Garland EDU-15B Service Manual

INSTALLATION, OPERATION &

SERVICING MANUAL

GARLAND EDU SERIES

DESIGNER ELECTRIC COUNTER EQUIPMENT

PLEASE READ ALL SECTIONS OF THIS MANUAL

FOR YOUR SAFETY:

DO NOT STORE OR USE GASOLINE

OR OTHER FLAMMABLE VAPORS OR

LIQUIDS IN THE VICINITY OF

THIS OR ANY OTHER

APPLIANCE

AND RETAIN FOR FUTURE REFERENCE.

THIS PRODUCT HAS BEEN CERTIFIED AS

COMMERCIAL COOKING EQUIPMENT AND

MUST BE INSTALLED BY PROFESSIONAL

PERSONNEL AS SPECIFIED.

WARNING:

IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE

CAN CAUSE PROPERTY DAMAGE, INJURY,

OR DEATH. READ THE INSTALLATION,

OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR

SERVICING THIS EQUIPMENT

INSTALLATION AND ELECTRICAL CONNECTION

MUST COMPLY WITH CURRENT CODES:

IN CANADA - THE CANADIAN ELECTRICAL

CODE PART 1 AND / OR LOCAL CODES.

IN USA – THE NATIONAL ELECTRICAL CODE

ANSI / NFPA – CURRENT EDITION.

ENSURE ELECTRICAL SUPPLY CONFORMS WITH

ELECTRICAL CHARACTERISTICS SHOWN ON

THE RATING PLATE.

Users are cautioned that maintenance and repairs must be performed by a Garland authorized service agent

using genuine Garland replacement parts. Garland will have no obligation with respect to any product that has been

improperly installed, adjusted, operated or not maintained in accordance with national and local codes or installation

instructions provided with the product, or any product that has its serial number defaced, obliterated or removed,

or which has been modified or repaired using unauthorized parts or by unauthorized service agents.

For a list of authorized service agents, please refer to the Garland web site at http://www.garland-group.com.

The information contained herein, (including design and parts specifications), may be superseded and is subject

to change without notice.

GARLAND COMMERCIAL INDUSTRIES, LLC

185 East South Street

Freeland, Pennsylvania 18224

Phone: (570) 636-1000

Fax: (570) 636-3903

GARLAND COMMERCIAL RANGES, LTD.

1177 Kamato Road, Mississauga, Ontario L4W 1X4

CANADA

Phone: 905-624-0260

Fax: 905-624-5669

Part # 4521353 (06/17/09) © 2005 Garland Commercial Industries,LLC

Part # 4521353 (06/17/09) Page 1

Part # 4521353 (06/17/09)Page 2

TABLE OF CONTENTS

DIMENSIONS AND SPECIFICATIONS .....4

INTRODUCTION........................6

Unpacking ...................................6

Product Application ..........................6

Serial Plate ...................................6

GENERAL INSTALLATION ...............7

Introduction .................................7

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Ventilation ...................................7

Electrical Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Installation Of Banking Plates .................7

Sanitary Counter Top Seal . . . . . . . . . . . . . . . . . . . . 8

Leg Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Installation Of Counter Stands (Optional) ......9

INDIVIDUAL MODEL INSTALLATIONS ....9

Solid Element Hot Plate; Model EDU-15HSE ....9

Wall Clearances .......................... 9

Electrical Supply.......................... 9

Controls ................................. 9

Before Operating the Hot Plate........... 10

Fryers: Models EDU-18F, EDU-18SF,

EDU-36FT And EDU-36SFT ...................10

Wall Clearances ......................... 10

Electrical Supply.........................10

Controls ................................ 10

Before Operating the Fryer ..............10

Griddles: Models EDU-15G, EDU-24G,

EDU-36G, Grooved Griddles: Models

EDU-15G-U, EDU-24G-U, EDU-24G-U1,

EDU-36G-U, EDU-36GU1, EDU-36G-U2 . . . . . . . 10

Wall Clearances ......................... 10

Electrical Supply.........................10

Controls ................................ 11

Before Operating the Griddle ............ 11

Calibration Instructions.................. 11

Broilers: ModelsEDU-15B, EDU-30B And

EDU-42B ....................................11

Wall Clearances ......................... 11

Electrical Supply......................... 11

Controls ................................ 11

Before Operating the Broiler ............. 11

COMMISSIONING .....................12

Food Warmer: Model EDU-15W ..............12

Wall Clearances ......................... 12

Electrical Supply......................... 12

Controls ................................ 12

Before Operating the Warmer............ 12

OPERATING INSTRUCTIONS............13

Safety Concerns . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Sealed Hot Plates . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Fryers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Griddles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

GENERAL MAINTENANCE AND

CLEANING ............................14

General Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Broilers .....................................14

Food Warmers ..............................14

Hot Plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Fryers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Griddles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Seasoning The Griddle...................15

Cleaning The Griddle .................... 15

Griddles Do’s and Don’t’s ................ 15

Broiler ......................................16

Food Warmers ..............................16

Regular Maintenance And Service . . . . . . . . . . . 16

SERVICING............................16

Hot Plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Griddles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Broilers .....................................18

Food Warmers ..............................18

FAULT FINDING .......................19

Sealed Hotplates Diagnostics ................19

Tubular Hotplates Diagnostics ...............19

Fryer Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Griddle Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . .20

Broiler Diagnostics ..........................20

Food Warmer Diagnostics ...................20

Part # 4521353 (06/17/09) Page 3

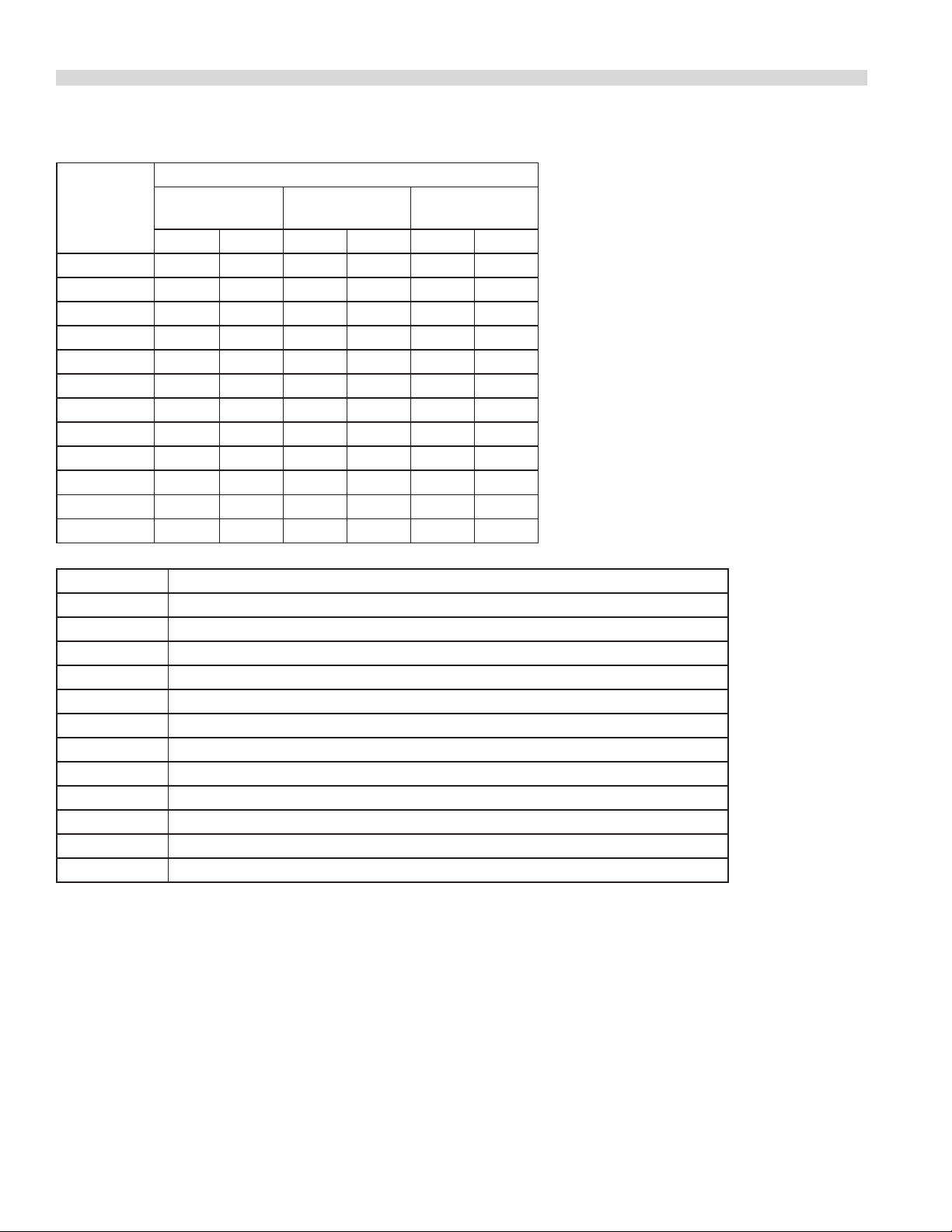

DIMENSIONS AND SPECIFICATIONS

OVERALL DIMENSIONS

MODEL

NUMBER

EDU-15HSE 15 381 24 610 11.25 286

EDU-18F 18 457 24 610 13 330

EDU-15SF 18 457 24 610 13 330

EDU-36FT 36 914 24 610 13 330

EDU-36SFT 30 914 24 610 13 330

EDU-15G 15 381 24 610 13.75 349

EDU-24G 24 620 24 610 13.75 349

EDU-36G 36 914 24 610 13.75 249

EDU-15B 15 381 24 610 13.75 349

EDU-30B 30 762 24 610 13,75 349

EDU-42B 42 1067 24 610 13.75 349

EDU-15W 15 381 24 610 11.50 292

Width Depth Height

In mm In mm In mm

MODEL PRODUCT DESCRIPTION

EDU-15HSE 15” (381mm) Wide Hot Plate With 8” (203mm) Solid Elements

EDU-18F 18” (457mm) Wide Fryer 5.3kw

EDU-18SF 18” (457mm) Wide Fryer 8.0 Kw

EDU-36FT 36” (914 Mm) Wide Twin Fryer 10.6 Kw

EDU-36SFT 36” (914 Mm) Wide Twin Fryer 16.0kw

EDU-15G 15” (381mm) Wide Griddle

EDU-24G 24” (610mm) Wide Griddle

EDU-36G 36” (914mm) Wide Griddle

EDU-15B 15” (381mm) Wide Broiler

EDU-30B 30” (762mm) Wide Broiler

EDU-42B 42” (1067mm) Wide Broiler

EDU-15W 15” (381mm) Wide Food Warmer

Part # 4521353 (06/17/09)Page 4

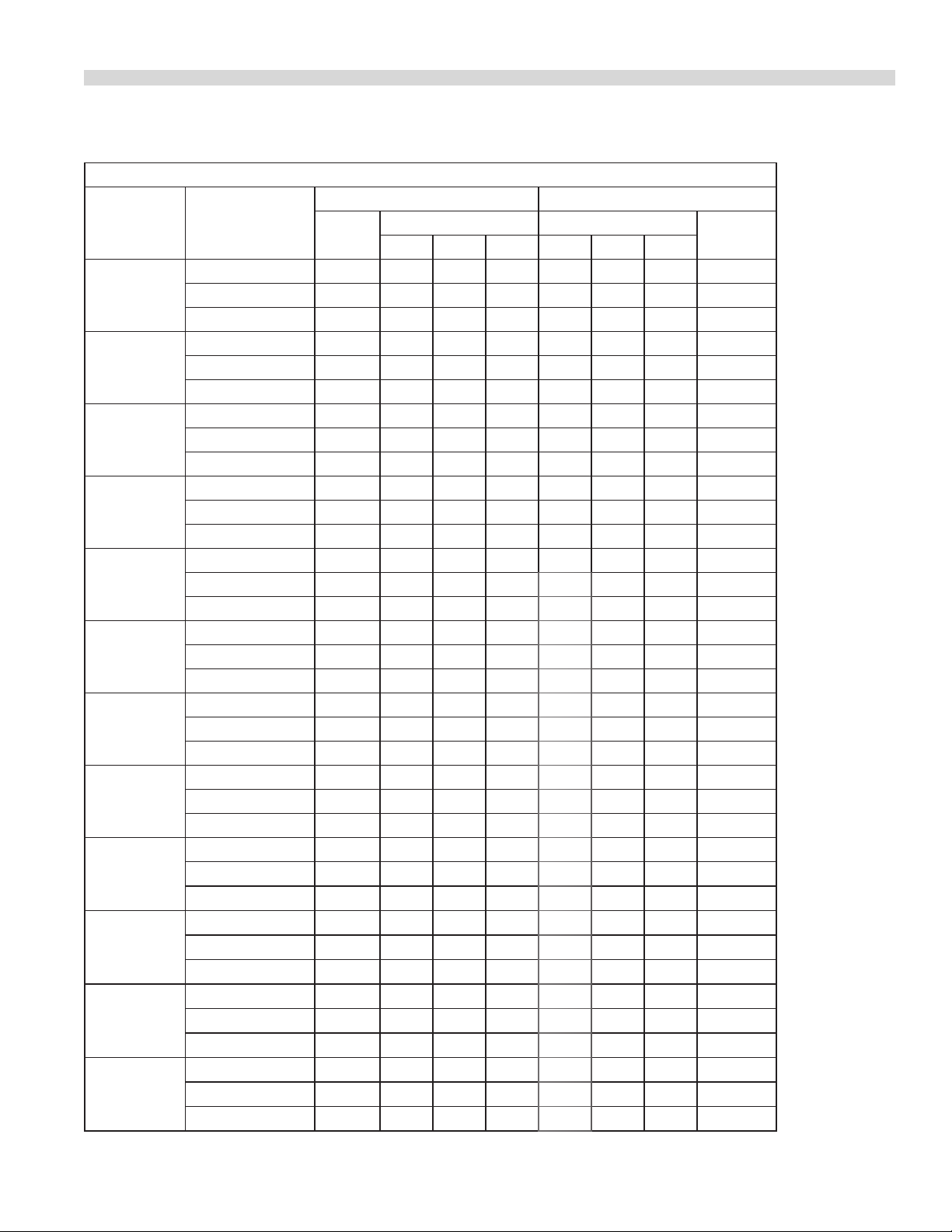

DIMENSIONS AND SPECIFICATIONS continued

LOADING CHART

KW LOAD AMPS

MODEL VOLTAGE

220V/380V 2N~ 4.8 2.4 2.4 0.0 10.8 10.8 0.0 21.6

EDU-15HSU

EDU-18F

EDU-18SF

EDU-36FT

EDU-36SFT

EDU-15G

EDU-24G

EDU-36G

EDU-15B

EDU-30B

EDU-42B

EDU-15W

230V/400V 2N~ 5.2 2.6 2.6 0.0 11.3 11.3 0.0 22.6

240V/415V 2N~ 5.2 2.6 2.6 0.0 10.8 10.8 0.0 21.7

220V~ 5.93 5.93 0.0 0.0 27.0 0.0 0.0 27.0

230V~ 5.3 5.3 0.0 0.0 23.0 0.0 0.0 23.0

240V~ 5.3 5.3 0.0 0.0 22.1 0.0 0.0 22.1

220V/380V 3N~ 7.3 2.4 2.4 2.4 11.1 11.1 11.1 33.2

230V/400V 3N~ 8.0 2.7 2.7 2.7 11.6 11.6 11.6 34.7

240V/415V 3N~ 8.0 2.7 2.7 2.7 11.1 11.1 11.1 33.2

220V/380V 2N~ 11.86 5.93 5.93 0.0 27.0 27.0 0.0 53.9

230V/400V 2N~ 10.6 5.3 5.3 0.0 23.0 23.0 0.0 46.1

240V/415V 2N~ 10.6 5.3 5.3 0.0 22.1 22.1 0.0 44.2

220V/380V 3N~ 14.6 4.9 4.9 4.9 22.2 22.2 22.2 66.5

230V/400V 3N~ 16.0 5.3 5.3 5.3 23.2 23.2 23.2 69.5

240V/421V 3N~ 16.0 5.3 5.3 5.3 22.2 22.2 22.2 66.6

220V~ 2.8 2.8 0.0 0.0 12.8 0.0 0.0 12.8

230V~ 3.4 3.35 0.0 0.0 14.6 0.0 0.0 14.6

240V~ 3.4 3.35 0.0 0.0 14.0 0.0 0.0 14.0

220V/380V 2N~ 5.6 2.8 2.8 0.0 12.8 12.8 0.0 25.6

230V/400V 2N~ 6.7 3.35 3.35 0.0 14.6 14.6 0.0 29.1

240V/415V 2N~ 6.7 3.35 3.35 0.0 14.0 14.0 0.0 27.9

220V/380V 3N~ 8.4 2.8 2.8 2.8 12.8 12.8 12.8 38.4

230V/400V 3N~ 10.1 3.35 3.35 3.35 14.6 14.6 14.6 43.7

240V/415V 3N~ 10.1 3.35 3.35 3.35 14.0 14.0 14.0 41.9

220V ~ 2.3 2.3 0.0 0.0 10.3 0.0 0.0 10.3

230V ~ 2.7 2.7 0.0 0.0 11.7 0.0 0.0 11.7

240V ~ 2.7 2.7 0.0 0.0 11.3 0.0 0.0 11.3

220V/380V 2N~ 4.5 2.3 2.3 0.0 10.3 10.3 0.0 20.6

230V/400V 2N~ 5.4 2.7 2.7 0.0 11.7 11.7 0.0 23.5

240V/415V 2N~ 5.4 2.7 2.7 0.0 11.3 11.3 0.0 22.5

220V/380V 3N~ 6.8 2.3 2.3 2.3 10.3 10.3 10.3 30.9

230V/400V 3N~ 8.1 2.7 2.7 2.7 11.7 11.7 11.7 35.2

240V/415V 3N~ 8.1 2.7 2.7 2.7 11.3 11.3 11.3 33.8

220V~ 1.12 1.12 0.0 0.0 5.1 0.0 0.0 5.1

230V~ 1.1 1.1 0.0 0.0 4.8 0.0 0.0 4.8

240V ~ 1.0 1.0 0.0 0.0 4.2 0.0 0.0 4.2

TOTAL

PER PHASE PER PHASE

L1 L2 L3 L1 L2 L3

1 PHASE

Part # 4521353 (06/17/09) Page 5

INTRODUCTION

IMPORTANT: The following instructions should be read

carefully as the manufacturer can not be held responsible for

any damage to property or persons as caused by incorrect

installation or operation of this equipment.

You have just purchased the nest commercial cooking

equipment available anywhere. Like any other ne,

precision built appliance, it should be given regular care

and maintenance. Periodic inspections by your dealer or a

qualied service agency are recommended.

Your new equipment must be installed and adjusted by a

competent person in accordance with the law. Failure to

install appliances correctly could lead to prosecution. It is

in your own interest and that safety to insure that the law is

compiled with.

Your Garland dealer or local authorized service agency is well

qualied to provide this service. Periodic inspections by your

dealer or a qualied service company are recommended

to check temperatures and to insure that moving parts

are operating. Whenever possible avoid overheating idle

equipment for this is the primary cause for increased service

cost.

Factory specied replacement parts must be used to

maintain listing. Use of “Generic” replacement parts may

create a hazard and will void the listing.

Unpacking

Product Application

Preparation of soups, stocks or sauces is done on a hot

plate where slow even cooking is desirable. Heating larger

quantities of food can be done more eciently than heating

small quantities. Pot and pans should be covered whenever

possible to reduce energy consumption.

High acid sauces, such as tomato should be cooked in

stainless steel vessels rather than aluminum since stainless

will not react chemically. Light colored sauces may be

discolored by the use of aluminum especially if stirred with

a metal spoon. Salty water may pit aluminum vessels if used

frequently.

NOTE: Many parts of the equipment are raw steel, i.e.,

griddle top, top grates, rings etc. and can react with moisture

forming rust. This is normal and not considered a defect.

Clean with stainless steel or ber pad. A light coating of salt

free oil may be applied to prevent further rusting.

Serial Plate

All electrical ratings are shown on the serial plate of each

unit and are readily visible by opening the enameled door

located below the control panel.

For proper operation, the information noted on the serial

plate of your new equipment must match your electrical

supply.

1 Check the crate/carton for possible damage sustained

during transit. Carefully remove the unit from the crate/

carton and again check for damage. Any damage must be

reported to the carrier immediately.

2. Any protective material covering stainless steel parts

must be removed.

3. The type of voltage supply that the equipment was

manufactured for at the factory is noted on the serial

plate and the packaging. This type of supply must be

used.

4. Do not remove permanently xed labels, warnings

or serial plates from the appliance, for this many void

approvals and create a safety hazard.

In the event you have any questions concerning the

installation, use, care or service of this or any other Garland

product, write or call our Product Service Department. When

corresponding with the factory or your local authorized

factory service center regarding service problems or

replacement parts, be sure to refer to the particular unit by

the correct model number (including the prex and sux

letters and numbers) and the warranty serial number. The

serial plate axed to the unit contains this information.

Part # 4521353 (06/17/09)Page 6

GENERAL INSTALLATION

REAR VIEW

Introduction

The Garland EDU series 230V and 240V complies with

the essential requirement of the directives 73/23/EEC,

89/336EEC, 93/68/EEC and the standards; EN60335, IEC529,

EN5501, eN6100-4-A, ENV502404, EN61000-4-4, ENV50142,

IEC1000-4-11, ENV50141. Also complies with the latest

edition of NSF#4.

Safety

This manual pertains to the EDU series counter equipment.

The reader/operator must interpret its contents to applicable

needs. If there is any question of interpretation of any

literature, please contact your authorized service agency or

our customer service department at the phone number in

the information pamphlet.

A qualied person must make the installation of these

products in accordance with local codes.

Always follow these safety precautions when operating these

appliances.

These units must only be operated by qualied persons. DO

NOT operate with out reading this manual.

DO NOT operate the appliance unless all service and access

panels are in place and fastened properly.

Electrical Supply

Before attempting the electrical connection, the serial plate

should be checked to ensure that the equipment’s electrical

characteristics agree.

The supply terminal block is accessible from the font. The

electrical supply must be adequate for the voltage, phase

and current marked on the serial plate.

Note: a means of disconnection from the supply having

a contact separation of at least 3 mm (0.12”) must be

incorporated in the xed wiring.

This equipment is intended to be installed with xed

permanent wiring.

Warning: This appliance must be earthed.

Single and three-phase connection:

Unless otherwise noted, all appliances are shipped from

the factory for three phase connection. A wiring diagram is

attached to the rear each appliance. Visually check all the

electrical connections. The appliance is wired at the factory

as specied on the order. If it is necessary to change the

phasing, refer to the wiring diagram.

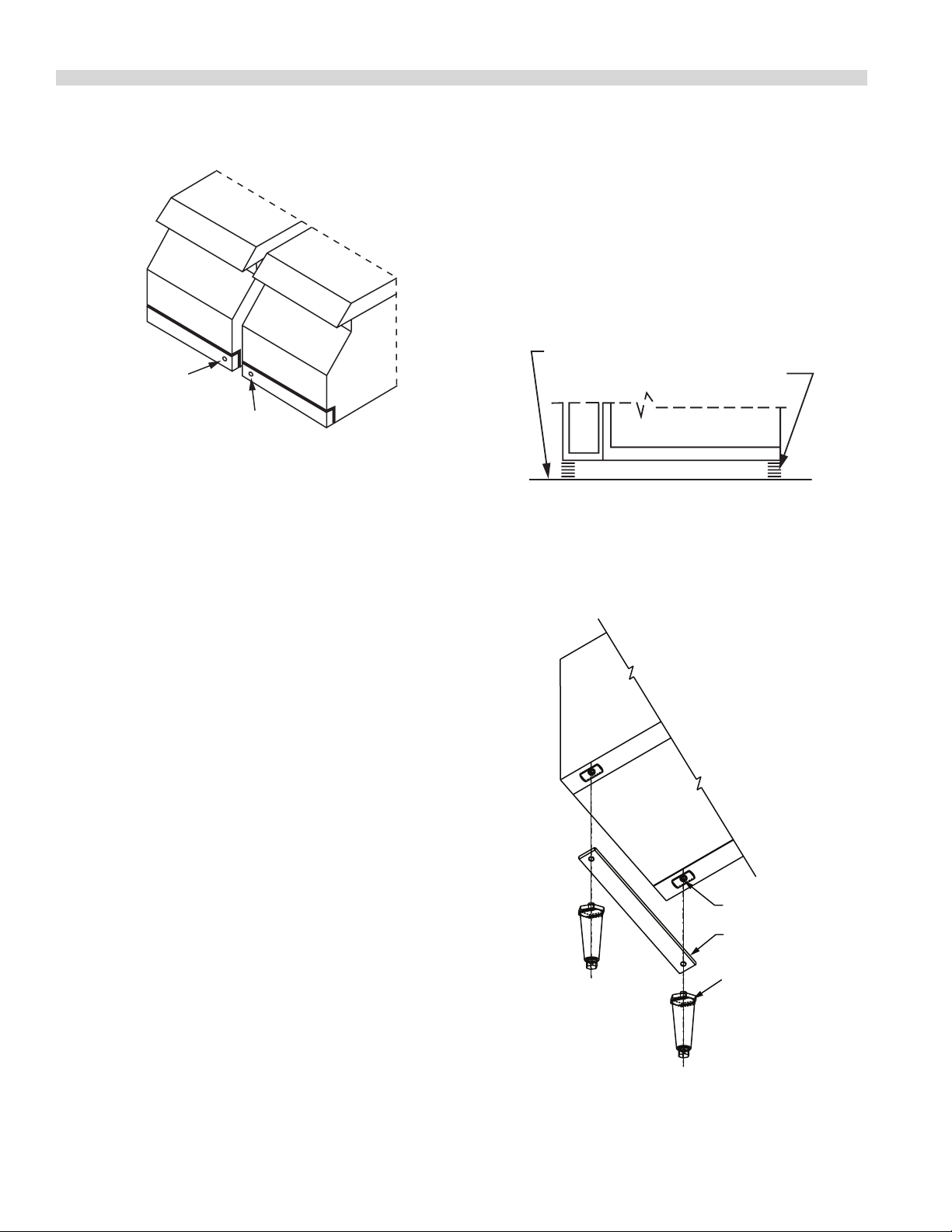

Installation Of Banking Plates

DO NOT attempt to repair or place any part of these

appliances unless all main power supplies have been

disconnected.

WARNING

To avoid personal injury; use extreme caution in setting up,

operating and cleaning these appliances to avoid coming

in contact with hot surfaces. Suitable protective clothing

should be worn or proper utensils used to prevent the risk of

burns.

Note all warning labels and marking on the appliance, which

call attention to further dangers and necessary precautions.

THESE APPLIANCES SHOULD NOT BE CLEANED WITH A

WATER JET.

Ventilation

The area in which the appliance is installed must be

adequately ventilated to provide air for removal of steam,

heat generated by the appliance etc. the use of mechanical

extract system should be considered and conform to local

codes.

All units may be installed independently or banked with

other ED or GD series equipment. To ensure a matching

and permanent t between units, two banking plates are

available for each unit to be installed. One at the front and

one at the rear of each two units being banked together.

If optional 4” (102mm) legs are supplied with unit, discard

leveling bolts and replace with legs.

Part # 4521353 (06/17/09) Page 7

FRONT VIEW

GENERAL INSTALLATION continued

COUNTER TOP

SILICONE SEALANT

BOTTOM OF UNIT

LEG CHANNEL

(QTY 2)

4" [102mm]

ADJUSTABLE LEG

(QTY 4)

LEG INSTALLATION

3. Lay a generous bead of silicone under the entire

4. Secure unit to counter top through the holes located on

5. Smooth the silicone seal into the crevice with nger or

1. Level each unit by adjustment of leveling bolts or legs.

Use a spirit level and level unit four ways; across front and

back and down left and right edges. Level all other units

to the rst unit.

NOTE: Griddles may not rest evenly on the unit body if units

are not leveled.

2. Remove acorn nuts at rear of unit.

Leg Installation

The leg channel is located onthe package base. This channel

must be installed when using the legs.

perimeter of appliance bottom.

the underside of the appliance using 10A sheet metal

screws.

tool to provide a cove seal.

3. Attach one banking plate in position at rear by placing

1/4” (6.4 mm) diameter holes in the banking plate over the

screw holes in the rear of units and fasten by replacing the

acorn nuts removed in step 2.

4. Push units into position on counter top or back bar.

5. To secure the front, open the lower front panel, place

banking plate over the two holes (one on each unit) and

secure banking plate using sheet metal screws supplied.

Sanitary Counter Top Seal

When appliance is installed without legs on a counter top, it

must be sealed in accordance with N.S.F. standards as per the

following instructions:

1. Appliance should be located on a level counter top

surface. Complete the electrical connection.

2. Thoroughly clean the appliance bottom perimeter and

the counter top area around the appliance perimeter.

Part # 4521353 (06/17/09)Page 8

Loading...

Loading...