Page 1

INSTALLATION AND

OPERATION MANUAL

GARLAND GD SERIES

GAS COUNTER UNITS

FOR YOUR SAFETY:

DO NOT STORE OR USE GASOLINE

OR OTHER FLAMMABLE VAPORS OR

LIQUIDS IN THE VICINITY OF

THIS OR ANY OTHER

APPLIANCE

WARNING:

IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE

CAN CAUSE PROPERTY DAMAGE, INJURY,

OR DEATH. READ THE INSTALLATION,

OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR

SERVICING THIS EQUIPMENT

AND RETAIN FOR FUTURE REFERENCE.

THIS PRODUCT HAS BEEN CERTIFIED AS

COMMERCIAL COOKING EQUIPMENT AND

MUST BE INSTALLED BY PROFESSIONAL

PERSONNEL AS SPECIFIED.

IN THE COMMONWEALTH OF MASSACHUSETTS

THIS PRODUCT MUST BE INSTALLED BY A

LICENSED PLUMBER OR GAS FITTER. APPROVAL

NUMBER: G-1-07-05-28

For Your Safety:

Post in a prominent location, instructions to be

followed in the event the user smells gas. This

information shall be obtained by consulting

your local gas supplier.

Users are cautioned that maintenance and repairs must be performed by a Garland authorized service agent

using genuine Garland replacement parts. Garland will have no obligation with respect to any product that has been

improperly installed, adjusted, operated or not maintained in accordance with national and local codes or installation

instructions provided with the product, or any product that has its serial number defaced, obliterated or removed,

or which has been modified or repaired using unauthorized parts or by unauthorized service agents.

For a list of authorized service agents, please refer to the Garland web site at http://www.garland-group.com.

The information contained herein, (including design and parts specifications), may be superseded and is subject

to change without notice.

PLEASE READ ALL SECTIONS OF THIS MANUAL

GARLAND COMMERCIAL INDUSTRIES

185 East South Street

Freeland, Pennsylvania 18224

Phone: (570) 636-1000

Fax: (570) 636-3903

Part # 4519762 (03/06) © 2005 Garland Commercial Industries, Inc.

Part # 4519762 (12/07) Page 1

GARLAND COMMERCIAL RANGES, LTD.

1177 Kamato Road, Mississauga, Ontario L4W 1X4

CANADA

Phone: 905-624-0260

Fax: 905-624-5669

Enodis UK LTD.

Swallow eld Way, Hayes, Middlesex UB3 1DQ ENGLAND

Telephone: 081-561-0433

Fax: 081-848-0041

Page 2

IMPORTANT INFORMATION

WARNING:

This product contains chemicals known to the state of california to cause cancer and/or birth defects

or other reproductive harm. Installation and servicing of this product could expose you to airborne

particles of glass wool/ceramic fibers. Inhalation of airborne particles of glass wool/ceramic fibers

is known to the state of california to cause cancer. Operation of this product could expose you to

carbon monoxide if not adjusted properly. Inhalation of carbon monoxide is known to the state of

california to cause birth defects or other reproductive harm.

Keep appliance area free and clear of combustibles.

Part # 4519762 (12/07)Page 2

Page 3

Part # 4519762 (12/07) Page 3

TABLE OF CONTENTS

IMPORTANT INFORMATION ............................................................2

SPECIFICATIONS.......................................................................4

PRE INSTALLATION.....................................................................4

Damage Check...................................................................................4

Rating Plate......................................................................................4

INSTALLATION.........................................................................5

General .........................................................................................5

Clearances.......................................................................................5

Gas Connections.................................................................................6

Leg Installation ..................................................................................6

Installation of Banking Plates.....................................................................6

Installation of Non-Combustible Counter Stands (Optional).......................................7

Ventilation.......................................................................................7

ADJUSTMENTS ........................................................................8

Burner Adjustments – All Units...................................................................8

Hot Plates........................................................................................8

Pilot Burner Adjustment ..................................................................... 8

Burner Operation............................................................................ 8

Fryers............................................................................................8

Before Operating the Fryer...................................................................8

Pilot Burner Adjustment ..................................................................... 8

To Operate Main Burner...................................................................... 8

Shutdown Instructions.......................................................................9

Calibration Instructions...................................................................... 9

Griddles.........................................................................................9

Lighting Instructions And Pilot Burner Adjustment ........................................... 9

Burner Operation............................................................................ 9

Hi-Lo Valve Adjustment...................................................................... 9

Calibration Instructions...................................................................... 9

Broilers.........................................................................................10

Pilot Burner Adjustment ....................................................................10

Burner Operation...........................................................................10

HI-LO Valve Adjustment..................................................................... 10

Flame Size......................................................................................10

Flame Size Chart............................................................................10

OPERATION FOR “FF” MODELS ........................................................11

Open Type Hot Plate............................................................................11

Broilers.........................................................................................11

Griddles........................................................................................11

OPERATION ALL MODLES .............................................................12

Lighting Standing Pilots - All Models.............................................................12

MAINTENANCE INSTRUCTIONS........................................................12

Cleaning Instructions ...........................................................................12

PARTS AND SERVICE..................................................................13

Page 4

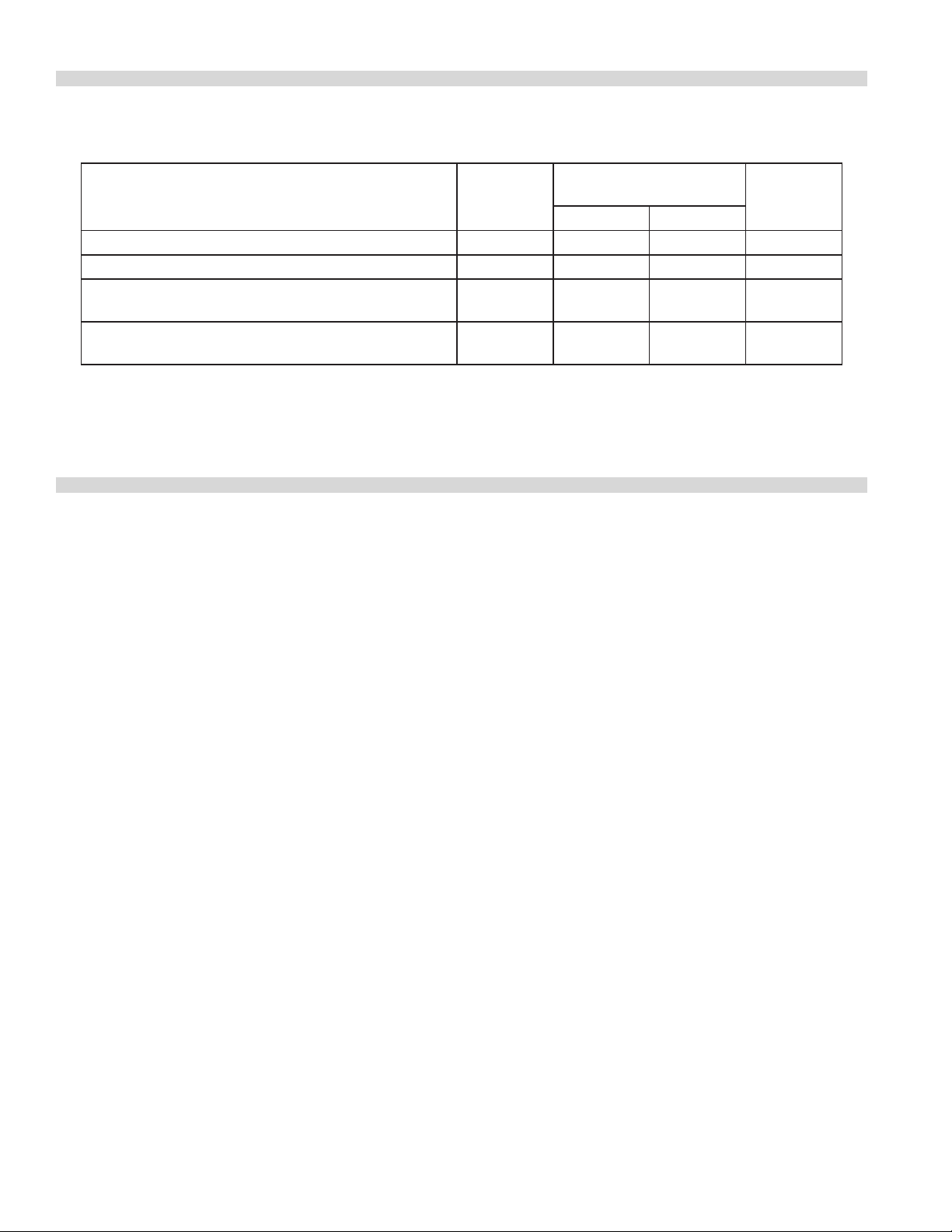

SPECIFICATIONS

MODEL NUMBER

GD-152H(J)(FF), GD-302H(J)(FF), GD-304H(J)(FF)

GD-15F(J) 1/2” 4.2 9.0 45,000

GD-15G(J)(FF), GD-15GTH(J), GD-24G(J)(FF),

GD-24GTH(J), GD-36G(J)(FF), GD-36GTH(J)

GD-18RB(J)(FF), GD-24RB(J)(FF),

GD-30RB(J)(FF), GD-36RB(J)(FF)

MANIFOLD

INLET SIZE

3/4” 4.0 10.0 14,800

3/4” 4.0 10.0 20,000

3/4” 4.0 10.0 15,000

OPERATING PRESSURE

“WC

NATURAL PROPANE

PRE INSTALLATION

Damage Check

Damage check: Check carton or crate for possible damage

incurred in shipping. After carefully uncrating, check for

“concealed” damage. Report any damage immediately to

your carrier.

When corresponding with the factory or your local

authorized factory service center regarding service problems

or replacement parts, be sure to refer to the particular unit

by the correct model number (including the prex and sux

letters and numbers) and the warranty serial number. The

rating plate axed to the unit contains this information.

INPUT

BTU/H

Rating Plate

All burner input ratings are shown on the serial, rating plate

of each unit and are readily visible by opening the enameled

door located below the control panel.

The correct type of gas for which the unit was manufactured

is noted on the rating plate, and this type of gas must be

used.

We suggest installation, maintenance and repairs should be

performed by your local authorized service agency listed in

your information manual pamphlet.

In the event you have any questions concerning the

installation, use, care or service of the product, write or call

our Product Service Department.

This product must be installed by professional personnel as

specied. Garland/U.S. Range products are not approved or

authorized for home or residential use, but are intended for

commercial applications only. Garland / U.S. Range will not

provide service, warranty, maintenance or support of any

kind other than in commercial applications.

Part # 4519762 (12/07)Page 4

Page 5

Part # 4519762 (12/07) Page 5

INSTALLATION

General

1. Carefully remove unit from carton or crate. Burner tie

wires and other packing material should be removed

from units. On stainless steel units, the protective

material covering the stainless steel should be removed

immediately after the unit is installed.

2. Remove top grates and place in a safe area to prevent

damage.

3. Should it be necessary to remove the steel griddle plate

on units equipped with griddle thermostats, the griddle

thermostat bulb and capillary must rst be withdrawn

from the bulb shield assembly, located on the underside

of the griddle plate. This can be accomplished with the

griddle front raised and supported by the griddle prop

located on the underside of the griddle plate. Loosen the

four pal nuts securing the bulb shield assembly to the

griddle plate and withdraw the griddle thermostat bulb.

4. When a griddle plate is being installed on units equipped

with griddle thermostats, the thermostat bulb must

be inserted in the groove between the plate and the

bulb shield assembly. This can be accomplished with

the griddle front raised and supported by the griddle

prop, located on the underside of the griddle plate. It is

important for accurate temperature control that the bulb

be located inside the groove. Tighten the four pal nuts

securing the bulb shield assembly to the griddle plate.

5. These units must be installed under an adequate

ventilation system. Refer to section titled Ventilation for

further instructions.

Clearances

MINIMUM INSTALLATION CLEARANCES TO

ADJACENT COMBUSTIBLE/NON-COMBUSTABLE

WALLS OR BASE

Sides & Back

Model #

Non

GD-152H(J)(FF),

GD-302H(J)(FF),

GD-304H(J)(FF)

GD-15F(J)

GD-15G(J)(FF),

GD-25G(J)(FF),

GD-36G(J)(FF),

GD-15GTH(J),

GD-24GTH(J),

GD-36GTH(J)

NON COMBUSTIBLE LOCATIONS ONLY

GD-18RB(J)(FF),

GD-24RB(J)(FF),

GD-30RB(J)(FF),

GD-36RB(J)(FF)

Combustible

6”

(152mm)

6”

(152mm)

6”

(152mm)

FOR INSTALLATION IN

N/A 0”

Combustible

0” Combustible

0”

0” Combustible

Floor Or

Base

Non

Combustible

Non

Combustible

6. All burner adjustments and setting shall be made by a

qualied gas technician.

Page 6

INSTALLATION Continued

Gas Connections

1. The installation and connection must comply with local

codes, or in the absence of local codes, with CAN/CGAB149 Installation Code or with the national Fuel Gas Code,

ANSI Z223.1/NFPA No. 54 – Latest Edition.

2. The correct type of gas for which the unit was

manufactured is noted on the rating plate, and this type

of gas must be used.

3. The gas pressure must be checked when the unit is

installed, to ensure that the unit gas pressure is the same

as specied on the rating plate. If necessary, pressure

adjustments can be made at the pressure regulator,

supplied on each unit.

4. Have a qualied gas technician check the gas pressure

to make certain that existing gas facilities (meter, piping,

etc.) will deliver the BTU’s of gas required at the unit with

no more than ½” water column pressure drop. When

checking pressure, be certain that all the equipment on

same gas line is turned to the “ON” position.

5. The appliance and its individual shut o valve must be

disconnected from the gas supply piping system during

any pressure testing of that system at test pressures in

excess of 1/2 PSIG. (3.45 KPA).

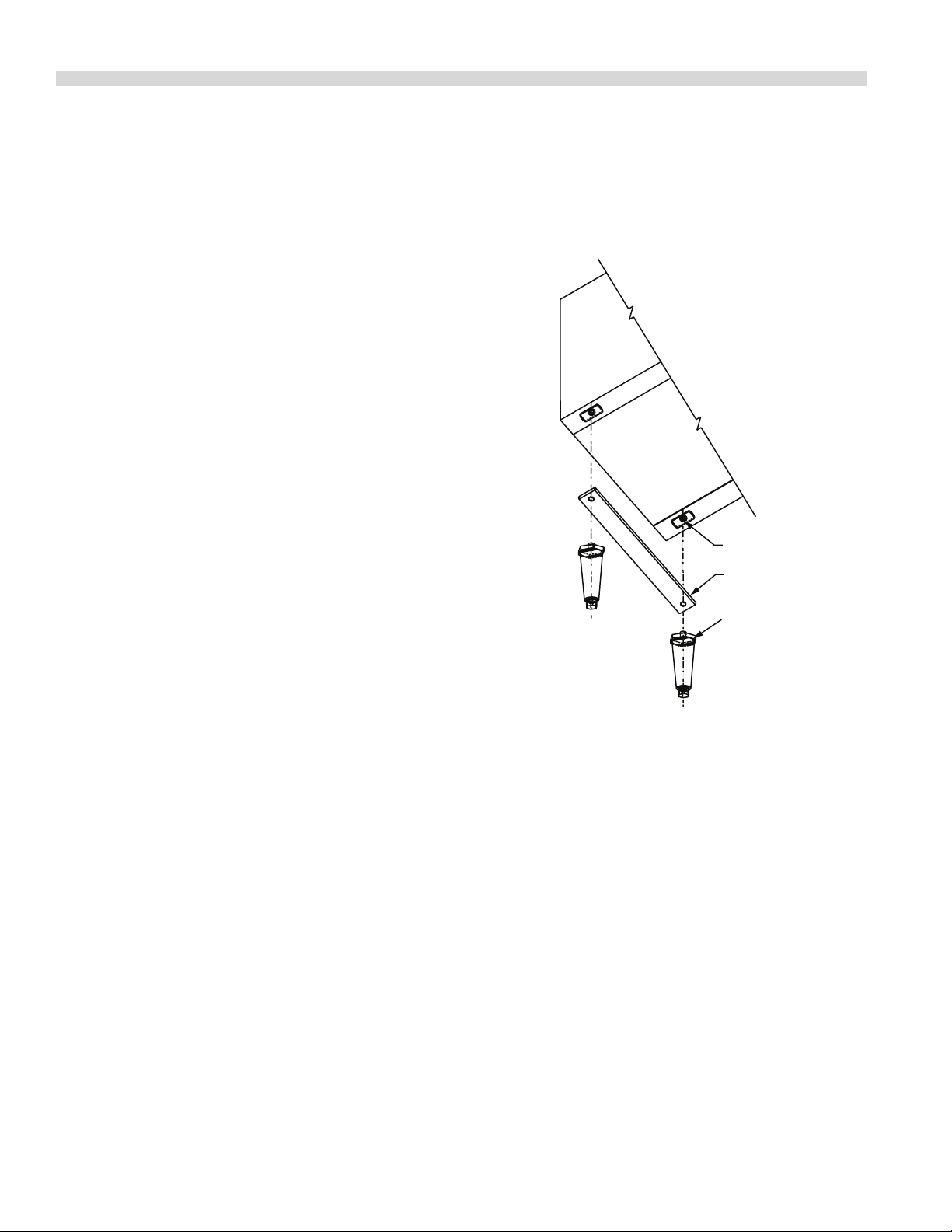

Leg Installation

The leg channel is located on the package base. This channel

must be installed when using the legs.

BOTTOM OF UNIT

LEG CHANNEL

(QTY 2)

4" [102mm]

ADJUSTABLE LEG

(QTY 4)

6. The appliance must be isolated from the gas supply

piping system by closing its individual manual shut o

valve during any pressure testing of the gas supply piping

system at test pressures equal to or less than 1/2 PSIG.

(3.45 KPA).

7. Make certain that the new piping, joints and connections

have been made in a clean manner and have been

purged, so that the piping compound, chips, etc., will not

clog pilots, valves and/or controls. Use pipe joint sealant

that is certied for use with liqueed petroleum gas.

8. WARNING: Check gas connections for leaks, using soap

solution or similar means. Do Not Check with an Open

Flame.

LEG INSTALLATION

Installation of Banking Plates

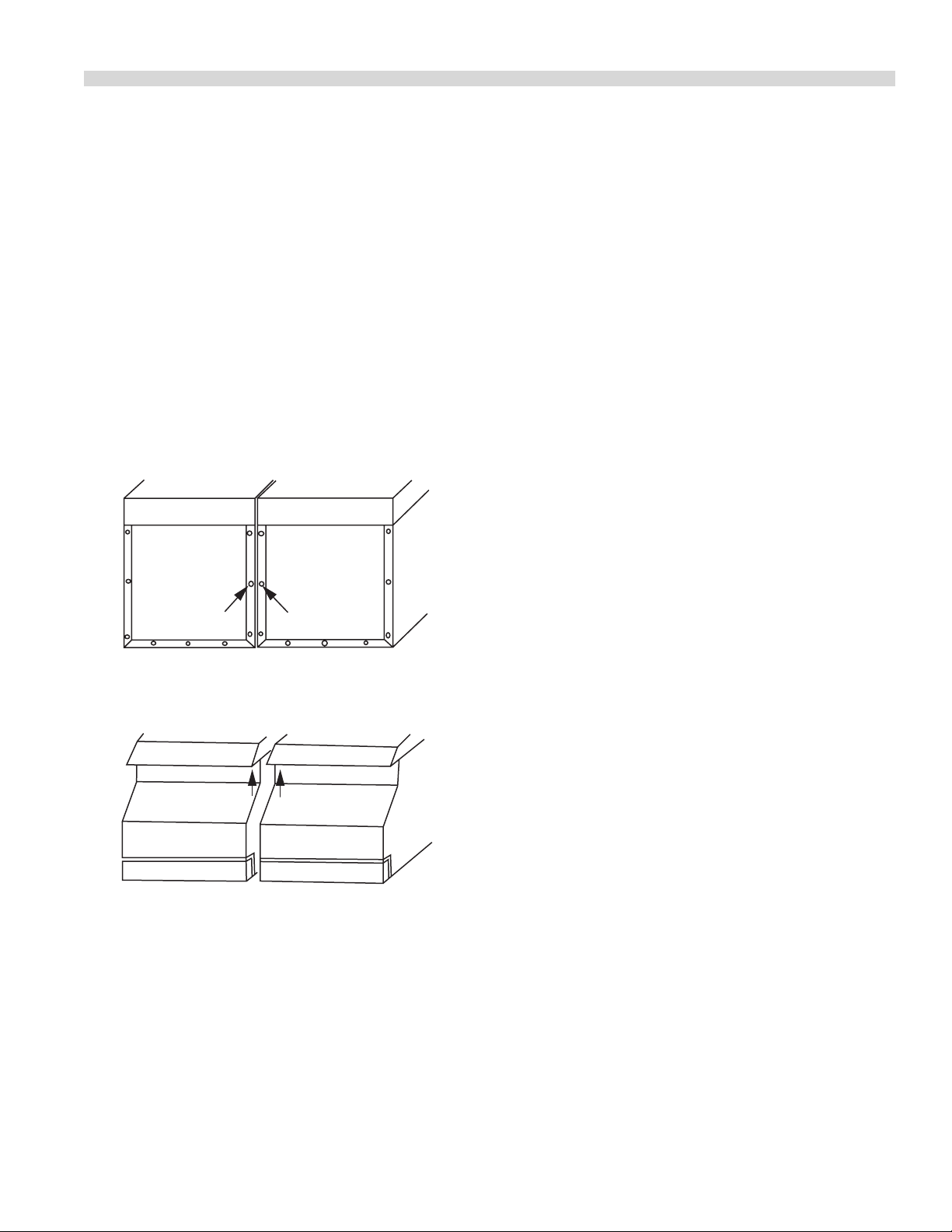

All units may be installed independently or banked with

other GD or ED Series equipment. To ensure a matching

and permanent t between units, two banking plates are

available for each unit to be installed. One at the front and

one at the rear of each two units being banked together.

1. Level each unit by adjustment of leveling bolts or legs.

Use a spirit level and level unit four ways; across front and

back and down left and right edges. Level all other units

to the rst unit.

Part # 4519762 (12/07)Page 6

Page 7

Part # 4519762 (12/07) Page 7

INSTALLATION Continued

Note: Griddles may not rest evenly on the unit body if units

are not leveled.

2. Remove sheet metal screws at rear of unit.

3. Attach one banking plate in position at rear by placing

the 1/4” (6 mm) diameter holes in the banking plate

over the screw holes in the rear of units and fasten by

replacing the sheet metal screws removed in Step 2.

4. Push units into position on counter top or back bar.

5. Remove the two acorn nuts from the sides being banked

(one for each control panel). Place banking plate over

the two protruding screw heads, replace acorn nuts and

tighten.

REAR VIEW

2. Remove and discard leveling bolts on unit to be installed

on a non-combustible counter stand.

3. Place units in desired position on counter stand, securing

the rst unit with 8-32 machine screws and at washers.

Insert 8-32 machine screws through the 7/32” (5 mm)

diameter holes in stand into the nutserts in the bottom of

GD Series units.

4. Connect banking plates as described in section titled.

Installation of Banking Plates.

5. Secure last unit to counter stand with 8-32 machine

screws and at washers. Insert 8-32 machine screws

through the 7/32” (5 mm) diameter holes in stand into

nutserts in the bottom of GD Series units

Ventilation

Counter equipment must be installed in a location in which

the facilities for ventilation permit satisfactory combustion

of gas and proper venting. Proper ventilation is imperative

for good operation of the appliance. The ideal method

of ventilating counter equipment is the use of a properly

designed ventilating canopy, which should extend at least

6”/152mm beyond all sides of the appliance (except against

the wall if the canopy is a wall installation). This is usually part

of a mechanical exhaust system.

Air Supply

FRONT VIEW

Installation of Non-Combustible

Counter Stands (Optional)

1. Assemble and level counter stand as illustrated in the

instructions found in the counter stand carton.

1. It is necessary that sucient room air ingress be allowed

to compensate for the amount of air removed by any

ventilating system. Otherwise, a subnormal atmospheric

pressure will occur, aecting the appliance operation

adversely and causing undesirable working conditions.

2. Appliances shall be located so as not to interfere with

proper circulation of air within the conned space. All gas

burners and pilots require sucient air to operate.

3. Large objects should not be placed in front of the

appliance which might obstruct the air ow through

the front. Do not obstruct the ow of combustion and

ventilation air.

4. Do not permit fans to blow directly at the appliance, and

wherever possible, avoid open windows adjacent to the

appliance sides and back; also wall type fans which create

air cross-currents within the room.

Page 8

ADJUSTMENTS

Burner Adjustments – All Units

1. Before making any adjustment, turn all gas valves

to “OFF”. Remove the burner tie wires, if not already

removed. Be sure all piping is gas tight and that air is

purged from lines.

2. All units are shipped from factory at burner ratings set

for the gas specied on the rating plate at normal gas

pressure. The only adjustment necessary is for that

governing air.

Air Adjustment: If necessary, the air is adjusted by rotating

the air shutter on burner. The burner must have enough air

that the tips of the ames are not yellow, but not so much air

that the ames will lift o the burner ports. Securely tighten

air shutter screw so air shutter cannot be moved.

Hot Plates

IMPORTANT: The ue must be installed prior to start-up.

Pilot Burner Adjustment

Each burner in the hot plate is equipped with a pilot. The

burner pilot is ignited by the piezo ignitor located behind the

front door.

The pilot has been adjusted at the factory; however, it may

require adjustments once installed. The pilot adjusting valve

is located under each burner valve.

Open the bottom door and use a long thin straight blade

screwdriver to adjust the valve. Refer to Flame Size Chart.

Burner Operation

The burner will light automatically from the pilot. Turn the

valve to the full “ON” position. Once the ame has ignited,

adjust the valve to the desired setting.

Fryers

Before Operating the Fryer

1. Before leaving the factory, the fryer was tested and the

thermostat calibrated with oil in the fry tank; therefore, it

is necessary to clean the fry tank before lling with frying

compound. Use detergent or other cleaning agents, with

hot water. Thoroughly rinse and dry fry tank.

2. BEFORE LIGHTING THE PILOT, ll the fry tank. NEVER

OPERATE THE PILOT OR BURNER WITH AN EMPTY FRY

TANK. It only takes a few minutes to completely ruin a fry

tank and void the warranty.

3. WARNING: When fryers are in use, fryer restraint chains/

cables must be installed in order to prevent the fryer from

tipping and splashing hot liquid. Hot shortening causes

severe burns. Never attempt to move a fryer when the

frypot is full. Drain frypot completely before moving fryer.

Pilot Burner Adjustment

1. Turn thermostat knob to lowest position.

2. Depress and turn automatic gas valve knob to “OFF”

position. Caution: Wait 5 minutes before lighting or

relighting pilot.

3. Turn automatic gas valve knob to “Pilot” position.

4. Push knob in, light pilot, and continue to hold knob in for

about 60 seconds after pilot light is lit.

5. Adjust pilot ame to 3/4” (19 mm).

6. If pilot does not continue to burn after releasing button,

repeat above procedure or…

7. Have a qualied Serviceman check the system. DO NOT

ALLOW ANYONE ELSE TO ATTEMPT REPAIRS.

To Operate Main Burner

1. If liquid frying compound is used, the main burner may

be turned on.

2. To ignite burner, turn automatic gas valve

counterclockwise to the “ON” position.

3. If a Hydrogenated (SOLID) frying compound is used,

pack the tank with compound and turn the main burner

on for approximately ve seconds and turn it o for

approximately ten seconds. Repeat until compound

is melted. If any smoke is seen during the process, the

heating action is being carried out too fast and the

frying compound is being scorched as well as possibly

damaging the fry tank.

Part # 4519762 (12/07)Page 8

Page 9

Part # 4519762 (12/07) Page 9

ADJUSTMENTS Continued

Shutdown Instructions

To shut down fryer for a short period, turn automatic gas

valve knob to the “PILOT” position.

For complete shutdown, turn automatic gas valve knob

clockwise to “PILOT” position, depress the knob, turn slightly

clockwise, release, and continue to turn clockwise to “OFF”.

Calibration Instructions

1. Field calibration is seldom necessary and should not

be attempted unless experience with cooking results

denitely proves that the control is not maintaining the

temperature to which the dial is set.

2. Suspend thermometer or thermocouple in the middle

of the fry tank, approximately 2” (51 mm) below the

shortening level.

3. Allow burner to cycle at least four times.

4. When the burner just cycles o after the fourth cycle,

compare reading of the thermometer or thermocouple

with thermostat setting.

5. If the two do not agree, ± 10°F (5°C), loosen the two set

screws on the thermostat knob.

6. Set the pointer at the temperature indicated by the

thermometer.

7. Tighten the set screw rmly.

8. Ensure the back surface of the knob is spaced away from

the dial plate at least the thickness of a dime.

NOTE: Do not turn adjusting shaft more than two turns in

either direction or permanent damage can result. This action

will void the Standard Fenwal thermostat warranty.

Griddles

IMPORTANT: The ue must be installed prior to start-up.

For the griddle equipped with thermostats the pilot and the

main burner are controlled by the ON-OFF valve. MAKE SURE

THE THERMOSTAT IN ON OFF POSITION. Turn on the main

valve and light the pilot with a match. The pilot adjusting

screw is located at the bottom of the thermostat.

Pilots ames must be 3/4 inch (19mm) long

Burner Operation

The burner will light automatically from the pilot. Turn the

valve to full “ON” position. Once the ame has ignited, adjust

the valve to the desired setting.

Hi-Lo Valve Adjustment

Griddles equipped with Hi-Lo valves require a low ame

setting. To adjust, proceed as follows:

1. Burner must be cold.

2. Be sure pilot ames are lit, and adjusted.

3. Turn dial to “LO” position, then remove dial.

4. With a screwdriver, turn the small adjusting screw inside

the valve stem and adjust to obtain the low cooking

temperature desired, maintaining a stable ame covering

the entire burner (minimum 3/16 inch (5 mm) long

ame).

5. Replace dial and turn to “OFF” position.

Calibration Instructions

1. Use a test instrument with a special disc type

thermocouple or a reliable surface type pyrometer. Note:

a drop of oil on the face of the disc will provide better

contact with the plate.

2 Set all griddle thermostats to 350°F (177°C). In order

to allow the griddle temperature to stabilize, the

thermostats must be allowed to cycle twice before taking

a test reading.

Lighting Instructions And

Pilot Burner Adjustment

Each griddle burner is equipped with a pilot.

For the HI-LO valve operated model, the pilot adjusting valve

pilot burner is located on the manifold to the left of each

griddle valve. Open the pilot valve with a screwdriver and

light the pilot with a match.

3. Check the griddle temperature when the thermostat

just cycles “OFF” by placing the thermocouple rmly on

the griddle surface directly above the sensing bulb of

the thermostat. The reading should be between 335°F

(168°C) and 365°F (185°C). If the reading is outside of

these limits, calibrate as follows:

4. Carefully remove the dial, not disturbing the shaft

position.

Page 10

ADJUSTMENTS Continued

5. Hold the shaft steady and with a small at screw driver

turn the calibration screw located inside the shaft

clockwise to decrease temperature or anti-clockwise to

increase temperature. Note: Each 1/4 turn of the screw

will create a change of approximately 25°F (14°C).

6. Replace the thermostat dial and repeat steps 1 through 3

to verify that a correct adjustment has been made.

Broilers

IMPORTANT: The ue must be installed prior to start-up.

Pilot Burner Adjustment

Each burner in the broiler is equipped with a pilot. The

burner pilot is ignited by the piezo ignitor located behind the

front door.

The pilot has been adjusted at the factory; however, it may

require adjustment once installed. The pilot adjusting valve is

located under each burner valve. Open the bottom door and

use a long thin straight blade screwdriver to adjust the valve.

Refer to Flame Size Chart.

Burner Operation

The burner will light automatically from the pilot. Turn the

valve to the full “ON” position. Once the ame has ignited,

adjust the valve to the desired setting.

HI-LO Valve Adjustment

Broilers are equipped with HI-LO valves which require a low

ame setting. To adjust, proceed as follows:

1. Burner must be cold.

2. Be sure pilot ames are lit and adjusted.

3. Turn dial to “LO” position, then remove dial.

4. With a screwdriver, turn the small adjusting screw inside

the valve stem and adjust to obtain the low cooking

temperature desired, maintaining a stable ame covering

the entire burner (minimum 3/16” (5 mm) long ame).

5. Replace dial and turn to “OFF” position.

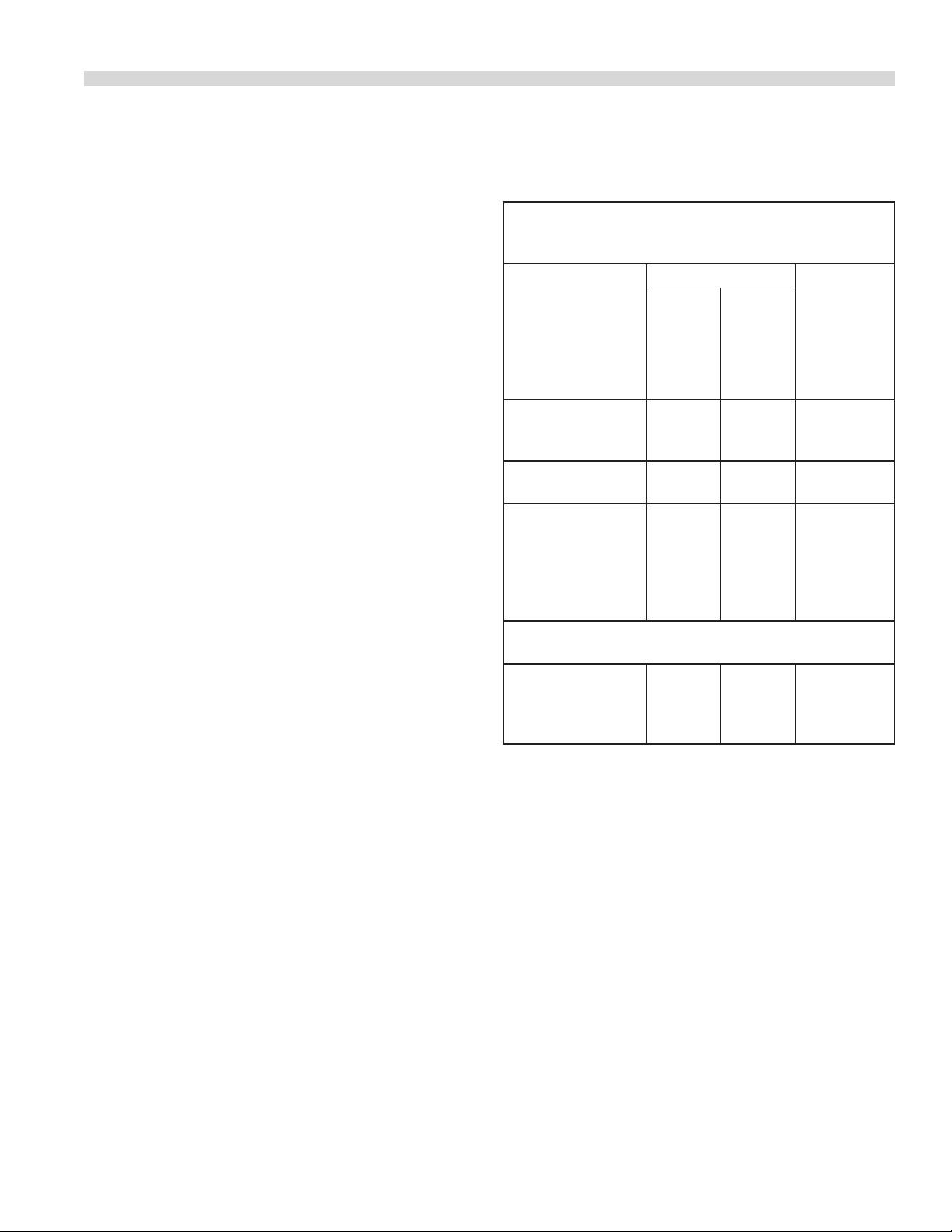

Flame Size

Flame Size Chart

The correct air and/or gas adjustment has been made when

a stable blue inner cone is obtained.

MODEL

NUMBER

GD-152H(FF) Hot Plate 1/2” [13 mm]

GD-302H(FF) Hot Plate 1/2” [13 mm]

GD-304H(FF) Hot Plate 1/2” [13 mm]

GD-15F Fryer 3/4” [19 mm]

GD-15G(FF) Griddle 3/4” [19 mm]

GD-15GTH Griddle 3/4” [19 mm]

GD-24G(FF) Griddle 3/4” [19 mm]

GD-24GTH Griddle 3/4” [19 mm]

GD-36G(FF) Griddle 3/4” [19 mm]

GD-36TGTH Griddle 3/4” [19 mm]

GD-18RB(FF) Broiler 1/2” [13 mm]

GD-24RB[FF] Broiler 1/2” [13 mm]

GD-30RB(FF) Broiler 1/2” [ 13 mm]

GD-36RB(FF) Broiler 1/2” [13 mm]

DESCRIPTION

PILOT FLAME

LENGTH

Part # 4519762 (12/07)Page 10

Page 11

Part # 4519762 (12/07) Page 11

OPERATION FOR “FF” MODELS

Open Type Hot Plate

All burners are equally rated and may be used either for

fast boiling or simmering. The pan supports will safely

accommodate pans from 125mm (5”) diameter. It is, however,

recommended that pans larger than 30mm (12”) diameter

should be heated on the rear burners.

NOTE: For maximum eciency and stability, use at

bottomed utensils and place centrally over burner head.

Lighting the Open Type Hot Plate

To light the open top burners:

Push in the tap and turn it anti-clockwise to the ignition

1.

position “

2. Holding the tap fully in, depress the ignitor button and

observe that the pilot lights. If it does not, repeatedly

depress the ignitor button until it does.

3. When the pilot is lit, continue to hold the tap in for 20

seconds, then release it. If the pilot goes out, wait for 5

minutes, then repeat from step 1.

4. When the pilot is established, push the tap in again and

turn it anti-clockwise to the full flame position “

the main burner

”.

.

” to light

4. When the pilot is established, push the tap in again and

turn it anti-clockwise to the full ame position “

the main burner.

5. For low ame or simmer, push the tap in and turn it anticlockwise to the

6. To shut the burner o, turn the dial to the “

and the safety device will disengage within 60 seconds.

“

”

position.

” to light

” position

Griddles

Griddle tops are designed to have food cooked directly on

the surface. Do not put pots or pans on the griddle surface.

This will scratch or nick the surface and result in improper

cooking or sticking of product. Never salt food over a griddle

since this will build up a gummy residue making it dicult to

clean.

Avoid hitting the surface of the griddle with the edge of a

spatula since this will cause nicks. The most frequently used

temperatures are 300°F (149°C )to 350°F (177°C). After one

ring, the griddle plate will discolour. This is normal and will

not aect cooking performance.

Check the grease container and drain frequently during

heavy use to prevent overow.

Lighting the Griddle

5

. To shut the burner off, turn the dial to the “

position and the safety device will disengage within 60

seconds.

”

Broilers

Lighting the Broiler

1. Push in the tap and turn it anti-clockwise to the ignition

position

2. Holding the tap fully in, depress the ignitor button and

observe that the pilot lights. If it does not, repeatedly

depress the ignitor button until it does.

3. When the pilot is lit, continue to hold the tap in for 20

seconds, then release it. If the pilot goes out, wait for 5

minutes, then repeat from step 1.

“

”

1. Push in the tap and turn it anti-clockwise to the ignition

position “

2. Holding the tap fully in, depress the ignitor button and

observe that the pilot lights. If it does not, repeatedly

depress the ignitor button until it does.

3. When the pilot is lit, continue to hold the tap in for 20

seconds, then release it. If the pilot goes out, wait for 5

minutes, then repeat from step 1.

4. When the pilot is established, push the tap in again and

turn it anti-clockwise to the full ame position “

the main burner.

5. For low ame or simmer, push the tap in and turn it anticlockwise to the “

6. To shut the burner o, turn the dial to the “

and the safety device will disengage within 60 seconds.

”.

” to light

” position.

” position

Page 12

OPERATION ALL MODLES

Lighting Standing Pilots - All Models

These units are not designed to be disconnected from

their gas connections and re-installed on a regular basis.

Quick connect gas lines should not be used. Once the gas

appliance has been installed by a licensed gas trades-person

all connections, pilot lights and controls have been inspected

for proper operation. All gas appliances that use standing

pilot systems are generally assumed to be operating with

the pilot on continuously. The units should not be restarted

except in the event of a gas service interruption to the

facility.

If a pilot ame does go out, here are the basic steps to check

before you re-light the pilot:

1. Check to see that all gas lines are in place and secured

and that there is no accumulation of gas inside the unit.

2. Check to make sure that the main shut o valve is in the

o position.

3. Turn the thermostat to the o position. (If applicable)

4. Turn on or open the main shut o valve to the appliance.

5. Depending on the appliance type:

Lower the front black enamel panel to the unit and

immediately depress the red button, which is the

piezo to ignite the pilot.

Or.

Remove the front valve panel and light the pilot

with a lighted taper, through pilot viewing hole.

6. The pilot should ignite within a few attempts. You will be

able to see the pilot ame through the observation hole

in the stainless steel front panel.

7. If you do not have a pilot ame established fairly quickly

and begin to smell gas, shut o the main valve and wait

ve minutes to let the gas build-up escape.

8. Only once the pilot ame has been established should

you turn on the burner control. When the burner control

is on it allows gas ow to the burner. If there is no pilot

ame it will allow gas to build up and cause possible

delayed ignition, which could result in an explosion.

MAINTENANCE INSTRUCTIONS

NOTE: Any maintenance or service involving disassembly

of components should be made by a qualied service

technician. Also, ensure gas supply to the appliance is shut

o.

You have purchased the nest commercial cooking

equipment available anywhere. Like any other ne precision

built piece of equipment, it should be given regular care and

maintenance.

Periodical inspections by your dealer or qualied service

agency are recommended to check temperatures,

adjustments and ensure moving parts are operative.

Whenever possible, avoid overheating idle equipment as this

is the primary cause for increased service costs.

When corresponding with the factory or your equipment

dealer regarding service problems or replacement parts,

be sure to refer to the particular unit by the correct model

number (including prex and sux letters and numbers) and

the serial or code number. The rating plate axed to the unit

contains this information.

“Regular Maintenance Ensures Peak Performance.”

Cleaning Instructions

Black Baked Enamel – Allow equipment to cool after use

and wash all grease deposits from exterior with a hot mild

detergent or soap solution. Dry thoroughly. Do not use

abrasives.

Nickel Plated – Wash when cool with a hot mild detergent or

soap solution. Do not use abrasives.

Stainless Steel – Normal soil may be removed with a

detergent or soap solution applied with a cloth.

Part # 4519762 (12/07)Page 12

Page 13

Part # 4519762 (12/07) Page 13

MAINTENANCE INSTRUCTIONS Continued

To remove grease that has baked on, apply cleanser to a

damp cloth or sponge and rub cleanser on the metal. NEVER

RUB WITH A CIRCULAR MOTION. Soil and burnt deposits

which do not respond can usually be removed by rubbing

the surface with Scotch-Brite scouring pads or Stainless

scouring pads. DO NOT USE ORDINARY STEEL WOOL.

PARTS AND SERVICE

It is easy to keep your Garland equipment working in top

condition.

Heat tint can be removed by a vigorous scouring in the

direction of the polish lines using Scotch-Brite scouring pads

or a Stainless scouring pad in combination with a powdered

cleanser.

Technical information and/or parts literature is available

through your local Authorized Garland Service Agency or

direct from Garland.

Page 14

Part # 4519762 (12/07)Page 14

Page 15

Pièce nº 4519762 (12/07)Page 14

de service agréée Garland ou directement auprès de Garland.

de la documentation sur les pièces auprès de votre agence

Vous pouvez obtenir des renseignements techniques et/ou

état de marche.

Il est facile de maintenir votre équipement Garland en bon

PIÈCES DE RECHANGE ET RÉPARATION

nettoyage en poudre.

récurer pour acier inoxydable combinés à un produit de

avec des tampons à récurer Scotch-Brite ou un tampon à

frottant vigoureusement dans le sens des lignes de polissage

La coloration causée par la chaleur peut être éliminée en

NE PAS UTILISER DE LAINE D’ACIER ORDINAIRE.

Scotch-Brite ou des tampons à récurer pour acier inoxydable.

éliminés en frottant la surface avec des tampons à récurer

qui ne se détachent pas ainsi peuvent habituellement être

UN MOUVEMENT CIRCULAIRE. La saleté et les dépôts brûlés

couler le produit sur le métal. NE JAMAIS FROTTER AVEC

nettoyage sur un chi on humide ou une éponge et faire

Pour éliminer la graisse cuite, appliquer du produit de

appliquée avec un chi on.

éliminées avec une solution de détergent ou de savon

Acier inoxydable – Les salissures normales peuvent être

de produits abrasifs.

très chaude de détergent doux ou de savon. Ne pas utiliser

Pièces nickelées – Les laver une fois froides avec une solution

pas utiliser de produits abrasifs.

très chaude de détergent doux ou de savon. Bien sécher. Ne

laver tous les dépôts graisseux à l’extérieur avec une solution

Émail noir – Laisser l’équipement refroidir après utilisation et

Instructions De Nettoyage

INSTRUCTIONS D’ENTRETIEN suite

Page 16

Pièce nº 4519762 (12/07) Page 13

représente la principale cause de coûts d’entretien.

possible, éviter de surchau er l’équipement inutilisé, car cela

que les pièces mobiles fonctionnement correctement. Si

pour véri er les températures, les réglages et s’assurer

une agence d’entretien quali ée sont recommandées

Des inspections périodiques par le concessionnaire ou

“Un entretien régulier assure des performances optimales.”

renseignements

code. La plaque signalétique xée à l’appareil contient ces

chi res du pré xe et du su xe) et le numéro de série ou de

le numéro de modèle correct (comprenant les lettres et

pièces de rechange, bien faire référence à l’appareil avec

équipement concernant des problèmes de service ou des

Pour correspondre avec l’usine ou votre concessionnaire en

régulière.

avec précision, il devra être nettoyé et entretenu de façon

cuisson au monde. Comme tout autre équipement fabriqué

Vous avez acheté le meilleur équipement commercial de

l’alimentation en gaz de l’appareil est coupée.

technicien d’entretien quali é. Véri er également que

démontage de composants devra être e ectué par un

NOTA : Tout entretien ou réparation impliquant le

INSTRUCTIONS D’ENTRETIEN

allumage retardé pourrait causer une explosion.

Si la veilleuse n’est pas allumée, le gaz s’accumule et un

de brûleur est ouverte, le gaz peut parvenir au brûleur.

amme de veilleuse ne soit établie. Quand la commande

8. Ne pas tourner la commande de brûleur avant que la

4. Ouvrez le robinet d’arrêt de l’appareil.

3. Tournez le thermostat en position d’arrêt. (Le cas échéant)

fermée.

2. Véri ez que le robinet d’arrêt principal est en position

dissipe.

et attendez cinq minutes pour que le gaz accumulé se

sentez une odeur de gaz, fermez le robinet principal

d’observation dans le panneau avant en acier inoxydable.

Vous pourrez voir la amme de la veilleuse par le trou

d’observation de la veilleuse.

veilleuse avec une mèche allumée, à travers le trou

veilleuse.

correspondant à l’allumeur piézoélectrique de la

et appuyez immédiatement sur le bouton rouge,

7. Si la veilleuse ne s’allume pas rapidement et que vous

6. La veilleuse devrait s’allumer au bout de quelques essais.

Retirez le panneau avant des robinets et allumez la

Ou

Abaissez le panneau avant émaillé noir de l’appareil

5. Selon le type d’appareil :

l’intérieur de l’appareil.

et bien xées et qu’il n’y a pas d’accumulation de gaz à

1. Véri ez que toutes les conduites de gaz sont en place

veilleuse :

Si la veilleuse s’éteint, véri ez ce qui suit avant de rallumer la

rallumés, sauf en cas de coupure de gaz dans les installations.

les veilleuses allumées. Les appareils ne devraient pas être

veilleuses permanentes fonctionnent de façon continue avec

que tous les appareils à gaz qui utilisent des systèmes de

et commandes doit être véri é. On suppose généralement

le fonctionnement correct des branchements, veilleuses

l’appareil à gaz a été installé par un professionnel licencié,

devra pas utiliser de conduites à raccord rapide. Une fois que

conduite de gaz et être rebranchés de façon régulière. On ne

Ces appareils ne sont pas conçus pour être débranchés de la

Tous Modèles

Allumage Des Veilleuses Permanentes –

UTILISATION DE TOUS LES MODÈLES

Page 17

Pièce nº 4519762 (12/07)Page 12

d’utilisation intensive pour éviter tout débordement.

Véri er et vider fréquemment le contenant à graisse en cas

de cuisson.

va se décolorer. Cela est normal et n’a ectera pas les résultats

(149°C ) à 350°F (177°C). Après une cuisson, la plaque du gril

Les températures le plus souvent utilisées vont de 300°F

».

délai de 60 secondes.

» et le dispositif de sécurité se désengagera dans un

«

6. Pour éteindre le brûleur, tourner le cadran à la position

aiguilles d’une montre jusqu’à la position « ».

sur le robinet et le tourner dans le sens contraire des

5. Pour obtenir une amme basse ou pour mijoter, appuyer

» pour allumer le brûleur principal.

«

contraire des aiguilles d’une montre jusqu’à la position

sur le robinet et le tourner complètement dans le sens

4. Quand la veilleuse est bien allumée, appuyer de nouveau

partir de l’étape 1.

la veilleuse s’éteint, attendre 5 minutes et recommencer à

robinet enfoncé pendant 20 secondes, puis le relâcher. Si

3. Une fois la veilleuse allumée, continuer de maintenir le

l’allumeur jusqu’à ce qu’elle s’allume.

ne s’allume pas, continuez d’appuyer sur le bouton de

de l’allumeur et véri er que la veilleuse s’allume. Si elle

2. En maintenant le robinet enfoncé, appuyer sur le bouton

«

aiguilles d’une montre jusqu’à la position

1. Enfoncer le robinet et le tourner dans le sens inverse des

Allumage Du Gril

car cela causera des entailles.

Éviter de heurter la surface du gril avec le bord d’une spatule

s’accumulera, rendant di cile le nettoyage du gril.

Ne jamais saler les aliments sur un gril car un résidu collant

des problèmes de cuisson ou d’adhérence des aliments.

gril. Cela risque de rayer ou d’entailler la surface et de causer

leur surface. Ne pas placer de pot ni de plats à la surface du

Les grils sont conçus pour cuire les aliments directement sur

Grils

délai de 60 secondes.

» et le dispositif de sécurité se désengagera dans un

«

6. Pour éteindre le brûleur, tourner le cadran à la position

aiguilles d’une montre jusqu’à la position « ».

sur le robinet et le tourner dans le sens contraire des

5. Pour obtenir une amme basse ou pour mijoter, appuyer

«

» pour allumer le brûleur principal.

contraire des aiguilles d’une montre jusqu’à la position

sur le robinet et le tourner complètement dans le sens

4. Quand la veilleuse est bien allumée, appuyer de nouveau

partir de l’étape 1.

la veilleuse s’éteint, attendre 5 minutes et recommencer à

robinet enfoncé pendant 20 secondes, puis le relâcher. Si

3. Une fois la veilleuse allumée, continuer de maintenir le

FONCTIONNEMENT DES MODÈLES « FF » suite

Page 18

Pièce nº 4519762 (12/07) Page 11

l’allumeur jusqu’à ce qu’elle s’allume.

ne s’allume pas, continuez d’appuyer sur le bouton de

de l’allumeur et véri er que la veilleuse s’allume. Si elle

2. En maintenant le robinet enfoncé, appuyer sur le bouton

.

»

«

aiguilles d’une montre jusqu’à la position

1. Enfoncer le robinet et le tourner dans le sens inverse des

Allumage de la rôtissoire

».

l’allumeur jusqu’à ce qu’elle s’allume.

ne s’allume pas, continuez d’appuyer sur le bouton de

de l’allumeur et véri er que la veilleuse s’allume. Si elle

2. En maintenant le robinet enfoncé, appuyer sur le bouton

aiguilles d’une montre jusqu’à la position «

1. Enfoncer le robinet et le tourner dans le sens inverse des

Pour allumer les brûleurs de plaque ouverte.

Rôtissoires

Allumage De La Plaque Chau ante De Type Ouvert

délai de 60 secondes.

» et le dispositif de sécurité se désengagera dans un

«

5. Pour éteindre le brûleur, tourner le cadran à la position

« » pour allumer le brûleur principal.

contraire des aiguilles d’une montre jusqu’à la position

sur le robinet et le tourner complètement dans le sens

4. Quand la veilleuse est bien allumée, appuyer de nouveau

partir de l’étape 1.

la veilleuse s’éteint, attendre 5 minutes et recommencer à

robinet enfoncé pendant 20 secondes, puis le relâcher. Si

3. Une fois la veilleuse allumée, continuer de maintenir le

brûleur.

des ustensiles à fond plat et les placer au centre de la tête de

NOTA : Pour une e cacité et une stabilité maximales, utiliser

supérieur à 30 mm (12 po).

chau er sur les brûleurs arrière les plats dont le diamètre est

(5 po) de diamètre. Cependant, il est recommandé de faire

accueillir en toute sécurité des plats à partir de 125 mm

rapidement ou laisser mijoter. Les supports de plat peuvent

peuvent être utilisés indi éremment pour faire bouillir

Tous les brûleurs ont un débit calori que identique et

Plaques Chau antes De Type Ouvert.

VEILLEUSE

FLAMME DE

LONGUEUR DE

DESCRIPTION

GD-36RB(FF) Rôtissoire 1/2” [13 mm]

GD-30RB(FF) Rôtissoire 1/2” [ 13 mm]

GD-24RB[FF] Rôtissoire 1/2” [13 mm]

GD-18RB(FF) Rôtissoire 1/2” [13 mm]

GD-36TGTH Gril 3/4” [19 mm]

GD-36G(FF) Gril 3/4” [19 mm]

GD-24GTH Gril 3/4” [19 mm]

GD-24G(FF) Gril 3/4” [19 mm]

GD-15GTH Gril 3/4” [19 mm]

GD-15G(FF) Gril 3/4” [19 mm]

MODÈLE

NUMÉRO DE

1/2” [13 mm]

1/2” [13 mm]

1/2” [13 mm]

VEILLEUSE

FLAMME DE

LONGUEUR DE

Chau ante

Chau ante

Chau ante

DESCRIPTION

FONCTIONNEMENT DES MODÈLES « FF »

GD-15F Friteuse 3/4” [19 mm]

GD-304H(FF) Plaque

GD-302H(FF) Plaque

GD-152H(FF) Plaque

MODÈLE

NUMÉRO DE

cône intérieur bleu stable.

Le réglage d’air et/ou de gaz est correct quand on obtient un

Tableau De Taille Des Flammest

Taille Des Flammes

RÉGLAGES suite

Page 19

Pièce nº 4519762 (12/07)Page 10

« OFF ».

5. Remettre en place le cadran et le tourner en position

3/16 po (5 mm)).

longueur minimale de

amme stable couvrant tout le brûleur ( amme d’une

température basse de cuisson souhaitée, maintenant une

l’intérieur de la tige du robinet et régler pour obtenir la

4. Avec un tournevis, tourner la petite vis de réglage à

3. Tourner le cadran en position « LO » et retirer le cadran.

2. S’assurer que les veilleuses sont allumées et réglées.

1. Le brûleur doit être froid.

comme suit :

réglage de amme basse. Pour e ectuer ce réglage, procéder

Les rôtissoires dotées de robinets Hi-Lo ont besoin d’un

Réglage Des Robinets HI-LO

amme allumée, régler le robinet selon le réglage souhaité.

Tourner le robinet à la position extrême « ON ». Une fois la

Le brûleur s’allume automatiquement avec la veilleuse.

Utilisation Des Brûleurs

des tailles des ammes.

droit long et n pour régler le robinet. Se reporter au tableau

Ouvrir la porte inférieure et utiliser une lame de tournevis

réglage de veilleuse est situé sous chaque robinet de brûleur.

qu’elle ait besoin de réglages une fois installée. Le robinet de

La veilleuse a été réglée en usine; cependant, il est possible

piézoélectrique situé derrière la porte avant.

veilleuse. La veilleuse de brûleur est allumée par l’allumeur

Chaque brûleur dans la rôtissoire est équipé d’une

Réglage Des Veilleuses

mise en marche.

IMPORTANT : Le conduit de fumée doit être installé avant la

Rôtissoires

étapes 1 à 3 pour véri er que le réglage est correct.

6. Remettre en place le cadran du thermostat et répéter les

la vis modi e la température d’environ 25°F (14°C)

augmenter la température. Nota : Chaque 1/4 de tour de

dans le sens contraire des aiguilles d’une montre pour

aiguilles d’une montre pour diminuer la température ou

la vis d’étalonnage à l’intérieur de l’axe dans le sens des

5. En immobilisant l’axe, tourner avec un petit tournevis plat

de l’axe.

4. Retirer soigneusement le cadran, sans modi er la position

est hors de ces limites, étalonner comme indiqué ci-après:

compris entre 335°F (168°C) et 365°F (185°C). Si le résultat

dessus du bulbe thermostatique. Le résultat devrait être

thermocouple sur la surface du gril, directement auvient juste de s’éteindre en appuyant fermement le

3. Véri er la température du gril quand le thermostat

la température.

laisser les thermostats cycler deux fois avant de mesurer

permettre à la température du gril de se stabiliser, il faut

2. Régler tous les thermostats de grils à 350°F (177°C). Pour

assurera un meilleur contact avec la plaque.

“ surface ”. Nota : une goutte d’huile sur la face du disque

spécial de type à disque ou un pyromètre able de type

1. Utiliser un instrument d’essai avec un thermocouple

Instructions D’étalonnage

« OFF ».

5. Remettre en place le cadran et le tourner en position

3/16 po (5 mm)).

longueur minimale de

amme stable couvrant tout le brûleur ( amme d’une

température basse de cuisson souhaitée, maintenant une

l’intérieur de la tige du robinet et régler pour obtenir la

4. Avec un tournevis, tourner la petite vis de réglage à

RÉGLAGES suite

Page 20

3. Tourner le cadran en position “ LO ” et retirer le cadran.

2. S’assurer que les veilleuses sont allumées et réglées.

1. Le brûleur doit être froid.

suit :

amme basse. Pour e ectuer ce réglage, procéder comme

Les grils dotés de robinets Hi-Lo ont besoin d’un réglage de

Réglage Des Robinets Hi-Lo

Pièce nº 4519762 (12/07) Page 9

thermomètre;

6. Régler le pointeur à la température indiquée sur le

vis de blocage du bouton du thermostat.

5. S’ils ne correspondent pas ± 10°F (5°C), desserrer les deux

thermocouple au réglage du thermostat.

cycle, comparez l’indication du thermomètre ou

4. Quand le brûleur vient de s’éteindre après le quatrième

quatre fois.

3. Attendre que le brûleur s’allume et s’éteigne au moins

amme allumée, régler le robinet selon le réglage souhaité

Tourner le robinet à la position extrême « ON ». Une fois la

Le brûleur s’allume automatiquement avec la veilleuse.

Utilisation Des Brûleurs

3/4 po (19 mm).

Les ammes des veilleuses doivent avoir une longueur de

en bas du thermostat.

avec une allumette. La vis de réglage de veilleuse est placée

D’ARRÊT. Ouvrir le robinet principal et allumer la veilleuse

arrêt). VÉRIFIER QUE LE THERMOSTAT EST EN POSITION

principal sont commandés par le robinet ON-OFF (MarchePour le gril doté de thermostats, la veilleuse et le brûleur

tournevis et allumer la veilleuse avec une allumette.

robinet de gril. Ouvrir le robinet de veilleuse avec un

de veilleuse est situé sur le collecteur, à gauche de chaque

Pour le modèle avec robinets HI-LO, le robinet de réglage

Chaque brûleur du gril est doté d’une veilleuse.

Réglage Des Veilleuses

Instructions D’allumage Et

mise en marche.

IMPORTANT : Le conduit de fumée doit être installé avant la

Grils

du thermostat Fenwal.

dommages permanents. Cela annulera la garantie standard

tours dans un sens ou dans l’autre sous peine de causer des

NOTA : Ne pas tourner l’axe de réglage de plus de deux

d’une pièce de 10 sous).

éloignée de la plaque du cadran (au moins l’épaisseur

8. Véri er que la surface noire du bouton est su samment

niveau du liquide à friture.

milieu du bain de friture, à environ 2 po (51 mm) sous le

2. Suspendre un thermomètre ou un thermocouple au

températures sur lesquelles sont réglées les commandes.

démontrent que les commandes ne maintiennent pas les

devra pas essayer de le faire sauf si les résultats de cuisson

1. L’étalonnage sur place est rarement nécessaire et on ne

Instructions D’étalonnage

montre jusqu’à « OFF ».

et continuer de tourner dans le sens des aiguilles d’une

légèrement dans le sens des aiguilles d’une montre, relâcher

montre à la position « PILOT », appuyer sur le bouton, tourner

robinet automatique de gaz dans le sens des aiguilles d’une

Pour éteindre complètement l’appareil, tourner le bouton du

position “PILOT”.

tournez le bouton du robinet automatique de gaz à la

Pour éteindre la friteuse pour une courte période de temps,

Instructions D’extinction

d’endommager le bassin de friture.

est trop rapide et le produit à friture brûle, ce qui risque

fumée se dégage pendant ce processus, le réchau age

jusqu’à ce que le produit à friture soit fondu. Si de la

l’éteindre pendant environ dix secondes. Recommencer

brûleur principal pendant environ cinq secondes, puis

(solide), remplir le bassin avec du produit et allumer le

3. En cas d’utilisation d’un produit à friture hydrogéné

position « ON ».

de gaz dans le sens inverse des aiguilles d’une montre à la

2. Pour allumer le brûleur, tourner le robinet automatique

possible d’allumer le brûleur principal.

1. En cas d’utilisation de produit à friture liquide, il est

7. Bien serrer la vis de blocage.

Pour Utiliser Le Brûleur Principal

RÉGLAGES suite

Page 21

Pièce nº 4519762 (12/07)Page 8

DES RÉPARATIONS.

NE LAISSER PERSONNE D’AUTRE ESSAYER D’EFFECTUER

7. Demander à un technicien quali é de véri er le système.

recommencer la procédure ou…

6. Si la veilleuse s’éteint quand on relâche le bouton,

5. Régler la amme de la veilleuse à 3/4 po (19 mm)

l’allumage de la veilleuse.

bouton enfoncé pendant environ 60 secondes après

4. Enfoncer le bouton, allumer la veilleuse et maintenir le

position “ Pilot ”.

3. Tourner le bouton du robinet automatique de gaz en

amme allumée, régler le robinet selon le réglage souhaité.

Tourner le robinet à la position extrême « ON ». Une fois la

Le brûleur s’allume automatiquement avec la veilleuse.

Utilisation Des Brûleurs

des tailles des ammes.

droit long et n pour régler le robinet. Se reporter au tableau

Ouvrir la porte inférieure et utiliser une lame de tournevis

avant d’allumer ou de rallumer la veilleuse.

gaz en position « OFF ». Attention : Attendre 5 minutes

2. Appuyer et tourner le bouton du robinet automatique de

basse.

1. Tourner le bouton du thermostat à la position la plus

Réglage Des Veilleuses

friteuse.

complètement le bassin de friture avant de déplacer la

friteuse quand le bassin de friture est plein. Vidanger

brûlures graves. Ne jamais essayer de déplacer une

le liquide chaud. Le produit à friture chaud cause des

d’empêcher la friteuse de se renverser et d’éclabousser

nécessaire d’installer des chaînes/câbles de retenue a n

3. AVERTISSEMENT : Quand des friteuses sont utilisées, il est

de friture et annuler la garantie.

quelques minutes pour détruire complètement un bassin

QUAND LE BASSIN DE FRITURE EST VIDE. Il su t de

friture. NE JAMAIS UTILISER LA VEILLEUSE OU LE BRÛLEUR

2. AVANT D’ALLUMER LA VEILLEUSE, remplir le bassin de

le bassin.

nettoyage et de l’eau très chaude. Bien rincer et assécher

de friture. Utiliser du détergent ou tout autre produit de

le bassin de friture avant de le remplir avec du produit

de friture. Pour cette raison, il est nécessaire de nettoyer

son thermostat étalonné avec de l’huile dans le bassin

1. Avant son départ de l’usine, la friteuse a été testée et

Avant D’utiliser La Friteuse

réglage de veilleuse est situé sous chaque robinet de brûleur.

qu’elle ait besoin de réglages une fois installée. Le robinet de

La veilleuse a été réglée en usine; cependant, il est possible

piézoélectrique situé derrière la porte avant.

veilleuse. La veilleuse de brûleur est allumée par l’allumeur

Chaque brûleur dans la plaque chau ante est équipé d’une

Réglage Des Veilleuses

mise en marche.

IMPORTANT : Le conduit de fumée doit être installé avant la

Plaques Chau antes

être déréglé.

d’obturateur d’air de façon à ce que celui-ci ne puisse pas

ne décollent pas des ori ces des brûleurs. Bien serrer la vis

ne soient pas jaunes, mais pas trop pour que les ammes

su samment d’air pour que les extrémités des ammes

l’obturateur d’air sur le brûleur. Le brûleur doit recevoir

Réglage de l’air Si nécessaire, on peut régler l’air en tournant

réglage à faire est celui de l’air d’appoint.

plaque signalétique, à la pression normale du gaz. Le seul

débits calori ques réglés pour le gaz indiqué sur la

2. Tous les appareils sont expédiés de l’usine avec des

conduites.

canalisations sont étanches et que l’air a été purgé des

si cela n’est pas déjà fait. S’assurer que toutes les

de gaz à « OFF ». Retirer les ls d’attache des brûleurs

1. Avant d’e ectuer des réglages, tourner tous les robinets

Friteuses

Réglage Des Brûleurs – Toutes Les Unités

RÉGLAGES

Page 22

courants d’air dans la pièce.

éviter également les ventilateurs muraux qui créent des

des fenêtres près des côtés et de l’arrière de l’appareil et

l’appareil et, dans la mesure du possible, éviter d’ouvrir

4. Éviter que des ventilateurs sou ent directement sur

ventilation.

Ne pas obstruer la circulation d’air de combustion et de

car ils pourraient obstruer l’admission d’air par l’avant.

3. Ne pas placer d’objets encombrants devant l’appareil,

su samment d’air pour fonctionner.

Tous les brûleurs à gaz et veilleuses ont besoin de

une bonne circulation de l’air dans un endroit con né.

2. Les appareils seront placés de façon à ne pas empêcher

des conditions de travail indésirables.

nuirait au bon fonctionnement de l’appareil et causerait

deviendrait inférieure à la pression atmosphérique, ce qui

système de ventilation. Dans le cas contraire, la pression

su samment d’air pour compenser l’air évacué par le

1. Il est nécessaire de laisser entrer dans la pièce

Pièce nº 4519762 (12/07) Page 7

incombustible.

devant être installés sur un socle de plan de travail

2. Retirer et jeter les boulons de mise à niveau des appareils

carton du socle.

comme indiqué dans les instructions se trouvant dans le

1. Assembler et mettre de niveau le socle de plan de travail

Incombustibles (Option)

Installation De Socles De Plan De Travail

place les écrous borgnes et les serrer.

plaque d’union sur les deux têtes de vis, remettre en

(un pour chaque panneau de commande). Placer la

5. Retirer les deux écrous borgnes des côtés xés en batterie

de travail ou le dossier du bar.

4. Pousser les appareils pour les mettre en place sur le plan

Alimentation En Air

habituellement partie d’un système d’évacuation mécanique.

contre le mur si la hotte est installée sur le mur). Elle fait

moins 6 po (152 mm) sur tous les côtés de l’appareil (sauf

correctement conçue, qui devrait se prolonger d’au

de comptoir est l’utilisation d’une hotte de ventilation

l’appareil. La méthode idéale de ventilation de l’équipement

correcte est impérative pour un bon fonctionnement de

satisfaisante du gaz et une aération correcte. Une ventilation

où les installations de ventilation assurent une combustion

L’équipement de comptoir doit être installé dans un endroit

Ventilation

série GD.

(5 mm) du socle dans les écrous au fond de l’appareil de

vis à métaux 8-32 à travers les trous de diamètre 7/32 po

de vis à métaux 8-32 et de rondelles plates. Insérer les

5. Fixer la dernière unité au socle de plan de travail à l’aide

intitulée : Installation des plaques d’union.

4. Relier les plaques d’union tel que décrit dans la section

série GD.

(5 mm) du socle dans les écrous au fond de l’appareil de

vis à métaux 8-32 à travers les trous de diamètre 7/32 po

vis à métaux de 8-32 et des rondelles plates. Insérer les

de plan de travail, en xant la première unité avec des

3. Placer les appareils dans les positions choisies sur le socle

remettant en place les vis Parker retirées à l’étape 2.

sur les trous de vis à l’arrière de l’appareil et les xer en

les trous de diamètre 1/4 po (6 mm) de la plaque d’union

3. Fixer une plaque d’union en place à l’arrière en mettant

2. Retirer les vis Parker à l’arrière de l’appareil.

appareils ne sont pas de niveau

Nota : Les grils peuvent ne pas reposer correctement, si les

avec la première.

de droite et de gauche. Mettre toutes les unités de niveau

travers à l’avant et à l’arrière et verticalement sur les bords

et mettre l’appareil de niveau dans quatre directions : en

de mise à niveau ou les pieds. Utiliser un niveau à bulle

1. Mettre chaque appareil de niveau en ajustant les boulons

VUE ARRIÈRE

INSTALLATION suite

Page 23

Pièce nº 4519762 (12/07)Page 6

VUE AVANT

similaires. Ne pas véri er avec une amme nue.

raccords avec une solution savonneuse ou des méthodes

8. AVERTISSEMENT : Véri er les fuites de gaz sur les

liqué é.

homologué pour une utilisation avec le gaz de pétrole

commandes. Utiliser du produit d’étanchéité pour joint

l’arrière de chacune des deux unités à installer.

type d’installation. Une plaque se trouve à l’avant et l’autre à

entre les unités, deux plaques d’union sont livrées pour ce

Pour assurer la correspondance et l’ajustement permanent

ou en série avec d’autres équipements de séries ED ou GD.

Toutes les unités peuvent être installées indépendamment

2

Installation Des Plaques D’union

etc. ne bouchent pas les veilleuses, robinets et/ou les

de façon à ce que la graisse à letage, les copeaux,

neufs ont été exécutés proprement et ont été purgés

7. S’assurer que les tuyauteries, joints et branchements

(3,45 kPa).

pressions d’essai supérieures ou égales à 1/2 lb/po

essai de pression du système d’alimentation en gaz à des

gaz en fermant son robinet d’arrêt individuel lors de tout

6. Cet appareil doit être isolé du système d’alimentation en

(QTÉ 4)

4 PO (102mm)

PIED RÉGLABLEDE

(QTÉ 2)

PROFILÉ DES PIEDS

DESSOUS DE L’UNITÉ

DES PIEDS

INSTALLATION

pro lé doit être installé quand on utilise les pieds.

Le pro lé des pieds est placé sous la base de l’ensemble. Ce

(3,45 kPa.)

2

pressions dépassant 1/2 lb/po

gaz lors de tout essai de pression de ce système à des

doivent être débranchés du système d’alimentation en

5. Cet appareil et son robinet d’arrêt du gaz individuel

conduite de gaz est en position de fonctionnement.

pression, s’assurer que tout l’équipement branché sur la

dépassant pas 1/2 po de colonne d’eau. Pour véri er la

l’appareil a besoin avec une chute de pression ne

(compteur, tuyauteries, etc.) fourniront les BTU dont

a n de s’assurer que les installations de gaz existantes

4. Faire véri er la pression du gaz par un technicien quali é

fourni sur chaque appareil.

pression peuvent être e ectués au régulateur de pression

sur la plaque signalétique. Si nécessaire, les réglages de

d’alimentation de l’appareil est identique à celle indiquée

l’appareil est installé, pour s’assurer que la pression

3. Il est nécessaire de véri er la pression du gaz quand

nécessaire d’utiliser ce type de gaz.

fabriqué est noté sur la plaque signalétique et il est

2. Le type correct de gaz pour lequel l’appareil a été

Gas Code, ANSI Z223.1/NFPA No. 54 – dernière édition.

Code d’installation CAN/CGA-B149 ou au national Fuel

aux codes locaux ou, en l’absence de codes locaux, au

1. L’installation et les connexions doivent être conformes

Installation Des Pieds

Connexions du gaz

INSTALLATION suite

Page 24

Pièce nº 4519762 (12/07) Page 5

technicien quali é spécialiste des appareils à gaz.

6. Tous les réglages des brûleurs doivent être faits par un

Ventilation.

complémentaires, se reporter à la section intitulée

de ventilation adéquat. Pour des instructions

5. Ces unités doivent être installées avec un système

Base

Plancher Ou

0 po Combustible

0 po Incombustible

0 po Combustible

Incombustible

S/O 0 po Incombustible

(152mm)

6 po

(152mm)

6 po

(152mm)

6 po

Combustible

GD-36RB(J)(FF)

GD-30RB(J)(FF),

GD-24RB(J)(FF),

GD-18RB(J)(FF),

INCOMBUSTIBLES UNIQUEMENT

POUR INSTALLATION DANS DES EMPLACEMENTS

GD-36GTH(J)

GD-24GTH(J),

GD-15GTH(J),

GD-36G(J)(FF),

GD-25G(J)(FF),

GD-15G(J)(FF),

GD-15F(J)

GD-304H(J)(FF)

GD-302H(J)(FF),

GD-152H(J)(FF),

Modèle nº

plaque de gril.

écrous Pal xant l’ensemble de protection du bulbe à la

le bulbe soit à l’intérieur de la rainure. Serrer les quatre

un contrôle précis de la température, il est important que

avec la béquille de gril situé sous la plaque de gril. Pour

est nécessaire de soulever l’avant du gril et de le soutenir

plaque et l’ensemble de protection du bulbe. Pour cela, il

thermostatique doit être inséré dans la rainure entre la

des appareils dotés de thermostats de gril, le bulbe

4. Quand une plaque de gril doit être installée sur

retirer le bulbe.

protection du bulbe thermostatique à la plaque du gril et

gril. Desserrer les quatre écrous Pal xant l’ensemble de

soutenir avec la béquille de gril situé sous la plaque de

cela, il est nécessaire de soulever l’avant du gril et de le

situé à la partie inférieure de la plaque de gril. Pour

être démontés de l’ensemble de protection du bulbe,

le tube capillaire du thermostat de gril doivent d’abord

les appareils dotés d’un thermostat de gril, le bulbe et

3. S’il est nécessaire de retirer la plaque de gril en acier sur

sûr pour qu’elles ne soient pas endommagées.

2. Retirer les grilles supérieures et les placer dans un endroit

l’installation des appareils.

Côtés Et Arrière

COMBUSTIBLES/INCOMBUSTIBLES

MURS OU D’UNE BASE

DÉGAGEMENTS MINIMUM D’INSTALLATION PRÈS DE

Dégagements

inoxydable doit être retiré immédiatement après

inoxydable, le matériau de protection couvrant l’acier

et le matériel d’emballage. Sur les appareils en acier

caisse. Retirer de l’appareil les ls d’attache des brûleurs

1. Retirer avec précaution l’appareil du carton ou de la

Généralités

INSTALLATION

Page 25

Pièce nº 4519762 (12/07)Page 4

signalétique xée à l’appareil contient ces renseignements.

et du su xe) et le numéro de série de garantie. La plaque

modèle correct (comprenant les lettres et chi res du pré xe

rechange, bien faire référence à l’appareil avec le numéro de

local concernant des problèmes de service ou des pièces de

Pour correspondre avec l’usine ou le centre de service agréé

d’utiliser ce type de gaz.

commerciales.

de n’importe quelle sorte pour des applications autres que

de services de réparation, garantie, entretien ou soutien

commerciales seulement. Garland / U.S. Range n’o re pas

ou résidentielle, mais sont destinés à des applications

pas agréés ni autorisés pour une utilisation personnelle

tel que spéci é. Les produits Garland/U.S. Range ne sont

Ce produit doit être installé par du personnel professionnel

est noté sur la plaque signalétique et il est nécessaire

Le type correct de gaz pour lequel l’appareil a été fabriqué

commande.

lisibles en ouvrant la porte émaillée sous le panneau de

plaque signalétique de chaque appareil et sont facilement

Tous les débits calori ques des brûleurs sont indiqués sur la

Plaque Signalétique

(BTU/H)

CALORIFIQUE

DÉBIT

communiquer avec le département de service des produits.

l’entretien ou la réparation du produit, écrire ou

En cas de questions concernant l’installation, l’utilisation,

dans la manuel d’informations.

réparations par une agence de service agrée locale gurant

Nous suggérons de faire faire l’installation, l’entretien et les

tout dommage au transporteur.

présence de dommages “ cachés ”. Signaler immédiatement

l’expédition. Après un déballage soigneux, véri er la

pour déceler d’éventuels dommages subis pendant

Véri cation des dommages : Véri er le carton ou la caisse

Véri cation Des Dommages :

PRÉINSTALLATION

3/4 po 4.0 10.0 15,000

3/4 po 4.0 10.0 20,000

3/4 po 4.0 10.0 14,800

PROPANE

po CE

NATUREL

GAZ

FONCTIONNEMENT

PRESSION DE

D’ENTRÉE

COLLECTEUR

DIMENSION DU

NUMÉRO DE MODÈLE

GD-30RB(J)(FF), GD-36RB(J)(FF)

GD-18RB(J)(FF), GD-24RB(J)(FF),

GD-24GTH(J), GD-36G(J)(FF), GD-36GTH(J)

GD-15G(J)(FF), GD-15GTH(J), GD-24G(J)(FF),

GD-15F(J) 1/2 po 4.2 9.0 45,000

GD-152H(J)(FF), GD-302H(J)(FF), GD-304H(J)(FF)

SPÉCIFICATIONS

Page 26

Pièce nº 4519762 (12/07) Page 3

PIÈCES DE RECHANGE ET RÉPARATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Instructions De Nettoyage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

INSTRUCTIONS D’ENTRETIEN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Allumage Des Veilleuses Permanentes – Tous Modèles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

UTILISATION DE TOUS LES MODÈLES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Grils . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Rôtissoires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Plaques Chau antes De Type Ouvert. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

FONCTIONNEMENT DES MODÈLES « FF » . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Tableau De Taille Des Flammest . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Taille Des Flammes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Réglage Des Robinets HI-LO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Utilisation Des Brûleurs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Réglage Des Veilleuses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Rôtissoires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Instructions D’étalonnage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Réglage Des Robinets Hi-Lo . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Utilisation Des Brûleurs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Instructions D’allumage Et Réglage Des Veilleuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Grils . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Instructions D’étalonnage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Instructions D’extinction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Pour Utiliser Le Brûleur Principal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Réglage Des Veilleuses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Avant D’utiliser La Friteuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Friteuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Utilisation Des Brûleurs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Réglage Des Veilleuses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Plaques Chau antes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Réglage Des Brûleurs – Toutes Les Unités . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

RÉGLAGES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Installation De Socles De Plan De Travail Incombustibles (Option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Installation Des Plaques D’union . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Installation Des Pieds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Connexions du gaz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6