaçant 2 brûleurs ouverts (7.6kW chacun).

Dégagements

Dégagements Applicables Pour Tous les Modèles Sauf Indication Contraire

Minimum Mur Combustible 14 po (356mm) 6 po (152mm) 6 po(152mm)

Minimum Mur Non Combustible 0 Po 0 po 0 po

Pression du Gaz et Débits Calori ques des Brûleurs Individuels

Amérique du Nord

ouverts, 24 po (610 mm), gril/rôtissoire surélevé, 1 four

à convection, 1 base de rangement

Côtés Plaque

de Cuisson

Modulaire

Surface

Côtés de la

Cuisinière

227,000

Arrière

65.70

221,000

63.90

Nat.

Série GF Garland

Plaque Ouverte (Détecteur de Flamme) 26,000 26,000

Plaque de Cuisson FF (au Lieu de Deux Brûleurs Ouverts) 18,000 18,000

Modèles à plaque à chaleur ciblée de 36 po seulement, par

section

Gril (au Lieu de 2 Brûleurs Ouverts) (Thermostat) 18,000 18,000

Gril Rôtissoire Surélevé (3 Brûleurs) 3 @ 11,000 3 @ 11,000

Brûleur de Four de 26 Po (H-Cast) (Standard ou Convection) 38,000 32,000

Four Économiseur d’espace (H-Cast) 32,000 28,000

4,5 Po c.e. Collecteur

BTU/h BTU/h

3@10,333 3@10,333

10 Po c.e. Collecteur

Gpl

CE Et Export Général

Nat. (G20) ,

Série GF Garland