Page 1

INSTALLATION AND

OPERATION MANUAL

CUISINE

INFRA-RED BROILER

FOR YOUR SAFETY:

DO NOT STORE OR USE GASOLINE

OR OTHER FLAMMABLE VAPORS OR

LIQUIDS IN THE VICINITY OF

THIS OR ANY OTHER

APPLIANCE

WARNING:

IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE

CAN CAUSE PROPERTY DAMAGE, INJURY,

OR DEATH. READ THE INSTALLATION,

OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR

SERVICING THIS EQUIPMENT

AND RETAIN FOR FUTURE REFERENCE.

THIS PRODUCT HAS BEEN CERTIFIED AS

COMMERCIAL COOKING EQUIPMENT AND

MUST BE INSTALLED BY PROFESSIONAL

PERSONNEL AS SPECIFIED.

IN THE COMMONWEALTH OF MASSACHUSETTS

THIS PRODUCT MUST BE INSTALLED BY A

LICENSED PLUMBER OR GAS FITTER. APPROVAL

NUMBER: G-1-07-05-28

For Your Safety:

Post in a prominent location, instructions to be

followed in the event the user smells gas. This

information shall be obtained by consulting

your local gas supplier.

Users are cautioned that maintenance and repairs must be performed by a Garland authorized service agent

using genuine Garland replacement parts. Garland will have no obligation with respect to any product that has been

improperly installed, adjusted, operated or not maintained in accordance with national and local codes or installation

instructions provided with the product, or any product that has its serial number defaced, obliterated or removed,

or which has been modified or repaired using unauthorized parts or by unauthorized service agents.

For a list of authorized service agents, please refer to the Garland web site at http://www.garland-group.com.

The information contained herein, (including design and parts specifications), may be superseded and is subject

to change without notice.

PLEASE READ ALL SECTIONS OF THIS MANUAL

GARLAND COMMERCIAL INDUSTRIES

185 East South Street

Freeland, Pennsylvania 18224

Phone: (570) 636-1000

Fax: (570) 636-3903

Part # 4517385 (02/20/08) © 2006 Garland Commercial Industries, Inc.

Part # 4517385 (02/20/08) Page 1

GARLAND COMMERCIAL RANGES, LTD.

1177 Kamato Road, Mississauga, Ontario L4W 1X4

CANADA

Phone: 905-624-0260

Fax: 905-624-5669

Enodis UK LTD.

Swallow eld Way, Hayes, Middlesex UB3 1DQ ENGLAND

Telephone: 081-561-0433

Fax: 081-848-0041

Page 2

IMPORTANT INFORMATION

WARNING:

This product contains chemicals known to the state of California to cause cancer and/or birth defects

or other reproductive harm. Installation and servicing of this product could expose you to airborne

particles of glass wool/ceramic fibers. Inhalation of airborne particles of glass wool/ceramic fibers

is known to the state of California to cause cancer. Operation of this product could expose you to

carbon monoxide if not adjusted properly. Inhalation of carbon monoxide is known to the state of

California to cause birth defects or other reproductive harm.

Keep appliance area free and clear of combustibles.

Part # 4517385 (02/20/08)Page 2

Page 3

Part # 4517385 (02/20/08) Page 3

TABLE OF CONTENTS

IMPORTANT INFORMATION..........................................2

TECHNICAL SPECIFICATIONS.........................................4

INTRODUCTION.....................................................5

General Information .............................................................5

Statutory Regulations............................................................5

INSTALLATION......................................................5

Siting............................................................................5

Clearances.......................................................................5

Installation Notes................................................................5

Appliances Equipped With Casters................................................6

Appliances Equipped With Legs ..................................................6

Ventilation Air ...................................................................6

Gas Connection..................................................................6

Electrical Connection ............................................................7

Testing & Adjustment............................................................7

OPERATION.........................................................7

Infra-Red Burners................................................................7

Initial Operation: Infra-Red Burners...............................................7

Operation: Infra-Red Burners.....................................................7

PRODUCT APPLICATION INFORMATION..............................8

Broiler...........................................................................8

Shut-Down......................................................................8

CARE & CLEANING ..................................................9

Stainless Steel ...................................................................9

Broiler Section...................................................................9

Instructions For Removal Of Grid Rack & Grid Rack Frame.........................10

Page 4

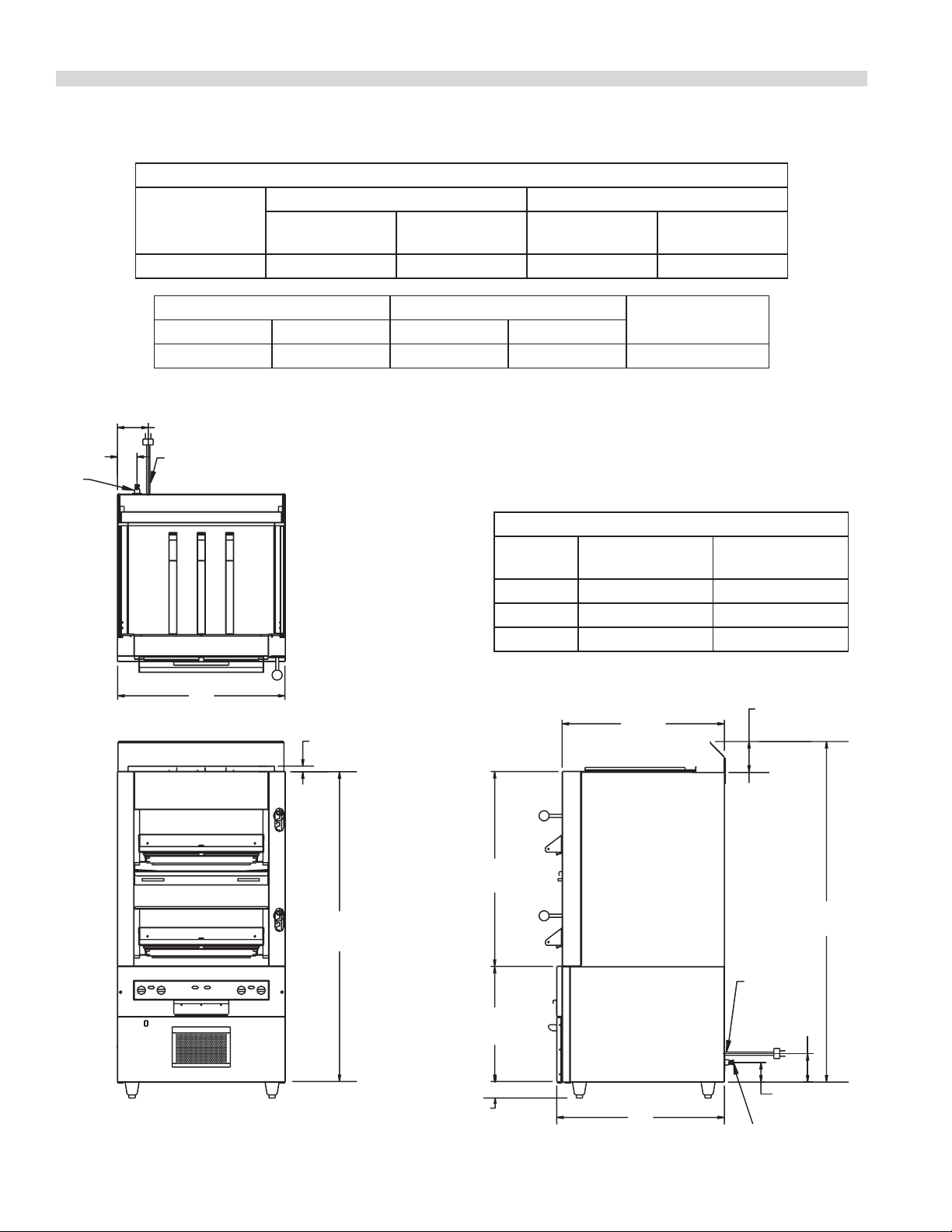

TECHNICAL SPECIFICATIONS

INDIVIDUAL BURNER INPUT RATINGS

Natural Gas Propane

Burner

Infra-Red 70,000 # 50 70,000 # 56

Input BTU/HR

Per Section

Orice

Size DMS

Input BTU/Hr

Per Section

Orice

Size DMS

4"

102mm]

AS

LET

MINIMUM SUPPLY PRESSURE MANIFOLD PRESSURE

Natural Gas Propane Natural Gas Propane

ELECTRICAL

SUPPLY*

7” WC 11” WC 6” WC 10” WC 120V 60Hz, 1Amp

*Note: Electrical diagram is on the rear of the appliance next to the supply wire.

6-1/4"

[159mm]

ELECTRICAL PLUG

MODEL DESIGNATIONS

Model Number Broiler Burner

C2100MX Infra-Red

CLEARANCES

Location

Combustible

Construction

Rear 6” (152mm) 0”

Left Side 6” (152mm) 0”

Right Side 6” (152mm) 0”

34"

[864mm]

TOLERANCE ± 1/8" [3mm]

1-1/8"

[29mm]

32-3/4"

[832mm]

Noncombustible

Construction

6-1/4"

[159mm]

62-7/8"

[1597mm]

39-1/2"

[1003mm]

23-3/8"

[594]

6"

[152mm]

34"

[864mm]

Part # 4517385 (02/20/08)Page 4

FLUE

DIVERTER

[CUSTOMER

INSTALLED]

ELECTRICAL

PLUG

5-3/4"

[146mm]

4"

[102mm]

GAS INLET

69-1/8"

[1756mm]

Page 5

Part # 4517385 (02/20/08) Page 5

INTRODUCTION

General Information

1. Check crate for possible damage sustained during transit.

Carefully remove unit from crate and again check for

damage. Any damage to the appliance must be reported

to the carrier immediately.

2. The wires for retaining the burners and other packing

material must be removed from units. Any protective

material covering stainless steel parts must also be

removed.

3. All equipment is shipped from the factory with legs

tted, unless otherwise specied. Where the range is to

be mounted on a dais or cove base, it is shipped without

legs. Legs must be tted to the oven where it is installed

on a combustible oor.

4. The type of gas and supply pressure that the equipment

was set-up for at the factory is noted on the data plate

and on the packaging. This type of gas supply must be

used.

5. Do not remove permanently axed labels, warnings or

data plates from the appliance, for this may invalidate the

manufacturer’s warranty.

Statutory Regulations

The installation of this appliance must be carried out by

a competent person and in accordance with the relevant

regulations, codes of practice and the related publications of

the country and destination.

The installation must conform to the National Fuel Gas Code

ANSI Z223.1-1998 or latest edition, NFPA No. 54 – latest

edition and National Electrical Code ANSI/NFPA 70-1990 or

latest edition and/or local code to assure safe and ecient

operation. In Canada, the installation must comply with CSA

B149.1 and local codes where applicable.

In Canada, electrical connections must comply with

applicable sections of the Canadian Electrical Code, C22.1

- 1990, latest edition, “Safety Standard for Installation,

Part 1” and C22.2- No. O-M 1982 latest edition, “General

Requirements, Part 2”.

INSTALLATION

This appliance is not recommended for residential

installation.

Siting

The oor on which the appliance is to be sited must be

capable of adequately supporting the weight of the

appliance and any ancillary equipment.

Units with ovens must be tted with legs if installed on a

combustible oor.

Clearances

Adequate clearance must be provided for servicing and

proper operation.

Location

Rear 6” (152mm) 0”

Left Side 6” (152mm) 0”

Right Side 6” (152mm) 0”

Combustible

Construction

Noncombustible

Construction

Installation Notes

Before assembly and connection check gas supply.

A. The type of gas for which the unit is equipped is stamped

on the data plate located behind the lower front panel.

Connect a unit stamped “NAT” only to natural gas;

connect one stamped “PRO” only to propane gas.

Page 6

INSTALLATION continued

B. If it is a new installation have the gas authorities check

the meter size and piping to assure that the unit is

supplied with the necessary amount of gas pressure

required for operation.

C. If it is additional or replacement equipment have the

gas authorities check the pressure to make certain that

existing meter and piping will supply fuel to the unit with

not more than 1/2” water column pressure drop.

NOTE: When checking gas pressure, be sure that all other

equipment on the same gas line is on.

The appliance and its individual shut-o valve must be

disconnected from the gas supply piping system during any

pressure testing of that system with pressures in excess of

1/2 PSIG (3.45kPa).

Appliances Equipped With Casters

1. The installation shall be made with a connector that

complies with the Standard for Connectors for Moveable

Gas Appliances, ANSI Z21.69/CSA 6.16, Addenda Z21.69B2006/CSA 6.16B-2006 (or latest edition), and a quickdisconnect device that complies with the Standard for

Quick Disconnects for Use with Gas Fuel, ANSI Z21.41/

CSA 6.9, Addenda Z21.41A-2005/CSA 6.16A-2005 (or

latest edition).

2. The front casters on the appliance are equipped with

brakes to limit the movement of the appliance without

placing any strain on the connector or quick-disconnect

device or its associated piping.

3. Please be aware that the required restraint is attached to

a bracket (which is located on the rear caster closest to

the gas connection) and if disconnection of the restraint

is necessary, be sure to reconnect the device after the

appliance has been returned to its original position.

Appliances Equipped With Legs

Ventilation Air

The following notes are intended to give general guidance.

For detailed recommendations, refer to the applicable

code(s) in the country of destination.

Proper ventilation is highly essential for optimum

performance. The ideal method of ventilating open-top

equipment is the use of a properly designed canopy which

should extend six inches (152mm), beyond all sides of the

appliance(s) and six feet, six inches (1981mm) above the

oor.

A strong exhaust will create a vacuum in the room. For an

exhaust vent to work properly, replacement air must enter

the room. The amount of air that enters must be equal to the

amount exhausted.

All gas burners and pilots need sucient air to operate. Large

objects should not be placed in front of the appliance(s) that

would obstruct the ow of air into the front.

Gas Connection

The local gas authority should be consulted at the

installation planning stage in order to establish the

availability of an adequate supply of gas and to ensure

that the meter is adequate for the required ow rate. The

pipe work from the meter to the appliances must be of an

appropriate size.

All xed (non-mobile) appliances MUST be tted with a

manual gas-cock upstream of the appliance to provide a

means of isolation for servicing or cleaning purposes. A

union or similar means of disconnection must be provided

between the gas-cock and the appliance.

A manually operable valve must be tted to the gas supply

to the kitchen to enable it to be isolated in an emergency.

Wherever practical, this shall be located either outside the

kitchen or near to an exit in a readily accessible position.

1. Raise the front of the appliance an block. Do not lay the

appliance on its back.

2. Position leg insert in leg retainer opening and tap upward

until the insert seats at the collar ange.

3. Repeat leg insert installation for the other legs and adjust

all four legs to the same height.

4. Legs can be further adjusted to level the appliance and to

compensate for uneven ooring.

Where it is not practical to do this, an automatic isolation

valve system shall be tted which can be operated from a

readily accessible position near to the exit.

At locations where the manual isolation valve is tted or

the automatic system can be reset, a notice MUST be tted

stating:

“ALL DOWNSTREAM BURNER AND PILOT VALVES MUST

BE TURNED OFF PRIOR TO ATTEMPTING TO RESTORE THE

SUPPLY. AFTER EXTENDED SHUT OFF, PURGE BEFORE

RESTORING GAS SUPPLY.”

Part # 4517385 (02/20/08)Page 6

Page 7

Part # 4517385 (02/20/08) Page 7

INSTALLATION continued

Electrical Connection

IMPORTANT – This appliance must be electrically grounded

in accordance with local codes.

Testing & Adjustment

All ttings and pipe connections must be tested for

leaks. Use approved gas leak detectors, soap solution or

equivalent, checking over and around all the ttings and

pipe connections. DO NOT USE A FLAME! Accessibility to

all gas lines and ttings require that valve panel(s), lower

front panel(s), and/or oven rack(s) be removed. All parts

removed, (including fasteners), should be stored safely for

re-installation.

1. Be sure that all valves are in the “OFF” position.

2. Turn on the main gas supply valve. Light all broiler pilots.

OPERATION

3. Leak test all valves and ttings as described at the

beginning of this section. Correct any leaks as required

and recheck.

4. Light the oven pilot.

All units are tested and adjusted at the factory, however,

burners and pilots should be checked upon installation and

adjusted if necessary.

CAUTION: Gas will ow to the top section burners even

if the broiler section pilots are not lit. Gas will not be

interrupted. It is the responsibility of the operator to

conrm the proper ignition of each burner as it is turned

on. Should ignition fail to occur 5 seconds after turning

a burner on, turn the burner o, wait 5 minutes, and try

again.

Infra-Red Burners

The GARLAND® Infra-Red Broiler is a direct radiant heavy

duty gas broiler utilizing four (4) extremely ecient gas

burners in each broiling section. The infra-red burners

provide for high speed broiling with rapid searing of product

so that natural juices and avor will be sealed in.

These special burners operate in a manner similar to that

of a conventional gas burner except that the radiation

surfaces consist of a series of ceramic blocks each containing

numerous small gas ports. These ceramic blocks are

connected utilizing a special compound that also seals all

seams of the radiating surface. The gas ame appears as a

red glow covering the entire ceramic surface.

A special wire mesh has been provided as an outside

surface beneath the ceramics to further increase the burner

eciency. This mesh will provide for additional infra-red

energy.

Initial Operation: Infra-Red Burners

1. Connect electrical supply.

2. Open gas service valve located in your supply line.

3. With a lighted taper, light the broiler pilots located at the

front of the unit. There is one pilot per pair of burners.

4. Pilot adjustment valves can be found on the manifold,

behind the control panel. The valves may be accessed

through holes in the control panel.

5. The pilots should be adjusted so that ame extends 1/2”

to 3/4” (12mm to 25mm) beyond the pilot shield.

Operation: Infra-Red Burners

1. Switch on (1) the main power switch.

2. Turn the broiler valve to HIGH.

Page 8

OPERATION continued

3. Immediately check ignition of the burners.

4. When ignition has been accomplished a blue ame will

cover the surface of the ceramics for 10-15 seconds.

5. The haze will disappear and the ceramics will glow red.

CAUTION: Should burner ignition fail within

Shut-Down

1. Turn all valves to the “OFF” position.

2. Switch o (0) the main power switch.

3. If the unit is to be shut down for an extended period of

time, close the in-line gas valve.

seconds, turn the burner valve o and repeat steps

through . If ignition continues to fail, consult your

factory authorized service agency.

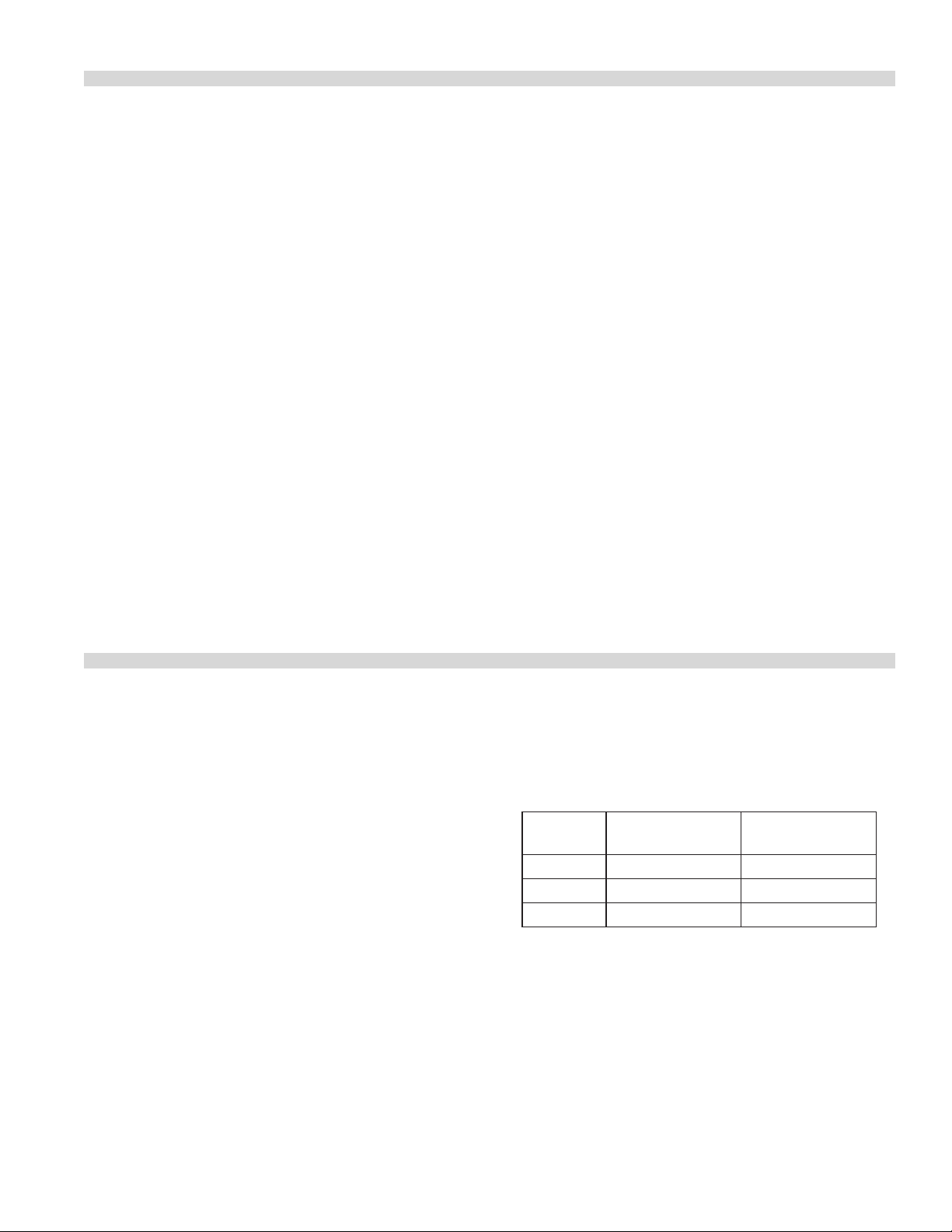

PRODUCT APPLICATION INFORMATION

Broiler

The following information is intended for use as a guide.

There are many variables that will eect the operation. As an

example, the temperature of the product when it is placed

on the rack for broiling will eect both the broiling time and

the quality of the nished product.

The broiler rack can be easily raised or lowered to provide for

the desired distance of the product from the heat source and

is readily pulled out for ease of loading and unloading.

It is suggested that all products be dipped in salt-free

oil before broiling to facilitate browning and to aid in

preventing the product from sticking to the broiler rack.

It must again be stressed that the times in the following table

are intended as a general guide only. The technique of the

operator and experience with infra-red broiling will eect

time, burner setting and rack position.

Part # 4517385 (02/20/08)Page 8

Page 9

Part # 4517385 (02/20/08) Page 9

PRODUCT APPLICATION INFORMATION continued

SUGGESTED BROILING TIME (EACH SIDE) IN MINUTES

Type of Product

Beef

Filet Mignon, Porterhouse 1/(25) 2-1/2 4 5-1/2

T-Bone, Club, Rib 1-1/2/(38) 2-1/2 4 5-1/2

Sirloin 2 (51) 3-1/2 5-1/2 6-1/2

Strip Sirloine 3/4 (19) 2-1/2 3-1/2 5

Ground Steak 1/2 (13) 1-1/2 2 2-1/2

Lamb

Loin, Rib Chops 1/(25) 3/1/2 4-1/2 —

Double Rib 2/(51) 4 6 —

Fish (Low burner setting, low rack position)

*Fish — — — 5

Fish Steak 1/2/(13) — — 4

Fish Steak 1/(25) — — 4-1/2

* It is recommended that thin let-ounder, sole, uke, etc., - be folded over before

cooking to increase its thickness.

Thickness

In/ (mm)

Rare

Minutes

Medium

Minutes

Well Done

Minutes

CARE & CLEANING

Disconnect the power supply to the appliance before

cleaning or servicing.

Stainless Steel

For routine cleaning just wash with hot water and detergent

solution. Wash just a small area at a time or the water will

evaporate leaving the chemicals behind causing streaking.

Rinse the washed area with a clean sponge dipped in a

sanitizing solution and wipe dry with soft clean cloth before

it can dry.

Use a paste (of water and a mild scouring powder) if you

have to, but never rub against the grain. All stainless steel has

been polished in one direction. Rub with the polish lines to

preserve the original nish. Then thoroughly rinse as before.

To prevent ngerprints there are several stainless steel

polishes on the market the leave and oily waxy lm. Do not

use on surfaces that will be in contact with food.

Stainless steel may discolor if overheated. These stains can

usually be removed by vigorous rubbing with a scouring

powder paste.

Use only stainless steel, wood or plastic tools if necessary

to scrape o heavy deposits of grease and oil. Do not use

ordinary steel scrapers or knives, as particles of the iron may

become imbedded and rust. STEEL WOOL SHOULD NEVER BE

USED.

Broiler Section

The M110XM lter should be removed and cleaned every

one to two days, depending on usage. The lter can be

cleaned by hand with dish detergent or run though the

dishwasher.

Remove, empty and wash the broiler grease drawer or

container at least once a day.

Page 10

CARE & CLEANING continued

On a single broiler unit the grease drawer is located inside

the valve panel. On a double broiler the grease from the

upper broiler section drains into a container suspended

from the front of the unit. The grease from the lower broiler

section drains through the hopper into a grease drawer

located inside the valve panel.

Remove and clean the grid rack inserts and grease drip chute

daily. Pull the grid rack forward and lift the grease rack insert

out of the frame. Remove the grease drip chute by pulling it

forward out of the rack frame guides.

Instructions For Removal Of

Grid Rack & Grid Rack Frame

Remove the broiler grid racks as follows:

1. Bring the grid rack down to the lowest adjustment

position.

2. Pull the entire grid rack out of the broiler as far as

possible.

3. Remove grid rack grease drip chute (located below wire

rack) by grasping hold of the chute and pulling forward

out of the frame guides.

4. Remove wire racks by lifting the front of each wire rack

over the rack front plate.

5. Pull the empty grid rack frame assembly as far forward

as possible (until the stops hit the front of the carriage

assembly), lift up on the handle and pull the rack

frame forward so the stops clear the carriage assembly.

Continue pulling the rack frame forward until the rear

bearings reach the notches in the carriage tracks and lift

the rear of the rack up and out of the carriage; the entire

frame is now free from the unit.

6. Place the rack raising lever in the highest position for

safety purposes.

Before cleaning the hopper, replace the grease drawer

to receive any drippings and solid particles freed by the

cleaning. The additional internal grease diverter should be

removed from the top section and cleaned at this time. The

diverter is removed by raising the rack assembly and lifting

up the front of the diverter. After disengaging the screws at

the front of the unit, pull the diverter forward and remove

from the unit.

Carriage mechanisms should be kept clean, particularly

around the roller bearings. If the roller bearings have been

washed clean or appear to be dry, they should be lubricated

using salt-free vegetable oil or a non-toxic high temperature

bearing lubricant.

Infra-Red Burners must be cleaned periodically by

a service professional.

Part # 4517385 (02/20/08)Page 10

Page 11

Part # 4517385 (02/20/08) Page 11

Page 12

Page 13

Page 14

Pièce n° 4517385 (02/20/08) Page 11

périodiquement par un professionnel de service.

Les brûleurs à infrarouge doivent être nettoyés

élevées.

pour roulements non toxique et résistant aux températures

être lubri és avec de l’huile végétale sans sel ou un lubri ant

à rouleaux ont été lavés ou semblent être secs, ils doivent

surtout autour des roulements à rouleaux. Si les roulements

Les mécanismes du chariot doivent être maintenus propres,

l’appareil.

de l’appareil, tirer le dé ecteur vers l’avant et le retirer de

avant du dé ecteur. Après avoir dégagé les vis à l’avant

soulevant l’ensemble de crémaillère et en soulevant la partie

et être nettoyé à ce moment. Le dé ecteur est retiré en

supplémentaire doit être retiré de la section supérieure

consécutives au nettoyage. Un dé ecteur à graisse interne

graisse a n d’y recueillir toutes des particules ou gouttes

Avant de nettoyer la trémie, remettre en place le tiroir à

ENTRETIEN ET NETTOYAGE suite

Page 15

Pièce n° 4517385 (02/20/08)Page 10

rôtissoire une fois par jour au moins.

Retirer, vider et laver le tiroir ou contenant à graisse de la

plus haute pour des raisons de sécurité.

6. Placer le levier de levage de crémaillère dans la position la

Tout le cadre est maintenant séparé de l’appareil.

soulever l’arrière de la crémaillère et le sortir du chariot.

arrière atteignent les encoches des rails du chariot et

de tirer le cadre vers l’avant jusqu’à ce que les roulements

puissent se dégager de l’ensemble du chariot. Continuer

crémaillère vers l’avant de manière à ce que les butées

du chariot), soulever la poignée et tirer le cadre de

(jusqu’à ce que les butées touchent l’avant de l’ensemble

5. Tirer l’ensemble du cadre vide aussi loin que possible

chaque grille par-dessus la plaque avant de la crémaillère.

4. Retirer les crémaillères de grilles en soulevant l’avant de la

tirant vers l’avant hors des guides du cadre.

trouvant sous la grille) en saisissant la trémie et en la

3. Retirer la trémie à graisse de la crémaillère de grille (se

rôtissoire aussi loin que possible.

2. Tirer l’ensemble de crémaillère de grille hors de la

possible de réglage.

1. Mettre la crémaillère de grille à la position la plus basse

Retirer les crémaillères de grille de la rôtissoire comme suit :

De Crémaillère De Grille

De La Crémaillère Et Du Cadre

Instructions De Démontage

cadre de crémaillère.

à graisse en la tirant vers l’avant pour la libérer des guides du

vers l’avant et soulever l’insert hors du cadre. Retirer la trémie

trémie à graisse tous les jours. Tirer la crémaillère de grille

Retirer et nettoyer les inserts de crémaillère de grille et la

trouvant à l’intérieur du panneau des robinets.

la section basse se vide par la trémie dans le tiroir à graisse se

un contenant suspendu à l’avant de l’appareil. La graisse de

à deux rôtissoires, la graisse de la section haute se vide dans

trouve à l’intérieur du panneau des robinets. Sur les appareils

Pour un appareil à rôtissoire simple, le tiroir à graisse se

vaisselle ou bien lavé dans le lave-vaisselle.

ltre peut être nettoyé à la main avec du produit de lavage à

les jours ou tous les deux jours, en fonction de l’utilisation. Le

Le ltre de l’appareil M110XM doit être retiré et nettoyé tous

Section Rôtissoire

UTILISER DE LAINE D’ACIER.

risquent de s’incruster dans les surfaces et rouiller. NE JAMAIS

ni de couteaux en acier ordinaire, car des particules de fer

tenaces de graisses ou d’huiles. Ne pas utiliser de grattoirs

bois ou en plastique pour gratter si nécessaire les résidus

Utiliser uniquement des outils en acier inoxydable, en

avec de la crème à base de poudre à récurer.

taches peuvent être éliminées en frottant vigoureusement

L’acier inoxydable peut se décolorer s’il est trop chau é. Ces

pouvant être en contact avec les aliments.

la surface. Ne pas utiliser de tels produits sur les surfaces

dans le commerce qui laissent un lm huileux ou cireux sur

extérieures, il existe de nombreux produits disponibles

Pour supprimer les empreintes digitales sur les surfaces

comme indiqué précédemment.

ce sens pour préserver l’apparence d’origine. Rincer ensuite

inoxydable sont polies dans un sens. Frotter en respectant

travailler à contre sens. Toutes les surfaces en acier

douce) si nécessaire, mais en prenant soin de ne jamais

Utiliser une pâte (mélange d’eau et de poudre à récurer

que la zone nettoyée ne sèche.

solution désinfectante et sécher avec un torchon doux avant

Rincer la surface lavée avec une éponge trempée dans une

traces de détergent.

la fois, sinon l’eau s’évaporera et laissera sur la surface des

solution d’eau et de détergent. Laver une petite surface à

Pour le nettoyage de routine, laver simplement avec une

Acier Inoxydable

nettoyage ou réparation.

Debrancher l’alimentation électrique de l’appareil avant tout

ENTRETIEN ET NETTOYAGE

Page 16

Minutes

Bien Cuit

Minutes

À point

Minutes

Saignant

po(mm)

Épaisseur

Pièce n° 4517385 (02/20/08) Page 9

pour en augmenter l’épaisseur.

* Il est recommandé de replier les lets minces de limande, sole, plie, etc. avant la cuisson

Darne De Poisson 1/(25) — — 4-1/2

Darne De Poisson 1/2/(13) — — 4

*Poisson — — — 5

Poisson (Réglage bas du brûleur- position basse de la grille)

Côtelette Double 2/(51) 4 6 —

Carré, Côtes 1/(25) 3/1/2 4-1/2 —

Agneau

Bifteck Haché 1/2 (13) 1-1/2 2 2-1/2

Entrecôte 3/4 (19) 2-1/2 3-1/2 5

Surlonge 2 (51) 3-1/2 5-1/2 6-1/2

Bifteck De Côte, Côte De Bœuf 1-1/2/(38) 2-1/2 4 5-1/2

Filet Mignon, Steak D’aloyau 1/(25) 2-1/2 4 5-1/2

Bœuf

Type De Produit

TEMPS DE CUISSON SUGGÉRÉS (DE CHAQUE CÔTÉ) EN MINUTES

faciliter le chargement et le déchargement du four.

et la source de chaleur, et on peut la tirer sans di culté pour

ou plus haut a n de créer la distance désirée entre le produit

réglage des brûleurs et la position de la grille.

matière de gril à infrarouges auront un e et sur le temps, le

seulement, La technique de l’utilisateur et son expérience en

dans les tableaux suivants sont donnés à titre indicatif

Nous insistons à nouveau sur le fait que les temps indiqués

brunissage et d‘empêcher les produits de coller à la grille.

non salée avant de les passer au gril a n de faciliter le

Il est conseillé de tremper tous les aliments dans de l’huile

La grille de la rôtissoire peut être facilement placée plus bas

peut a ecter le temps de cuisson et la qualité du produit ni.

moment de son introduction dans l’appareil pour le rôtissage

fonctionnement. Par exemple, la température du produit au

guide d’utilisation. De nombreux facteurs peuvent a ecter le

Les informations suivantes sont fournies a n de servir de

Rôtissoire

INFORMATION SUR LES APPLICATIONS DU PRODUIT

Page 17

Pièce n° 4517385 (02/20/08)Page 8

bouclier des veilleuses.

amme dépasse de 1/2 po à 3/4 po (12 mm à 25 mm) le

5. Les veilleuses doivent être réglées de manière à ce que la

commande.

possible d’y accéder par les ori ces du panneau de

le collecteur, derrière le panneau de commande. Il est

4. Les robinets de réglage de veilleuses se trouvent sur

veilleuse par paire de brûleurs.

de la rôtissoire se trouvant à l’avant de l’appareil. Il y a une

3. À l’aide d’une mèche en ammée, allumer les veilleuses

fermer le robinet de la canalisation de gaz.

3. Si l’appareil doit être éteint pour une période prolongée,

principal (0).

2. Couper l’alimentation électrique à l’interrupteur

1. Tourner tous les robinets en position « OFF ».

Arrêt

pas, contacter le centre de services agréé de l’usine.

OFF et répéter les étapes 1 à 5. Si l’allumage ne se produit

pas dans les 5 secondes, tourner le robinet du brûleur sur

AVERTISSEMENT : Si l’allumage du brûleur ne se produit

5. Le halo disparaît et la céramique devient rouge.

surface de la céramique pendant 10-15 secondes.

4. Une fois l’allumage établi, une amme bleue couvre la

3. Véri er immédiatement l’allumage des brûleurs.

2. Tourner le robinet de la rôtissoire sur la position HIGH.

1. Mettre sur ON (1) l’interrupteur principal d’alimentation.

2. Ouvrir le robinet de gaz sur la canalisation d’alimentation.

1. Brancher l’alimentation électrique.

Utilisation Initiale : Brûleurs À Infrarouge

brûleur. Ce treillis augmente encore l’énergie infrarouge.

la céramique a n d’augmenter encore le rendement du

Un treillis métallique spécial sert de surface extérieure sous

la céramique.

apparaît comme un halo rouge couvrant toute la surface de

tous les joints de la surface radiante. La amme du gaz

sont xés à l’aide d’un scellant spécial qui scelle également

important d’ori ces pour le gaz. Ces blocs de céramique

des blocs de céramique comportant chacun un nombre

les surfaces radiantes sont constituées d’un nombre de séries

d’un brûleur à gaz conventionnel à cette di érence près que

Ces brûleurs spéciaux fonctionnent de façon similaire à celle

demeurent à l’intérieur.

les produits de manière à ce que les sucs et les saveurs

un rôtissage à haute vitesse et saisissent rapidement

section de la rôtissoire. Les brûleurs à infrarouge assurent

ses quatre (4) brûleurs à gaz à haut rendement pour chaque

à chaleur radiante directe destinée à l’usage intensif grâce à

La rôtissoire à infrarouge GARLAND est une rôtissoire à gaz

Utilisation : Brûleurs À Infrarouge

Brûleurs À Infrarouge

FONCTIONNEMENT

Page 18

Pièce n° 4517385 (02/20/08) Page 7

brûleur, attendre 5 minutes et essayer de nouveau.

secondes après l’ouverture du robinet, fermer le robinet du

Dans le cas où l’allumage ne se ferait dans un délai de 5

l’allumage de tous les brûleurs dont le robinet est ouvert.

coupée. Il est de la responsabilité de l’utilisateur de véri er

sont pas allumées. L’alimentation en gaz ne sera pas

supérieure même si les veilleuses de cette section ne

ATTENTION : Le gaz alimentera les brûleurs de la section

de l’installation et réglés si nécessaire.

les brûleurs et les veilleuses doivent être véri és au moment

Tous les appareils sont testés et réglés en usine. Cependant,

4. Allumer la veilleuse du four.

fuites si nécessaire et véri er de nouveau.

comme décrit dans la procédure ci-dessus. Réparer les

3. Véri er la présence de fuites aux robinets et raccords,

toutes les veilleuses de la section haute.

2. Ouvrir le robinet principal d’alimentation en gaz. Allumer

position « OFF ».

1. Véri er que tous les robinets et thermostats sont en

réutiliser ensuite.

de xation) doivent être soigneusement rangées pour les

supérieures. Toutes les pièces retirées (y compris les moyens

correctement les grils, les plaques de cuisson et grilles

nécessaire de retirer ou au moins de soulever et de supporter

panneau(x) inférieur(s) avant et les grilles du four. Il peut être

est nécessaire de retirer le(s) panneau(x) des robinets, le(s)

accéder à toutes les canalisations de gaz et aux raccords il

connexions de tuyaux. NE PAS UTILISER DE FLAMME ! Pour

produits équivalents, appliqués sur et autour des raccords et

détecteurs de fuites approuvés, de l’eau savonneuse ou des

testés pour détecter les fuites éventuelles. Utiliser des

Tous les raccords et connexions de tuyaux doivent être

Essais Et Réglages

conformément aux codes locaux.

IMPORTANT – Cet appareil doit être relié à la terre

Connexion Électrique

PROLONGÉE. PURGER AVANT DE REBRANCHER LE GAZ ».

D’OUVRIR L’ALIMENTATION. APRÈS UN PÉRIODE D’ARRÊT

AMONT DOIVENT ÊTRE MIS EN POSITION D’ARRÊT AVANT

« TOUS LES ROBINETS DE BRÛLEURS ET DE VEILLEUSES EN

automatique :

d’installation du robinet d’isolement ou du système

L’avertissement suivant DOIT être a ché à l’endroit

d’accès près de la sortie.

robinet d’isolement doit être installé à un endroit facile

Lorsque cela est impossible, un système automatique de

d’une sortie dans un endroit facile d’accès.

ce robinet sera installé soit à l’extérieur de la cuisine ou près

cuisine en cas d’urgence. Chaque fois que cela est possible,

l’arrivée de gaz dans la cuisine pour permettre d’isoler la

Un robinet à commande manuelle doit être installé sur

l’appareil.

de déconnexion doit être installé entre le robinet de gaz et

ou de nettoyage. Un raccord union ou tout autre moyen

pouvoir isoler l’appareil lors de toute intervention d’entretien

d’un robinet de gaz manuel en amont de l’appareil pour

Tous les appareils xes (non mobiles) DOIVENT être équipés

INSTALLATION (suite)

Page 19

Pièce n° 4517385 (02/20/08)Page 6

remis dans sa position d’origine.

oublier de rebrancher l’appareil après que celui-ci ait été

approprié.

entre le compteur et les appareils doit être de diamètre

compteur correspond au débit nécessaire. La canalisation

d’une alimentation en gaz su sante et de s’assurer que le

plani cation de l’installation de façon à établir la disponibilité

Consulter la compagnie locale de gaz au moment de la

Connexion Du Gaz

empêcher la circulation d’air à l’avant.

placer d’objets encombrants devant l’appareil, a n de ne pas

su samment d’air pour fonctionner et on ne devra pas

Tous les brûleurs à gaz et les veilleuses ont besoin de

doit être égale à la quantité d’air évacué.

pénètre dans la pièce. La quantité d’air entrant dans la pièce

correctement, il est nécessaire que de l’air de remplacement

pièce. Pour qu’une ventilation d’aspiration fonctionne

Une forte ventilation d’aspiration créera un vide dans la

pieds six pouces (1981 mm) au-dessus du sol.

(152 mm), au-delà des cotés des appareils et se trouver à six

correctement conçue qui devra se prolonger de six pouces

un équipement à ammes nues est d’utiliser une hotte

fonctionnement optimal. La méthode idéale pour ventiler

Une ventilation correcte est essentielle pour un

destination.

consulter le(s) code(s) applicable(s) dans le pays de

générales. Pour des recommandations plus détaillées,

Les remarques suivantes constituent des indications

Air De Ventilation

l’appareil de niveau et compenser un sol inégal.

4. Les pieds peuvent être encore réglés pour mettre

pieds et régler les quatre pieds à la même hauteur.

3. Répéter l’installation des inserts de pied pour les autres

dans la bride à collier.

de retenue du pied et taper jusqu’à ce qu’il soit en place

2. Positionner l’insert de pied dans l’ouverture du dispositif

coucher l’appareil sur le dos.

1. Soulever l’avant de l’appareil et le bloquer. Ne pas

Appareils Équipées De Pieds

débranchement de ce dispositif est nécessaire, ne pas

en regardant la cuisinière depuis l’arrière) et si le

xé à un support (situé sur la roulette arrière droite,

3. Attention : Un dispositif de retenue obligatoire est

débranchement rapide ou les conduits connexes.

exercer aucun e ort sur le connecteur ou le dispositif de

freins pour limiter le déplacement de l’appareil sans

2. Les roulettes avant de l’appareil seront équipées de

2005/CSA 6.16A-2005 (ou la dernière édition).

with gas fuel, ANSI Z21.41/CSA 6.9, Addenda Z21.41Ala norme Standard for Quick-Disconnect Devices for use

(ou la dernière édition) et un raccord rapide conforme à

Z21.69/CSA 6.16, Addenda Z21.69B-2006/CSA 6.16B-2006

norme Connectors for Movable Gas Appliances, ANSI

1. L’installation sera faite avec un raccord conforme à la

Appareils Équipés De Roulettes

système si la pression est supérieure à 1/2 PSIG (3,45 kPa).

pendant toutes les manœuvres d’essai de pression de ce

déconnectés de la canalisation d’alimentation en gaz

L’appareil et son robinet individuel d’arrêt doivent être

canalisation sont allumés.

s’assurer que tous les appareils installés sur la même

REMARQUE : Lors de la véri cation de la pression du gaz,

colonne d’eau.

chute éventuelle de pression ne dépassant pas 1/2 po de

canalisation existants alimenteront l’appareil avec une

véri er la pression a n de s’assurer que le compteur et la

additionnel, demander à la compagnie locale de gaz de

C. S’il s’agit d’un équipement de remplacement ou

fonctionnement.

être alimenté avec la pression de gaz nécessaire à son

et de la canalisation pour s’assurer que l’appareil peut

compagnie de gaz locale de véri er la taille du compteur

B. S’il s’agit d’une nouvelle installation, demander à la

propane.

ceux estampillés « PRO » doivent l’être uniquement au

NAT » doit uniquement être connectés au gaz naturel,

le panneau avant inférieur. Les appareils estampillés «

estampillé sur la plaque signalétique se trouvant derrière

A. Le type de gaz pour lequel l’appareil est équipé est

INSTALLATION (suite)

Page 20

l’alimentation en gaz.

Avant de procéder au montage et à la connexion, véri er

Remarques Sur L’installation

Pièce n° 4517385 (02/20/08) Page 5

Combustible

Construction Non

Combustible

Construction

Côté Droit 6 Po (152mm) 0 Po

Côté Gouche 6 Po (152mm) 0 Po

Arriére 6 Po (152mm) 0 Po

Endroit

fonctionnement correct.

Prévoir un dégagement su sant pour les réparations et un

Dégagement

générales, partie 2 ».

C22.2-No.O-M 1982 (ou la dernière édition), « Exigences

l’installation, partie 1 » et la norme

1990 (ou la dernière édition) « Normes de sécurité pour

sections applicables du Code canadien de l’électricité, C22.1Au Canada, la connexion électrique doit être conforme aux

aux codes locaux le cas échéant.

Au Canada, l’installation doit être conforme au CSA-149.1 et

local pour assurer une fonctionnement sécuritaire et e cace.

ANSI/NFPA 70-1990 ou la dernière édition et/ou au code

édition et National Electrical Code

Z 223.1-1998 ou à la dernière édition, NFPA No 54 - dernière

L’installation doit être conforme au National Fuel Code ANSI

pays de destination.

codes d’usage et publications connexes en vigueur dans le

personne compétente et conformément aux règlements,

L’installation de cet appareil doit être e ectuée par une

Réglementation Légale

cela peut annuler la garantie du fabriquant.

signalétiques appliqués à demeure sur l’équipement, car

5. Ne pas retirer les étiquettes, avertissements ou plaques

s’ils sont installés sur un plancher combustible.

Les appareils munis d’un four doivent être équipés de pieds

équipement auxiliaire.

convenablement le poids de l’appareil et de tout autre

Le plancher d’installation de l’appareil doit pouvoir supporter

Emplacement

résidentielle.

Cet appareil n’est pas recommandé pour une installation

INSTALLATION

d’alimentation en gaz doit être utilisé.

sur la plaque signalétique et sur l’emballage. Ce type

lesquels l’équipement a été réglé en usine sont indiqués

4. Le type de gaz et la pression d’alimentation pour

combustible.

installés sur le four quand celui-ci est monté sur un sol

elle est expédiée sans pieds. Des pieds doivent être

cuisinière doit être montée sur une base avec plinthe,

en place, sauf indication contraire. Dans les cas où la

3. Tout l’équipement est expédié de l’usine avec les pieds

inoxydable doit également être retiré.

le matériel de protection couvrant les pièces en acier

d’emballage doivent être retirés des appareils. Tout

2. Les ls de fer retenant les brûleurs et autres matériaux

immédiatement au transporteur.

de dommages. Tout dommage doit être signalé

l’appareil de la caisse et véri er de nouveau la présence

survenus durant le transport. Retirer avec précaution

1. Véri er la caisse pour déceler les dommages éventuels

Informations Générales

INTRODUCTION

Page 21

Pièce n° 4517385 (02/20/08)Page 4

ENTRÉE DU GAZ

4"

[146mm]

5-3/4"

[1756mm]

69-1/8"

[102mm]

ÉLECTRIQUE

PRISE

INSTALLÉ]

[CUTOMER

DÉVIATEUR

FUMÉE

[159mm]

6-1/4"

[864mm]

34"

[832mm]

32-3/4"

[152mm]

6"

[594]

23-3/8"

[1003mm]

39-1/2"

[1597mm]

62-7/8"

[29mm]

1-1/8"

TOLÉRANCE ± 1/8" [3mm]

[864mm]

34"

Combustible

Construction Non

Ori ce

ÉLECTRIQUE *

ALIMENTATION

Taille DMS

Combustible

Construction

DÉGAGEMENT

Côté Droit 6 Po (152mm) 0 Po

Arriére 6 Po (152mm) 0 Po

Endroit

C2100MX Infrarouge

Numéro De Modèle Brûleur De Rôtissoire

DÉSIGNATIONS DES MODÈLES

Par Section

Débit Btu/h

Côté Gouche 6 Po (152mm) 0 Po

DU GAZ

ENTRÉE

PRISE ÉLECTRIQUE

[159mm]

6-1/4"

[102mm]

4"

*Note : Le schéma est situé à l’arrière de l’appareil à côté du câble électrtrique et se troure également dans ce manuel.

7 Po WC 11 Po C.E. 6 Po C.E. 10 PoC.E. 120V 60Hz, 1A

Gaz Naturel Propane Gaz Naturel Propane

PRESSION DU COLLECTEUR

D’ALIMENTATION EN GAZ

PRESSION MINIMALE

Infrarouge 70,000 # 50 70,000 # 56

Taille DMS

Ori ce

Par Section

Débit Btu/h

Brûleur

Gaz Naturel Propane

DÉBITS CALORIFIQUES DES BRÛLEURS INDIVIDUELS

SPÉCIFICATIONS TECHNIQUES

Page 22

Pièce n° 4517385 (02/20/08) Page 3

De Crémaillère De Grille . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Instructions De Démontage De La Crémaillère Et Du Cadre

Section Rôtissoire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Acier Inoxydable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

ENTRETIEN ET NETTOYAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Rôtissoire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

INFORMATION SUR LES APPLICATIONS DU PRODUIT . . . . . . . . . . . . . . . . . . 9

Arrêt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Utilisation : Brûleurs À Infrarouge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Utilisation Initiale : Brûleurs À Infrarouge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Brûleurs À Infrarouge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

FONCTIONNEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Essais Et Réglages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Connexion Électrique . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Connexion Du Gaz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Air De Ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Appareils Équipées De Pieds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Appareils Équipés De Roulettes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Remarques Sur L’installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Dégagement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Emplacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Réglementation Légale . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Informations Générales . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

SPÉCIFICATIONS TECHNIQUES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

INFORMATIONS IMPORTANTES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

TABLE DES MATIÈRES

Page 23

Pièce n° 4517385 (02/20/08)Page 2

AVERTISSEMENT

dégagés et ne pas y stocker de produits combustibles

Maintenir les abords de l’appareil

d’autres problèmes reproductifs.

est reconnue par l’état de Californie comme pouvant causer des malformations congénitales ou

exposer au monoxyde de carbone en cas de mauvais réglage. L’inhalation de monoxyde de carbone

est reconnue par l’état de Californie comme causant le cancer. L’utilisation de ce produit peut vous

verre/fibres céramiques. L’inhalation de ces particules de laine de verre ou de fibres céramiques

L’installation et l’entretien de ce produit peut vous exposer aux poussières de laine de

le cancer et/ou des malformations congénitales ou d’autres problèmes de reproduction.

Ce produit contient des produits chimiques reconnus par l’état de Californie comme causant

INFORMATIONS IMPORTANTES

Page 24

Pièce n° 4517385 (02/20/08) Page 1

Pièce nº 4517385 (02/20/08) © 2006 Garland Commercial Industries, Inc.

Télécopieur : 081-848-0041

Téléphone : 081-561-0433

ANGLETERRE

Swallow eld Way, Hayes, Middlesex UB3 1DQ

Enodis UK LTD.

.

être obtenue auprès du fournisseur de gaz local

détectée par l’utilisateur. Cette information peut

instructions à suivre en cas d’odeur de gaz

Placer dans un endroit bien en vue les

Pour votre sécurité

D’AUTORISATION : G-1-07-05-28

MONTEUR D’INSTALLATION AU GAZ. NUMÉRO

DOIT ÊTRE INSTALLÉ PAR UN PLOMBIER OU UN

DANS L’ÉTAT DU MASSACHUSETTS, CE PRODUIT

Télécopieur : 905-624-5669

Téléphone : 905-624-0260

CANADA

1177 Kamato Road, Mississauga, Ontario L4W 1X4

GARLAND COMMERCIAL RANGES, LTD.

L’ÉQUIPEMENT.

AVANT D’INSTALLER OU DE RÉPARER

D’UTILISATION ET D’ENTRETIEN

MENT LES INSTRUCTIONS D’INSTALLATION,

SURES OU LA MORT. LIRE SOIGNEUSE-

DES DOMMAGES MATÉRIELS, DES BLES-

ENTRETIEN MAL FAITS PEUVENT CAUSER

MODIFICATIONS, DES RÉPARATIONS OU UN

UNE INSTALLATION, DES RÉGLAGES, DES

AVERTISSEMENT

Télécopieur : (570) 636-3903

Téléphone : (570) 636-1000

Freeland, Pennsylvanie 18224

185 East South Street

GARLAND COMMERCIAL INDUSTRIES

conception et les spéci cations des pièces) peuvent être remplacés ou modi és sans préavis.

de Garland à : http://www.garland-group.com. Les renseignements contenus dans le présent document (y compris la

ou par des agents d’entretien non autorisés. Pour obtenir la liste des agents de service autorisés, consulter le site web

numéro de série aurait été mutilé, oblitéré ou supprimé ou qui aurait été modi é ou réparé avec des pièces non autorisées

codes nationaux et locaux ou aux instructions d’installation fournies avec le produit ou n’importe quel produit dont le

en ce qui concerne n’importe quel produit mal installé, réglé, utilisé ou qui n’aurait pas été entretenu conformément aux

d’entretien autorisé par Garland utilisant des pièces de rechange d’origine Garland. Garland n’aura aucune obligation

L’attention des utilisateurs est attirée sur le fait que l’entretien et les réparations doivent être e ectués par un agent

PROFESSIONNEL TEL QUE SPÉCIFIÉ.

ET DOIT ÊTRE INSTALLÉ PAR DU PERSONNEL

QU’ÉQUIPEMENT PROFESSIONNEL DE CUISSON

CE PRODUIT A ÉTÉ HOMOLOGUÉ EN TANT

ULTÉRIEUREMENT.

MANUEL ET LE CONSERVER POUR S’Y REPORTER

APPAREIL OU DE TOUT AUTRE APPAREIL

INFLAMMABLES À PROXIMITÉ DE CET

OU D’AUTRES VAPEURS OU LIQUIDES

NE PAS STOCKER NI UTILISER D’ESSENCE

POUR VOTRE SÉCURIT:

LIRE TOUTES LES SECTIONS DU PRÉSENT

SÉRIE CUISINE

EN INFRAROUGE

RÔTISSOIRE

ET D’INSTALLATION

MANUEL D’UTILISATION

Loading...

Loading...