Garland EDU-15HSE, EDU-18F, EDU-15SF, EDU-36FT, EDU-36SFT Installation And Operation Manual

...Page 1

INSTALLATION, OPERATION &

SERVICING MANUAL

GARLAND EDU SERIES

DESIGNER ELECTRIC COUNTER EQUIPMENT

PLEASE READ ALL SECTIONS OF THIS MANUAL

FOR YOUR SAFETY:

DO NOT STORE OR USE GASOLINE

OR OTHER FLAMMABLE VAPORS OR

LIQUIDS IN THE VICINITY OF

THIS OR ANY OTHER

APPLIANCE

AND RETAIN FOR FUTURE REFERENCE.

THIS PRODUCT HAS BEEN CERTIFIED AS

COMMERCIAL COOKING EQUIPMENT AND

MUST BE INSTALLED BY PROFESSIONAL

PERSONNEL AS SPECIFIED.

WARNING:

IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE

CAN CAUSE PROPERTY DAMAGE, INJURY,

OR DEATH. READ THE INSTALLATION,

OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR

SERVICING THIS EQUIPMENT

INSTALLATION AND ELECTRICAL CONNECTION

MUST COMPLY WITH CURRENT CODES:

IN CANADA - THE CANADIAN ELECTRICAL

CODE PART 1 AND / OR LOCAL CODES.

IN USA – THE NATIONAL ELECTRICAL CODE

ANSI / NFPA – CURRENT EDITION.

ENSURE ELECTRICAL SUPPLY CONFORMS WITH

ELECTRICAL CHARACTERISTICS SHOWN ON

THE RATING PLATE.

Users are cautioned that maintenance and repairs must be performed by a Garland authorized service agent

using genuine Garland replacement parts. Garland will have no obligation with respect to any product that has been

improperly installed, adjusted, operated or not maintained in accordance with national and local codes or installation

instructions provided with the product, or any product that has its serial number defaced, obliterated or removed,

or which has been modified or repaired using unauthorized parts or by unauthorized service agents.

For a list of authorized service agents, please refer to the Garland web site at http://www.garland-group.com.

The information contained herein, (including design and parts specifications), may be superseded and is subject

to change without notice.

GARLAND COMMERCIAL INDUSTRIES, LLC

185 East South Street

Freeland, Pennsylvania 18224

Phone: (570) 636-1000

Fax: (570) 636-3903

GARLAND COMMERCIAL RANGES, LTD.

1177 Kamato Road, Mississauga, Ontario L4W 1X4

CANADA

Phone: 905-624-0260

Fax: 905-624-5669

Part # 4521353 (06/17/09) © 2005 Garland Commercial Industries,LLC

Part # 4521353 (06/17/09) Page 1

Page 2

Part # 4521353 (06/17/09)Page 2

Page 3

TABLE OF CONTENTS

DIMENSIONS AND SPECIFICATIONS .....4

INTRODUCTION........................6

Unpacking ...................................6

Product Application ..........................6

Serial Plate ...................................6

GENERAL INSTALLATION ...............7

Introduction .................................7

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Ventilation ...................................7

Electrical Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Installation Of Banking Plates .................7

Sanitary Counter Top Seal . . . . . . . . . . . . . . . . . . . . 8

Leg Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Installation Of Counter Stands (Optional) ......9

INDIVIDUAL MODEL INSTALLATIONS ....9

Solid Element Hot Plate; Model EDU-15HSE ....9

Wall Clearances .......................... 9

Electrical Supply.......................... 9

Controls ................................. 9

Before Operating the Hot Plate........... 10

Fryers: Models EDU-18F, EDU-18SF,

EDU-36FT And EDU-36SFT ...................10

Wall Clearances ......................... 10

Electrical Supply.........................10

Controls ................................ 10

Before Operating the Fryer ..............10

Griddles: Models EDU-15G, EDU-24G,

EDU-36G, Grooved Griddles: Models

EDU-15G-U, EDU-24G-U, EDU-24G-U1,

EDU-36G-U, EDU-36GU1, EDU-36G-U2 . . . . . . . 10

Wall Clearances ......................... 10

Electrical Supply.........................10

Controls ................................ 11

Before Operating the Griddle ............ 11

Calibration Instructions.................. 11

Broilers: ModelsEDU-15B, EDU-30B And

EDU-42B ....................................11

Wall Clearances ......................... 11

Electrical Supply......................... 11

Controls ................................ 11

Before Operating the Broiler ............. 11

COMMISSIONING .....................12

Food Warmer: Model EDU-15W ..............12

Wall Clearances ......................... 12

Electrical Supply......................... 12

Controls ................................ 12

Before Operating the Warmer............ 12

OPERATING INSTRUCTIONS............13

Safety Concerns . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Sealed Hot Plates . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Fryers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Griddles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

GENERAL MAINTENANCE AND

CLEANING ............................14

General Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Broilers .....................................14

Food Warmers ..............................14

Hot Plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Fryers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Griddles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Seasoning The Griddle...................15

Cleaning The Griddle .................... 15

Griddles Do’s and Don’t’s ................ 15

Broiler ......................................16

Food Warmers ..............................16

Regular Maintenance And Service . . . . . . . . . . . 16

SERVICING............................16

Hot Plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Griddles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Broilers .....................................18

Food Warmers ..............................18

FAULT FINDING .......................19

Sealed Hotplates Diagnostics ................19

Tubular Hotplates Diagnostics ...............19

Fryer Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Griddle Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . .20

Broiler Diagnostics ..........................20

Food Warmer Diagnostics ...................20

Part # 4521353 (06/17/09) Page 3

Page 4

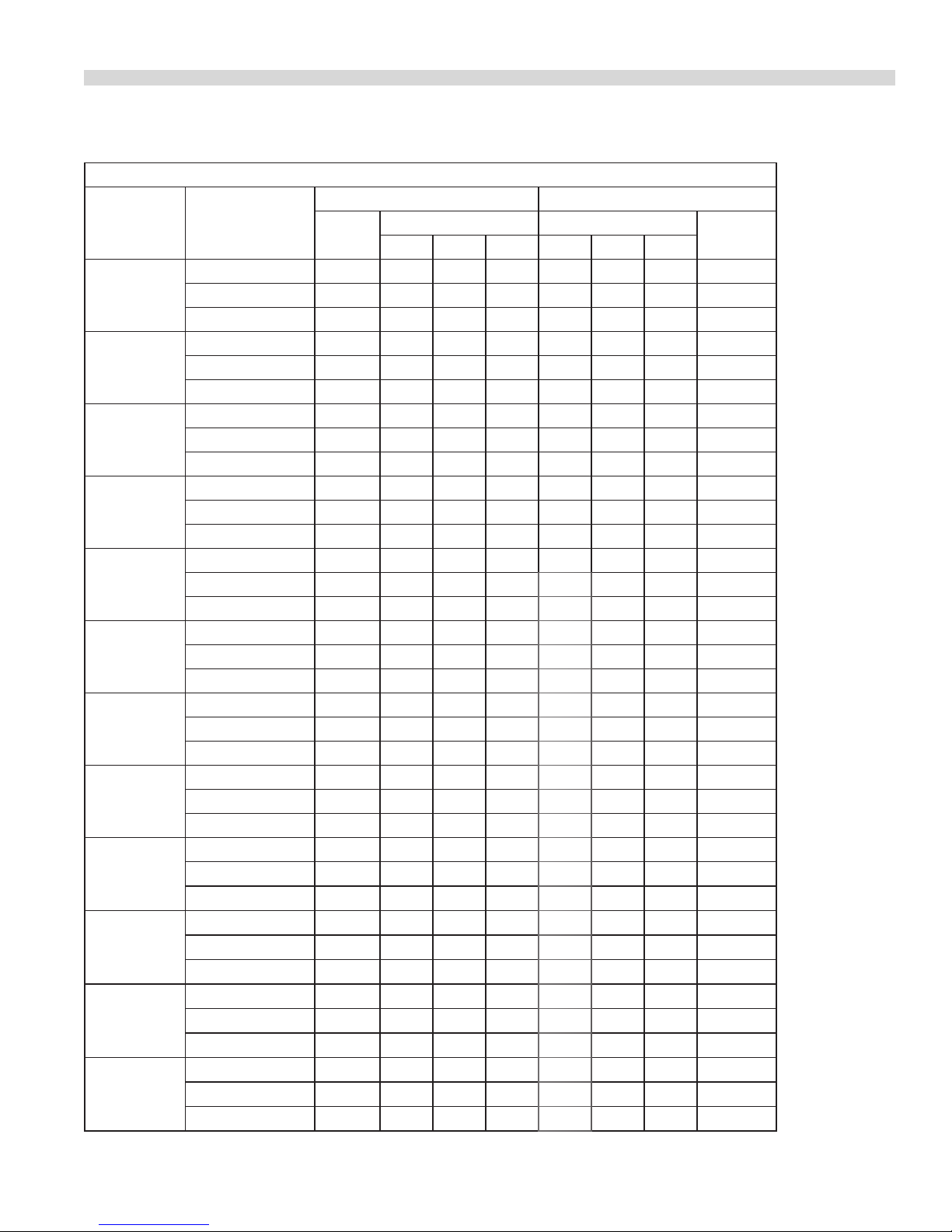

DIMENSIONS AND SPECIFICATIONS

OVERALL DIMENSIONS

MODEL

NUMBER

EDU-15HSE 15 381 24 610 11.25 286

EDU-18F 18 457 24 610 13 330

EDU-15SF 18 457 24 610 13 330

EDU-36FT 36 914 24 610 13 330

EDU-36SFT 30 914 24 610 13 330

EDU-15G 15 381 24 610 13.75 349

EDU-24G 24 620 24 610 13.75 349

EDU-36G 36 914 24 610 13.75 249

EDU-15B 15 381 24 610 13.75 349

EDU-30B 30 762 24 610 13,75 349

EDU-42B 42 1067 24 610 13.75 349

EDU-15W 15 381 24 610 11.50 292

Width Depth Height

In mm In mm In mm

MODEL PRODUCT DESCRIPTION

EDU-15HSE 15” (381mm) Wide Hot Plate With 8” (203mm) Solid Elements

EDU-18F 18” (457mm) Wide Fryer 5.3kw

EDU-18SF 18” (457mm) Wide Fryer 8.0 Kw

EDU-36FT 36” (914 Mm) Wide Twin Fryer 10.6 Kw

EDU-36SFT 36” (914 Mm) Wide Twin Fryer 16.0kw

EDU-15G 15” (381mm) Wide Griddle

EDU-24G 24” (610mm) Wide Griddle

EDU-36G 36” (914mm) Wide Griddle

EDU-15B 15” (381mm) Wide Broiler

EDU-30B 30” (762mm) Wide Broiler

EDU-42B 42” (1067mm) Wide Broiler

EDU-15W 15” (381mm) Wide Food Warmer

Part # 4521353 (06/17/09)Page 4

Page 5

DIMENSIONS AND SPECIFICATIONS continued

LOADING CHART

KW LOAD AMPS

MODEL VOLTAGE

220V/380V 2N~ 4.8 2.4 2.4 0.0 10.8 10.8 0.0 21.6

EDU-15HSU

EDU-18F

EDU-18SF

EDU-36FT

EDU-36SFT

EDU-15G

EDU-24G

EDU-36G

EDU-15B

EDU-30B

EDU-42B

EDU-15W

230V/400V 2N~ 5.2 2.6 2.6 0.0 11.3 11.3 0.0 22.6

240V/415V 2N~ 5.2 2.6 2.6 0.0 10.8 10.8 0.0 21.7

220V~ 5.93 5.93 0.0 0.0 27.0 0.0 0.0 27.0

230V~ 5.3 5.3 0.0 0.0 23.0 0.0 0.0 23.0

240V~ 5.3 5.3 0.0 0.0 22.1 0.0 0.0 22.1

220V/380V 3N~ 7.3 2.4 2.4 2.4 11.1 11.1 11.1 33.2

230V/400V 3N~ 8.0 2.7 2.7 2.7 11.6 11.6 11.6 34.7

240V/415V 3N~ 8.0 2.7 2.7 2.7 11.1 11.1 11.1 33.2

220V/380V 2N~ 11.86 5.93 5.93 0.0 27.0 27.0 0.0 53.9

230V/400V 2N~ 10.6 5.3 5.3 0.0 23.0 23.0 0.0 46.1

240V/415V 2N~ 10.6 5.3 5.3 0.0 22.1 22.1 0.0 44.2

220V/380V 3N~ 14.6 4.9 4.9 4.9 22.2 22.2 22.2 66.5

230V/400V 3N~ 16.0 5.3 5.3 5.3 23.2 23.2 23.2 69.5

240V/421V 3N~ 16.0 5.3 5.3 5.3 22.2 22.2 22.2 66.6

220V~ 2.8 2.8 0.0 0.0 12.8 0.0 0.0 12.8

230V~ 3.4 3.35 0.0 0.0 14.6 0.0 0.0 14.6

240V~ 3.4 3.35 0.0 0.0 14.0 0.0 0.0 14.0

220V/380V 2N~ 5.6 2.8 2.8 0.0 12.8 12.8 0.0 25.6

230V/400V 2N~ 6.7 3.35 3.35 0.0 14.6 14.6 0.0 29.1

240V/415V 2N~ 6.7 3.35 3.35 0.0 14.0 14.0 0.0 27.9

220V/380V 3N~ 8.4 2.8 2.8 2.8 12.8 12.8 12.8 38.4

230V/400V 3N~ 10.1 3.35 3.35 3.35 14.6 14.6 14.6 43.7

240V/415V 3N~ 10.1 3.35 3.35 3.35 14.0 14.0 14.0 41.9

220V ~ 2.3 2.3 0.0 0.0 10.3 0.0 0.0 10.3

230V ~ 2.7 2.7 0.0 0.0 11.7 0.0 0.0 11.7

240V ~ 2.7 2.7 0.0 0.0 11.3 0.0 0.0 11.3

220V/380V 2N~ 4.5 2.3 2.3 0.0 10.3 10.3 0.0 20.6

230V/400V 2N~ 5.4 2.7 2.7 0.0 11.7 11.7 0.0 23.5

240V/415V 2N~ 5.4 2.7 2.7 0.0 11.3 11.3 0.0 22.5

220V/380V 3N~ 6.8 2.3 2.3 2.3 10.3 10.3 10.3 30.9

230V/400V 3N~ 8.1 2.7 2.7 2.7 11.7 11.7 11.7 35.2

240V/415V 3N~ 8.1 2.7 2.7 2.7 11.3 11.3 11.3 33.8

220V~ 1.12 1.12 0.0 0.0 5.1 0.0 0.0 5.1

230V~ 1.1 1.1 0.0 0.0 4.8 0.0 0.0 4.8

240V ~ 1.0 1.0 0.0 0.0 4.2 0.0 0.0 4.2

TOTAL

PER PHASE PER PHASE

L1 L2 L3 L1 L2 L3

1 PHASE

Part # 4521353 (06/17/09) Page 5

Page 6

INTRODUCTION

IMPORTANT: The following instructions should be read

carefully as the manufacturer can not be held responsible for

any damage to property or persons as caused by incorrect

installation or operation of this equipment.

You have just purchased the nest commercial cooking

equipment available anywhere. Like any other ne,

precision built appliance, it should be given regular care

and maintenance. Periodic inspections by your dealer or a

qualied service agency are recommended.

Your new equipment must be installed and adjusted by a

competent person in accordance with the law. Failure to

install appliances correctly could lead to prosecution. It is

in your own interest and that safety to insure that the law is

compiled with.

Your Garland dealer or local authorized service agency is well

qualied to provide this service. Periodic inspections by your

dealer or a qualied service company are recommended

to check temperatures and to insure that moving parts

are operating. Whenever possible avoid overheating idle

equipment for this is the primary cause for increased service

cost.

Factory specied replacement parts must be used to

maintain listing. Use of “Generic” replacement parts may

create a hazard and will void the listing.

Unpacking

Product Application

Preparation of soups, stocks or sauces is done on a hot

plate where slow even cooking is desirable. Heating larger

quantities of food can be done more eciently than heating

small quantities. Pot and pans should be covered whenever

possible to reduce energy consumption.

High acid sauces, such as tomato should be cooked in

stainless steel vessels rather than aluminum since stainless

will not react chemically. Light colored sauces may be

discolored by the use of aluminum especially if stirred with

a metal spoon. Salty water may pit aluminum vessels if used

frequently.

NOTE: Many parts of the equipment are raw steel, i.e.,

griddle top, top grates, rings etc. and can react with moisture

forming rust. This is normal and not considered a defect.

Clean with stainless steel or ber pad. A light coating of salt

free oil may be applied to prevent further rusting.

Serial Plate

All electrical ratings are shown on the serial plate of each

unit and are readily visible by opening the enameled door

located below the control panel.

For proper operation, the information noted on the serial

plate of your new equipment must match your electrical

supply.

1 Check the crate/carton for possible damage sustained

during transit. Carefully remove the unit from the crate/

carton and again check for damage. Any damage must be

reported to the carrier immediately.

2. Any protective material covering stainless steel parts

must be removed.

3. The type of voltage supply that the equipment was

manufactured for at the factory is noted on the serial

plate and the packaging. This type of supply must be

used.

4. Do not remove permanently xed labels, warnings

or serial plates from the appliance, for this many void

approvals and create a safety hazard.

In the event you have any questions concerning the

installation, use, care or service of this or any other Garland

product, write or call our Product Service Department. When

corresponding with the factory or your local authorized

factory service center regarding service problems or

replacement parts, be sure to refer to the particular unit by

the correct model number (including the prex and sux

letters and numbers) and the warranty serial number. The

serial plate axed to the unit contains this information.

Part # 4521353 (06/17/09)Page 6

Page 7

GENERAL INSTALLATION

REAR VIEW

Introduction

The Garland EDU series 230V and 240V complies with

the essential requirement of the directives 73/23/EEC,

89/336EEC, 93/68/EEC and the standards; EN60335, IEC529,

EN5501, eN6100-4-A, ENV502404, EN61000-4-4, ENV50142,

IEC1000-4-11, ENV50141. Also complies with the latest

edition of NSF#4.

Safety

This manual pertains to the EDU series counter equipment.

The reader/operator must interpret its contents to applicable

needs. If there is any question of interpretation of any

literature, please contact your authorized service agency or

our customer service department at the phone number in

the information pamphlet.

A qualied person must make the installation of these

products in accordance with local codes.

Always follow these safety precautions when operating these

appliances.

These units must only be operated by qualied persons. DO

NOT operate with out reading this manual.

DO NOT operate the appliance unless all service and access

panels are in place and fastened properly.

Electrical Supply

Before attempting the electrical connection, the serial plate

should be checked to ensure that the equipment’s electrical

characteristics agree.

The supply terminal block is accessible from the font. The

electrical supply must be adequate for the voltage, phase

and current marked on the serial plate.

Note: a means of disconnection from the supply having

a contact separation of at least 3 mm (0.12”) must be

incorporated in the xed wiring.

This equipment is intended to be installed with xed

permanent wiring.

Warning: This appliance must be earthed.

Single and three-phase connection:

Unless otherwise noted, all appliances are shipped from

the factory for three phase connection. A wiring diagram is

attached to the rear each appliance. Visually check all the

electrical connections. The appliance is wired at the factory

as specied on the order. If it is necessary to change the

phasing, refer to the wiring diagram.

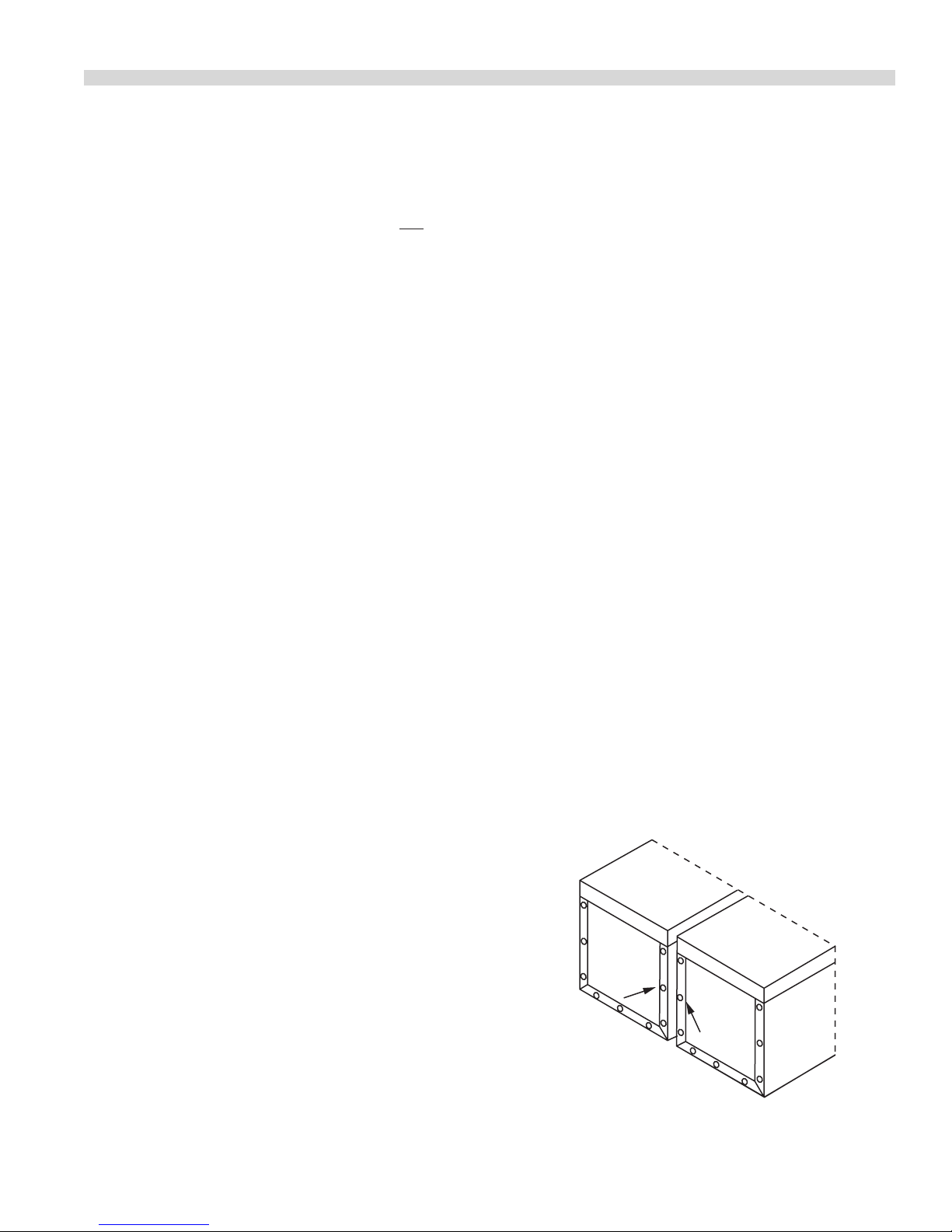

Installation Of Banking Plates

DO NOT attempt to repair or place any part of these

appliances unless all main power supplies have been

disconnected.

WARNING

To avoid personal injury; use extreme caution in setting up,

operating and cleaning these appliances to avoid coming

in contact with hot surfaces. Suitable protective clothing

should be worn or proper utensils used to prevent the risk of

burns.

Note all warning labels and marking on the appliance, which

call attention to further dangers and necessary precautions.

THESE APPLIANCES SHOULD NOT BE CLEANED WITH A

WATER JET.

Ventilation

The area in which the appliance is installed must be

adequately ventilated to provide air for removal of steam,

heat generated by the appliance etc. the use of mechanical

extract system should be considered and conform to local

codes.

All units may be installed independently or banked with

other ED or GD series equipment. To ensure a matching

and permanent t between units, two banking plates are

available for each unit to be installed. One at the front and

one at the rear of each two units being banked together.

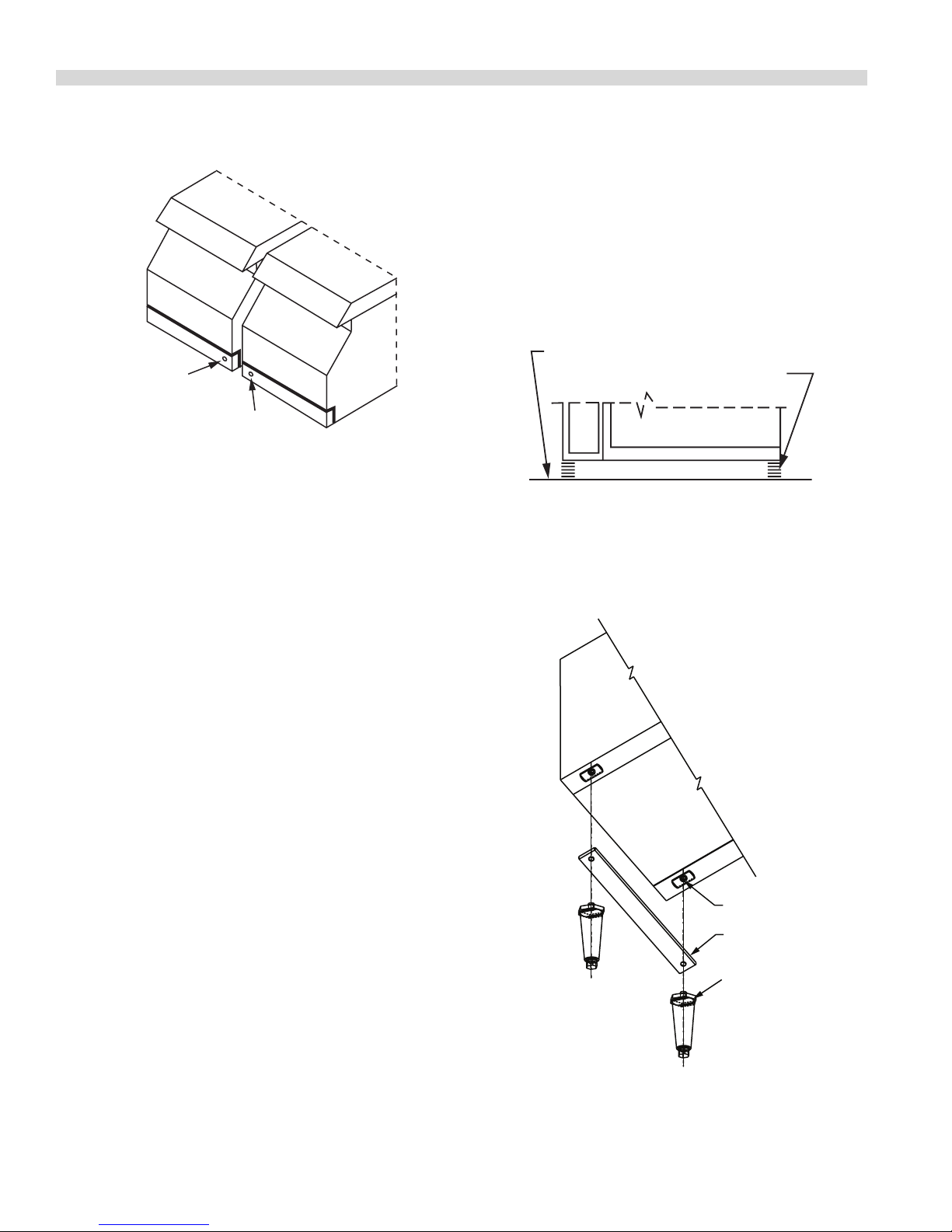

If optional 4” (102mm) legs are supplied with unit, discard

leveling bolts and replace with legs.

Part # 4521353 (06/17/09) Page 7

Page 8

FRONT VIEW

GENERAL INSTALLATION continued

COUNTER TOP

SILICONE SEALANT

BOTTOM OF UNIT

LEG CHANNEL

(QTY 2)

4" [102mm]

ADJUSTABLE LEG

(QTY 4)

LEG INSTALLATION

3. Lay a generous bead of silicone under the entire

4. Secure unit to counter top through the holes located on

5. Smooth the silicone seal into the crevice with nger or

1. Level each unit by adjustment of leveling bolts or legs.

Use a spirit level and level unit four ways; across front and

back and down left and right edges. Level all other units

to the rst unit.

NOTE: Griddles may not rest evenly on the unit body if units

are not leveled.

2. Remove acorn nuts at rear of unit.

Leg Installation

The leg channel is located onthe package base. This channel

must be installed when using the legs.

perimeter of appliance bottom.

the underside of the appliance using 10A sheet metal

screws.

tool to provide a cove seal.

3. Attach one banking plate in position at rear by placing

1/4” (6.4 mm) diameter holes in the banking plate over the

screw holes in the rear of units and fasten by replacing the

acorn nuts removed in step 2.

4. Push units into position on counter top or back bar.

5. To secure the front, open the lower front panel, place

banking plate over the two holes (one on each unit) and

secure banking plate using sheet metal screws supplied.

Sanitary Counter Top Seal

When appliance is installed without legs on a counter top, it

must be sealed in accordance with N.S.F. standards as per the

following instructions:

1. Appliance should be located on a level counter top

surface. Complete the electrical connection.

2. Thoroughly clean the appliance bottom perimeter and

the counter top area around the appliance perimeter.

Part # 4521353 (06/17/09)Page 8

Page 9

GENERAL INSTALLATION continued

Installation Of Counter Stands (Optional)

1. Assemble and level counter stand as illustrated in the

instructions found in the counter stand carton.

2. Remove and discard leveling bolts on unit to be installed

on counter stand.

3. Place units in desired position on counter stand, securing

the rst unit with 8-32 machine screws and at washers.

Insert 8-32 machine screws through the 7/32” (5mm)

diameter holes in stand into the nutserts in the bottom of

EDU Series unit.

4. Connect banking plates as described in section titled,

5. Secure last unit to counter stand with 8-32 machine screws

INDIVIDUAL MODEL INSTALLATIONS

Solid Element Hot Plate;

Model EDU-15HSE

Wall Clearances

Do not install the appliance closer to a wall of combustible

material than :

Back: 1-1/2” (38mm)

Sides 1-1/2” (38mm)

Electrical Supply

Before attempting the electrical connection, the rating noted

on the serial plate should be checked, to ensure that the

appliance electrical characteristics and the supply electrical

characteristics agree. The electrical supply must be adequate

for the voltage, phase and current marked on the serial plate.

Use only wires suitable for 75°C (167°F).

Controls

Solid element hot plates are controlled by six heat switches.

There are three boiling and three simmering positions. Turn

the switch left or right from the o position to the desired

number, one being the lowest setting and six being the

highest.

Switch

Position

Installation of Banking Plates.

and at washers. Inserts 8-32 machine screws through

the 7/32” (5mm) diameter holes in stand into the nutserts

in the bottom of EDU series unit.

Wattage Heat

1 240

2 340

3 450 Medium

4 1300

6 2600

Low

(Simmer)

High (Boil)5 1750

The supply cable entrance is located on the right side, when

facing the rear of the unit. The cable is fed towards the front

through a wire way.

A knockout is provided near the front left side of the unit,

located behind the control panel. To access the knockout,

loosen the two acorn nuts and hinge the control panel

downwards. The terminal block is also located in this area.

Part # 4521353 (06/17/09) Page 9

This hot plate is protected against overheating when

running empty or when using poor quality cookware, by a

unique built-in bimetal protector switch. The protector cuts

down the power automatically under the above conditions

before overriding the regulator switch and returning itself to

normal, this is an important feature.

Page 10

INDIVIDUAL MODEL INSTALLATIONS continued

Before Operating the Hot Plate

The top working surface has a heat resistant coating. Before

using the sealed hot plates for the rst time, they should

be heated for a short period without a pan, to harden and

burn o the protective coating (3-5 minutes at the highest

setting).

Fryers: Models EDU-18F, EDU-18SF,

EDU-36FT And EDU-36SFT

Wall Clearances

Do not install appliance closer to a wall of combustible

material than:

Back: 0”

Sides: 0”

Electrical Supply

Before attempting the electrical connection, the rating

on the serial plate should be checked to ensure that the

appliance electrical characteristics and the supply electrical

characteristics agree. The electrical supply must be adequate

for the voltage, phase and current marked on the serial plate.

Use only wires suitable for 75° C (167°F).

A knockout is provided on the right side, when facing the

rear of the unit, for the supply cable entrance. Access to the

terminal block is gained by removing the fry tank assembly,

the rear shield and contactor box cover, all are located at the

rear of the fryer.

Controls

1. All EDU series fryers are equipped with a manually

re-settable high limit, located at the rear of the

element termination box. In the event that shortening

temperatures exceed normal limits, the high limits will

trip and can only be reset by pushing the red button

when the shortening has cooled.

2. All EDU series fryers are equipped with a precision

electronic thermostat, which has been factory calibrated

and is designed to hold that calibration. There should

never be the need to calibrate this thermostat in the eld.

Should there ever be an abnormal discrepancy in the set

point and actual temperatures, or repeated tripping of

the new high limit occurs, this fryer should be serviced by

an authorized Garland service agency.

Before Operating the Fryer

1. Before leaving the factory, the fryer was tested and the

thermostat calibrated with oil in the fry tank. Therefore it

is necessary to clean the fry tank and the elements before

lling with frying compound. Use detergent or other

cleaning agents, with hot water. Thoroughly rinse and dry

the fry tank.

2. To remove the fry tank, raise the element assembly by

means of the handle until the support engages, holding

the element assembly in the upright position. The

element assembly is lowered by moving the support/lock

stop to release the element assembly from the upright

position.

Griddles: Models

EDU-15G, EDU-24G, EDU-36G,

Grooved Griddles: Models

EDU-15G-U, EDU-24G-U, EDU-24G-U1, EDU36G-U, EDU-36GU1, EDU-36G-U2

Wall Clearances

Do not install appliance closer to a wall of combustible

material than:

Back: 1-1/2” (38mm)

Sides: 1” (25mm)

Electrical Supply

Before attempting the electrical connection, the rating

on the serial plate should be checked to ensure that the

appliance electrical characteristics and the supply electrical

characteristics agree. The electrical supply must be adequate

for the voltage, phase and current marked on the serial plate.

Use only wires suitable for 75° C (167°F).

The supply cable entrance is located on the right side, when

facing the rear of the unit. The cable is fed toward the front

through a wire way.

A knockout is provided near the front side of the unit, located

behind the control panel. To access the knockout, loosen the

two acorn nuts and hinge the control panel downwards, the

terminal block is located in this area.

Part # 4521353 (06/17/09)Page 10

Page 11

INDIVIDUAL MODEL INSTALLATIONS continued

Controls

All EDU griddles are equipped with snap action thermostats.

Before Operating the Griddle

1. Remove the protective coating on the griddle

surface and side splashers using a mild

detergent.

2. Thoroughly rinse the griddle with a vinegar water

solution (3/4 cup vinegar per quart of water) and dry

thoroughly with a clean cloth.

3. The Griddle must be seasoned before operation, see the

general maintenance and cleaning section for seasoning

instructions.

Calibration Instructions

1. Field calibration is seldom necessary and should not

be attempted unless experience with cooking results

denitely proves that the control is not maintaining the

temperature to which the dial is set.

2. Should calibration be required, use a test instrument

(pyrometer) with a special disc type thermocouple or

reliable “surface” type thermometer. Note: A drop of oil on

the face of the disc will provide a better contact.

3. Turn the griddle temperature dials to 350°F (177°C). In

order to allow the griddle temperatures to stabilize, the

controls must be allowed to cycle twice before taking a

test reading.

4. Check the temperature reading when the control has just

cycled “OFF” (as indicated by the cycling amber pilot), by

placing the sensor rmly on the griddle surface, directly

above the sensing bulb of the control. If the temperature

does not read with in 8° C (15°F) of the dial setting,

recalibrate as follows:

5. Carefully remove the thermostat dial making sure that

the setting is not disturbed.

6. Hold the dial shaft steady and with a slim screwdriver,

turn the calibration screw, located in the dial shaft,

clockwise to decrease and counter clockwise to increase

the temperature. Example: 1/4 Turn = 18° C (35°F).

7. Replace the thermostat dial and repeat steps 2 though 4

to verify that the correct adjustment has been made.

Broilers: Models

EDU-15B, EDU-30B And EDU-42B

Wall Clearances

Do not install closer to a wall of combustible material than:

Back: 9” (229mm)

Side: 9” (229mm)

Electrical Supply

Before attempting the electrical connection, the rating

on the serial plate should be checked to ensure that the

appliance electrical characteristics and the supply electrical

characteristics agree. The electrical supply must be adequate

for the voltage, phase and current marked on the serial plate.

Use only wires suitable for 90° C (194°F).

The supply cable entrance is located on the front side, when

facing the rear of the unit. The cable is fed toward the front

through a wire way.

A knock out is provided near the front left side of the unit,

located behind the control panel. To access the knockout,

loosen the two acorn nuts and hinge the control panel

downwards, the terminal block is located in this area.

Controls

Innite switches (energy regulators) are used to control the

elements.

High to 5 High heat

5 to 3 Medium heat

3 to Lo Low heat

Setting the switched between these numbers will give

intermediate heat. Switches are reversible and may be

turned left or right.

Before Operating the Broiler

1. Before leaving the factory, the castings were coated with

oil to prevent corrosion. Therefore, it is necessary to clean

the castings before seasoning and cooking.

2. Turn the broiler control dial/s to “HI” and allow to run

empty for 15 minutes. Turn the dial/s to “OFF” and allow

castings to cool. Clean o any residue with a detergent

soaked cloth.

Part # 4521353 (06/17/09) Page 11

Page 12

INDIVIDUAL MODEL INSTALLATIONS continued

3. Using a dry cloth, rub a thin layer of cooking oil into the

casting surface. Oil should be an unsalted shorting or

high temperature cooking oil. Turn the control dial/s to

#4 and allow to run empty for 15 to 30 minutes. This will

season the cooking surface and prevent product from

sticking.

Food Warmer: Model EDU-15W

Wall Clearances

Do not install closer to a wall of combustible material than:

Back: 1” (25mm)

Sides: 1” (25mm)

Electrical Supply

Before attempting the electrical connection, the rating

on the serial plate should be checked to ensure that the

appliance electrical characteristics and the supply electrical

characteristics agree. The electrical supply must be adequate

for the voltage, phase and current marked on the serial plate.

Use only wires suitable for 90° C (194°F).

The supply cable entrance is located on the right side, when

facing the rear of the unit. The cable is fed toward the front

through a wire way.

A knockout is provided near the front left side of the unit,

located behind the control panel. The access the knockout,

loosen the two acorn nuts and hinge the control panel

downward, the thermal block is located on this area.

Controls

Innite switches (energy regulators) are used to control the

elements.

High to 5 High heat

5 to 3 Medium heat

3 to Lo Low heat

Setting the switched between these numbers will give

intermediate heat. Switches are reversible and may be

turned left or right.

Before Operating the Warmer

Before use, it is recommended that the inside of the tank be

cleaned with a detergent soaked cloth, to remove fabricating

and protective oils. Rinse with clean water and dry with a

clean cloth.

COMMISSIONING

1. Ensure that all controls are in the o position and turn on

the main electrical supply.

2. Operate each section of (each) appliance in accordance

with the instructions given in the Operating section.

3. Check that the/each appliance functions correctly and

that the voltage supply to the/each appliance does

not drop more that 5% when all sections are operated

simultaneously.

4. When the operation has been checked, turn all controls

to the o position. Hand this manual to the purchaser

for retention and instruct them in ecient and safe

operation of the appliance/s. This manual should be

retained for future reference.

Part # 4521353 (06/17/09)Page 12

Page 13

OPERATING INSTRUCTIONS

Safety Concerns

It is the responsibility of the supervisor or equivalent person

to ensure that the users of this equipment wear suitable

protective clothing and draw attention to the fact that some

parts will, by necessity, become very hot and will cause burns

if touched accidentally.

Sealed Hot Plates

All purpose sealed top elements provide an easy-clean top.

They are intended for boiling, simmering, satué and other

top cooling.

Operating practices are very important for the ecient use of

these elements:

1. Pot bottoms must be at. This increased the heat transfer

to the pot. Do not use either convex or concave in excess

of 1 mm (1/32”).

2. Use pots with the same diameter as the element when

possible. This will reduce the heat up time.

3. Do not preheat the element. Elements are protected with

a high limit, which automatically reduces the element to

a lower power. It will increase the heat up if this occurs.

4. Use a lid to cover the posts when boiling water.

Operating The Sealed Hot Plate

1. Before using the sealed hot plates for the rst time, they

should be heated at a setting #3 for 5 minutes, then

turned o and allowed to cool. This will harden and burn

o the protective coating.

2. Set the six heat switch dial to the desired position for 1 to 6.

Sealed Hot Plate Application Guide:

Application Dial Setting Wattage

Boiling,

Frying,

Braising

Simmering

Warming 1 240

Shutting Down The Sealed Hot Plate:

6 2600

5 1750

4 1300

3 450

2 340

Fryers

Operating The Fryer:

1. For liquid frying compound, ll the fry tank to bottom oil

line stamped at the rear of the tank (9 liters, 8 quarts). This

allows for oil expansion as heat is applied. Do not ll with

cold oil any higher than the bottom line; overow may

occur as heat expands the oil. Set the power switch to

the “ON” position and turn the thermostat to the desired

frying position.

2. If a hydrogenated (solid) frying compound is used,

measure 17 pounds (7.7 Kg) into the dry tank. Note: pack

the compound, to ensure that the element assembly is

completely covered with the compound.

CAUTION: Never set a complete block of solid shortening on

top of heating elements.

3. Set the power switch to the “ON” position and turn

the thermostat dial to 121°C (250°F) until enough

of the compound has melted to cover the element

assembly. Then turn the thermostat to the desired frying

temperature.

4. Ensure that the oil level is at the top OIL LEVEL line when

the oil is at its cooking temperature. It may be necessary

to add oil or shortening to bring the levels up to the

proper mark, after reaching cooking temperature.

5. Never place more product in the basket than half full.

Griddles

Griddle tops are designed to have food cooked directly on

the surface. Do not put pots or pans on the griddle surface,

since this will scratch or nick the surface and result in

improper cooking or sticking of product. Never salt food over

a griddle since this will built up a gummy residue making it

dicult to clean.

Avoid hitting the surface of the griddle with the edge a

spatula since it will cause nicks. The most frequently used

temperatures are 149° C to 177°C (300° F to 500° F). After one

ring, the griddle plate will discolor, this is normal and will not

aect cooking performance.

Note: The griddle must be seasoned before initial use, see

griddle seasoning in General Maintenance and Cleaning

section.

1. Turn the six heat switch to the “OFF” position.

Part # 4521353 (06/17/09) Page 13

Page 14

OPERATING INSTRUCTIONS continued

Operating the Griddle:

Note: Ensure that the electrical supply to the appliance is

turned “ON”.

1. Set the thermostat/s to the desired temperatures.

2. The griddle is ready for use when the amber indicator

light cycles o.

Shutting Down The Griddle:

1. Turn the thermostat/s to the “OFF” position.

Broilers

Operating The Broiler:

Innite switches are used to control broiler casting

temperatures.

“Hi” to 5 for high heat (Hi being the maximum).

5 to 3 for medium heat.

3 to ‘’Lo” for low heat.

Setting the switches between any of the above numbers will

give intermediate heat. Switches are reversible and may be

turned right or left.

Food Warmers

CAUTION: DO NOT OPERATE THE WARMER DRY! THE WARMER

MUST BE OPERATED WITH WATER IN THE TANK.

The food warmer has been designed to have water in the tank

for even heating. The end walls of the tank have embossed

lines. The higher line is for “max”, the lower for “min”. The tank

should be lled with clean water to a point between the two

lines. Do not ll about the top line, nor below the bottom line.

Water will evaporate during use, do not allow water to fall

below the bottom line.

Operating The Food Warmer

A innite switch is used to control the temperature in the

tank.

“Hi” to 5 for high heat (Hi being the maximum).

5 to 3 for medium heat.

3 to ‘’Lo” for low heat.

Setting the switches between any of the above numbers will

give intermediate heat. Switches are reversible and may be

turned right or left.

Note: Periodic checks should be made during operation to

ensure that the water level does not go below the lower

embossed line. Should it do so, top o with fresh water.

GENERAL MAINTENANCE AND CLEANING

WARNING: THESE APPLIANCES SHOULD NOT BE CLEANED

WITH A WATER JET.

General Cleaning

Stainless steel should be cleaned using a mild detergent,

a soft cloth and hot water. If it is necessary to use a nonmetallic scouring pad, always rub in the direction of the grain

in the metal to prevent scratching. Wash a small area at a

time and rinse the washed area with a clean sponge dipped

into a disinfectant and wipe dry with a soft clean cloth before

it can dry.

Use only stainless steel, wood or plastic tools to scrape

o heavy deposits of grease or oil. Do not use ordinary

steel scrapers or knives, as particles of iron may become

embedded and rust.

NEVER USE STEEL WOOL.

Enameled surfaces should be allowed to cool down before

cleaning. Wipe exposed cleaning, when cool, with a mild

detergent and hot water. Stubborn reside spots may be

removed with a scouring pad. Dry thoroughly with a clean

cloth.

Painted surfaces should only be cleaned with a mild

detergent. Rinse with a clean sponge and hot water. Dry

thoroughly with a clean cloth. NOTE: Use of a scouring pad or

powdered cleanser on painted surfaces will wear away paint

surfaces and must be discouraged.

Part # 4521353 (06/17/09)Page 14

Page 15

GENERAL MAINTENANCE AND CLEANING continued

Hot Plates

The design of the sealed hot plates provides an easy clean

top surface. Clean any spills with a cloth soaked in a mild

detergent and hot water. For any build up of burned on

grease or food spills, use only a non metallic scouring pad,

always rub in the direction of the grain of the metal to

prevent scratching. Rinse with a sponge dipped in clean hot

water and dry thoroughly with a clean cloth.

Fryers

Cleaning The Fry Tank

1. If a liquid frying compound is used, allow the compound

to cool, then raise the element assembly by means of the

handle until the support engages and let the oil run o

the elements into the fry tank. Wipe the surface oil o the

elements to prevent dripping into the unit bottom when

the tank is removed. Lift out the fry tank and empty the

oil into a lter, after ltering it is then ready for re-use.

Clean the tank in the pot wash area with a mild detergent

and hot water. Rinse with a sponge dipped in a vinegar

and water solution. (3/4 cup of vinegar to 1 quart of

water) and dry thoroughly with a clean cloth.

2. If hydrogenated (solid) frying compound is used that has

been allowed to cool and become solidied, rst turn the

thermostat dial to 121°C (250°F) until the compound is

in a liquid state. Turn the thermostat dial/s to o “O”. Lift

the element assembly by means of the handle until the

support engages and let the oil run o the elements into

the fry tank. Then proceed as described in step 1 to lter

the compound and clean the fry tank.

3. Clean the top of the unit with a cloth soaked in a mild

detergent and hot water, including the front of the

element assembly housing. Rinse with a clean cloth

dipped in clean hot water, Dry thoroughly with a clean

cloth.

4. Repeat step 1 and set the thermostat dial/s to 135°C

(275°F).

5. Repeat steps 2&3. The griddle is now ready for use.

Cleaning The Griddle

1. Use a standard 64-76mm (2-1/2 to 3”) scraper or spatula,

scrape the griddle surface (to remove food particles or oil

residue) towards the grease trough using even back to

front strokes. Deposit debris into the chute.

2. Pour shortening or oil onto the griddle surface, using a

front to back motion. Clean the griddle using a griddle

stone or grill screen. Always with the grain of the steel,

never sideways.

3. Using a clean cloth, rub a thin layer of cooking oil onto

the griddle surface.

4. Remove the grease drawer, empty and wash thoroughly

with a mild detergent and water. Repeat.

5. Re-season the griddle as detailed above. The griddle is

now ready for use.

Griddles Do’s and Don’t’s

D o’s

1. Season the griddle. This will prevent foods from sticking

and make it easier to keep the surface clean.

2. Keep the surface clean. Scraping the surface throughout

production to clear food and oil prevents build up

and will conserve energy and prevent the plate from

overheating.

3. Turn the temperature down during slow periods.

Reducing the temperature or turning sections o during

slow periods will conserve energy and prevent the plate

from overheating.

Griddles

Seasoning The Griddle

1. Using a clean cloth rub a thin layer of cooking oil onto

the griddle surface. Oil should be an unsalted shorting or

high temperature cooking oil.

2. Set the griddle thermostat dial/s to 55°C (130°F) and

heat the griddle surface until the oil begins to caramelize

(turning a golden brown). Once this occurs, turn the

thermostat dial/s to “OFF”.

3. Scrape o the caramelized oil with a standard spatula.

Part # 4521353 (06/17/09) Page 15

Don’t’s

1. Do not use salt to clean the griddle surface. Salt is

corrosive and can cause pitting on the griddle.

2. Do not allow metal utensils (spatula, scraper, etc.) to

nick and/or dent the surface of the griddle. The edges of

these utensils are sharp and will create divots were oil can

collect in and caramelize which causes sticking.

3. Do not use the griddle as a hot top. A large pan or pot will

trap the heat and cause the griddle plates to warp.

Page 16

GENERAL MAINTENANCE AND CLEANING continued

4. Do not set the thermostat dials to high stop to preheat

faster. Preheating at the desired temperature takes 15-20

minutes. High stop does not heat faster and only serves

to overheat the griddle.

Broiler

Cleaning (After Each Use)

To clean the broiler castings after a period of heavy use, turn

the control switch dial/s to “HI”. This will creates a “self-clean”

burn o of product residue oil, continue until incinerating

smoke reduces. Turn the switch dials to o (“O”) and allow to

cool. With a sti brush, clean the castings from front to back.

Complete the casting cleaning process with a cloth soaked in

a mild detergent and hot water solution. (3/4 cup of vinegar

per quart of water) and dry thoroughly with a clean cloth.

Tilt the castings up and clean the grease collector under the

castings, pushing any food residue through the opening into

the grease tray.

Remove the grease tray, drain and thoroughly clean with a

mild detergent and hot water. Rinse and dry thoroughly.

After cleaning the castings, rub a thin layer of oil onto the

casting surface with a clean cloth. The broiler is now ready for

use.

Food Warmers

Empty the water from the tank and clean any lime deposit

with a non-metallic scouring pad. Clean with a cloth soaked

in a mild detergent and hot water. Rinse with a sponge

dipped in clean hot water and dry with a clean cloth.

The top of the unit can be cleaned with a cloth soaked in

a mild detergent and hot water. For food spill build up, a

non-metallic scouring pad can be used, always rub in the

direction of the grain of the metal to prevent scratching.

Rinse with a sponge dipped in clean hot water and dry

thoroughly.

Regular Maintenance And Service

To ensure long life, ecient and safe operation of you

equipment, it is recommended that a maintenance and

servicing program be carried out at regular intervals, the

frequency of which will vary, depending on the installation

conditions and amount of usage. Usually once per year is

adequate.

Servicing must be carried out by competent persons in

accordance with the law.

It is essential that the instructions in this manual are strictly

followed for the safe and economical operation of the

equipment. If it is known or suspected that a fault exists on

an appliance, that appliance must not be used until the fault

has been rectied by a competent person.

SERVICING

Regular servicing by a competent person according to the

law is recommended to ensure the continued safe and

ecient performance of the appliance/s.

Factory specied replacement parts must be used to

maintain listing. Use of “Generic” replacement parts may

create a hazard and will void the listing.

We suggest that servicing be performed by your local

authorized service agency or other competent persons,

according to the law.

Warning: Turn o the electrical mains before commenting

any service work.

Hot Plates

Elements:

If it is necessary to replace a faulty solid element, rst turn o

all electrical mains.

1. Loosen the two acorn nuts that secure the control panel

and hinge the panel downwards.

2. Remove the two screws that secure the element access

plate in the switch guard. Remove the access plate.

Part # 4521353 (06/17/09)Page 16

Page 17

SERVICING continued

3. Reach in though the access opening with a 10mm

wrench and remove the nuts that secure the wire-way,

at the center of each element and drop the wire-way.

Remove the second nut that at the center of the element,

remove the ground wires and drop the second screening

sheet. Lift out the faulty element.

4. Remove one wire at a time for the faulty element and

immediately connect it to the same terminal on the

replacement element. Discard faulty element.

5. Install the replacement element in the hot plate top with

the element terminations in the original position. Secure

with the screening sheet, ground wire and nut.

6. Reassemble in the reverse order.

Six Heat Switch

If it is necessary to change faulty switch, rst turn o

electrical mains.

1. Loosen the two acorn nuts securing the control panel

and hinge the control panel downwards.

2. Remove the dial from the faulty switch and remove the

two screws that secure the switch to the control panel.

Leave the wires attached to the faulty switch, until the

replacement switch has been mounted on the control

panel.

3. Remove one wire at a time from the faulty switch and

immediately connect it to the same terminal on the new

switch.

4. Reassemble in the reverse order.

Indicator Lamp:

If it is necessary to change the indicator lamp, rst turn o

the electrical mains.

Thermostat:

If it is necessary to replace a thermostat, rst turn o the

electrical main.

1. Loosen the two acorn nuts securing the control panel

and hinge the control panel downward.

2. Remove the clip/s that secures the griddle to the body, at

the front.

3. Raise the griddle and engage the support prop in the

hole in the switch guard.

4. Loosen the two nuts that secure the clamp over the

sensing bulb and withdraw this bulb.

5. Remove the two screws that secure the thermostat to the

control panel, after rst removing the control dial.

6. Disconnect the wires from the taps on the thermostat. Be

sure to note which terminal on the thermostat.

7. Remove the faulty thermostat and re-assemble the

replacement thermostat in the reverse order.

Indicator Lamp:

If it is necessary to replace an indicator lamp, rst turn o the

electrical mains.

1. Loosen the two acorn nuts securing the control panel

and hinge the panel downward.

2. Disconnect the supply wires to the lamp body and

remove the faulty lamp.

3. Install the replacement lamp in the control panel.

4. Reassemble in the reverse order.

Element:

1. Loosen the two acorn nuts securing the control panel

and hinge the panel downwards.

2. Disconnect the supply wires to the lamp body and

remove the faulty lamp.

3. Install the replacement lamp in the control panel.

4. Reassemble in reverse order.

Griddles

Follow the instructions in Griddle installation, calibration to

check thermostat calibration.

Part # 4521353 (06/17/09) Page 17

If it is necessary to replace a griddle element, rst turn o all

the electrical mains.

1. Loosen the two acorn nuts securing the control panel

and hinge the control panel downward.

2. Remove the clip/s that secure the griddle to the body, at

the front.

3. Raise the griddle and engage the support prop in the

hole in the switch guard.

4. Disconnect the wires from the element terminal.

Page 18

SERVICING continued

5. Remove the wire grounding the element clamp to the

body and remove the nuts that secure the element

clamp/bae to the bottom of the griddle plate. Lower

the clamp/bae and remove the faulty element.

6. Reassemble the replacement element, secure properly

with the clamp/bae.

7. Reassemble in reverse order.

Broilers

Elements:

To replace a faulty element, rst turn o all electrical mains.

1. Raise the relevant casting sucient to remove the tilting

stop rod toward the rear.

2. Lift out the casting and element assembly. Remove the

clamps that secure the faulty element to the casting,

remove the four screws that secure the element to the

termination box and remove the faulty element.

3. Install the replacement element,

4. Reassemble in the reverse order.

Innite Switch (Energy Regulator):

To replace a faulty innite switch, rst turn o the electrical

mains.

1. Loosen the two acorn nuts that secure the control panel

and hinge the control panel downward.

2. Remove the dial of the faulty switch and remove the

two screws that secure the switch to the control panel.

Leave the wires attached to the faulty switch, until the

replacement switch has been mounted on the control

panel.

3. Remove one wire at a time from the faulty switch and

immediately connect it to the same terminal on the new

switch.

4. Reassemble in the reverse order.

2. Disconnect the supply wires to the lamp body and

remove the faulty lamp.

3. Install the replacement lamp in the control panel.

4. Reassemble in the reverse order.

Food Warmers

Elements:

If it is necessary to replace a faulty element, rst turn o the

electrical mains.

1. Lift out the tank. Remove the screws (4) that secure

the bae above the element and lift up the element.

Disconnect the wires from the element terminals and

take out the faulty element.

2. Reconnect the wires to the terminals of the replacement

element.

3. Reassemble in the reverse order.

Innite Switch:

If it is necessary to replace a faulty switch, rst turn o all

electrical mains.

1. Loosen the two acorn nuts securing the control panel

and hinge the panel downward.

2. Remove the dial from the faulty switch and remove the

two screws that secure the switch to the control panel.

Leave the wires attached to the faulty switch until the

replacement has been mounted on the control panel.

3. Remove one wire at a time from the faulty switch and

immediately connect it to the same terminal on the new

switch.

4. Reassemble in the reverse order.

Indicator Lamp:

If it is necessary to change the indicator lamp, rst turn o

the electrical mains.

Indicator Lamp:

If it is necessary to change the indicator lamp, rst turn o

the electrical mains.

1. Loosen the two acorn nuts securing the control panel

and hinge the panel downwards.

1. Loosen the two acorn nuts securing the control panel

and hinge the panel downwards.

2. Disconnect the supply wires to the lamp body and

remove the faulty lamp.

3. Install the replacement lamp in the control panel.

4. Reassemble in the reverse order.

Part # 4521353 (06/17/09)Page 18

Page 19

FAULT FINDING

If servicing is required, we suggest that servicing be performed by your local authorized service agency or other competent

persons, according to the law.

Sealed Hotplates Diagnostics

PROBLEM POSSIBLE CAUSE SOLUTION

Water in pot does not boil

or water takes too long

to boil; with switch set to

position “6”.

Tubular Hotplates Diagnostics

PROBLEM POSSIBLE CAUSE SOLUTION

Hotplate too hot or cold. Defective innite switch. Replace indenite switch.

Hotplate not heating at all Defective heating element. Replace element.

Pot has irregular bottom. Use a at bottom pot.

Pot too large for element size. Use a smaller diameter pot

Pot too small for element size. Use a larger diameter pot.

Element was preheated before pot was

placed on elements.

One element circuit may be defective. Replace heating element.

Six heat switch my be defective. Replace six heat switch.

Defective innite switch. Replace indenite switch.

Allow element to cool protector. Protector

will reset.

Fryer Diagnostics

PROBLEM POSSIBLE CAUSE SOLUTION

Power indicator is on.

Heating indicator comes

on. Fryer is not recovering

or heating evenly.

Red indicator light is on.

Fryer is not heating.

Power indicator is on.

Heating indicator is o.

Fryer is not heating. Red

indicator is o.

One or more elements are defective. Replace element.

Sensor is defective. Replace sensor.

Thermostat is defective. Replace thermostat.

A contactor is defective. Replace contactor.

High temperature limit has been tripped. Lift the elements and reset the limit red

button, the lower elements into fry tank.

Thermostat may be defective. Replace thermostat.

Contactor my be defective. Replace contactor.

HI Limit may be defective. Replace hi limit.

Sensor circuit open. Check sensor connection/replace sensor.

Thermostat may be defective. Replace thermostat.

Sensor my be defective. Replace sensor.

Short circuit in sensor connection. Check sensor connection/replace sensor.

Part # 4521353 (06/17/09) Page 19

Page 20

FAULT FINDING continued

Griddle Diagnostics

PROBLEM POSSIBLE CAUSE SOLUTION

Griddle too hot or

not hot enough.

Griddle heating unevenly. Adjacent section is operating at a dierent

Thermostat out of calibration. Recalibrate thermostat.

temperature.

A defective thermostat. Replace thermostat.

A defective element. Replace element.

Check adjacent section heating.

Griddle was not thoroughly heated

before use.

Allow more time for griddle to saturate;

increase warm up time.

Broiler Diagnostics

PROBLEM POSSIBLE CAUSE SOLUTION

Casting too hot or not hot

enough.

Casting heating unevenly

or not heating at all.

Defective innite switch. Replace innite switch.

Defective innite switch. Replace innite switch.

Defective element Replace element.

Food Warmer Diagnostics

PROBLEM POSSIBLE CAUSE SOLUTION

Food Warmer tank not hot

enough or too hot.

Defective innite switch. Replace innite switch.

Defective element Replace element.

Tank bottom is warped (possibly run dry) Replace tank.

Part # 4521353 (06/17/09)Page 20

Page 21

Part # 4521353 (06/17/09) Page 21

Page 22

Part # 4521353 (06/17/09)Page 22

Page 23

Part # 4521353 (06/17/09) Page 23

Page 24

Loading...

Loading...