Page 1

INSTALLATION AND

OPERATION MANUAL

GARLAND G-BRL & GF-BRL

SERIES BROILERS

Includes Models: G18-BRL, G24-BRL, G30-BRL,

Only GF Series Broilers are CE Approved

Français . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 13

Españo. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Página 27

G36-BRL, G48-BRL, GF18-BRL,GF24-BRL,GF30-BRL

and GF36-BRL

FOR YOUR SAFETY:

DO NOT STORE OR USE GASOLINE

OR OTHER FLAMMABLE VAPORS OR

LIQUIDS IN THE VICINITY OF

THIS OR ANY OTHER

APPLIANCE

PLEASE READ ALL SECTIONS OF THIS MANUAL

AND RETAIN FOR FUTURE REFERENCE.

THIS PRODUCT HAS BEEN CERTIFIED AS

COMMERCIAL COOKING EQUIPMENT AND

MUST BE INSTALLED BY PROFESSIONAL

PERSONNEL AS SPECIFIED.

WARNING:

IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE

CAN CAUSE PROPERTY DAMAGE, INJURY,

OR DEATH. READ THE INSTALLATION,

OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR

SERVICING THIS EQUIPMENT

Users are cautioned that maintenance and repairs must be performed by a Garland authorized service agent

using genuine Garland replacement parts. Garland will have no obligation with respect to any product that has been

improperly installed, adjusted, operated or not maintained in accordance with national and local codes or installation

instructions provided with the product, or any product that has its serial number defaced, obliterated or removed,

or which has been modified or repaired using unauthorized parts or by unauthorized service agents.

For a list of authorized service agents, please refer to the Garland web site at http://www.garland-group.com.

The information contained herein, (including design and parts specifications), may be superseded and is subject

to change without notice.

IN THE COMMONWEALTH OF MASSACHUSETTS

THIS PRODUCT MUST BE INSTALLED BY A

LICENSED PLUMBER OR GAS FITTER.

For Your Safety:

Post in a prominent location, instructions to be

followed in the event the user smells gas. This

information shall be obtained by consulting

your local gas supplier.

GARLAND COMMERCIAL INDUSTRIES,LLC

185 East South Street

Freeland, Pennsylvania 18224

Phone: (570) 636-1000

Fax: (570) 636-3903

Part # 4525958 (05/15/09) © 2008 Garland Commercial Industries, LLC

Part # 4525958 (05/15/09) Page 1

GARLAND COMMERCIAL RANGES, LTD.

1177 Kamato Road, Mississauga, Ontario L4W 1X4

CANADA

Phone: 905-624-0260

Fax: 905-624-5669

Enodis UK LTD.

5E Langley Business Centre

Station Road, Langley SL3 8DS Great Britain

Phone: 01753 485900

Fax: 01753 4859011

Page 2

IMPORTANT INFORMATION

WARNING:

This product contains chemicals known to the State of California to cause cancer and/or birth

defects or other reproductive harm. Installation and servicing of this product could expose you

to airborne particles of glass wool/ceramic fibers. Inhalation of airborne particles of glass wool/

ceramic fibers is known to the State of California to cause cancer. Operation of this product could

expose you to carbon monoxide if not adjusted properly. Inhalation of carbon monoxide is known

to the State of California to cause birth defects or other reproductive harm.

Keep appliance area free and clear of combustibles.

Part # 4525958 (05/15/09)Page 2

Page 3

TABLE OF CONTENTS

IMPORTANT INFORMATION..........................................2

DIMENSIONS AND SPECIFICATIONS – BROILERS.......................4

North America & General International Markets................................4

Australian Market ............................................................4

CE Aproved Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Pressure Settings/Injector Size ................................................5

Heat Input ...................................................................5

Gas Inlet Size.................................................................5

GF Series CE Approved Gas Categories ........................................5

Approximate Total Input Ratings With All Burners Operating At LOW...........5

DIMENSIONS AND SPECIFICATIONS – STANDS ........................6

PRE INSTALLATION..................................................7

Unpacking .......................................................................7

Safety Information ...............................................................7

INSTALLATION ......................................................7

Rating Plate Location .............................................................7

Statutory Regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Australia Specic Regulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Gas Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Gas Connections .................................................................8

Counter Line Installations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Location .....................................................................8

Sanitary Counter Top Seal.....................................................8

Leg Installation...............................................................9

Assembly Of Counter Stand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Installation for Units Equipped with Casters...................................10

Cabinet Bases ...............................................................10

Assembly Of Broiler .............................................................10

Ventilation ......................................................................10

OPERATION........................................................11

Grid Rack Seasoning Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Lighting Instructions ............................................................11

CLEANING AND MAINTENANCE .....................................12

Cleaning Care of the Grid Racks ..................................................12

Exterior Finish Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Part # 4525958 (05/15/09) Page 3

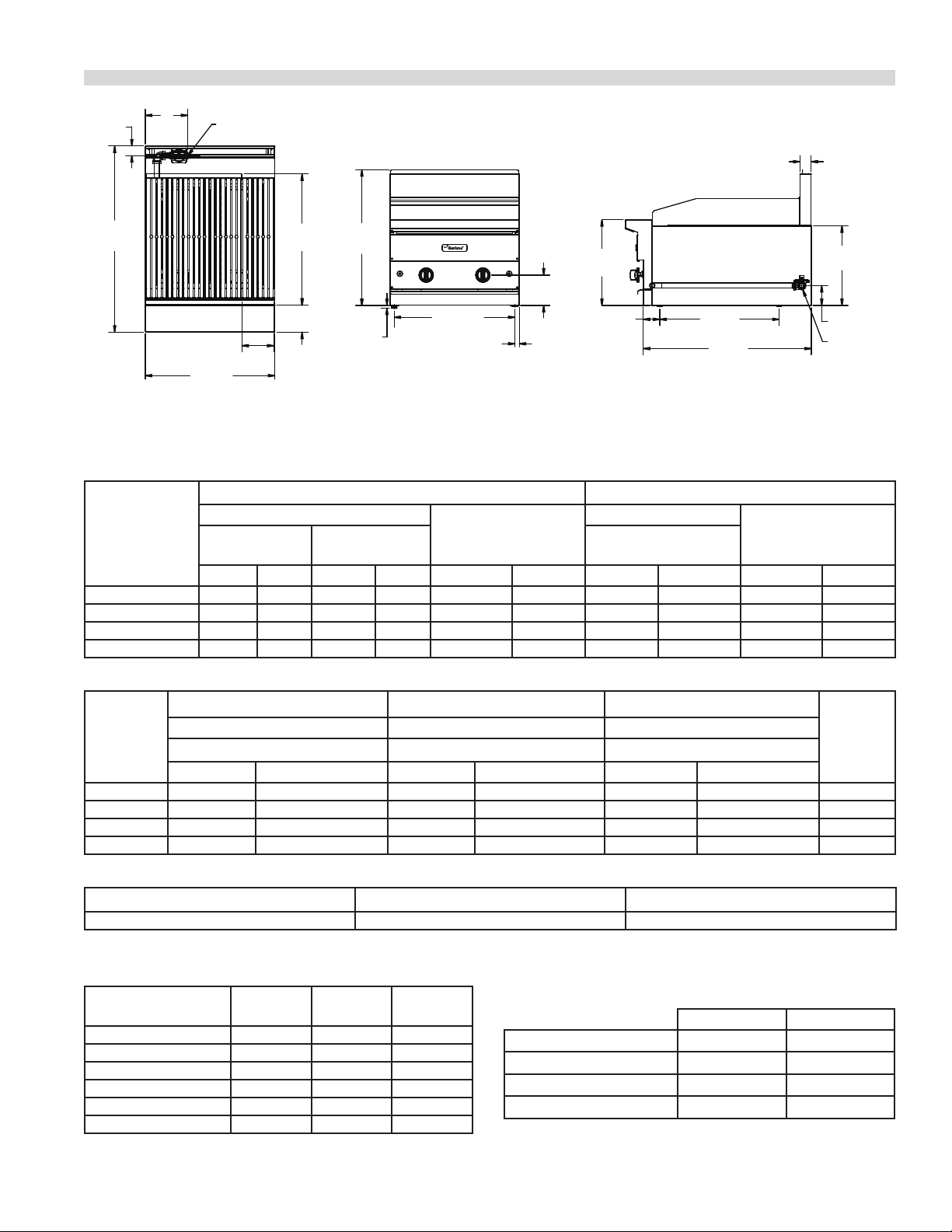

Page 4

REAR GAS

CONNECTION

3/4-14 NPT

7-7/8"

[200mm]

2-3/8"

[61mm]

34-1/2"

[876mm]

24-1/4"

[617mm]

5"

[127mm]

5-7/8"

[149mm]

WIDTH

25-1/8"

[638mm]

3/16" [5mm] MIN

1/2" [13mm] MAX

22-3/8"

[568mm]

7/8" [21mm]

2-1/8"

[53mm]

15-7/8"

[404mm]

3"

[77mm]

22-1/8"

[562mm]

31-1/8"

[709mm]

REAR GAS CONNECTION

3/4-14 NPT

4"

[100mm]

14-3/4"

[375mm]

5"

[125mm]

DIMENSIONS AND SPECIFICATIONS – BROILERS

Product Dimensions and Shipping Specializations

Model Width

Height

W/O Legs

Depth

Shipping

lbs/kg Cu Ft BTU/Hr kW/Hr

North American and CE1

Inputs

No of

Total Input Ratings

Burners

G18-BRL 18" (457mm) 25-1/8" (636mm) 34-1/2" (876mm) 190/86 21 3 45,000 13.2

G24-BRL 24" (610mm) 25-1/8” (636mm) 34-1/2" (876mm) 240/109 21 4 60,000 17.6

G30-BRL 30" (762mm) 25-1/8” (636mm) 34-1/2" (876mm) 290/131 29.5 5 75,000 22

G36-BRL 36" (914mm) 25-1/8” (636mm) 34-1/2" (876mm) 340/154 29.5 6 90,000 26.4

G48-BRL 48" (1219mm) 25-1/8” (636mm) 34-1/2" (876mm) 375/170 37 8 120,000 35.2

1

GF18-BRL 18" (457mm) 25-1/8” (636mm) 34-1/2" (876mm) 190/86 21 3 45,000 12.0

1

GF24-BRL 24" (610mm) 25-1/8” (636mm) 34-1/2" (876mm) 240/109 21 4 60,000 16.0

1

GF30-BRL 30" (762mm) 25-1/8” (636mm) 34-1/2" (876mm) 290/131 29.5 5 75,000 20.0

1

GF36-BRL 36" (914mm) 25-1/8” (636mm) 34-1/2" (876mm) 340/154 29.5 6 90,000 24.0

1

NOTE: Only GF series broilers with ame failure features are CE approved.

G-BRL Models

North America & General International Markets

Natural (G20)

Operating Manifold Pressure

4.5” wc

(11.2mbar)

LPG (G31)

(24.9mbar)

10” wc

For use in non-combustible locations only.

Installation Clearances From

Non Combustible Materials (all models)

Australian Market

Natural 4” wc (1.0kPa) LPG 10” wc (2.49 kpa)

MJ/H Injector Dia. MJ/H Injector Dia.

15.8 1.9 mm 15.8 1.1 mm

Rear Sides

0” 0”

Operating Manifold Pressure

Input Per Burner

Part # 4525958 (05/15/09)Page 4

Page 5

DIMENSIONS AND SPECIFICATIONS – BROILERS continued

A*

REAR GAS

CONNECTION

1-3/8"

[45mm]

34-1/2"

[876mm]

24-1/4"

[617mm]

5"

[127mm]

5-7/8"

[149mm

WIDTH

25-1/8"

[638mm]

3/16"

[5mm] MIN

1/2"

[13mm] MAX

22-3/8"

[568mm]

7/8" [21mm]

5-5/8"

[143mm]

2"

[53mm]

15-7/8"

[404mm]

3"

[77mm]

22-1/8"

[562mm]

31-1/8"

[91mm]

14-3/4"

[375mm]

3-5/8"

[94mm]

REAR GAS

CONNECTION

GF-BRL Models

*For units supplied with regulator dimension ‘A’ is 7-7/8” (200mm) with a 3/4” – 14 NPT connection.

European (CE) units are not supplied with regulator, but include with an adaptor 3/4” –14 BSPT.

CE Aproved Models

Pressure Settings/Injector Size

2nd Family, Groups H, L & E 3rd Family, Group 3P

Setting Pressure

MODEL

G20 @ 20

mbar inlet

G25 @ 25

mbar inlet

Injector Size

mbar “WC mbar “WC DMS mm mbar “WC DMS mm

GF18-BRL 11.2 4.5 14.9 6 50 1.78 24.9 10 58 1.07

GF24-BRL 11.2 4.5 14.9 6 50 1.78 24.9 10 58 1.07

GF30-BRL 11.2 4.5 14.9 6 50 1.78 24.9 10 58 1.07

GF36-BRL 11.2 4.5 14.9 6 50 1.78 24.9 10 58 1.07

Setting Pressure

G31 @ 37/50 mbar

inlet

Injector Size

Heat Input

2nd Family, Groups H & E 2nd Family, Group L 3rd Family, Group 3P

MODEL

(G20 @ 20/25 mbar) NAT (G25 @ 25 mbar) NAT (G31 @ 37/50 mbar) PROPANE

Per Burner / Total Per Burner / Total Per Burner / Total

# Of

Burners

kW BTU/HR kW BTU/HR kW BTU/HR

GF18-BRL 4.0 / 12.0 15,000 / 45,000 4.0 / 12.0 15,000 / 45,000 4.0 / 12.0 15,000 / 45,000

GF24-BRL 4.0 / 16.0 15,000 / 60,000 4.0 / 16.0 15,000 / 60,000 4.0 / 16.0 15,000 / 60,000

GF30-BRL 4.0 / 20.0 15,000 / 75,000 4.0 / 20.0 15,000 / 75,000 4.0 / 20.0 15,000 / 75,000

GF36-BRL 4.0 / 24.0 15,000 / 90,000 4.0 / 24.0 15,000 / 90,000 4.0 / 24.0 15,000 / 90,000

3

4

5

6

Gas Inlet Size

Model Width Connection Connection CE Models (ISO7-1)

23-5/8” (600mm) & 35-1/2” (900mm) 3/4” NPT Rear Gas Connection 3/4” (19.1mm) BSPT

GF Series CE Approved Gas Categories

Part # 4525958 (05/15/09) Page 5

Country

Gas

Category

Gas

Type

Pressure

(mbar)

GB, IE, ES, PT, GR I2H G20 20

BE, FR I2E+ G20 20/25

DE I2E G20 20

GB, IE, ES, PT, BE, FR I3P G31 37

GB, FR, NL, DE, ES I3P G31 50

NL I3P G31 30

Approximate Total Input Ratings

With All Burners Operating At Low

GF18-BRL 4.5 16,875

GF24-BRL 6.0 22,500

GF30-BRL 7.5 28,125

GF36-BRL 9.0 33,750

kW BTU/h

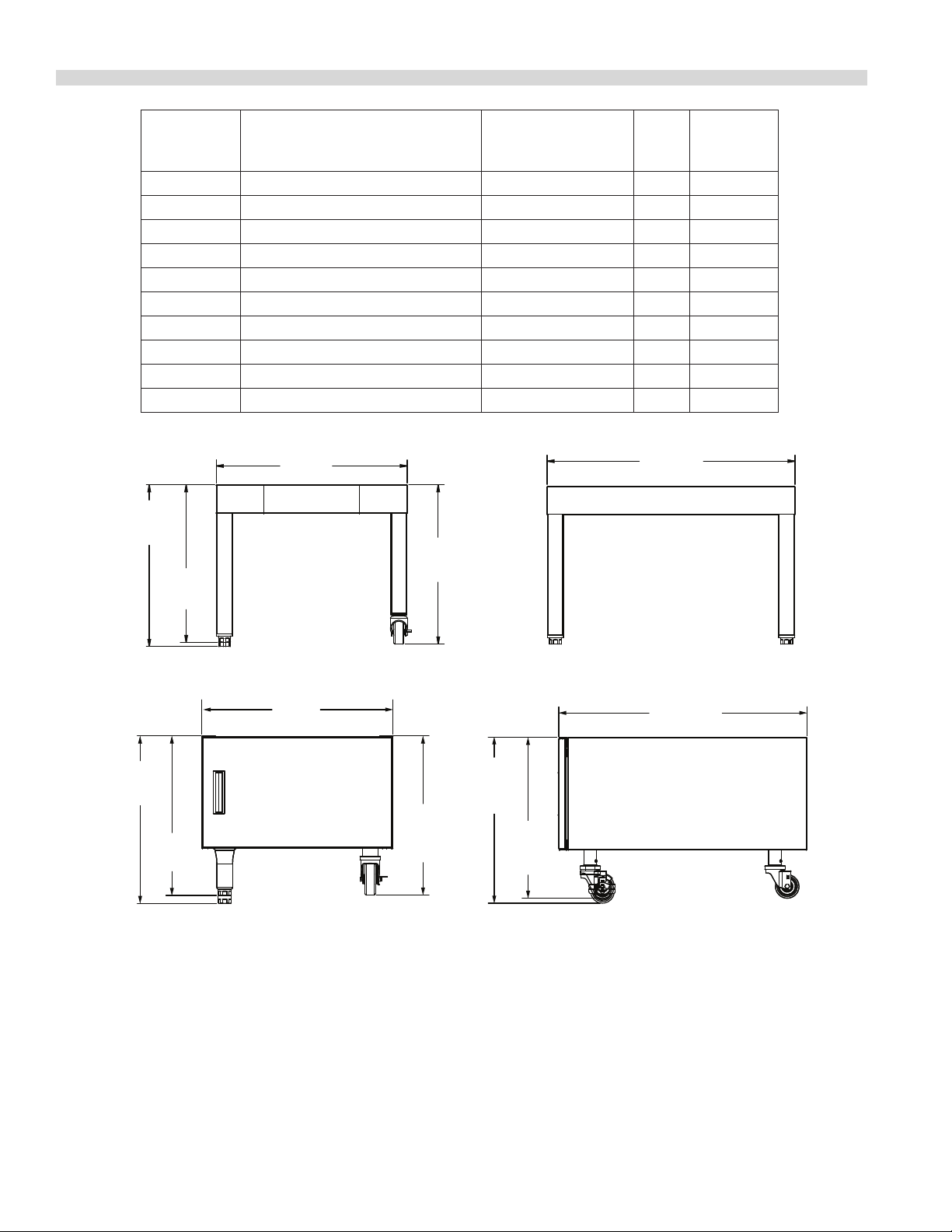

Page 6

DIMENSIONS AND SPECIFICATIONS – STANDS

WIDTH

21"

[534mm]

LEG MAX

20"

[ 509mm]

LEG MIN

20"

[508mm]

NON ADJ

CASTER

20-7/16"

[529mm]

MAX ADJ

CASTER

20-3/16"

[513mm]

MIN ADJ

CASTER

31-3/16"

[719mm]

DEPTH

G24-BRL-CAB

WIDTH

20-5/16"

[516mm]

LEG MAX

19-7/16"

[504mm]

LEG MIN

20"

[508mm]

CASTERS

31-3/16"

[792mm]

DEPTH

G24-BRL-STD

Model

Number

Description

Use With

Broiler Model

Cu. Ft.

Ship

Weight

Lb/ Kg

G18-BRL-STD Floor Stand 18” (457mm) Wide G18-BRL & GF18-BRL 4.5 30/14

G24-BRL-STD Floor Stand 24” (610mm) Wide G24-BRL & GF24-BRL 4.5 40/18

G30-BRL-STD Floor Stand 30” (762mm) Wide G30-BRL & GF30-BRL 4.5 50/23

G36-BRL-STD Floor Stand 36” (914mm) Wide G36-BRL & GF36-BRL 4.5 55/25

G48-BRL-STD Floor Stand 48” (1219mm) Wide G48-BRL 5.5 58/26

G18-BRL-CAB Closed Cabinet 18” (457mm) Wide G18-BRL & GF18-BRL 21 40/18

G24-BRL-CAB Closed Cabinet 24” (610mm) Wide G24-BRL & GF24-BRL 21 45/20

G30-BRL-CAB Closed Cabinet 30” (762mm) Wide G30-BRL & GF30-BRL 29.5 50/23

G36-BRL-CAB Closed Cabinet 36” (914mm) Wide G36-BRL & GF36-BRL 29.5 60/27

G48-BRL-CAB Closed Cabinet 48” (1219mm) Wide G48-BRL 37 65/29.5

• Manylocalcodesexist,anditistheresponsibilityoftheOwnerandtheInstallertocomplywiththosecodes.

• Garlandreservestherighttochangeorimproveproductspecificationswithoutnotification.

• Garlandproductsarenotapprovedorauthorizedforhomeorresidentialuse,butareintendedforcommercialapplica-

tions only. Garland will not provide service, warranty, maintenance or support of any kind other than in commercial

applications.

Part # 4525958 (05/15/09)Page 6

Page 7

PRE INSTALLATION

Unpacking

GARLAND strongly recommends this unit be inspected for

possible freight damage while carrier driver is on site.

1. Remove carton. In case of damage, all packing materials

must be retained for carrier inspection.

2. Carefully inspect the broiler for any physical signs of

damage, such as scratches, dents and missing knobs.

3. With carrier driver on your site, note damage on freight

bill. Call carrier for inspection.

If you are checking equipment after carrier has departed,

you have approximately fteen (15) days to request a freight

damage inspection be made by the carrier’s agent.

INSTALLATION

When corresponding with the factory or your local

authorized factory service center regarding service problems

or replacement parts, be sure to refer to the particular unit

by the correct model number (including the prex and sux

letters and numbers) and the warranty serial number. The

rating plate axed to the unit contains this information.

We suggest installation, maintenance, and repairs should be

performed by your local authorized service agency listed in

your information manual pamphlet.

If concealed damage claim is led with carrier beyond 15

days, GARLAND cannot be held responsible and carrier will

make it incumbent upon the consignee to oer reasonable

evidence that the carrier was at fault.

Safety Information

WARNING: Accessible parts may become hot during use.

Young children should be kept away.

This appliance is for professional use and should only be

used by qualied personnel.

This appliance is not intended for use by persons (including

children) with reduced physical, sensory or mental

capabilities, or lack of experience and knowledge, unless

they have been given supervision or instruction concerning

use of the appliance by a person responsible for their safety.

Statutory Regulations

Installation must be carried out by a competent person and

in accordance with the relevant regulations, codes of practice

and the related publications of the country of destination.

In European countries, installation must be carried out by

a competent person and in accordance with the relevant

regulations, codes of practice and the related publications of

the country of destination.

In the event you have any questions concerning the

installation, use, care or service of the product, write or call

our Product Service Department.

This product must be installed by professional personnel as

specied. Garland/U.S. Range products are not approved or

authorized for home or residential use, but are intended for

commercial applications only. Garland / U.S. Range will not

provide service, warranty, maintenance, or support of any

kind other than in commercial applications.

Rating Plate Location

The rating plate is located by removing the grease tray, it is

located on left hand side grease slide support.

Part # 4525958 (05/15/09) Page 7

In The United States of America, the installation must

conform to the National Fuel Gas Code ANSI Z223.1, or latest

edition, NFPA No.54 - latest edition/or local code to assure

safe and ecient operation. In Canada, the installation must

comply with CSA B149.1 and local codes.

Australia Specic Regulation

This appliance must be installed in accordance with the

manufacturer’s instructions, local gas tting regulations and

requirements of AS 5601/AG 601 installation code. All burner

adjustments and setting should be made by a qualied gas

technician.

Page 8

INSTALLATION continued

Gas Supply

A. The type of gas for which the unit is equipped is stamped

on the rating plate. Connect a unit stamped “NAT” only

to natural gas; connect those stamped “PRO” only to

propane gas.

B. If it is a new installation, have gas authorities check meter

size and piping to assure that the unit is supplied with

sucient amount of gas pressure required to operate the

unit.

C. If it is additional equipment or replacement, have a

qualied gas technician check the gas pressure to make

certain that existing gas facilities (meter, piping, etc.) will

deliver the BTU’S of gas required at the unit with no more

than 1/2” water column pressure drop. When checking

pressure, be certain that other equipment on the same

gas line is on at full rate.

NOTE: When checking pressure, be sure that all other

equipment on the same gas line is on. If the broiler has

been supplied with a regulator it has been preset to

match specications on the unit’s rating plate. All units

require regulators and should be adjusted accordingly to

manufacturer specications.

D. The appliance and its individual shut o (supplied by

others) must be disconnected from the gas supply piping

system during any pressure testing of that system at

pressures in excess of 1/2 PSI (3.45 KPa).

E. Gas supply connection is made in back lower left hand

corner of unit. A readily accessible approved type of hand

valve should be installed on each supply line. Test for

leaks – Do Not Use An Open Flame.

F. A pressure tap plug is supplied with the units and it

is installed on the manifold. The valve panel must be

removed to use the pressure tap. The gas pressure must

be checked when the unit is installed, to insure that the

unit gas pressure is the same as specied on the rating

plate. If necessary, pressure adjustments must be made at

the pressure regulator.

G. If it is a completely new installation, have gas lines,

meter size piping and piping installed and checked by a

qualied gas technician.

H. Make certain that the new piping, joints, and connections

have been made in a clean manner and have been

purged, so that the piping compound, chips, etc., will not

clog pilots, valves, and/or controls. Use pipe joint sealant

that is resistant to liqueed petroleum gas.

WARNING: Check gas connections for leaks. Use a soap

solution or similar means. Do Not Use An Open Flame!

Gas Connections

All broilers have a rear gas 3/4” NPT or 3/4”-14NPT

connections. CE models have 3/4”-14 BSPT thread adapter.

NOTE: Adequate clearance must be provided for servicing

and proper operation.

Counter Line Installations

Location

Unpack units carefully and provide the necessary space

on counter or back bar. All units must be installed in noncombustible locations.

A. Location of the unit should be in an area where

make-up air is available to support proper combustion.

Make-up air should be supplied in such a manner as to

pass through the front of the unit. Do not obstruct frontair ow.

B. In accordance with standard gas appliance operation,

the unit should be located under a ventilation hood of

applicable size and capacity. See ventilation instructions.

Sanitary Counter Top Seal

When the broiler is installed on a counter top, the National

Sanitation Foundation, (NSF), recommends that it be

sealed in accordance with NSF standards per the following

instructions:

1. Unit should be located on a non-combustible, level

counter top surface.

2. Thoroughly clean the bottom perimeter of the broiler and

the counter top around the bottom of the broiler.

3. Apply a generous bead of silicone sealant around the

entire outside perimeter of the broiler bottom.

4. The broiler can be secured to the counter top by inserting

the 3/8-inch diameter crating bolts through the counter

from the bottom, (via predrilled 1/2” diameter holes), and

threading them into the nut inserts in the bottom of the

unit.

5. Smooth the silicone sealant with a nger or tool to

provide a cover seal.

Part # 4525958 (05/15/09)Page 8

Page 9

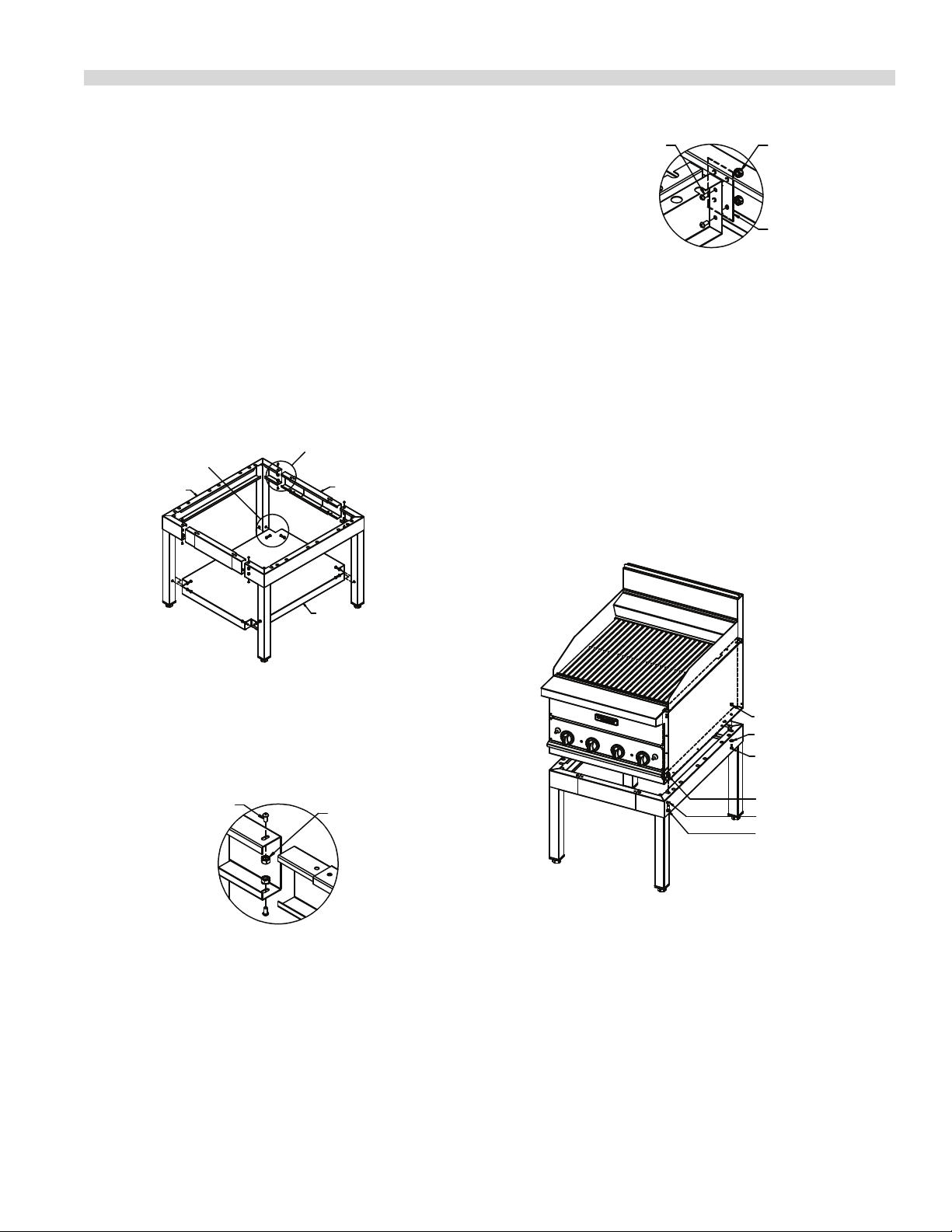

INSTALLATION continued

SLEEVE ASSEMBLY

SHELF

SIDE LEG

ASSEMBLY

DETAIL 2

DETAIL 1

DETAIL 1

10-24 X 3/8"

MACHINE SCREW

10-24

LOCK NUT

10-24 X 3/8"

MACHINE SCREW

10-24

LOCK NUT

CENTER

SUPPORT

BRACKET

DETAIL 2

1/4-20 LOCK NUT

1/4 WASHER

1/4-20 X 5/8 BOLT

FASTER ON BROILER

3/8 LOCK WASHER

3/8-16 X 5/8 BOLT

GF24 BROILER STAND

WITH LEGS SHOWN

Leg Installation

1. All units are shipped with N.S.F. approved legs. These legs

must be installed to provide a minimum clearance of

four (4) inches between the counter top and bottom of

the unit in order to meet National Sanitation Foundation

requirements.

2. When using the legs described above, raise front of unit

and screw leg into leg retaining nut provided at each

corner of unit, repeat at rear.

3. Unit may be leveled by adjusting legs. Use a spirit level

and level unit (by cooking grids) four (4) ways: across the

front and back and down the sides.

Assembly Of Counter Stand

1. Slide the side leg assembly into the sleeve assembly and

fasten with a screw and a nut in 8 places (2 per joint) as

shown in detail 1.

3. Prior to placing the unit on the stand:

a. Remove levelling feet from unit.

b. Remove grates/rods/burners etc. to lighten unit and

team lift onto stand.

4. Attach the broiler to the stand at the back with (2) 1/4”

bolts, washers and lock nuts as shown. (One for each

corner.)

NOTE: for 48” broiler there are (4) mounting locations at

the back.

2. Place the center support bracket inside of the sleeve

assembly. Mount the center support to the bracket with

2 screws and nuts (detail 2). Repeat for the other side.

Sleeve assemblies should be sandwiched between the

center support and center support bracket. Repeat for

other center support.

Part # 4525958 (05/15/09) Page 9

5. Attach the broiler to the stand at the front with (2) 3/8”

bolts & lock washers as shown. Bolt with thread into

fasteners attached to the bottom side of the broiler (one

for each corner).

NOTE: for 48” broiler there are (4) mounting locations at

the back.

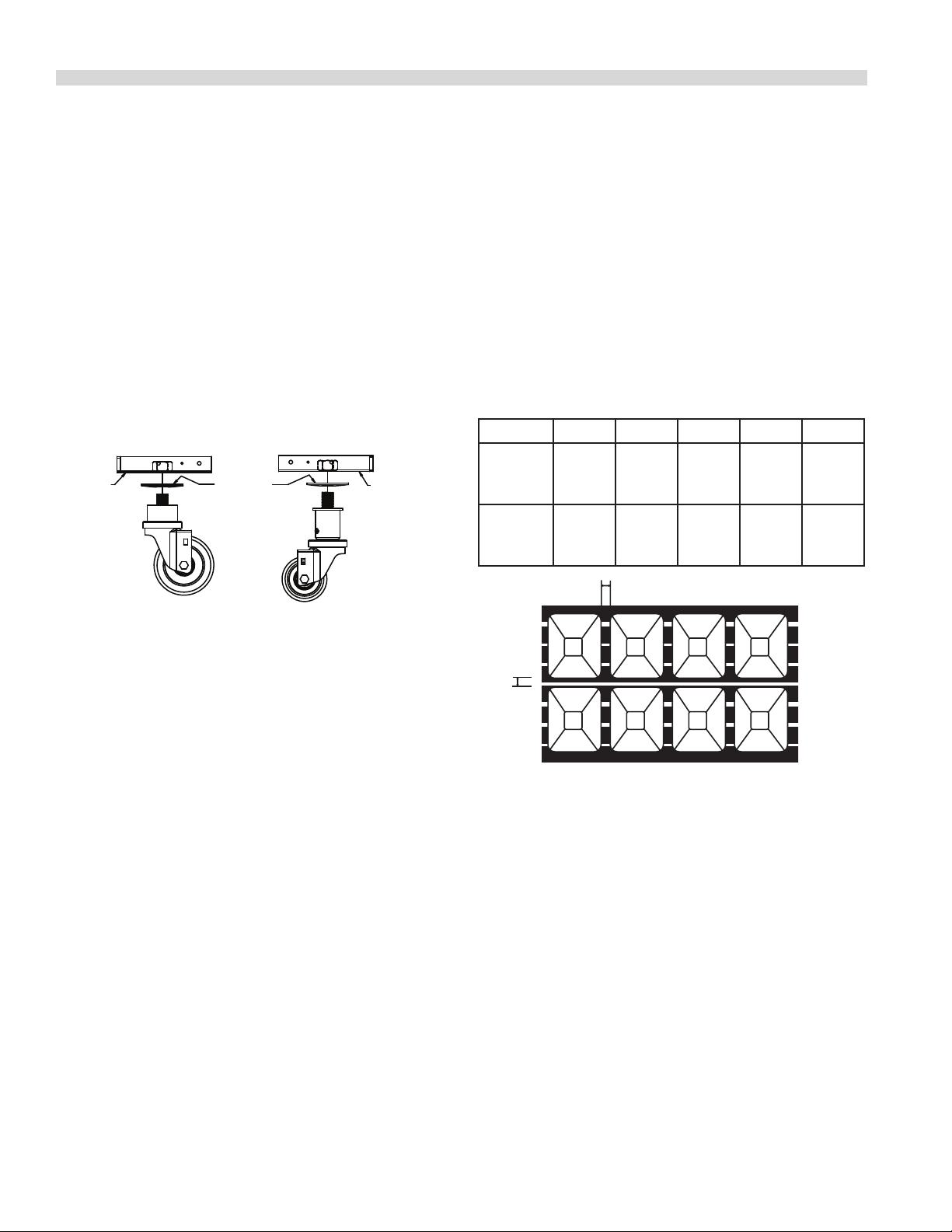

Page 10

BOTTOM

OF

APPLIANCE

WASHER

PROTECTIVE

PLASTIC ON

THIS SIDE

FIXED CASTER

(SHOWN W/O BRAKE)

ADJUSTABLE CASTER

(SHOWN W/O BRAKE)

BOTTOM

OF

APPLIANCE

INSTALLATION continued

Installation for Units Equipped with Casters

A. The installation shall be made with a connector that

complies with the Standard for Connectors for Moveable

Gas Appliances, ANSI Z./CSA ., Addenda

Z.B-/CSA .B- (or latest edition), and a

quick-disconnect device that complies with the Standard

for Quick Disconnects for Use with Gas Fuel, ANSI Z./

CSA ., Addenda Z.A-/CSA .A- (or latest

edition).

B. Raise the front of the appliance and block. Do not lay the

appliance on its back.

C. Caster are threaded to be easily screwed into the holes

provided on the bottom of the range. It is important to

add the washers supplied to help distribute force on the

range when being moved.

Assembly Of Broiler

Steel Grate Rods

Each broiler is supplied with (14) 15”/381mm, (18-BRL),

21”/533mm, (24-BRL), 26” /660mm, (30-BRL), 31”/787mm,

(36-BRL) or 2 sets of 21”/533mm (48-BRL) long steel rods.

These rods are to be installed in the grooves on the support

brackets, which are atop the burners.

Briquettes

For best cooking results, it is recommended that the correct

amount of briquettes are installed in the broiler. Refer to

the table and drawing below for the proper arrangement

of briquettes. When all the briquettes have been placed as

instructed, install the top grate sections.

MODEL 18-BRL 24-BRL 30-BRL 36-BRL 48-BRL

Rows

front

to rear

Rows

left

to right

7 7 7 7 7

7 11 14 17 22

D. Place the washer on the caster stem as shown. Since

the washer is slightly cupped, it is critical that the side

with the plastic is up and mates with the bottom of the

appliance. With the washer in place, thread the caster

onto the appliance tightly. It is not necessary to remove

the plastic from the washer.

E. The front casters of the unit are equipped with brakes

to limit the movement of the unit without depending

on the connector and any quick-disconnect device or its

associated piping to limit the appliance movement.

F. Please be aware, there is a restraint on the unit and if

disconnection of the restraint is necessary, be sure to

reconnect the restraint after the unit has been returned

to its originally installed position.

Cabinet Bases

Cabinet base options are available for all broiler models.

Cabinets are pre-assembled at time of delivery except legs or

casters.

Ventilation

The following notes are intended to give general guidance.

For detailed recommendations, refer to the applicable

code(s) in the country of destination.These appliances shall

be installed in a room with sucient ventilation to prevent

the occurrence of hazardous concentrations of combustion

by-products.

A good ventilation system is important for satisfactory

performance and it is recommended to install the broiler

under a power vented canopy.

Local and/or National Codes dictate the need of ventilation

system to be used with this type of equipment. The following

information is provided to give examples of available

ventilation system concepts.

Part # 4525958 (05/15/09)Page 10

Page 11

INSTALLATION continued

Two basic types of power ventilations are in use today. One

type is the overhead hood or canopy and the other is the

under shelf exhaust system. The latter oers simplicity of

installation and minimum cleaning expense. Both require

ame-proof lters for easy grease removal.

OPERATION

Grid Rack Seasoning Instructions

To insure long life and service, it is imperative that the

cooking surface be carefully broken in or seasoned in the

following manner:

1. Remove all factory applied protective material by

washing with hot water and a mild detergent or soap

solution. Rinse and dry thoroughly.

2. Apply a thin coat of olive oil or other high grade salt free

cooking oil to the cooking surface. Wipe away excess.

3. Turn all valves to a low setting and allow grid racks to

heat slowly for thirty (30) minutes. Allow oil to remain on

cooking surface three (3) to four (4) minutes, then wipe o.

4. Reset valves to desired operating temperature and apply

a second coat of oil and leave for two (2) or three (3)

minutes after grid rack reaches temperature. Then wipe

o surplus.

Your broiler is now ready to use.

The ventilator must be connected to a duct of suitable size

with an exhaust blower capable of removing a minimum of

325 CFM’S of air per square foot of broiler surface.

Models GF(18,24,30.36)-BRL

1. Push in the valve knob and turn counter-clockwise to the

ignition position.

2. While holding the knob fully in, depress the ignitor

button and visually conrm that the pilot lights are on.

If the pilot does not light, repeatedly press the ignitor

button until ignition is achieved.

3. After the pilot is lit, continue to hold the valve knob in for

at least 20 seconds, then release it. If the pilot goes out,

wait ve, (5), minutes, then repeat the procedure.

4. When the pilot is established, push in the valve knob

again and turn it counter-clockwise to the full ame

position, igniting the main burner.

5. For low ame or simmer, push in the valve knob and turn

it to the low ame position.

6. To turn the burner o, push in and turn the valve knob to

the circular “OFF” symbol.

NOTE: Unless products contain sucient fat, grid racks must

be seasoned before each use. Re-season after thorough

cleaning of the cooking surface.

Lighting Instructions

Models G(18,24,39,36,48)-BRL

1. One pilot serves two burners and is located between

those burners.

2. Push red spark buttons several times to ignite pilot

burners.

3. Ensure pilots are lit by viewing through pilot view hole on

front of unit.

Part # 4525958 (05/15/09) Page 11

Shut down

1. Turn all gas valves o.

2. If the unit is to be shut down for an extended period of

time, turn the in-line service valve to the “OFF” position,

(this valve is not factory supplied).

Page 12

CLEANING AND MAINTENANCE

Cleaning Care of the Grid Racks

Establish a regular cleaning schedule. It is necessary to

avoid obstruction and to allow proper combustion and

performance.

1. Grid racks should be wiped daily while still warm, using a

heavy cloth or other grease absorbing material to remove

grease and burnt food before they burn into the grid.

Remove burnt materials, such as carbonized grease or

food, with a sti wire brush. Do Not use Any Type Of Steel

wool. Small particles may be left on the grid surface and

get into food products.

2. Grid racks should be washed thoroughly using a wire

brush and a hot, mild detergent or soap solution. Rinse

with clear, warm water.

3. Dry thoroughly.

4. Re-season grid racks as outlined in seasoning

instructions.

5. Empty grease tray(s) frequently and wash daily in hot,

mild detergent or soap solution.

6. Do not waste gas or abuse equipment by leaving

valves at high temperature settings while not in

use. Throughout all idling periods, set valves as low

temperature setting to keep grids warm. Re-set valves as

required for periods of heavy load. Turn valves to OFF at

end of daily operation.

Exterior Finish Cleaning

Establish a regular schedule. Any spills should be wiped o

immediately.

1. Wipe exposed, clean-able surface when cool with a mild

detergent and hot water. Stubborn residue spots may be

removed with a light weight non-metallic scouring pad.

Dry thoroughly with a clean cloth.

2. Stainless steel should be cleaned using a mild detergent,

a soft cloth, and hot water. If it is necessary to use a

non-metallic scouring pad, always rub in the direction of

the grain in the metal to prevent scratching. Use a water

based stainless steel cleaner (such as Drackett Twinkle), if

you want a high shine.

3. The side splash or main top of the broiler can be cleaned

with hot water and a soap solution. A degreaser may

be used as well. To make the cleaning easier, you may

remove the main top assembly. To remove the main top,

rst lift and remove all grids, then lift the main top o.

When nished cleaning, dry thoroughly and lightly coat

with cooking oil or spray with cooking oil such as PAM. If

not coated, rust will form.

7. When the grill is running, never use objects such as

sheet pans to cover the gill in order to hold in heat in an

attempt to burn o grease or other debris.

Part # 4525958 (05/15/09)Page 12

Page 13

MANUEL

D’INSTALLATION ET

D’UTILISATION

RÔTISSOIRES GARLAND

SÉRIES G-BRL ET GF-BRL

Seules les rôtissoires série GF sont agréées CE

Comprend les modèles : G18-BRL, G24-BRL,

G30-BRL, G36-BRL, G48-BRL, GF18-BRL,

GF24-BRL,GF30-BRL et GF36-BRL

POUR VOTRE SÉCURITÉ:

NE PAS STOCKER NI UTILISER D’ESSENCE OU

D’AUTRES VAPEURS OU LIQUIDES INFLAM-

MABLES À PROXIMITÉ DE CET APPAREIL OU

DE TOUT AUTRE APPAREIL.ER

APPLIANCE

LIRE TOUTES LES SECTIONS DU PRÉSENT MANUEL ET LE CONSERVER POUR S’Y REPORTER

ULTÉRIEUREMENT.

CE PRODUIT A ÉTÉ HOMOLOGUÉ EN TANT

QU’ÉQUIPEMENT PROFESSIONNEL DE CUISSON

ET DOIT ÊTRE INSTALLÉ PAR DU PERSONNEL

AVERTISSEMENT :

UNE INSTALLATION, DES RÉGLAGES, DES

MODIFICATIONS, DES RÉPARATIONS OU UN

ENTRETIEN MAL FAITS PEUVENT CAUSER

DES DOMMAGES MATÉRIELS, DES BLES-

SURES OU LA MORT. LIRE SOIGNEUSEMENT

LES INSTRUCTIONS D’INSTALLATION,

D’UTILISATION ET D’ENTRETIEN

AVANT D’INSTALLER OU DE RÉPARER

L’ÉQUIPEMENT.

L’attention des utilisateurs est attirée sur le fait que l’entretien et les réparations doivent être effectués par un agent

d’entretien autorisé par Garland utilisant des pièces de rechange d’origine Garland. Garland n’aura aucune obligation

en ce qui concerne n’importe quel produit mal installé, réglé, utilisé ou qui n’aurait pas été entretenu conformément

aux codes nationaux et locaux ou aux instructions d’installation fournies avec le produit ou n’importe quel produit

dont le numéro de série aurait été mutilé, oblitéré ou supprimé ou qui aurait été modifié ou réparé avec des pièces

non autorisées ou par des agents d’entretien non autorisés. Pour obtenir la liste des agents de service autorisés,

consulter le site web de Garland à : http://www.garland-group.com. Les renseignements contenus dans le présent

document (y compris la conception et les spécifications des pièces) peuvent être remplacés ou modifiés sans préavis.

PROFESSIONNEL TEL QUE SPÉCIFIÉ.

DANS L’ÉTAT DU MASSACHUSETTS, CE PRODUIT

DOIT ÊTRE INSTALLÉ PAR UN PLOMBIER OU UN

MONTEUR D’INSTALLATION AU GAZ CERTIFIÉ.

Pour votre sécurité :

Placer dans un endroit bien en vue les instruc-

tions à suivre en cas d’odeur de gaz détectée

par l’utilisateur. Cette information peut être

obtenue auprès du fournisseur de gaz local.

GARLAND COMMERCIAL INDUSTRIES, LLC

185 East South Street

Freeland, Pennsylvanie 18224

Téléphone : (570) 636-1000

Télécopieur : (570) 636-3903

Part # 4525958 (05/15/09) © 2008 Garland Commercial Industries, LLC

Pièce nº 4525958 (05/15/09) Page 13

GARLAND COMMERCIAL RANGES, LTD.

1177 Kamato Road, Mississauga, Ontario L4W 1X4

CANADA

Téléphone : 905-624-0260

Télécopieur : 905-624-5669

Enodis UK LTD.

5E Langley Business Centre

Station Road, Langley SL3 8DS Great Britain

Téléphone : 01753 485900

Télécopieur : 01753 485901

Page 14

INFORMATIONS IMPORTANTES

AVERTISSEMENT :

Ce produit contient des produits chimiques reconnus par l’état de Californie comme causant le

cancer et/ou des malformations congénitales ou d’autres problèmes de reproduction. L’installation

et l’entretien de ce produit peut vous exposer aux poussières de laine de verre/fibres céramiques.

L’inhalation de ces particules de laine de verre ou de fibres céramiques est reconnue par l’état de

Californie comme causant le cancer. L’utilisation de ce produit peut vous exposer au monoxyde

de carbone en cas de mauvais réglage. L’inhalation de monoxyde de carbone est reconnue par

l’état de Californie comme pouvant causer des malformations congénitales ou d’autres problèmes

reproductifs.

Maintenir les abords de l’appareil dégagés et

ne pas y stocker de produits combustibles.

Pièce nº 4525958 (05/15/09)Page 14

Page 15

TABLE DES MATIÈRES

INFORMATIONS IMPORTANTES .....................................14

DIMENSIONS ET SPÉCIFICATIONS - RÔTISSOIRES .....................16

Marchés Nord-Américain Et Internationaux Généraux .........................16

Marché Australien ...........................................................16

Modèles homologués CE ........................................................17

Réglages De Pression/Taille Des Injecteurs....................................17

Débit Calorique . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Dimension D’entrée Du Gaz..................................................17

Série GF - Homologué CE - Catégories de gaz.................................17

DIMENSIONS ET SPÉCIFICATIONS - SOCLES ..........................18

PRÉINSTALLATION .................................................19

Déballage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Informations De Sécurité ........................................................19

INSTALLATION .....................................................19

Emplacement De La Plaque Signalétique .........................................19

Réglementation Légale . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Clause Spécique à l’Australie . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Alimentation En Gaz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Gas Connections ................................................................20

Installations Sur Plan De Travail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Emplacement ...............................................................20

Joint Sanitaire De Plan De Travail ............................................21

Installation des pieds ........................................................21

Montage Des Socles De Plan De Travail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Installation Des Appareils Équipés De Roulettes...............................22

Bases De Meuble ............................................................22

Montage De La Rôtissoire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Ventilation ......................................................................23

FONCTIONNEMENT ................................................24

Instructions D’apprêtage De La Crémaillère De Grille . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Instructions d’allumage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

ENTRETIEN ET NETTOYAGE .........................................25

Nettoyage des crémaillères de grille . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Nettoyage Du Fini Extérieur . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Pièce nº 4525958 (05/15/09) Page 15

Page 16

CONNEXION

ARRIÈRE DU GAZ

3/4-14 NPT

7-7/8"

[200mm]

2-3/8"

[61mm]

34-1/2"

[876mm]

24-1/4"

[617mm]

5"

[127mm]

5-7/8"

[149mm]

LARGEUR

25-1/8"

[638mm]

3/16" [5mm] MIN

1/2" [13mm] MAX

22-3/8"

[568mm]

7/8" [21mm]

2-1/8"

[53mm]

15-7/8"

[404mm]

3"

[77mm]

22-1/8"

[562mm]

31-1/8"

[709mm]

CONNEXION

ARRIÈRE DU GAZ

3/4-14 NPT

4"

[100mm]

14-3/4"

[375mm]

5"

[125mm]

DIMENSIONS ET SPÉCIFICATIONS - RÔTISSOIRES

Dimensions Des Produits Et Spécialisations D’expédition

Modèle Largeur

Hauteur

Sans Pieds

Profondeur

Expédition

lbs/kg Cu Ft BTU/Hr kW/Hr

Amérique du Nord et CE1

Entrées

Nb De

Brûleurs

Débits Caloriques

Totaux

G18-BRL 18 po(457mm) 25-1/8 po(636mm) 34-1/2 po(876mm) 190/86 21 3 45,000 13.2

G24-BRL 24 po(610mm) 25-1/8 po(636mm) 34-1/2 po(876mm) 240/109 21 4 60,000 17.6

G30-BRL 30 po(762mm) 25-1/8 po(636mm) 34-1/2 po(876mm) 290/131 29.5 5 75,000 22

G36-BRL 36 po(914mm) 25-1/8 po(636mm) 34-1/2 po(876mm) 340/154 29.5 6 90,000 26.4

G48-BRL 48 po(1219mm) 25-1/8 po(636mm) 34-1/2 po(876mm) 375/170 37 8 120,000 35.2

1

GF18-BRL 18 po(457mm) 25-1/8 po(636mm) 34-1/2 po(876mm) 190/86 21 3 45,000 12.0

1

GF24-BRL 24 po(610mm) 25-1/8 po(636mm) 34-1/2 po(876mm) 240/109 21 4 60,000 16.0

1

GF30-BRL 30 po(762mm) 25-1/8 po(636mm) 34-1/2 po(876mm) 290/131 29.5 5 75,000 20.0

1

GF36-BRL 36 po(914mm) 25-1/8 po(636mm) 34-1/2 po(876mm) 340/154 29.5 6 90,000 24.0

1

NOTA : Seules les rôtissoires série GF avec fonctions de détection de amme sont agréées CE

Modèles G-BRL

Pour utilisation dans des emplacements

incombustibles uniquement.

Marchés Nord-Américain Et

Internationaux Généraux

Natural (G20)

Pression De Fonctionnement Du Collecteur

4,5 po CE

(11,2 mbars)

LPG (G31)

10 po wc

(24,9mbar)

Dégagements d’installation par rapport aux

matériaux non combustibles(Tous les modèles)

Marché Australien

Pression De Fonctionnement Du Collecteur

Natural 4 po CE (1.0kPa) LPG 10po CE (2,49 kpa)

MJ/H Dia. Injecteur. MJ/H Dia. Injecteur.

15,8 1,9 mm 15,8 1,1 mm

Arrière Côtés

0 po 0 po

Entrée par brûleur

Pièce nº 4525958 (05/15/09)Page 16

Page 17

DIMENSIONS ET SPÉCIFICATIONS – RÔTISSOIRES (suite)

A*

CONNEXION

ARRIÈRE DU GAZ

CONNEXION

ARRIÈRE

DU GAZ

1-3/8"

[45mm]

34-1/2"

[876mm]

24-1/4"

[617mm]

5"

[127mm]

5-7/8"

[149mm

LARGEUR

25-1/8"

[638mm]

3/16"

[5mm] MIN

1/2"

[13mm] MAX

22-3/8"

[568mm]

7/8" [21mm]

5-5/8"

[143mm]

2"

[53mm]

15-7/8"

[404mm]

3"

[77mm]

22-1/8"

[562mm]

31-1/8"

[91mm]

14-3/4"

[375mm]

3-5/8"

[94mm]

Modèles GF-BRL

*Pour les unités livrées avec régulateur, la dimension «A» est de 7-7/8 po (200 mm) avec une connexion 3/4 po – 14 NPT.

Les unités destinées à l’Europe (CE) ne sont pas livrées avec régulateur, mais avec un adaptateur 3/4 po –14 BSPT.

Modèles homologués CE

Réglages De Pression/Taille Des Injecteurs

2ème Famille Groupes H L et E 3ème Famille Groupe 3p

Pression De Réglage

MODÈLE

Entrée G20 à

20 mbar

Entrée G25 à

25 mbar

Taille Injecteur

mbar po CE mbar po CE DMS mm mbar po CE DMS mm

GF18-BRL 11,2 4,5 14,9 6 50 1,78 24,9 10 58 1,07

GF24-BRL 11,2 4,5 14,9 6 50 1,78 24,9 10 58 1,07

GF30-BRL 11,2 4,5 14,9 6 50 1,78 24,9 10 58 1,07

GF36-BRL 11,2 4,5 14,9 6 50 1,78 24,9 10 58 1,07

Pression De Réglage

Entrée G31 à 37/50

mbar

Taille Injecteur

Débit Calorique

2ème Famille, Groupes H Et E 2ème famille, Groupe, L 3ème Famille, Groupe 3P

MODÈLE

(G20 à 20/25 mbar) Gaz nat. (G25 à 25 mbar) Gaz nat. (G31 à 37/50 mbar) PropaneE

Par Brûleur / Total Par Brûleur / Total Par Brûleur / Total

Nb De

Brûleurs

kW BTU/H kW BTU/H kW BTU/H

GF18-BRL 4,0 / 12,0 15 000 / 45 000 4,0 / 12,0 15 000 / 45 000 4,0 / 12,0 15 000 / 45 000

GF24-BRL 4,0 / 16,0 15 000 / 60 000 4,0 / 16,0 15 000 / 60 000 4,0 / 16,0 15 000 / 60 000

GF30-BRL 4,0 / 20,0 15 000 / 75 000 4,0 / 20,0 15 000 / 75 000 4,0 / 20,0 15 000 / 75 000

GF36-BRL 4,0 / 24,0 15 000 / 90 000 4,0 / 24,0 15 000 / 90 000 4,0 / 24,0 15 000 / 90 000

3

4

5

6

Dimension D’entrée Du Gaz

Largeur Du Modèle Connexion Connexion Modèles CE (ISO7-1)

23-5/8 po (600mm) & 35-1/2 po (900mm) Connexion Arrière Du Gaz 3/4 Po NPT 3/4 po (19,1mm) BSPT

Série GF - Homologué CE - Catégories de gaz

Pièce nº 4525958 (05/15/09) Page 17

Pays

Catégorie

De Gaz

Type De

Gaz

Pression

(mbar)

GB, IE, ES, PT, GR I2H G20 20

BE, FR I2E+ G20 20/25

DE I2E G20 20

GB, IE, ES, PT, BE, FR I3P G31 37

GB, FR, NL, DE, ES I3P G31 50

NL I3P G31 30

Rapprochez Les Estimations Totales D’entrée Avec

Tous Les Brûleurs Fonctionnant Au BAS

GF18-BRL 4.5 16,875

GF24-BRL 6.0 22,500

GF30-BRL 7.5 28,125

GF36-BRL 9.0 33,750

kW BTU/H

Page 18

DIMENSIONS ET SPÉCIFICATIONS - SOCLES

LARGEUR

21"

[534mm]

PIED MAX

20"

[ 509mm]

PIED MIN

20"

[508mm]

ROULETTE

NON RÉGL

20-7/16"

[529mm]

RÉGL. MAX.

ROULETTE

20-3/16"

[513mm]

RÉGL. MIN.

ROULETTE

31-3/16"

[719mm]

PROFONDEUR

G24-BRL-CAB

LARGEUR

20-5/16"

[516mm]

PIED MAX

19-7/16"

[504mm]

PIED MIN

20"

[508mm]

ROULETTES

31-3/16"

[792mm]

PROFONDEUR

G24-BRL-STD

Numéro De

Modèle

Description

À Utiliser Avec

Rôtissoire Modèle

pi³

Poids

d’expédition

Lb/ Kg

G18-BRL-STD Socle De Plancher 18 po (457 mm) De Large G18-BRL & GF18-BRL 4,5 30/14

G24-BRL-STD Socle De Plancher 24 Po (610mm) De Large G24-BRL & GF24-BRL 4,5 40/18

G30-BRL-STD Socle De Plancher 30 Po (762mm)De Large G30-BRL & GF30-BRL 4,5 50/23

G36-BRL-STD Socle De Plancher 36 Po (914mm) De Large G36-BRL & GF36-BRL 4,5 55/25

G48-BRL-STD Socle De Plancher 48 Po (1219mm) De Large G48-BRL 5,5 58/26

G18-BRL-CAB Meuble Fermé 18 po (457 mm) De Large G18-BRL & GF18-BRL 21 40/18

G24-BRL-CAB Meuble Fermé 24 Po (610mm) De Large G24-BRL & GF24-BRL 21 45/20

G30-BRL-CAB Meuble Fermé 30 Po (762mm) De Large G30-BRL & GF30-BRL 29,5 50/23

G36-BRL-CAB Meuble Fermé 36 Po (914mm) De Large G36-BRL & GF36-BRL 29,5 60/27

G48-BRL-CAB Meuble Fermé 48 Po (1219mm)De Large G48-BRL 37 65/29.5

• Ilexistedenombreuxcodeslocaux,etilestdelaresponsabilitédupropriétaireetdel’installateurderespecterces

codes.

• Garlandseréserveledroitdemodifieroud’améliorerlesspécificationsdesproduitssanspréavis.

• LesproduitsGarlandnesontpasagréésniautoriséspouruneutilisationpersonnelleourésidentielle,maissontdesti-

nés à des applications commerciales seulement.. Garland n’offre pas de services de réparation, garantie, entretien ou

soutien de n’importe quelle sorte pour des applications autres que commerciales.

Pièce nº 4525958 (05/15/09)Page 18

Page 19

PRÉINSTALLATION

Déballage

GARLAND recommande fortement d’inspecter l’appareil

en présence du transporteur pour vérier la présence de

dommages causés pendant le transport.

1. Retirer la carton. En cas de dommage, tous les matériaux

d’emballage doivent être conservés pour inspection par

le transporteur.

2. Inspecter soigneusement la rôtissoire pour déceler les

signes de dommages comme des rayures, bosses et

boutons manquants.

3. Pendant que le conducteur du camion est sur place, noter

les dommages sur la facture de transport. Appeler le

transporteur pour demander une inspection.

En cas de vérication de l’équipement après le départ du

transporteur, vous avez environ quinze (15) jours pour

demander une inspection de dommages de transport par

l’agent du transporteur.

Si une réclamation de dommages non apparents est

déposée auprès du transporteur au-delà de 15 jours,

GARLAND ne peut pas être tenue pour responsable et le

transporteur demandera au destinataire de fournir la preuve

que le transporteur était responsable.

Informations De Sécurité

AVERTISSEMENT : Des pièces accessibles peuvent devenir

chaudes pendant l’utilisation. Maintenir les jeunes enfants

éloignés.

Cet appareil est pour à usage professionnel et devrait

seulement être employé par le personnel qualié.

Cet appareil n’est pas destiné à être utilisé par des

personnes (y compris des enfants) ayant des capacités

physiques, sensorielles ou mentales réduites ou un manque

d’expérience et de connaissances à moins qu’elles n’aient

reçu une supervision ou des instructions concernant

l’utilisation de cet appareil d’une personne responsable de

leur sécurité.

INSTALLATION

Pour correspondre avec l’usine ou le centre de service agréé

local concernant des problèmes de service ou des pièces de

rechange, bien faire référence à l’appareil avec le numéro de

modèle correct (comprenant les lettres et chires du préxe

et du suxe) et le numéro de série de garantie. La plaque

signalétique xée à l’appareil contient ces renseignements.

Nous suggérons de faire faire l’installation, l’entretien et les

réparations par une agence de service agrée locale gurant

dans la manuel d’informations.

En cas de questions concernant l’installation, l’utilisation,

l’entretien ou la réparation du produit, écrire ou

communiquer avec le département de service des produits.

Ce produit doit être installé par du personnel professionnel

tel que spécié. Les produits Garland/U.S. Range ne sont

pas agréés ni autorisés pour une utilisation personnelle

ou résidentielle, mais sont destinés à des applications

commerciales seulement. Garland / U.S. Range n’ore pas

de services de réparation, garantie, entretien ou soutien

de n’importe quelle sorte pour des applications autres que

commerciales.

Emplacement De La Plaque Signalétique

On découvre la plaque signalétique en retirant le plateau à

graisse; elle est située sur le support gauche de glissière du

plateau à graisse.

Réglementation Légale

L’installation de cet appareil doit être faite par une personne

compétente et conformément aux règlements concernés,

codes de pratique et publications connexes du pays de

destination.

Dans les pays européens, l’installation doit être faite par une

personne compétente et conformément aux règlements

concernés, codes de pratique et publications connexes du

pays de destination.

Aux États-Unis, l’installation doit être conforme au National

Fuel Gas Code Code ANSI Z223.1, ou la dernière édition, la

norme NFPA No.54 – dernière édition/ou le code local pour

assurer un fonctionnement sécuritaire et ecace. Au Canada,

l’installation doit être conforme à la norme CSA B149.1 et aux

codes locaux.

Pièce nº 4525958 (05/15/09) Page 19

Page 20

INSTALLATION (suite)

Clause Spécique à l’Australie

Cet appareil doit être installé conformément aux instructions

du fabricant, aux règlements locaux relatifs aux raccords de

gaz et aux exigences du code d’installation AS 5601 / AG

601. Tous les réglages des brûleurs doivent être faits par un

technicien qualié spécialiste des appareils à gaz.

Alimentation En Gaz

A. Le type de gaz pour lequel l’appareil est équipé

est estampillé sur la plaque signalétique située

(modèles G80) derrière le panneau supérieur avant,

(modèles 80B-40SD & ESD) à l’intérieur des portes du

compartiment. Brancher un appareil estampillé “ NAT ”

au gaz naturel et un appareil estampillé “ PRO ” au gaz

propane.

B. S’il s’agit d’une installation neuve, faire vérier par

le fournisseur de gaz le diamètre du compteur et

des conduites an de s’assurer que l’appareil reçoit

une pression de gaz susante pour fonctionner

correctement.

C. S’il s’agit d’un équipement supplémentaire ou de

remplacement, faire vérier la pression du gaz par un

technicien qualié an de s’assurer que les installations

de gaz existantes (compteur, tuyauteries, etc.) fourniront

les BTU dont l’appareil a besoin avec une chute de

pression ne dépassant pas 1/2 po de colonne d’eau. Lors

de la vérication de la pression, s’assurer que les autres

équipements sur la même conduite de gaz fonctionnent

à leur débit maximal.

F. Un bouchon de prise de pression est fourni avec les

appareils et est installé sur le collecteur. Le panneau des

robinets doit être retiré pour utiliser la prise de pression.

Il est nécessaire de vérier la pression du gaz quand

l’appareil est installé, pour s’assurer que la pression

d’alimentation de l’appareil est identique à celle indiquée

sur la plaque signalétique. Si nécessaire, des réglages de

pression doivent être faits au régulateur de pression.

G. S’il s’agit d’une installation complètement nouvelle,

faire installer et vérier les conduites de gaz, la taille du

compteur et celles des tuyauteries par un technicien en

gaz qualié.

H. S’assurer que les tuyauteries, joints et branchements

neufs ont été exécutés proprement et ont été purgés

de façon à ce que la graisse à letage, les copeaux,

etc. ne bouchent pas les robinets des veilleuses ni les

commandes. Utiliser du produit d’étanchéité pour joint

qui résiste au gaz de pétrole liquéé.

AVERTISSEMENT : Vérier la présence de fuites sur les

connexions de gaz. Utiliser une solution savonneuse ou une

méthode similaire. Ne pas utiliser de amme nue!

Gas Connections

Toutes les rôtissoires ont des connexions du gaz arrière

3/4 po NPT ou 3/4 po-14NPT. Les modèles CE ont un letage

3/4 po 14 NPT qui comprend un adaptateur.

NOTA : Un dégagement susant doit être prévu pour

l’entretien et l’utilisation.

NOTA : Pour vérier la pression du gaz, s’assurer que tous les

autres équipements branchés sur la même conduite de gaz

sont allumés. Si la rôtissoire a été livrée avec un régulateur,

celui-ci a été préréglé pour correspondre aux spécications

de la plaque signalétique de l’unité. Toutes les unités ont

besoin de régulateurs et doivent être ajustées conformément

aux spécications du fabricant.

D. Cet appareil et son robinet d’arrêt du gaz individuel (non

fourni par Garland) doivent être débranchés du système

d’alimentation en gaz lors de tout essai de pression de ce

système à des pressions dépassant 1/2 lb/po2 (3,45 kPa).

E. Le branchement d’alimentation en gaz est situé dans

le coin arrière inférieur gauche de l’appareil. Un robinet

manuel facilement accessible et de type homologué

devrait être installé sur chaque conduite d’alimentation.

Vérications des fuites – Ne pas utiliser de amme nue.

Installations Sur Plan De Travail

Emplacement

Déballer soigneusement les appareils et prévoir l’espace

nécessaire sur le plan de travail ou la barre arrière. Tous

les appareils doivent être installés dans des endroits

incombustibles.

A. L’emplacement des appareils est vital et ils devront être

placés à un endroit où il y a susamment d’air d’appoint

pour assurer une combustion correcte. L’air d’appoint

devra être fourni de façon à passer par l’avant de

l’appareil. Ne pas obstruer le débit d’air par l’avant.

B. Conformément aux normes d’utilisation des appareils

à gaz, l’appareil devrait être placé sous une hotte de

ventilation de taille et de capacité correspondantes. Voir

les instructions de ventilation.

Pièce nº 4525958 (05/15/09)Page 20

Page 21

INSTALLATION (suite)

ENSEMBLE DE DOUILLE

ÉTAGÈRE

ENSEMBLE

DE PIED

LATÉRAL

DÉTAIL 2

DÉTAIL 1

DÉTAIL 1

10-24 X 3/8"

VIS À MÉTAUX

10-24

ÉCROU DE

BLOCAGE

10-24 X 3/8"

VIS À MÉTAUX

10-24

CONTRE-ÉCROU

FIXATION

DE SUPPORT

CENTRAL

DÉTAIL 2

Joint Sanitaire De Plan De Travail

Quand la rôtissoire est installée sur un plan de travail, la

National Sanitation Foundation, (NSF), recommande qu’elle

soit étanchéiée conformément à ses normes selon les

instructions suivantes :

1. L’appareil devrait être placé sur une surface de plan de

travail incombustible et de niveau.

2. Nettoyer soigneusement le périmètre inférieur de

la rôtissoire et le plan de travail autour du fond de la

rôtissoire.

3. Appliquer une bonne couche de produit d’étanchéité à

base de silicone tout autour du périmètre extérieur du

fond de la rôtissoire.

4. La rôtissoire peut être xée au plan de travail en insérant

les boulons de 3/8 po de diamètre à travers le comptoir

depuis le dessous (dans des trous prépercés de ½ po de

diamètre) et en les vissant dans les inserts à écrous dans

le fond de l’appareil.

5. Lisser le produit d’étanchéité au silicone avec un doigt ou

un outil pour obtenir un joint lisse.

Montage Des Socles De Plan De Travail

1. Glisser l’ensemble de pied latéral dans l’ensemble de

douille et xer avec une vis et un écrou à 8 endroits (2 par

joint) comme illustré sur le détail 1.

Installation des pieds

1. Tous les appareils sont expédiés avec des pieds

homologués par la NSF. Ces pieds doivent installés pour

assurer un espace de quatre (4) pouces entre le comptoir

et le bas de l’appareil an de respecter les exigences de la

National Sanitation Foundation.

2. Lors de l’utilisation des pieds décrits ci-dessous, soulever

l’avant de l’appareil et visser le pied dans l’écrou de

retenue du pied prévu dans chaque coin de l’appareil;

refaire la même chose à l’arrière.

3. L’appareil doit être mis de niveau en réglant les pieds.

Utiliser un niveau à bulle pour mettre l’appareil de niveau

(en se basant sur les grilles de cuisson) dans les quatre (4)

sens. entre l’avant et l’arrière et aussi sur les côtés.

2. Placer la xation de support central dans l’ensemble de

douille. Monter le support central sur la xation avec 2 vis

et écrous (détail 2). Répéter l’opération pour l’autre côté.

Les ensembles de douille doivent être placés entre le

support central et la xation de support central. Répéter

pour l’autre support central.

3. Avant de placer l’unité sur le socle :

a. Retirer les pieds de mise à niveau de l’appareil.

b. Retirer les grilles/tiges/brûleurs, etc. pour alléger

l’appareil et le soulever à plusieurs sur le socle.

Pièce nº 4525958 (05/15/09) Page 21

Page 22

ÉCROU DE BLOCAGE 1/4-20T

RONDELLE 1/4 PO

BOULONS 1/4-20 X 5/8 PO

FIXATION SUR LA RÔTISSOIRE

RONDELLE DE BLOCAGE 3/8

BOULONS 3/8-16 X 5/8

SOCLE

RÔTISSOIRE GF24

AVEC PIEDS

ILLUSTRÉ

INSTALLATION (suite)

FOND

DE

L’APPAREIL

PLASTIQUE

DE PROTECTION

DE LA RONDELLE

DE CE CÔTÉ

ROULETTE FIXE

(ILLUSTRÉE AVEC FREIN)

ROULETTE RÉGLABLE

(ILLUSTRÉE SANS FREIN)

FOND

DE

L’APPAREIL

4. Fixer la rôtissoire au socle à l’arrière avec (2) boulons

de 1/4 po, des rondelles et écrous de blocage comme

illustré. (Un dans chaque coin.)

NOTA : pour la rôtissoire de 48 po, il y a (4) emplacements

de montage à l’arrière.

5. Fixer la rôtissoire au socle à l’arrière avec (2) boulons

de 3/8 po, et des rondelles de blocage comme illustré.

Boulon avec le letage dans les xations xées à la partie

inférieure de la rôtissoire (une dans chaque coin).

NOTA : pour la rôtissoire de 48 po, il y a (4) emplacements

de montage à l’arrière.

Installation Des Appareils Équipés De Roulettes

A. L’installation sera faite avec un raccord conforme à la

norme Connectors for Movable Gas Appliances, ANSI

Z./CSA ., Addenda Z.B-/CSA .B-

(ou la dernière édition) et un raccord rapide conforme à

la norme Standard for Quick-Disconnect Devices for use

with gas fuel, ANSI Z./CSA ., Addenda Z.A-/

CSA .A- (ou la dernière édition).

B. Soulever l’avant de l’appareil et l’immobiliser. Ne pas

coucher l’appareil sur l’arrière.

C. Les roulettes sont letées pour être vissées facilement

dans les trous prévus sous la cuisinière. Il est important

d’ajouter les rondelles fournies an de mieux répartir la

force sur la cuisinière quand elle est déplacée.

D. Placer la rondelle sur la tige de la roulette comme illustré.

Étant donné que la rondelle est légèrement concave, il est

essentiel que le côté avec le plastique soit orienté vers le

haut et en contact avec le fond de l’appareil. La rondelle

étant en place, visser à fond la roulette sur l’appareil. Il

n’est pas nécessaire de retirer le plastique de la rondelle.

E. Les roulettes avant de l’appareil sont dotées de freins

qui limitent les déplacements de l’appareil sans que

le connecteur ou le raccord rapide ou sa tuyauterie

n’interviennent pour limiter les mouvements de

l’appareil.

F. Notez qu’un dispositif de xation est xé à l’appareil et

que s’il est nécessaire de détacher le dispositif de xation,

ne pas oublier de le rattacher une fois que l’appareil a été

remis dans sa position d’installation d’origine.

Bases De Meuble

Des options de base de meuble existent pour tous les

modèles de rôtissoire. Les meubles sont prémontés au

moment de la livraison, à l’exception de pieds ou roulettes.

Montage De La Rôtissoire

Tiges De Grille En Acier

Chaque rôtissoire est livrée avec (14) tiges en acier d’une

longueur de 15 po/381mm (18-BRL), 21 po/533mm (24BRL), 26 po /660mm (30-BRL), 31 po/787mm (36-BRL) ou

2 ensembles de of 21 po/533mm (48-BRL). Ces tiges sont

montées dans les rainures des supports, qui sont au-dessus

des brûleurs.

Pièce nº 4525958 (05/15/09)Page 22

Page 23

INSTALLATION (suite)

Briquettes

Pour obtenir les meilleurs résultats de cuisson, il est

recommandé d’installer la quantité correcte de briquettes

dans la rôtissoire. Se reporter au tableau et au dessin cidessous pour la mise en place des briquettes. Une fois

que toutes les briquettes ont été mises en place selon les

instructions, mettre en place les sections de grille supérieure.

MODÈLE 18-BRL 24-BRL 30-BRL 36-BRL 48-BRL

Rangées

d’avant

en arrière

Rangées

de

gauche à

droite

7 7 7 7 7

7 11 14 17 22

Ventilation

Les notes suivantes sont prévues pour donner des conseils

généraux. Pour des recommandations détaillées, référezvous aux codes appliable dans le pays de destination.

Ces appareils seront installés dans une chambre avec

le ventialtion susant d’empêcher l’occurrence des

concentrations dangereuses des sous-produits de

combustion.

Un bon système de ventilation est important pour des

résultats satisfaisants et il est recommandé d’installer

l’appareil sous une hotte à ventilation électrique.

Les codes locaux et/ou nationaux précisent si un système de

ventilation doit être utilisé avec ce type d’équipement. Les

renseignements suivants sont donnés à titre d’exemples de

conceptions de systèmes de ventilation disponibles.

Deux types de base de ventilation électrique sont utilisés

aujourd’hui. Un type est la hotte aspirante et l’autre est

le système d’aspiration sous étagère Le dernier ore une

installation plus simple et des dépenses de nettoyage

minimales. Les deux doivent être équipés de ltres ignifugés

pour éliminer facilement les graisses.

Le ventilateur doit être relié à un conduit de taille convenable

équipé d’un ventilateur d’aspiration capable d’évacuer un

minimum de 325 pi/mn d’air par pied carré de surface de

rôtissoire.

Pièce nº 4525958 (05/15/09) Page 23

Page 24

FONCTIONNEMENT

Instructions D’apprêtage

De La Crémaillère De Grille

Pour pouvoir utiliser longtemps l’appareil, il est impératif de

« rôder » ou apprêter soigneusement la surface de cuisson de

la façon suivante :

1. Éliminer tout produit de protection appliqué en usine

en lavant avec de l’eau très chaude et un détergent

doux ou une solution savonneuse. Rincer et sécher

soigneusement.

2. Appliquer une ne couche d’huile d’olive ou d’une autre

huile de cuisson sans sel de haute qualité sur la surface de

cuisson. Essuyer tout excès.

3. Ouvrir tous les robinets à un réglage bas et laisser les

crémaillères de grille chauer lentement pendant

trente (30) minutes. Laisser l’huile restant sur la surface

de cuisson pendant trois (3) à quatre (4) minutes, puis

essuyer.

4. Régler les robinets à la température de fonctionnement

souhaitée et appliquer une seconde couche d’huile et la

laisser pendant deux (2) à trois (3) minutes après que la

crémaillère de grille ait atteint la température. Essuyer

ensuite l’huile en excès.

Votre rôtissoire est prête à être utilisée.

NOTA : À moins que les aliments ne contiennent

susamment de gras, les crémaillères de grille doivent être

apprêtées avant chaque utilisation. Apprêter de nouveau

après un nettoyage soigné de la surface de cuisson.

2. Appuyer plusieurs fois sur les boutons d’allumage rouges

pour allumer les veilleuses.

3. Vérier que les veilleuses sont allumées en regardant

dans les trous de vérication des veilleuses à l’avant de

l’appareil.

Modèles GF(18, 24, 30, 36)-BRL

1. Enfoncer le bouton du robinet et le tourner dans le sens

inverse des aiguilles d’une montre jusqu’à la position

d’allumage.

2. En maintenant le robinet complètement enfoncé,

appuyer sur le bouton de l’allumeur et vérier que les

veilleuses s’allument. Si la veilleuse ne s’allume pas,

continuer d’appuyer sur le bouton de l’allumeur jusqu’à

l’allumage de la veilleuse.

3. Une fois la veilleuse allumée, continuer de maintenir

le bouton du robinet enfoncé pendant au moins 20

secondes, puis le relâcher. Si la veilleuse s’éteint, attendre

cinq (5) minutes et recommencer la procédure.

4. Quand la veilleuse est bien allumée, appuyer de nouveau

sur le bouton du robinet et le tourner dans le sens

contraire des aiguilles d’une montre jusqu’à la position de

amme, ce qui allume le brûleur principal.

5. Pour obtenir une amme basse ou pour mijoter, appuyer

sur le bouton du robinet et le tourner jusqu’à la position

de amme basse.

6. Pour éteindre le brûleur, tourner le bouton du robinet

jusqu’au symbole circulaire d’arrêt (« OFF »).

Instructions d’allumage

Modèles G(18,24,39,36,48)-BRL

1. Une veilleuse allume deux brûleurs et est placée entre ces

brûleurs.

L’extinction

1. Fermer tous les robinets de gaz.

2. Seulement si l’appareil doit être arrêté pour une longue

période de temps, fermer le robinet de service en ligne

(ce robinet n’est pas fourni par l’usine).

Pièce nº 4525958 (05/15/09)Page 24

Page 25

ENTRETIEN ET NETTOYAGE

Nettoyage des crémaillères de grille

Établir un calendrier de nettoyage régulier. Il est nécessaire

d’éviter toute obstruction et de permettre une combustion

et un rendement corrects.

1. Les crémaillères de grille doivent être essuyées chaque

jour pendant qu’elles sont encore chaudes, avec un

torchon épais ou un autre matériau absorbant la graisse

an d’éliminer la graisse et les aliments brûlés avant qu’ils

ne brûlent dans la grille. Éliminer les produits brûlés

comme la graisse ou les aliments carbonisés avec une

brosse métallique dure. Ne pas utiliser de laine d’acier. Les

petites particules peuvent être laissées sur la surface de la

grille et pénètrent dans les produits alimentaires.

2. Les crémaillères de grille doivent être lavées

soigneusement avec une brosse métallique et une

solution très chaude de détergent doux ou de savon.

Rincer à l’eau claire chaude.

3. Bien sécher.

4. Apprêter de nouveau les crémaillères de grille comme

indiqué dans les instructions d’apprêtage.

5. Vider fréquemment les plateaux à graisse et les laver

chaque jour dans une solution très chaude de détergent

doux ou de savon.

6. Ne pas gaspiller de gaz ni abîmer l’équipement en laissant

les robinets réglés sur des températures élevés quand

l’appareil n’est pas utilisé. Pendant les périodes d’attente,

régler les robinets sur le réglage de température basse

an de maintenir les grilles chaudes. Modier le réglage

des robinets selon besoin pendant les périodes de forte

activité. Tourner les robinets sur OFF à la n de la journée.

7. Quand le gril fonctionne, ne jamais utiliser d’objets

comme des plateaux pour couvrir le gril an de

concentrer la chaleur pour brûler la graisse ou d’autres

débris.

Nettoyage Du Fini Extérieur

Établir un calendrier régulier. Les déversements devront être

essuyés immédiatement.

1. Essuyer la surface nettoyable exposée quand elle est

froide avec de l’eau chaude et un détergent doux. Les

résidus rebelles peuvent être éliminés avec un tampon

à récurer non métallique. Bien essuyer avec un chion

propre.

2. L’acier inoxydable devra être nettoyé avec un détergent

doux, un chion doux et de l’eau chaude. S’il est

nécessaire d’utiliser un tampon à récurer non métallique,

toujours frotter dans le sens du grain du métal pour éviter

de rayer. Utiliser un produit de nettoyage pour acier

inoxydable à base d’eau (comme Drackett Twinkle), si

vous voulez obtenir un brillant superbe.

3. Les éclaboussures sur les côtés ou la table de cuisson

principale de la rôtissoire peuvent être nettoyées avec

de l’eau très chaude et une solution savonneuse; on

peut aussi utiliser un produit dégraissant. Pour faciliter

le nettoyage, il est possible de retirer la table de cuisson

principale. Pour cela, soulever d’abord et retirer toutes

les grilles, puis retirer la table de cuisson en la soulevant.

Une fois le nettoyage terminé, sécher soigneusement

et appliquer une ne couche d’huile de cuisson ou

pulvériser de l’huile de cuisson comme celle de marque

PAM. En l’absence d’huile, il se formera de la rouille.

Pièce nº 4525958 (05/15/09) Page 25

Page 26

Pièce nº 4525958 (05/15/09)Page 26

Page 27

MANUAL DE INSTA-

LACIÓN Y OPERACIÓN

PARRILAS GARLAND

SERIES G-BRL Y GF-BRL

Sólo las parrillas eléctricas serie GF han sido aprobadas por la CE

PARA SU SEGURIDAD:

NO ALMACENE O UTILICE GASOLINA U

OTROS VAPORES O LÍQUIDOS INFLAMABLES

EN LAS CERCANÍAS DE ESTE O CUALQUIER

OTRO ARTEFACTO.

Incluye Los Modelos: G18-BRL, G24-BRL,

G30-BRL, G36-BRL, G48-BRL, GF18-BRL,

GF24-BRL,GF30-BRL Y GF36-BRL

LEA TODAS LAS SECCIONES DE ESTE MANUAL Y

GUÁRDELO PARA FUTURAS CONSULTAS.

ESTE PRODUCTO HA SIDO CERTIFICADO COMO

EQUIPO DE COCINA COMERCIAL Y DEBE SER

INSTALADO POR PERSONAL PROFESIONAL

SEGÚN LO ESPECIFICADO.

ADVERTENCIA:

MODIFICACIÓN, SERVICIO O

MANTENIMIENTO INCORRECTO PUEDEN

OCASIONAR DAÑOS A LA PROPIEDAD,

LESIONES O LA MUERTE. LÉASE

MINUCIOSAMENTE LAS INSTRUCCIONES

DE INSTALACIÓN, OPERACIÓN Y

MANTENIMIENTO ANTES DE INSTALAR O

DAR MANTENIMIENTO A ESTE EQUIPO

EN EL COMMONWEALTH DE MASSACHUSETTS

ESTE PRODUCTO DEBE SER INSTALADO POR

UN PLOMERO O INSTALADOR DE APARATOS DE

GAS CON LICENCIA.

Para su seguridad:

Coloque en una ubicación prominente las

instrucciones a seguirse en caso de que el

usuario huela gas. Esta información se obtendrá

consultando a su proveedor de gas local.

A los usuarios se les advierte que el mantenimiento y las reparaciones deben ser realizados por un agente de servicio

autorizado de Garland que utilice repuestos genuinos de Garland. Garland no tendrá ninguna obligación con respecto

a cualquier producto que haya sido incorrectamente instalado, ajustado, operado o no mantenido de acuerdo con los

códigos nacionales y locales o las instrucciones de instalación provistas con el producto, o cualquier producto al que se

le haya desfigurado, borrado o quitado su número de serie, o que ha sido modificado o reparado utilizando repuestos

no autorizados o por agentes de servicio no autorizados. Para una lista de agentes de servicio autorizados, por favor

consulte el sitio Web de Garland en http://www.garland-group.com. La información contenida aquí, (incluso el diseño y

las especificaciones de partes), puede ser reemplazada y esta sujeta a cambios sin previo aviso.

GARLAND COMMERCIAL INDUSTRIES, LLC

185 East South Street

Freeland, Pennsylvania 18224

Teléfono: (570) 636-1000

Fax: (570) 636-3903

GARLAND COMMERCIAL RANGES, LTD.

1177 Kamato Road, Mississauga, Ontario L4W 1X4

CANADÁ

Teléfono: 905-624-0260

Fax: 905-624-5669

Enodis UK LTD.

5E Langley Business Centre

Station Road, Langley SL3 8DS Great Britain

Teléfono: 01753 485900

Fax: 01753 485901

Parte # 4525958 (05/15/09) © 2008 Garland Commercial Industries, LLC

Parte # 4525958 (05/15/09) Página 27

Page 28

INFORMACIÓN IMPORTANTE

ADVERTENCIA:

Este producto contiene sustancias químicas que el Estado de California las conoce como causantes

de cáncer y/o defectos de nacimiento u otro daños reproductivos. La instalación y el mantenimiento

de este producto podrían exponerle a partículas aerotransportadas de lana de vidrio / fibras

de cerámica. Es un hecho conocido por el Estado de California que la inhalación de partículas

aerotransportadas de la lana de vidrio / fibras de cerámica causan cáncer. La operación de este

producto podría exponerle al monóxido de carbono si no está debidamente ajustado. Es un hecho

conocido por el Estado de California que la inhalación de monóxido de carbono causa defectos de

nacimiento u otros daños reproductivos.

Mantenga la zona del artefacto libre y alejada de combustibles.

Parte # 4525958 (05/15/09)Página 28

Page 29

TABLA DE CONTENIDO

INFORMACIÓN IMPORTANTE .......................................28

DIMENSIONES Y ESPECIFICACIONES – PARRILLAS ....................30

Mercados de América del Norte e Internacional General ......................30

Mercado Australiano ........................................................30

Modelos aprobados por la CE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Ajustes De Presión /Tamaño Del Inyector .....................................31