Garelick 74003 User Manual

Assembly and Installation Instructions for

Tandem Seat Slide Models 74001, 74002, 74003

Form 12.507

ASSEMBLY INFORMATION

Read instructions thoroughly before starting assembly and

installation.

Because of the wide variety of possible installations, mounting

hardware is not supplied. Recommended fasteners should be

#14 or #16 stainless steel wood screws long enough to

penetrate approximately 3/4 to 7/8 of the thickness of the

seat substrate but not long enough to protrude through it as

they may cause injury if sat upon.

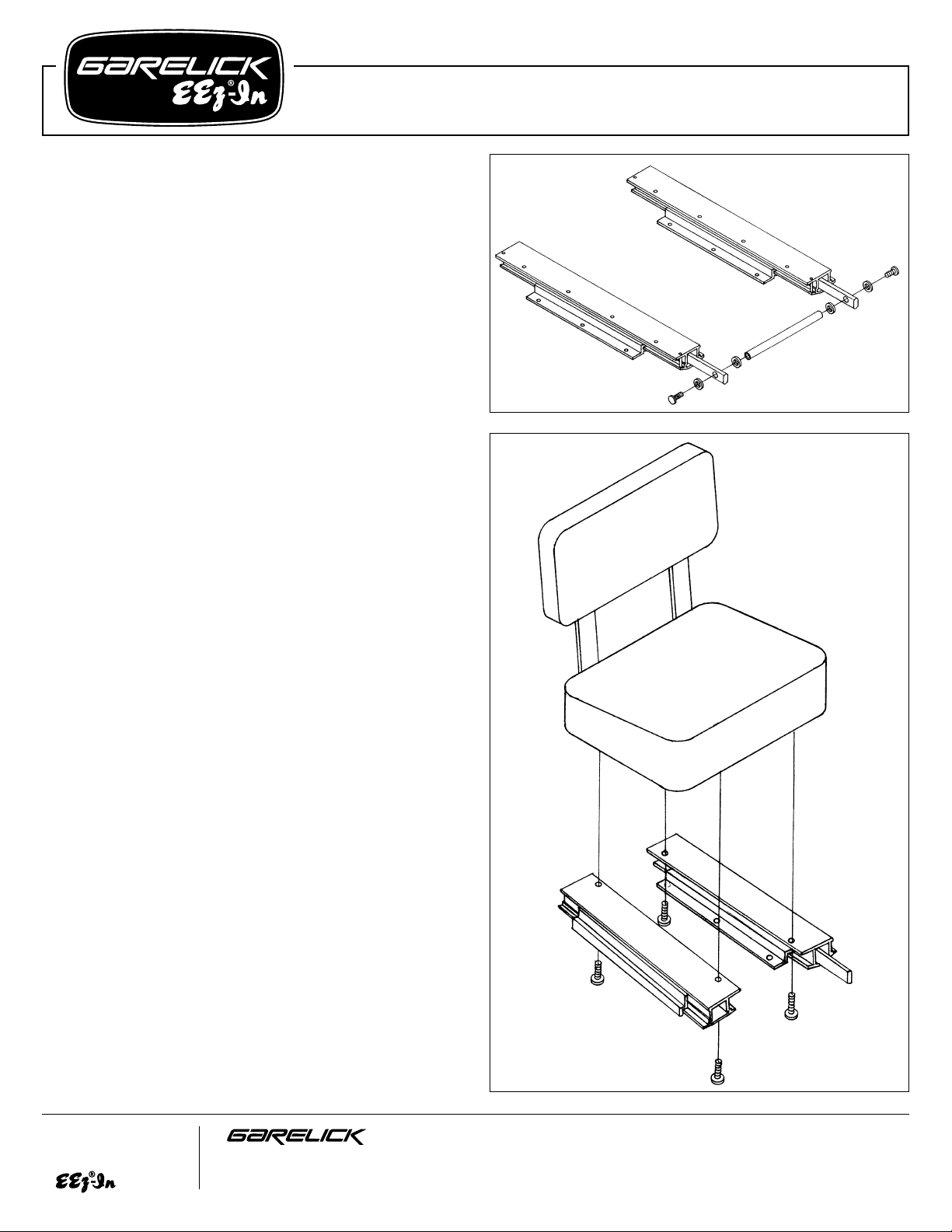

ASSEMBLY INSTRUCTIONS FOR 74001

Refer to Fig. 1

1. Remove slide rails and cross bar from packaging. Remove

1 screw from each end of the cross bar.

2. Install the cross bar between the release handles of the

slide rails by placing one rubber washer on both sides of

each handle, aligning the holes and inserting a screw to

fasten into the ends of the cross bar. Do not over tighten as

the rubber must flex to allow for movement of the cross

bar.

ASSEMBLY INSTRUCTIONS FOR 74001, 74002, 74003

Refer to Fig. 2 and Fig. 3.

1. Turn the seat upside down to expose the seat bottom; center

seat slide rails left-to-right and front-to-back. For models

74002 and 74003 determine which side is preferred for

the release handle and then set the rails approximately 4"

in from each side of the seat. Use a tape measure to assure

that the rails are parallel to each other. This is critical to the

operation of the sliding action. Mark 3 or 4 holes in each

rail, depending on model of unit being installed, onto the

seat bottom.

2. Drill 6 or 8 pilot holes, depending on model of unit being

installed, of suitable size for the screws to be used. Fasten

rails to seat bottom finger tight. Measure between the rails

front and back to assure the rails are parallel before final

tightening of the screws. Record this measurement for

later reference.

3. Set the slide adjustment to the middle setting so there is

equal upper slide extrusion extending from either end of

the lower slide extrusion. Turn the seat right side up.

4. Determine the desired location for mounting the seat. If the

surface is covered in carpeting, place a piece of cardboard

or poster board over the area and secure with tape.

Position the seat in the desired location, keeping in mind

the seat will slide approximately 3” fore and aft. Mark the

4 outside comers of the lower slide extrusions on the

cardboard. Remove the seat and turn it upside down.

(over)

Write for

a Complete

Catalog

Phone: 651-459-9795

PO Box 8, 644 2nd Street E-mail: mail@garelick.com

St. Paul Park, Minnesota 55071 On the Web: www.garelick.com

1/02

FIG. 2

FIG. 1

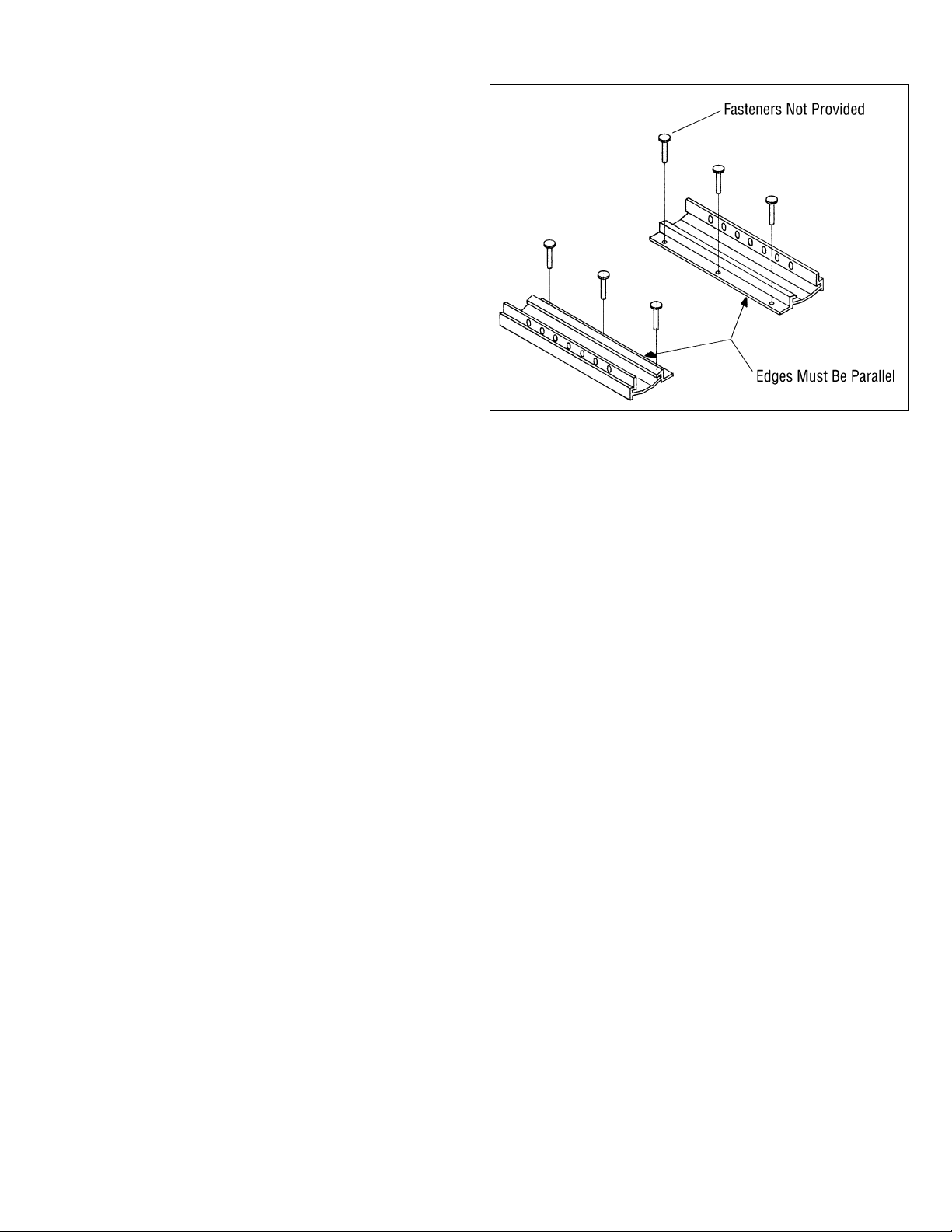

5. Make a mental note of which side of the lower slide

extrusion the mounting holes are on. Release the slide lock

handle and remove the lower slide extrusions by sliding

them in the direction opposite the release handle.

6. Place the lower slide extrusions within the 4 outside corner

marks on the cardboard, be sure the mounting holes are

on the correct side. Measure the distance between the rails

and confirm the dimension as the same measurement

recorded in step 2. Carefully mark the position of the 6

mounting holes so as not to move the rails out of position.

7. Drill 6 pilot holes of suitable size for the screws to be used.

Remove the cardboard or poster board and discard.

8. Fasten rails to the mounting surface. Continue checking the

rails for proper position using the measurement from step

2 before finishing tightening of screws. Remember, it is

critical that the rails remain parallel in order to slide. If

this instruction is not followed the slide will bind and not

slide freely.

9. Carefully line up seat and rails, slide seat into position from

front to back. The release handle will have to be in the

released position in order for full engagement of the rails.

10. Test the operation of the slide by sitting in the seat and

moving the release handle to the full left, push back with

your feet and the slide should move smoothly to the rear.

Pull forward and the slide should move forward. There

should be a slight resistance from the viscosity of the grease

but there should not be any binding. If the slide binds, then

the rails are improperly installed and need to be adjusted

as instructed in steps 6 through 8.

OPERATING INSTRUCTIONS

1. Sit in the seat with feet flat on the deck. Grasp slide lock

release handle and move it to the left until it stops. Push to

the rear with your feet and the slide will adjust to the rear.

Release the handle and the lock will automatically hunt for

the next stop position. There is a lock position every inch

for approximately 6" of adjustment. To adjust forward,

repeat the above procedure except to pull with your feet

and the slide will adjust forward. Release the handle and

the unit will find a stop position.

2. To maintain proper operation over time, it is recommended

that the slide rails and locking pin be lubricated

occasionally with a light grease. Lubricants have a

tendency to dissipate over time and as this happens the

slide will become difficult to operate. Use a light marine or

automotive grease and brush a thin coat on all

mating/sliding surfaces.

FIG. 3

Loading...

Loading...