Page 1

INSTALLATION & OPERATION MANUAL

GARLAND ED SERIES

ELECTRIC COUNTER UNITS

PLEASE READ ALL SECTIONS OF THIS MANUAL

FOR YOUR SAFETY:

DO NOT STORE OR USE GASOLINE

OR OTHER FLAMMABLE VAPORS OR

LIQUIDS IN THE VICINITY OF

THIS OR ANY OTHER

APPLIANCE

AND RETAIN FOR FUTURE REFERENCE.

THIS PRODUCT HAS BEEN CERTIFIED AS

COMMERCIAL COOKING EQUIPMENT AND

MUST BE INSTALLED BY PROFESSIONAL

PERSONNEL AS SPECIFIED.

WARNING:

IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE

CAN CAUSE PROPERTY DAMAGE, INJURY,

OR DEATH. READ THE INSTALLATION,

OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR

SERVICING THIS EQUIPMENT

INSTALLATION AND ELECTRICAL CONNECTION

MUST COMPLY WITH CURRENT CODES:

IN CANADA - THE CANADIAN ELECTRICAL

CODE PART 1 AND / OR LOCAL CODES.

IN USA – THE NATIONAL ELECTRICAL CODE

ANSI / NFPA – CURRENT EDITION.

ENSURE ELECTRICAL SUPPLY CONFORMS WITH

ELECTRICAL CHARACTERISTICS SHOWN ON

THE RATING PLATE.

Users are cautioned that maintenance and repairs must be performed by a Garland authorized service agent

using genuine Garland replacement parts. Garland will have no obligation with respect to any product that has been

improperly installed, adjusted, operated or not maintained in accordance with national and local codes or installation

instructions provided with the product, or any product that has its serial number defaced, obliterated or removed,

or which has been modified or repaired using unauthorized parts or by unauthorized service agents.

For a list of authorized service agents, please refer to the Garland web site at http://www.garland-group.com.

The information contained herein, (including design and parts specifications), may be superseded and is subject

to change without notice.

GARLAND COMMERCIAL INDUSTRIES, LLC

185 East South Street

Freeland, Pennsylvania 18224

Phone: (570) 636-1000

Fax: (570) 636-3903

GARLAND COMMERCIAL RANGES, LTD.

1177 Kamato Road, Mississauga, Ontario L4W 1X4

CANADA

Phone: 905-624-0260

Fax: 905-624-5669

Part # 4521653 (08/12/09) © 2005 Garland Commercial Industries, LLC

Part # 4521653 (08/12/09) Page 1

Page 2

IMPORTANT INFORMATION

WARNING:

This product contains chemicals known to the state of california to cause cancer and/or birth defects

or other reproductive harm. Installation and servicing of this product could expose you to airborne

particles of glass wool/ceramic fibers. Inhalation of airborne particles of glass wool/ceramic fibers

is known to the state of California to cause cancer.

Part # 4521653 (08/12/09)Page 2

Page 3

TABLE OF CONTENTS

IMPORTANT INFORMATION.............2

DIMENSIONS AND SPECIFICATIONS .....4

GENERAL INSTALLATION ...............5

Unpacking ...................................5

Serial Plate ..................................5

Statutory Regulations ........................5

Installation Of Banking Plates .................5

Sanitary Countertop Seal .....................5

Installation Of Counter Stands (Optional) ......6

Leg Installation ..............................6

INDIVIDUAL MODEL INSTALLATIONS....7

Hot Plate – Model ED-15H ....................7

Wall Clearances .......................... 7

Supply Connection....................... 7

Electrical Connection..................... 7

Controls ................................. 7

Solid Elements Hot Plate –

Model ED-15HSE / ED-15THSE .................7

Wall Clearances .......................... 7

Supply Connection....................... 7

Electrical Connection..................... 7

Controls ................................. 7

Before Operating The Hot Plate ........... 7

Sealed Hot Plates.........................7

Operating The Sealed Hot Plate........... 8

Fryers – Models ED-15F, ED-15SF, ED-30FT & ED-

30SFT .......................................8

Wall Clearance ........................... 8

Supply Connection....................... 8

Electrical Connection..................... 8

Before Operating the Fryer ............... 8

Operating Suggestions ................... 8

Controls ................................. 9

Griddles – Models: ED-15G,

ED-24G & ED-36G

Grooved Griddles – Models:

ED-15G-U, ED-24-U,

ED-24G-U1, ED-36G-U,

ED-36-U1 & ED-36G-U2. . . . . . . . . . . . . . . . . . . . . . . 9

Wall Clearances .......................... 9

Supply Connection....................... 9

Electrical Connection..................... 9

Controls ................................. 9

Calibration Instructions................... 9

Broilers – Models: ED-15B,

ED-30B & ED-42B ...........................10

Wall Clearance .......................... 10

Supply Connection...................... 10

Electrical Connection.................... 10

Controls ................................10

Food Warmers –

Models ED-15W & ED-15WP ..................10

Wall Clearances .........................10

Supply Connection...................... 10

Electrical Connection.................... 10

Controls ................................10

Operating Instructions...................10

CLEANING AND MAINTENANCE........11

Cleaning Exterior Finishes ...................11

Fryers ......................................11

Griddle Top Plates ...........................11

Seasoning............................... 11

Cleaning ............................... 11

Broiler .....................................11

Broiler Grates Surfaces................... 11

Broiler Interior and Under Broiler Grates . . 12

Periodic Cleaning........................ 12

Part # 4521653 (08/12/09) Page 3

Page 4

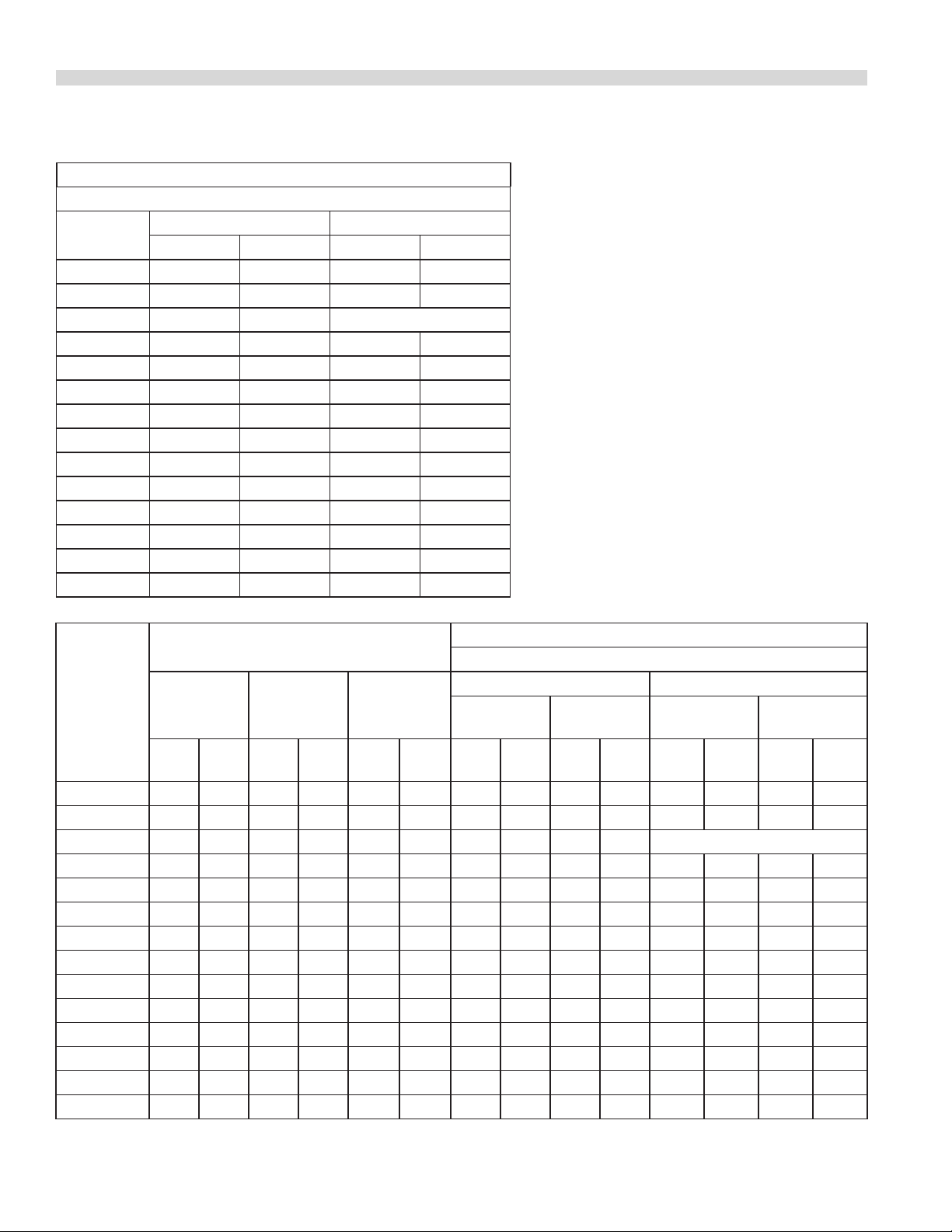

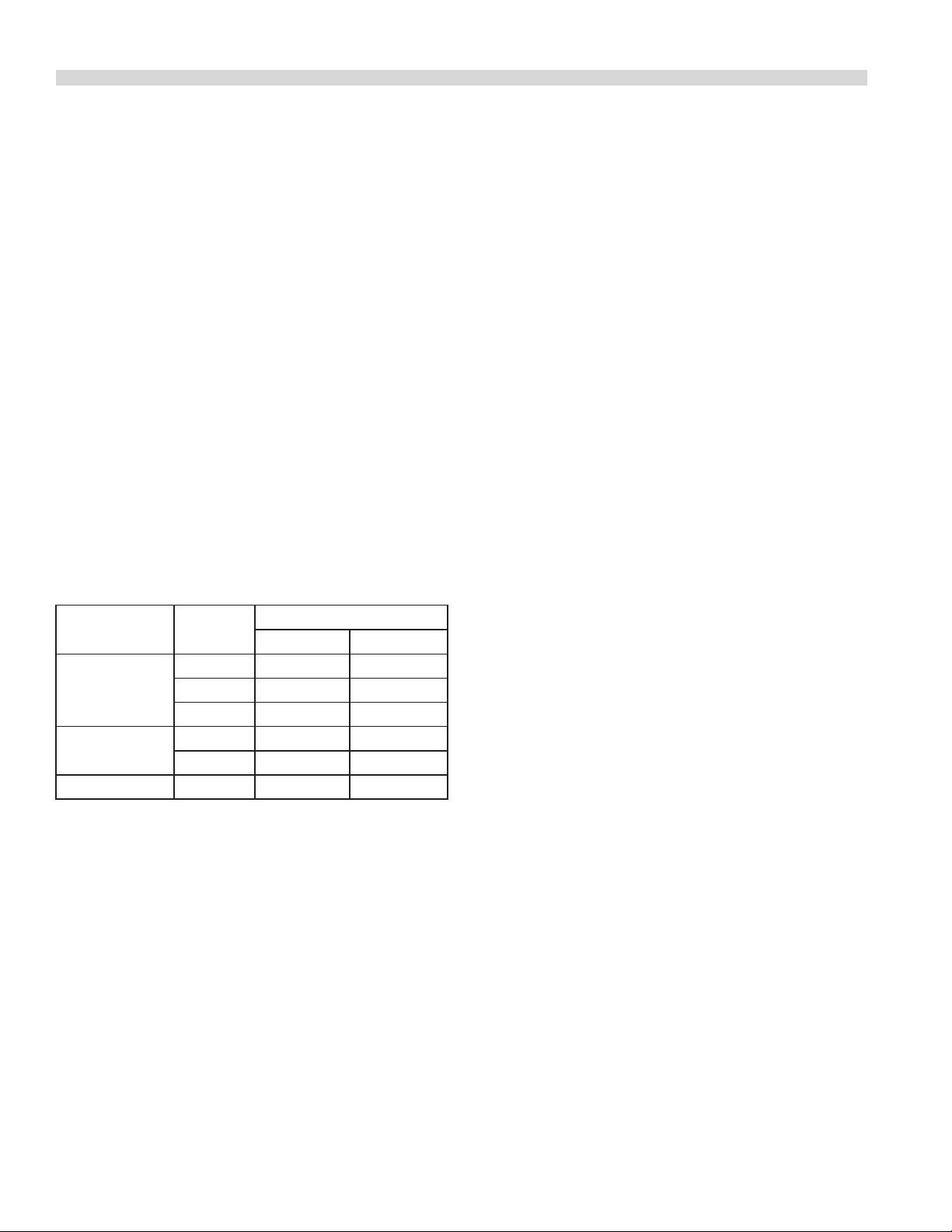

DIMENSIONS AND SPECIFICATIONS

LOADING AND VOLTAGE CHART

Total KW Loading

MODEL

NUMBER

ED-15H 4.2 4.2 4.2 4.2

ED-15HSE 5.2 5.2 5.2 5.2

ED-15THSE 4.0 4.0 Contact Factory

ED-15F 5.3 5.3 5.93 5.3

ED-15SF 8.0 8.0 8.0 8.0

ED-30FT 10.6 10.6 11.86 10.3

ED-30SFT 16.0 16.0 16.0 16.0

ED-15G 3.4 3.4 3.4 3.4

ED-24G 6.7 6.7 6.7 6.7

ED-36G 10.1 10.1 10.1 10.1

ED-15B 2.7 2.7 2.7 2.7

ED-30B 5.4 5.4 5.4 5.4

ED-42B 8.1 8.1 8.1 8.1

ED-15W 1.0 1.0 1.12 1.0

North America Export

208V 240V 220V/380V 240V/415V

OVERALL DIMENSIONS

MODEL

NUMBER

ED-15H 15 381 24 610 11.25 286 21 18 18 16 20 18 10 9

ED-15HSE 15 381 24 610 11.25 286 25 22 22 19 24 22 12 11

ED-15THSE 15 381 24 610 11.25 286 19.2 16.7 16.7 14.4 Contact Factory

ED-15F 15 382 24 610 13 330 26 23 N/A N/A 27 23 N/A N/A

ED-15SF 15 381 24 610 13 330 39 34 23 20 37 34 13 12

ED-30FT 30 762 24 610 13 330 51 45 45 39 54 45 27 22

ED-30SFT 30 762 24 610 13 330 77 67 45 39 73 67 25 23

ED-15G 15 381 24 610 13.75 349 17 14 N/A N/A 16 14 N/A N/A

ED-24G 24 620 24 610 13.75 349 33 28 28 25 31 28 16 14

ED-36G 36 914 24 610 13.75 249 49 42 28 25 46 42 16 14

ED-15B 15 381 24 610 13.75 349 13 12 N/A N/A 13 12 N/A N/A

ED-30B 30 762 24 610 13,75 349 39 34 23 20 37 34 13 12

ED-42B 42 1067 24 610 13.75 349 39 34 23 20 37 34 13 12

ED-15W 15 381 24 610 11.50 292 5 5 N/A N/A 6 5 N/A N/A

Width Depth Height

In mm in mm in mm 208V 240V 208V 240V

North America Export

Single

Phase

PHASE AND AMPERAGE CHART

Nominal Amps Per Line

HI Line 3

Phase

Single Phase

240V/

380V

240V/

425V

Hi Line 2 0r 3

Phase

220V/

380V

240V/

415V

Part # 4521653 (08/12/09)Page 4

Page 5

GENERAL INSTALLATION

Unpacking

Carefully remove units from cartons. Remove all packing

materials from units. The protective material covering the

stainless steel should be removed immediately after the unit

is installed.

Serial Plate

All electrical ratings are shown on the serial plate of each

unit and are readily visible by opening the enameled door

located below the control panel.

Ensure electrical supply conforms with electrical

characteristics shown on the rating plate.

Statutory Regulations

The installation and connection should comply with current

codes in Canada – The Canadian Electrical Code Part 1

and / or local codes. In USA – The National Electrical Code

ANSI / NFPA – Current Edition.

Ventilation requirements can vary by country, state or

providence, please consult with local authorities having

jurisdiction for code requirements.

5. To secure the front, open the lower front panel, place

banking plate over the two holes (one on each unit) and

secure banking plate using sheet metal screws supplied.

REAR VIEW

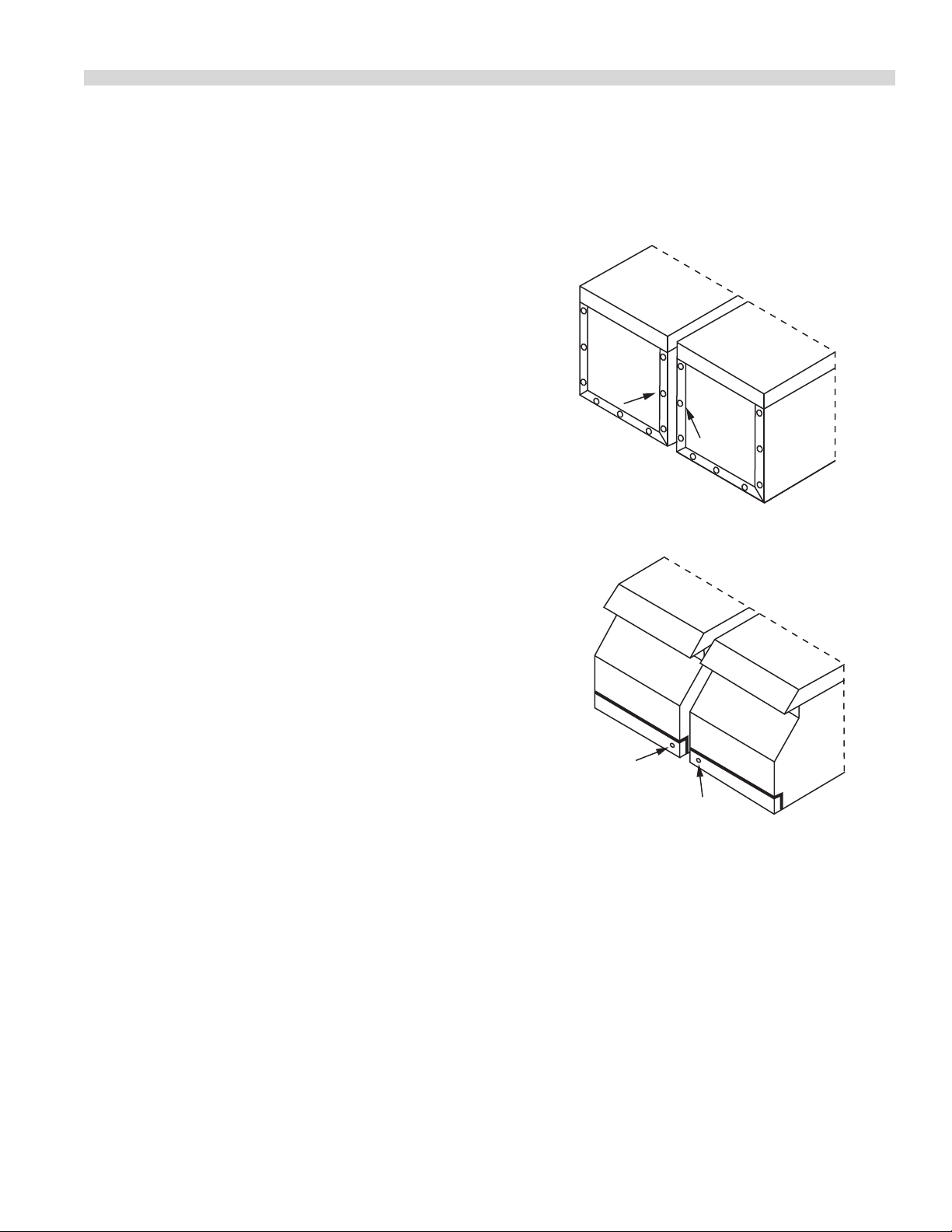

Installation Of Banking Plates

All units may be installed independently or banked with

other ED or GD series equipment. To ensure a matching

and permanent t between units, two banking plates are

available for each unit to be installed. One at the front and

one at the rear of each two units being banked together. If

optional 2 1/2” (64mm) legs are supplied with unit, discard

leveling bolts and replace with legs.

1. Level each unit by adjustment of leveling bolts or legs.

Use a spirit level and level unit four ways; across front and

back and down left and right edges. Level all other units

to the rst unit.

NOTE: Griddles may not rest evenly on the unit body if units

are not leveled.

2. Remove acorn nuts at rear of unit.

3. Attach one banking plate in position at rear by placing 1/4”

(6mm) diameter holes in the banking plate over the screw

holes in the rear of units and fasten by replacing the acorn

nuts removed in step 2.

4. Push units into position on counter top or back bar.

FRONT VIEW

Sanitary Countertop Seal

When appliance is installed without legs on a counter top, it

must be sealed in accordance with N.S.F. standards as per the

following instructions:

1. Appliance should be located on a level counter top

surface. Complete the electrical connection.

2. Thoroughly clean the appliance bottom perimeter and

the counter top area around the appliance perimeter.

3. Lay a generous bead of silicone under the entire

perimeter of appliance bottom.

Part # 4521653 (08/12/09) Page 5

Page 6

GENERAL INSTALLATION continued

4. Secure unit to counter top through the holes located on

the underside of the appliance using 10A sheet metal

screws.

5. Smooth the silicone seal into the crevice with nger or

tool to provide a cove seal.

COUNTER TOP

SILICONE SEALANT

Installation Of Counter Stands (Optional)

1. Assemble and level counter stand as illustrated in the

instructions found in the counter stand carton.

2. Remove and discard leveling bolts on unit to be installed

on counter stand.

3. Place units in desired position on counter stand, securing

the rst unit with 8-32 machine screws and at washers.

Insert 8-32 machine screws through the 7/32” (5mm)

diameter holes in stand into the nutserts in the bottom of

ED Series unit.

4. Connect banking plates as described in section titled,

Installation of Banking Plates.

5. Secure last unit to counter stand with 8-32 machine

screws and at washers. Inserts 8-32 machine screws

through the 7/32” (5mm) diameter holes in stand into the

nutserts in the bottom of ED series unit.

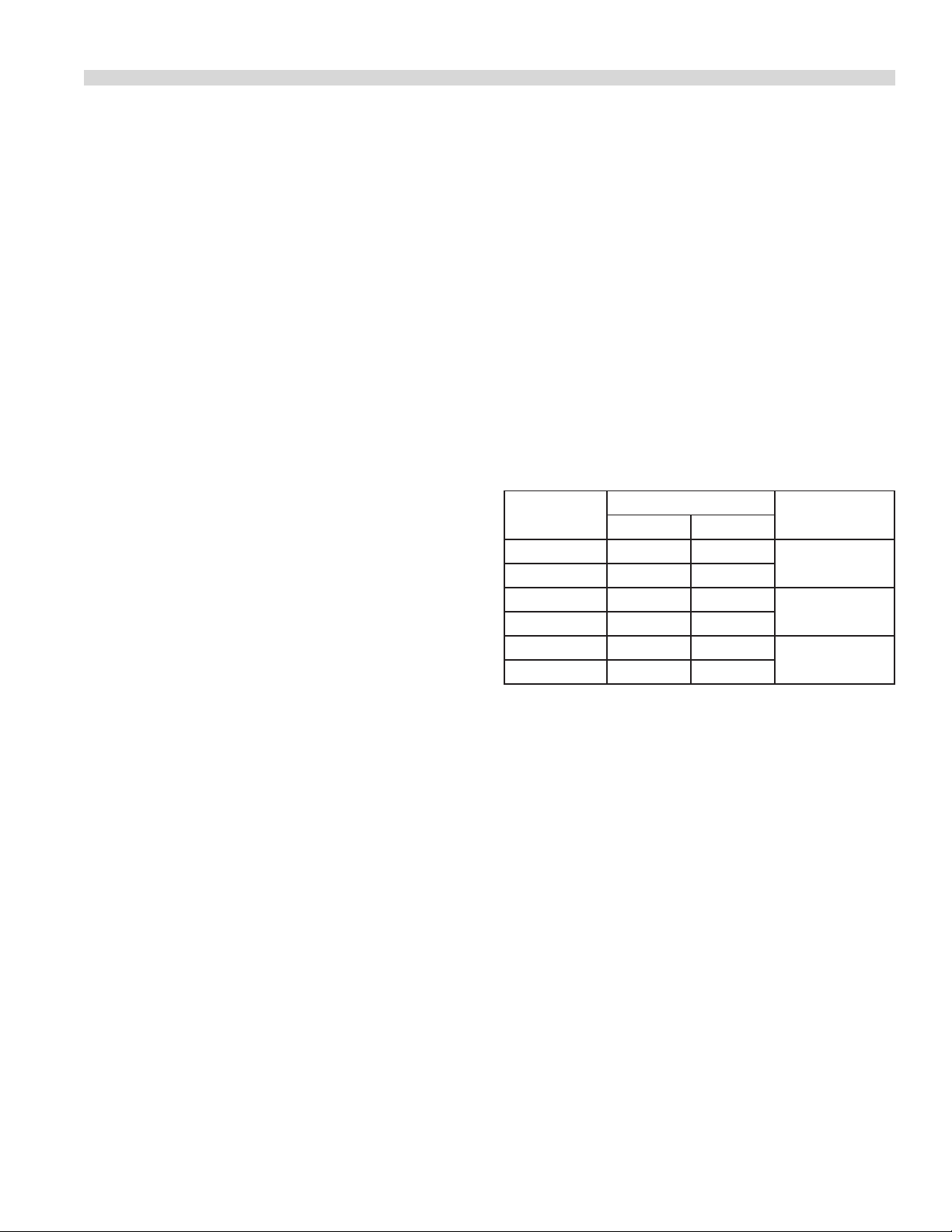

Leg Installation

The leg channel is located on the package base. This channel

must be installed when using the legs.

BOTTOM OF UNIT

LEG CHANNEL

(QTY 2)

4" [102mm]

ADJUSTABLE LEG

(QTY 4)

LEG INSTALLATION

Part # 4521653 (08/12/09)Page 6

Page 7

INDIVIDUAL MODEL INSTALLATIONS

Hot Plate – Model ED-15H

Wall Clearances

Do not install appliance closer to a wall of combustible

material than:

Back 1 ½” (38mm)

Sides 1 ½” (38mm)

Supply Connection

For supply connection, use wire suitable for 90°C (194°F).

Electrical Connection

A knockout is provided near the front left side of the unit

located behind the control panel. To view knockout, loosen

the two acorn nuts and hinge control panel downward. The

terminal block is also located in this area.

The supply cable entrance is located on the right side when

facing the rear of the unit. The cable is fed towards the front

through a wire way.

Controls

Innite switches are used to control the tubular elements:

HI to 5 - High Heat

5 to 3 - Medium Heat

3 to LO - Low Heat

Setting of switches between the numbers will give

intermediate heat. Switches are reversible and may be

turned right or left.

Solid Elements Hot Plate –

Model ED-15HSE / ED-15THSE

Electrical Connection

A knockout is provided near the front left side of the unit

located behind the control panel. To view knockout, loosen

the two acorn nuts and hinge control panel downward. The

terminal block is also located in this area.

The supply cable entrance is located on the right side when

facing the rear of the unit. The cable is fed towards the front

through a wire way.

Controls

Solid element hot plates are controlled by a six heat switch.

There are three boiling and three simmering positions. Turn

the switch left or right from the o position to the desired

number, one being the lowest setting and six being the

highest.

SWITCH

POSITION

1 240 200

2 340 305

3 450 450

4 1300 950

5 1750 1400

6 2600 2000

This hot plate is protected against overheating when running

empty or when using poor quality cookware, by a unique

built-in bimetal protector switch.

This protector cuts down the power automatically under the

above conditions, overriding the regular switch and it resets

itself when conditions return to normal. This is an important

safety feature.

WATTAG E

15HSE 15THSE

HEAT

Low (Simmer)

Medium

High (Boil)

Wall Clearances

Do not install appliance closer to a wall of combustible

material than:

Back 1 ½” (38mm)

Sides 1 ½” (38mm)

Supply Connection

For supply connection, use wire suitable for 75°C (167°F).

NOTE: - All 208V 1 phase 60 hZ ED-15THSE models are

equipped with a 4-ft (1219mm) power cord and

NEMA L6-30P plug (HUBBELL HBL2621 or equivalent).

Part # 4521653 (08/12/09) Page 7

Before Operating The Hot Plate

The top working surface has a heat resistant coating. Before

using the sealed hot plates for the rst time, they should

be heated for a short period without a pan to harden and

burn o the protective coating (3-5 minutes at the highest

setting).

Sealed Hot Plates

All purpose sealed top elements provide an ease-clean top.

They are intended for boiling, simmering, sauté and other

top cooking.

Page 8

INDIVIDUAL MODEL INSTALLATIONS continued

Operating practices are very important for the ecient use of

these elements:

1. Pot bottoms must be at. This increases heat transfer to

the pot. Do not use pots with either convex or concave in

excess of 1mm (1/32”).

2. Use pots with the same diameter as the elements when

possible. This will reduce heat up time.

3. Do not preheat the element. Elements are protected with

a high limit which automatically reduces the element to a

lower power. It will increase heat up time if this occurs.

4. Use a lid to cover the pots when boiling water.

Operating The Sealed Hot Plate

1. Before using the sealed hot plates for the rst time they

should be heated at setting 3 for 5 minutes, then turned

o and allowed to cool. This will harden and burn o the

protective coating.

2. Set the six heat switch dial to the desired position from 1

to 6.

APPLICATION

Boiling, Frying,

Braising

Simmering

Warming 1 240 200

Shutting down the sealed hot plate:

1. Turn the six heat switch to the o “O” position.

DIAL

SETTING

6 2300 2000

5 1750 1400

4 1300 950

3 450 450

2 340 305

ED-15HSE ED-15THSE

WATTAG E

Supply Connection

For supply connection, use wire suitable for 75°C (167°F).

Electrical Connection

A knockout is provided on the right side when facing the

rear of the unit. Access to the terminal block is gained by

removing the fry tank assembly, the rear shield and contactor

box cover all located at the rear of the fryer.

Before Operating the Fryer

1. Before leaving the factory, the fryer was tested and the

thermostat calibrated with oil in the fry tank; therefore, it

is necessary to clean the fry tank and the elements before

lling with frying compound. Use detergent or other

cleaning agents, with hot water. Thoroughly rinse and dry

fry tank.

2. To remove the fry tank, raise the element assembly by

means of the handle until the support engages, holding

the element assembly in the upright position. The

element assembly is lowered by moving the lock stop to

release unit from upright position.

Operating Suggestions

1. For liquid oil ll the frypot with oil to the bottom OIL

LEVEL line located on the rear of the frypot. This allows

for oil expansion as heat is applied. Do not ll cold oil any

higher than the bottom line; overow may occur as heat

expands the oil.

2. When using a solid frying compound, pack the tank

with the compound then turn the fryer on and o every

10 seconds and repack until compound has melted.

The fryer capacity is 17 Lbs. (7.7Kg) per tank. Scorched

shortening cuts down on the useable life and could

damage the fryer.

Fryers – Models ED-15F, ED-15SF, ED-30FT &

ED-30SFT

Wall Clearance

Do not install appliance closer to a wall of combustible

material than:

Back 1/2” (13mm)

Sides 1/2” (13mm)

CAUTION: Never set a complete block of solid shortening on

top of heating elements.

3. Ensure that the oil level is at the top OIL LEVEL line when

the oil is at its cooking temperature. It may be necessary

to add oil or shortening to bring the levels up to the

proper mark, after reaching cooking temperature.

4. To prolong shortening life, avoid over heating and reduce

the temperature during idle periods.

5. Ensure shorting is up to frying temperature before

adding foods.

Part # 4521653 (08/12/09)Page 8

Page 9

INDIVIDUAL MODEL INSTALLATIONS continued

6. To increase the life of the shortening, it should be ltered

with Garland fryer lter cones daily or more often, if

necessary.

7. Baskets should never be more than half full.

8. Keep fat at operating level.

9. Fry pieces of similar size at the same time for best results.

10. Excessive moisture should be shaken from the product

before frying.

11. Your shortening manufacturer can supply excellent frying

and shortening guides.

Controls

1. All ED series fryers are equipped with a manually

resettable high limit located at the rear of the element

termination box. In the event that shortening

temperatures exceed normal limits, the high limit will trip

and can only be reset by pushing the red button when

shortening has cooled.

2. All ED series are equipped with a precision electronic

thermostat which has been factory calibrated and is

designed to hold that calibration. There should never be

the need to calibrate this thermostat in the eld. Should

there ever be an abnormal discrepancy in the set point

of actual temperatures, or repeated tripping on the high

limit occurs, the fryer should be serviced by an authorized

Garland service agency.

Electrical Connection

A knockout is provided near the front left side of the unit

located behind the control panel. To view knockout, loosen

the two acorn nuts and hinge control panel downward. The

terminal block is also located in this area.

The supply cable entrance is located on the right side when

facing the rear of the unit. The cable is fed towards the front

through a wire way.

Controls

Griddles are equipped with snap action thermostats.

Calibration Instructions

1. Field calibration is seldom necessary and should not

be attempted unless experience with cooking results

denitely proves that the control is not maintaining the

temperature to which the dial is set.

2. Should calibration be required, use a test instrument

(pyrometer) which special disc type thermocouple or

reliable “surface” type thermometer.

NOTE: A drop of oil on face of disc will provide better

contact.

3. Turn ALL griddle temperature control dials to 350°F

(177°C). In order to allow griddle temperature to stabilize,

the controls must be allowed to cycle twice before taking

a test reading.

Griddles – Models: ED-15G,

ED-24G & ED-36G

Grooved Griddles – Models:

ED-15G-U, ED-24-U,

ED-24G-U1, ED-36G-U,

ED-36-U1 & ED-36G-U2

Wall Clearances

Do not install appliance closer to a wall of combustible

material than:

Back 1 1/2” (38mm)

Sides 1” (25mm)

Supply Connection

For supply connection, use wire suitable for 75°C (167°F).

Part # 4521653 (08/12/09) Page 9

4. Check temperature reading when control just cycles

“OFF” (as indicated by the cycling amber pilot), by placing

sensor rmly on griddle surface directly above sensing

bulb of control. If the temperature does not read within

15°F (8°C) of the dial setting recalibrate as follows.

5. Carefully remove the thermostat dial making sure the

setting is not disturbed.

6. Hold dial shaft steady and with a screwdriver, turn

calibration screw located inside the dial shaft, clockwise

to decrease and counterclockwise to increase the

temperature.

EXAMPLE: 1/4 turn = 35°F (19°C)

7. Replace thermostat dial and repeat steps 2 through 4 to

verify correct adjustment has been made.

Page 10

INDIVIDUAL MODEL INSTALLATIONS continued

Broilers – Models: ED-15B,

ED-30B & ED-42B

Wall Clearance

Do not install appliance closer to a wall of combustible

material than:

Back 9” (229mm)

Sides 9” (229mm)

Supply Connection

For supply connection, use wire suitable for 90°C (194°F).

Electrical Connection

A knockout is provided near the front left side of the unit

located behind the control panel. To view knockout, loosen

the two acorn nuts and hinge control panel downward. The

terminal block is also located in this area.

The cable entrance is located on the right side when facing

the rear of the unit. The cable is fed towards the front

through a wire way.

Controls

Innite switches are used to control the elements.

HI to 5 - High heat

5 to 3 - Medium Heat

3 to LO - Low Heat

Setting of switches between the numbers will give

intermediate heat. Switches are reversible and may be

turned right or left.

Food Warmers – Models ED-15W & ED-15WP

Wall Clearances

Do not install appliance closer to a wall of combustible

material than:

Back 1” (25mm)

Sides 1” (25mm)

Electrical Connection

NOTE: Applicable to Model ED-15W only.

A knockout is provided near the front left side of the unit

located behind the control panel. To view knockout, loosen

the two acorn nuts and hinge control panel downward. The

terminal block is also located in this area.

The supply cable entrance is located on the right side when

facing the rear of the unit. The cable is fed towards the front

through a wire way.

Controls

Innite switches are used to control the elements.

HI to 5 - High Heat

5 to 3 - Medium Heat

3 to LO - Low Heat

Setting of switches between the numbers will give

intermediate heat. Switches are reversible and may be

turned right or left.

Operating Instructions

ED series food warmers are supplied with a removable tank

assembly. Fill tank with 1-1/4” (32mm) to 1-1/2” (38,mm) of

water.

While not supplied with the food warmer it uses a 200

series of Gastronorm cafeteria pan and any arrangement

of 200 series pans in various sizes may be used. Individual

preference of the operation will determine sizes of inserts

to be used. Pans may be purchased from your kitchen

equipment dealer.

CAUTION: Do Not Allow The Tank Assembly To Run Dry.

ED Series food warmers are wet type only. Operating these

units dry for extended periods may cause the tank assembly

to warp and void the warranty.

Supply Connection

NOTE: Applicable to Model ED-15W only. Model

ED-15WP is a 115 volt unit supplied with a grounded cord

and plug.

For Model ED-15W, use a wire suitable for 90°C (194°F).

Part # 4521653 (08/12/09)Page 10

Page 11

CLEANING AND MAINTENANCE

Cleaning Exterior Finishes

Black Baked Enamel – Allow equipment to cool after use

and wash all grease deposits from exterior with a hot mild

detergent or soap solution. Dry thoroughly. Do not use

abrasives.

Brushed Chrome Or Brushed Nickel – Wash when cool with

a hot mild detergent or soap solution. Do not use abrasives.

Stainless Steel – Normal soil may be removed with a

detergent or soap solution applied with a cloth.

To remove grease that has baked on, apply cleanser to a

damp cloth or sponge and rub cleanser on the metal in

the direction of the polishing lines of the metal. Never rub

in circular motion. Soil and brunt deposits, which do not

respond, can usually be removed by rubbing the surface with

Scotch-Brite scouring pads or stainless scouring pads. DO

NOT USE ORDINARY STEEL WOOL.

Heat tint can be removed by vigorous scouring in the

direction of the polish lines using Scotch-Brite scouring pads

or stainless scouring pad in combination with powdered

cleanser.

Exterior surfaces should be cleaned daily before debris is

allowed to heat and bake onto the surfaces.

Fryers

3. Clean the top of the unit with a cloth soaked in a mild

detergent and hot water, including the front of the

element assembly housing. Rinse with a clean cloth

dipped in clean hot water, Dry thoroughly with a clean

cloth.

Griddle Top Plates

Seasoning

Before being used for the rst time, all the griddle surfaces

must be seasoned.

1. Wash griddle with a hot detergent or soap solution, rinse

and dry thoroughly.

2, Set the griddle heat to lowest possible temperature for 30

minutes. Apply a thin lm of cooking oil.

3. Allow oil to remain on griddle 5 minutes then wipe o.

4. Reset heat to medium temperature and apply a second

lm of oil.

5. Wipe o excess after 5 minutes. Reset heat to cooking

temperature and apply a nal lm of oil wiping o

surplus after 3 minutes.

The griddle is now seasoned and ready for use. The griddle

may be re-seasoned at any time by cleaning thoroughly and

following the seasoning procedure.

Cleaning The Fry Tank

1. If a liquid frying compound is used, allow the compound

to cool, then raise the element assembly by means of the

handle until the support engages and let the oil run o

the elements into the fry tank. Wipe the surface oil o the

elements to prevent dripping into the unit bottom when

the tank is removed. Lift out the fry tank and empty the

oil into a lter, after ltering it is then ready for re-use.

Clean the tank in the pot wash area with a mild detergent

and hot water. Rinse with a sponge dipped in a vinegar

and water solution. (3/4 cup of vinegar to 1 quart of

water) and dry thoroughly with a clean cloth.

2. If hydrogenated (solid) frying compound is used that has

been allowed to cool and become solidied, rst turn the

thermostat dial to 121°C (250°F) until the compound is

in a liquid state. Turn the thermostat dial/s to o “O”. Lift

the element assembly by means of the handle until the

support engages and let the oil run o the elements into

the fry tank. Then proceed as described in step 1 to lter

the compound and clean the fry tank.

Cleaning

Griddle plates should be wiped daily while still warm.

Remove carbonized grease or food with spatula. When

necessary, clean griddle surfaces thoroughly using a ne

griddle brick or a liquid griddle cleaner (available from your

kitchen equipment dealer). Polish the griddle surface to a

bright nish. For stubborn residue wash the griddle surfaces,

rinse and dry thoroughly. Re-season griddle.

Broiler

Broiler Grates Surfaces

Broiler grates – or cooking racks are manufacture from a

cast iron material. For maximum eciency the racks should

be scraped and wiped down daily. Grease and other food

particles char and carbonize onto the rack surfaces building

up becoming harder to clean.

Part # 4521653 (08/12/09) Page 11

Page 12

CLEANING AND MAINTENANCE continued

Broiler Interior and Under Broiler Grates

Debris and grease that gathers inside the broiler and must be

removed.

Daily

1. Lowering the front black enamel panel and remove the

grease drawer to be empty. NEVER operate the broiler

without the grease drawer. A magnetic door catch on

the grease drawer holds the front panel closed, acting as

a simple safety reminder. The front panel will not close

when the grease drawer is not in place.

2 In order for an electric broiler to heat up the cooking

racks/grates the electric elements must be attached

to the grates. After the broiler has cooled down, clean

inside the broiler under these grates using the broiler

grate lifter supplied with the broiler to lift the racks. Once

the grates are lifted a prop will kick out that is attached to

the underside of the grates to hold assembly up. This will

allow you access to clean the inside the broiler.

Periodic Cleaning

Over time debris carbonizes on the broiler grates requiring

major cleaning with detergent soap or degrease agent. The

broiler racks can be completely removed from the attached

elements for cleaning.

WARNING: All power should be shut o prior to cleaning.

1. Lift the broiler grates as described in the daily cleaning

section.

2 You will see the elements clamps that attaches the

elements to grates. Remove the element clamps and

clean the broiler racks.

3. Reverse the above procedure to reassemble the broiler.

After major cleaning it is recommended that you re-season

the broiler grates. Broiler grates are manufactured from cast

iron, which is a porous material. Major cleaning removes the

oils in the metal that helps prevent food from sticking to the

cook surface requiring re-seasoning.

To re-season the grates heat the broiler at a low temperature

setting then rub cooking oil into the broiler rack. At this point

you are ready to begin cooking again. If food is still sticking

to the broiler grate rub more cooking oil onto the grates.

WARNING : NEVER use tin foil inside the broiler as it is a

reective material and it could cause the temperature to

escalate beyond the normal range of the broiler design.

Part # 4521653 (08/12/09)Page 12

Page 13

Part # 4521653 (08/12/09) Page 13

Page 14

Page 15

Page 16

Pièce nº 4521653 (08/12/09) Page 13

delà de la plage pour laquelle la rôtissoire est conçue.

qui pourrait causer une augmentation de la température aul’intérieur de la rôtissoire car il s’agit d’un matériau ré ecteur

AVERTISSEMENT : NE JAMAIS utiliser de feuille d’étain à

rôtissoire, frotter encore les grilles avec de l’huile.

cuisson. Si les aliments continuent de coller aux grilles de la

de cuisson. Vous pouvez alors commencer de nouveau la

à basse température puis frotter les grilles avec de l’huile

Pour apprêter de nouveau les grilles, chau er la rôtissoire

apprêtage.

à la surface de cuisson, ce qui nécessite donc un nouvel

trouvant dans le métal qui empêchent les aliments de coller

matériau poreux. Un nettoyage majeur élimine les huiles se

grilles de la rôtissoire sont fabriquées en fonte, qui est un

d’apprêter de nouveau les grilles de la rôtissoire. Les

Après chaque nettoyage important, il est recommandé

rôtissoire.

3. Inverser la procédure ci-dessus pour remonter la

nettoyer les grilles de la rôtissoire.

sont alors visibles. Retirer les pinces des éléments et

2 Les pinces des éléments xant les éléments aux grilles

section de nettoyage quotidien.

1. Lever les grilles de la rôtissoire comme décrit dans la

avant le nettoyage.

AVERTISSEMENT : L’alimentation électrique doit être coupée

le nettoyage.

peuvent être retirées complètement des éléments xés pour

détergent ou agent dégraissant. Les grilles de la rôtissoire

la rôtissoire, ce qui nécessite un nettoyage majeur avec

Avec le temps, les débris se carbonisent sur les grilles de

Nettoyage Périodique

l’intérieur de la rôtissoire pour le nettoyer.

maintenir l’ensemble levé. Cela permet d’accéder à

xée à la partie inférieure des grilles sort et permet de

rôtissoire. Une fois les grilles soulevées, une béquille

utiliser le dispositif de levage des grilles fourni avec la

nettoyer l’intérieur de la rôtissoire sous ces grilles en

être xés aux grilles. Une fois que la rôtissoire a refroidi,

éléments électriques des grilles de cuisson doivent

2 Pour qu’une rôtissoire électrique puisse chau er, les

ENTRETIEN ET NETTOYAGE suite

Page 17

Pièce nº 4521653 (08/12/09)Page 12

savon, rincer et sécher soigneusement.

le tiroir à graisse n’est pas en place.

sécurité. Le panneau avant ne peut pas être fermé quand

maintient fermé le panneau avant et sert de rappel de

tiroir à graisse Un loquet magnétique sur le tiroir à graisse

à graisse à vider. NE JAMAIS utiliser la rôtissoire sans le

1. . Abaisser le panneau émaillé noir avant et retirer le tiroir

Chaque Jour

1. Laver le gril avec une solution chaude de détergent ou de

du gril doivent être apprêtées.

Avant de les utiliser pour la première fois, toutes les surfaces

Apprêtage

Plaques Supérieures De Gril

rôtissoire doivent être éliminés.

Les débris et la graisse qui s’accumulent à l’intérieur de la

Rôtissoire

Intérieur De La Rôtissoire Et Sous Les Grilles De La

s’accumulent en devenant plus di ciles à nettoyer.

d’aliment se carbonisent sur les surfaces des grilles et

grattées et essuyées chaque jour. La graisse et les particules

fonte. Pour une e cacité maximale, les grilles doivent être

Les grilles de la rôtissoire – ou grilles de cuisson – sont en

Surfaces Des Grilles De La Rôtissoire

Rôtissoire

Apprêter de nouveau le gril.

rebelles, laver les surfaces du gril, rincer et sécher à fond.

la surface du gril pour obtenir un ni brillant. Pour les résidus

auprès de votre fournisseur d’équipement pour cuisine). Polir

ou un produit de nettoyage liquide pour gril (disponible

nettoyer à fond les surfaces du gril avec une pierre à gril ne

ou les aliments carbonisés avec la spatule. Si nécessaire,

pendant qu’elles sont encore chaudes. Éliminer la graisse

Les plaques du gril doivent être essuyées chaque jour

Nettoyage

nettoyant à fond et en suivant la procédure d’apprêtage.

peut apprêter de nouveau le gril à n’importe moment en le

Le gril est maintenant apprêté et prêt à être utilisé. On

d’huile en essuyant l’excès après 3 minutes.

température de cuisson et appliquer une couche nale

5. Essuyer l’excès au bout de 5 minutes. Régler le gril à la

une deuxième couche d’huile.

4. Régler le gril sur une température moyenne et appliquer

propre et sécher avec un chi on propre.

avec un chi on propre trempé dans de l’eau chaude

trempé dans de l’eau chaude et du détergent doux Rincer

de l’ensemble d’éléments chau ants avec un chi on

3. Nettoyer le dessus de l’appareil ainsi que l’avant du carter

ltrer le produit à friture et nettoyer le bassin.

le bassin. Procéder ensuite comme décrit à l’étape 1 pour

s’enclenche et laisser le produit à friture s’égoutter dans

d’éléments avec la poignée jusqu’à ce que le support

cadran du thermostat sur arrêt « O ». Soulever l’ensemble

ce que le produit à friture devienne liquide. Tourner le

tourner le cadran du thermostat sur 121°C (250°F) jusqu’à

que l’on a laissé refroidir et se solidi er, commencer par

2. En cas d’utilisation de produit à friture hydrogéné (solide)

d’eau) et sécher soigneusement avec un chi on sec.

vinaigre dans l’eau. (3/4 de tasse de vinaigre pour 1 litre

Rincer avec une éponge trempée dans une solution de

des marmites avec un détergent doux et de l’eau chaude.

réutilisée. Nettoyer le bassin dans le secteur de lavage

l’huile dans un ltre; après ltration, elle est prête à être

fois le bassin retiré. Soulever le bassin à friture et vider

éviter qu’ils ne s’égouttent dans le fond de l’appareil une

le bassin de friture. Essuyer l’huile des éléments pour

du support et laisser l’huile couler des éléments dans

chau ants avec la poignée jusqu’à enclenchement

produit refroidir, puis soulever l’ensemble d’éléments

1. En cas d’utilisation de produit à friture liquide, laisser le

Nettoyage Du Bassin De Friture

Friteuses

cuire sur les surfaces.

quotidiennement avant que les débris puissent chau er et

Les surfaces extérieures doivent être nettoyées

3. Laisser l’huile sur le gril pendant 5 minutes, puis l’essuyer.

de cuisson.

pendant 30 minutes. Appliquer une mince couche d’huile

2. Régler le gril à la température la plus basse possible

nettoyage en poudre.

récurer pour acier inoxydable combinés à un produit de

avec des tampons à récurer Scotch-Brite ou un tampon à

frottant vigoureusement dans le sens des lignes de polissage

La coloration causée par la chaleur peut être éliminée en

ENTRETIEN ET NETTOYAGE suite

Page 18

Pièce nº 4521653 (08/12/09) Page 11

appliquée avec un chi on.

éliminées avec une solution de détergent ou de savon

Acier Inoxydable – Les salissures normales peuvent être

ORDINAIRE.

pour acier inoxydable. NE PAS UTILISER DE LAINE D’ACIER

tampons à récurer Scotch-Brite ou des tampons à récurer

habituellement être éliminés en frottant la surface avec des

et les dépôts brûlés qui ne se détachent pas ainsi peuvent

jamais frotter avec un mouvement circulaire. La saleté

le métal dans le sens des lignes de polissage du métal. Ne

de nettoyage sur un chi on ou un éponge humide et frotter

Pour éliminer la graisse cuite sur place, appliquer le produit

l’ensemble de réservoir et annuler la garantie.

de temps prolongées peut causer un gauchissement de

L’utilisation de ces appareils sans eau pendant des périodes

Les chau e-plats série Ed sont de type humide seulement.

ATTENTION : Ne pas laisser l’ensemble de réservoir sans eau.

équipements de cuisine.

peuvent être achetés auprès de votre concessionnaire en

on déterminera les tailles des bacs à utiliser. Les bacs

200 en di érentes tailles. En fonction de l’établissement,

on peut utiliser n’importe quel ensemble de bacs série

celui-ci utilise un bac cafétéria Gastronom série 200 et

Même si les bacs ne sont pas fournis avec le chau e-plats,

po (38 mm) d’eau.

cuve amovible. Remplir la cuve avec1-1/4 po (32 mm) à 1-1/2

Les chau e-plats série ED sont fournis avec un ensemble de

savon. Ne pas utiliser de produits abrasifs.

avec une solution très chaude de détergent doux ou de

Chrome Ou Nickel Brossé – Laver les pièces une fois froides

sécher. Ne pas utiliser de produits abrasifs.

solution très chaude de détergent doux ou de savon. Bien

et laver tous les dépôts graisseux à l’extérieur avec une

Émail Noir – Laisser l’équipement refroidir après utilisation

Nettoyage Des Finis Extérieurs

ENTRETIEN ET NETTOYAGE

réversibles et peuvent tourner à gauche ou à droite.

un réglage de chau e intermédiaire. Les commutateurs sont

Le fait de placer les commutateurs entre les chi res donne

3 à LO - Chau age Faible

5 à 3 - Chau age Moyen

HI à 5 - Chau age Fort

commander les éléments tubulaires.

Des commutateurs à réglage in ni sont utilisés pour

Commandes

de câble.

Le câble doit passer vers l’avant de l’appareil par un passage

lorsque l’on se place en face de la partie arrière de l’appareil.

L’entrée du câble d’alimentation se trouve sur le côté droit

bornier se trouve également dans cette zone.

borgnes et basculer le panneau de commande vers le bas. Le

Pour voir l’entrée défonçable, desserrer les deux écrous

de l’appareil se trouvant derrière le panneau de commande.

Une entrée défonçable est prévue près du côté avant gauche

NOTA : Applicable au modèle ED-15W seulement.

Instructions D’utilisation

Connexions Électriques

INSTALLATIONS DES MODÈLES INDIVIDUELS suite

Page 19

Pièce nº 4521653 (08/12/09)Page 10

Côtés : 9 po (229 mm)

Arrière : 9 po (229 mm)

combustibles inférieure à :

Ne pas installer l’appareil à une distance de matériaux

une température de 90°C (194°F).

Pour le modèle ED-15W, utiliser un câble convenant pour

Dégagements Par Rapport Aux Murs

un cordon d’alimentation et une che avec prise de terre.

ED-15WP est un appareil fonctionnant en 115 volts livré avec

NOTA : Applicable au modèle ED-15W seulement. Le modèle

Connexion D’alimentation

Côtés 1 po (25 mm)

Arrière 1 po (25 mm)

combustibles inférieure à :

Ne pas installer l’appareil à une distance de matériaux

Dégagements Par Rapport Aux Murs

Chau e-plats : Modèles: EDU-15W Et ED-15WP

réversibles et peuvent tourner à gauche ou à droite.

un réglage de chau e intermédiaire. Les commutateurs sont

Le fait de placer les commutateurs entre les chi res donne

3 à LO - Chau age Faiblet

5 à 3 - Chau age Moyen

HI à 5 - Chau age Fort

commander les éléments tubulaires.

Des commutateurs à réglage in ni sont utilisés pour

Commandes

42B

Rôtissoires – Modèles : ED-15B, ED-30B Et ED-

étapes 2 à 4 pour véri er que le réglage est correct.

7. Remettre en place le cadran du thermostat et répéter les

EXEMPLE : 1/4 tour = 35°F (19°C)

dans le sens contraire pour augmenter la température.

dans le sens des aiguilles d’une montre pour diminuer et

la vis d’étalonnage située à l’intérieur de l’axe du cadran,

6. Immobiliser l’axe du cadran et, avec un tournevis, tourner

attention à ne pas modi er le réglage.

5. Retirer soigneusement le cadran du thermostat en faisant

la température du cadran, réétalonner comme suit :

contrôle. Si la température di ère de plus de 15°F (8°C) de

gril, directement au-dessus du bulbe thermostatique de

en maintenant fermement le capteur à la surface du

l’alimentation (comme indiqué par le témoin ambre),

4. Véri er la température quand la commande COUPE

deux fois avant de mesurer la température.

du gril de se stabiliser, il faut laisser les commandes cycler

du gril à 350°F (177°C). Pour permettre à la température

3. Tourner TOUS les cadrans de commande de température

de câble.

Le câble doit passer vers l’avant de l’appareil par un passage

lorsque l’on se place en face de la partie arrière de l’appareil.

L’entrée du câble d’alimentation se trouve sur le côté droit

bornier se trouve également dans cette zone.

borgnes et basculer le panneau de commande vers le bas. Le

Pour voir l’entrée défonçable, desserrer les deux écrous

de l’appareil se trouvant derrière le panneau de commande.

Une entrée défonçable est prévue près du côté avant gauche

meilleur contact.

Nota : Une goutte d’huile à la surface du disque assurera un

disque ou un thermomètre able de type « surface ».

d’essai (pyromètre) avec thermocouple spécial de type à

2. Si un étalonnage est nécessaire, utiliser un instrument

températures sur lesquelles sont réglées les commandes.

démontrent que les commandes ne maintiennent pas les

devra pas essayer de le faire sauf si les résultats de cuisson

1. L’étalonnage sur place est rarement nécessaire et on ne

Connexions Électriques

Instructions D’étalonnage

une température de 90°C (194°F).

Pour la connexion d’alimentation, utiliser un câble convenant à

Connexion D’alimentation

Les grils sont équipés de thermostats à rupture brusque.

Commandes

INSTALLATIONS DES MODÈLES INDIVIDUELS suite

Page 20

Pièce nº 4521653 (08/12/09) Page 9

guides sur la friture et l’utilisation du shortening.

11. Votre fabricant de shortening peut vous o rir d’excellents

de câble.

Le câble doit passer vers l’avant de l’appareil par un passage

lorsque l’on se place en face de la partie arrière de l’appareil.

L’entrée du câble d’alimentation se trouve sur le côté droit

bornier se trouve également dans cette zone.

borgnes et basculer le panneau de commande vers le bas. Le

Pour voir l’entrée défonçable, desserrer les deux écrous

de l’appareil se trouvant derrière le panneau de commande.

Une entrée défonçable est prévue près du côté avant gauche

Connexions Électriques

à une température de 75°C (167°F).

Pour la connexion d’alimentation, utiliser un câble convenant

Connexion D’alimentation

Côtés : 1 po (25 mm)

Arrière : 1-1/2 po (38 mm)

combustibles inférieure à :

Ne pas installer l’appareil à une distance de matériaux

Dégagements Par Rapport Aux Murs

ED-36-U1 Et ED-36G-U2

ED-24G-U1, ED-36G-U,

ED-15G-U, ED-24-U,

Grils Rainurés – Modèles :

Grils – Modèles : ED-15G, ED-24G Et ED-36G;

par une agence de réparation agréée par Garland.

du dispositif à maximum, la friteuse devra être réparée

températures réelles ou en cas de déclenchement répété

di érence anormale entre le point de réglage et les

ce thermostat sur place. Dans le cas où il y aurait une

ne devrait pas être nécessaire d’étalonner de nouveau

en usine et est conçu pour conserver cet étalonnage. Il

thermostat électronique de précision qui a été étalonné

2. Tous les appareils de la série ED sont équipés d’un

refroidi.

sur le bouton rouge une fois que le produit de friture a

se déclenche et ne peut être réenclenché qu’en appuyant

dépassent les limites normales, le dispositif à maximum

Dans le cas où les températures du produit de friture

à l’arrière du boîtier de raccordement des éléments.

dispositif à maximum réenclenchable à la main placé

1. Toutes les friteuses de série ED sont équipées d’un

Commandes

frire.

10. Éliminer du produit l’humidité en excès avant de le faire

taille similaire.

9. Pour de meilleurs résultats, faire frire des morceaux de

8. Maintenir le niveau de produit pour friture.

7. Les paniers ne doivent jamais être plus que moitié pleins.

ou plus souvent si nécessaire.

avec des cônes à ltrer pour friteuse Garland, chaque jour

6. Pour augmenter la durée de vie du shortening, le ltrer

friture avant d’ajouter les aliments.

5. S’assurer que le shortening a atteint la température de

d’inactivité.

surchau e et réduire la température pendant les périodes

4. Pour prolonger la durée de vie du shortening, éviter toute

cuisson de atteinte.

jusqu’à la marque appropriée, après température de

l’huile ou le rapetissement pour apporter les niveaux

température de cuisson. Il peut être nécessaire d’ajouter

NIVEAU supérieure d’HUILE quand l’huile est à sa

3. Assurez-vous que le niveau d’huile est à la ligne DE

rapetissement plein sur des éléments de chau e.

ATTENTION : Ne placez jamais un bloc complet de

être utilisé et pourrait endommager la friteuse.

Lb. (7,7 kg) par bassin. Du shortening brûlé ne peut plus

qu’il soit tout fondu. La capacité de la friteuse est de 17

toutes les 10 secondes et rajouter du produit jusqu’à ce

produit dans le bassin puis allumer la friteuse et l’éteindre

2. En cas d’utilisation de produit à friture solide, tasser le

l’huile.

peut se produire pendant que la chaleur augmente

huile froide plus haut que le résultat ; le débordement

pendant que la chaleur est appliquée. Ne remplissez pas

du frypot. Ceci tient compte de l’expansion d’huile

à la ligne DE NIVEAU inférieure d’HUILE située sur l’arrière

1. Pour la su sance liquide d’huile le frypot avec de l’huile

Suggestions D’utilisation

butée de verrouillage de la position haute.

L’ensemble des éléments est abaissé en déplaçant la

maintenant l’ensemble des éléments en position haute.

l’aide de la poignée jusqu’à l’engagement du support

2. Pour retirer le bassin de friture, soulever les éléments à

INSTALLATIONS DES MODÈLES INDIVIDUELS suite

Page 21

Pièce nº 4521653 (08/12/09)Page 8

assécher le bassin.

produit de nettoyage et de l’eau chaude. Bien rincer et

du produit de friture. Utiliser du détergent ou tout autre

bassin de friture et les éléments avant de la remplir avec

friture. Pour cette raison, il est nécessaire de nettoyer le

thermostat étalonné avec de l’huile dans le bassin de

1. Avant son départ de l’usine, la friteuse a été testée et son

Avant D’utiliser La Friteuse

le couvercle du boîtier du contacteur à l’arrière de la friteuse.

retirant l’ensemble du bassin de friture, le bouclier arrière et

on est face à l’arrière de l’appareil. On accède au bornier en

Une entrée défonçable est prévue sur le côté droit quand

Alimentation Électrique

à une température de 75°C (167°F).

Pour la connexion d’alimentation, utiliser un câble convenant

Connexion D’alimentation

Côtés : 1/2 po (13mm)

Arrière : 1/2 po (13mm)

combustibles inférieure à :

Ne pas installer l’appareil à une distance de matériaux

Dégagements Par Rapport Aux Murs

ED-15SF, ED-30FT Et ED-30SFT

Friteuses : Modèles ED-15F,

« OFF ».

1. 1. Placer le commutateur à 6 positions en position

Arrêt Des Plaques Chau antes Scellées :

entre 1 et 6.

2. Placer le commutateur à 6 positions à la positon choisie

brûler le revêtement de protection.

arrêter et les laisser refroidir. Cette opération fera durcir et

les faire chau er pendant 5 minutes sur le réglage 3, les

1. Avant la première utilisation des plaques chau antes,

Utilisation De La Plaque Chau ante Scellée

bouillir de l’eau.

4. Utiliser un couvercle sur les marmites utilisées pour faire

augmentera le temps de montée en température.

automatiquement sa puissance d’alimentation. Ceci

protégés par un dispositif automatique qui réduit

3. Ne pas préchau er les éléments. Les éléments sont

chau age.

similaire à celui de la plaque. Ceci réduit le temps de

2. Utiliser, autant que possible, des marmites d’un diamètre

convexes ou concaves de plus de 1 mm (1/32 po).

le transfert de la chaleur. Ne pas utiliser de marmites

1. Le dessous des marmites doit être bien plat. Ceci optimise

l’utilisation e cace de ces éléments :

Les pratiques d’utilisation sont très importantes pour

ED-15THSE

ED-15HSE

Puissance

2 340 305

3 450 450

4 1300 950

5 1750 1400

6 2300 2000

L’interrupteur

Réglage De

Frire,

Mijoter

Braiser

Bouillir,

Réchau er 1 240 200

cuisson sur plaque.

faire bouillir, mijoter, braiser et pour tout autre procédé de

d’une plaque facile à nettoyer. Ils peuvent être utilisés pour

Les éléments de chau e scellés tout usage o rent l’avantage

Plaques Chau antes Scellées

protection (3- 5 minutes au réglage le plus fort).

ustensiles dessus a n de durcir et de brûler le revêtement de

être chau ées pendant une courte période de temps sans

chau antes scellées pour la première fois, elles doivent

Application

revêtement résistant à la chaleur. Avant d’utiliser les plaques

La surface de travail supérieure de la plaque porte un

Avant D’utiliser La Plaque Chau ante

INSTALLATIONS DES MODÈLES INDIVIDUELS suite

Page 22

(Bouillir)

Fort

Moyen

(Mijoter)

Faible

Chaleur

Pièce nº 4521653 (08/12/09) Page 7

normale. Ceci est une importante caractéristique de sécurité.

lorsque les conditions de fonctionnement reviennent à la

le réglage de l’interrupteur normal et restitue la puissance

électrique dans les conditions décrites plus haut, annulant

Ce dispositif coupe automatiquement l’alimentation

protection bimétallique intégré de conception unique.

de cuisson de mauvaise qualité, par un interrupteur de

en cas d’allumage à vide ou en cas d’utilisation d’ustensiles

Cette plaque chau ante est protégée contre la surchau e

6 2600 2000

5 1750 1400

4 1300 950

3 450 450

2 340 305

1 240 200

15HSE 15THSE

Puissance

l’interrupteur

Position De

haut.

chi re choisi, le chi re 1 étant le plus bas et le chi re 6 le plus

par rapport à la position Arrêt (OFF), pour le placer sur le

pour mijoter. Tourner le commutateur à gauche ou à droite

par un commutateur à 6 positions, 3 pour faire bouillir et 3

Les plaques chau antes à éléments pleins sont commandées

Commandes

de câble.

Le câble doit passer vers l’avant de l’appareil par un passage

lorsque l’on se place en face de la partie arrière de l’appareil.

L’entrée du câble d’alimentation se trouve sur le côté droit

Côtés 1 1/2 po (38 mm)

Arrière 1 1/2 po (38 mm)

combustibles inférieure à :

Ne pas installer l’appareil à une distance de matériaux

Dégagements Par Rapport Aux Murs

ED-15HSE / ED-15THSE

Plaque Chau ante À Éléments Pleins – Modèle

réversibles et peuvent tourner à gauche ou à droite.

un réglage de chau e intermédiaire. Les commutateurs sont

Le fait de placer les commutateurs entre les chi res donne

3 à LO - Chau age Faible

5 à 3 - Chau age Moyen

Hi à 5 - Chau age Fort

commander les éléments tubulaires :

Des commutateurs à réglage in ni sont utilisés pour

Commandes

de câble.

Le câble doit passer vers l’avant de l’appareil par un passage

lorsque l’on se place en face de la partie arrière de l’appareil.

L’entrée du câble d’alimentation se trouve sur le côté droit

bornier se trouve également dans cette zone.

borgnes et basculer le panneau de commande vers le bas. Le

Pour voir l’entrée défonçable, desserrer les deux écrous

de l’appareil se trouvant derrière le panneau de commande.

Une entrée défonçable est prévue près du côté avant gauche

bornier se trouve également dans cette zone.

borgnes et basculer le panneau de commande vers le bas. Le

Pour voir l’entrée défonçable, desserrer les deux écrous

de l’appareil se trouvant derrière le panneau de commande.

Une entrée défonçable est prévue près du côté avant gauche

Alimentation Électrique

L6-30P (HUBBELL HBL2621 ou equivalent)

seront munis d’un cordon electrique de 4 pieds de long, NEMA

NOTA: - Tout les modeles ED-15THSE a 208V 1 phase 60 hZ,

à une température de 75°C (167°F).

Pour la connexion d’alimentation, utiliser un câble convenant

Connexion D’alimentation

Alimentation Électrique

à une température de 90°C (194°F).

Pour la connexion d’alimentation, utiliser un câble convenant

Connexion D’alimentation

Côtés 1 1/2 po (38 mm)

Arrière 1 1/2 po (38 mm)

combustibles inférieure à :

Ne pas installer l’appareil à une distance de matériaux

Dégagements Par Rapport Aux Murs

Modèle ED -15H

Plaque Chau ante –

INSTALLATIONS DES MODÈLES INDIVIDUELS

Page 23

Pièce nº 4521653 (08/12/09)Page 6

DES PIEDS

INSTALLATION

(QTÉ 4)

DE 4 PO [102 mm]

PIED RÉGLABLE

(QTÉ 2)

GORGE DES PIEDS

FOND DE L’UNITÉ

devant être installés sur un socle de plan de travail.

carton du socle.

comme indiqué dans les instructions se trouvant dans le

2. Retirer et jeter les boulons de mise à niveau des appareils

1. Assembler et mettre de niveau le socle de plan de travail

De Comptoir (Option)

Installation Des Socles

Cette gorge doit être installée quand on utilise les pieds.

La gorge pour les pieds est située sur la base de l’ensemble.

Installation Des Pieds

série EDU.

mm) du socle et dans les écrous au fond de l´appareil de

à métaux 8-32 à travers les trous de diamètre 7/32 po (5

de vis à métaux 8-32 et de rondelles plates. Insérer les vis

5. Fixer la dernière unité au socle de plan de travail à l’aide

section Installation des plaques d’union.

4. Connecter les plaques d’union comme décrit dans la

série ED.

(5 mm) du socle dans les écrous au fond de l’appareil de

vis à métaux 8-32 à travers les trous de diamètre 7/32 po

vis à métaux de 8-32 et des rondelles plates. Insérer les

de plan de travail, en xant la première unité avec des

3. Placer les appareils dans les positions choisies sur le socle

PLAN DE TRAVAIL

AU SILICONE

PRODUIT D’ÉTANCHÉITÉ

un doigt ou un outil a n d’obtenir un joint à gorge.

5. Lisser le joint de silicone en le poussant dans la fente avec

trouvant sous l’appareil et en utilisant des vis à tôle 10A.

4. Fixer l’appareil au plan de travail en utilisant les trous se

périmètre du fond de l’appareil.

3. Disposer un généreux cordon de silicone sous tout le

l’appareil.

l’appareil et le plan de travail autour du périmètre de

2. Nettoyer soigneusement le périmètre inférieur de

niveau. Terminer les connexions électriques.

1. L’appareil doit être installé sur un plan de travail de

comme suit :

travail, il doit être scellé conformément aux normes N.S.F.

Lorsque l’appareil est installé sans les pieds sur un plan de

Étanchéité Sanitaire Du Plan De Travail

INSTALLATION GENERALE suite

Page 24

Pièce nº 4521653 (08/12/09) Page 5

appareils ne sont pas de niveau.

Note : Les grils peuvent ne pas reposer correctement, si les

VUE AVANT

VUE ARRIÈRE

avec la première.

de droite et de gauche. Mettre toutes les unités de niveau

travers à l’avant et à l’arrière et verticalement sur les bords

et mettre l’appareil de niveau dans quatre directions : en

de mise à niveau ou les pieds. Utiliser un niveau à bulle

1. Mettre chaque appareil de niveau en ajustant les boulons

boulons de mise à niveau et les remplacer par les pieds.

2-1/2 po (64 mm) en option sont livrés avec l’unité, jeter les

l’arrière de chacune des deux unités à installer. Si les pieds de

type d’installation. Une plaque se trouve à l’avant et l’autre à

entre les unités, deux plaques d’union sont livrées pour ce

Pour assurer la correspondance et l’ajustement permanent

ou en série avec d’autres équipements de séries ED ou GD.

Toutes les unités peuvent être installées indépendamment

Installation Des Plaques D’union

matière de code.

autorités locales ayant juridiction pour les exigences en

fonction du pays, de l’état ou de la province; consulter les

Les exigences en matière de ventilation peuvent varier en

Code ANSI / NFPA - Édition En Vigueur.

et/ou les codes. Locaux. Aux États-unis - Le National Electrical

vigueur au Canada - Le Code Électrique Canadien, Partie 1

L’installation et la connexion doivent respecter les codes en

Réglementation Légale

signalétique.

aux caractéristiques électriques indiquées sur la plaque

S’assurer que l’alimentation électrique est conforme

appareil) et xer la plaque à l’aide des vis à tôle fournies.

la plaque d’union sur les deux trous (un sur chaque

5. Pour xer l’avant, ouvrir le panneau inférieur avant, placer

de travail ou le dossier du bar.

4. Pousser les appareils pour les mettre en place sur le plan

l’aide des écrous borgnes retirés à l’étape 2.

sur les trous de vis à l’arrière de l’appareil et les serrer à

les trous de diamètre ¼ po (6,4 mm) de la plaque d’union

3. Fixer une plaque d’union en place à l’arrière en mettant

2. Retirer les écrous borgnes à l’arrière de l’appareil.

en ouvrant la porte émaillée sous le panneau de commande.

plaque de série de chaque appareil et sont facilement lisibles

Toutes les indications électriques sont présentes sur la

Plaque Signalétique

retirés aussitôt après l’installation de l’appareil.

protection des surfaces en acier inoxydable doivent être

les matériaux d’emballage des appareils. Les matériaux de

Retirer soigneusement les appareils des cartons. Retirer tous

Déballage

INSTALLATION GENERALE

Page 25

415V

240V/

380V

220V/

Phases

Hi Line 2 Ou 3

Pièce nº 4521653 (08/12/09)Page 4

425V

240V/

380V

240V/

Monophasé

Triphasé

Hi Line

Ampérage Nominal Par Ligne

TABLEAU PHASES ET AMPÉRAGE

Monophasé

Amérique Du Nord Export

Po mm Po mm Po mm 208V 240V 208V 240V

Largeur Profondeur Hauteur

DIMENSIONS TOTALES

DE

ED-15W 15 381 24 610 11.50 292 5 5 N/A N/A 6 5 N/A N/A

ED-42B 42 1067 24 610 13.75 349 39 34 23 20 37 34 13 12

ED-30B 30 762 24 610 13,75 349 39 34 23 20 37 34 13 12

ED-15B 15 381 24 610 13.75 349 13 12 N/A N/A 13 12 N/A N/A

ED-36G 36 914 24 610 13.75 249 49 42 28 25 46 42 16 14

ED-24G 24 620 24 610 13.75 349 33 28 28 25 31 28 16 14

ED-15G 15 381 24 610 13.75 349 17 14 N/A N/A 16 14 N/A N/A

ED-30SFT 30 762 24 610 13 330 77 67 45 39 73 67 25 23

ED-30FT 30 762 24 610 13 330 51 45 45 39 54 45 27 22

ED-15SF 15 381 24 610 13 330 39 34 23 20 37 34 13 12

ED-15F 15 382 24 610 13 330 26 23 N/A N/A 27 23 N/A N/A

ED-15THSE 15 381 24 610 11.25 286 19.2 16.7 16.7 14.4 Contacter l’usine

ED-15HSE 15 381 24 610 11.25 286 25 22 22 19 24 22 12 11

ED-15H 15 381 24 610 11.25 286 21 18 18 16 20 18 10 9

MODÈLE

NUMÉRO

ED-15W 1.0 1.0 1.12 1.0

ED-42B 8.1 8.1 8.1 8.1

ED-30B 5.4 5.4 5.4 5.4

ED-15B 2.7 2.7 2.7 2.7

ED-36G 10.1 10.1 10.1 10.1

ED-24G 6.7 6.7 6.7 6.7

ED-15G 3.4 3.4 3.4 3.4

ED-30SFT 16.0 16.0 16.0 16.0

ED-30FT 10.6 10.6 11.86 10.3

ED-15SF 8.0 8.0 8.0 8.0

ED-15F 5.3 5.3 5.93 5.3

ED-15THSE 4.0 4.0 Contacter l’usine

ED-15HSE 5.2 5.2 5.2 5.2

ED-15H 4.2 4.2 4.2 4.2

208V 240V 220V/380V 240V/415V

Amérique Du Nord Export

Puissance Totale Kw

TABLEAU DE CHARGE ET DE TENSION

MODÈLE

NUMÉRO DE

DIMENSIONS ET SPÉCIFICATIONS

Page 26

Pièce nº 4521653 (08/12/09) Page 3

Commandes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Suggestions D’utilisation. . . . . . . . . . . . . . . . . . 9

Avant D’utiliser La Friteuse . . . . . . . . . . . . . . . . 8

Nettoyage Périodique . . . . . . . . . . . . . . . . . . . 13

De La Rôtissoire . . . . . . . . . . . . . . . . . . . . . . . . . 12

Intérieur De La Rôtissoire Et Sous Les Grilles

Surfaces Des Grilles De La Rôtissoire. . . . . . 12

Rôtissoire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Nettoyage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Apprêtage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Plaques Supérieures De Gril . . . . . . . . . . . . . . . . . 12

Friteuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Nettoyage Des Finis Extérieurs . . . . . . . . . . . . . . 11

ENTRETIEN ET NETTOYAGE . . . . . . . . . . . . 11

Instructions D’utilisation . . . . . . . . . . . . . . . . . 11

Commandes . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Connexions Électriques . . . . . . . . . . . . . . . . . 11

Connexion D’alimentation . . . . . . . . . . . . . . . 10

Dégagements Par Rapport Aux Murs . . . . 10

EDU-15W Et ED-15WP . . . . . . . . . . . . . . . . . . . . . . . 10

Chau e-plats : Modèles:

Commandes . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Connexions Électriques . . . . . . . . . . . . . . . . . 10

Connexion D’alimentation . . . . . . . . . . . . . . . 10

Dégagements Par Rapport Aux Murs . . . . 10

Modèles : ED-15B, ED-30B Et ED-42B . . . . . . . . . 10

Rôtissoires –

Instructions D’étalonnage . . . . . . . . . . . . . . . 10

Commandes . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Connexions Électriques . . . . . . . . . . . . . . . . . . 9

Connexion D’alimentation . . . . . . . . . . . . . . . . 9

Dégagements Par Rapport Aux Murs . . . . . 9

ED-36-U1 Et ED-36G-U2 . . . . . . . . . . . . . . . . . . . . . . 9

ED-24G-U1, ED-36G-U,

ED-15G-U, ED-24-U,

Grils Rainurés – Modèles :

Grils – Modèles : ED-15G, ED-24G Et ED-36G;

Alimentation Électrique. . . . . . . . . . . . . . . . . . . 8

Connexion D’alimentation . . . . . . . . . . . . . . . . 8

Dégagements Par Rapport Aux Murs . . . . . 8

ED-15SF, ED-30FT Et ED-30SFT . . . . . . . . . . . . . . . . 8

Friteuses : Modèles ED-15F,

Utilisation De La Plaque Chau ante Scellée 8

Plaques Chau antes Scellées. . . . . . . . . . . . . . 8

Avant D’utiliser La Plaque Chau ante . . . . . 8

Commandes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Alimentation Électrique. . . . . . . . . . . . . . . . . . . 7

Connexion D’alimentation . . . . . . . . . . . . . . . . 7

Dégagements Par Rapport Aux Murs . . . . . 7

ED-15HSE / ED-15THSE . . . . . . . . . . . . . . . . . . . . . . .7

Plaque Chau ante À Éléments Pleins – Modèle

Commandes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Alimentation Électrique. . . . . . . . . . . . . . . . . . . 7

Connexion D’alimentation . . . . . . . . . . . . . . . . 7

Dégagements Par Rapport Aux Murs . . . . . 7

Modèle ED -15H . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Plaque Chau ante –

INDIVIDUELS . . . . . . . . . . . . . . . . . . . . . . . . . . 7

INSTALLATIONS DES MODÈLES

Installation Des Pieds . . . . . . . . . . . . . . . . . . . . . . . .6

De Comptoir (Option) . . . . . . . . . . . . . . . . . . . . . . . . 6

Installation Des Socles

Étanchéité Sanitaire Du Plan De Travail . . . . . . . . 6

Installation Des Plaques D’union . . . . . . . . . . . . . . 5

Réglementation Légale . . . . . . . . . . . . . . . . . . . . . . 5

Plaque Signalétique . . . . . . . . . . . . . . . . . . . . . . . . . 5

Déballage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

INSTALLATION GENERALE . . . . . . . . . . . . . . 5

DIMENSIONS ET SPÉCIFICATIONS . . . . . . . 4

INFORMATIONS IMPORTANTES . . . . . . . . . 2

TABLE DES MATIÈRES

Page 27

Pièce nº 4521653 (08/12/09)Page 2

AVERTISSEMENT

est reconnue par l’état de Californie comme causant le cancer.

verre/fibres céramiques. L’inhalation de ces particules de laine de verre ou de fibres céramiques

L’installation et l’entretien de ce produit peut vous exposer aux poussières de laine de

le cancer et/ou des malformations congénitales ou d’autres problèmes de reproduction.

Ce produit contient des produits chimiques reconnus par l’état de Californie comme causant

INFORMATIONS IMPORTANTES

Page 28

Pièce nº 4521653 (08/12/09) Page 1

Pièce n° 4521653 (08/12/09) © 2004 Garland Commercial Industries, LLC

Télécopieur : 905-624-5669

Téléphone : 905-624-0260

CANADA

1177 Kamato Road, Mississauga, Ontario L4W 1X4

GARLAND COMMERCIAL RANGES, LTD.

SIGNALÉTIQUE.

ÉLECTRIQUES FIGURANT SUR LA PLAQUE

EST CONFORME AUX CARACTÉRISTIQUES

VÉRIFIER QUE L’ALIMENTATION ÉLECTRIQUE

CODE ANSI / NFPA – ÉDITION EN VIGUEUR.

LOCAUX. AUX É.-U. – LE NATIONAL ELECTRICAL

DE L’ÉLECTRICITÉ, PARTIE 1 ET/OU LES CODES

VIGUEUR: AU CANADA – LE CODE CANADIEN

DEVRONT ÊTRE CONFORMES AUX CODES EN

L’INSTALLATION ET LES CONNEXIONS

Télécopieur : (570) 636-3903

Téléphone : (570) 636-1000

Freeland, Pennsylvanie 18224

185 East South Street

GARLAND COMMERCIAL INDUSTRIES, LLC

conception et les spéci cations des pièces) peuvent être remplacés ou modi és sans préavis.

de Garland à : http://www.garland-group.com. Les renseignements contenus dans le présent document (y compris la

ou par des agents d’entretien non autorisés. Pour obtenir la liste des agents de service autorisés, consulter le site web

numéro de série aurait été mutilé, oblitéré ou supprimé ou qui aurait été modi é ou réparé avec des pièces non autorisées

codes nationaux et locaux ou aux instructions d’installation fournies avec le produit ou n’importe quel produit dont le

en ce qui concerne n’importe quel produit mal installé, réglé, utilisé ou qui n’aurait pas été entretenu conformément aux

d’entretien autorisé par Garland utilisant des pièces de rechange d’origine Garland. Garland n’aura aucune obligation

L’attention des utilisateurs est attirée sur le fait que l’entretien et les réparations doivent être e ectués par un agent

L’ÉQUIPEMENT.

AVANT D’INSTALLER OU DE RÉPARER

D’UTILISATION ET D’ENTRETIEN

MENT LES INSTRUCTIONS D’INSTALLATION,

SURES OU LA MORT. LIRE SOIGNEUSE-

DES DOMMAGES MATÉRIELS, DES BLES-

ENTRETIEN MAL FAITS PEUVENT CAUSER

MODIFICATIONS, DES RÉPARATIONS OU UN

UNE INSTALLATION, DES RÉGLAGES, DES

AVERTISSEMENT

PROFESSIONNEL TEL QUE SPÉCIFIÉ.

ET DOIT ÊTRE INSTALLÉ PAR DU PERSONNEL

QU’ÉQUIPEMENT PROFESSIONNEL DE CUISSON

CE PRODUIT A ÉTÉ HOMOLOGUÉ EN TANT

ULTÉRIEUREMENT.

POUR VOTRE SÉCURIT:

MANUEL ET LE CONSERVER POUR S’Y REPORTER

LIRE TOUTES LES SECTIONS DU PRÉSENT

GARLAND SÉRIE ED

UNITÉS ÉLECTRIQUES DE PLAN DE TRAVAIL

APPAREIL OU DE TOUT AUTRE APPAREIL

INFLAMMABLES À PROXIMITÉ DE CET

OU D’AUTRES VAPEURS OU LIQUIDES

NE PAS STOCKER NI UTILISER D’ESSENCE

MANUEL D’UTILISATION ET D’INSTALLATION

Loading...

Loading...