Page 1

INSTALLATION AND

AIR

PAC

OPERATION MANUAL

MODELS AP1, APA & AP4

ELECTRIC DECK OVEN OVENS

FOR YOUR SAFETY:

DO NOT STORE OR USE GASOLINE

OR OTHER FLAMMABLE VAPORS OR

LIQUIDS IN THE VICINITY OF

THIS OR ANY OTHER

APPLIANCE

Includes counter top and four compartment ovens

PLEASE READ ALL SECTIONS OF THIS MANUAL

AND RETAIN FOR FUTURE REFERENCE.

THIS PRODUCT HAS BEEN CERTIFIED AS

COMMERCIAL COOKING EQUIPMENT AND

MUST BE INSTALLED BY PROFESSIONAL

PERSONNEL AS SPECIFIED.

WARNING:

IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE

CAN CAUSE PROPERTY DAMAGE, INJURY,

OR DEATH. READ THE INSTALLATION,

OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR

SERVICING THIS EQUIPMENT

INSTALLATION AND ELECTRICAL CONNECTION

MUST COMPLY WITH CURRENT CODES:

IN CANADA - THE CANADIAN ELECTRICAL

CODE PART 1 AND / OR LOCAL CODES.

IN USA – THE NATIONAL ELECTRICAL CODE

ANSI / NFPA – CURRENT EDITION.

ENSURE ELECTRICAL SUPPLY CONFORMS WITH

ELECTRICAL CHARACTERISTICS SHOWN ON

THE RATING PLATE.

Users are cautioned that maintenance and repairs must be performed by a Garland authorized service agent

using genuine Garland replacement parts. Garland will have no obligation with respect to any product that has been

improperly installed, adjusted, operated or not maintained in accordance with national and local codes or installation

instructions provided with the product, or any product that has its serial number defaced, obliterated or removed,

or which has been modified or repaired using unauthorized parts or by unauthorized service agents.

For a list of authorized service agents, please refer to the Garland web site at http://www.garland-group.com.

The information contained herein, (including design and parts specifications), may be superseded and is subject

to change without notice.

GARLAND COMMERCIAL INDUSTRIES

185 East South Street

Freeland, Pennsylvania 18224

Phone: (570) 636-1000

Fax: (570) 636-3903

GARLAND COMMERCIAL RANGES, LTD.

1177 Kamato Road, Mississauga, Ontario L4W 1X4

CANADA

Phone: 905-624-0260

Fax: 905-624-5669

Enodis UK LTD.

Swallow eld Way, Hayes, Middlesex UB3 1DQ ENGLAND

Telephone: 081-561-0433

Fax: 081-848-0041

Part # 1382636 Rev 05 (01/25/08) © 2004 Garland Commercial Industries, Inc.

Part # 1382636 Rev 5 (01/25/08) Page 1

Page 2

IMPORTANT INFORMATION

WARNING:

This product contains chemicals known to the state of california to cause cancer and/or birth defects

or other reproductive harm. Installation and servicing of this product could expose you to airborne

particles of glass wool/ceramic fibers. Inhalation of airborne particles of glass wool/ceramic fibers

is known to the state of California to cause cancer.

Part # 1382636 Rev 5 (01/25/08)Page 2

Page 3

TABLE OF CONTENTS

IMPORTANT INFORMATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

DIMENSIONS AND SPECIFICATIONS, MODELS AP1 & AP-A . . . . . . . . . . . . . 4

DIMENSIONS AND SPECIFICATIONS, MODEL AP4. . . . . . . . . . . . . . . . . . . . . . 5

INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Rating Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Installation for Ovens Equipped with Legs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Installation for Ovens Equipped with Casters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Stacking Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

OPERATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Break-In Period . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Start Up Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

CONCEPT OF AIR IMPINGEMENT COOKING . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

COOKING CHART . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Part # 1382636 Rev 5 (01/25/08) Page 3

Page 4

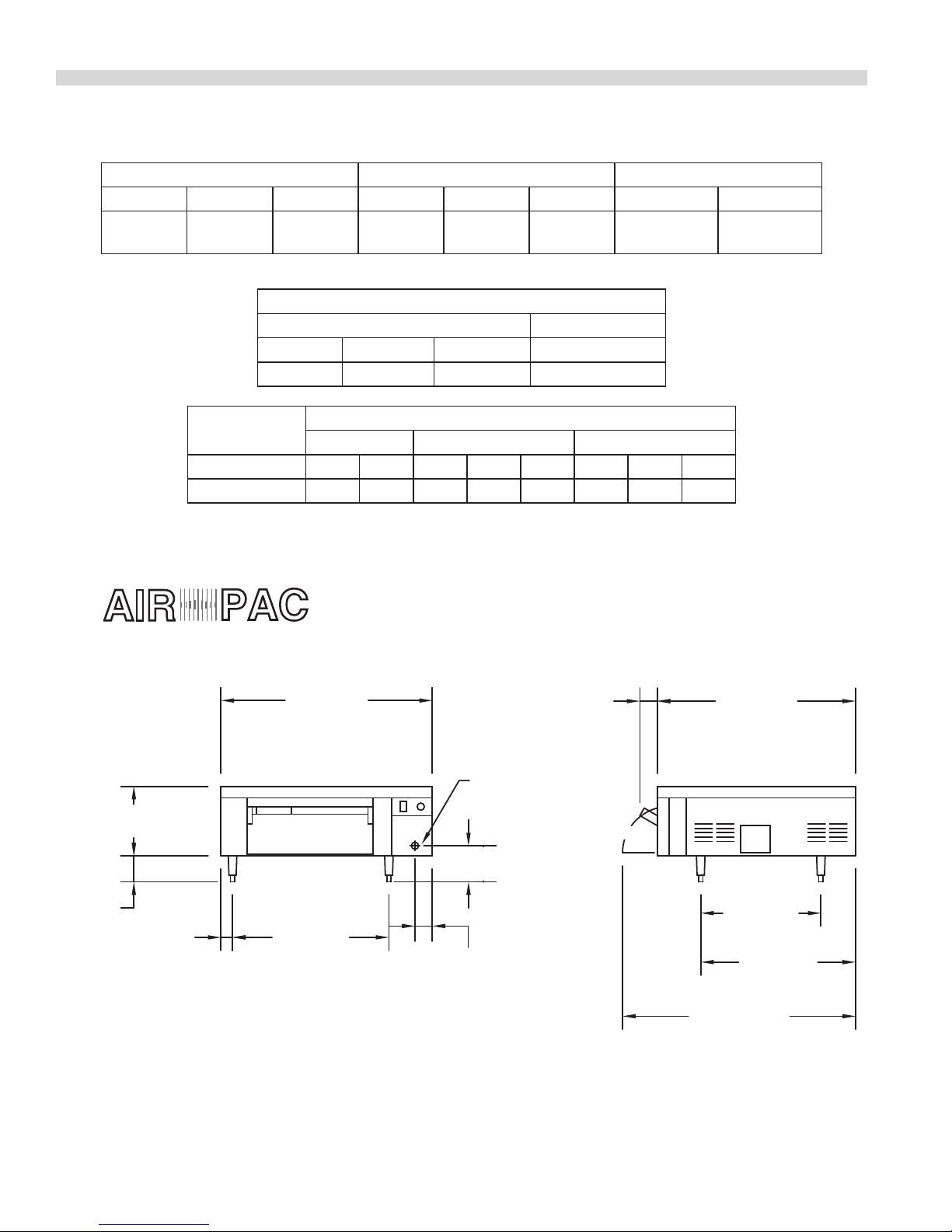

DIMENSIONS AND SPECIFICATIONS, MODELS AP1 & AP-A

36-1/2"

[927mm]

27"

[686mm]

2"

[51mm]

34-1/4"

[870mm]

3"

[76mm]

20-3/4"

[527mm]

26-3/4"

[679mm]

40-1/4"

[1022mm]

DOOR OPEN

3"

[76mm]

12"

[305mm]

REAR

CABLE

ENTRANCE

4-1/2"

[114mm]

6-1/4"

[159mm]

AIR

PAC

Oven Interior Dimensions* Exterior Dimensions Shipping Weight Lbs./Kg

Width Height Depth Width Height Depth Crated Uncrated

19-1/4”

(489mm)

4-3/4”

(121mm)

*With rack in place Two xed rack positions: 1-1/8” (28mm) and 1-5/8”(41mm)

17-3/4”

(451mm)

Combustible Wall Clearance Entry Clearance

Left Right Rear Crated

0” (0mm) 6” (152mm) 6” (152mm) 32” (813mm)

36-1/2”

(927mm)

Instillation Notes

16-1/2”

(419mm)

34-1/4”

(870mm)

230/104 140/64

Electrical

Requirements

Total kW 208V 240V X Y Z X Y Z

5.2 25 21.7 17 10 17 15 9 15

208 VAC = 197 VAC to 219 VAC 240 VAC = 220 VAC to 252 VAC

Single Phase 208V/3 Phase 240V/3 Phase

Nominal Amperes Per Line

Part # 1382636 Rev 5 (01/25/08)Page 4

Page 5

DIMENSIONS AND SPECIFICATIONS, MODEL AP4

36-1/2"

[927mm]

3"

[76mm]

34-1/4"

[870mm]

20-1/4"

[514mm]

DECK

30-1/4"

[768mm]

DECK

40-1/4"

[1022mm]

DECK

50-1/4"

DECK

6"

[152mm]

7-1/2"

[191mm]

7"

[178mm]

40"

[1016mm]

16-1/4"

[413mm]

2"

[51mm]

6-1/2"

[165mm]

OPEN SHELF

AREA

ADJUSTABLE

CASTERS

28"

[711mm]

REAR

CABLE

ENTRANCE

10.4KW

EACH

3"

[76mm]

REAR CABLE

ENTRANCE

TO RANGE

64-1/4"

[1632mm]

TO

65-3/4"

RANGE

10"

[254mm]

AIR

PAC

Oven Interior Dimensions* Exterior Dimensions Shipping Wt. Lbs./Kg

Width Height Depth Width Height Depth Crated Uncrated

19-1/4”

(489mm)

4-3/4”

(121mm)

17-3/4”

(451mm)

36-1/2”

(927mm)

64-3/4” to 66”

(1145mm) to (1676mm)

34-1/4”

(870mm)

*With rack in place Two xed rack positions: 1-1/8” (28mm) and 1-5/8”(41mm)

Installation Notes

Combustible Wall Clearance Entry Clearance

Left Right Rear Crated Uncrated

0” (0mm) 6” (152mm) 6” (152mm) 44” (1118mm) 35" (889mm)

800/363 650/295

Electrical

Requirements

kW Loading

208V/240V

208V 240V

L1 L2 L3 L1 L2 L3

Three Phase Nominal Amps Per Line

Two Circuits

Per Two Decks

20.8 Total

10.4 (per 2 Decks)

34 19.6 34 29.4 17 29.4

** Canada - 1 Circuit Only 20.8 Total (per 4 Decks) 68 39.2 68 58.8 34 58.8

** - Per CEC Part 1 2006, 26-744

Part # 1382636 Rev 5 (01/25/08) Page 5

Page 6

INTRODUCTION

Periodic inspections by your dealer or a qualied service

agency are recommended.

We suggest installation, maintenance and repairs should be

performed by your local authorized service agency listed

in your information manual pamphlet, or you may call the

factory at 1-800-424-2411.

INSTALLATION

Clearances

The clearance from combustibles on the AP1 & AP4 is six (6”)

inches, (152mm) on the right and rear side and zero (0”) on

the left. It is recommended that there be six (6”) (152 mm) of

clearance on the right side for fuse panel access.

Location

Proper placement of the oven will ensure operator and

satisfactory performance. Adequate clearance must be

provided for servicing, ventilation (if applicable), and

proper operation. The oven must be kept free and clear of

combustible material.

WARNING Control components may experience reduced

life if exposed to high temperatures. We recommend not

exposing control areas to temperatures above 140 degrees

Fahrenheit for a continuous period of time. For this reason,

care must be taken on installation to allow air ow around

units, especially when placed near other heat producing

sources. We recommend 6” (152 mm) spacing to the control

side of oven from other heat producing sources.

Installation for Ovens Equipped with Legs

Rating Plate

When corresponding with the factory or your local

authorized factory service center regarding service problems

or replacement parts, be sure to refer to the particular unit

by the correct model number (including the prex and sux

letters and numbers) and the warranty serial number. The

rating plate axed to the unit contains this information.

Installation for Ovens Equipped with Casters

It is recommended that in the use of casters a strain relief be

installed on the appliance. This will prevent any excess strain

on the terminal connection if the appliance is rolled out for

cleaning or servicing.

The front casters of the unit are equipped with brakes to

limit the movement of the oven without depending on the

connector and any quick disconnect device or its associated

wiring to limit the appliance movement.

Please be aware, there is a restraint on the unit and if

disconnection of the restraint is necessary, be sure to

reconnect the restraint after the oven has been returned to

its originally installed position.

Stacking Instructions

To Stack APA on top of an AP1 Unit

WARNING The maximum number of units to be stacked is

two additional units on top of the single base unit.

WARNING DISCONNECT ALL WIRING AND PLUGS FROM

ELECTRICAL SOURCE.

The AP1 counter unit is shipped with four (4) legs. This unit

is stackable up to three (3) units. The AP1 is considered the

base appliance and the APA is the stacking appliance.

WARNING: The base of counter appliance must be installed

with minimum 4” legs. The base appliance needs air

ow from the bottom for proper operation and is a NSF

requirement.

CAUTION: DO NOT LAY UNIT ON SIDES OR TOP.

Items required to complete stacking procedure:

1 – AP1 oven with top and legs.

1 or 2 APA ovens without top and legs.

Phillips screwdriver

7/16” open end wrench.

Part # 1382636 Rev 5 (01/25/08)Page 6

Page 7

OFF

Garland

1

2

3

8

9

7

4

5

6

INSTALLATION Continued

Assembly Instructions

1. Remove the back covers #5 from all units.

2. Remove the side panel #4 and the panel from the control

box #1.

3. Remove the front covers #3 and #2 from all units. The

door must be opened to remove these screws.

4. The top should lift o of the base unit. Set the top aside.

10. Do the same to the adjoining bottom bolt of the top unit.

11. Attach the stacking ange between the two loosened

bolts.

12. Repeat this process for an additional unit if desired.

13. Setting top #6 on the top unit.

14. Attach all side and rear panels, all front covers.

Ventilation

WARNING Do not place any obstruction on the top of the

appliances’ vent hold. Inadequate ventilation may result in

high ambient temperature at the rear of the oven. Excessive

ambient temperature can cause tripping of the blower motor

thermal overload protection device. This condition must be

corrected immediately to avoid damage to the blower motor.

Electrical Connections

The AP1, APA and AP4 are not supplied with any type of

cord and plug. Before attempting the electrical connection,

the rating plate should be checked to ensure that the

unit’s electrical characteristics and the supply electrical

characteristics agree.

Installation of the wiring must be made in accordance

with the applicable codes: National Electrical Code (for

US Installations), and Canadian Electrical Code Part 1 (for

Canadian Installations). For Canadian Installations, cooking

appliances shall have only one point of connection for power

supply.

5. Place the rst AP-A unit to be stacked on top the base

unit.

6. Loosen the top left and top right hex head bolt of the

base unit front frame #8. Do not remove.

7. Loosen the bottom left and bottom right hex head

bolt used to attach the front frame #8 of the unit to be

stacked.

8. Find two pieces of the stacking ange #7. Insert the

ange behind the head of each loosened bolt so as the

ange will join the two units together. The ange of the

stacking ange should point to the rear of the units.

9. Loosen the top hex head bolt used to attach the left rear

side panel mount #9 to the oven.

Part # 1382636 Rev 5 (01/25/08) Page 7

1. Switch panel size.

2. Overload protection.

3. Wire type.

4. Wire size.

5. Temperature limitations of the wires.

6. Method of connection (Cable, Conduit, etc.)

The service line enters through the rear of the unit and is to

be connected to the terminal block. Refer to wiring diagram

provided on the rear of the unit. Input voltage and phasing

must match the units voltage and phasing. Visual check all

electrical connections. Energize electric service to units.

Page 8

OPERATION

NOTE: Disconnect line cord from power supply before

cleaning or servicing.

Break-In Period

When oven is new, operate it for one hour at 450 degrees

before you begin your normal cooking operation. After

cooling, wipe the interior, including the racks, with a clean

damp cloth.

Start Up Procedure

After the appliance has been properly installed and a start up

performance check has been performed you are now ready

to start up the oven.

1. Inspect the oven interior for packing material.

2. Activate power switch (A) to “ON” position.

To Adjust Oven Temperature Set Point - Press “Up” arrow.

The top display will show “SP”, followed by current set point

temperature (blinks). Press “Up” or “Down” arrows to adjust

desired oven temperature. The display will return to actual

oven temperature after 2 seconds.

Timer Setting and Preset Adjustment – The timer display

will be blank when Timer is O. Press “Down” arrow once. “t1”

will display followed by ashing time setting (minutes). Press

“Up” or “Down” arrow to adjust to desired time. This time will

be saved as “t1”, which will be the preset. The display will go

blank after 5 seconds.

To Start Timer – Press the Timer Control button once to start

timer countdown. The timer will automatically start at the

Preset time. Press the Timer Control to turn timer o.

Temporary Timer Adjustment – If the timer setting is

altered while the timer is running, this setting will only apply

to the current cycle until the timer has run down. Preset “t1”

will not be aected.

Independent Top Burner Adjustment – Adjustment of

the top oven elements can be made by adjusting the dial

adjacent to the Oven Temperature Control. Example: If you

want to increase bottom browning you would reduce top

heat by turning dial to low (1), (1 – low, 6 – high). This will

not aect internal oven temperature.

At the end of the timed cycle, an audible buzzer will sound

for 3 seconds. NOTE: The timer only serves as a signal

function and does not control heating elements or oven

temperature in any way.

LED Indicators:

K1 - Yellow; indicates heating elements are on

K2 - Green; illuminated when timer is running

K3 - Red; illuminated when audible buzzer is on

Error Message Display:

If there is a fault with the oven temperature sensor, the

Temperature Display on the controller will indicate “199”

(ashing), and the audible buzzer may sound continuously.

Heating elements will be automatically disabled (by factory

default setting). Turn the appliance o and contact a service

person for further assistance.

Part # 1382636 Rev 5 (01/25/08)Page 8

Page 9

OPERATION Continued

K1 K2 K3

Timer Display

LED Indicators

Oven Temperature Controller

Oven

Temperature.

Set Point

Timer Control

CONCEPT OF AIR IMPINGEMENT COOKING

The “Air Pac” Oven produced by GARLAND COMMERCIAL

INDUSTRIES, INC., utilizes a revolutionary cooking concept,

called “AIR IMPINGEMENT”. It provides exceptional baked

food product quality in far less time than conventional

devices on the market. The “AIR IMPINGEMENT” system

directs a high velocity stream of heated air at the food

product being baked. This blast eect penetrates the

boundary layer of air encircling the product and heats the

food more eciently, because the air concentrates heat on

the food product. Greater heat transfer rates, which results in

products baking two to four times faster than conventional

means, are possible with “AIR IMPINGEMENT”.

The “AIR IMPINGEMENT” process develops the high velocity

air stream with a specially designed fan that draws superheated air from a heat source (electric elements). This air

is directed through a plenum chamber to patented “JET

PLATES” which have hundreds of focused jet ports that

“impinge” the heated air onto the food product surface. The

heated air is re-cycled to the heat source after striking the

food product, thus reducing energy consumption.

The “AIR IMPINGEMENT” process is tolerant enough for

sensitive food products and eects proper crisping and even

browning of such products as they pass through the oven,

because air is the medium which heats the food product.

Increase Value

Decrease Value

Part # 1382636 Rev 5 (01/25/08) Page 9

The “Air Pac” oven is supplied with one (1) wire rack that

has two positions. The optional rack that is a “Perf Rack”

that gives you the “ON THE DECK” type of baking. The two

position rack is used with the variable top heat control.

Page 10

COOKING CHART

Time and Temperature will vary depending upon load size and temperature, mixture and density or product. Use this guide to

develop your own cooking charts.

Italian Entrees

Product Temp. Time Load volume

Cheese Pizza 14” Par Baked Crust 525 5:10 1 Pizza Middle Baked on Pan

2 Topping Pizza Par Baked Crust 525 5:15 1 Pizza Middle Baked on Pan

3 Topping Pizza Deluxe, Multiple Toppings 525 5:30 1 Pizza Middle Baked on Pan

Cheese/Pepperoni 12” Pan 635 2:45 1 Pizza Middle Baked on Wire Rack

Sausage Deluxe 12” Pizza 635 2:55 1 Pizza Middle Baked on Wire Rack

Pepperoni 6” Pizza 635 2:45 2 Pizza Middle Baked on Wire Rack

Pepperoni 6” Pizza 635 2:45 3 Pizza Middle Baked on Wire Rack

16” Fresh Dough Pizza 475 7:30 1 Pizza Middle In Pan

16” Fresh Dough Pizza 475 6:30 1 Pizza Middle On Deck

16” Fresh Dough Pizza 475 7:00 1 Pizza Middle On Screen

12” Fresh Dough Pizza 525 5:30 1 Pizza Middle Baked on Pan

12” Fresh dough Pizza 525 5:30 1 Pizza Middle Fine Mesh Screen

12” Fresh dough Pizza 525 5:00 1 Pizza Middle On Deck

Lasagna 3 lbs. 550 15-17 min. 6x9 Pan Top Refrigerated Load Temp.

Stromboli 475 7-10 min. 13x18 pan Middle On Screen /Pan

Calzone 475 7-10 min. 2 Pieces Middle On Fine Mesh

Frozen Ravioli – (6) 400 18:00 6 Pieces Middle In Pan

Rack

Pos.

Comments

Meats and Poultry

Chicken Nuggets .5 oz 400 18 min. 3 Dozen Top Open Mesh Screen

Fresh Chicken (Breaded) 2-3 oz. llet 450 10 min 12-15 Top Open Mesh Screen

Frozen Chicken(Pre Breaded) .5 – 1 oz. 500 9 min. 18-24 Top Open Mesh Screen

Chicken Breast – 2 lbs. 400 25 min. One Middle Open Mesh Screen

Hot Dogs Wrapped in Crescent Rolls 375 7-8 min. 10 Top Baked on Pan

Seafood Entrees

Frozen Fish Sticks (Breaded) .4 oz 375 7 min. 4 Dozen Top Open Mesh Screen

Lobster Tail 550 3-5 min. 6 Middle Sautéed Dish/ Frozen

Lobster Scampi 550 3-5 min. 24/4 Servings Middle Sautéed Dish/ Frozen

Sautéed Scallops 550 3-5 min. 6 Servings Middle Sautéed Dish/ Frozen

Part # 1382636 Rev 5 (01/25/08)Page 10

Page 11

COOKING CHART Continued

Baked Potatoes & Rice

Product Temp Time Load Volume

Baked Potatoes 6 – 6 ½ oz. 400 35 min 20 Count Middle On Wire Rack

Baked Potatoes 6 – 6 ½ oz. 400 35 min. 10 Count Middle On Wire Rack

Baked Potatoes 8 lbs. of 16 oz. 400 45 min. 10 Count Middle On Wire Rack

Long Grain Rice 400 17 min.

1 Cup Rice,

2 Cups Water

Rack

Pos

Middle 2” Deep Pan

Comments

Baked Goods

Breadsticks 375 8 min. 8 Count Middle 13 x 18 Sheet Pan

Fresh Buttermilk Biscuits 400 14-15 min. 14-16 count Top 13 x 18 Sheet Pan

Biscuits Frozen Ready Bake 425 17 min. 16 Count Middle 13 x 18 Sheet Pan

White Cake Dry Mix 325 20 mi. 3 Pounds Middle 13 x 18 Sheet Pan

Cornbread 325 8-10 min. Middle 4x8 Pan

Chocolate Chip Cookies 1 oz. 325 12-Nov 18 Count Middle 13x18 Pan /Frozen

Sugar Cookies 1 oz. 325 11-12 min. 18 Count Middle 13x18 Pan /Frozen

Oatmeal Chip Cookies 350 11 min. 18 Count Middle 13x18 Pan /Frozen

Plain Muns 2.5 oz. 325 8-9 min. 12 count Middle In Liner Cup

Apple Cinnamon Muns 3 oz. 2-3/4 dia. 400 9 min. 12 Count Middle Heavy Wall Pan

Blueberry Muns 400 10-11 min. 12 count Middle Heavy Wall Pan

Banana Nut Muns 2.5 oz. 3-1/2 dia. 400 10-11 min. 12 Count Middle Heavy Wall Pan

Frozen Apple Pie 40 oz 375 30-35 min. Middle Frozen

Frozen Cherry Pie 46 oz.. 375 30-35 min. Middle Frozen

Cinnamon Sweet Reg. Roll 375 7 min. 8 Count Top 9” Round Pan

Dinner Rolls 400 4-5 min. 24 count Top 13x18 Sheet Pan

Crescent Rolls Reg. 375 6-7 min. Top 13x18 Sheet Pan

Part # 1382636 Rev 5 (01/25/08) Page 11

Page 12

Loading...

Loading...