Page 1

INSTALLATION AND

OPERATION MANUAL

GARLAND COUNTER TOP

HOT PLATES & GRIDDLES

MODELS: E24-12H, E24-24G,

E24-36G, E24-48G,

E24-60G & E24-72G

FOR YOUR SAFETY:

DO NOT STORE OR USE GASOLINE

OR OTHER FLAMMABLE VAPORS OR

LIQUIDS IN THE VICINITY OF

THIS OR ANY OTHER

APPLIANCE

PLEASE READ ALL SECTIONS OF THIS MANUAL

AND RETAIN FOR FUTURE REFERENCE.

THIS PRODUCT HAS BEEN CERTIFIED AS

COMMERCIAL COOKING EQUIPMENT AND

MUST BE INSTALLED BY PROFESSIONAL

PERSONNEL AS SPECIFIED.

WARNING:

IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE

CAN CAUSE PROPERTY DAMAGE, INJURY,

OR DEATH. READ THE INSTALLATION,

OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR

SERVICING THIS EQUIPMENT

INSTALLATION AND ELECTRICAL CONNECTION

MUST COMPLY WITH CURRENT CODES:

IN CANADA - THE CANADIAN ELECTRICAL

CODE PART 1 AND / OR LOCAL CODES.

IN USA – THE NATIONAL ELECTRICAL CODE

ANSI / NFPA – CURRENT EDITION.

ENSURE ELECTRICAL SUPPLY CONFORMS WITH

ELECTRICAL CHARACTERISTICS SHOWN ON

THE RATING PLATE.

Users are cautioned that maintenance and repairs must be performed by a Garland authorized service agent

using genuine Garland replacement parts. Garland will have no obligation with respect to any product that has been

improperly installed, adjusted, operated or not maintained in accordance with national and local codes or installation

instructions provided with the product, or any product that has its serial number defaced, obliterated or removed,

or which has been modified or repaired using unauthorized parts or by unauthorized service agents.

For a list of authorized service agents, please refer to the Garland web site at http://www.garland-group.com.

The information contained herein, (including design and parts specifications), may be superseded and is subject

to change without notice.

GARLAND COMMERCIAL INDUSTRIES

185 East South Street

Freeland, Pennsylvania 18224

Phone: (570) 636-1000

Fax: (570) 636-3903

GARLAND COMMERCIAL RANGES, LTD.

1177 Kamato Road, Mississauga, Ontario L4W 1X4

CANADA

Phone: 905-624-0260

Fax: 905-624-5669

Enodis UK LTD.

Swallow eld Way, Hayes, Middlesex UB3 1DQ ENGLAND

Telephone: 081-561-0433

Fax: 081-848-0041

Part # 1009080 Rev 5 (01/25/08) © 2004 Garland Commercial Industries, Inc.

Part # 1009080 Rev 5 (01/25/08) Page 1

Page 2

IMPORTANT INFORMATION

WARNING:

This product contains chemicals known to the state of california to cause cancer and/or birth defects

or other reproductive harm. Installation and servicing of this product could expose you to airborne

particles of glass wool/ceramic fibers. Inhalation of airborne particles of glass wool/ceramic fibers

is known to the state of California to cause cancer.

Part # 1009080 Rev 4 (01/25/08)Page 2

Page 3

TABLE OF CONTENTS

IMPORTANT INFORMATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

DIMENSIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

ELECTRICAL SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Rating Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Leg Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

E24-12H Hot Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

E24 Series Griddles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

INITIAL OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Griddle Seasoning Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

OPERATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Open Type Burners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

E24 Series Griddles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Calibration of the Griddle Thermostat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

MAINTENANCE AND CLEANING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Exterior Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Cleaning Of Top Surface Heating Elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Griddle Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Part # 1009080 Rev 5 (01/25/08) Page 3

Page 4

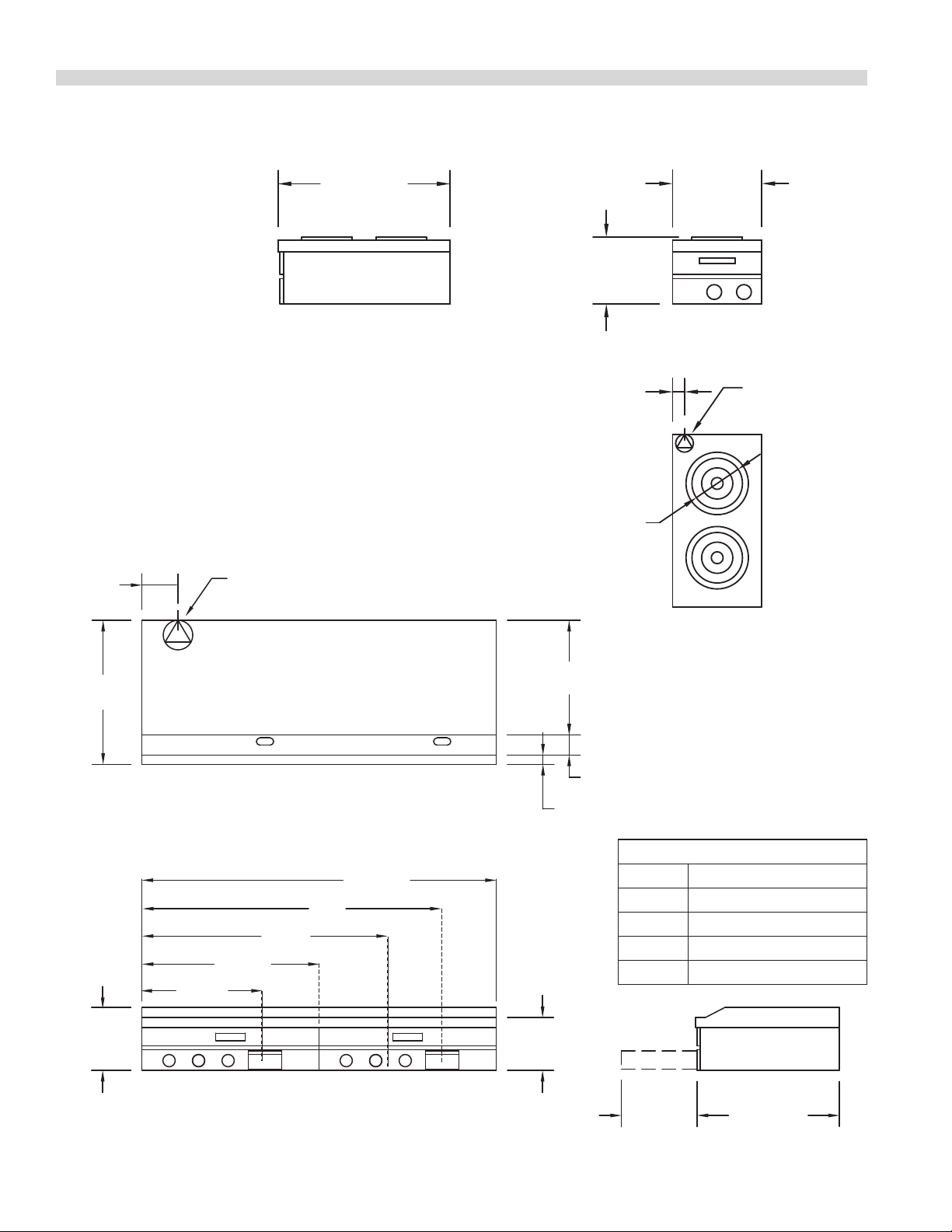

DIMENSIONS

29-1/4"

[743mm]

23-1/4"

[591mm]

4-1/8"

[105mm]

1-7/8"

[48mm]

7"

[178mm]

12-13/16"

[325mm]

72"

[1829mm]

28-29/32"

[734mm]

15-3/8"

[391mm]

10-3/4"

[273mm]

REAR CABLE

ENTRANCE

24"

[610mm]

36"

[914mm]

48"

[1219mm]

60"

[1524mm]

15"

[381mm]

29"

[737mm]

11-1/4"

[286mm]

2"

[51mm]

8-1/2"

[Ø216mm]

TYP

REAR CABLE

ENTRANCE

E24-12H

E24-24G, E24-36G, E24-48G E2460G and E24-72G

GRIDDLE SUFFIX DEFINITIONS

-24G 24 “ (610mm) Griddle

-36G 36” (914mm) Griddle

-48G 48” (1219 mm) Griddle

-60G 60” (1524 mm) Griddle

-72G 72” (1829 mm) Griddle

Add 4” (102mm) to height if sanitary legs are used

Part # 1009080 Rev 4 (01/25/08)Page 4

Page 5

ELECTRICAL SPECIFICATIONS

E24 Grill Loading Chart – Delta (Domestic Wiring)

Model Voltage Total KW

208 8 0.0 4.0 4.0 19.2 19.2 33.3 38.5

E24-24G

E24-36G

E24-48G

E24-60G

E24-72G

240 8 0.0 4.0 4.0 16.7 16.7 28.9 33.3

480 8 0.0 4.0 4.0 8.3 8.3 14.4 16.7

208 12 4.0 4.0 4.0 33.3 33.3 33.3 57.7

240 12 4.0 4.0 4.0 28.9 28.9 28.9 50.0

480 12 4.0 4.0 4.0 14.4 14.4 14.4 25.0

208 16 4.0 4.0 8.0 50.9 33.3 50.9 76.9

240 16 4.0 4.0 8.0 44.1 28.9 44.1 66.7

480 16 4.0 4.0 8.0 22.0 14.4 22.0 33.3

208 20 4.0 8.0 8.0 50.9 50.9 66.6 96.2

240 20 4.0 8.0 8.0 44.1 44.1 57.7 83.3

480 20 4.0 8.0 8.0 22.0 22.0 28.9 41.7

208 24 8.0 8.0 8.0 66.6 66.6 66.6 115.4

240 24 8.0 8.0 8.0 57.7 57.7 57.7 100.0

480 24 8.0 8.0 8.0 28.9 28.9 28.9 50.0

Total kW Load Amps Per Phase

kW X-Y kW Y-Z KW X-Z AX AY AZ

Single

Phase

Model Voltage Total KW

E24-24G

E24-36G

E24-48G

E24-60G

E24-72G

415V 2N~

(240/415V)

380V 2N~

(220/380V)

415V 2N~

(240/415V)

380V 2N~

(220/380V)

415V 2N~

(240/415V

380V 2N~

(220/380V)

415V 2N~

(240/415V)

380V 2N~

(220/380V)

415V 2N~

(240/415V)

380V 2N~

(220/380V)

8.0 4.0 4.0 0.0 16.7 16.7 0.0 33.3 240

6.7 3.4 3.4 0.0 15.3 15.3 0.0 30.5 220

12.0 4.0 4.0 4.0 16.7 16.7 16.7 50.0 240

10.1 3.4 3.4 3.4 15.3 15.3 15.3 45.8 220

16.0 4.0 8.0 4.0 16.7 33.3 16.7 66.7 240

13.4 3.4 6.7 3.4 15.3 30.5 15.3 61.1 220

20.0 8.0 8.0 4.0 33.3 33.3 16.7 83.3 240

16.8 6.7 6.7 3.4 30.5 30.5 15.3 76.4 220

24.0 8.0 8.0 8.0 33.3 33.3 33.3 100.0 240

20.2 6.7 6.7 6.7 30.5 30.5 30.5 91.6 220

E24 Grill Loading Chart – Export (wye)

Total kW Load Amps Per Phase

kW L1 kW L2 KW L3 AL1 AL2 AL3

A

1 Phase

Single Phase

Voltage

Part # 1009080 Rev 5 (01/25/08) Page 5

Page 6

ELECTRICAL SPECIFICATIONS Continued

LOADING CHART E24-H Hot Plate

Nominal Amperes Per Line

Model

E24-12H 4.2 15.2 8.8 8.8 17.5 10.1 10.1 17.5 20.2

Export voltage available on request – Specify wiring required

kW loadings are reduced on 220 volt systems.

Standard wiring 240 volt (220/240) or 208 volt (197/219) single or three phase

Total Kw

Load

240V 208V

X Y Z X Y Z

3 Phase Single Phase

INTRODUCTION

240V 208V

Your new equipment should be given regular care and

maintenance. Periodic inspections by your dealer or a

qualied service agency are recommended.

This product has been certied as commercial cooking

equipment and must be installed by professional personnel

as specied.

Rating Plate

When corresponding with the factory or your local

authorized factory service center regarding service problems

or replacement parts, be sure to refer to the particular unit

by the correct model number (including the prex and sux

letters and numbers) and the warranty serial number. The

rating plate axed to the unit contains this information. The

rating plate is located on the main back panel behind the

unit, on hot plates. For griddles the plate is located on the

grease drawer slide, remove the grease drawer to access.

Before attempting the electrical connection, the rating

pate should be checked to ensure that the unit’s electrical

characteristics and the supply characteristics agree.

Part # 1009080 Rev 4 (01/25/08)Page 6

Page 7

INSTALLATION

Unpacking

Unpack units carefully and provide the necessary space on

counter of back bar. All units must be installed following the

minimum back and side clearances stated on the tag axed

to each individual unit. To insure proper eld wiring size

check tag attached to the rear of the unit near knockout.

Leg Installation

1. All units are shipped with N.S.F. approved legs. These

legs must be installed to provide a minimum clearance

of 4” (102mm) between he counter top and bottom of

the appliance in order to meet the National Sanitation

Foundation requirements.

2. When using the legs described above, raise the front of

the appliance and screw the leg into the leg-retaining nut

provided at each corner of the appliance, repeat at each

rear.

3. The unit may be leveled by adjusting the legs. Use a spirit

level and level the appliance four (4) ways: across the

front and back; and down left and right edges.

NOTE: Griddles may not rest evenly on the appliance body if

the appliances are not leveled.

Electrical Connections

Before attempting the electrical connection, the rating

plate should be checked to ensure that the unit’s electrical

characteristics and the supply characteristics agree.

Installation of the wiring must be made in accordance with

UL 197 Commercial Electric Cooking Appliance Standards,

Local and/or National Electrical Code, and ANSI/NFPA 701990 and include.

1. Switch panel size

2. Overload protection

3. Wire type

4. Wire size

5. Temperature limitations of the wires

6. Method of connection (Cable, Conduit, etc.)

The service line enters though the rear of the unit and is

to be connected to the terminal block. Input voltage and

phasing must match the unit’s voltage and phasing.

Visually check all electrical connections.

Energize the electrical connections.

NOTE: Appliances are not internally fused. They must be

connected to a suitable disconnect box in accordance with

local code.

E24-12H Hot Plate

Electrical connection to the terminal may be made though

the knockout on the main back. Front access is gained by

raising the rear surface element and removing bowl. The

terminal block shield is located toward the back lower left of

the unit.

E24 Series Griddles

The electrical connections may be made though the

knockout at the rear of the unit to the terminal block located

behind the terminal block shield.

Front access is gained by raising and propping the griddle

plate. The terminal block shield is toward the back and left

of the appliance. Remove the shield to expose the terminal

block. Make the necessary connection and replace the shield.

These appliances have no fusing.

Part # 1009080 Rev 5 (01/25/08) Page 7

Page 8

INITIAL OPERATION

Before use allow the griddle plate to reach room

temperature. Clean the griddle surface thoroughly by

washing with hot water and mild soap to remove rust

preventative. Rinse and dry well.

Griddle Seasoning Instructions

1 Remove all factory applied protective material by

washing with hot water, mild detergent or soap solution.

2. Apply a thin coat of cooking oil to the griddle surface,

about one ounce per square foot of griddle surface.

Spread over the entire griddle surface with a cloth to

create a thin lm. Wipe o any excess oil with a cloth.

OPERATION

3. Turn on all thermostats, some discoloration will occur

when heat is applied to the steel.

4. Heat the griddle slowly for 15 to 20 minutes, then wipe

away the oil. Repeat the procedure 2 to 3 times until the

griddle has a slick, mirror like nish. Do this until you have

reached the desired cooking temperature.

IMPORTANT: Do not attain 450° F (232° C) (on the thermostat

control) during the “break-in” period. The griddle will not

require re-seasoning if it is used properly, if the griddle is

over heated and product begins to stick to the surface it may

be necessary to repeat the seasoning process again. If the

griddle is cleaned with soap and water it will be necessary to

re-season the griddle surface again.

Open Type Burners

It should be pointed out that the open burners are not

designed or intended heavy-duty service. Use of large

stockpots will severely damage the surface elements and

is not normally covered under the warranty policy! It is

recommended that cooking utensils no larger than 10” (254

mm) in diameter and with a capacity no larger than 1 gallon

(3.79 liters) be used on the surface elements.

Innite switches are used to control the front and rear

heating elements. Numbers on switch knobs provide the

following:

HI – 5 High Heat

5 – 3 Medium Heat

3 – LO Low Heat

Setting the switches between these numbers will give

intermediate heats. Switches are reversible and may be

turned right or left.

Surface heating units should not be left on high heat if not

covered by a cooking utensil. Turn the switch to number 4

position or lower when units are idling. Failure to do this will

shorten the life of the surface heating elements.

Two (2) pilot indicator lamps are provided, one for each

heating unit and these will illuminate when heat is being

produced by the elements.

E24 Series Griddles

All E24 series griddles are thermostatically controlled

from 125° to 450°F (52° to 232° C). To operate, turn the

thermostats to desired temperature. Indicator lamps will

come “ON” and as the griddle areas reach the desired

temperature the indicator lamp will go “OFF”. As the

thermostats call for more heat, the indicator lamps will

come “ON” and will continue to cycle “OFF” and “ON” as the

thermostat operates.

Do not waste electricity or abuse equipment by leaving

thermostat at high temperature settings if not required.

Throughout all idling periods, set the thermostat to low

temperature settings to keep the griddle warm. Re-set

thermostat as required for periods of heavy use. Turn the

thermostat to “OFF” at end of daily operation.

Part # 1009080 Rev 4 (01/25/08)Page 8

Page 9

OPERATION Continued

Dial Shaft

Calibration Screw Head

Calibration

Screw Head

Increase

Decrease

1/4" Turn

Calibration of the Griddle Thermostat

Equipped with commercial duty snap action electric

thermostats, these units are designed to open on

temperature rise. Field re-calibration is seldom necessary and

should not be resorted to unless experience with cooking

results denitely proves that the control is not maintaining

the temperature to which the dial is set.

NOTE: NO ATTEMPT TO RECALIBRATE THE GRIDDLE CONTROL

SHOULD BE MADE WITHIN THE WARRANTY PERIOD. IF

THE CONTROL IS OUT ± 20° F FROM THE DIAL SETTING,

THE CONTROL WILL BE REPLACES UNDER WARRANTY.

IF SOMEONE ATTEMPTS RECALIBRATION DURING THE

WARRANTY PERIOD THERE WILL BE NO WARRANTY ON THE

CONTROL THAT WAS TAMPERED WITH.

Calibration Instructions

1. Use a test instrument (surface pyrometer) with a special

disc type thermocouple or reliable “surface” type

thermometer. Note: A drop of oil on the face of the disc

will provide better contact with the griddle plate.

2. Turn all griddle thermostats to 350° F (177° C). In order

to allow the griddle temperature to stabilize the controls

must be allowed to cycle three times before taking a test

reading.

4. Carefully remove the thermostat dial, not disturbing the

dial setting.

5. Hold the dial shaft steady and with a screwdriver turn the

calibration screw, (that is located inside the thermostat

shaft), clockwise to decrease and counter-clockwise to

increase the temperature. A 1/4 turn = 25°F change

6. Replace the thermostat dial and repeat steps 1 through 3

to verify if the correct adjustment has been made.

3. Check the temperature reading when the thermostat

If the average is more than the 20° tolerance, recalibrate

cycles o by placing the sensor rmly on the center

of each section of the griddle surface. Take a second

temperature reading when they thermostat cycles back

on. Make a note of this reading. The average of the two

readings should be ± 20° of 350° set temperature.

as follows.

Part # 1009080 Rev 5 (01/25/08) Page 9

Page 10

MAINTENANCE AND CLEANING

NOTE: Disconnect line cord from the power supply or turn

the power o at the circuit breaker before cleaning of

servicing for your protection against electric shock.

Exterior Cleaning

Establish a regular cleaning schedule. Any spills should be

wiped o immediately.

1. Wipe exposed, cleanable surface when cool with a mild

detergent and hot water. Stubborn residue spots may be

removed with a lightweight non-metallic scouring pad.

Dry thoroughly with a clean cloth.

2. Stainless steel should be cleaned using a mild detergent,

a soft scouring pad and hot water. If it necessary to use a

non-metallic scouring pad, always rub in the direction of

the grain in the metal to prevent scratching. Use a water

based stainless steel cleaner (Dracket Twinkle), if you

want a high shine. Never use steel wool on Stainless steel.

3. The control panel surface is easily cleaned with hot water,

soap and a soft cloth. Do not use hard abrasives, solvent

type materials or metallic scouring pads since these will

scratch or cloud the surface.

4 Never spay the perforated areas or control panel with

steam or water, this will allow moisture into the control

cavity which could damage electrical components.

Cleaning Of Top Surface Heating Elements

Surface elements may be raised to permit removal of the

spillover burner bowl located under the surface elements.

Spillover burner bowls may be cleaned, wiped dry and

replaced. The Cooking top may be wiped with a damp cloth

using a mild detergent and warm water. Rinse with clear,

warm water and dry thoroughly.

Griddle Cleaning.

To produce evenly cooked, perfectly browned griddle

products, keep the griddle free from carbonized grease.

Carbonized grease on the surface hinders the transfer of

heat from the griddle surface to the food product. This

results in uneven browning and loss of cooking eciency

and worst of all, carbonized grease tends to cling to griddle

foods, giving them a highly unsatisfactory and unappetizing

appearance. To keep the griddle clean and operating at peak

performance, follow these simple instructions.

1. After each use clean the griddle thoroughly with a grill

scraper or spatula. Wipe o any excess debris left from

the cooking process.

2. Once a day clean the griddle surface with a grill brick

and grill pad. Remove the grease container and clean

thoroughly, in the same manner as any ordinary cooking

utensil.

3. Once a week clean the griddle surface thoroughly. If

necessary, use a grill stone or grill pad over the griddle

surface. Rub with the grain of the metal while still warm.

A detergent may be used on the plate surface to help

clean it, but care must be taken to be sure it is thoroughly

removed. After removal of the detergent, the surface

of the plate should be covered with a thin lm of oil to

prevent rusting. To remove discoloration, use a nonabrasive cleaner. Before re-using the griddle must be

re-seasoned. Keep the griddle drain tube to the grease

container clear at all times.

Empty grease trough below the griddle frequently. The front

grease trough should be washed using a hot, mild detergent

or soap solution. Rinse with clear, warm water and dry

thoroughly.

CAUTION: This griddle plate is steel, but the surface is

relatively soft and can be scored or dented by careless use of

a spatula. Be careful not to dent, scratch, or gorge the plate

surface. This will cause food to stick in those areas. Also, note,

since this is a steel griddle if a light coat of oil is not always

present, rust will develop on exposed area.

Part # 1009080 Rev 4 (01/25/08)Page 10

Page 11

Part # 1009080 Rev 5 (01/25/08) Page 11

Page 12

Loading...

Loading...