Garland BH/BA 1500, BH/BA 1800, BH/BA 2500, BH/BA 3000, BH/BA 3500 Instructions For Use Manual

...Page 1

-1-

090908_Instructions for use RTCS Base- and Wok-Li ne_ E.d oc

INSTRUCTIONS FOR USE

INDUCTION TABLETOP UNITS

RTCS Base-Line/Wok-Line

with RTCS-Technology

BH/BA 1500

BH/BA 1800

BH/BA 2500

BH/BA 3000

BH/BA 3500

SH/BA 3500

SH/BA 5000

SH/WO 3500

SH/WO 5000

SH/WO 8000

Page 2

-2-

090908_Instructions for use RTCS Base- and Wok-Li ne_ E.d oc

CONTENT

1 General remarks ................................................................................................................ 3

1.1 Description of danger signs ........................................................................................... 3

1.2 Purpose of induction cookers ........................................................................................ 4

2 Description of products ..................................................................................................... 5

2.1 Scope of supply ............................................................................................................. 5

2.2 Products ......................................................................................................................... 5

2.3 RTCS Base-Line/Wok-Line units at a glance ............................................................... 6

2.4 Technical Data ............................................................................................................... 8

3 Installation .......................................................................................................................... 9

3.1 Scope of supply ............................................................................................................. 9

3.2 Requirements of installation .......................................................................................... 9

3.3 Definition of interfaces .................................................................................................. 9

3.4 One cooking point unit BH/BA 1500, BH/BA 1800, BH/BA 2500, BH/BA 3000 and

BH/BA 3500 ................................................................................................................ 10

3.5 One cooking point unit SH/BA 3500 and SH/BA 5000 .............................................. 10

3.6 SH/WO 3500, SH/WO 5000 and SH/WO 8000 .......................................................... 11

3.7 Installation ................................................................................................................... 11

4 Operation test ................................................................................................................... 12

5 Operation .......................................................................................................................... 13

5.1 Cooking process .......................................................................................................... 13

5.2 Comfort ........................................................................................................................ 13

6 Safety instructions ........................................................................................................... 14

6.1 Risk in the event of non-observance of the safety information ................................... 14

6.2 Safety conscious work ................................................................................................. 14

6.3 Safety information for the operator/operating personnel ............................................ 14

6.4 Improper operating methods ........................................................................................ 15

6.5 Unauthorized reconstruction and use of spare parts .................................................... 15

6.6 Pan detection ............................................................................................................... 15

6.7 Control of the heating area .......................................................................................... 15

7 Out of operation ............................................................................................................... 16

8 Fault finding/Rectification .............................................................................................. 17

8.1 Fault finding with error code ....................................................................................... 17

8.2 Fault finding without error code .................................................................................. 18

9 Cleaning ............................................................................................................................ 20

10 Support ............................................................................................................................. 21

11 Waste disposal concept .................................................................................................... 22

Page 3

-3-

090908_Instructions for use RTCS Base- and Wok-Li ne_ E.d oc

1 General remarks

These instructions for use contain information which is fundamentally important and must be

taken into account during assembly, operation and maintenance. They must therefore be read

very carefully before installation and operation by the responsible specialist staff and the

operator(s). They must always be available for consultation at the place of operation.

1.1 Description of danger signs

This symbol identifies the safety information

which may cause danger (personal injury) for

people at non-observance of proper operation.

This dangerous voltage warning symbol

indicates a risk of electric shock and hazards

from dangerous voltage.

CAUTION

Indicates a hazard or unsafe practice which

could result in minor personal injury or

property damage.

Electromagnetic field

To reduce the risk of fire or electric shock, do

not remove or open cover.

No user serviable parts inside.

Refer servicing to qualified personnel.

Information signs mounted directly on the cooker must be observed at all times and kept in a

fully legible condition.

Warning

Risk of fire or electric shock

Do not open

Page 4

-4-

090908_Instructions for use RTCS Base- and Wok-Li ne_ E.d oc

1.2 Purpose of induction cookers

The induction cookers RTCS Base-Line are specially suitable as cookers in the kitchen or for

the preparation of meals on the table. A cooker can be used for cooking, warming up, keeping

warm, flambéing, roasting, etc. food. The cooking or finishing process with RTCS Base-Line

induction units must be carried out with recommended types and sizes of pans. Do not use

any NO NAME pans.

Please use just perfect pan material!

Page 5

-5-

090908_Instructions for use RTCS Base- and Wok-Li ne_ E.d oc

2 Description of products

2.1 Scope of supply

The unit is delivered completely and in working order.

2.2 Products

We dispose of several basic types with different performances and measurements. Built in a

robust method of construction, they are compact and powerful with a revolutionary

technology in a complete case of CrNi-steel. Our accessories are coordinated with the „RTCS

Base-Line“ units. Equipped with continuous control, they allow efficient cooking.

Simple operation with rotary switch with integrated mains switch

Compact powerful electronics enable flat construction and safe operation

A maximum of safety thanks to multiple functions of protection and checking

Short cooking time

Electronic checking of the energy supply

Compact measurement – light weight

Fulfills the latest directions:

EN 60335-1/-2/-36, EN 62233

UL 197; CAN/CSA/C 22.2 No.109,

CE-conform

Page 6

-6-

090908_Instructions for use RTCS Base- and Wok-Li ne_ E.d oc

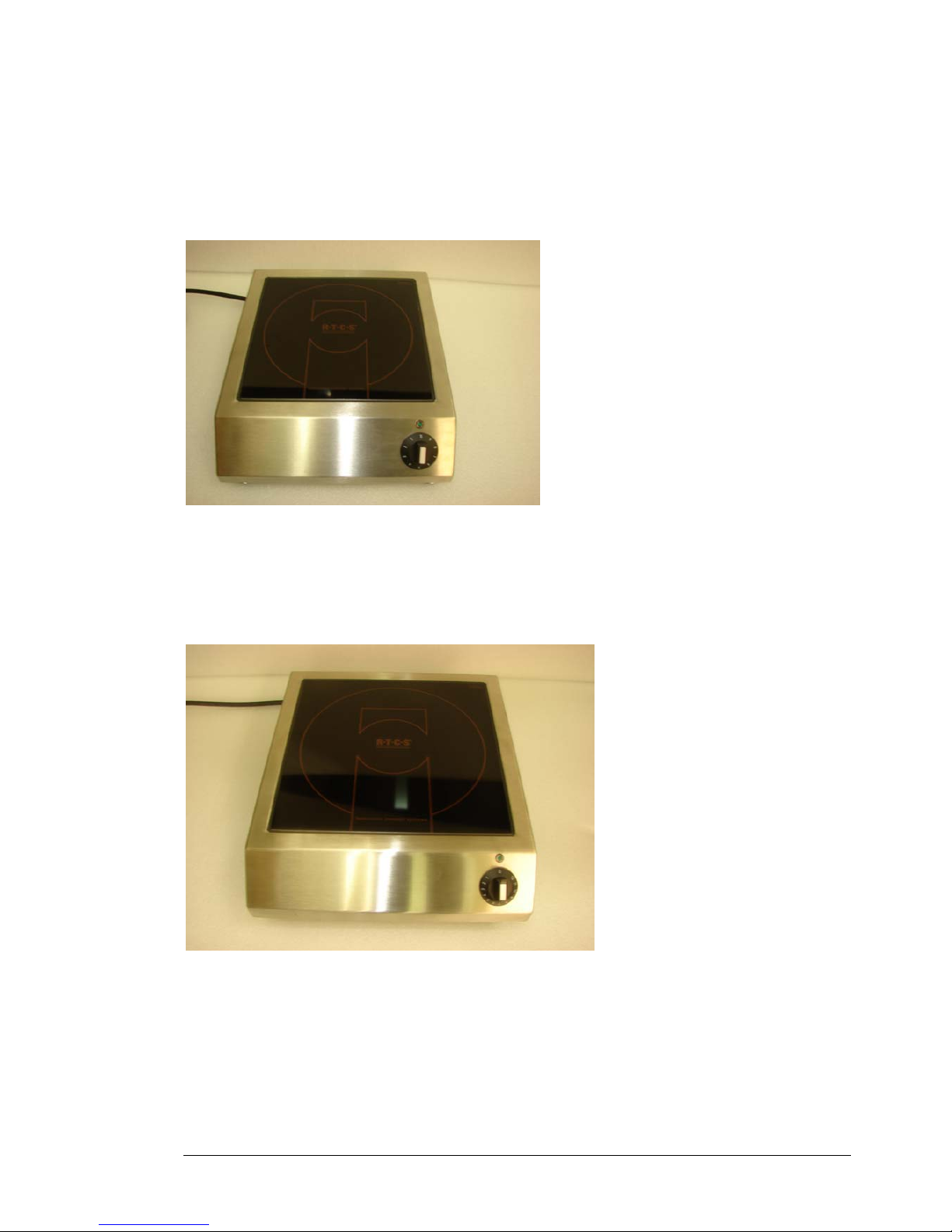

2.3 RTCS Base-Line/Wok-Line units at a glance

Before carrying out function checks, the operator must know how to operate the cooker.

Model BH/BA

Model SH/BA

Page 7

-7-

090908_Instructions for use RTCS Base- and Wok-Li ne_ E.d oc

Model SH/WO

Control knob

The number that points to the indicator operation marks the actual position of the control

knob.

OFF-position:

0 points to the indication operation

ON-position:

Any position where not 0 points to the indicator

operation.

Page 8

-8-

090908_Instructions for use RTCS Base- and Wok-Li ne_ E.d oc

2.4 Technical Data

Type Dimensions Ceran plate

BH/BA 320 x 380 x 107 mm 260 x 260 mm

SH/BA 380 x 440 x 140 mm 320 x 320 mm

SH/WO 380 x 440 x 200 mm

300 mm

Type Voltage Power Weight

BH/BA 1500 120 V 1,5 kW 9 kg

BH/BA 1800 120 V 1,8 kW 9 kg

BH/BA 2500 208 / 230 / 240 V 2,5 kW 9 kg

BH/BA 3000 208 / 230 / 240 V 3,0 kW 9 kg

BH/BA 3500 208 / 230 / 240 V 3,5 kW 9 kg

SH/BA 3500 208 / 230 / 240 V 3,5 kW 12 kg

SH/BA 5000 208 / 230/ 400 / 440 V 5,0 kW 13 kg

SH/WO 3500 208 / 230 / 240 V 3,5 kW 13 kg

SH/WO 5000 208 / 230 / 400 / 440 V 5,0 kW 15 kg

SH/WO 8000 400 / 440 V 8,0 kW 16 kg

Operating conditions

Max. tolerance of the nominal supply voltage +6/-10 %

Supply frequency 50/60 Hz

Protection class IP X0

Minimal diameter of the pan 12 cm (5 inches)

Max. ambient temperature Storage > -20 - +70C

Function > + 5 - +40C

Max. relative humidity of air Storage > 10 % - 90 %

Function > 30 % - 90 %

Page 9

-9-

090908_Instructions for use RTCS Base- and Wok-Li ne_ E.d oc

3 Installation

3.1 Scope of supply

The unit is delivered completely and in working order.

3.2 Requirements of installation

The cooker has to be set up on an even place like a table. The air inlet and air outlet must not

be blocked (behind min. 4cm and sideways min. 2cm distance). The unit must never touch the

rear- or the sidewall. The area must be able to withstand a loading of 40 kg. The control knob

to operate the cooker must be easily accessible.

3.3 Definition of interfaces

Please observe the following rules:

Check and ensure that the supply voltage matches the voltage given on the specification

plate.

The electrical connections must satisfy local house installation regulations. The valid,

national and local electrical regulations must be observed.

This induction unit is equipped with a mains cable which can be connected with the

necessary plug to the socket. The connector must be easily accessible to disconnect the

unit from the net.

When faulty-current circuit breakers are used, they must be rated for a breaking current of

more than 30mA.

This induction unit is equipped with an air cooling system. Make sure that the air supply

and air exhaust are not blocked (wall, fabric, etc).

This induction unit is equipped with an additional grease filter. But make sure that the

induction unit does not take in hot ambient air (concerns units standing side by side, or

one behind the other, or standing near a frying pan or an oven) and high steam content in

the surroundings (concerns units standing next to pasta cookers, steamers or a water bath).

The induction unit must not be placed near or on a hot surface.

The air intake temperature must be under 40C.

The operating staff has to make sure that installation, support and inspection is done by

qualified personnel.

Page 10

-10-

090908_Instructions for use RTCS Base- and Wok-Li ne_ E.d oc

3.4 One cooking point unit BH/BA 1500, BH/BA 1800, BH/BA 2500,

BH/BA 3000 and BH/BA 3500

3.5 One cooking point unit SH/BA 3500 and SH/BA 5000

Page 11

-11-

090908_Instructions for use RTCS Base- and Wok-Li ne_ E.d oc

3.6 SH/WO 3500, SH/WO 5000 and SH/WO 8000

3.7 Installation

The cooker must always be set up on a clean and even surface (table, base, etc.) at it’s

designated site. The cooker stands on non-slip rubber pads and is not permanently installed. It

must be set up in a way that it cannot fall down or move in an uneven position. The conditions

for the „place of installation" must be guaranteed.

CAUTION

If the voltage is wrong, the cooker can be

damaged.

The installation of the electricity must be fitted by approved installation contractors in

accordance with specific national and local installation in conformity with all safety

regulations. The warning signs and rating plates on the units must strictly be followed.

Check and ensure that the supply voltage and the line current matches the specifications given

on the rating plate.

Max. tolerance of supply voltage +6/-10 %

Supply frequency 50/60 Hz

Turn control knob to off position („0“)

Connect the unit to the power socket

(The unit is delivered completely with mains cable and plug.)

The installation is now finished and an operating test must be done according to chapter 4.

Page 12

-12-

090908_Instructions for use RTCS Base- and Wok-Li ne_ E.d oc

4 Operation test

Remove all objects from the glass ceramic cooking zone, verify if this area is neither cracked

nor broken. Do not use it when the glass ceramic cooking zone is cracked or broken,

immediately switch off and disconnect the cooker from the outlet.

CAUTION

The glass ceramic cooking zone is warmed up

from the heat of the pan. To avoid injuries

(burning) do not touch this area.

Use a pan that is suitable for induction cooking, having a bottom diameter of at least 12 cm.

Put some water in the pan and place it in the center of the heating area.

Turn the control knob ON (in a position between 1 and 12 (9)). The indicator will

illuminate lights (green) and the water will be heated.

Take the pan away from the heating area, the indicator light will flash

Place the pan back on the heating area, the indicator light will illuminate and the heating

process will continue.

Turn the control knob in the OFF-position, the heating process will stop, indicator light

turns off.

The shining indicator light operation means that energy is being transferred to the pan.

If the indicator operation remains off, check the following:

Is the cooker connected to the outlet?

Is the control knob in ON position?

Do you use a suitable pan (bottom diameter at least 12cm (5“), pan made of suitable

material)?

Is the pan placed in the center of the heating area?

To verify if the pan is suitable, use a permanent magnet and find out if it sticks to the bottom

of the pan. If not, your pan is not suitable for induction cooking. Choose a pan which is

recommended for induction cooking.

If in spite of all positive controls and tests the cooker doesn’t work, refer to the Fault Finding

Section.

Page 13

-13-

090908_Instructions for use RTCS Base- and Wok-Li ne_ E.d oc

5 Operation

5.1 Cooking process

The induction cooker is switched on with the control knob (OFF ON) the cooker is immediately ready for operation. The illuminated indicator operation lights means that energy is

being transferred to the pan. The power rating is set by turning the control knob. The

inductive power depends on the position of the potentiometer:

Position 1 > minimum power

Position 9 > maximum power (BH/BA)

Position 12 > maximum power

Due to the following characteristics, the operator must be more attentive when using the

induction cooker than it would be required with other appliances. The heat storage capacity of

this system is very low. If the heating level is changed with the control knob, the food is

immediately exposed to a different temperature. Do not put empty pans on the glass

ceramic cooking zone, first put grease or liquidity into the pan and start cooking process after

that. Adjust carefully the heating level to the required cooking mode. Set and adjust the power

with the control knob.

The welding of the bottom of steadily overheated pans can get loose and lead to a

deformation. A strong and punctiform overheating can damage the detector.

The pan should always remain in the center of the heating area, otherwise, the bottom of the

pan is heated unequally and the food inside the pan may burn. The hot pan must not cover

neither the silicone joint nor the housing (heat may dry out the silicone joint and it may

break), this can lead to a failure of the device. When heating up oil or grease, constantly

check the pan to prevent oil and grease from overheating and burning.

If a GN-pan shall be heated up by induction just use cooking position 1 or 2.

5.2 Comfort

The cooker only transmits energy if a pan is placed on the heating area, independently of the

position of the control knob. If you take the pan away from the heating area, power transfer

stops immediately. If the pan is put back on the heating area, the selected power will be

transferred to the pan again.

After switching the cooker to the off position the cooking will stop. The heat is only saved in

the pan.

Page 14

-14-

090908_Instructions for use RTCS Base- and Wok-Li ne_ E.d oc

6 Safety instructions

6.1 Risk in the event of non-observance of the safety information

Danger for persons, for the environment and for the cooker can result of non-observance of

the safety information. Certain risks may be associated with non-observance of precautions,

including:

Danger to persons through electrical causes

Danger to persons through overheated pans

Danger to persons through an overheated cooking platform (ceran plate)

6.2 Safety conscious work

The safety information contained in these instructions for use, the existing national regulation

for the prevention of accidents as well as any internal working, operating and safety

regulation stipulated by the operator must be observed.

6.3 Safety information for the operator/operating personnel

The heating area is warmed up from the heat of the pan. To avoid injuries (burning) do not

touch the heating area.

To avoid overheating of pans by means of evaporating the contents, don’t heat up pans

unattended.

Switch the control knob off if you take the pan away for a while. This will avoid having

the heating process continue automatically when a pan is placed back on the heating area.

So, if any person starts to use the cooker, he/she will have to start the heating process by

turning the control knob in the ON-position.

Do not insert any piece of paper, cardboard, cloth, etc. between the pan and the heating

area, as this might initiate a fire.

As metallic objects are heated up very quickly when placed on the operating heating area,

do not place any other objects (closed cans, aluminium foil, cutlery, jewelry, watches etc.)

on the induction cooker. Persons with a pacemaker should ask their doctor whether they

are safe near an induction cooker or not.

Aluminium foil and plastic vessels are not to be placed on the hot surface.

The surface must not be used for storage.

Do not place credit cards, phone cards, cassette tapes, or other objects that are sensitive to

magnetism on the Ceran plate.

Page 15

-15-

090908_Instructions for use RTCS Base- and Wok-Li ne_ E.d oc

The induction cooker has an internal air-cooling system. Do not obstruct the air inlet- and

air outlet-slots with objects (cloth). This would cause overheating and therefore the cooker

would switch off.

Avoid liquid entering into the cooker. Do not let water or food overflow the pan. Do not

clean the cooker with a jet of water.

Protection against steam admission because high steam content in the surroundings

(concerns units standing next to pasta cookers, steamers or a water bath).

If the heating area (Ceran plate) is cracked or broken, the induction cooker must be

switched off and disconnected from the electric connection. Don’t touch any parts inside

the cooker.

Do not use pans with an uneven bottom.

If the supply cord is damaged, it must be replaced by the manufacturer, its service agent or

a similarly qualified person in order to avoid a hazard.

6.4 Improper operating methods

The operating reliability of the cookers can only be guaranteed with proper use. The limit

values may be exceeded on no account.

6.5 Unauthorized reconstruction and use of spare parts

Reconstruction of the cooker or changes to the cooker are not allowed. Contact the

manufacturer if you intend to make any changes on the cooker. To guarantee the safety, just

use genuine spare parts and accessories authorized by the manufacturer. The use of other

components voids all warranties.

6.6 Pan detection

Pans having a diameter smaller than 12cm are not detected. During pan detection, the

indicator operation flashes. No power is transferred and the indicator lamp flashes if no pan or

an unsuitable pan is detected.

6.7 Control of the heating area

The heating area is controlled with a temperature sensor. Overheated pans (hot oil, empty

pans) can be detected. Energy transfer will be stopped. The induction unit must be re-started

after it has cooled down.

Page 16

-16-

090908_Instructions for use RTCS Base- and Wok-Li ne_ E.d oc

7 Out of operation

If the cooker is not in use, make sure that the control knob is in the „OFF“ position. If you do

not use the cooker for a longer period (several days) unplug the unit. Make sure that no liquid

can enter into the cooker and do not clean the cooker with a jet of water.

Page 17

-17-

090908_Instructions for use RTCS Base- and Wok-Li ne_ E.d oc

8 Fault finding/Rectification

The cookers may only be opened by authorized service personnel.

CAUTION

Do not open the cooker!

Dangerous electric voltage inside!

Stop any actions if the heating area (Ceran plate) is cracked or broken, the induction cooker

must be switched off and disconnected from the electric supply. Don’t touch any parts inside

the cooker.

8.1 Fault finding with error code

Number of flashing

signals (Code)

Possible cause Action to take

E03

- . . . - . . .

Overheated heat sink Let unit cool down

Check air filter and air flow

Air-cooling system obstructed Verify that air inlet and air outlet

are not obstructed with objects

Clean air filter

E04

- . . . . - . . . .

Overheated cooking zone Let unit cool down

Check air filter and air flow

E05

-. . . . .-. . . . .-

Error on power switch Contact service agent

E06

- . . . . . . - . . . . . .

Overheated electronic Let unit cool down

Check air filter and air flow

Ambient temperature too high

(the cooling system is not able to

keep the cooker in normal

operating conditions)

Verify that no hot air is sucked in

by the fan

Reduce the ambient temperature,

the air inlet temperature must be

lower than 40ºC/110ºF

E07

- . . . . . . . - . . . . . . .

Empty cooked pan Switch the unit off to reset the

empty cooking detector

E08

- . . . . . . . . - . . . . . . . .

Error on sensing element Contact service agent

Order of error message: The indicator lamp flashes for an interval of 0,6 sec. The number of

the following short flashes has to be counted and informs about the kind of error

corresponding to the above mentioned code system.

The code will repeat until the error is cancelled.

Page 18

-18-

090908_Instructions for use RTCS Base- and Wok-Li ne_ E.d oc

8.2 Fault finding without error code

Fault Possible Cause Action to take

No heating

Indicator operation

is OFF (dark)

No mains supply Check the electrical supply (cable

plugged onto the wall socket)

Check preliminary fuses

Control knob is in OFFposition

Turn control knob ON

Cooker is defective Unplug the unit from the electrical

supply and contact your service

partner

No heating

Indicator operation

is flashing

(If an error code is

flashing see section

„Fault finding” with

error code)

Pan is too small (bottom

diameter less than 12 cm,

only BH/IN and SH/IN)

Use a suitable pan

Pan is not placed in the

center of the heating area

(the cooker cannot detect the

pan)

Move the pan to the center of the

heating area

Unsuitable pan Choose a pan recommended for

induction cooking 1)

Cooker defective Unplug the unit from the electrical

supply and contact your service

partner

Poor heating

Indicator operation

is ON (shining)

Used pan is not appropriate Use a pan recommended for induction

cooking and compare the result with

„your“ pan

Air-cooling system

obstructed

Verify that air inlet and air outlet are

not obstructed with objects

Ambient temperature is too

high (the cooling system is

not able to keep the cooker in

normal operating conditions

2)

Verify that no hot air is sucked in by

the fan

Reduce the ambient temperature. The

air inlet temperature must be lower

than 40ºC/110ºF

One phase is missing (only

units with three phase

supply)

Check preliminary fuses

Cooker defective Unplug the unit from the electrical

supply and contact your service

partner

Page 19

-19-

090908_Instructions for use RTCS Base- and Wok-Li ne_ E.d oc

Fault Possible Cause Action to take

No reaction to

control knob

positions

Control knob defective Unplug the unit from the electrical

supply and contact your service

partner

Heating cycle

switches off and on

Within minutes, fan

is active

Air inlet or outlet obstructed Remove objects from air inlet and air

outlet slots, clean the slots

Fan dirty Clean fan

Heating cycle

switches off and on

Within minutes, fan

is never active

Fan defective Ask your supplier for repair service

Fan control defective

After a long

permanent

operating time, the

heating switches off

and on within

minutes

Coil overheated, cooking

area too hot

Switch cooker off, remove pan and

wait until the cooking area has cooled

off

Empty pan

Pan with overheated oil

Small metallic

objects (e.g. spoon)

are heated up on the

cooking area

Pan detection circuit is

defective

Ask your supplier for repair service

1)

To verify, if the pan is suitable, use a permanent magnet and find out if it sticks on the

bottom of the pan. If not, your pan is not suitable for induction cooking. Choose a pan

which is recommended for induction cooking. Choose pan material suitable for induction

units.

2)

The cooling-system (fan) starts to operate when the ambient temperature in the control area

exceeds 55ºC/130ºF. At heat temperatures higher than 70ºC/160ºF the controller

automatically reduces the power to keep the unit in normal operating conditions. The

cooker runs in a non continuous mode. This mode can be heard.

Page 20

-20-

090908_Instructions for use RTCS Base- and Wok-Li ne_ E.d oc

9 Cleaning

List with common types of soiling and recommendations how to treat them:

Type of soiling Treatment

Slight soiling, no burned residues Wipe with a moist cloth (scotch), without cleaning agent

Fatty spots

(sauces, soups, ...)

Polychrom

Sigolin chrom, Inox cream

Vif Super cleaner

Supernettoyant, Sida, Wiener Klak

Pudol System

Lime deposits, caused by water

which has boiled over

Polychrom

Sigonlin chrome, Inopx cream

Vif Supercleaner

Supernettoyant

Strong glimmering metallic

colour changes

Polychrom

Sigolin chrom

Mechanic cleaning

Razor blade

Non-scratching sponge

Grease filter

Clean this filter once a week by putting it in the

dishwasher

Sugar, sugar containing food,

plastic, aluminum foil

Immediately scrape off the sugar, plastic or aluminum

foil residues thoroughly from the hot cooking area, e.g.

with a razor blade.

After removal of the residues, clean it with a cleaning

agent.

If the heating area soiled with residues of sugar, plastic or

aluminum foil cools down without prior cleaning, the

ceramic surface might become deformed by pinheadsized pits.

The cleaning of the Ceran glass is identical to other similar surfaces like glass. Do not use

corrosive or abrasive cleaning agents, such as grill- and oven-sprays, stain- and rust-removers,

scouring powder and rough sponges.

Before being cleaned, the Ceran glass must be cooled down.

Other maintenance and servicing work other than cleaning as described here, must be done by

authorized service personnel.

Make sure that no liquid can enter in the induction unit.

Page 21

-21-

090908_Instructions for use RTCS Base- and Wok-Li ne_ E.d oc

10 Support

A good maintenance of the induction cooker requires a regular cleaning, care and servicing.

The operator has to ensure, that all components relevant for safety are in perfect working

order at all times.

The cooker should be examined at least once a year by an authorized technician.

CAUTION

Do not open the induction unit, dangerous

electric voltage inside.

The cookers may only be opened by authorized personnel.

Page 22

-22-

090908_Instructions for use RTCS Base- and Wok-Li ne_ E.d oc

11 Waste disposal concept

The symbol on the product or on its packaging indicates that this product may not be

treated as household waste. Instead it shall be handed over to the applicable collection point

for the recycling of electrical and electronic equipment. By ensuring this product is disposed

of correctly, you will help prevent potential negative consequences for the environment and

human health, which could otherwise be caused by inappropriate waste handling of this

product. For more detailed information about recycling of this product, please contact your

local city office, your household waste disposal service or the shop where you purchased the

product.

When the life cycle of the cooker ends, make sure that you dispose it correctly.

Avoid abuse:

The cooker may not be used by any person not having the appropriate qualifications. Avoid

that the cooker, provided for disposal, can be brought back into operation.

The cooker is built up with common electrical, electromechanical and electronic parts. No

batteries are used.

The operator is responsible for a proper and safe disposal of the cooker.

Loading...

Loading...