Page 1

INSTALLATION AND

TM

OPERATION MANUAL

GAS BAKE AND PIZZA

OVENS

FOR YOUR SAFETY:

DO NOT STORE OR USE GASOLINE

OR OTHER FLAMMABLE VAPORS OR

LIQUIDS IN THE VICINITY OF

THIS OR ANY OTHER

APPLIANCE

WARNING:

IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE

CAN CAUSE PROPERTY DAMAGE, INJURY,

OR DEATH. READ THE INSTALLATION,

OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR

SERVICING THIS EQUIPMENT

AND RETAIN FOR FUTURE REFERENCE.

THIS PRODUCT HAS BEEN CERTIFIED AS

COMMERCIAL COOKING EQUIPMENT AND

MUST BE INSTALLED BY PROFESSIONAL

PERSONNEL AS SPECIFIED.

IN THE COMMONWEALTH OF MASSACHUSETTS

THIS PRODUCT MUST BE INSTALLED BY A

LICENSED PLUMBER OR GAS FITTER. APPROVAL

NUMBER: G-1-07-05-28

For Your Safety:

Post in a prominent location, instructions to be

followed in the event the user smells gas. This

information shall be obtained by consulting

your local gas supplier.

Users are cautioned that maintenance and repairs must be performed by a Garland authorized service agent

using genuine Garland replacement parts. Garland will have no obligation with respect to any product that has been

improperly installed, adjusted, operated or not maintained in accordance with national and local codes or installation

instructions provided with the product, or any product that has its serial number defaced, obliterated or removed,

or which has been modified or repaired using unauthorized parts or by unauthorized service agents.

For a list of authorized service agents, please refer to the Garland web site at http://www.garland-group.com.

The information contained herein, (including design and parts specifications), may be superseded and is subject

to change without notice.

PLEASE READ ALL SECTIONS OF THIS MANUAL

GARLAND COMMERCIAL INDUSTRIES

185 East South Street

Freeland, Pennsylvania 18224

Phone: (570) 636-1000

Fax: (570) 636-3903

Part # 1382670 (12/07) © 2005 Garland Commercial Industries, Inc.

Part # 1382670 (12/07) Page 1

GARLAND COMMERCIAL RANGES, LTD.

1177 Kamato Road, Mississauga, Ontario L4W 1X4

CANADA

Phone: 905-624-0260

Fax: 905-624-5669

Enodis UK LTD.

Swallow eld Way, Hayes, Middlesex UB3 1DQ ENGLAND

Telephone: 081-561-0433

Fax: 081-848-0041

Page 2

IMPORTANT INFORMATION

WARNING:

This product contains chemicals known to the state of california to cause cancer and/or birth defects

or other reproductive harm. Installation and servicing of this product could expose you to airborne

particles of glass wool/ceramic fibers. Inhalation of airborne particles of glass wool/ceramic fibers

is known to the state of california to cause cancer. Operation of this product could expose you to

carbon monoxide if not adjusted properly. Inhalation of carbon monoxide is known to the state of

california to cause birth defects or other reproductive harm.

Keep appliance area free and clear of combustibles.

Part # 1382670 (12/07)Page 2

Page 3

TABLE OF CONTENTS

Important Information . . . . . . . . . . . . . . . . . 2

Dimensions And Specications . . . . . . . . . 4

Gas Type and Connections . . . . . . . . . . . . . . . . . . . 5

Model Number Identication . . . . . . . . . . . . . . . . . 5

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Rating Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Delivery and Inspection . . . . . . . . . . . . . . . . . . . . . . 6

Location of the Oven . . . . . . . . . . . . . . . . . . . . . . . . . 6

Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Canopy Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Direct Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Direct Connection Instructions . . . . . . . . . . . . . . . 7

Gas Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Possible Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Air Shutter Adjustments . . . . . . . . . . . . . . . . . . . . . 10

Application Trouble Shooting . . . . . . . . . . . . . . . 11

Adjustments. . . . . . . . . . . . . . . . . . . . . . . . . . 12

Oven Door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Burner ame Adjustment. . . . . . . . . . . . . . . . . . . . 12

Intermittent Pilot Instructions -

Honeywell S286 . . . . . . . . . . . . . . . . . . . . . . 13

Lighting and Shutdown Instructions . . . . . . . . . 13

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

First Stage – Trial for Pilot Ignition . . . . . . . . 13

Second Stage – Main Burner Operation . . 13

Safety Lockout Time (S86 & S86D Only). . . 13

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Preliminary Check . . . . . . . . . . . . . . . . . . . . . . . 13

Electrical Connections . . . . . . . . . . . . . . . . . . . . . . .8

Electrical Grounding Instructions . . . . . . . . . . . . . 8

Unit Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Leg Installation – All Models . . . . . . . . . . . . . . . . . . 8

Assembly of Double Unit . . . . . . . . . . . . . . . . . . . . . 8

Concept Of Air Impingement Cooking. . . 9

S86 Checkout And Trouble Shooting . . . . . 13

Check Grounding . . . . . . . . . . . . . . . . . . . . . . . 13

Check Spark Ignition Circuit. . . . . . . . . . . . . . 14

Control Module Flame Sensor Circuit. . . . . 14

Trouble Shooting. . . . . . . . . . . . . . . . . . . . . . . . 17

Maintenance And Cleaning . . . . . . . . . . . . 18

Oven Exterior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Oven Interior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Bottom Jet Plate Installation . . . . . . . . . . . . . . . . . 18

Part # 1382670 (12/07) Page 3

Page 4

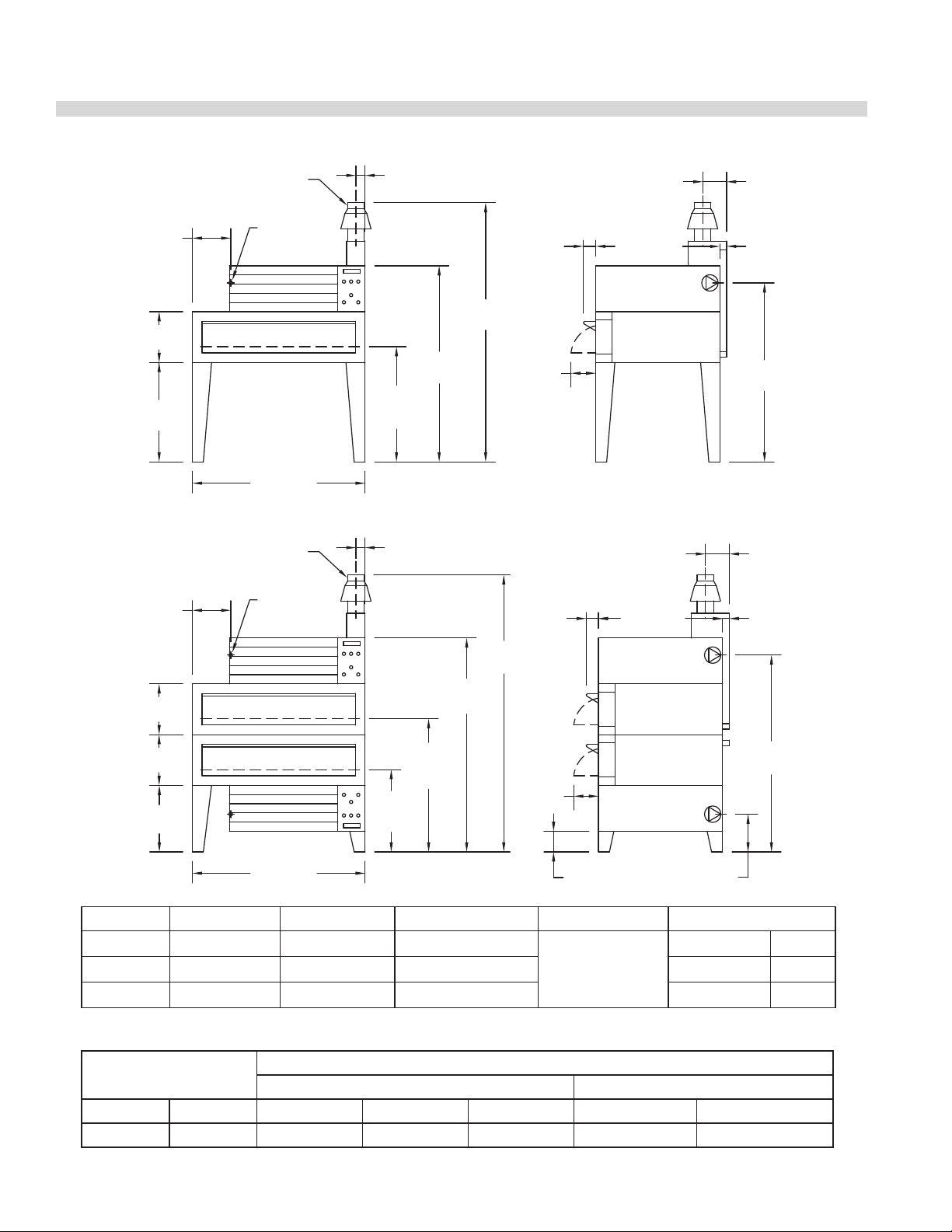

DIMENSIONS AND SPECIFICATIONS

30"

[762mm]

DECK

48-1/2"

[1232mm]

DECK

36-1/4"

[921mm]

18-1/2"

[470mm]

18-1/2"

[470mm]

18-1/2"

[470mm]

24-1/4"

[616mm]

78"

[1981mm]

101"

[2565mm]

10-3/4"

[273mm]

4-1/2"

[114mm]

45-1/4"

[1149mm]

4-1/2"

[114mm]

10-3/4"

[273mm]

4-1/2"

[114mm]

45-1/4"

[1149mm]

4-1/2"

[114mm]

9"

[229mm]

71-3/4"

[1822mm]

13-3/4"

[349mm]

63"

[1600mm]

42"

[1067mm]

DECK

71-1/2"

[1816mm]

94-1/2"

[2400mm]

3-3/8"

[86mm]

6" DIA

[152 mm]

6" DIA

[152 mm]

3-3/8"

[86mm]

7-1/2"

[191mm]

9"

[229mm]

14"

[356mm]

14"

[356mm]

65-1/4"

[1657mm]

63"

[1600mm]

3/4" NPT

REAR GAS

INLET

3/4" NPT

REAR GAS

INLET

MODEL INPUT (BTU) DECK AREA PIZZA CAPACITY MOTOR SHIPPING WT.

G56PB 80,000 14.0 Sq. Ft. (6) 18”

G56PT 80,000 14.0 Sq. Ft. (6) 18” 1000 lbs. 455 kg

G56PT/B 160,000 28.0 Sq. Ft. (12) 18” 2@1000 lbs. 910 kg

Gas input ratings shown here are for installations tip to 2,000 feet (610mm) above sea level.

BTU input ratings must be derated for high altitude installations.

OPERATING

PRESSURE

Nat Pro Sides Rear Base Crated Uncrated

3.5” WC 10.0” WC 6” (152mm) 6” (152mm) 8” (203mm) 45” (1143mm) 35-1/2” (902mm)

120V, 1Ø, 60Hz

15 Amps

(1 per deck)

MINIMUM CLEARANCES

Installation to Combustible Wall Entry

1000 lbs. 455 kg

Part # 1382670 (12/07)Page 4

Page 5

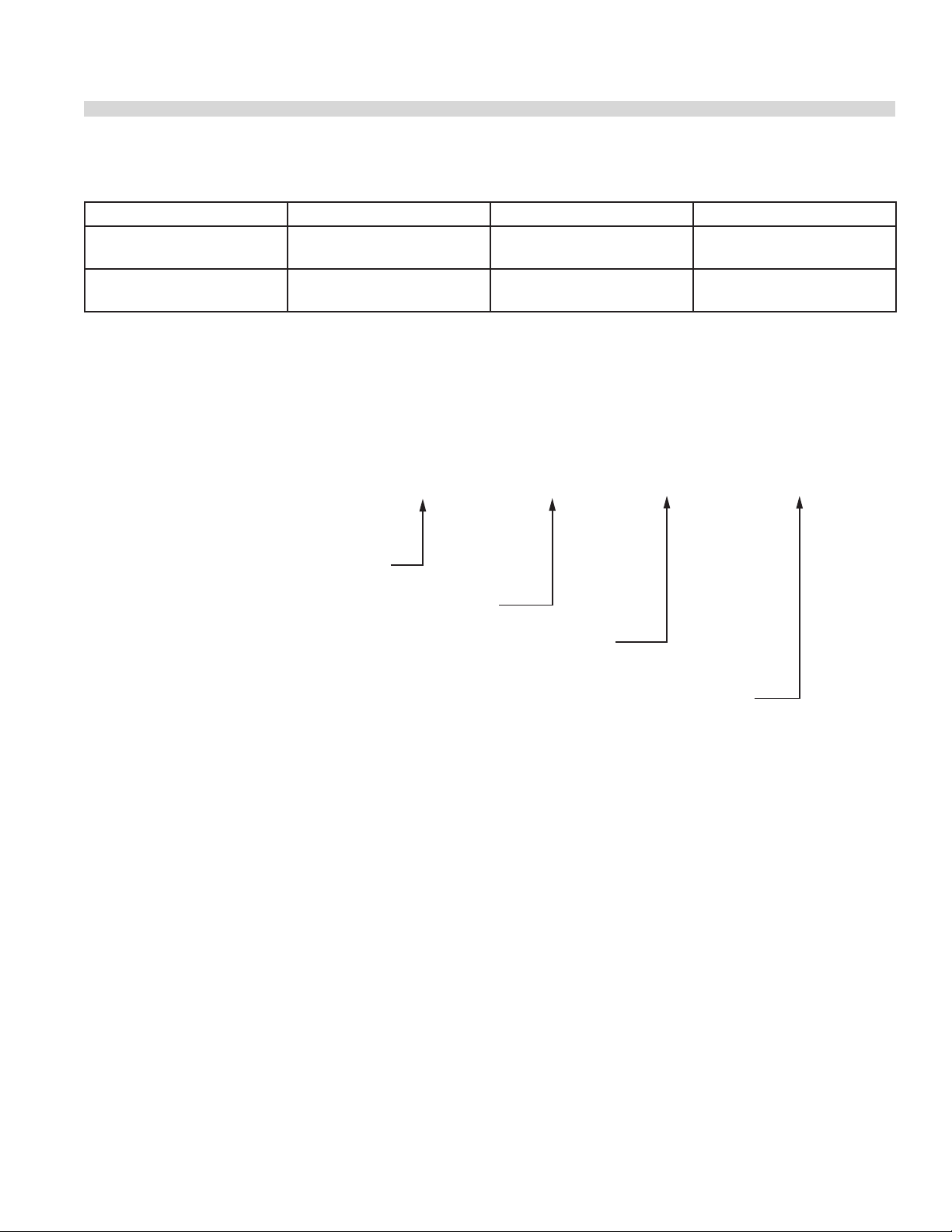

SPECIFICATIONS

EXAMPLE:

G 56 P T

INPUT G = GAS MODEL

DECK WITH IN INCHES

TYPE OF OVEN; P = PIZZA

NO LETTER = BAKE

POWER MODULE; T = TOP

B = BOTTOM

Gas Type and Connections

MODEL TYPE DESCRIPTION CONNECTIONS

G56T, G56B,

G56PT and G56PB

G56T/B

G56PTB

Natural or

Propane gas

Natural or

Propane gas

Single Deck

Double Deck

3/4 NPT Gas Inlet Line Cord

Supplied

(2) 3/4 NPT Gas Inlets

2 Line Cords Supplied

Model Number Identication

The model numbering system used indicates the input type,

deck size, intended application, and power module position

The model number on your oven is printed on the ratings

label, located on the side of the control panel housing.

Part # 1382670 (12/07) Page 5

Page 6

INTRODUCTION

Like any ne, precision built piece of equipment, your

appliance, should be given regular car and maintenance.

Periodic inspections by your local dealer or a qualied

service agent are recommended.

Rating Plate

When corresponding with the factory or your local

authorized factory service center regarding service problems

or replacement parts, be sure to refer to the particular unit

by the correct model number (including the prex and sux

letters and numbers) and the warranty serial number. The

rating plate located on the side of the control panel housing

contains this information.

INSTALLATION

The importance of proper installation of commercial

gas cooking equipment cannot be overstressed. Proper

performance of the equipment is dependent, in great part,

on the compliance of the installation with the manufacturer’s

specications. In addition compliance with the National

Fuel Gas code ANSI Z 223.1-1988/NFPA and/or Local Code is

required to assure safe and ecient operation.

In Canada, the installation and connection must comply with

CAN/CGA – B149 Installation codes and local codes where

applicable.

We suggest installation, maintenance and repairs should be

performed by your local authorized service agency listed in

your information manual pamphlet.

In the event you have any questions concerning the

installation, use, care or service of the product, write or call

our Product Service Department.

This product must be installed by professional personnel as

specied. Garland/U.S. Range products are not approved or

authorized for home or residential use, but are intended for

commercial applications only. Garland / U.S. Range will not

provide service, warranty, maintenance or support of any

kind other than in commercial applications.

Location of the Oven

Appliances shall be installed in a location in which the

facilities for ventilation permit satisfactory combustion of gas

and proper venting. Appliances shall be located so as not to

interfere with proper circulation of air within the conned

space. When buildings are so tight that normal inltration

does not provide the necessary air, outside air shall be

introduced.

Clearances

All burner adjustments and setting shall be made by a

qualied gas technician.

Delivery and Inspection

Upon delivery of your GARLAND Gas AIR DECK, inspect

the carton for external damage. Uncrate oven and check

for concealed damage. Any evidence of damage should be

noted on the delivery receipt which must be signed by the

driver.

Unit must be installed with no less than six inches (6”,

152mm) clearance from combustible construction at both

sides and rear.

Ventilation

Local codes and conditions vary greatly from one area

to another and must be complied with, following are

the minimum requirements for good ventilation. Please

remember these are general recommendations or

guidelines, you may have a special conditioner problem that

will require the services of a ventilation engineer or specialist.

Proper ventilation is the oven owner’s responsibility.

Improper ventilation can inhibit oven performance.

Part # 1382670 (12/07)Page 6

Page 7

INSTALLATION Continued

T

ermination Less than 10 feet (3 meters) from ridge

Less than 10 feet (3 meters)

2' (60cm)

Min.

3' (90cm) Min.

Termination More than 10 feet (3 meters) from ridge

More than 10' (3 meters)

3' (90cm) Min.

6" Stove Pipe

Draft Diverter

Heat

Collector

Oven

Flue

Gas

Pipe

15"

10"

16"

Canopy Method

The ideal method of venting a gas oven is through the use of

a properly designed canopy which should extend six inches

beyond all sides of the appliance and six feet six inches

from the oor. A strong exhaust fan will create a vacuum

in the room, for an exhaust system vent to work properly,

replacement air must enter the room in which the vent is

located. The amount of air which enters must equal the

amount exhausted.

Direct Connection

An unrestricted vent pipe that provides exit air at the oven

of a minimum of 55 C.F.M. per oven must be provided for the

vent pipe at the top of the oven. The vent pipe should be a

minimum of 6” (152mm) in diameter. A direct connect kit can

be obtained through your dealer.

Do not Undersize Vent Pipe. This can cause resistance to ow

and impede good venting. If a horizontal run must be used

it should rise no less than 1/4” for each linear foot or run. The

ue should rise two feet to three feet above the roof line or

two feet to three feet above any portion of a building within

a horizontal distance of ten feet.

Direct Connection Instructions

The G56P-T/B (or double deck), may be direct vented to the

outside. In order to accomplish direct venting and maintain

proper oven operation, it is necessary to install a Direct

Venting Kit part #CK4529. This kit consists of a Heat Collector

(Part #1190100). The Heat Collector Box is mounted over the

ue at the rear of the oven and Draft Diverter is attached to

the top of the Heat collector as shown on next page.

The Heat Collector must be positioned over the rear ue and

as far forward as possible on top of oven. It is necessary to

mark and drill mounting holes on oven top to fasten Heat

Collector securely in place.

An unrestricted vent pipe that provides exit air at the oven

of a minimum of 55 C.F.M. per oven must be provided for the

vent pipe at the top of the oven. The vent pipe should be a

minimum of 6” (152mm) in diameter. A direct connect kit can

be obtained through your dealer.

Part # 1382670 (12/07) Page 7

Gas Connections

The 1” NPT inlet of the rear must be considered in piping

the gas supply for double deck units. Undersized gas supply

line(s) may restrict the gas supply and aect performance.

If other gas appliances are supplied by the same supply

line, the supply line must be sized to carry the combined

volume without causing more than 1/2” pressure drop at the

manifold of each appliance on the line at full rate.

Page 8

INSTALLATION Continued

The appliance and its individual shuto valve must be

disconnected from the gas supply piping system during any

pressure testing of that system at pressures in excess of

1/2 PSIG (3.45 KP2).

The appliance must be isolated from the gas supply piping

system by closing its individual manual shuto valve during

any pressure testing of the gas supply piping system at test

pressures equal to or less then

1/2 PSIG (3.45 KP2).

NOTE: During installation there will be air in the gas line. This

air will have to be bled o before ignition can be established.

The electrical ignition system has a four second lock-out as a

safety device.

Electrical Connections

A 15 AMP service must be provided for each oven. For 115

Volt usage a cord and plug is provided but connection to

the electrical service must comply with local codes or in

the absence of local codes with the National electrical code

ANSI/NFPA No. 70-1987 (or latest edition).

Each oven is electrically equipped with a cord set with a

three prong plug which ts all standard 115 Volt three prong

grounded receptacle. A wiring diagram is attached to the

rear of the unit.

POWER FAILURE: In the event of a power failure, no

attempt should be made to operate this oven. This unit is

gas operated but has electrical features, motors, controls

and burner systems.

Electrical Grounding Instructions

WARNING: All ovens, when installed, must be electrically

grounded in accordance with local codes, or in the absence

of local codes with the Nation Electrical code ANSI/NFPA 701987 (or latest edition).

This appliance is equipped with a three prong (grounding)

plug for your protection against shock hazard and should be

plugged directly into a properly grounded three pronged

receptacle. Do not cut or remove the grounding prong

from this plug.

Unit Assembly

1. Before assembly and connection check gas supply and

electrical service. It is recommended that a separate

electrical circuit be provided for the Air Deck. A single

unit will require 15 AMPS and a double will require a

20 AMP circuit.

2. Gas conditions for this unit are listed on the rating

plate, located just forward of the Louvered Panel of the

Power Module. If this is a new installation, have the gas

authorities check meter size and piping to assure that

existing meter and piping will supply fuel at the oven

with 3.5” W/C (for Natural Gas) or 10.0” W/C (for L.P. Gas)

and not more than 1/2” water column pressure drop.

NOTE: When checking pressure, be sure that all other

equipment on the same gas line is on. A gas pressure

regulator is built into the combination control valve and no

adjustment is needed.

Leg Installation – All Models

1. Oven is crated and shipped on its base. When uncrating,

the bottom of unit is exposed to facilitate leg installation.

Position the legs inside front and rear corners from frame.

Start each bolt, threading them into the weld nuts on

the base frame. Four (4) bolts with washers must be used

to secure each leg in place. Tighten the bolts evenly and

securely. The legs are interchangeable front to back, for

models “B” – longer legs for left side – shorter legs for

mounting to Power Module section: See line drawing.

Assembly of Double Unit

1. Install legs on bottom unit. Then place in position desired.

2. Place 2 x 4’s on top of the lower section about six inches

from each side, running front to rear.

3. Raise the top section and position it on the 2 x 4’s so that

the front, rear and sides of top section with the lower

oven section. Carefully remove the 2 x 4’s lowering the

upper oven into place. It is not necessary to bolt the

sections together.

Part # 1382670 (12/07)Page 8

Page 9

CONCEPT OF AIR IMPINGEMENT COOKING

The “AIR DECK” Oven produced by GARLAND COMMERCIAL

INDUSTRIES INC., utilizes a revolutionary cooking concept,

called “AIR IMPINGEMENT”. It provides exceptional baked

food product quality in far less time than conventional

devices on the market. The “AIR IMPINGEMENT” system

directs a high velocity stream of heated air at the food

product being baked.

This blast eect penetrates the boundary layer of air

encircling the product and heats the food more eciently,

because the air concentrates heat on the food product.

Greater heat transfer rates, results in products baking two to

four times faster than conventional means, are possible with

“AIR IMPINGEMENT”.

OPERATION

The “AIR IMPINGEMENT” process develops the high velocity

air stream with a specially designed fan that draws superheated air from a heat source (either gas or electric). This

air is directed through a plenum chamber to patented “JET

PLATES” which have hundreds of focused jet ports that

“impinge” the heated air onto the food product surface. The

heated air is re-cycled to the heat source after striking the

food product, thus reducing energy consumption.

The “AIR IMPINGEMENT” process is tolerant enough for

sensitive food products and eects proper crisping and even

browning of such products as they pass through the oven,

because air is the medium which heats the food product. The

adjustable air controls for top and bottom jet plates allow

further enhancement of cooking.

Once the equipment has been installed and tested by

qualied professional personnel, the oven is ready for

operation.

Many of the parts used in the oven have a thin protective

oil covering. The oil should be burned o before the oven is

used for the production of food products. It is normal for the

unit to smoke while burning o excess oil. Washing the deck

of the oven with a damp clean cloth and mild soap solution

will remove some of the protective oil coating.

To start the oven, switch the power to on. Set oven

temperature dial to 400 degrees and let oven heat and

operate at this temperature for at least one hour.

The “Air Deck” utilizes an automatic ignition and pilot

ame sensing system. During normal operation, the power

burner will cycle on and o as necessary to maintain oven

temperature. There is a short “time delay” built into the

circuitry, and you should not be alarmed when the oven

“calls for heat” and the power burner does not operate

immediately.

You will nd that cooking with the “Air Deck” oven will be

much faster than the standard Bake/Roast and Pizza Ovens.

You will have to experiment with your recipes to become

accustomed to this new method. For example the warmup time is shorter than standard ovens. The oven can be

warmed and ready for use in as little as twenty (20) minutes.

A large pizza can be ready to serve in as little as ve (5)

minutes. These are “ideal conditions” times and will vary with

ventilation and use.

Heat control vent shutters (2), are located on the right side of

the oven cavity. These shutters must be adjusted to provide

the air ow top and bottom that you desire for your cooking

needs. Adjusting these shutters will provide you with many

cooking variations.

If unit fails to operate, it is recommended that only qualied

service personnel perform the repairs on this unit. A

troubleshooting chart is provided in this manual to assist

qualied service personnel in repair of the unit. However,

before you call a service technician you may want to make a

few simple checks. Make sure electricity and gas are available

to the oven prior to calling a Service Technician.

CAUTION: Disconnect power supply before attempting to

clean or service.

Part # 1382670 (12/07) Page 9

Page 10

OPERATION Continued

Decrese Air

Decrese Air

Increase Air

Increase Air

Upper Damper

Lower Damper

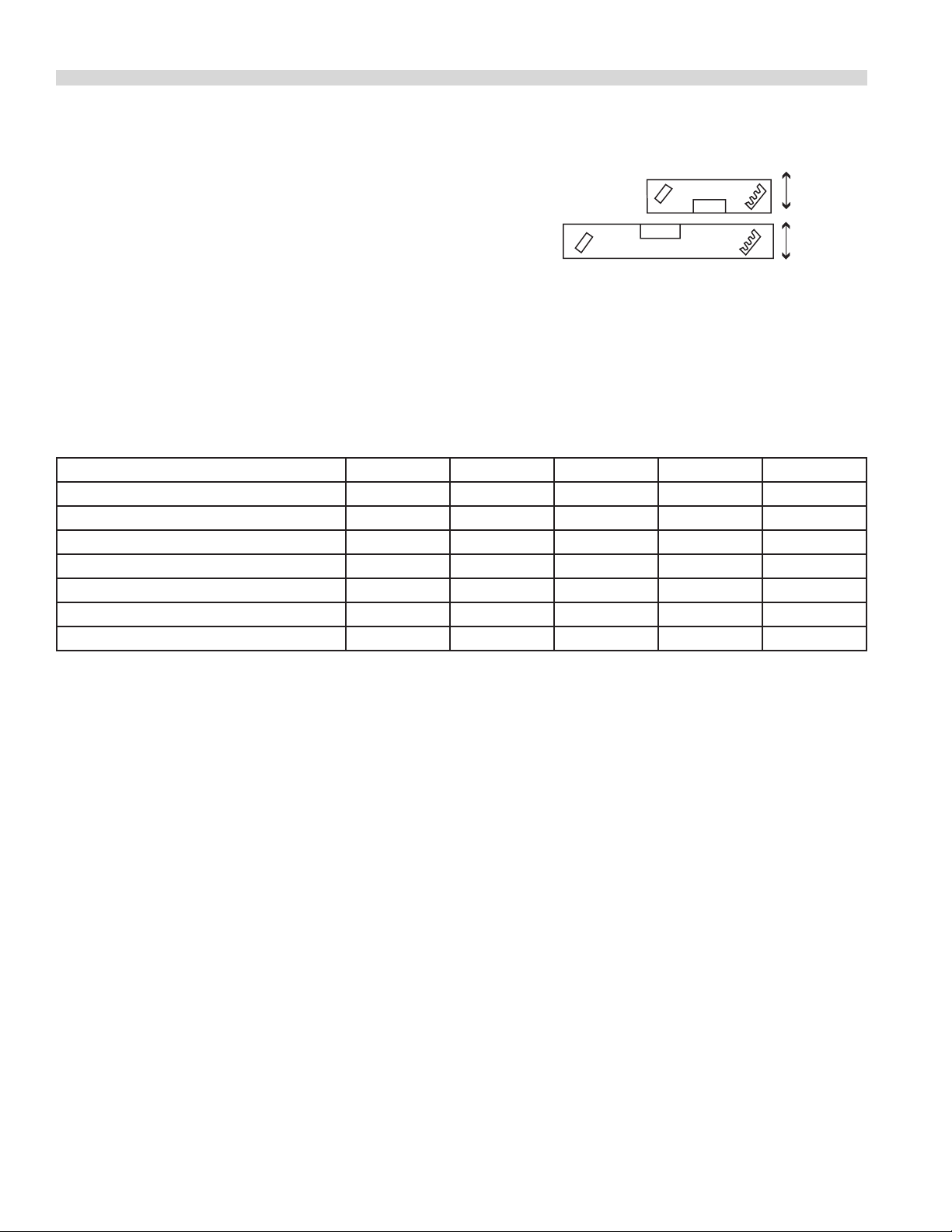

Air Shutter Adjustments

To adjust the dampers, loosen wing nut holding damper

position, with deck and damper tool provided, insert the

damper end of the tool into the receptacle on the damper,

and raise the damper to disengage the damper from the

notched position, slide the damper at a 45 degree angle to

engage the next position, retighten wing nut.

Possible Settings

PIZZA PRODUCT TIME TEMP F TEMP C UPPER LOWER

Fresh Dough Cheese Pizza 6:00-7:00 450-575 234-250 Fully Closed Fully Open

Fresh Dough with Toppings 7:30-8:30 450-475 234-250 1/2 Open Fully Open

Pre-Baked Dough Cheese Pizza 5:00-6:00 450-475 234-250 1/2 Open Fully Open

Pre-Baked Dough with Toppings 5:30-6:30 450-475 234-250 1/2 Open Fully Closed

Pre-Cooked Black Porcelain Pan 10:00-12:00 475-500 250-260 Fully Closed Fully Open

Deep Pan Pizza 8:30-9:30 475-500 250-260 Fully Closed Fully Open

Pre-Baked Party Pizza 16:00-20:00 475-500 250-260 Fully Closed Fully Open

To increase Top air, adjust upper damper “down”. Position in

notch, and tighten thumb screw.

To increase Bottom Air, adjust lower damper “up”. Position

damper in notch, and tighten thumb screw.

Part # 1382670 (12/07)Page 10

Page 11

OPERATION Continued

Application Trouble Shooting

Dark Pizza Top 1 Decrease top air by adjusting upper damper “up”

2 Decrease cooking time

3 Decrease temperature.

Pizza Top Too Light 1 Increase top air by adjusting upper damper “down”.

2 Increase cooking time

3 Increase temperature.

Pizza Bottom too Dark 1 Decrease bottom air by adjusting lower damper “down

2 Decrease cooking time

3 Decrease temperature

Pizza Bottom and Top Too Light 1 Increase cooking time

2 Increase temperature

Pizza bottom and Top Too Dark 1 Decrease cooking time

2 Decrease temperature

Pizza Bottom Too Dark and Top too Light 1 Increase top air by adjusting top damper “down”

2 Decrease bottom air by adjusting bottom damper “down”

3 Lower cooking temperature and decrease bottom air by adjusting

bottom damper “down”

4 Lower cooking temperature and increase top air by adjusting top

damper “down”

Pizza Bottom Too Light and Top Too Dark 1 Decrease top air by adjusting top damper “up”

2 Increase bottom air by adjusting bottom damper “up”

3 Increase cooking temperature and decrease top air by adjusting upper

damper “up”.

Part # 1382670 (12/07) Page 11

Page 12

NATURAL

7/8"

PROPANE

1/2"

ADJUSTMENTS

NOTE: Each oven has been factory tested and adjusted

prior to shipment. It may be necessary to further adjust

the oven as part of a proper installation. Such adjustments

are the responsibility of the installer. Adjustments are not

considered defects in material or workmanship, and they are

not covered under the original equipment warranty.

Oven Door

The “AIR DECK” oven door has adjustability as a design

feature. Although it is factory set, the tension can be adjusted

to suit the operator’s preference. In addition, after a long

period of hard use, the tension can be readjusted as required.

To adjust door tension it is necessary to remove left and

right front corners of unit by the two sheet metal screws.

This exposes the door hinge and spring assembly. The spring

hook passed through a bracket. A 1/4” x 20 nut is on the

spring hook forward of the bracket. If it is available, use a

7/16” deep socket and ratchet to turn the nut clockwise to

increase spring tension or counter-clockwise to relieve spring

tension. Make sure to adjust both sides equally.

The oven door is properly adjusted if the door remains fully

open and if the spring tension carries the door to the full

closed position from the half-closed position. Replace the

corner and fasten with screws.

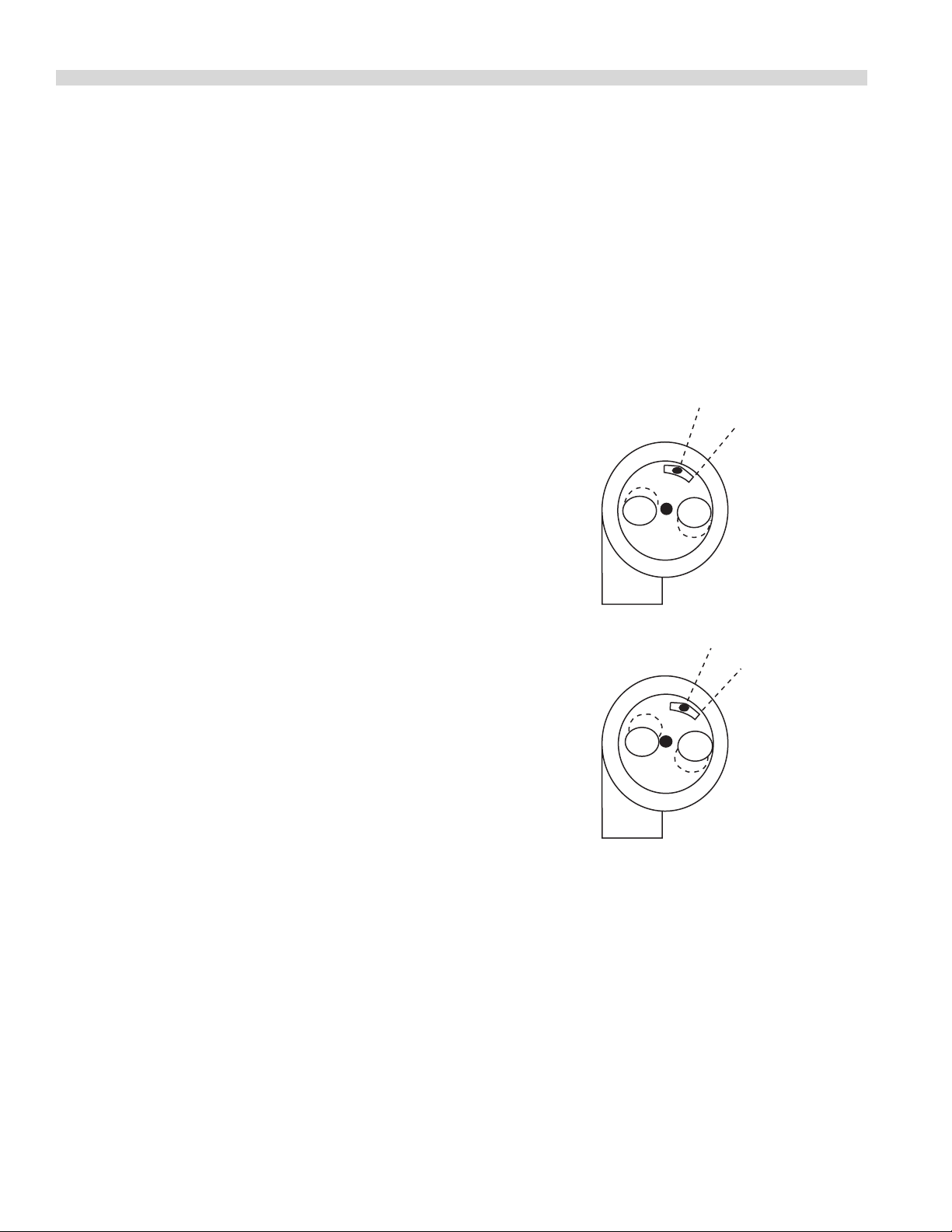

Burner ame Adjustment

The “AIR DECK” utilizes a power burner assembly as a heat

source. To ensure peak eciency, a proper air-fuel mixture is

necessary. There is an inspection port (window) on the power

burner. There is an air shutter located on the blower motor

that should be adjusted to provide a good blue ame with

no yellow tips.

Below is a drawing illustrating the proper way to check the

burner blower air shutter adjustment.

Part # 1382670 (12/07)Page 12

Page 13

INTERMITTENT PILOT INSTRUCTIONS - HONEYWELL S286

Lighting and Shutdown Instructions

Starting Burner

1. Turn the gas valve control knob to “OFF” wait ve

minutes.

2. Turn gas valve control knob to “ON”.

3. Turn power switch to “ON”, fan will turn on.

4. Turn thermostat to desired temperature setting.

5. If the burner does not light, turn the thermostat to “OFF”

and wait ve minutes then repeat step (4).

Shutting Burner Down

1. Turn thermostat to “OFF”.

2. Turn power switch to “OFF”.

3. Turn gas valve control knob to “OFF”.

4. Turn main shuto valve to “OFF”.

Operation

First Stage – Trial for Pilot Ignition

On every call for heat (system start), the S86 performs an

internal safe-start check shows that a ame-simulating

condition is present.

Safety Lockout Time (S & SD Only)

The safety lockout timer circuit starts timing the moment

the trial for pilot ignition starts. When the timing period runs

out, the trial for ignition ends, and the control module goes

into lockout. Before another attempt to start can be made

the S86 must be reset. Reset by adjusting the thermostat or

controller below room temperature, or to its “OFF” position.

An alternate method is to shut the system power “OFF”. If

normal ignition does not occur, use the trouble shooting

table to determine the problem.

Service

Preliminary Check

The following visual checks should be made before trouble

shooting and after installation of maintenance.

1. Check power to appliance and S86

2. Manual shuto cocks in gas line to appliance must be

open.

3. Make certain all wiring connections are clean and tight.

4. S86C & D module must not be in safety lockout. First deenergize the system and wait at least one (1) minute. This

resets the module allowing a return to start condition.

Then energize the system.

5. Review the S86 system normal sequence of operation.

During a normal start, the S86 opens the rst operator in

the gas control. This allows gas to ow to the pilot burner.

Simultaneously, the electronic spark generator in the S86

produces a 30,000 volt spark pulse output. This voltage

produces a spark at the pilot burner ignitor/sensor rod,

igniting the gas owing around the electrode. If the pilot

ame is not detected during the trial for pilot ignition, the

S86A and B will continue trying for pilot ignition until a ame

is established. The S86C and D contain a safety lockout timer

to limit the trial for pilot ignition period.

S Checkout And Trouble Shooting

NOTE: On servicing S86A, B, C and D models.

The S86E, F, G and H models can be used to directly replace

S86A, B, C and D models (E replaces A model, F replaces B, G

replaces C model and H replaces D model) and the S86B and D

can be used to replace S86F and H, respectively. However, the

S86A and C cannot be used to replace the S86E and G module

on IPI systems that use VR8520 gas controls. VR8440 or VR8520

valves will not function properly with the S86A or C.

Second Stage – Main Burner Operation

Check Grounding

When the pilot ame is established, a ame rectication

circuit is completed to the burner ground. The S86 ame

sending circuit detects the ame current and shuts the

spark generator o. At the same time the second operator

(main) is opened in the gas control, allowing fast ow to

the main burner. The pilot ame ignites the main burner

conventionally. On the S86C and D the ame current also

holds the safety lockout timer in the reset, or normal,

operating condition.

Part # 1382670 (12/07) Page 13

A common ground is required for the pilot burner, the

ignitor-sensor, the GND terminal of the S86, and the main

burner. The main burner generally serves as the common

ground. If the ground is poor or erratic, safety shutdowns

may occur occasionally even though operation is normal at

the time of the checkout. Therefore, if nuisance shutdowns

have been reported, be sure to check the grounding.

Page 14

INTERMITTENT PILOT INSTRUCTIONS Continued

Note: If the ground circuit path is incomplete the S86C, D, G

and H system control will allow one trial-for-ignition before

going into safety lockout.

Electrical grounding connections at the pilot burner,

ignitor/sensor and S86 must be clean and tight. If lead wire

is damaged or deteriorated, use only No. 14 of 18 gauge,

moisture-resistant, thermoplastic insulated wire with

105C. (221 F) minimum rating as replacement. Excessive

temperature at the ceramic ame rod insulator can also

permit electrical leakage to ground. Examine the ame rod

and mounting bracket, and correct if bent out of position.

Replace Q345, Q346 Q348 or ignitor/sensor if insulator is

cracked.

Check Spark Ignition Circuit

The electronic module and step-up transformer in the S86

provides spark ignition at 15,000 Volts (open circuit). This

circuit can be checked at the S86 module as follows:

1. Turn o the manual gas cock to prevent the ow of gas.

2. Disconnect the ignition cable at the S86 stud terminal to

isolate the circuit from the pilot burner/ignitor/sensor,

and prepare a short jumper lead using heavily insulated

wire, such as ignition cable.

CAUTION: Do not touch either stripped end of jumper or

stud terminal. This is a very high voltage circuit and electrical

shock can result. Perform the test immediately upon

energizing the system – before the S86C,D,G goes into safety

lockout and interrupts the spark circuit.

4. An arc length of 1/8” (3.2 mm) or more indicates

satisfactory voltage output. Replace the S86 if not arc can

be established or the maximum gap is less then 1/8” (3.2

mm), and the fuse and power to the S86 input terminal

was okay.

Control Module Flame Sensor Circuit

The control module provides AC power to the ignitor/sensor

which the pilot burner ame recties to direct current. If the

ame signal back to the control module is not at least 1.5 µA

DC, the system will lockout. The output of the ame sensing

circuit cannot be checked directly, so check the ame

sensing circuit indirectly by checking the ame sensing

current from the ignitor/sensor to the control module as

follows.

1. Connect a meter (DC micrometer scale) in series with

the ame signal ground wire as shown below. Use the

Honeywell W136A Test Meter, or equivalent. Disconnect

the ground wire at the control module.

3. Energize the S86, touch one end of the jumper rmly to

the S86 ground terminal (GND). Do not disconnect the

existing ground lead. Move the free end slowly toward

the stud terminal to establish a spark and then pull the

lead wire slowly away from the stud. Note the length of

the gap at which arcing stops.

Connect the red (positive) lead of the meter to the free

end of the ground wire. Connect the black (negative)

meter lead to the quick-connect ground terminal on the

control module.

2. Restart the system and read the meter. The ame sensor

current must be at least 1.5µA, and the reading must be

steady. If the reading is below the value designated or the

reading is unsteady, check the pilot ame and electrical

connections as described above. Also, replace the ignitor/

sensor if the ceramic insulator is cracked.

Part # 1382670 (12/07)Page 14

Page 15

THERMOSTAT (CONTROLLER)

CALLS FOR HEAT

1

SAFE-START CHECK

MUST NOT BE ANY FLAME OR

FLAME SIMULATING CONDITION

SPARK GENERATOR POWERED

FIRST VALVE (PILOT)

OPERATOR OPENS

2

POWER INTERRUPTION

SYSTEM SHUTS OFF, RESTARTS WHEN

POWER IS RESTORED.

PILOT FLAME FAILURE

SECOND MAIL OPERATOR CLOSES,

S86 STARTS TRAIL FOR IGNITION

3

IF FLAME OR FLAME SIMULATION

CONDITION PRESENT SYSTEM

FAILS TO START

4

PILOT BURNER LIGHTS

S86 SENSES FLAME CURRENT

PILOT BURNER OPERATION

OR

PILOT BURNER DOES NOT LIGHT

S86A OR B - TRIAL FOR IGNITION

CONTINUES, S86C OR D - GOES

INTO LOCKOUT AFTER TRIAL FOR

IGNITION TIMES OUT.

IF FLAME CURRENT SENSED

SPARK GENERATOR OFF.

SECOND VALVE OPERATOR

(MAIN) OPENS

5

6

MAIN BURNER OPERATION

S86 MONITORS PILOT FLAME

CURRENT

7

THERMOSTAT (CONTROLLER)

SATISFIED - VALVES CLOSED

PILOT AND MAIN BURNERS

ARE OFF.

START

STAGE 1

TRAIL FOR

IGNITION

STAGE 2

MAIN

BURNER

OPERATION

END

SEQUENCE OF OPERATION

INTERMITTENT PILOT INSTRUCTIONS Continued

Part # 1382670 (12/07) Page 15

Page 16

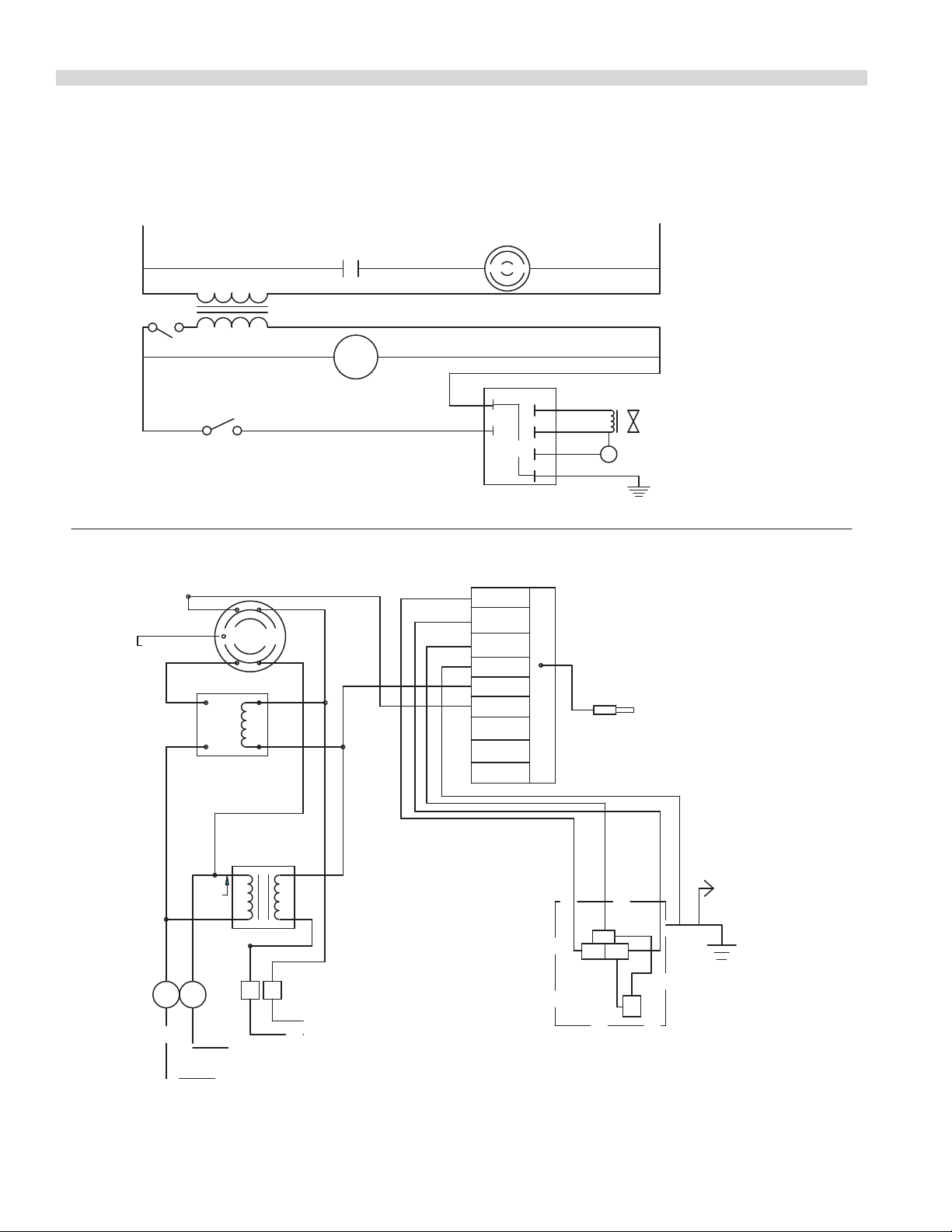

INTERMITTENT PILOT INSTRUCTIONS Continued

SWITCH

CENTRIFUGAL

CONTROL

SB6

25V

25V

GND

MAIN GAS VALVE

PILOT VALVE

MOTOR RELAY COIL

THERMOSTAT

TRANSFORMER

NEUT

HOT

MOTOR RELAY

MOTOR

EP SYSTEM

HONEYWELL

SWITCH

CENTRIFUGAL

TO ELECTRODE

BLUE

WHT

RED

GND

PV

MV/PV

MV

SB6

HONEYWELL

24V

RED

RED YEL

YEL

MOTOR

BLK

BLK

BLK

MOTOR RELAY

WHT

YEL

BLK

BLK

TH/TR

TRTH

VALVE

GAS

YEL

BLK

TRANSFORMER

L2

L1

TT

TO THERMOSTAT

115V SUPPLY

COMMON

TO LINE

"A"

CORD

24V

TH-W

SPARK

1 2 3 4 5 6 7 98

Part # 1382670 (12/07)Page 16

Page 17

INTERMITTENT PILOT INSTRUCTIONS Continued

NO

NO

NO

NO

NO

NO

NO

NO

START

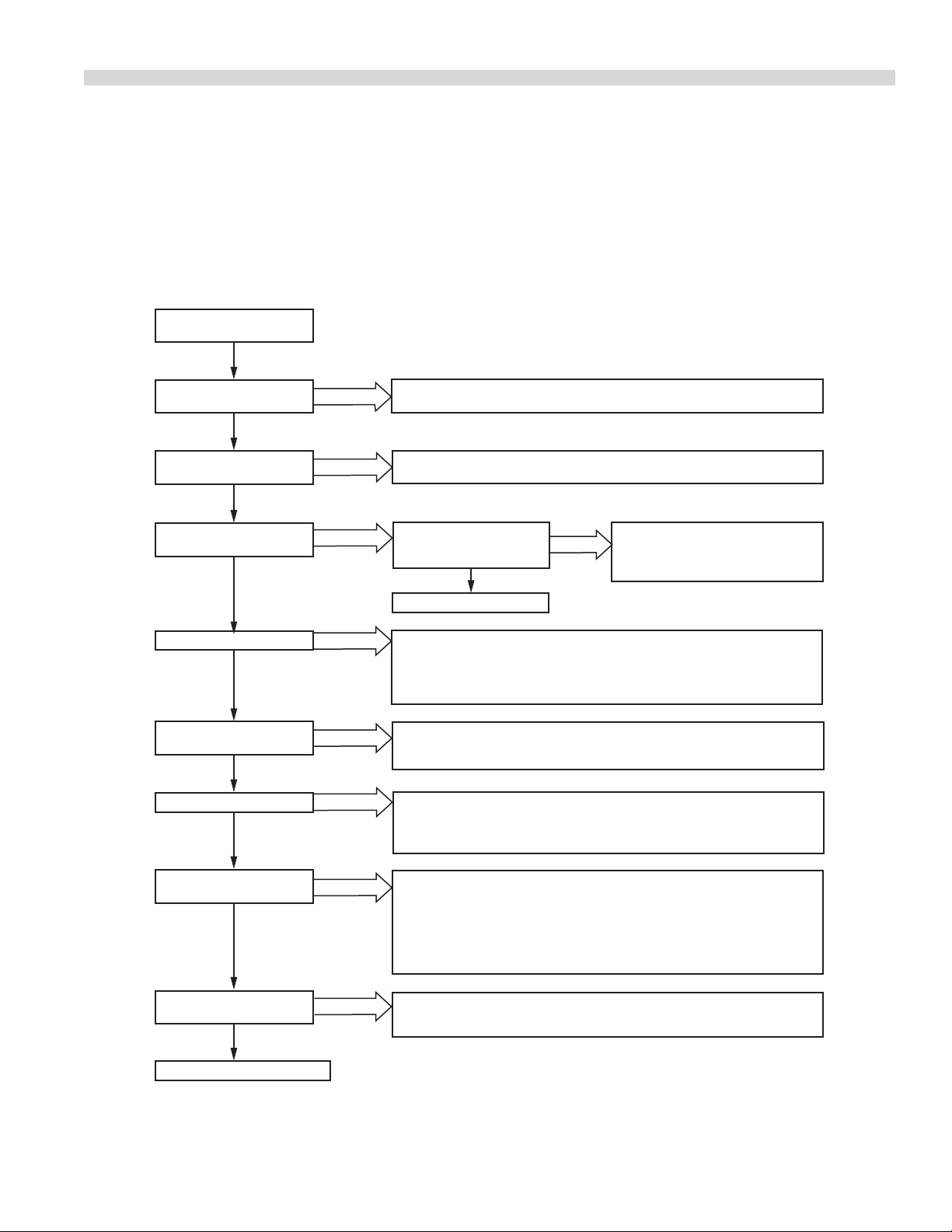

TROUBLE SHOOTING

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

IS POWER ON MEASURE 25 V

THERMOSTAT CALLS

FOR HEAT

SPARK ACROSS

IGNITER / SENSOR GAP

PILOT BURNER LIGHTS

SPARK STOPS WHEN

PILOT IS LIT

MAIN BURNER LIGHTS

SYSTEM RUNS UNTIL

CALL FOR HEAT ENDS

CALL FOR HEAT ENDS:

SYSTEM SHUTS OFF

TROUBLE SHOOTING ENDS

CHECK LINE VOLTAGE POWER, LOW VOLTAGE TRANSFORMER,

AND LOW VOLTAGE WIRING.

CHECK THERMOSTAT AND CONTROLLERS.

PULL IGNITION LEAD

AND CHECK SPARK AT

IGNITION STUD.

CHECK IGNITION CABLE,

GROUND WIRING, ELECTRODE

CERAMIC INSULATOR AND

GAP AND CORRECT.

CHECK THAT ALL MANUAL GAS COCKS ARE OPEN, SUPPLY

TUBING AND PRESSURES ARE GOOD, AND PILOT BURNER ORIFICE

IS NOT BLOCKED. CHECK ELECTRICAL CONNECTIONS BETWEEN

CONTROL AND PILOT OPERATOR ON GAS CONTROL. CHECK FOR

24 V AT TERMINALS 1 & 5, IF NO VOLTAGE REPLACE CONTROL.

REPLACE

CHECK CONTINUITY OF IGNITION CABLE AND GROUND WIRE.

CHECK THAT PILOT FLAME COVERS BOTH ELECTRODES. IF

CHECKS ARE OKAY, REPLACE MODULE.

CHECK FOR 24 V AT TERMINALS 3 & 5. IF NO VOLTAGE REPLACE

MODULE. CHECK ELECTRICAL CONNECTIONS BETWEEN

MODULE AND GAS CONTROL. IF OKAY, REPLACE GAS CONTROL.

CHECK CONTINUITY OF IGNITION CABLE AND GROUND WIRE.

NOTE: IF GROUND IS POOR OR ERRATIC SHUTDOWNS MAY OCCUR

OCCASIONALLY EVEN THOUGH OPERATION IS NORMAL AT THE

TIME OF THE CHECKOUT. CHECK FOR EXCESSIVE HEAT AT

ELECTRODE INSULATOR (TEMPERATURE ABOUT 600° F (315° C)

CAUSES SHORT TO GROUND). IF CHECK ARE OKAY, REPLACE

MODULE.

CHECK FOR PROPER THERMOSTAT OR CONTROLLER

OPERATION REMOVE AT MODULE; IF VALVE CLOSES, REPLACE

MODULE, IF NOT, REPLACE GAS CONTROL.

REPEAT PROCEDURE UNTIL TROUBLE FREE OPERATION IS OBTAINED.

NO

Trouble Shooting

NOTE: The Electronic S86 Control Module cannot be

repaired. If troubleshooting indicates a malfunction in the

S86 the S86 module must be replaced. Intermittent pilot

systems should be serviced only by trained and experienced

personnel.

Part # 1382670 (12/07) Page 17

Page 18

MAINTENANCE AND CLEANING

R

H

T

Note: The short sided

end of the jet plate shown

should be installed in the center

of the unit with the short end down

(toward bottom of unit)

Oven Exterior

Stainless Steel Surface

Stainless Steel surfaces can often be cleaned adequately

using a mild soap and warm water solution on a sponge or

soft cloth. Dry Thoroughly.

Stubborn stains or heat tint may require the use of a

commercial type cleaner, such as Penny-Brite or CopperBrite, rubbed in with a dry cloth or Stainless Steel pad. Always

rub in the direction of the polished lines. Rinse thoroughly

with fresh water and wipe dry.

Oven Interior

Aluminied Steel Surfaces

Aluminied Steel Surfaces should be cleaned with a damp soft

cloth and mild household detergent.

The oven deck and bottoms (Jet Plates) are removable. The

deck should be kept as clean as possible. Heavy spills and

carbon deposits, that are not easily removed with a soap and

water solution, should be scraped loose and removed.

NOTE: Top “Jet Plates” are not removable.

WARNING: Failure to clean oven perforated deck surface and

“Jet Plate” will degrade baking performance

CAUTION: disconnect power supply before attempting

cleaning or servicing.

Bottom Jet Plate Installation

After periodic jet plate cleaning, they should be reinstalled

in the following manner. Plate marked “R or “RHT” should be

placed into unit on right hand side.

Periodic removal of the deck and “Jet Plates” is strongly

recommended. This will enable you to remove any build-up

of deposits on the “Jet Plates”, and access the oven bottoms.

Particles may drop through the openings in the “Jet Plates”.

The entire oven bottom should be cleaned at least once a

year and more often under heavy usage conditions.

The jet plate marked “L” or “LHT” should be placed on the left

side in the same manner as right plate (see note).

Part # 1382670 (12/07)Page 18

Page 19

Part # 1382670 (12/07) Page 19

Page 20

Loading...

Loading...