Garelick 71092 User Manual

Operator Instructions for the

Auxilliary Hydraulic Outboard Motor Bracket

Model No: 71092

Form 12.575

READ ALL INSTRUCTIONS AND

WARNING LABELS

PRIORTO OPERATION

7 1/2 to 25 HP Rating

175 lb Motor Weight Limit

- WARNINGS -

Failure to observe these points could result

in personal injury or damage to bracket,

motor, and/or boat!

1. Do not exceed the stated H.P. rating or

weight

Mounting Instructions:

Note:

motor bracket is 14". This travel is based on

installation that is perpendicular to the water

surface. The travel will be different if placed on

a positive or negative angled transom. If the

transom is more than 10 degrees out of

perpendicular, it is recommended to fabricate

a wedge spacer out of suitable material such

as starboard, aluminum, or finished hardwood.

The wedged spacer must fit the mounting

brackets of the motor bracket completely.

! CAUTION !

could cause the hydraulic valve to draw air

during operation and thus prevent the assembly

from operating within normal parameters.

Step 1:

The motor bracket is shipped in the vertical

position. To complete installation, it is

necessary to activate the bracket to the full

down position. Please follow step 2 in the

"Lower Auxiliary Motor Bracket" section.

The approximate travel of the outboard

- Failure to follow these instructions

2. Make sure the motor clamps are tight

before use.

3. Use a safety cable when operating your

motor.

4. Remove the handle while underway.

5. Raise and tilt motor when not in use.

6. Use safety strap when motor is not in use.

7. Remove your motor from the bracket

when trailering.

8. Avoid abrupt maneuvers and/or sharp

turns.

9. Do not raise or lower bracket when motor

is running.

10. Avoid contact with moving parts.

11. Keep pivot bolts lubricated to insure

smooth operation.

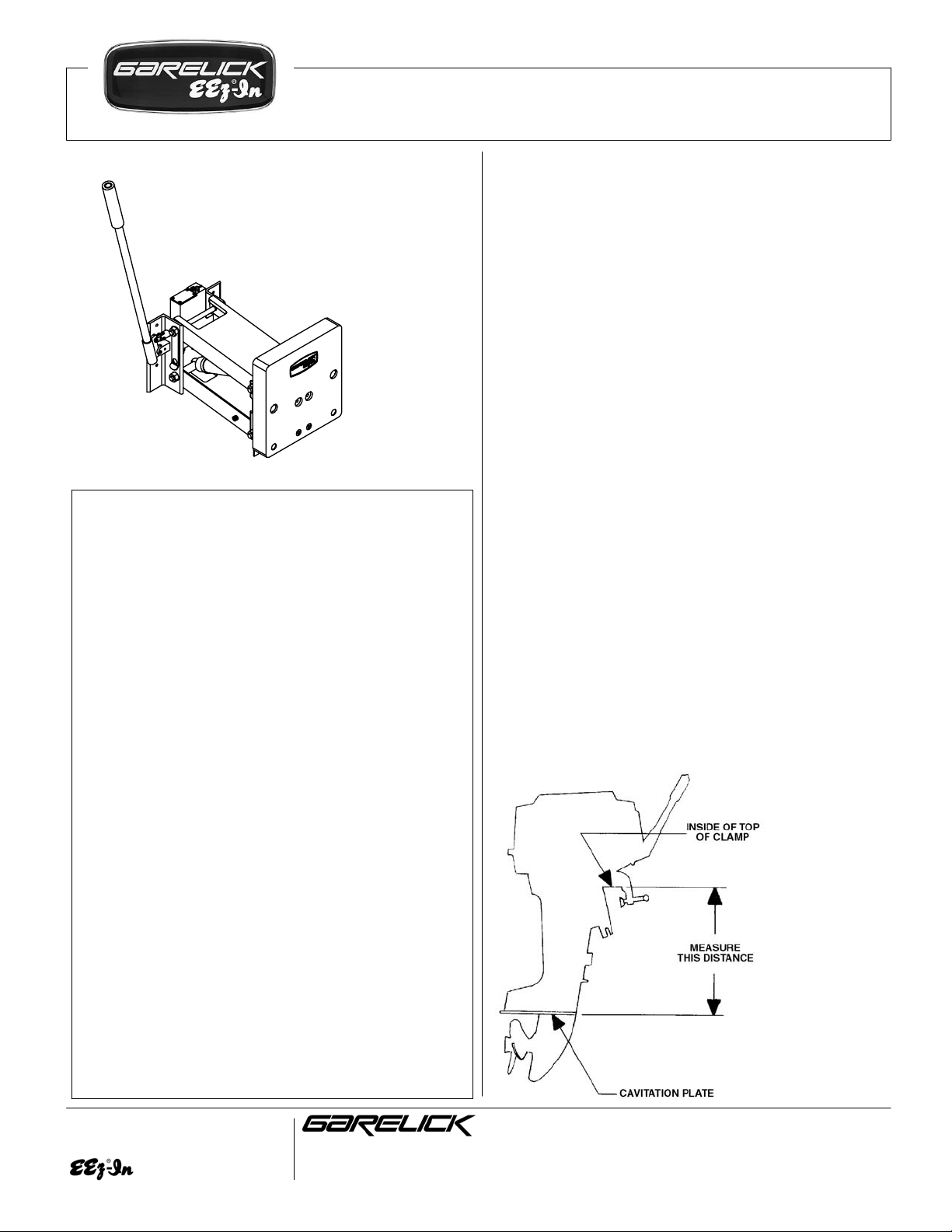

Step 2:

Measure the distance on your outboard motor

between the cavitation plate and the upper

inside edge of the mounting clamp (see fig 1).

Cut a stick to this length and tape it to the

mounting board with one end flush with the

top of the board (see fig 2).

Figure 1

Write for

a Complete

Catalog

644 2nd Street, PO Box 8

St. Paul Park, Minnesota 55071

Phone: 651-459-9795

E-mail: mail@garelick.com

Website: www. garelick.com

04/06

Operator Instructions for the

Auxilliary Hydraulic Outboard Motor Bracket

Model No: 71092

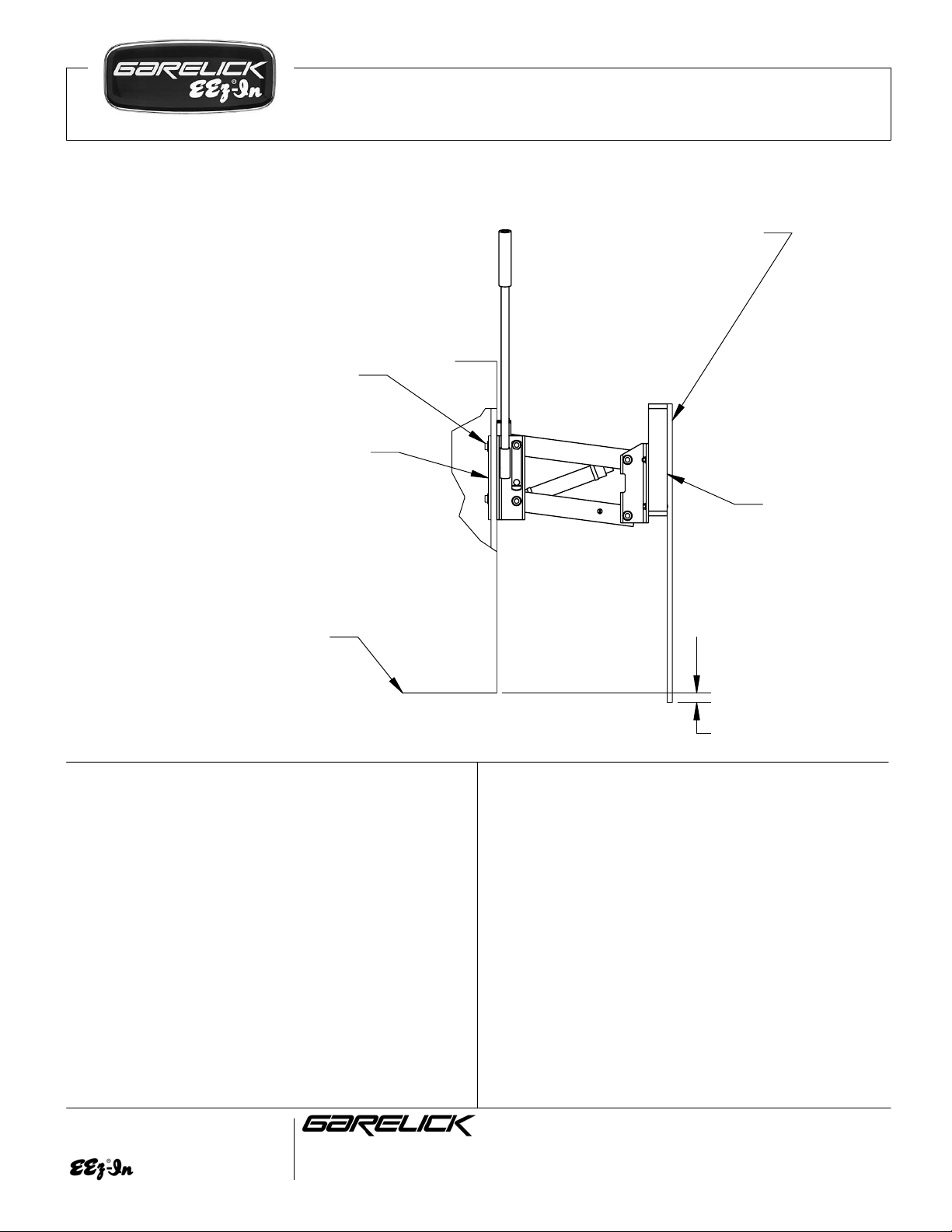

Stick flush with top of bracket

Stick length = Distance from cavitation

plate to upper inside edge of mounting

clamp

Mounting bolts: It is recommended

that "bolt-through" arrangement be

used with with washers and nylon

locknuts or lock washers.

(not included)

Backing plate

(not included)

Form 12.575

Note: Full

down Position

Boat Bottom

Figure 2

Step 3:

Choose the most appropriate side of your transom

for mounting the bracket. Position the bracket so it

will not interfere with the turning operation of your

main motor or rudder. Slide the bracket up or

down so that the bottom of the stick (from step 2)

is approximately 1" to 2" below the bottom of the

boat. NOTE: The bottom of the stick represents

the cavitation plate on your outboard motor, which

must be below the the boat's bottom for best

performance.

Step 4:

Mark 4 mounting holes using the holes in the

bracket. Gain access to the inside of the transom

where the installation is to be bolted through and

make sure the area is clear of any fuel lines,

electrical lines, or obstacles.

1.00

Step 5:

Remove the bracket and using the marks from

step 4 drill (4) holes to accommodate the mounting

hardware as described in figure 3 (NOTE: due to

the various styles of boats, mounting hardware

and backing plates are not provided).

Step 6:

Attach the motor bracket to the transom after

coating the inside surfaces of the mounting flanges

and backing plates with a marine adhesive/sealant

compound.

Step 7:

Motor bracket is now ready for use. Refer to the

motor manufacturer for mounting instructions

and practices. WARNING: Attach safety cable

to motor prior to use.

Write for

a Complete

Catalog

644 2nd Street, PO Box 8

St. Paul Park, Minnesota 55071

Phone: 651-459-9795

E-mail: mail@garelick.com

Website: www. garelick.com

04/06

Loading...

Loading...