Page 1

INSTALLATION AND

OPERATION MANUAL

G24 SERIES GAS COUNTER EQUIPMENT

& G20 SERIES STOCK POT RANGES

FOR YOUR SAFETY:

DO NOT STORE OR USE GASOLINE

OR OTHER FLAMMABLE VAPORS OR

LIQUIDS IN THE VICINITY OF

THIS OR ANY OTHER

APPLIANCE

WARNING:

IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE

CAN CAUSE PROPERTY DAMAGE, INJURY,

OR DEATH. READ THE INSTALLATION,

OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR

SERVICING THIS EQUIPMENT

Users are cautioned that maintenance and repairs must be performed by a Garland authorized service agent

using genuine Garland replacement parts. Garland will have no obligation with respect to any product that has been

improperly installed, adjusted, operated or not maintained in accordance with national and local codes or installation

instructions provided with the product, or any product that has its serial number defaced, obliterated or removed,

or which has been modified or repaired using unauthorized parts or by unauthorized service agents.

For a list of authorized service agents, please refer to the Garland web site at http://www.garland-group.com.

The information contained herein, (including design and parts specifications), may be superseded and is subject

to change without notice.

PLEASE READ ALL SECTIONS OF THIS MANUAL

AND RETAIN FOR FUTURE REFERENCE.

THIS PRODUCT HAS BEEN CERTIFIED AS

COMMERCIAL COOKING EQUIPMENT AND

MUST BE INSTALLED BY PROFESSIONAL

PERSONNEL AS SPECIFIED.

IN THE COMMONWEALTH OF MASSACHUSETTS

THIS PRODUCT MUST BE INSTALLED BY A

LICENSED PLUMBER OR GAS FITTER. APPROVAL

NUMBER: G-1-07-05-28

For Your Safety:

Post in a prominent location, instructions to be

followed in the event the user smells gas. This

information shall be obtained by consulting

your local gas supplier.

GARLAND COMMERCIAL RANGES, LTD.

1177 Kamato Road, Mississauga, Ontario L4W 1X4

CANADA

Phone: 905-624-0260

Fax: 905-624-5669

Part # 4519655 (08/27/10)

Part #4519655 (08/27/10) Page 1

Page 2

IMPORTANT INFORMATION

WARNING:

This product contains chemicals known to the state of california to cause cancer and/or birth defects

or other reproductive harm. Installation and servicing of this product could expose you to airborne

particles of glass wool/ceramic fibers. Inhalation of airborne particles of glass wool/ceramic fibers

is known to the state of california to cause cancer. Operation of this product could expose you to

carbon monoxide if not adjusted properly. Inhalation of carbon monoxide is known to the state of

california to cause birth defects or other reproductive harm.

Keep appliance area free and clear of combustibles.

Part #4519655 (08/27/10)Page 2

Page 3

TABLE OF CONTENTS

IMPORTANT INFORMATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

SPECIFICATIONS, G24 SERIES GRIDDLES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Rating Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

INSTALLATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Gas Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Inlet Manifold Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

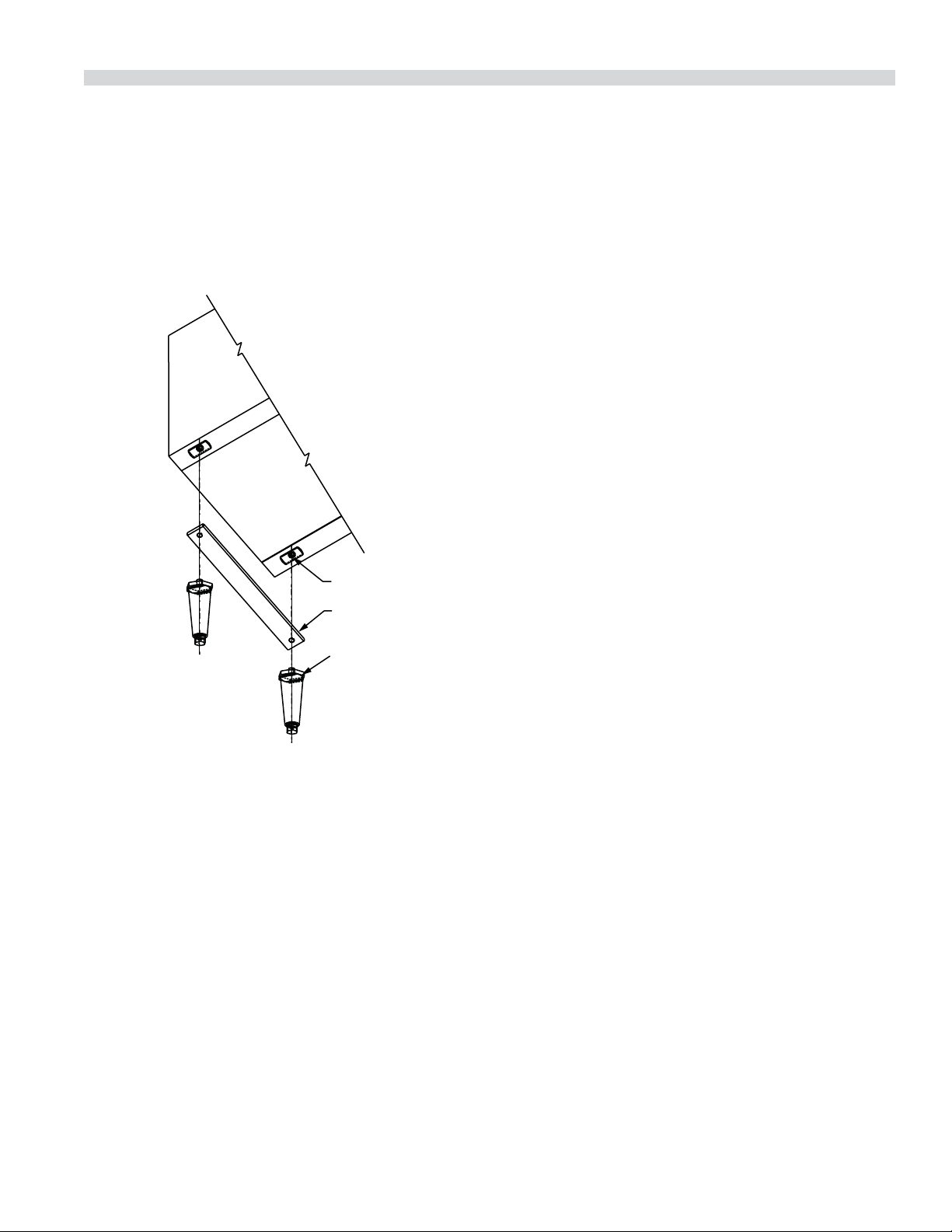

Leg Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Installation of Banking Plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Installing Equipment on Counter Stands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

OPERARATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Hot Plate – Model G24-15H . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

G24 Griddles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

G20-SP and G20-SPH Stock Pot Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Lighting Standing Pilots - All Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

FLAME SIZE CHART – ALL MODELS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

CLEANING AND MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Exterior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Top Sections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Griddle Top . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Open Top . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Stock Pot Ranges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Part #4519655 (08/27/10) Page 3

Page 4

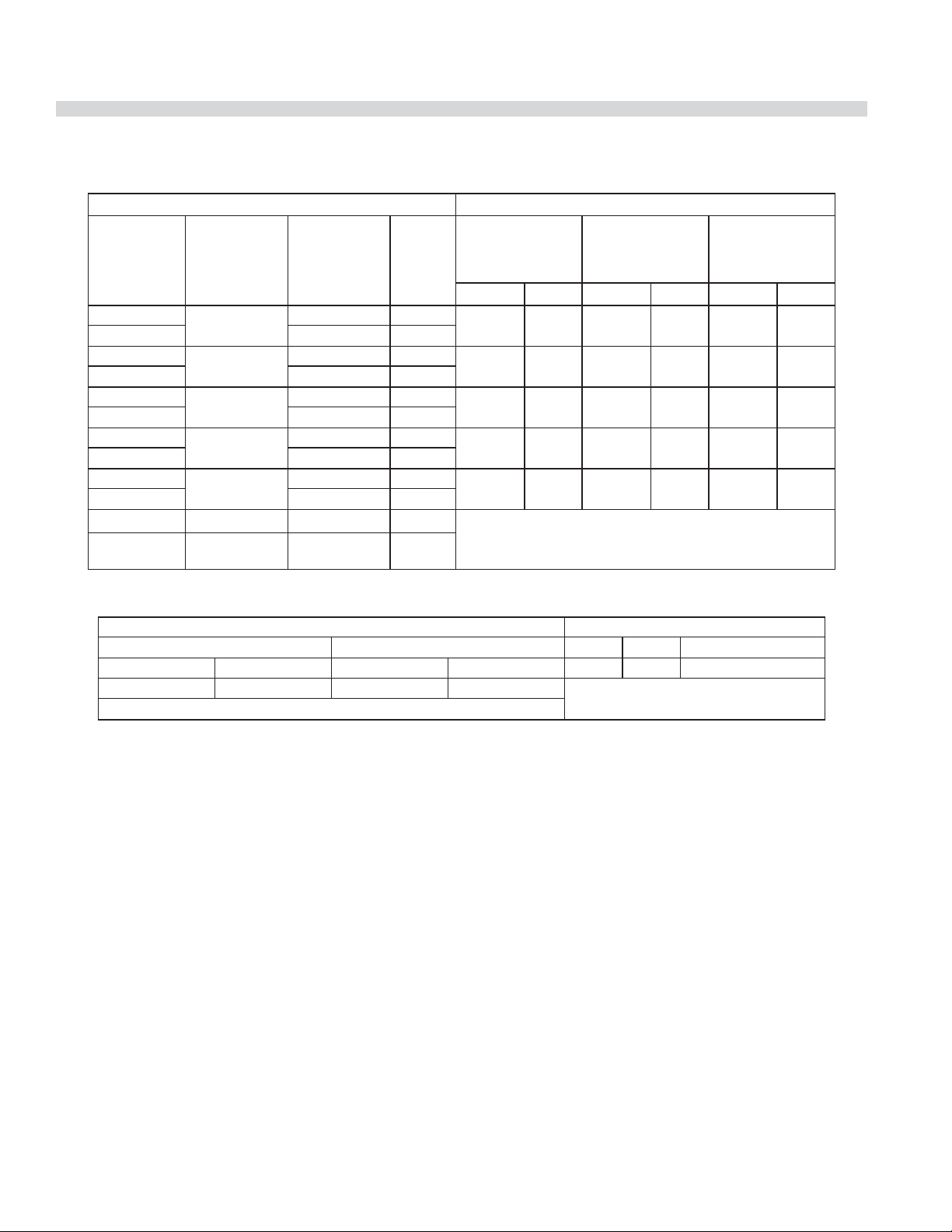

SPECIFICATIONS, G24 SERIES GRIDDLES

G24 Series Gas Counter Units Engineering Data

Input Chart Natural & Propane Gas Griddle Production Capacities

Meat Patties

Model Description Controls BTU/HR

G24-24G

G24-24GTHX 2 Thermostats

G24-36G

G24-36GTHX 3 Thermostats

G24-18G

G24-48GTHX 4 Thermostats

G24-60G

G24-60GTHX 5 Thermostats

G24-72G

G24-72GTHX 6 Thermostats

G24-15H Hot Plate 2 Valves 29,000

G20-SP/SPH

24” (610mm)

Griddle

36” (914mm)

Griddle

48” (1219mm)

Griddle

60” (1524mm)

Griddle

72” (1829mm)

Griddle

20” (508mm)

Wide Stock Pot

2 Hi-lo Valves 66,500

60,000

3 Hi-lo Valves 100,000

90,000

4 Hi-lo Valves 133,000

120,000

5 Hi-lo Valves 166,500

150,000

6 Hi-lo Valves 200,000

180,000

1 In nite Valve 60,000

3 Oz. (85 g)

350° F (177°C)

Per Load Hourly Per Load Hourly Per Load Hourly

33 165 27 540 27 135

50 250 40 800 40 200

67 335 53 1060 53 265

83 415 67 1340 67 335

100 500 80 1600 80 400

Fried Eggs

300°F(149°C)

Pancakes

4” Dia. (102mm)

Not Applicable

Minute Steaks

4oz(112g)

350° F (177° C)

Installation Notes

Gas Pressure Required Combustible Wall Clearances: In (mm)

Supply Operating Pressures Manifold Operating Pressures

Natural Propane Natural Propane 6(152) 6(152) Non-combustible

7” WC (17.5 mbar) 11” WC (27.5mbar) 4” WC (10 mbar) 10” WC (24mbar)

Note: For use with Natural & L.P Gas only

Sides Back Base

NOTE: Installation clearance reductions are

applicable only where local codes permit

Ratings shown are for natural gas installations up to 2000 feet (610m) above sea level. BTU input ratings must be de-rated

for high altitude installations. Specify altitude of product if over 2000 feet (610m)

Optional CS 24 Series Stands

Floor Stands: Heavy-duty stands of open design with seamless welded square tube legs. Black nish Storage shelf

supplied with stands up to 36” (1914mm) wide. Working height of all units on stands 35-1 /2” (902mm) Stand widths

available in 15” (381 mm), 24” (610mm), 30” (762mm), 36” (914mm), 48” (1219 mm), 60” (1524mm) and 72” (1829mm).

Example for G24-36G griddle. Specify CS24-36 stand.

NOTE: • Many local codes exist, and it is the responsibility of the Owner and the Installer to comply with those codes.

• Garland reserves the right to change or improve our speci cations without noti cation.

• These appliances are intended for commercial use by professionally trained personnel.

Part #4519655 (08/27/10)Page 4

Page 5

INTRODUCTION

Rating Plate

When corresponding with the factory or your local

authorized factory service center regarding service problems

or replacement parts, be sure to refer to the particular unit

by the correct model number (including the pre x and su x

letters and numbers) and the warranty serial number. The

rating plate a xed to the unit contains this information.

The rating plate is visible by removing the lower front panel

on the G22 Series, the drip tray on the G24 Series or the valve

panel on the G20 Series.

INSTALLATION

We suggest installation, maintenance and repairs should be

performed by your local authorized service agency listed in

your information manual pamphlet.

In the event you have any questions concerning the

installation, use, care or service of the product, write or call

our Product Service Department.

This product must be installed by professional personnel as

speci ed. Garland/U.S. Range products are not approved or

authorized for home or residential use, but are intended for

commercial applications only. Garland / U.S. Range will not

provide service, warranty, maintenance or support of any

kind other than in commercial applications.

General Information

1. Damage check: check carton or crate for possible damage

incurred in shipping. After carefully uncrating, check for

“concealed” damage. Report any damage immediately to

your carrier.

2. Carefully remove unit from carton or crate. Burner tie

wires and other packing material should be removed

from units. On stainless steel and brushed units, the

protective material covering the stainless steel should be

removed immediately after the unit is installed.

3. Remove valve panels, top grates or fry tank and place in a

safe area to prevent damage.

4. Should it be necessary to remove the steel griddle plate

on units equipped with griddle thermostat, the griddle

thermostat bulb and capillary must rst be withdrawn

from the bulb shield assembly, located on the underside

of the griddle plate. This can be accomplished with the

griddle front raised and supported by the griddle prop

located on the underside of the griddle plate. Loosen the

four pal nuts securing the bulb shield assembly to the

griddle plate and withdraw the griddle thermostat bulb.

5. When a griddle plate is being installed on units equipped

with griddle thermostats, the thermostat bulb must

be inserted in the groove between the plate and the

bulb shield assembly. This can be accomplished with

the griddle front raised and supported by the griddle

prop, located on the underside of the griddle plate. It is

important for accurate temperature control that the bulb

be located inside the groove. Tighten the four pal nuts

securing the bulb shield assembly to the griddle plate.

Part #4519655 (08/27/10) Page 5

Page 6

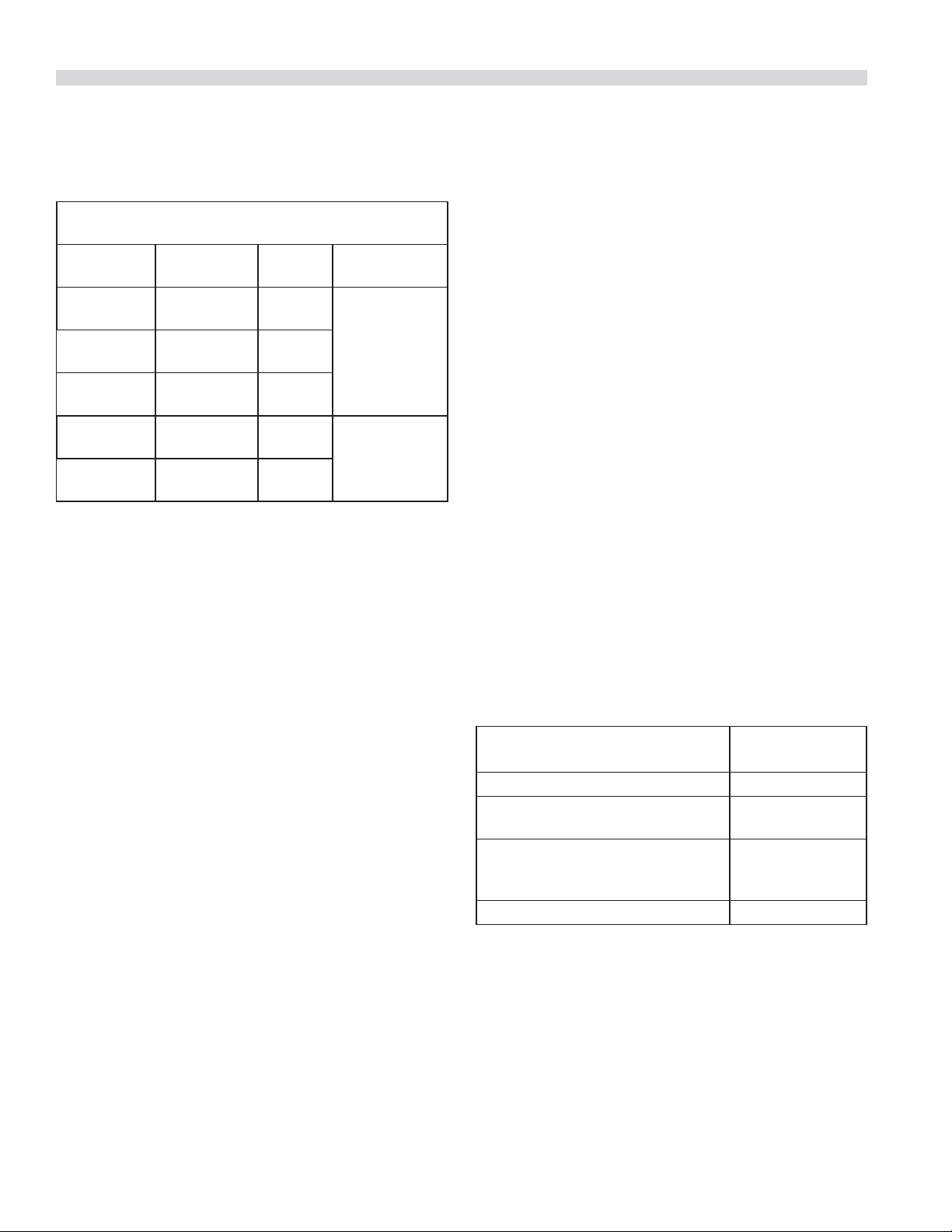

INSTALLATION continued

Clearances

Minimum Installation Clearances To Adjacent

Combustible Walls And Type Of Floor Or Base

Description

Hot Plate G24-15H

Griddle

Griddle

Stock Pot

Range

Stock Pot

Range

Model Or

Series

G24 Series

(HI-LO)

G24 Series

(Thermostat)

G20-SP

G20-SPH

Sides &

Back

6”

(152mm)

6”

(152mm)

6”

(152mm)

6”

(152mm)

6”

(152mm)

Type Of Floor

Or Base

Non

Combustible or

Combustible

with

2” (51 mm) Legs

Combustible

Gas Connections

The importance of proper installation of commercial

gas cooking equipment cannot be overstressed. Proper

performance of the equipment is dependent, in great part,

on the compliance of the installation with the manufacturer’s

speci cations. In addition compliance with the National

Fuel Gas code ANSI Z 223.1-1988/NFPA and/or Local Code is

required to assure safe and e cient operation.

In Canada, the installation and connection must comply with

CAN/CGA – B149 Installation codes and local codes where

applicable.

All burner adjustments and setting shall be made by a

quali ed gas technician.

1. The correct type of gas for which the unit was

manufacture is noted on the rating plate, and this type of

gas must be used.

2. The required manifold gas pressure for normal operation

is 7” water column for use on Natural gas and 11”

water column for use on Propane gas, unless speci ed

di erently on the rating plate.

3. Have a quali ed gas technician check the gas pressure

to make certain that existing gas facilities (meter, piping,

etc.) will deliver the BTU’s of gas required at the unit with

no more than 1/2” water column pressure drop. When

checking pressure, be certain that all the equipment on

same gas line is turned to the “ON” position.

4. Make certain that new piping, joints and connections

have been made in a clean manner and have been

purged, so that the piping compound, chips, etc., will not

clog pilots valves, and / or controls. Use pipe joint sealant

that is CGA approved for use with lique ed petroleum gas.

5. WARNING: Check gas connections for leaks, using soap

solution or similar means. DO NOT CHECK WITH AN OPEN

FLAME.

The appliance and its individual shuto valve must be

disconnected from the gas supply piping system during any

pressure testing of that system at pressures in excess of

1/2 PSIG (3.45 KP2).

The appliance must be isolated from the gas supply piping

system by closing its individual manual shuto valve during

any pressure testing of the gas supply piping system at test

pressures equal to or less then 1/2 PSIG (3.45 KP2)

Inlet Manifold Size

The inlet manifold size for connection to main gas supply is

as follows:

MODEL NUMBER

G24-15H 3/4” N.P.T.

G24-24G, G-24GTHX, G24-36G &

G24-36GTHX

G24-48G, G24-48GTHX,

G24-60G, G24-60GTHX, G24-72G &

G24-72GTHX

G20-SP & G20-5PH 3/4” N.P.T.

MANIFOLD

INLET SIZE

3/4” N.P.T.

1” N.P.T.

Part #4519655 (08/27/10)Page 6

Page 7

INSTALLATION continued

T

Leg Installation

G24 Series

The leg channel is located on the package base. This channel

must be installed when using the legs.

BOTTOM OF UNI

LEG CHANNEL

(QTY 2)

4" [102mm]

ADJUSTABLE LEG

(QTY 4)

NOTE: Griddles may not rest evenly on the unit body, if

units are not leveled.

2. Remove upper front panel (if not already removed) by

removing the thumb screws on each side of the panel.

3. Place the banking plate in position, over the two bolts

located in the main sides below the panel mounting

brackets.

NOTE: Install recessed (stepped) centre portion of

banking plate tight to the main sides of the units being

banked. Secure in place with two hex nuts supplied.

4. Replace and secure upper front panels.

5. Connect gas supply line using either rear or bottom inlet,

as desired. A readily accessible approved type of hand

valve should be installed on each supply line. Test For

Leaks.

Installing Equipment on Counter Stands

CS24 Series Stands

1. Assemble and level counter stand as illustrated in the

instructions found in the counter stand carton.

2. Remove and discard leveling bolts on unit to be installed

on the counter stand.

LEG INSTALLATION

Installation of Banking Plates

G24 Series

All units may be installed independently or banked with

other G24 or E24 Series equipment. To ensure a matching

and permanent t between units, a front banking plate is

supplied with each unit. If 2” (51 mm) legs are supplied with

nit, discard leveling bolts and replace with 2” (51 mm) legs.

1. Level each unit by adjusting leveling bolts or legs. Use a

spirit level and level unit four ways; across front and back

and down left and right edges. Level all other units to the

rst unit, securing each unit to the adjacent unit.

3. Remove only the side, front and rear sheet metal screws

in the main bottom of units to be placed on the outer

sides of the stand.

4. Place units in desired position on the counter stand,

securing the rst unit with sheet metal screws removed in

paragraph 3, by inserting the sheet metal screws through

the 9/32 inch (7 mm) diameter holes in stand, into the

holes from which the sheet metal screws were removed.

5. Connect banking plates as described in G24 Series

Installation Of Banking Plates.

6. Secure last unit to the counter stand with sheet metal

screws removed in paragraph 3. Insert sheet metal screws

through the 9/32 inch (7 mm) diameter holes in stand,

into the holes from which the sheet metal screws were

removed.

Part #4519655 (08/27/10) Page 7

Page 8

OPERATION

Hot Plate – Model G24-15H

Pilot Burner Adjustment

1. Remove ring grates and top grate, if not already removed.

2. Adjust the pilot valve, located on the manifold between

the two burner valves, to a yellow ame 1/2 inch (13 mm)

long (This adjustment can be made through the opening

in the upper front panel, around the rear burner valve.)

3. Replace ring grates and top grate.

To Operate Main Burner

1. Hi-speed non-clog burners light automatically from the

pilot.

2. Turn left valve full “ON” to light front burner. Turn right

valve full “ON” to light rear burner.

G24 Griddles

Lighting & Pilot Burner Adjustment

Each griddle burner is equipped with a pilot.

For the HI-LO valve operated model, the pilot adjusting valve

burner pilot is located on the manifold to the right of each

griddle valve. Open the pilot valve with a screwdriver and

light the pilot with a match.

5. Replace dial and turn to “OFF” position.

Calibration Instructions

1. Use a test instrument with a special disc type

thermocouple or a reliable surface type pyrometer. Note:

a drop of oil on the face of the disc will provide better

contact with the plate.

2. Set all griddle thermostats to 350°F. In order to allow the

griddle temperature to stabilize, the thermostats must be

allowed to cycle twice before taking a test reading.

3. Check the griddle temperature when the thermostat just

cycles “OFF” by placing the thermocouple rmly on the

griddle surface directly above the sensing bulb of the

thermostat. The reading should be between 335°F and

365°F. If the reading is outside of these limits, calibrate as

follows:

4. Carefully remove the dial, not disturbing the shaft

position.

5. Hold the shaft steady and with a small at screw driver

turn the calibration screw located inside the shaft

clockwise to decrease temperature or anti-clockwise to

increase temperature. Note: Each 1/4 turn of the screw

will create a change of approximately 25°F.

6. Replace the thermostat dial and repeat steps 1 through 3

to verify that a correct adjustment has been made.

For the griddle equipped with thermostats (GTHX) the pilot is

located to the left of the ON-OFF valve. Open the pilot valve

with a screwdriver and light the pilot with a match.

Pilots ames must be 3/4 inch (19mm) long .

Hi-Lo Valve Adjustment

Griddles equipped with Hi-Lo valves require a low ame

setting. To adjust, proceed as follows:

1. Burner must be cold.

2. Be sure pilot ames are lit and adjusted.

3. Turn dial to “LO” position, then remove dial.

4. With a screwdriver, turn the small adjusting screw inside

the valve stem and adjust to obtain the low cooking

temperature desired, maintaining a stable ame covering

the entire burner (minimum 3/16 inch (5 mm) long

ame)).

G20-SP and G20-SPH Stock Pot Range

Pilot Burner Adjustment

G20-SP Stock Pot Range

1. The pilot adjusting valve is located on the manifold.

2. With valve panel in place, the pilot can be adjusted with a

long thin screwdriver to obtain a 7/16 inch (11 mm) long

ame. (This adjustment can be made through the small

hole located on the valve panel.)

Part #4519655 (08/27/10)Page 8

Page 9

OPERATION continued

G20-SPH Stock Pot Range

This stock pot range is equipped with an automatic safety

pilot system. Should the pilot go out, the main burner gas

supply is automatically shut o . To light and adjust the pilot:

1. Remove the valve panel if not already removed.

2. Depress the red button of the automatic pilot valve and

light pilot.

3. Hold red button depressed for one minute after pilot has

been ignited.

4. Adjust pilot ame to a 7/16 inch (11 mm) long ame.

5. If pilot does not continue to burn after releasing button,

repeat above procedure or …

6. Have a quali ed serviceman check the system. Do not

allow anyone else to attempt repairs.

7. Once the pilot is lit it is not necessary to repeat lighting

procedure, unless the pilot is extinguished for any reason.

Hi-Med-Lo Valves

The G20-SP and G20-SPH stock pot ranges are equipped with

Hi-Med-Lo valves. No adjustment is necessary.

A pressure tap is supplied with the unit and it is installed

on the manifold, downstream of the main valve. The gas

pressure must be checked when the unit is installed, to

ensure that the unit gas pressure is the same as speci ed on

the rating plate. If necessary, pressure adjustments, must be

made at the pressure regulator.

Lighting Standing Pilots - All Models

These units are not designed to be disconnected from

their gas connections and re-installed on a regular basis.

Quick connect gas lines should not be used. Once the gas

appliance has been installed by a licensed gas trades-person

all connections, pilot lights and controls have been inspected

for proper operation. All gas appliances that use standing

pilot systems are generally assumed to be operating with

the pilot on continuously. The units should not be restarted

except in the event of a gas service interruption to the

facility.

If a pilot ame does go out, here are the basic steps to check

before you re-light the pilot:

1. Check to see that all gas lines are in place and secured

and that there is no accumulation of gas inside the unit.

2. Check to make sure that the main shut o valve is in the

o position.

3. Turn the thermostat to the o position. (If applicable)

4. Turn on or open the main shut o valve to the appliance.

5. Depending on the appliance type:

Lower the front black enamel panel to the unit and

immediately depress the red button, which is the

piezo to ignite the pilot.

Or.

Remove the front valve panel and light the pilot with

a lighted taper, through pilot viewing hole.

6. The pilot should ignite within a few attempts. You will be

able to see the pilot ame through the observation hole

in the stainless steel front panel.

7. If you do not have a pilot ame established fairly quickly

and begin to smell gas, shut o the main valve and wait

ve minutes to let the gas build-up escape.

8. Only once the pilot ame has been established should

you turn on the burner control. When the burner control

is on it allows gas ow to the burner. If there is no pilot

ame it will allow gas to build up and cause possible

delayed ignition, which could result in an explosion.

Part #4519655 (08/27/10) Page 9

Page 10

FLAME SIZE CHART – ALL MODELS

The correct air and/or gas adjustment has been made when a stable blue inner cone is obtained.

(Refer to chart for ame size.)

MODEL

OR

SERIES

G24 Series Griddle 3/4” (19 mm) 5/8” (16 mm)

G20-SP & G20-SPH Stock Pot Range 7/16” (11 mm) 3/8” (10 mm)

DESCRIPTION PILOT FLAME LENGTH

BURNER FLAME LENGTH - NORMAL

PRESSURE - VALVE OR THERMOSTAT

FULL OPEN

CLEANING AND MAINTENANCE

NOTE: Any maintenance or service involving disassembly of

components should be made by a quali ed service technician.

Also, ensure gas supply to the appliance is shut o .

You have purchased the nest commercial cooking

equipment available anywhere. Like any other ne precision

built piece of equipment, it should be given regular care and

maintenance.

Periodical inspections by your dealer or quali ed service

agency are recommended to check temperatures,

adjustments and ensure moving parts are operative.

Whenever possible, avoid overheating idle equipment as this

is the primary cause for increased service costs.

When corresponding with the factory or your equipment

dealer regarding service problems or replacement parts,

be sure to refer to the particular unit by the correct model

number (including pre x and su x letters and numbers) and

the serial or code number. The rating plate a xed to the unit

contains this information.

“Regular Maintenance Ensures Peak Performance.”

Exterior

Black baked enamel – Allow the equipment to cool after use

and was all grease deposits from the exterior with a hot mild

detergent or soap solution. Dry thoroughly. DO NOT USE

ABRASIVES.

Brushed chrome or brushed nickel – Wash when cool with a

hot mild detergent or soap solution. DO NOT USE ABRASIVES.

Stainless steel – Normal soil may be removed with a

detergent or soap solution applied with a cloth.

To remove grease that has baked on, apply cleanser to a

damp cloth or sponge. Rub the cleanser on the metal in the

direction of the polished lines of the metal. NEVER RUB IN

A CIRUCLAR MOTION. Soil and burnt deposits that do not

respond can usually be removed by rubbing the surface with

Scotch-Brite scouring pads or stainless scouring pads. DO

NOT USE ORDINARY STEEL WOOL.

Heat tint can be removed by a vigorous scouring in the

direction of the polish lines using Scotch-Brite scouring pads

or stainless scouring pad in combination with powdered

cleanser.

Part #4519655 (08/27/10)Page 10

Page 11

CLEANING AND MAINTENANCE continued

Top Sections

Griddle Top

Seasoning – Before being used for the rst time, all griddle

surfaces must be seasoned. Was the griddle with a hot

detergent or soap solution, rinse and dry thoroughly. Set

the Griddle heat to the lowest possible temperature for 30

minutes. Apply a thin lm of cooking oil. Allow the oil to

remain on the griddle for 5 minutes and then wipe o . Rest

the heat to medium temperature and apply a second lm

of oil. Wipe o excess after 5 minutes. Rest the heat to the

cooking temperature and apply a nal lm of oil, wiping

o excess after 3 minutes. The griddle is now seasoned and

ready for use. The griddle may be re-seasoned at any time by

cleaning thoroughly and following the seasoning procedure.

Cleaning. – Griddle plates should be wiped daily while still

warm. Remove carbonized grease or food with a spatula.

When necessary, clean the griddle surface thoroughly using

a ne griddle brick or a liquid griddle cleaner (available from

your kitchen equipment dealer.). Polish the griddle surface

to a bright nish. Wash the griddle surface, rinse and dry

thoroughly. Re-season the griddle.

Operating Suggestions

1. Avoid overheating the griddle as this causes sticking and

grease carbonization resulting in a hard to clean surface.

2. Do not hit spatula on griddle plate as this will nick the

surface

Open Top

Porcelain Tops & Grates – Top grates should be washed daily

with a hot detergent or soap solution and dried thoroughly.

Drop Pans – Should be emptied and washed daily

Operating Suggestions

1. Avoid the use of oversized pots.

2. Avoid spillovers

3. Covered pots will boil faster

Stock Pot Ranges

Cast Iron Top – When cast iron tops (which are covered in

grease) arrive at the end users, the following seasoning and

care is recommended.

1. Wash the top grates with hot mild detergent or soap

solution. Dry thoroughly, rub with vegetable oil on all

exposed surfaces in the direction of the grain.

2. Soiled and burnt deposits can be removed with a wire

brush. Di cult to remove burnt deposit can usually be

removed using an oven cleaner. Wash, dry thoroughly,

then rub with vegetable oil.

3. Continuing this procedure will prohibit the development

of rust and will eventually form a non-stick surface, with

the caramelization of oil on the cast iron top grates.

3. Clean the grease tray often to eliminate spillovers.

Part #4519655 (08/27/10) Page 11

Cleaning – Use a hot mild detergent or soap solution to

clean the exterior daily. Dry thoroughly.

Page 12

Page 13

Page 14

Part #4519655 (08/27/10) Page 11

savonnesue. Assécher complètement.

extérieure, utiliser un détergent doux et chaud ou solution

Nettoyage – Pour un nettoyage quotidien sur la surface

sur las surface de cuisson.

une surface antiadhésive, avec la caramélisation de l’huile

développement de la rouille et éventuellement donnera

3. Le prolongement de cette procédure empêchera le

complètement.

détergent chaud ou une solution savonneuse et asséchée

cuisson devrait être nettoyée quotidiennement avec un

Surface De Cuisson En Porcelaine - La surface de

Feux Overts

débordements

3 Nettoyez le tiroir à graisse a n d’éliminer les

et ensuite frotter avec de l’huile végétale.

d’un nettoyeur pour fours. Laver, assécher complètement

une brosse métallique. Les dépots brûlés di ciles à l’aide

2. Les dépots de saleté brûlée peuvent être enlevés avec

surface exposées, toujours dans le sens du grain.

complètement. Avec de l’huile végétale, frotter toutes les

doux et chaud ou une solution savoneuse. Assécher

1. Laver las surface de cuisson avec un détergent

recouverte de graisse et elle doit être nettoyée comme suite :

aux consommateurs avec la surface de coiccon en fonte

Surface De Cuisson En Fonte – Les appareils sont livres

Pot-Au-Feu

3. Des chaudrons couvents bouilleront plus rapidement.

2. Evitez les débordements.

1. Evitez l’usage de chaudrons demesurés.

Suggestions Au Mode D’emploi

quotidiennement.

Lèchefrites – Devraient être vidées et lavées

e riterait la surface.

2 Evitez de frapper las spatule sure las plaque, ce qui

surchau er la plaque à frire.

1. A n d’éviter las carbonisation des graisses, ne pas

Suggestions Au Mode D’Emploi

bien. Conditionnez à nouveau.

brillant. Lavez la surface de las plaque, rincez et asséchez

vendeur d’équipement de cuisine). Polir la surface à un ni

pierre ou un nettoyeur liquide spécial (disponible chez votre

Lorsque nécessaire bien nottoyer la surface en utilisant une

Enlevez les aliments et la graisse carbonisés avec une spatule.

quotidiennement pendant qu’elles sont encore chaudes.

Nettoyage – Les plaques à frire doivent être essuyées

à fond et en suivant les instructions précédentes.

être conditionnée à nouveau en aucun temps en la nettoyant

maintenant conditionnée et prête à être inutilisée. Elle peut

reposer 3 minutes et enlevez le surplus d’huile. La plaque est

cuisson et appliquez une dernière couche d’huile. Laizzez

d’huile. Réglez à nouveau la chaleur à la température de

d’huile. Laissez reposer 5 minutes et essuyez le surplus

température moyenne et appliquez une deuxième couche

ENTRETIEN ET NETTOYAGE suit

Page 15

Part #4519655 (08/27/10)Page 10

l’huile 5 minutes et essuyez. Réglez à nouveau à la

Appliquez une mince couche d’huile de cuisson. Laissez

de las plaque à frire 30 minutes à la plus basse température.

out un détergent, rincez et asséchez bien. Réglez la chaleur

plaque à frire en utilisant une solution chaude savonneuse

doivent être conditionnées avant d’ être utilisées. Lavez las

Conditionnement – Toutes les surfaces des plaques à frire

Plaques À Frire

Surfaces De Cuisson

aurez recours à un nettoyeur spécial.

ACIER. Si le procédé mentionne n’ est pas su sant, vous

du métal avec un tampon Scotch-Brite ou un tampon d’

en frottant vigoureusement dans la direction del las texture

Tourte décoloration causée par la chaleur peut être enlevée

NE PAS UTILISER DE LAINE D’ACIER ORDINAIRE.

Scotch-Brite ou des tampons à récurer pour acier inoxydable.

éliminés en frottant la surface avec des tampons à récurer

qui ne se détachent pas ainsi peuvent habituellement être

UN MOUVEMENT CIRCULAIRE. La saleté et les dépôts brûlés

couler le produit sur le métal. NE JAMAIS FROTTER AVEC

nettoyage sur un chi on humide ou une éponge et faire

Pour éliminer la graisse cuite, appliquer du produit de

appliquée avec un chi on.

éliminées avec une solution de détergent ou de savon

Acier inoxydable – Les salissures normales peuvent être

mentionné. NE PAS EMPLOYER D’ ABRASIFS.

Fini Chrome Ou Nickel – Même procédure que ci-haut

Essuyez bien. NE PAS EMPLOYER D’ ABRASIFS.

parois avec une solution savonneuse ou un détergent doux.

Émail Cuit Noir – Laissez refroidir l’appareil et nettoyez les

Extérieur

“Un entretien régulier assure des performances optimales.”

renseignements.

code. La plaque signalétique xée à l’appareil contient ces

chi res du pré xe et du su xe) et le numéro de série ou de

le numéro de modèle correct (comprenant les lettres et

pièces de rechange, bien faire référence à l’appareil avec

équipement concernant des problèmes de service ou des

Pour correspondre avec l’usine ou votre concessionnaire en

représente la principale cause de coûts d’entretien.

possible, éviter de surchau er l’équipement inutilisé, car cela

que les pièces mobiles fonctionnement correctement. Si

pour véri er les températures, les réglages et s’assurer

une agence d’entretien quali ée sont recommandées

Des inspections périodiques par le concessionnaire ou

régulière.

avec précision, il devra être nettoyé et entretenu de façon

cuisson au monde. Comme tout autre équipement fabriqué

Vous avez acheté le meilleur équipement commercial de

l’alimentation en gaz de l’appareil est coupée.

technicien d’entretien quali é. Véri er également que

démontage de composants devra être e ectué par un

NOTA : Tout entretien ou réparation impliquant le

THERMOSTAT OUVERT AU MAX.

NORMALE – ROBINET OU

DE BRÛLEUR – PRESSION

VEILLEUSEH

FLAMME DE

LONGUEUR DE FLAMME

LONGUEUR DE

DESCRIPTION

ENTRETIEN ET NETTOYAGE

G20-SP & G20-SPH Cuisinière à marmite 7/16 po (11 mm) 3/8 po (10 mm)

G24 Série Gril 3/4 po (19 mm) 5/8 po (16 mm)

SÉRIE

MODÈLE OU

(Se reporter au tableau pour la taille de amme.)

Le réglage d’air et/ou de gaz est correct quand on obtient un cône intérieur bleu stable..

TABLEAU DES TAILLES DE FLAMME – TOUS LES MODÈLES

Page 16

et un allumage retardé pourrait causer une explosion.

brûleur. Si la veilleuse n’est pas allumée, le gaz s’accumule

gril ou le thermostat est ouvert, le gaz peut atteindre le

robinet du gril ou le thermostat. Quand le robinet du

8. Une fois la amme de la veilleuse allumée, ouvrez le

accumulé se dissipe.

principal et attendez cinq minutes pour que le gaz

et que vous sentez une odeur de gaz, fermez le robinet

7. Si la amme de la veilleuse ne s’allume pas rapidement

Part #4519655 (08/27/10) Page 9

régulateur de pression.

nécessaire, les réglages de pression doivent être e ectués au

est identique à celle indiquée sur la plaque signalétique. Si

pour s’assurer que la pression d’alimentation de l’appareil

de véri er la pression du gaz quand l’appareil est installé,

sur le collecteur, en aval du robinet principal. Il est nécessaire

Une prise de pression est livrée avec l’appareil et est montée

nécessaire.

de robinets à trois réglages Hi-Med-Lo. Aucun réglage n’est

Les cuisinières à marmite G20-SP et G20-SPH sont dotées

d’observation de la veilleuse.

veilleuse avec une mèche allumée, à travers le trou

veilleuse.

correspondant à l’allumeur piézoélectrique de la

et appuyez immédiatement sur le bouton rouge,

d’observation dans le panneau avant en acier inoxydable.

Vous pourrez voir la amme de la veilleuse par le trou

6. La veilleuse devrait s’allumer au bout de quelques essais.

Retirez le panneau avant des robinets et allumez la

Ou

Abaissez le panneau avant émaillé noir de l’appareil

5. Selon le type d’appareil :

4. Ouvrez le robinet d’arrêt de l’appareil.

échéant).

3. Tournez le thermostat en position d’arrêt. (Le cas

fermée.

2. Véri ez que le robinet d’arrêt principal est en position

l’intérieur de l’appareil.

et bien xées et qu’il n’y a pas d’accumulation de gaz à

1. Véri ez que toutes les conduites de gaz sont en place

Robinets Hi-Med-Lo

est éteinte pour une raison quelconque.

recommencer la procédure d’allumage, sauf si la veilleuse

7. Une fois la veilleuse allumée, il n’est pas nécessaire de

réparations.

Ne laisser personne d’autre essayer d’e ectuer des

6. Demander à un technicien quali é de véri er le système.

recommencer la procédure ou.

5. Si la veilleuse s’éteint quand on relâche le bouton,

(11 mm).

4. Régler la amme de veilleuse à une longueur de 716 po

une fois la veilleuse allumée.

3. Maintenir enfoncé le bouton rouge pendant une minute

veilleuse et allumer la veilleuse.

2. Appuyer sur le bouton rouge du robinet automatique de

1. Retirer le panneau des robinets si cela n’est pas déjà fait.

automatiquement. Pour allumer et régler la veilleuse :

l’alimentation en gaz du brûleur principal est coupée

automatique de veilleuse de sécurité. Si la veilleuse s’éteint,

Cette cuisinière à marmite est dotée d’un système

veilleuse :

Si la veilleuse s’éteint, véri ez ce qui suit avant de rallumer la

rallumés, sauf en cas de coupure de gaz dans les installations.

les veilleuses allumées. Les appareils ne devraient pas être

veilleuses permanentes fonctionnant de façon continue avec

que tous les appareils à gaz qui utilisent des systèmes de

et commandes doit être véri é. On suppose généralement

le fonctionnement correct des branchements, veilleuses

l’appareil à gaz a été installé par un professionnel licencié,

devra pas utiliser de conduites à raccord rapide. Une fois que

conduite de gaz et être rebranchés de façon régulière. On ne

Ces appareils ne sont pas conçus pour être débranchés de la

Allumage Des Veilleuses Permanentes

Cuisinière à marmite G-SPH

des robinets.)

e ectuer ce réglage par le petit trou situé sur le panneau

amme d’une longueur de 7/16 po (11 mm). (On peut

la veilleuse avec un long tournevis n pour obtenir une

2. Le panneau des robinets en place, il est possible de régler

collecteur.

1. Le robinet de réglage de veilleuse est situé sur le

Cuisinière à marmite G20-SP

Réglage des veilleuses

Cuisinière À Marmite G20-SP et G20-SPH

UTILISATION suite

Page 17

Part #4519655 (08/27/10)Page 8

1. Le brûleur doit être froid.

suit :

amme basse. Pour e ectuer ce réglage, procéder comme

Les grils dotés de robinets Hi-Lo ont besoin d’un réglage de

étapes 1 à 3 pour véri er que le réglage est correct.

6. Remettre en place le cadran du thermostat et répéter les

la vis modi e la température d’environ 25°F.

augmenter la température. Nota : Chaque 1/4 de tour de

dans le sens contraire des aiguilles d’une montre pour

aiguilles d’une montre pour diminuer la température ou

la vis d’étalonnage à l’intérieur de l’axe dans le sens des

5. En immobilisant l’axe, tourner avec un petit tournevis plat

de l’axe.

4. Retirer soigneusement le cadran, sans modi er la position

étalonner de la façon suivante :

365°F. Si la température est à l’extérieur de ces limites,

devrait indiquer une température comprise entre 335 et

dessus du bulbe thermostatique. Le thermocouple

thermocouple sur la surface du gril, directement auvient juste de s’éteindre en appuyant fermement le

3. Véri er la température du gril quand le thermostat

extinction avec de prendre les mesures du test.

laisser les thermostats e ectuer deux cycles allumagepermettre à la température du gril de se stabiliser, on doit

2. Régler tous les thermostats du gril à 350°F. Pour

assurera un meilleur contact avec la plaque.

« surface ». Nota : une goutte d’huile sur la face du disque

spécial de type à disque ou un pyromètre able de type

1. Utiliser un instrument d’essai avec un thermocouple

Instructions d’étalonnage

Réglage Des Robinets Hi-Lo

3/4 po (19 mm).

Les ammes des veilleuses doivent avoir une longueur de

allumette.

veilleuse avec un tournevis et allumer la veilleuse avec une

située à gauche du robinet ON-OFF. Ouvrir le robinet de la

Pour le modèle doté de thermostats (GTHX), la veilleuse est

allumer la veilleuse avec une allumette.

de gril. Ouvrir le robinet de veilleuse avec un tournevis et

veilleuse est situé sur le collecteur à droite de chaque robinet

Pour le modèle avec robinets HI-LO, le robinet de réglage de

Chaque brûleur du gril est doté d’une veilleuse.

Allumage et réglage des veilleuses

Grils G24

« ON » le robinet de droite pour allumer le brûleur arrière.

pour allumer le brûleur avant. Tourner complètement sur

2. Tourner complètement sur « ON » le robinet de gauche

automatiquement à partir de la veilleuse.

1. Les brûleurs haute vitesse anticolmatage s’allument

Pour utiliser le brûleur principal

supérieure.

3. Remettre en place les grilles annulaires et la grille

« OFF ».

5. Remettre en place le cadran et le tourner en position

longueur minimale de 3/16 po (5 mm)).

amme stable couvrant tout le brûleur ( amme d’une

température basse de cuisson souhaitée, maintenant une

l’intérieur de la tige du robinet et régler pour obtenir la

4. Avec un tournevis, tourner la petite vis de réglage à

3. Tourner le cadran en position « LO » et retirer le cadran.

2. S’assurer que les veilleuses sont allumées et réglées.

supérieur avant, autour du robinet de brûleur arrière.)

peut être e ectué à travers l’ouverture du panneau

jaune d’une longueur de 1/2 pouce (13 mm). (Ce réglage

les deux robinets de brûleurs, pour obtenir une amme

2. Régler le robinet de veilleuse, situé sur le collecteur entre

n’a pas encore été fait.

1. Retirer les grilles annulaires et la grille supérieure, si cela

Réglage des veilleuses

Plaque Chau ante – Modèle G24-15H

UTILISATION

Page 18

Part #4519655 (08/27/10) Page 7

vis Parker.

socle, puis dans les trous où se trouvaient auparavant les

Parker dans les trous de diamètre 9/32 po (7 mm) dans le

avec les vis Parker retirées au paragraphe 3. Insérer les vis

6. Fixer le dernier appareil sur le socle de plan de travail

section Installation des plaques d’union Série G24.

5. Connecter les plaques d’union comme décrit dans la

vis Parker.

socle, puis dans les trous où se trouvaient auparavant les

Parker dans les trous de diamètre 9/32 po (7 mm) dans le

vis Parker retirées au paragraphe 3 et en insérant les vis

de plan de travail, en xant le premier appareil avec les

4. Placer les appareils dans la position souhaitée sur le socle

extérieurs du socle.

dans le fond principal des appareils à placer sur les côtés

3. Retirer seulement les vis Parker latérales, avant et arrière

devant être installés sur un socle de plan de travail.

2. Retirer et jeter les boulons de mise à niveau des appareils

carton du socle.

comme indiqué dans les instructions se trouvant dans le

1. Assembler et mettre de niveau le socle de plan de travail

Socles série CS24

De Plan De Travail

Installation De L’équipement Sur Les Socles

présence de fuites.

installé sur chaque conduite d’alimentation. Véri er la

facilement accessible et de type homologué devrait être

au choix l’entrée arrière ou avant. Un robinet manuel

5. Brancher la canalisation d’alimentation en gaz en utilisant

chaque appareil à l’appareil voisin.

appareils, par rapport au premier appareil, en xant

bords de droite et de gauche. Mettre de niveau les autres

en travers à l’avant et à l’arrière et verticalement sur les

et mettre l’appareil de niveau dans quatre directions :

de mise à niveau ou les pieds. Utiliser un niveau à bulle

1. Mettre chaque appareil de niveau en ajustant les boulons

pieds.

jeter les boulons de mise à niveau et les remplacer par les

appareil. Si les pieds de 2 po (51 mm) sont livrés avec l’unité,

appareils, une plaque d’union avant est fournie avec chaque

Pour assurer une adaptation parfaite et permanente entre les

ou en série avec d’autres équipements de séries G24 ou E24.

Toutes les unités peuvent être installées indépendamment

Série G24

Installation Des Plaques D’union

DES PIEDS

INSTALLATION

(QTÉ 4)

4 PO (102mm)

PIED RÉGLABLEDE

(QTÉ 2)

PROFILÉ DES PIEDS

DESSOUS DE L’UNITÉ

4. Remettre en place et xer les panneaux supérieurs avant.

écrous hexagonaux fournis.

appareils montés en rangée. Fixer en place avec les deux

la plaque d’union serrée contre les côtés principaux des

NOTA : Monter la partie centrale encastrée (étagée) de

montage du panneau.

situés sur les deux côtés principaux, sous les supports de

3. Mettre en place la plaque d’union sur les deux boulons

panneau.

déposé) en retirant les vis à ailettes de chaque côté du

2. Déposer le panneau avant supérieur (s’il n’a pas été déjà

pro lé doit être installé quand on utilise les pieds.

Le pro lé des pieds est placé sous la base de l’ensemble. Ce

Série G24

les appareils ne sont pas de niveau.

NOTA : Les grils peuvent ne pas reposer correctement, si

Installation Des Pieds

INSTALLATION suite

Page 19

Part #4519655 (08/27/10)Page 6

1 po NPT

3/4 po NPT.

D’ENTRÉE

COLLECTEUR

DIMENSION DU

(3,45 kPa).

2

G20-SP & G20-5PH 3/4 po NPT

G24-72G & G24-72GTHX

G24-60G, G24-60GTHX,

G24-48G, G24-48GTHX,

G24-36G & G24-36GTHX

G24-24G, G-24GTHX,

G24-15H 3/4 po NPT

NUMÉRO DE MODÈLE

l’alimentation principale en gaz est la suivante :

La dimension du collecteur d’entrée pour le branchement à

Dimension Du Collecteur D’entrée

d’essai supérieures ou égales à 1/2 lb/po

pression du système d’alimentation en gaz à des pressions

en fermant son robinet d’arrêt individuel lors de tout essai de

Cet appareil doit être isolé du système d’alimentation en gaz

signalétique.

le propane, sauf indication contraire sur la plaque

avec le gaz naturel et de 11 po de colonne d’eau pour

fonctionnement normal est de 7 po de colonne d’eau

2. La pression de gaz requise dans le collecteur pour une

nécessaire d’utiliser ce type de gaz.

fabriqué est noté sur la plaque signalétique et il est

1. Le type correct de gaz pour lequel l’appareil a été

technicien quali é spécialiste des appareils à gaz.

Tous les réglages des brûleurs doivent être faits par un

codes locaux le cas échéant.

conformes aux codes d’installation CAN/CGA – B149 et aux

Au Canada, l’installation et le branchement doivent être

e cace.

code local pour assurer un fonctionnement sécuritaire et

National Fuel Gas code ANSI Z 223.1-1988/NFPA et/ou au

du fabricant. De plus, il est nécessaire de se conformer au

partie, de la conformité de l’installation aux spéci cations

fonctionnement correct de l’équipement dépend, en grande

correcte d’un équipement commercial de cuisson à gaz. Le

On n’insistera jamais assez sur l’importance d’une installation

(3,45 kPa).

2

dépassant 1/2 lb/po

de tout essai de pression de ce système à des pressions

être débranchés du système d’alimentation en gaz lors

Cet appareil et son robinet d’arrêt du gaz individuel doivent

similaires. NE PAS VÉRIFIER AVEC UNE FLAMME NUE..

raccords avec une solution savonneuse ou des méthodes

5. AVERTISSEMENT : Véri er les fuites de gaz sur les

pétrole liqué é.

homologué par la CGA pour une utilisation avec le gaz de

commandes. Utiliser du produit d’étanchéité pour joint

ne bouchent pas les robinets des veilleuses et/ou les

de façon à ce que la graisse à letage, les copeaux, etc.

neufs ont été exécutés proprement et ont été purgés

4. S’assurer que les tuyauteries, joints et branchements

conduite de gaz est en position de fonctionnement.

pression, s’assurer que tout l’équipement branché sur la

dépassant pas ½ po de colonne d’eau. Pour véri er la

l’appareil a besoin avec une chute de pression ne

(compteur, tuyauteries, etc.) fourniront les BTU dont

a n de s’assurer que les installations de gaz existantes

3. Faire véri er la pression du gaz par un technicien quali é

(51 mm)

De 2 Po

Avec Pieds

Ou

Non

OU BASE

TYPE DE

Combustible

Combustible

Combustible

PLANCHER

(152 mm)

6 po

(152 mm)

6 po

(152 mm)

6 po

(152 mm)

6 po

(152 mm)

6 po

ARRIÈRE

CÔTÉ ET

G20-SPH

G20-SP

(Thermostat)

G24 Series

(HI-LO)

G24 Series

G24-15H

OU SÉRIE

MODÈLE

Connexions Du Gaz

marmite

Cuisinière à

marmite

Cuisinière à

Gril

Gril

chau ante

Plaque

DESCRIPTION

Type De Plancher Ou Base

Rapport Aux Murs Combustibles Adjacents Et

Dégagements Minimum D’installation Par

Dégagements

INSTALLATION suite

Page 20

Part #4519655 (08/27/10) Page 5

bulbe à la plaque de gril.

les quatre écrous Pal xant l’ensemble de protection du

que le bulbe soit placé à l’intérieur de la rainure. Serrer

un contrôle précis de la température, il est important

avec la béquille de gril situé sous la plaque de gril. Pour

est nécessaire de soulever l’avant du gril et de le soutenir

plaque et l’ensemble de protection du bulbe. Pour cela, il

thermostatique doit être inséré dans la rainure entre la

des appareils dotés de thermostats de gril, le bulbe

5. Quand une plaque de gril doit être installée sur

retirer le bulbe.

protection du bulbe thermostatique à la plaque du gril et

gril. Desserrer les quatre écrous Pal xant l’ensemble de

soutenir avec la béquille de gril situé sous la plaque de

cela, il est nécessaire de soulever l’avant du gril et de le

situé à la partie inférieure de la plaque de gril. Pour

être démontés de l’ensemble de protection du bulbe,

le tube capillaire du thermostat de gril doivent d’abord

les appareils dotés d’un thermostat de gril, le bulbe et

4. S’il est nécessaire de retirer la plaque de gril en acier sur

pour qu’ils ne soient pas endommagés.

ou le bassin de friture et les ranger dans un endroit sûr

3. Retirer les panneaux des robinets, les grilles supérieures

l’installation des appareils.

l’acier inoxydable doit être retiré immédiatement après

inoxydable et brossé, le matériau de protection couvrant

et le matériel d’emballage. Sur les appareils en acier

caisse. Retirer de l’appareil les ls d’attache des brûleurs

2. Retirer avec précaution l’appareil du carton ou de la

immédiatement tout dommage au transporteur.

véri er la présence de dommages « cachés ». Signaler

pendant l’expédition. Après un déballage soigneux,

caisse pour déceler d’éventuels dommages subis

1. Véri cation des dommages : véri er le carton ou la

Informations Générales

commerciales.

de n’importe quelle sorte pour des applications autres que

de services de réparation, garantie, entretien ou soutien

commerciales seulement. Garland / U.S. Range n’o re pas

ou résidentielle, mais sont destinés à des applications

pas agréés ni autorisés pour une utilisation personnelle

tel que spéci é. Les produits Garland/U.S. Range ne sont

Ce produit doit être installé par du personnel professionnel

communiquer avec le département de service des produits.

l’entretien ou la réparation du produit, écrire ou

En cas de questions concernant l’installation, l’utilisation,

dans la manuel d’informations.

réparations par une agence de service agrée locale gurant

Nous suggérons de faire faire l’installation, l’entretien et les

INSTALLATION

G24 ou le panneau des robinets sur la série G20.

inférieur avant sur la série G22, le bac récepteur sur la série

On peut voir la plaque signalétique en retirant le panneau

signalétique xée à l’appareil contient ces informations.

et du su xe) et le numéro de série de garantie. La plaque

modèle correct (comprenant les lettres et chi res du pré xe

rechange, bien faire référence à l’appareil avec le numéro de

local concernant des problèmes de service ou des pièces de

Pour correspondre avec l’usine ou le centre de service agréé

Plaque Signalétique

INTRODUCTION

Page 21

Part #4519655 (08/27/10)Page 4

professionnelle.

• Ces appareils sont destinés à une utilisation commerciale par du personnel ayant acquis une formation

• Garland se réserve le droit de modi er ou d’améliorer nos spéci cations sans préavis.

ces codes.

NOTA : • Il existe de nombreux codes locaux, et il est de la responsabilité du propriétaire et de l’installateur de respecter

mm), 48 po (1 219 mm), 60po (1 524 mm) et 72 po (1 829 mm). Exemple pour le gril G24-36G. Spéci er socle CS24-36

1/2 po (902 mm). Socles disponibles dans les largeurs suivantes : 15 po (381 mm), 24 po (610 mm), 30 po (762 mm), 36 po (914

de rangement fournie avec supports jusqu’à 36 po (1 914 mm) de large. Hauteur de travail de tous les appareils sur socles : 35

Socles de plancher : Socles robustes de conception ouverte avec pieds en tubes carrés soudés sans joints. Fini noir. Étagère

Socles en option série CS24

d’installation du produit en si elle est supérieure à 2 000 pieds (610 m).

de la mer. Les débits calori ques en BTU doivent être réduit en cas d’installation dans des altitudes élevées. Spéci er l’altitude

Les débits calori ques s’appliquent à des installations de gaz naturel inférieures à 2000 pi (610 m) d’altitude au-dessus du niveau

Nota : Utilisation avec du gaz naturel et du GPL seulement

(17,5 mbars)

7 po CE

Gaz Naturel Propane Gaz Naturel Propane

Approvisionnement

Pression De Fonctionnement du

Base

Incombustible

lorsque les codes locaux les autorisent.

d’installation ne sont applicables que

NOTA : Les réductions de dégagement

6(152) 6(152)

(4 mbars)

10 po CE

Côtés Arrière

Aux Murs Combustibles : Po (mm)

Dégagements Par Rapport

(10 mbars)

4 po CE

(27,5 mbars)

11 po CE

Collecteur

Pression De Fonctionnement du

Pression De Gaz Requise

Notes d’installation

Sans Objet

100 500 80 1600 80 400

83 415 67 1340 67 335

67 335 53 1060 53 265

50 250 40 800 40 200

33 165 27 540 27 135

Par Heure

Charge

Par

350° F (177° C)

4oz(112g)

Par Heure

Bifteck Minute

Charge

Par

Dia 4 po (102 mm)

Crêpes

300°f(149°C)

Œufs Poêlés

Par Heure

Charge

Par

350° F (177°C)

3 Oz. (85 g)

Hachée

Galettes De Viande

60,000

60,000

BTU/H

Robinet

1 In nie

6 Robinet Hi-lo 200,000

5 Robinet Hi-lo 166,500

4 Robinet Hi-lo 133,000

3 Robinet Hi-lo 100,000

2 Thermostats

2 Robinet Hi-lo 66,500

Marmite

Large Cuisinière À

20 Po (508mm) De

(1829 mm)

Gril 72 po

(1524 mm)

Gril 60 po

(1219 mm)

Gril 48 po

(914 mm)

Gril 36 po

(610 mm)

Gril 24 po

G20-SP/SPH

G24-15H Plaque chau ante 2 Robinets 29,000

G24-72GTHX 6 Thermostats 180,000

G24-72G

G24-60GTHX 5 Thermostats 150,000

G24-60G

G24-48GTHX 4 Thermostats 120,000

G24-18G

G24-36GTHX 3 Thermostats 90,000

G24-36G

G24-24GTHX

G24-24G

Modèle Description Commandes

Tableau D’entrée Gaz Naturel & Propane Capacités De Production Du Gril

Données techniques des unités de plan de travail à gaz série G24

SPÉCIFICATIONS, GRILS SÉRIE G24

Page 22

Part #4519655 (08/27/10) Page 3

Pot-Au-Feu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Feux Overts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Plaques À Frire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Surfaces De Cuisson . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Extérieur . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

ENTRETIEN ET NETTOYAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

TABLEAU DES TAILLES DE FLAMME – TOUS LES MODÈLES . . . . . . . . . . . . 10

Allumage Des Veilleuses Permanentes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Cuisinière À Marmite G20-SP et G20-SPH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Grils G24 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Plaque Chau ante – Modèle G24-15H . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

UTILISATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Installation De L’équipement Sur Les Socles De Plan De Travail . . . . . . . . . . . . . . . . . . . . .7

Installation Des Plaques D’union . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Installation Des Pieds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Dimension Du Collecteur D’entrée . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Connexions Du Gaz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Dégagements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Informations Générales . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

INSTALLATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Plaque Signalétique . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Notes d’installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

SPÉCIFICATIONS, GRILS SÉRIE G24 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

INFORMATIONS IMPORTANTES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

TABLE DES MATIÈRES

Page 23

Part #4519655 (08/27/10)Page 2

AVERTISSEMENT

dégagés et ne pas y stocker de produits combustibles

Maintenir les abords de l’appareil

d’autres problèmes reproductifs.

est reconnue par l’état de Californie comme pouvant causer des malformations congénitales ou

exposer au monoxyde de carbone en cas de mauvais réglage. L’inhalation de monoxyde de carbone

est reconnue par l’état de Californie comme causant le cancer. L’utilisation de ce produit peut vous

verre/fibres céramiques. L’inhalation de ces particules de laine de verre ou de fibres céramiques

L’installation et l’entretien de ce produit peut vous exposer aux poussières de laine de

le cancer et/ou des malformations congénitales ou d’autres problèmes de reproduction.

Ce produit contient des produits chimiques reconnus par l’état de Californie comme causant

INFORMATIONS IMPORTANTES

Page 24

Part #4519655 (08/27/10) Page 1

Pièce nº 4519655 (08/27/10)

Télécopieur : 905-624-5669

Téléphone : 905-624-0260

CANADA

1177 Kamato Road, Mississauga, Ontario L4W 1X4

GARLAND COMMERCIAL RANGES, LTD.

conception et les spéci cations des pièces) peuvent être remplacés ou modi és sans préavis.

de Garland à : http://www.garland-group.com. Les renseignements contenus dans le présent document (y compris la

ou par des agents d’entretien non autorisés. Pour obtenir la liste des agents de service autorisés, consulter le site web

numéro de série aurait été mutilé, oblitéré ou supprimé ou qui aurait été modi é ou réparé avec des pièces non autorisées

codes nationaux et locaux ou aux instructions d’installation fournies avec le produit ou n’importe quel produit dont le

en ce qui concerne n’importe quel produit mal installé, réglé, utilisé ou qui n’aurait pas été entretenu conformément aux

d’entretien autorisé par Garland utilisant des pièces de rechange d’origine Garland. Garland n’aura aucune obligation

L’attention des utilisateurs est attirée sur le fait que l’entretien et les réparations doivent être e ectués par un agent

.

être obtenue auprès du fournisseur de gaz local

détectée par l’utilisateur. Cette information peut

instructions à suivre en cas d’odeur de gaz

Placer dans un endroit bien en vue les

Pour votre sécurité

D’AUTORISATION : G-1-07-05-28

MONTEUR D’INSTALLATION AU GAZ. NUMÉRO

DOIT ÊTRE INSTALLÉ PAR UN PLOMBIER OU UN

DANS L’ÉTAT DU MASSACHUSETTS, CE PRODUIT

PROFESSIONNEL TEL QUE SPÉCIFIÉ.

ET DOIT ÊTRE INSTALLÉ PAR DU PERSONNEL

QU’ÉQUIPEMENT PROFESSIONNEL DE CUISSON

CE PRODUIT A ÉTÉ HOMOLOGUÉ EN TANT

ULTÉRIEUREMENT.

MANUEL ET LE CONSERVER POUR S’Y REPORTER

LIRE TOUTES LES SECTIONS DU PRÉSENT

L’ÉQUIPEMENT.

D’UTILISATION ET D’ENTRETIEN

AVERTISSEMENT

POUR VOTRE SÉCURIT:

AVANT D’INSTALLER OU DE RÉPARER

MENT LES INSTRUCTIONS D’INSTALLATION,

SURES OU LA MORT. LIRE SOIGNEUSE-

DES DOMMAGES MATÉRIELS, DES BLES-

ENTRETIEN MAL FAITS PEUVENT CAUSER

MODIFICATIONS, DES RÉPARATIONS OU UN

UNE INSTALLATION, DES RÉGLAGES, DES

APPAREIL OU DE TOUT AUTRE APPAREIL

INFLAMMABLES À PROXIMITÉ DE CET

OU D’AUTRES VAPEURS OU LIQUIDES

NE PAS STOCKER NI UTILISER D’ESSENCE

CUISINIÈRES À MARMITE SÉRIE G20

ÉQUIPEMENT DE COMPTOIR À GAZ SÉRIE G24 ET

D’UTILISATION

INSTRUCTIONS D’INSTALLATION ET

Loading...

Loading...