Page 1

INSTALLATION OPERATION

AND SERVICE MANUAL

G2000 SERIES GAS BAKE AND

ROAST DECK OVENS

FOR YOUR SAFETY:

DO NOT STORE OR USE GASOLINE

OR OTHER FLAMMABLE VAPORS OR

LIQUIDS IN THE VICINITY OF

THIS OR ANY OTHER

APPLIANCE

WARNING:

IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE

CAN CAUSE PROPERTY DAMAGE, INJURY,

OR DEATH. READ THE INSTALLATION,

OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR

SERVICING THIS EQUIPMENT

AND RETAIN FOR FUTURE REFERENCE.

THIS PRODUCT HAS BEEN CERTIFIED AS

COMMERCIAL COOKING EQUIPMENT AND

MUST BE INSTALLED BY PROFESSIONAL

PERSONNEL AS SPECIFIED.

IN THE COMMONWEALTH OF MASSACHUSETTS

THIS PRODUCT MUST BE INSTALLED BY A

LICENSED PLUMBER OR GAS FITTER. APPROVAL

NUMBER: G-1-07-05-28

For Your Safety:

Post in a prominent location, instructions to be

followed in the event the user smells gas. This

information shall be obtained by consulting

your local gas supplier.

Users are cautioned that maintenance and repairs must be performed by a Garland authorized service agent

using genuine Garland replacement parts. Garland will have no obligation with respect to any product that has been

improperly installed, adjusted, operated or not maintained in accordance with national and local codes or installation

instructions provided with the product, or any product that has its serial number defaced, obliterated or removed,

or which has been modified or repaired using unauthorized parts or by unauthorized service agents.

For a list of authorized service agents, please refer to the Garland web site at http://www.garland-group.com.

The information contained herein, (including design and parts specifications), may be superseded and is subject

to change without notice.

PLEASE READ ALL SECTIONS OF THIS MANUAL

GARLAND COMMERCIAL INDUSTRIES

185 East South Street

Freeland, Pennsylvania 18224

Phone: (570) 636-1000

Fax: (570) 636-3903

Part # P125 Rev 1 (05/20/08) © 2005 Garland Commercial Industries, Inc.

Part # P125 Rev 1 (05/20/08) Page 1

GARLAND COMMERCIAL RANGES, LTD.

1177 Kamato Road, Mississauga, Ontario L4W 1X4

CANADA

Phone: 905-624-0260

Fax: 905-624-5669

Enodis UK LTD.

Swallow eld Way, Hayes, Middlesex UB3 1DQ ENGLAND

Telephone: 081-561-0433

Fax: 081-848-0041

Page 2

IMPORTANT INFORMATION

WARNING:

This product contains chemicals known to the state of california to cause cancer and/or birth defects

or other reproductive harm. Installation and servicing of this product could expose you to airborne

particles of glass wool/ceramic fibers. Inhalation of airborne particles of glass wool/ceramic fibers

is known to the state of california to cause cancer. Operation of this product could expose you to

carbon monoxide if not adjusted properly. Inhalation of carbon monoxide is known to the state of

california to cause birth defects or other reproductive harm.

Keep appliance area free and clear of combustibles.

Part # P125 Rev 1 (05/20/08)Page 2

Page 3

TABLE OF CONTENTS

Important Information . . . . . . . . . . . . . . . . . 2

Dimensions And Specications,

G2000 Series . . . . . . . . . . . . . . . . . . . . . . . . . . 4

OVEN SPECIFICATIONS . . . . . . . . . . . . . . . . . 5

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . 5

Garland Variety Ovens . . . . . . . . . . . . . . . . . . . . . . . 5

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . 6

Pre-Installation Instructions . . . . . . . . . . . . . . . . . . 6

Rating Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Location of the Oven . . . . . . . . . . . . . . . . . . . . . . . . . 6

Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Legs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Assembly of Two-Section Oven . . . . . . . . . . . . . . . 7

Installation of Oven Vent . . . . . . . . . . . . . . . . . . . . . 7

Top Trim Installation . . . . . . . . . . . . . . . . . . . . . . . . . 8

Ovens with Optional Light Feature . . . . . . . . . . . . 8

Gas Connection-Single & Multiple Ovens . . . . . . 8

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Burn O – Deck Curing . . . . . . . . . . . . . . . . . . . . . . 10

User Guide – Timetable for Roasting . . . . . . . . . 11

User Guide – Timetable for Baking . . . . . . . . . . . 13

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . .14

Painted Finishes . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Stainless Steel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Oven Interior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Cleaning of Oven Hearth . . . . . . . . . . . . . . . . . . . .14

Adjustments. . . . . . . . . . . . . . . . . . . . . . . . . . 15

Oven Door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Thermocouple Replacement . . . . . . . . . . . . . . . . 15

Magnet Assembly & Thermocouple Test . . . . . 15

Oven Burners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Thermostat Operation . . . . . . . . . . . . . . . . . . . . . . 16

Instructions for FDO Heavy Duty Control . . . . . 17

By-Pass Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . 17

Recalibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Installation Of Oven Heat Deectors,

Corderite/Steel Hearths &

Inner Oven Linings . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Ventilation and Air Supply . . . . . . . . . . . . . . . . . . . . 9

Installation of a Direct Flue . . . . . . . . . . . . . . . . . . . 9

Part # P125 Rev 1 (05/20/08) Page 3

Page 4

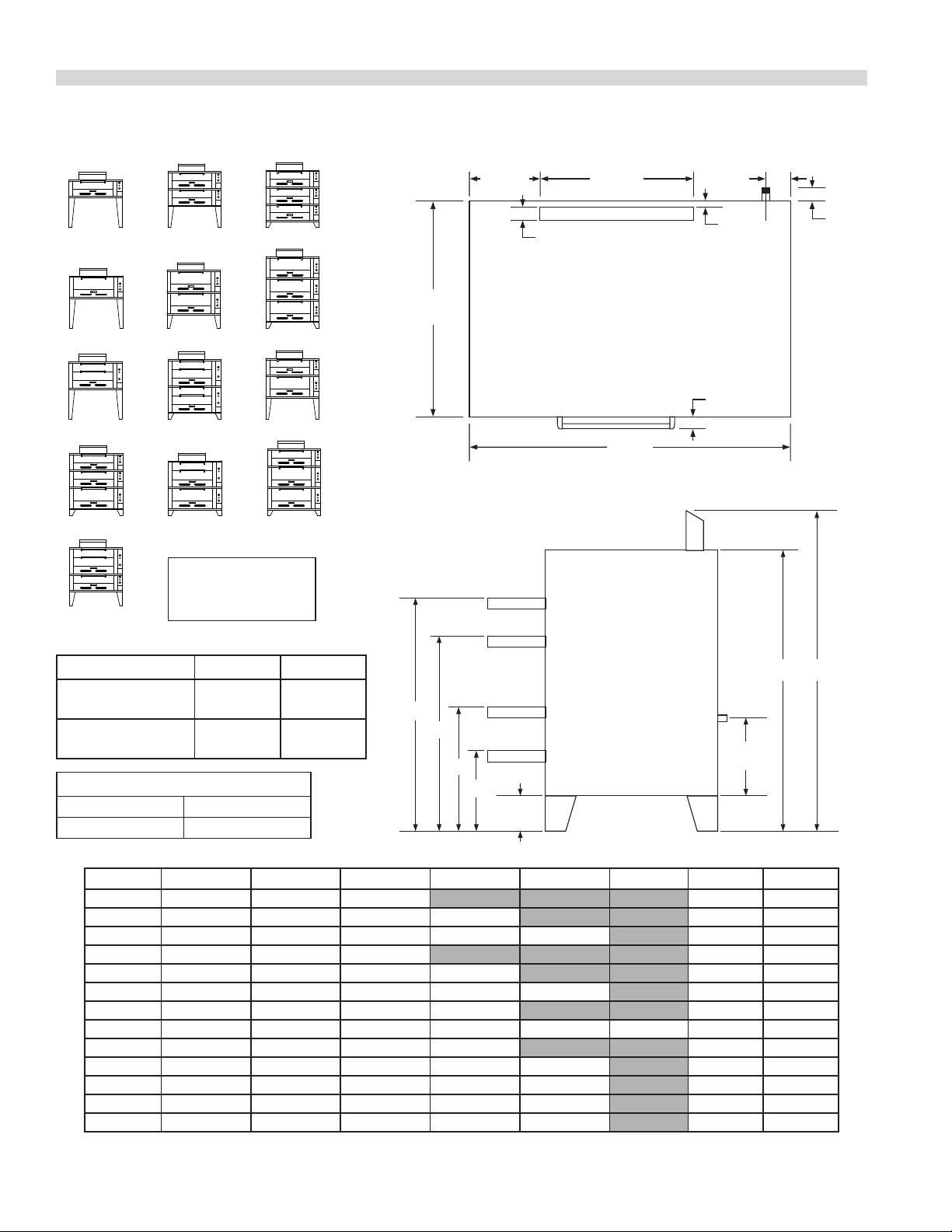

DIMENSIONS AND SPECIFICATIONS, G2000 SERIES

17"

(432mm)

G

C

D

E

F

B

A

3/4" NPT

GAS INLET

55-1/4"

(1416mm)

10-5/8"

(280mm)

2"

(51mm)

1"

(25mm)

2-1/4"

(57mm)

3"

(76mm)

27-7/8"

(708mm)

2"

(51mm)

38-1/4"

(972mm)

G2121-71

G2073

7B

7B

7B

12R

7B

G2121-771

G2071

7B

12R

12R

T7B

T7B

12R

G2122

G2771

G2072

7B

7B

12R

12R

T7B

7B

7B

T7B

T7B

12R

12R

12R

G2123

G2122-71

G2772

G2071-771

G2121-72

G2121

12R

7B

7B

12R

7B = 7" Bake

T7B = Twin 7" Bake

12R = 12" Roast

All Models Natural Propane

Manifold

Operating Pressure

Minimum

Supply Pressure

Clearances To Combustible Wall

Sides Back

1” (25mm) 6” (152mm)

MODEL A B C D E F G Total BTU

G2071

G2072

G2073

G2121

G2122

G2123

G2771

G2772

G2121-71

G2121-72

G2121-771

G2122-71

G2071-771

5.5" WC

(13.7 Mbar)

7.,0" WC

(17.4 Mbar)

50" (1270mm) 58" (1473mm) 401⁄2" (1664mm) 31" (787mm) 40,000

581⁄2" (1270mm) 661⁄2" (1689mm) 311⁄2" (800mm) 49" (1283mm) 22" (559mm) 80,000

60" (1524mm) 68" (1727mm) 151⁄2" (394mm) 33" (838mm) 501⁄2" (1283mm) 6" (152mm) 120,000

55" (1397mm) 63" (1600mm) 401⁄2" (1664mm) 31" (787mm) 40,000

601⁄2" (1537mm) 681⁄2" (1740mm) 231⁄2" (597mm) 46" (1168mm) 14" (356mm) 80,000

75" (1905mm) 83" (2018mm) 151⁄2" (394mm) 38" (965mm) 601⁄2" (1537mm) 6" (152mm) 120,000

60" (1524mm) 68" (1727mm) 401⁄2" (1664mm) 501⁄2" (1283mm) 31" (787mm) 50,000

621⁄2" (1587mm) 701⁄2" (1791mm) 151⁄2" (394mm) 251⁄2" (648mm) 43" (1092mm) 53" (1346mm) 6" (152mm) 100,000

631⁄2" (1613mm) 711⁄2" (1816mm) 311⁄2" (800mm) 54" (1372mm) 22" (559mm) 80,000

65" (1651mm) 73" (1854mm) 151⁄2" (394mm) 38" (965mm) 551⁄2" (1410mm) 6" (152mm) 120,000

571⁄2" (1460mm) 651⁄2" (1664mm) 151⁄2" (394mm) 38" (965mm) 48" (1219mm) 6" (152mm) 90,000

70" (1778mm) 78" (1981mm) 151⁄2" (394mm) 38" (965mm) 601⁄2" (1537mm) 6" (152mm) 120,000

601⁄2" (1537mm) 681⁄2" (1664mm) 231⁄2" (597mm) 41" (1041mm) 51" (1295mm) 14" (356mm)

10.0" WC

(24.9 Mbar

11.0" WC

(27.4 Mbar)

Part # P125 Rev 1 (05/20/08)Page 4

90,000

Page 5

OVEN SPECIFICATIONS

General

Construction:

Ovens are of the sectional type with each section operating

independently. Sectional type with each section operating

independently. Sectional design makes it easy to add

additional sections as required. Heavy duty modular

construction minimizes the use of hard to clean screws and

bolts on the exterior of the oven. Cleaning is easier and more

complete. Sections are supported on heavy steel legs, which

are easily changed as sections are added. Oven legs are

standard equipment.

Bake Section:

Bake section interior is 42” x 32” x 7” each section. The ¾”

corderite deck is provided as standard equipment. A 12

gauge steel hearth may be substituted if specied before

placing order.

General Purpose Section:

Two compartments 42” x 32” x 7” each section. Each provided

with its own deck and door. Standard deck is ¾” thick

corderite. A 12 gauge hearth may be substituted if specied

before placing order.

Roast Sections:

The 12” roast interior is 42” x 32” x 12”. Interior of the 16”

sections is 42” x 32” x 16”. A 12 gauge steel hearth is provided

as standard for both 12” gauge steel hearth is provided as

standard for both 12” and 16” sections. A corderite deck is

available as an optional extra.

Burners:

Each oven is heated by two “U” shaped lance ported burners

ring directly on heavy steel tread plate between the burners

and the deck. In each oven section, a heavy duty throttling/

snap action gas thermostat controls burners to provide a

150º to 500º Fahrenheit temperature range aording low

temperature holding feature. Each section is further provide

with an independent ON/OFF gas valve and 100% safety

pilot system.

Venting:

Flue deector is provided to meet ventilation system

requirements. Internal ues connect for stacking.

Oven Door:

Oven door is engineered with precise balance and

exceptional durability. Door opens to full width of oven

cavity and to exact level of horizontal oven deck for

unobstructed loading. Door will support tin excess of 250

pounds of load.

INTRODUCTION

Garland Variety Ovens

The dependable line of Garland Variety Heavy Duty Bake and

Roast Ovens are designed for use where quality foods are

prepared in mass quantity. These ovens are ideal for hotels,

hospital, schools, larger cafeterias, dining rooms and all other

high production operations.

Basic Variety Oven sections are designed for stacking to

provide an innite choice of bake and roast combinations.

Independently operated oven sections with separate

controls, aord the advantage of cooking a variety of

products at dierence temperatures at the same time.

Part # P125 Rev 1 (05/20/08) Page 5

GARLAND’S new Variety Oven line was designed to give

years of dependable service. Engineering excellence assures

customers of quality construction and products that perform

well. This addition to the GARLAND family of commercial

cooking products is testimony to the dedicated eorts of

our employees, who have pride in their workmanship and

therefore, build better products that reect this spirit.

Page 6

INTRODUCTION Continued

Rating Plate

When corresponding with the factory or your local

authorized factory service center regarding service problems

or replacement parts, be sure to refer to the particular unit

by the correct model number (including the prex and sux

letters and numbers) and the warranty serial number. The

rating plate axed to the unit contains this information.

We suggest installation, maintenance and repairs should be

performed by your local authorized service agency listed in

your information manual pamphlet.

In the event you have any questions concerning the

installation, use, care or service of the product, write or call

our Product Service Department.

This product must be installed by professional personnel as

specied. Garland/U.S. Range products are not approved or

authorized for home or residential use, but are intended for

commercial applications only. Garland / U.S. Range will not

provide service, warranty, maintenance or support of any

kind other than in commercial applications.

Location of the Oven

Appliances shall be installed in a location in which the

facilities for ventilation permit satisfactory combustion of gas

and proper venting. Appliances shall be located so as not to

interfere with proper circulation of air within the conned

space. When buildings are so tight that normal inltration

does not provide the necessary air, outside air shall be

introduced.

Clearances

NOTE: Unit must be installed with no less than

6 inches (152mm) clearance from combustible construction

at both sides and rear. Installation to non-combustible

construction is (0”) clearance at both sides and rear. The unit

suitable for installation on combustible oors.

INSTALLATION

Pre-Installation Instructions

The importance of proper installation of commercial

gas cooking equipment cannot be over stressed. Proper

performance of the equipment is dependent, in great part,

on the compliance of the installation with the manufacturer’s

specications. The installation and connections must comply

with local codes, or in the absence of local codes, with

CAN/CGA-B149 installation code or with the National Fuel

Gas code, ANSI Z 223.1/NFPA No. 54 – latest edition.

All burner adjustments and setting shall be made by a

qualied gas technician.

A. The type of gas for which the unit is equipped is stamp on

the date plate located behind lower front panel. Connect

a unit stamped “NAT” only to natural gas; connect a unit

stamped “PRO” only to propane gas.

B. If it is a new installation, have gas authorities check meter

size and piping to assure that the unit is supplied with

sucient amount of gas pressure required to operate the

unit.

C. If it is additional or replacement equipment, have gas

authorities check pressure to make certain that existing

meter and piping will supply fuel at the unit with not

more than 1/2” water column pressure drop.

Part # P125 Rev 1 (05/20/08)Page 6

Page 7

Bottom Flue

Cover Patch

INSTALLATION Continued

D. Obtain a pressure regulator to deliver gas at the pressure

shown on the rating plate. This unit is supplied with a

pressure regulator.

NOTE: When checking pressure be sure that all other

equipment on the same gas line is on. A pressure regulator

is supplied with GARLAND equipped. Set regulator to deliver

gas at pressure shown on rating plate. Installation must

conform with the national Fuel Gas Code ANSI Z223.1-Latest

Edition/NFPA No. 54-Latest Edition and/or local code to

assure safe and ecient operation.

NOTE: In Canada, the installation shall be in accordance

with CAN/CGA-B149.1 NATURAL GAS INSTALLATION CODE

or CAN/CGA-B149.2 PROPANE GAS INSTALLATION CODE and

local codes where applicable.

NOTE: The appliance and its individual shut-o (supplied by

others) must be disconnected from the gas supply piping

system during any pressure testing of that system at test

pressures in excess of 1/2 PSI (3.45kPa).

The appliance must be isolated from the gas supply piping

by closing its individual manual shut-o (supplied by others)

during any pressure testing of the gas supply piping system

at test pressures equal to or less than ½ PSI (3.45 kPa).

NOTE: Adequate clearance must be provided for servicing

and proper operation.

Legs

Assembly of Two-Section Oven

Before raising the upper section into its proper position,

check at the rear centre of the underside of the upper section

(as per drawing). The rectangular ue opening should be

open. If the ue opening is covered, remove the “Bottom Flue

cover Patch” and discard.

Be sure that the top trim cap (stainless steel angle iron square

frame) is not installed on the lower or middle ovens. Place

2 x 4’s on the top of the lower or middle ovens. Place

2 x 4’s on the top of the lower oven section – about 6” in from

each side, running front to back. Raise the top section and

position it on the 2 x 4’s so that the front, rear and sides of the

top section line up with the lower section. The internal upper

ue will telescope over the internal lower ue.

Raise the front of the oven. Position the legs inside the front

corners of the angle from frame. Start each bolt, threading

them into the weld nuts on the angle base frame. Four (4)

bolts and four (4) washers must be used to secure each leg in

place. Tighten the bolts evenly and securely. Raise and block

the rear of the oven and fasten the rear legs as above.

Part # P125 Rev 1 (05/20/08) Page 7

The upper oven section bottom frame will telescope or

capture the bottom unit. It is not necessary to bolt the

section together.

Installation of Oven Vent

1. The most ecient system for ventilating this oven is

a properly designed hood. This hood should extend

6 inches beyond the front and sides of the oven and

the back, unless oven is against a re resistive wall. The

design of the hood should be such that it will not pull the

heat too rapidly out of the oven through the ue.

Page 8

INSTALLATION Continued

FLUE DEFLECTOR

FIGURE 1

BAROMETRIC

DAMPER

DRAFT HOOD

FIGURE 2

The ue deector provided (Fig. 1) should be installed

to prevent this situation from occurring. Set the ue

deector in place over the anges of the internal ue. The

sloped opening of the ue deector will be to the front.

Fasten the side anges of the ue deector by means of

the sheet metal screws provided.

2. If the oven must be connected to a direct ue, this ue

should rise 10 feet above the roof of the building in

which the oven is installed, or 10 feet above any portion

of a building within a horizontal distance of 10 feet. The

draft hood provided must be installed. In addition, it is

necessary that barometric draft control (available from

Garland) be installed. (See Fig. 2)

The draft hood should be positioned with its vertical

bottom opening over the vertical anges of the oven

ue. The anges of the draft hood should be to the sides

and front. Fasten the draft hood to the oven by means of

sheet metal screws through the holes on each side ange

at the bottom of the draft hood.

The barometric damper must be installed to conform

with the applicable instructions packed with the

barometric damper. The relief opening of the barometric

damper should be located so that it is not obstructed by

any part of the oven or adjacent constructions.

The barometric damper should be installed as close to

the draft hood as possible, while conforming to code

requirements.

Under no circumstances should ue pipe with less than

a 6 inch diameter be installed between the oven and the

chimney termination.

If more than one appliance is connected to a single

vent, the vent shall be sized in accordance with sound

engineering principles.

Top Trim Installation

The front of the top trim is formed as a channel. Open the

upper oven door. Hold the top trim with the rear raised

and slide its lower ange into position in the oven opening

between the right and the left front columns. Lower the top

trim into position over the oven top. The top trim does not

require that it be bolted or fastened into position.

Ovens with Optional Light Feature

Important: This appliance must be electrically grounded in

accordance with local codes, or in the absence of local codes,

the Canadian Electrical Code C22.1 or with the National

electrical code ANSI/NFPA No. 70 (latest edition whichever is

applicable.

Warning – Electric Grounding Instructions

This appliance is equipped with a three prong (grounding)

plug for your protection against shock hazard and must be

plugged into a properly grounded three prong receptacle.

Do not cut or remove the grounding prong from this plug.

A wiring diagram is attached to the back of the unit.

Gas Connection-Single & Multiple Ovens

Single Oven

Install the pressure regulator (supplied) with the outlet

(arrowhead) connected to the tail pipe. The ¾” N.P.T. inlet of

the pressure regulator must be considered in piping the gas

supply. Each group of ovens should be supplied (by others)

with an in-line manual shut o valve.

Part # P125 Rev 1 (05/20/08)Page 8

Page 9

INSTALLATION Continued

PRESSURE

REGULATOR

GAS

SUPPLY

STACKING PIPE KIT

FOR COMBINATION OVEN

DIAGRAM "A"

INNER OVEN LINING

RIGHT AND LEFT

DECK SPACER

RIGHT, REAR AND LEFT

DECK

HEAT DEFLECTOR

HEAT DEFLECTOR PAN (2)

DECK FRAME (Ref.)

DIAGRAM "B"

Each stack of oven sections may be piped individually as

described above. Each stack should be provided with its own

manual gas shut o valve as described. If the ovens are to be

piped using all of the materials provide, refer to diagram “A”.

Multiple Ovens

If the ovens are to be stacked, they may be piped as shown

in the diagram “A”. Again, as stated above, a readily accessible

gas shut o valve of an approved type should be installed in

the supply line.

The steel hearth is designed as a one-piece welded assembly

and will pass through the oven door opening. The rear of the

steel hearth assembly rests on the heat deectors inside the

rear angle support. Centre the steel hearth assembly within

the oven. Install the aluminized inner oven linings provided,

as shown in Diagram “B”.

IMPORTANT: All gas burners and pilots need sucient air to

operate and large objects should not be placed in front of

this appliance which would obstruct the air ow through the

front.

Ventilation and Air Supply

Installation Of Oven Heat Deectors,

Corderite/Steel Hearths &

Inner Oven Linings

All models require that two part oven heat deectors (heavy

gauge diamond plate) and two heat deector pans (in oven

with corderite deck material) or one heat deector pan (in

oven with steel deck), be installed above the oven burners

to give even heat throughout the oven. Install the heat

deector pan(s) in the centre of the oven deck frame. Install

the heat deectors on top of the heat deector pans, with

the rough side up.

Both deectors should be brought together to make the

centre seam as tight as possible.

The corderite hearth assembly consists of two sections

installed within deck spacers, as shown in Diagram “B”. Install

the two (2) aluminized inner oven linings in the front and

rear channels by rst placing the rear of each in each rear

channel. Then raise the front of each aluminized inner oven

linings over and down into the front channels.

Part # P125 Rev 1 (05/20/08) Page 9

Proper ventilation is highly important for good operation.

The ideal method of venting a gas deck oven is through the

use of a properly designed canopy which should extend 6”

beyond all sides of the appliance and 6’6” from the oor.

A strong exhaust fan will create a vacuum in the room. For an

exhaust system vent to work properly, replacement air must

enter the room in which the vent is located. For proper air

balance, contact your local H.V.A.C. contractor.

Installation of a Direct Flue

When the installation of a canopy type exhaust hood is

impossible, the oven may be direct vented. Before direct

venting check your local codes on ventilation.

If the unit is to be connected directly to a direct ue, it is

necessary that an 8” draft diverter be installed to insure

proper ventilation. First remove the canopy diverter (shown

in Diagram “A”), and replace with a Garland designed down

draft diverter (P/N1056497 painted or 1056496 stainless

steel). Connect directly to the Garland designed down draft

diverter with your stove pipe.

Page 10

INSTALLATION Continued

NOTE: Each oven has been factory tested and adjusted prior

to shipment. It may be necessary to further adjust the oven

as part of a proper installation. Such adjustments are the

responsibility of the installer.

OPERATION

Once the equipment has been installed and tested by

qualied professional personnel, the oven is ready for

operation. If the pilot is not lit, proceed as follows:

1. Check the oven gas valve. It should be in the “OFF”

position. If not, turn this valve to the “OFF” position.

2. Remove the lower front panel by turning the special selfretaining fasteners.

3. Ignition of the pilot is made by passing a lighted taper

through the access hole in the front air shield, or by

removing this shield while pressing in and holding the

red reset button of the oven safety valve. This button is

reached through the access hole in the centre section of

the side control panel. Release the red button after the

pilot has been lit, approximately 45 seconds. If the pilot

does not remain lit, repeat after waiting 5 minutes.

4. After the oven pilot is lit, replace the front air shield and

lower front panel.

Burn O – Deck Curing

Adjustments are not considered defects in material and

workmanship, and they are not covered under the original

equipment warranty.

Do Not Undersize The Vent Pipe! This can cause resistance

to ow and impede good eciency.

The oven may now be shut down by turning the gas control

valve to the “OFF” position and turning the thermostat back

to its lowest setting.

NOTE: You cannot turn the oven o just by turning the oven

thermostat down. You must turn the gas valve to the “OFF”

position.

It will not be necessary to extinguish the oven pilot unless

the oven is to remain unused for a long period of time.

After the hearth is “cured”, the oven is ready for operation.

1. If the oven pilot has been extinguished, go through steps

1 through 4, as previously listed.

2. All models that have the corderite hearths should be

preheated for no less than one (1) hour. This will bring

the oven interior to the desired temperature and will

provide time for the hearth and the oven interior surfaces

to absorb and store heat required for optimum oven

performance. All models that have steel hearths will

require approximately 25 minutes to preheat.

Many of the parts used in the oven have a thin protective

oil covering. This oil should be burned o before the oven

is used for production of food. The following burn o

procedure will also service to “cure” the oven hearth. If the

curing procedure is not followed, there is a potential for the

deck material to crack.

Turn the oven thermostat dial back to the 300°F setting

and run the oven at this temperature for at least an hour.

Repeat at 400°F and 500°F. the total “curing” process is

accomplished in a 3 hour period of time.

3. After preheating, the oven is ready for use.

4. Distribute the load evenly on the deck. Space pans

equally from each other and the side of the oven.

5. Planning will avoid unbalanced baking as a result of

adding product after loading goods have started to bake.

6. Do not open door unnecessarily. Repositioning of

product is not required in most cases.

Part # P125 Rev 1 (05/20/08)Page 10

Page 11

OPERATION Continued

7. When using the G-2771 or the G-2772 General Purpose

Oven for the same product, load the upper compartment

rst, then the lower compartment. It is normal for

the upper compartment (in this specic model only)

to be 30°F to 60°F lower in temperature than the

lower chamber. When product is done in the lower

compartment, remove same. Check upper compartment,

allowing additional time if required.

8. Before loading, preheat oven at least 25°F higher than

desired temperature for Strong bottoms and Light tops.

When loading of oven is completed, turn control down to

desired temperature. For products requiring Strong tops,

turn oven temperature control up 25°F for the nal 8 – 10

minutes of baking.

The following is intended only as guide. Temperature and

time requirements will be aected by specic recipes,

varying methods of food preparation, quality of ingredients

and personal preferences, as well as numerous other factors.

Your own techniques, coupled with the recommendations of

this guide, will permit you to establish your own chart.

User Guide – Timetable for Roasting

CUT WEIGHT (LB.) OVEN ° F INTERNAL TEMP. °F MIN./LB.

Beef

Standing Rib 6-8 300°-235° 140° Rare 23-25

Standing Rib (7 Rib) 20-25 300° 160° Rare 27-30

125° Rare 11

140° Med 12

150° Well 13

Round (Rump & Shank O ) 50 250° 140° Med 12

Rolled Rib 5-7 300°-350° 140° Rare 32

160° Med 38

170° Well 48

Rib Eye 4-6 350° 140° Rare 18-20

160° Med 20-22

170° Well 22-24

Tenderloin (1/2) 2-3 425° 140° Rare 45-60

Whole 4-6 425° 140° Rare 45-60

Rolled Rump (High Quality) 4-6 300°-325° 150°-170° 35-40

Sirloin Tip (High Quality) 3 1/2-4 300°-325° 150°-170° 35-40

Veil

Leg 5-8 300°-325° 170° 23-35

Loin 4-6 300°-325° 170° 30-35

Rib (Rack) 3-5 300°-325° 170° 35-40

Rolled Shoulder 4-6 300°-325° 170° 40-45

Note: This list is intended only as a guide

Chart continued on next page

Part # P125 Rev 1 (05/20/08) Page 11

Page 12

OPERATION Continued

User Guide – Timetable for Roasting continued

CUT WEIGHT (LB.) OVEN ° F INTERNAL TEMP. °F MIN./LB.

Lamb

Leg 5-8 300°-325° 175°-180° 30-35

Shoulder 4-6 300°-325° 175°-180° 30-35

Rolled 3-5 300°-325° 175°-180° 40-45

Cushion 3-5 300°-325° 175°-180° 30-35

Pork, (Fresh)

Loin Centre 3-5 325°-350° 170° 30-35

Half 3-5 325°-350° 170° 35-40

Blade/Sirlion 3-4 325°-350° 170° 40-45

Picnic Shoulder 5-8 325°-350° 185° 30-35

Rolled 3-5 325°-350° 185° 40-45

Cushion Style 3-5 325°-350° 185° 35-40

Boston Shoulder 4-6 325°-350° 185° 45-50

Leg (Fresh Ham)

Whole -Bone In 10-14 325°-350° 185° 25-30

Whole -Boneless 7-8 325°-350° 185° 40-45

Half - Bone In 5-7 325°-350° 185° 40-45

Pork, (Smoked)

Ham (Uncooked)

Whole 10-14 300°-325° 160° 18-20

Half 5-7 300°-325° 160° 22-25

Shank/Butt 3-4 300°-325° 160° 35-40

Ham (Cooked)

Whole 10-14 325° 130° 15

Half 5-7 325° 130° 18-24

Picnic Shoulder 3-5 300°-325° 170° 35

Shoulder Roll 2-3 300°-325° 170° 35-40

Canadian Style Bacon 2-4 300°-325° 160° 35-40

Poultry (All Not Stued)

Chicken-Roasters 2 1/2-3 325° 36

Turkeys 14-16 300° 22

25-30 350° 16

Ducks 4-5 325° 36

Note: This list is intended only as a guide

Part # P125 Rev 1 (05/20/08)Page 12

Page 13

OPERATION Continued

User Guide – Timetable for Baking

PRODUCT OVEN °F TIME

Breads

White Bread 375°-425° 30-40 Min.

Wheat Bread 375°-425° 30-40 Min.

Rye Bread 400° 40-60 Min.

Corn Bread (Individual) 375°-425° 25-30 Min.

Cakes

White Sheet 375° 30-35 Min.

Yellow Sheet 375° 30-35 Min.

Angel Food 400° 20-30 Min.

Devil’s Food 350° 20-30 Min.

Cookies

Sugar 375° 15 Min.

Chocolate Chip 375° 15 Min.

Butter 400° 10-15 Min.

Macroons 350° 20 Min.

Pies

Apple 400°-425° 50-60 Min.

Cherry 400°-425° 50-60 Min.

Pumpkin 375°-425° 30-40 Min.

Custard 375°-425° 30-40 Min.

Rolls

Clover Leaf 400° 15-20 Min.

Parkerhouse 400°-425° 15-20 Min.

Biscuits 425° 20 Min.

Danish Pastry 375° 20-30 Min.

Note: This list is intended only as a guide

Part # P125 Rev 1 (05/20/08) Page 13

Page 14

MAINTENANCE

We suggest maintenance and repairs to be performed by an

GARLAND AUTHORIZED SERVICE AGENT. The listing provided

with your oven is titled “Maintenance and Repair Centres”.

Painted Finishes

Establish a regular cleaning schedule. Any spills should be

wiped o immediately.

The oven should be permitted to cool down before cleaning

exterior surfaces. Wipe exposed, cleanable surface when cool

with a mild detergent and hot water. Stubborn residue spots

may be removed with a light weight, non-metallic scouring

pad. Dry thoroughly with a clean cloth.

Stainless Steel

For routine cleaning, just wash with a hot water and

detergent solution. Wash just a small area at a time or the

water will evaporate leaving the chemicals behind causing

streaking.

Rinse the washed area with a clean sponge dipped in a

sanitizing solution. Wash just a small area at a time or the

water will evaporate leaving the chemicals behind causing

streaking.

Rinse the washed area with a clean sponge dipped in a

sanitizing solution and wipe dry with a soft clean cloth

before it can dry.

Use a paste (of water and a mild scouring powder) if you

have to, but never rub against the grain. All stainless steel has

been polished in one direction. Rub with the polish lines to

preserve the original nish. Then thoroughly rinse as before.

Use only stainless steel, wood or plastic tools, if necessary,

to scrape o heavy deposits of grease and oil. Do not use

ordinary steel scrapers or knives as particles of the iron may

become imbedded and rust. STEEL WOOL SHOULD NEVER BE

USED.

Oven Interior

Standard aluminized steel interior surfaces. The oven linings,

back linings and top linings are formed with heavy gauge

steel with aluminum fused into its surface. This provides

a reectance of heat back to the food being prepared.

The aluminum virtually eliminates the possibility of rust

formation.

To clean the aluminized interior, use a concentrated

detergent on a plastic pad to remove burned on soil. DO NOT

use steel wool, oven cleaners or abrasive powders. These will

remove the aluminum. Rinse with warm water on soft cloth.

Be sure to remove all traces of detergent. Any discoloration

which may remain after the soil build-up has been removed

will not aect the performance of the oven.

Cleaning of Oven Hearth

The oven hearth should be kept clean and free of carbon by

using a long handled, sti wire brush or scraper to loosen

burned on carbon. Sweep the hearth clean with a soft brush.

You may use a damp cloth to wipe the hearth, but DO NOT

FLOOD THE HEARTH WITH WATER OR USE A VERY WET

CLOTH! If excess water is used, the hearths may crack upon

next use.

To prevent ngerprints, there are several stainless steel

polishes on the market that leave an oily or waxy lm. Do not

use on surfaces that will be in contact with food.

Stainless Steel may discolour if overheated. These stains can

usually be removed by vigorous rubbing with a scouring

powder paste.

Part # P125 Rev 1 (05/20/08)Page 14

Page 15

ADJUSTMENTS

Oven Door

The Garland oven door has adjustability as a design feature.

Although it is factory set, the tension can be adjusted to suit

the operator’s preference. In addition, after a long period of

hard use, the tension can be readjusted as required.

1. Where the top trim cap overlaps the columns, it must be

removed to permit their removal.

2. Open the oven door, reach over the top of the oven, lift

the rear of the top trim cap up, sliding it forward towards

the draft hood (or ue diverter). This will move the lower

front ange of the top trim cap far enough forward so

that the entire trim cap may be raised up. Slide the trim

cap back over the oven top to clear the columns.

3. Remove the lower front panel by turning the special self

retaining fasteners. Loosen but do not remove the screws

which fasten the lower front panel supports to the right

and left side frames.

4. Remove the screw from the inner top corner of each

column. Remove the columns by pulling each down and

out. You now have access to each adjustable spring hook.

Thermocouple Replacement

NOTE: each oven has been factory tested and adjusted

prior to shipment. It may be necessary to further adjust

the oven as part of a proper installation. Such adjustments

are the responsibility of the installer. Adjustments are not

considered defects in material or workmanship, and they are

not covered under the original equipment warranty.

Accessibility of the control manifold is gained by removing

the lower control level panel (held by one sheet metal screw)

and the control panel (fastened by sheet metal screws in

its upper and lower front corners). Retain both parts and

the sheet metal screws for reassembly. Access to the burner

manifold is attained by removing the lower front panel and

the front air shield.

The unit is provided with an oven safety valve. Its sensing

element (or thermocouple) is replaceable. The properly

adjusted pilot ame provides a blue ame enveloping

the end of the thermocouple tip for 3/8” to 1/2. The

thermocouple should glow dull red.

The pilot adjustment valve is in an elbow above the shut o

valve.

5. The spring hook passes through a bracket. A 1/4 x 20

nut is on the spring hook forward of the bracket. If it is

available, use a 7/16” deep socket in the ratchet wrench

to turn the nut clockwise to increase spring tension or

counter-clockwise to relieve spring tension.

6. The oven door is properly adjusted if the door remains fully

open and if the spring tension carries the door to the full

closed position from the half-closed position.

7. Replace the columns. Retighten the lower front panel

support screws. Replace the lower front panel. Slide

the top trim cap forward so that its rear rides on top of

the oven, and its lower front ange can be repositioned

between the columns. Push the trim cap back so that its

rear and side anges t down over the oven.

A thermocouple nut should be started and turned all the way

in by hand. An additional quarter turn with a small wrench

will then be sucient to seat the lock washer and maintain

adequate contact. A too loose or too tight connection of

the thermocouple nut to the automatic pilot valve can

prevent the thermocouple from activating the valve. A visual

examination of the thermocouple lead should be made to

make sure that there are no cracks or ruptures. Every eort

has been made to ensure trouble-free performance of this

system with a minimum of service.

Magnet Assembly & Thermocouple Test

Heating the thermocouple tip by the pilot ame produces an

electrical potential that is used to energize the magnet that,

in turn, holds open the main and pilot valves. When the pilot

is “OUT” or improperly adjusted, insucient heat is applied

to the thermocouple tip to product adequate electrical

generation that results in the control shutting itself o.

If, while following the proper lighting procedures, the

magnet cannot be made to “HOLD”, inspect the pilot ame

for proper size and adjustment (see pilot burner adjustment).

If the magnet will still not hold, make the following checks:

Part # P125 Rev 1 (05/20/08) Page 15

Page 16

ADJUSTMENTS Continued

BLACK

RED

Terminal Boss

Adapter

Thermocouple Tube

Fig. A

4

5

0

5

0

0

5

5

0

1

5

0

3

0

0

2

5

0

3

0

0

3

5

0

4

0

0

Calibration

Lock Screws

By-pass Flame

Adjuster

Indicator Mark

Calibration

Plate

Dial

Stop

MODEL

FDO

Closed Circuit Test

To make the closed circuit test, remove the thermocouple

lead from the magnet contact. Place an adapter in the

magnet contact and turn the thermocouple into the adapter,

nger tight. Connect millivolt meter leads to adapter and

thermocouple lead as shown in Figure “A”.

Re-light pilot. Read meter after pilot has been burning three

minutes. If pilot will not continue burning, depress and hold

red button to check thermocouple output for this closed

circuit check. If sucient (normal output is 20 to 28 millivolts)

millivolt output is noted, (less than 176 millivolts), replace

thermocouple.

After checking the thermocouple in closed circuit, blow out

the pilot ame, watching the millivolt meter. The magnet

should continue to hold for a drop of at least ve millivolts.

If the magnet doesn’t hold for a drop of ve millivolts, you

would have a false safety condition and frequent pilot

outages. After this closed circuit check is made with the main

burner o, the main burner should then be operated with

the millivolt meter in position to check the eect of the main

burner on the millivolt output.

Oven Burners

The oven burner orices are xed and cannot be adjusted.

Proper rate is achieved if the gas supply pressure is adequate.

Pressure may be checked by the 1/8” N.P.T. manifold pressure

tap. Properly adjusted oven burner air shutters will

Provide for a distinct blue ame over the entire port are

of the burners, at full rate. If readjustment has been made,

tighten the air shutter screw to prevent movement of the air

shutter.

Thermostat Operation

It is normal for a hydraulic thermostat cycling with a

temperature swing of 45° to 50°. When checking calibration,

rst; allow the thermostat to cycle a minimum of four

(4) times, second; place your temperature sensor in the

geometric centre of the empty oven, two inches (2”) o

the oven deck. When the thermostat cycles o, write down

that temperature, wait until the temperature cycles on and

write the temperature down. Average the two readings. That

average should be ± 20° of the set point temperature.

Example: Thermostat set point is 300°, rst cycle O at 325°.

Cycle back ON at 291°. The average of 325° and 291° is 309°.

The thermostat is cycling eight degrees (8”) above the dial

setting. This thermostat is within the ± 20° tolerance and

the appliance is under warranty, have the authorized agent

calibrate the thermostat. If the thermostat is beyond 50°,

have the thermostat replaced.

Open circuit Test

1. Disconnect thermocouple from safety valve.

2. Attach thermocouple to millivolt test instrument.

3. Heat sensor end of thermocouple with ame, monitoring

millivolt meter.

4. If millivolt reading is below 17 millivolts, replace

thermocouple.

Part # P125 Rev 1 (05/20/08)Page 16

Page 17

ADJUSTMENTS Continued

Instructions for FDO Heavy Duty Control

This model FDO is a precision made instrument, carefully set

at the factory to accurately control oven temperatures, from

500°F (260°C) to 150°F (66°C). All adjustments are accessible

from the front of the appliance after removing the dial. To

remove dial, grasp knob portion and pull straight out.

By-Pass Adjustment

1. With oven cold, turn dial counter-clockwise slowly from

“Low Stop”, until bypass seat just snaps on.

2. Remove Dial.

3. With screwdriver, turn bypass ame adjuster screw

counter-clockwise to increase the bypass ame, or

clockwise to decrease the entire burner ame to a

minimum stable ame.

4. Replace dial. CAUTION: While making this adjustment, if

the oven should become heated while the dial is set at a

low range below 350°F (177°C), the bypass ame will shut

o completely. If this occurs, turn dial counter-clockwise

slowly until bypass gas snaps on. Then check bypass

adjustment as stated.

Recalibration

Field recalibration is seldom necessary, and should not be

resorted to unless poor cooking results, denitely proves that

the control is not maintaining the temperature to which the

dial is set. To check oven temperature when recalibrating,

use an indicating potentiometer or a reliable mercury oven

thermometer.

1. Place the thermocouple of test instrument or

thermometer in the geometric centre of the oven.

2. Light the main burner. Observe which indicator mark

aligns with the low stop position of the dial. Use this

indicator mark for all settings.

3. Turn dial so 400°F (240°C) lines up with the “Low Stop”

indicator mark.

4. Allow the oven, or appliance, to heat and thermostat

too cycle three times. After sucient time, check

temperature. If the temperature does not read with ± 20°

of the dial setting, recalibrate as follows:

5. Pull dial straight o without turning thermostat shaft.

6. Hold calibration plate and loosen the two calibration

screws until the plate can be moved independently of the

control.

7. Turn calibration plate so that the instrument or

thermometer reading is in line with the indicator mark.

Hold plate and tighten screws rmly.

8. Replace dial.

9. NOTE: If the above adjustment is prevented by the two

loosened calibration lock screws being in contact with

the ends of the screw clearance plate to the proper

location, reassemble screws in the other tapped holes

designed for them.

NOTE: no attempt to recalibrate the oven control should

be made within the warranty period. If the control is out ±

20°F from the dial setting, have authorized agent calibrate

under warranty. If the control is out more than 50°, have

the thermostat replaced, (if within the warranty period),

if someone other than the authorized agent attempts

recalibration during the warranty period, there will be no

warranty on the control that was tampered with.

Part # P125 Rev 1 (05/20/08) Page 17

Page 18

Part # P125 Rev 1 (05/20/08)Page 18

Page 19

Part # P125 Rev 1 (05/20/08) Page 19

Page 20

Loading...

Loading...