Garland EFW800 Service Manual

SERVICE/PARTS

MANUAL

GARLAND FONDANT WARMER

MODEL EFW800

®

FOR YOUR SAFETY:

DO NOT STORE OR USE GASOLINE

OR OTHER FLAMMABLE VAPORS OR

LIQUIDS IN THE VICINITY OF

THIS OR ANY OTHER

APPLIANCE

PLEASE READ ALL SECTIONS OF THIS MANUAL

AND RETAIN FOR FUTURE REFERENCE.

THIS PRODUCT HAS BEEN CERTIFIED AS

COMMERCIAL COOKING EQUIPMENT AND

MUST BE INSTALLED BY PROFESSIONAL

PERSONNEL AS SPECIFIED.

WARNING:

IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE

CAN CAUSE PROPERTY DAMAGE, INJURY,

OR DEATH. READ THE INSTALLATION,

OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR

SERVICING THIS EQUIPMENT

INSTALLATION AND ELECTRICAL CONNECTION

MUST COMPLY WITH CURRENT CODES:

IN CANADA - THE CANADIAN ELECTRICAL

CODE PART 1 AND / OR LOCAL CODES.

IN USA – THE NATIONAL ELECTRICAL CODE

ANSI / NFPA – CURRENT EDITION.

ENSURE ELECTRICAL SUPPLY CONFORMS WITH

ELECTRICAL CHARACTERISTICS SHOWN ON

THE RATING PLATE.

Users are cautioned that maintenance and repairs must be performed by a Garland authorized service agent

using genuine Garland replacement parts. Garland will have no obligation with respect to any product that has been

improperly installed, adjusted, operated or not maintained in accordance with national and local codes or installation

instructions provided with the product, or any product that has its serial number defaced, obliterated or removed,

or which has been modified or repaired using unauthorized parts or by unauthorized service agents.

For a list of authorized service agents, please refer to the Garland web site at http://www.garland-group.com.

The information contained herein, (including design and parts specifications), may be superseded and is subject

to change without notice.

GARLAND COMMERCIAL RANGES LTD.

1177 Kamato Road, Mississauga, Ontario

L4W 1X4 CANADA

Phone: 905-624-0260

Fax: 905-624-5669

Part # 4521056 Rev 2 (02/21/12) © 2012 Garland Commercial Ranges Ltd.

Part # 4521056 Rev 2 (02/21/12) Page 1

IMPORTANT INFORMATION

WARNING:

This product contains chemicals known to the state of California to cause cancer and/or birth defects

or other reproductive harm. Installation and servicing of this product could expose you to airborne

particles of glass wool/ceramic fibers. Inhalation of airborne particles of glass wool/ceramic fibers

is known to the state of California to cause cancer.

Part # 4521056 Rev 2(02/21/12)Page 2

TABLE OF CONTENTS

IMPORTANT INFORMATION. . . . . . . . . . . . . 2

DIMENSIONS AND SPECIFICATIONS . . . . . 4

GENERAL INFORMATION . . . . . . . . . . . . . . . 5

Serial Plate Location . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Wall Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Electrical Rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

OPERATING INSTRUCTIONS. . . . . . . . . . . . . 6

Operating Procedure . . . . . . . . . . . . . . . . . . . . . . . . . 6

Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

SEQUENCE OF OPERATION . . . . . . . . . . . . . 7

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . 8

SERVICING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

PARTS REPLACEMENT . . . . . . . . . . . . . . . . . 11

To Access Components . . . . . . . . . . . . . . . . . . . . . . 11

Heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

High Limit Thermostat . . . . . . . . . . . . . . . . . . . . . . 11

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Thermistor Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . 12

UPDATING PROGRAMS . . . . . . . . . . . . . . . . 13

MAINTENANCE AND CLEANING. . . . . . . . 13

WIRING DIAGRAM . . . . . . . . . . . . . . . . . . . . 15

EFW800 PARTS BREAKDOWN . . . . . . . . . .16

EFW800 PARTS LIST . . . . . . . . . . . . . . . . . . . 17

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

System Block Diagram . . . . . . . . . . . . . . . . . . . . . . . 9

Service Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Visual Inspection . . . . . . . . . . . . . . . . . . . . . . . . . 9

System Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

SENSOR DATA . . . . . . . . . . . . . . . . . . . . . . . .10

Temperature - Resistance/Voltage Table . . . . .10

Sensor Diagnostic Procedure . . . . . . . . . . . . . . . . 11

Part # 4521056 Rev 2 (02/21/12) Page 3

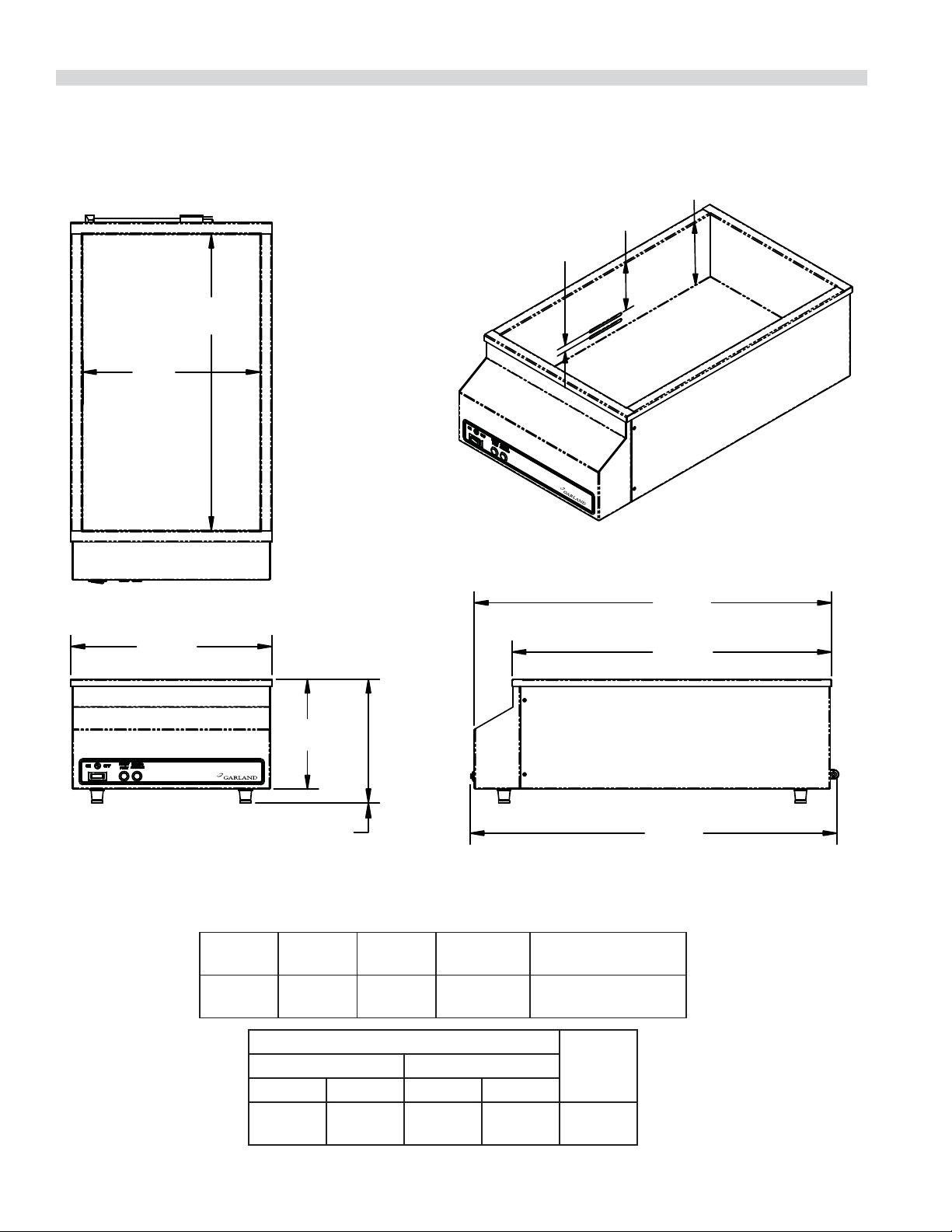

DIMENSIONS AND SPECIFICATIONS

20"

[508mm]

12"

[305mm]

5.20"

[132mm]

4.02"

[102mm]

0.50"

[12.7mm]

13.55"

[344mm]

7.42"

[189mm]

8.34" MIN [219mm]

8.78" MAX [223mm]

Voltage Phase kW

120 1 .80 6.7

Clearances

Installation Entry

Sides Rear Crated Uncrated

0” 0"

15.8"

(401mm)

Nominal

Amperes

13.55"

(344mm)

24.11"

[612mm]

21.56"

[548mm]

24.75"

[629mm]

Connection Type

6' cord

w/NEMA 5-15P plug

Shipping

Weight

29 lb

(13.2kg)

Part # 4521056 Rev 2(02/21/12)Page 4

GENERAL INFORMATION

Users are cautioned that maintenance and repairs should

be performed by a Garland authorized service agent using

genuine Garland replacement parts. Garland will have

no obligation with respect to any product that has been

improperly installed, adjusted, operated or not maintained

in accordance with national and local codes or installation

instructions provided with the product, or any product that

has its serial number defaced, obliterated or removed, or

which has been modi ed or repaired using an authorized

parts or by unauthorized service agents. For a list of

authorized service agents, please refer to the Garland web

site at www.garland-group.com or www.garlandcanada.ca.

The information contained herein (including design and parts

speci cations) may be superseded and is subject to change

without notice.

It is essential that the instructions in this manual be strictly

followed for the safe and economical operation of this

equipment. If it is known or suspected that a fault exists

on an appliance the appliance must not be used until a

competent person has recti ed the fault. Service personnel

should refer to the service manual supplied with the

appliance.

Serial Plate Location

Electrical rating is shown on the serial plate and is readily

visible on the rear of the unit next to the power supply cord

inlet.

Safety

• DO NOT operate this appliance unless all service and

access panels are in place and fastened properly.

• DO NOT attempt to repair or replace any part of this

appliance unless all main power supplies have been

disconnected.

• DO NOT clean this appliance unless the power supply is

disconnected.

• DO NOT immerse appliance in water.

WARNING:

To avoid serious personal injury:

• USE EXTREME CAUTION when setting up, operating and

cleaning these appliances to avoid coming into contact

with hot surfaces. Suitable protective clothing should be

worn or proper utensils should be used to prevent the

risk of burns.

• NOTE all warning labels and markings on this appliance,

which call attention to further dangers and necessary

precautions.

Wall Clearances

Back: 0

Sides: 0

Electrical Rating

• A quali ed person must make the installation in

accordance with the authority having jurisdiction and

local codes.

• This unit must only be operated by a quali ed person. DO

NOT operate without reading this manual.

Part # 4521056 Rev 2 (02/21/12) Page 5

Voltage Power Current Power Inlet

120VAC,

60HZ

800

Watts

6.7

Amps

NEMA

5-15P

OPERATING INSTRUCTIONS

This appliance requires water in the tank for even heating.

Before rst use it is recommended that the inside of the

tank be cleaned with a detergent soaked cloth, to remove

fabricating and protective oils. Rinse with clean water and

dry with a clean cloth.

The EFW800 is a full size 12” x 20” (305mm x 508mm)

capacity fondant warmer. It is designed to maintain fondant

temperature at 115 °F (46 °C). To achieve this, the appliance

heats a water bath slightly higher than the required fondant

temperature.

Operating Procedure

1. Fill the tank with water so that the level is between the

minimum and maximum embossed lines on the inside

wall of the tank.

2. Insert pans with a maximum depth not exceeding 4”

(102mm).

3. Plug appliance into electrical outlet.

4. Turn on the appliance by pressing the switch marked ON

– OFF in the ON position.

5. Lamp Test: After the control has initialized, the amber

WARNING indicator will illuminate for 10 seconds. This

lets the operator know the lamp is functioning.

6. The appliance will initially heat the bath of water to a

temperature of 145°F (63°C), then maintain it at 122°F, ±3

°F (50°C, ±2 °C). Temperatures are measured with a lid or

pans in covering the tank.

1

2

3

Indicators

1. The power switch is illuminated when the switch is in the

ON position and power is applied to the appliance.

2. The green READY lamp indicates the water bath has

reached its normal operating temperature. Fresh cold

fondant may take longer to heat. See the section Fondant

Heating Hints for more details in the Operating Manual

4521055.

3. The amber WARNING lamp has multiple functions. A

ashing WARNING lamp indicates a low water condition. If

the amber lamp is illuminated continuously it indicates a

temperature sensor failure and service personnel should

be contacted.

NOTE: Periodic checks should be made during operation

to ensure that the water level does not fall below the lower

embossed line. Should it do so, top up with fresh cold water.

We recommend cleaning the tank and lling with clean cold

water to the embossed line after a low water condition.

IMPORTANT: After a low water condition, ll with cold

water. Only cold water will reset the ashing lamp.

Adding hot water will not reset the low water condition

immediately. The lamp will continue to ash if the water

temperature does not drop below 100°F (38°C).

Part # 4521056 Rev 2(02/21/12)Page 6

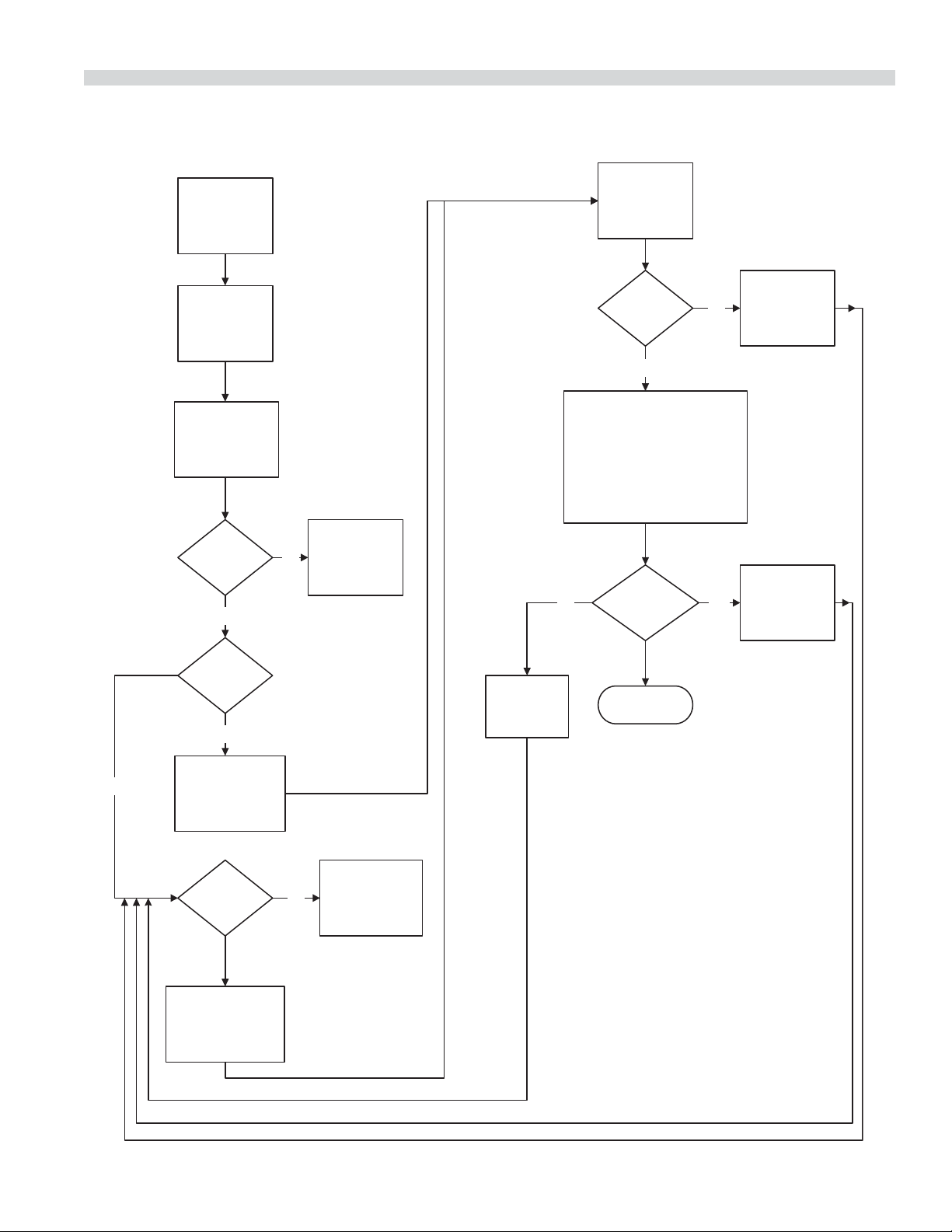

SEQUENCE OF OPERATION

Turn on Power

Every heat cycle

check for a low

water condition

Contol

initializes

(delay)

Warning Lamp

test - illuminates

for 10 seconds

Is Sensor

OK

Yes

Is water

temperature

below

100F

Yes

No

Timed heater

output and

illuminate

warning

indicator

Keep warning

indicator

ashing

Low Water?

Yes

Set low water condition, ash

warning indicator for 10

minutes; reduce heating power

to 50%. Add cold water

(reduce sensor temperature to

100F) to reset low water

condition or reset if the

condition is corrected after 3

heating cycles.

No

Low Water

condition

reset?

End

Continue normal

No

Continue normal

Yes

operation

operation

Initiate fast

No

heating set point water will heat to

145F then go to

normal set point

Is Sensor OK No

Initiate normal set

point (nominal 122F)

(input selects

calibration oset)

Timed heater

output and

illuminate

warning indicator

Part # 4521056 Rev 2 (02/21/12) Page 7

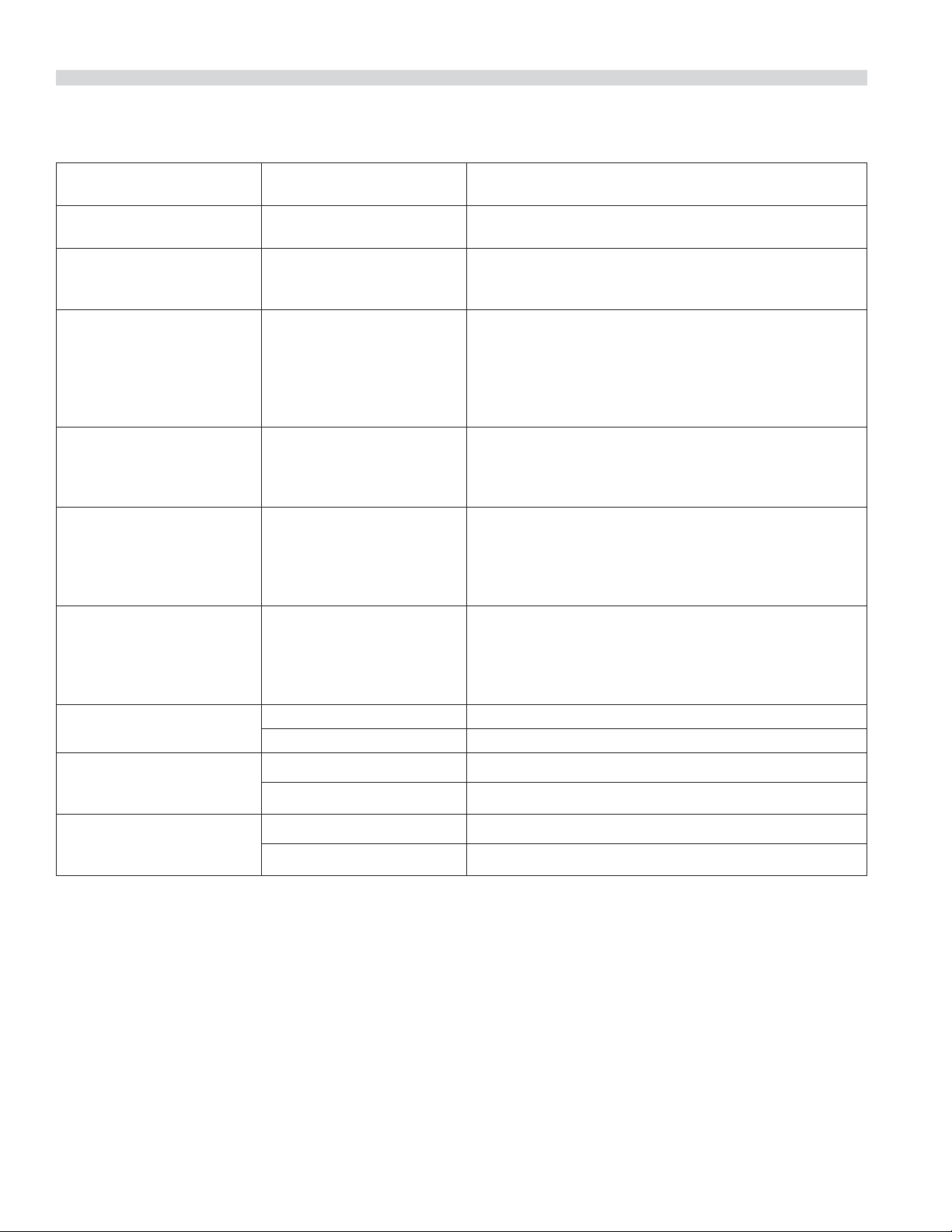

TROUBLESHOOTING

DESCRIPTION OF PROBLEM

Warning indicator lamp is

ashing.

Warning indicator lamp

ashes after lling with water.

Warning indicator lamp is

on continuously and water

temperature is high.

Warning indicator lamp is on

continuously, temperature is

normal.

Water temperature and

fondant temperature is high

by 2 to 4°F (1 to 2.5°C).

Water temperature and

fondant temperature is low

by 2 to 4°F (1 to 2.5°C).

Heaters are not heating. No

indicators come on.

Green indicator does not

illuminate but unit works

properly.

Amber warning indicator

does not illuminate for 10

seconds at power up.

POSSIBLE

CAUSE

Water in tank is low. Fill with cold water.

The water was not cold

enough to reset the low

water condition.

Sensor could be shorted or

the temperature abnormally

high.

Sensor could be open or

shorted but the control

is functioning in a timed

heating cycle mode.

Calibration adjustment is

required.

Calibration adjustment is

required.

Red light on controller. Replace controller.

No lights on power supply. Replace power supply.

Indicator lamp is defective. Replace lamp.

Control relay is defective. Replace controller.

Indicator lamp is defective. Replace lamp.

Control relay is defective. Replace controller.

The lamp will automatically turn o in 10 minutes.

Replacing the water in the tank with cold water will reset

the low water condition immediately.

Is water bath above 180°F (82°C)? Yes, sensor may be

shorted or control relay shorted.

Is water bath above 150°F (65°C) but below 180°F (82°C)?

Sensor or circuit out of calibration.

Check sensor resistance, check control output relay for

shorts. Replace sensor or control if necessary.

Check sensor resistance and replace if necessary.

Verify power supply is adjusted to 12.0V DC. Moving jumper

may not be necessary.

Moving the calibration jumper from input terminal I5 to I4

reduces the temperature by 4°F (2.5°C) or to I3 reduces the

temperature by 2°F (1°C).

Verify power supply is adjusted to 12.0V DC. Moving jumper

may not be necessary.

Moving the calibration jumper from input terminal I5 to I1

increases the temperature by 2°F (1°C) or to I2 increases the

temperature by 4°F (2.5°C).

WHAT TO DO

Part # 4521056 Rev 2(02/21/12)Page 8

SERVICING

Introduction

Although this appliance has only an on-off switch and

two indicating lamps there is a computerized control to

provide accurate temperature control, fault diagnostics and

low water detection. In most cases of component failure

the control is designed to allow the appliance to continue

operating in a service mode. It is important to understand

the operation of the control and how it reacts to faults in

order to properly diagnose and correct faults.

In order to maintain the safety and accuracy of the appliance

it is also important to closely follow the parts replacement

procedures and inspection guidelines. For safety and

optimum performance use only parts obtained through

Garland or an authorized service agency.

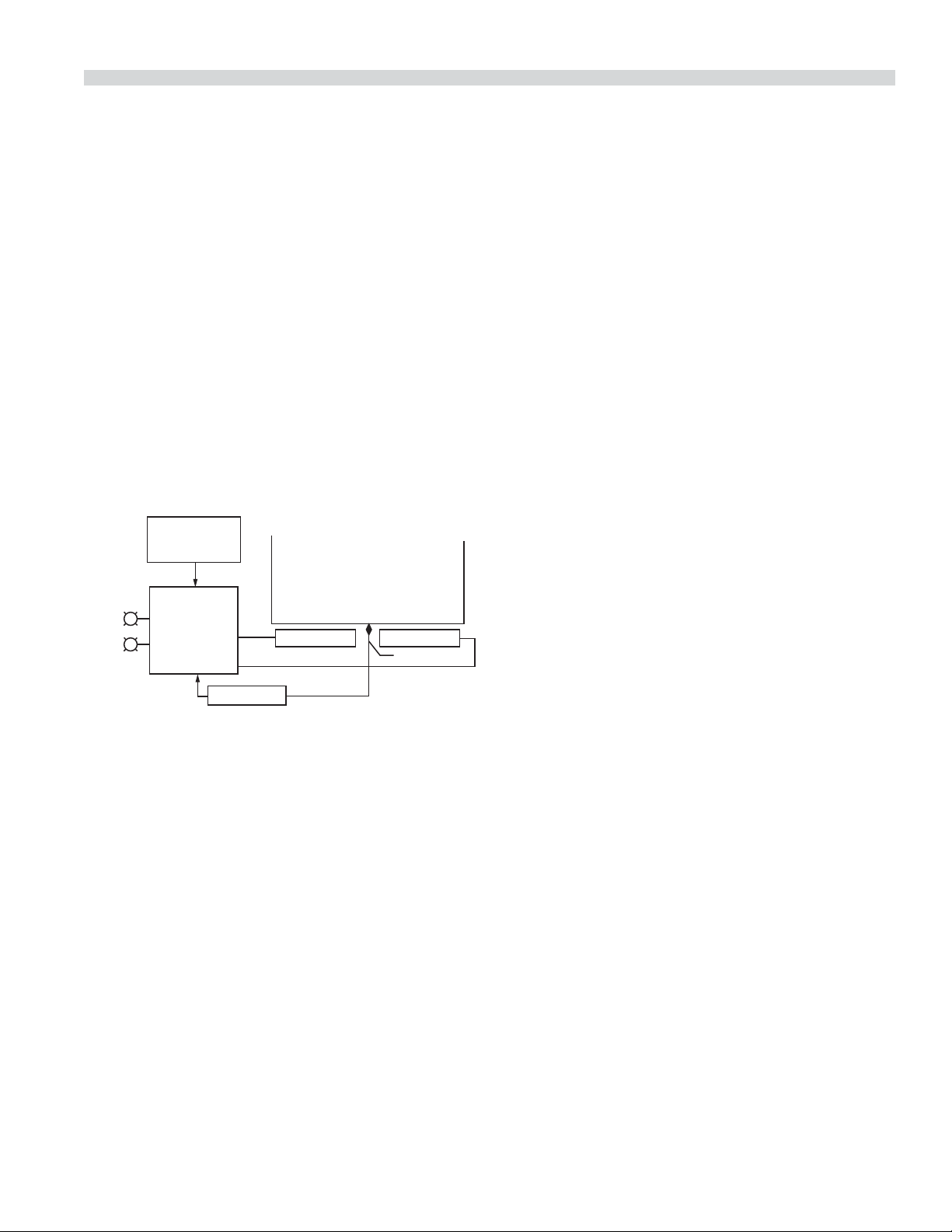

System Block Diagram

Power Supply

Tank

Computer

Control

Heater

Indicators

Sensor Input

Heater

Sensor

Service Procedure

When performing any service operations on this equipment

it is important to perform the following inspections to

maintain the performance and safety of the appliance.

Visual Inspection

1. Unplug the unit.

2. Drain the liquid from the tank.

3. Turn the unit over and remove the bottom.

4. Examine the insulation. It should not be moist or wet. Wet

insulation could indicate the unit has been immersed in

water. Assess any potential damage.

5. Remove the bottom insulation. Examine the silicon

heaters. There should be no staining or delamination

from the tank.

6. Examine the high limit thermostats and the position of

the high limit bracket. The bracket is positioned so both

limit thermostats are over the heaters. There should be

no gap between the bracket and the heater. If there

is, remove the bracket and bend it slightly so it makes

contact with the heaters.

7. Look for any loose or damaged wiring.

8. Check fuse FS1.

System Checks

Check the Following in Powered State.

Warning: before applying power make sure the components

are located in a safe manner. Always perform the visual

inspection described above before applying power. Do not

apply power if there is any damage to heaters, wiring or any

components that might compromise safety.

The front control section can be removed from the body by

removing the 4 screws on the sides and loosening the 2 nuts

that attach the front section to the tank.

• Check for a green indicator on the power supply. If there

is no indicator on, check input voltage to the power

supply. If there is 120V AC present at the input terminals

and no output the power supply must be replaced. There

are no serviceable components in the power supply.

• Check the output of the power supply. It should be

12.0V DC ± 0.1V DC. There is a voltage adjustment

potentiometer next to the green indicator. If the power

supply cannot be adjusted to 12.0V DC

± 0.1V DC, it could indicate there is a problem either with

the power supply or the load attached to it (the controller

or sensing circuit). Typically if a voltage regulator is

defective the voltage error will be greater than 2 volts.

• Check the voltage between 12 volt – terminal and the

load side of fuse FS1. 12 volts should be present.

• Check the indicator lamp on the electronic control. In

normal conditions it will be green. If it appears red the

control has malfunctioned. If the indicator is red the

control must be replaced.

Part # 4521056 Rev 2 (02/21/12) Page 9

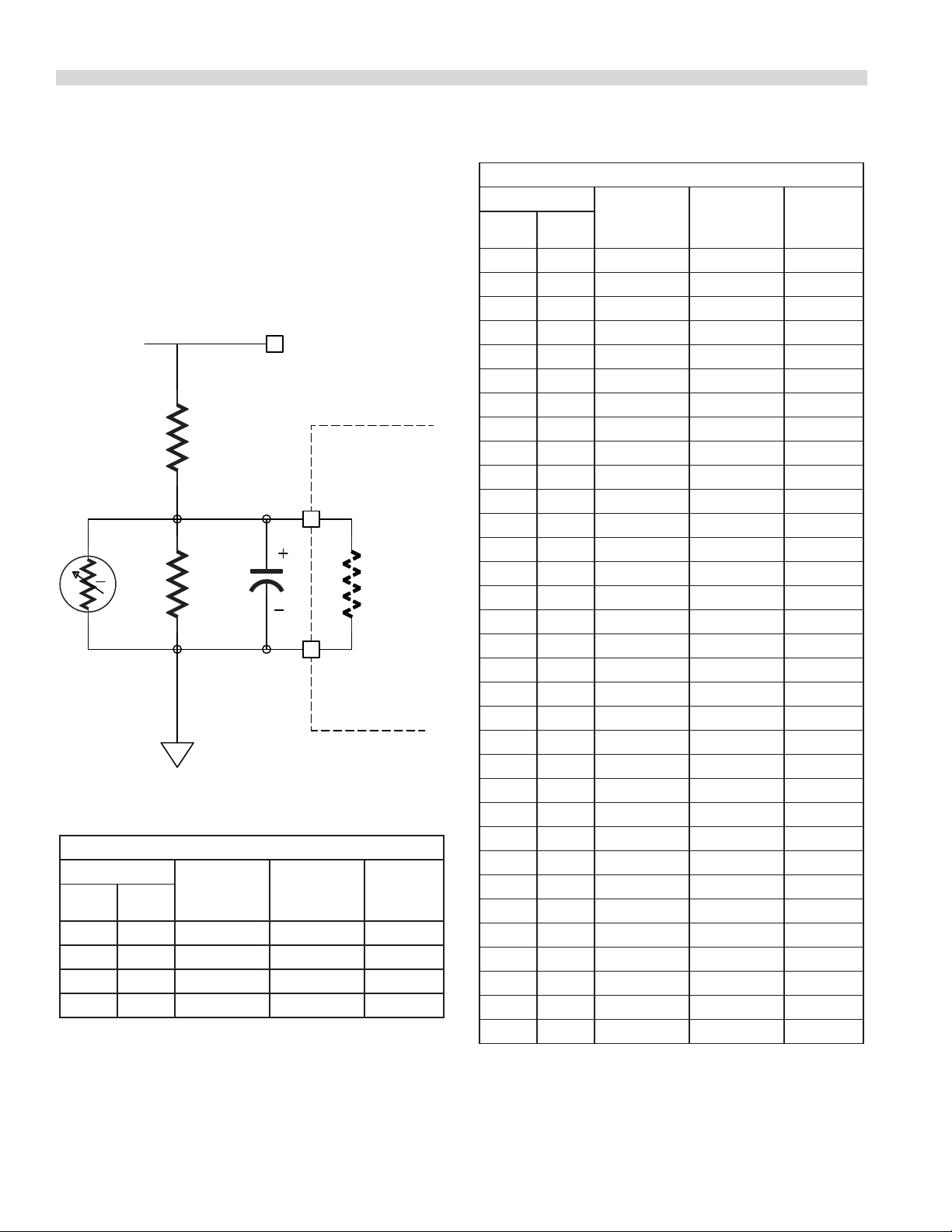

SENSOR DATA

I6, -12V

R1

R2

VR1

The sensor used on the model is an NTC (negative

temperature coe cient) thermistor. This is a sensor whose

resistance decreases with an increase in temperature.

The sensing circuit is arranged as a voltage divider circuit

shown below. The data chart shows the thermistor resistance

out of the circuit, in the circuit and voltage measured at the

input if the circuit is energized versus temperature.

+12VDC

11k, 1%

10k

temperature

sense

I8

computer

t

20k 1%

internal

resistance

76k ohm

C1

22uf

Temperature - Resistance/Voltage Table

Temperature - Resistance/Voltage

Temperature

°C °F

150 302 187.2 185.01 0.20

145 293 210.3 207.54 0.22

140 284 236.9 233.41 0.25

135 275 267.5 263.06 0.28

Resistance

Out Of

Circuit

In-Circuit

Resistance

Voltage

In Circuit

(I8 to -)

Temperature - Resistance/Voltage

Temperature

°C °F

130 266 303.0 297.31 0.32

125 257 344.2 336.88 0.36

120 248 392.2 382.72 0.40

115 239 448.3 435.96 0.46

110 230 514.1 497.93 0.52

105 221 591.6 570.29 0.59

100 212 683.1 654.85 0.67

95 203 791.6 753.91 0.77

90 194 920.9 870.28 0.88

85 185 1075 1006.65 1.01

80 176 1261 1167.98 1.15

75 167 1485 1357.67 1.32

70 158 1756 1580.69 1.51

65 149 2087 1843.95 1.72

63 145 2256 1974.84 1.83

60 140 2491 2152.37 1.96

55 131 2989 2514.34 2.23

50 122 3604 2935.76 2.53

45 113 4369 3424.15 2.85

40 104 5326 3985.40 3.19

35 95 6530 4623.27 3.55

30 86 8056 5339.34 3.92

25 77 10000 6129.03 4.29

20 68 12500 6985.29 4.66

15 59 15720 7888.23 5.01

10 50 19920 8821.56 5.34

5 41 25440 9759.33 5.64

0 32 32740 10672.18 5.91

-5 23 42470 11533.50 6.14

-10 14 55580 12322.86 6.34

-15 5 73390 13023.59 6.51

-20 -4 97820 13627.55 6.64

-25 -13 131700 14134.09 6.75

Resistance

Out Of

Circuit

In-Circuit

Resistance

Voltage

In Circuit

(I8 to -)

Part # 4521056 Rev 2(02/21/12)Page 10

SENSOR DATA continued

Sensor Diagnostic Procedure

1. Visual inspection – is sensor mounted correctly? Is there

any visible damage to the sensor wires?

2. Check sensor resistance for open or short circuit

conditions.

PARTS REPLACEMENT

To Access Components

1. Unplug the unit.

2. Drain the liquid from the tank.

3. Turn the unit over and remove the bottom (10 screws).

4. Access front controls by removing 4 screws from the sides

and loosen 2 nuts securing the front section to the tank.

3. Check sensor resistance and compare with the sensor

temperature.

4. Check the power supply voltage. It must be 12.0V DC.

5. Check the voltage at the control input. Does it match the

above table?

8. Peel the protective liner from the heater. Carefully align

the heater making sure it is square and even with one

edge of the tank. Start applying the heater from the

narrow edge in a slightly curved manner. Press the heater

to the tank applying from one side to the other. Applying

the heater in this manner will reduce the chance of

trapping air between the heater and the tank. Press the

heater down across the entire surface of the heater. This

helps to set the adhesive.

Heater

1. Remove the High Limit Bracket.

2. Remove the Bracket Spacer.

3. The heater is attached to the tank bottom with a pressure

sensitive adhesive. To remove the old heater, disconnect

the heater electrical connections. Peel the old heater

away from the tank.

4. Scrape as much of the old adhesive from the tank with a

sharp blade.

5. Use a 150-200 grit water paper to take o any remaining

adhesive. It is important to remove the old adhesive.

Installing the new heater without removing the old

adhesive will reduce the heat transfer to the tank and

reduce the life of the heater.

6. Clean the area with isopropyl alcohol. Clean any lint or

bers from the surface.

7. Replace the Bracket Spacer. This is to ensure the heater is

placed so it does not interfere with the bracket.

9. Replace the high limit bracket. If must make contact with

both heaters. The bracket may have to be bent slightly

toward the heaters.

10. Connect the wires, one to the high limit and the other to

the red wire.

11. Test and re-assemble the unit.

High Limit Thermostat

1. Remove the electrical connections.

2. Remove 2, 4-40 nuts from the old thermostat.

3. Verify the part number and temperature value is correct.

Component identi cation varies with manufacturer.

The Honeywell version is marked L215 (opens at

215°F/102°C). The Selco version is marked OA-220 (open

at 220°F/104°C).

4. Install the new thermostat.

5. Replace the 2, 4-40 nuts. Do not over tighten.

6. Replace the electrical connections.

7. Test and re-assemble the unit.

Part # 4521056 Rev 2 (02/21/12) Page 11

Loading...

Loading...