Garelick 75082 User Manual

Assembly and Installation Instructions for

Seat Slides

Form 12.213

ASSEMBLY INFORMATION

1. Read instructions completely before starting assembly.

NOTE: This product comes in two separate cartons. One

contains the seat cushions; the seat base is in the other.

ASSEMBLY INSTRUCTIONS

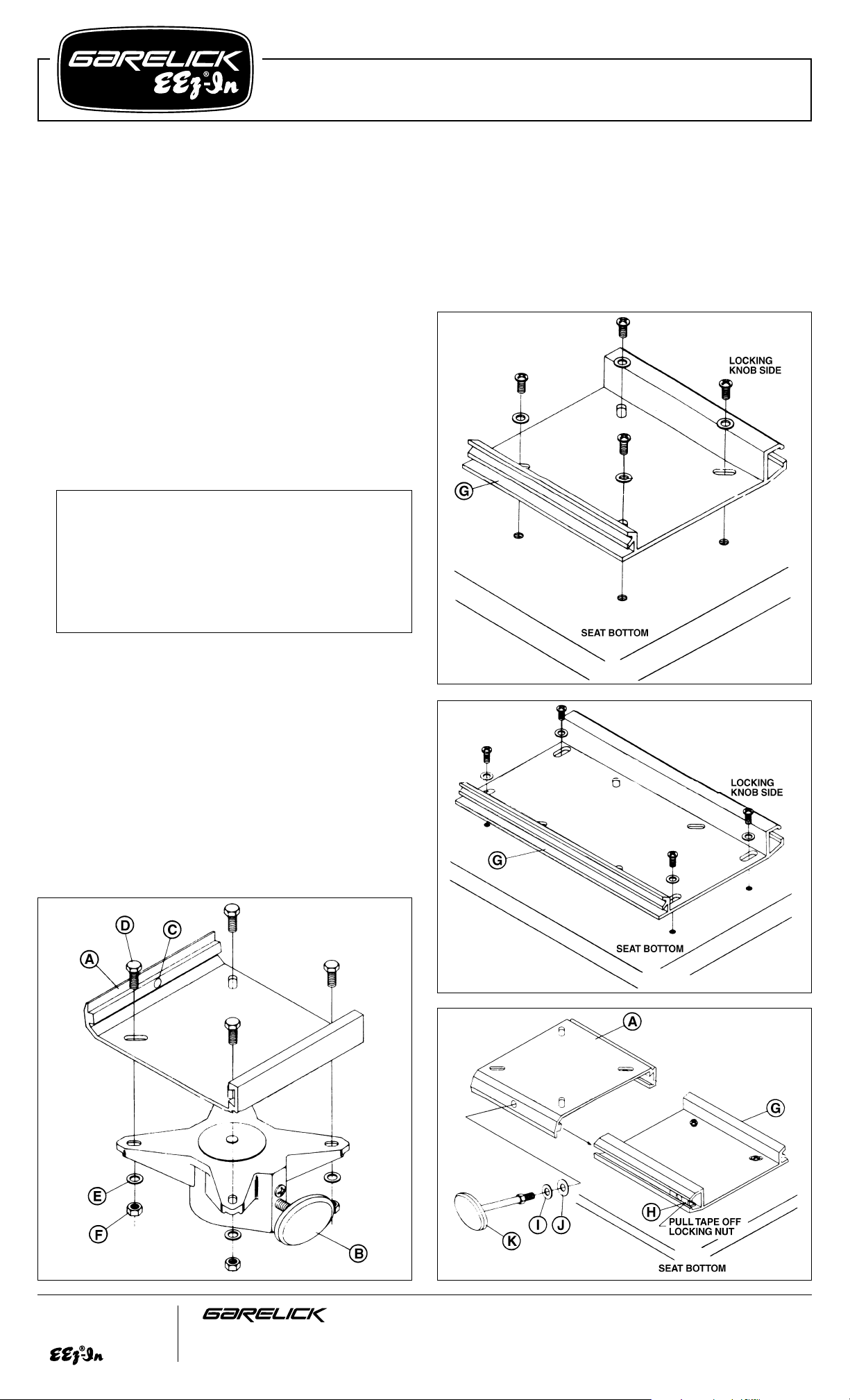

Refer to Fig. 1

1. Position your spider on the slideplate (A) so the spider’s

knob (B) will be opposite the locking hole (C).

2. Align the 4 slotted holes in both the spider casting and the

slideplate, insert screws (D) through the slideplate and the

spider casting. Secure in position with washers (E) and

locknuts (F).

Refer to Fig. 2A or 2B

1. Position the trackplate (B) on your seat’s bottom.

2. Align the holes in both the seat and trackplate. Secure the

trackplate to your seat with appropriate hardware.

NOTE: Fastener Suggestion is illustrated. Mounting

hardware is provided with some slide models.

NOTE: All EEZ-In seats use

1

⁄4"-20 threaded T-nuts.

SPECIAL NOTE: When attaching a slide to an EEZ-In

rotational molded seat:

A. Remove the reinforcement brackets from the seat

bottom prior to installation.

B. Make certain that the portion of the screw entering

the seat shell’s T-nut does not exceed 3/8". Seat

shell T-nuts are

1

⁄4"-20 thread. Use only 1⁄4"-20

machine screws.

Refer to Fig. 3

1. Pull the packing tape off the trackplate’s locking nut (H) and

align the holes in the nut and poly sleeve if necessary.

2. Slip the slideplate (A) onto the trackplate (G) as shown.

3. Align the holes in the locking nut and sideplate. Slip the

stainless steel washers (I) and the poly washer (J) onto the

locking knob (K). Insert the locking knob into the slide

plate’s hole and thread it into the locking nut. Secure the

slide in position.

FIG. 1

FIG. 3

FIG. 2B

Write for

a Complete

Catalog

Phone: 651-459-9795

PO Box 8, 644 2nd Street E-mail: mail@garelick.com

St. Paul Park, Minnesota 55071 On the Web: www.garelick.com

12/01

TO OPERATE

Loosen the locking handle and slide your chair to the desired

position. Tighten the handle to secure the slide in place.

CARE AND MAINTENANCE

1. Periodically check all fasteners to insure that they are

secure.

2. If necessary, lubricate your slide and spider with a suitable

marine grade grease for longevity and smooth operation.

FIG. 2A

Loading...

Loading...