Garland GCM24-280 Installation Manual

U

:

4

INSTALLATION AND

OPERATION MANUAL

GARLAND INFRA-RED SALAMANDER BROILERS AND

INFRA-RED CHEESE MELTERS

FOR YOUR SAFETY:

DO NOT STORE OR USE GASOLINE

OR OTHER FLAMMABLE VAPORS OR

LIQUIDS IN THE VICINITY OF

THIS OR ANY OTHER

APPLIANCE

WARNING:

IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE

CAN CAUSE PROPERTY DAMAGE, INJURY,

OR DEATH. READ THE INSTALLATION,

OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR

SERVICING THIS EQUIPMENT

AND RETAIN FOR FUTURE REFERENCE.

THIS PRODUCT HAS BEEN CERTIFIED AS

COMMERCIAL COOKING EQUIPMENT AND

MUST BE INSTALLED BY PROFESSIONAL

PERSONNEL AS SPECIFIED.

IN THE COMMONWEALTH OF MASSACHUSETTS

THIS PRODUCT MUST BE INSTALLED BY A

LICENSED PLUMBER OR GAS FITTER. APPROVAL

NUMBER: G-1-07-05-28

For Your Safety:

Post in a prominent location, instructions to be

followed in the event the user smells gas. This

information shall be obtained by consulting

your local gas supplier.

Users are cautioned that maintenance and repairs must be performed by a Garland authorized service agent

using genuine Garland replacement parts. Garland will have no obligation with respect to any product that has been

improperly installed, adjusted, operated or not maintained in accordance with national and local codes or installation

instructions provided with the product, or any product that has its serial number defaced, obliterated or removed,

or which has been modified or repaired using unauthorized parts or by unauthorized service agents.

For a list of authorized service agents, please refer to the Garland web site at http://www.garland-group.com.

The information contained herein, (including design and parts specifications), may be superseded and is subject

to change without notice.

PLEASE READ ALL SECTIONS OF THIS MANUAL

GARLAND COMMERCIAL INDUSTRIES, LLC

185 East South Street

Freeland, Pennsylvania 18224

Phone: (570) 636-1000

Fax: (570) 636-3903

Part # 1382669 Rev 1 (11/19/08) © 2005Garland Commercial Industries, LLC

Part # 1382669 Rev 1 (11/19/08) Page 1

GARLAND COMMERCIAL RANGES, LTD.

1177 Kamato Road, Mississauga, Ontario L4W 1X4

CANADA

Phone: 905-624-0260

Fax: 905-624-5669

Enodis

Swallowe

Telephone

Fax: 081-8

IMPORTANT INFORMATION

WARNING:

This product contains chemicals known to the state of california to cause cancer and/or birth defects

or other reproductive harm. Installation and servicing of this product could expose you to airborne

particles of glass wool/ceramic fibers. Inhalation of airborne particles of glass wool/ceramic fibers

is known to the state of california to cause cancer. Operation of this product could expose you to

carbon monoxide if not adjusted properly. Inhalation of carbon monoxide is known to the state of

california to cause birth defects or other reproductive harm.

Keep appliance area free and clear of combustibles.

Units included in this manual are:

Salamander Models: MIR34L, IR36-280L, IR-280WL,

IR36-380CL, IR60-280L

Cheese Melter Models: GCM-2C, GCM-3C, GCM-6C,

GCM24-280G, CM36-280,

GCM72-280, MCM34

Part # 1382669 Rev 1 (11/19/08)Page 2

TABLE OF CONTENTS

IMPORTANT INFORMATION.............2

DIMENSIONS AND SPECIFICATIONS,

MODEL MIR 34L........................4

DIMENSIONS AND SPECIFICATIONS,

MODEL IR-280L SERIES .................5

DIMENSIONS AND SPECIFICATIONS,

CHEESE MELTER........................6

GENERAL INFORMATION ...............7

Salamander Performance and Construction . . 7

Cheese Melter Performance and

Construction................................ 7

Rating Plate ................................. 7

INSTALLATION.........................8

Statutory Regulations ....................... 8

Wall Mounted Salamanders, Cheese Melters

or Counter Mounted Salamander

or Cheese Melters .......................... 11

Ventilation and Air Supply .................. 11

Clearances: ................................ 11

OPERATION...........................12

Pilot Lighting Instructions................... 12

Main Burner Operation ..................... 12

Burn o Period . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Energy Conservation ....................... 12

Shut Down Instructions..................... 12

Main Burner Adjustments................... 12

MAINTENANCE AND CLEANING........13

Daily....................................... 13

Monthly ................................... 13

Gas Connections ............................ 8

Pressure Regulators in Battery Installations . . . 8

Installation of Salamander to a Range ........ 9

Assembly Instructions Salamander/

Cheese Melters.............................. 9

M-Series Salamanders/Cheese Melters .... 9

Models IR60-280L, GCM60-280........... 10

Models IR48-280L or GCM48-280

Mounting to 48” Range

with one Full Size Oven.................. 10

Exterior Cleaning ........................... 13

Part # 1382669 Rev 1 (11/19/08) Page 3

DIMENSIONS AND SPECIFICATIONS, MODEL MIR 34L

1-3/4"

[44mm]

7"

[178mm]

30-11/16"

[779mm]

34"

[864mm]

3/4"

[19mm]

15"

[381mm]

3-1/4"

[83mm]

REAR GAS

INLET ON

"W" & "C"

MODELS

34-1/2"

[876mm]

3-1/2"

[89mm]

[457mm]

9”

[229mm]

3-1/2"

[89mm]

18"

1-3/8"

[35mm]

REAR GAS

INLET ON

"W" & "C"

MODELS

4-1/2"

[114mm]

1/2" NPT

[13mm]

TOP GAS

INLET

INSTALLATION NOTES

Combustible Wall Clearances 1 Entry Clearances Manifold Operating Pressure

Sides: 6" (152mm)

Back: 6" (152mm)

Crated: 39 3/4" (997mm)

Uncrated: 34-3/4" (870mm)

Natural: 6" WC (15mbar)

Propane: 10" WC (25mbar)

1NOTE: Installation clearance reductions are applicable only where local codes permit.

Data applies only to North America

Commercial cooking equipment requires an adequate ventilation system. For additional information, refer to the

National Fire Protection Association's standard NFPA96.

Gas input ratings shown here are for installations up to 2,000 ft. (610m) above sea level.

Part # 1382669 Rev 1 (11/19/08)Page 4

DIMENSIONS AND SPECIFICATIONS, MODEL IR-280L SERIES

Width

Model

IR36-280L 36" (914mm) H286 200/91 29" (737mm) 21" (533mm)

IR48-280L 48"(1219mm) H288 230/105 29" (737mm) 21" (533mm)

IR60-280L 60" (1524mm)) H284 & H287 260/118 29" (737mm) 21" (533mm)

IR72-280L 72" (1829mm) H289 280/127 29" (737mm) 21" (533mm)

(36" Broiler Plus Applicable Width

Flue Riser W/shelf)

Use With H280

Series Model

Shipping Wt.

Lbs./Kgs.

Entry Clearances: In (mm)

Crated Uncrated

Note Salamander Broiler on Left Side. Right Side Optional

Manifold Operating Pressure Installation Clearances Total Input Orice

Natural Propane Sides Rear

6"WC (15mbar) 10"WC (25mbar) 6"(152mm) 6"(152mm) #48F #55F

1-3/4"

[44mm]

1/2" N.P.T

TOP GAS

INLET

3-1/4"

[83mm]

OPTIONAL

REAR

GAS INLET

4-1/2"

40,000 BTU/HR (11.7Kw)

Gas input ratings shown for installations up to

2000 ft., (610m), above sea level.

For use on noncombustible oors

Commercial cooking equipment requires an

adequate ventilation system. For additional

information, refer to the National Fire Protection

Association's standard NFPA96.

NAT PRO

[114mm]

This product is not approved for residential use.

34"

1-3/4"

[45mm]

18"

[457mm]

[864mm]

15"

[381mm]

30"

[762mm]

15"

[381mm]

9"

[229mm]

1-3/8"

[35mm]

OPTIONAL

REAR

GAS

INLET

3-1/2"

36"

[89mm]

[914mm]

Part # 1382669 Rev 1 (11/19/08) Page 5

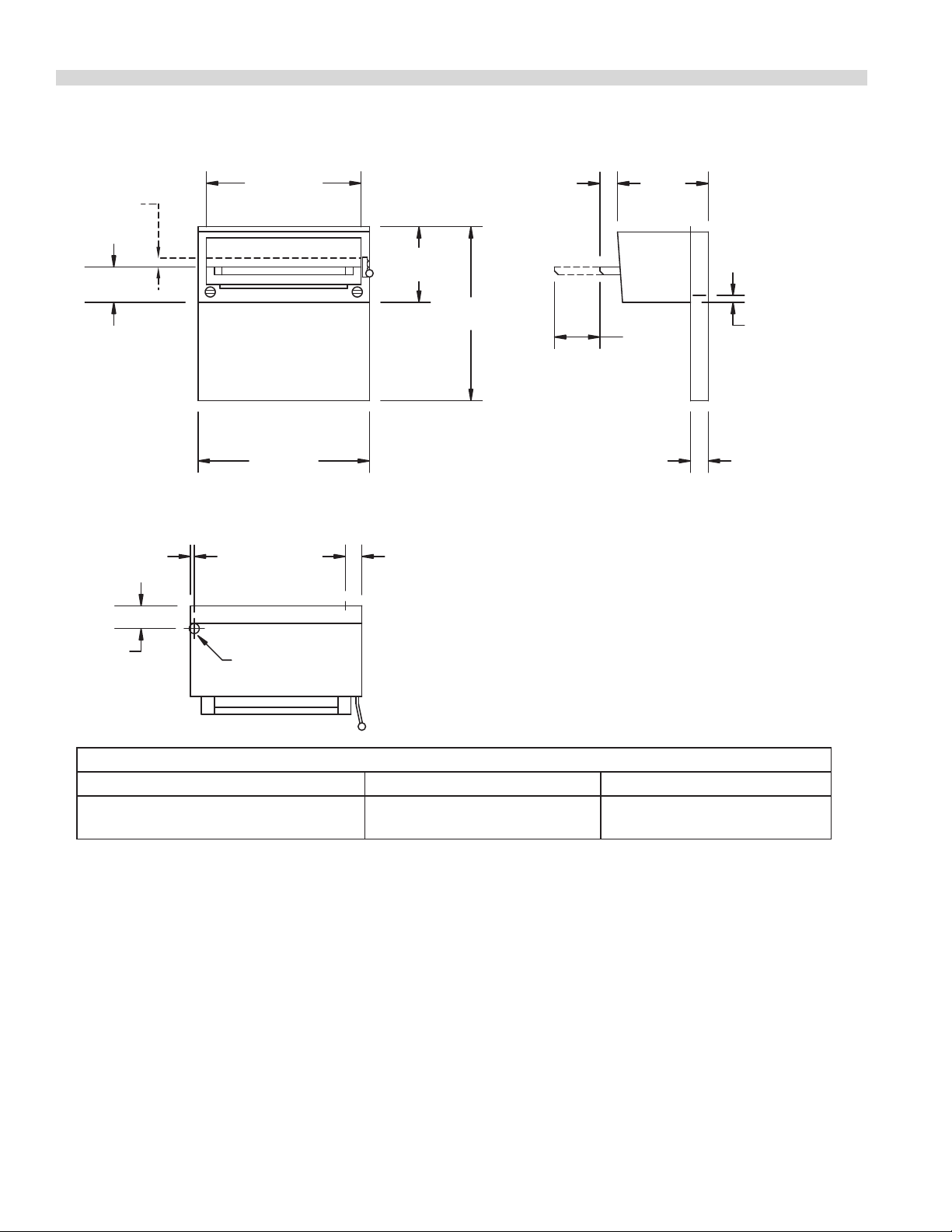

DIMENSIONS AND SPECIFICATIONS, CHEESE MELTER

Model Width Depth Height

GCM 24-280 24" (610,mm) 19" (483mm) 37-1/4" (946mm)

Entry Clearances: All Models

GCM 36-280 36" (314mm) 19" (483mm) 37-1/4" (946mm) Crated Uncrated

MCM 34 34" (864mm) 19" (483mm) 37-1/4" (946mm) 24"(610mm 20"(508mm)

Note: Data applies only to North America

Manifold Operating Pressure Installation Clearances Input: Natural and Propane Orice

Natural Propane Sides Rear

6" WC (15 mbar) 10" WC (25 mbar) 6" (152mm) 6" (152mm)

15,000 BTU/Hr (4.39 Kw) per Burner

30,000 BTU/Hr (8.79 Kw) Total

NOTE: Installation clearance reductions are applicable

Model Shipping Wt. (Lbs./Kg)

GCM 34 180/82

GCM 36-280 180/82

GCM 60-280 220/100

GCM 72-280 240/109

only where local codes permit

Commercial cooking equipment requires an adequate

ventilation system. For additional information, refer

to the National Fire Protection Association's standard

NFPA96.

Gas input ratings shown for installations up to 2000 ft.,

(610m), above sea level.

This product is not approved for residential use.

21-1/4"

[540mm]

Nat #50F

Pro #57F

20"

[508mm]

17-3/8"

[441mm]

20"

[508mm]

17-3/8"

[441mm]

31-1/4"

[794mm]

8-3/8"

[213mm]

5-13/32

[137mm]

483mm]

8-3/8”

[213mm]

5-13/32"

[137mm]

19"

15-1/2"

[394mm]

2-1/4"

[57mm]

1/2" N.P.T.

[13mm]

TOP GAS

INLET

24"

[610mm]

2"

[51mm]

[949mm]

3-1/2"

[89mm]

37-3/8"

19"

[483mm]

2-1/4"

[57mm]

1/2" N.P.T. [13mm]

TOP GAS INLET

34"

[864mm]

15-1/2"

[394mm]

[51mm]

37-3/8"

[949mm]

3-1/2"

[89mm]

2"

Part # 1382669 Rev 1 (11/19/08)Page 6

GENERAL INFORMATION

The range-mounted, gas Infra-Red Salamander Broiler and

Infra-Red Cheese Melter is designed as M Series and H/P280

Series Models for perfect match and t. The range-mounted,

gas Infra-Red Cheese Melter Broiler is designed as 40 Series

and H/P280 Series Models for perfect match and t. Ideal for

preparing melted cheese dishes, casseroles, au gratin dishes,

soués, Mexican food and other ethnic foods.

Garland/U.S. Range products are not approved or authorized

for home or residential use, but are intended for commercial

applications only. Garland / U.S. Range will not provide

service, warranty, maintenance or support of any kind other

than in commercial applications.

Salamander Performance and Construction

Two Hi-Low gas valves provide individual control of the (2)

atmospheric-type 20,000 BTU gas infra-red burners for the

Salamander. “LO” position is adjustable for most eld gas

pressure situations. Fast preheat and uniform production is

provided by the high-eciency, infra-red burners. Unique

atmospheric design eliminates the need for fans and lters.

Heat is directed downward to the large -380 square inch

plus – heavy duty broiling rack. Rack is easily removed from

spring balanced rack assembly. Rack assembly rolls out

for ease of loading and unloading. Rack assembly raises

and lowers with positive locking in three positions. Fullwidth grease deector attached to the underside of the

rack assembly channels hot drippings to a large capacity

drain pan even when rack assembly is rolled out. The rack

assembly and drain pan are easily removed for cleaning.

The MIR34L is 34” wide and is supported by heavy-formed

brackets with stainless steel back-splash. Front and sides of

salamander are stainless steel.

IR36-280 is 36” wide, supported by heavy-formed brackets.

Salamander front & back-splash is stainless steel with black

baked enamel sides.

IR60-280L has a nished width of 60” which includes a 24”

wide shelf. Salamander front and back-splash is stainless

steel with black baked enamel sides.

Cheese Melter

Performance and Construction

Twenty-four inch wide model has a single atmospheric

type, 15,000 BTU gas infra-red burner. Thirty-four and thirty

six inch wide models each have two (2) atmospheric type,

15,000 BTU has infra-red burners. Burners are individually

controlled by three (3) position three (2) heat valves (HI, LO,

OFF). Fast preheat and uniform production is provided by

the high-eciency, infra-red burners. Unique atmospheric

design eliminates the need for fans and lters. Heat is

directed downward to the large heavy chrome-plated rack.

Sturdy chrome-plated rack guides support the rack, which

is adjustable to three (3) positions. Rack and rack guides are

easily removed for cleaning.

H/P280 Series and 40 Series range mounted cheese melters

are securely supported by heavy formed brackets.

H/P280 Series and 40 Series cheese melters are standard with

stainless steel fronts. Backsplash and remainder of exterior

are nished in black baked enamel. Pressure regulator is

standard.

Rating Plate

When corresponding with the factory or your local

authorized factory service center regarding service problems

or replacement parts, be sure to refer to the particular unit

by the correct model number (including the prex and sux

letters and numbers) and the warranty serial number. The

rating plate axed to the unit contains this information.

We suggest installation, maintenance and repairs should be

performed by your local authorized service agency listed in

your information manual pamphlet.

In the event you have any questions concerning the

installation, use, care or service of the product, write or call

our Product Service Department.

This product has been certied as commercial cooking

equipment and must be installed by professional personnel

as specied.

Part # 1382669 Rev 1 (11/19/08) Page 7

INSTALLATION

Statutory Regulations

The importance of the proper installation of Commercial

Gas Cooking Equipment cannot be over stressed. Proper

performance of the equipment is dependent, in great part,

on the compliance of the installation with the manufacturer’s

specications. Installation must conform to local codes or,

in the absence of local codes, with the National Fuel code,

ANSI Z223.1, Natural Gas Installation Code, CAN/GCA-B149.1

or the Propane Installation Code, CAN/CGA-B149.2, as

applicable.

Gas Connections

Before assembly and connection, check gas supply.

A. The type of gas for which the unit is equipped is stamped

on the data plate located on the lower front frame,

simply remove the drip pan for easy access. Connect a

unit stamped “NAT” only to natural gas; connect those

stamped “PRO” only to propane gas.

B. If it is a new installation, have gas authorities check meter

size and piping to assure that the unit is supplied with

sucient amount of gas pressure required to operate the

unit.

C. If it is additional equipment or replacement have a

qualied gas technician check the gas pressure to make

certain that existing gas facilities (meter piping, etc.) will

deliver the BTU’s of gas required at the unit with no more

than 1/2” water column pressure drop. When checking

pressure, be certain that other equipment on the same

gas line is on at full rate.

NOTE: When checking pressure, be sure that all other

equipment on the same gas line is on. A pressure regulator is

supplied with Garland Infra-Red Broilers. Regulator is preset

at deliver gas at pressure shown on the rating plate.

D. The appliance and its individual shut o (supplied by

others) must be disconnected from the gas supply piping

system during any pressure testing of that system at

pressures in excess of 1/2” psi (3.45 kPa).

E. The appliance must be isolated from the gas supply

piping system by closing its individual manual shut o

valve (supplied by others) during any pressure testing of

the gas supply piping system at test pressures equal to or

less than 1/2 psi (3.45 kPa).

F. Gas supply connection is made in back lower left hand

corner of unit. A readily accessible approved type of hand

valve should be installed on each supply line. Test for

leaks – DO NOT USE ANY OPEN FLAME.

G. A pressure tap plug is supplied with the units and it is

installed on the manifold. The drip pan must be removed

to use the pressure tap. The gas pressure must be

checked when the unit is installed, to insure that the unit

gas pressure is the same as specied on the rating plate.

If necessary, pressure adjustments must be made at the

pressure regulator, supplied on each Infra-Red Broiler.

NOTE: the pressure regulator is located at the top rear of the

salamander.

H. If it is completely new installation, have gas lines, meter

size piping and piping installed and checked by a

qualied gas technician.

I. Make certain that the new piping, joints and connections

have been made in a clean manner and have been

purged, so that the piping compound, chips, etc, will not

clog pilots, valves and/or controls. Use pipe joint sealant

that is resistant to liqueed petroleum gas.

WARNING Check gas connections for leaks. Use a soap

solution or similar means. DO NOT USE AN OPEN FLAME!

Note: This appliance is not recommended for residential

installation.

Pressure Regulators in Battery Installations

1. Must have a maximum regulation capacity for the total

connected load.

2. The pressure regulator(s) installed must be listed by a

nationally recognized agency.

3. The pressure regulator(s) must have a pressure

adjustment range to allow adjustment to the manifold

pressure on the appliance rating plate.

4. Unless the manifold pressure on all connected appliances

is the same, a separate regulator must be supplied for

each appliance(s) having dierent manifold pressures.

5. Gas supply lines may be connected at right, left or

both ends of a battery or at the tee connections on

spreader plates. If ve (5) or more units are placed in a

battery, more that one (1) supply line should be used. A

readily accessible, approved type of hand shut o valve

(supplied by others) should be installed on each supply

line.

Part # 1382669 Rev 1 (11/19/08)Page 8

INSTALLATION Continued

CAUTION: Local codes may require that the pressure

regulator be externally vented. This is to be supplied by

others.

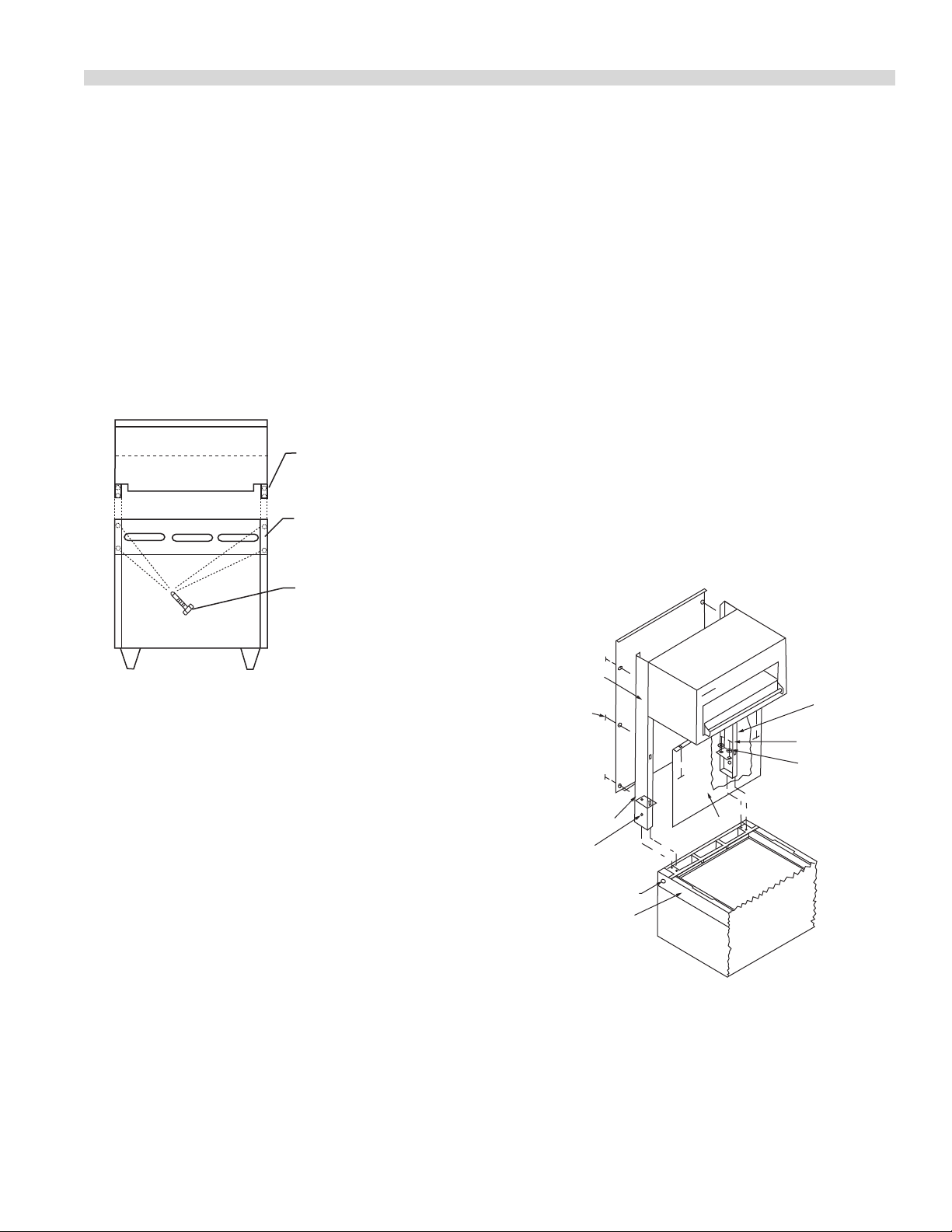

Installation of Salamander to a Range

Models IR36-280L, GCM24-280, GCM26-280

1. The back of the range must be easily accessible

2. Position the salamander on rear of the range slipping

uprights into burner box sides.

3. Securely fasten using hardware shown.

Upright

Burner Box

Side

1/4" x 3/4"

Type "B"

Washer Hex Head SMS

4 Req'd

Assembly Instructions

Salamander/Cheese Melters

M-Series Salamanders/Cheese Melters

1. Remove front panel #5 by removing two (2) sheet metal

screws from under side of salamander/cheese melter and

pushing front panel downward.

2. With back panel #4 still attached to the left #2 and right

#3 uprights drop uprights into the rectangular cutouts at

the rear of the range.

3. Fasten uprights #2 and #3 to the range #1 with four (4)

5/16” -18 bolts and at washers #6 and #7.

4. If unit is in a battery line up, fasten adjacent units

together at hole marked “X” with 1/4” -20 bolts, nuts and

washers.

5. Install front panel #5 previously removed. Attach front

panel #5 to salamander/cheese melter with two (2) sheet

metal screws

"X"

4

GARLAND

8

2

"X"

1

5

~

3

6

7

Part # 1382669 Rev 1 (11/19/08) Page 9

Loading...

Loading...