Garelick 71091 User Manual

Mounting and Operating Instructions for

Heavy Duty Outboard Motor Bracket

Models 71090 and 71091

Form 12.295

OUTBOARD MOTOR BRACKET MOUNTING INSTRUCTIONS

Transom Mounting Hardware NOT

Supplied Due to Various

Transom Thicknesses.

Recommend 5/16" Stainless Steel Fasteners

1. Read instructions completely before starting assembly.

2. Motor bracket must remain in “UP” position throughout

installation.

3. DO NOT operate motor bracket unless motor is installed

on bracket and is attached to the boat.

4. This bracket is under spring tension. Exercise extreme

caution when adjusting and installing.

MOUNTING INSTRUCTIONS

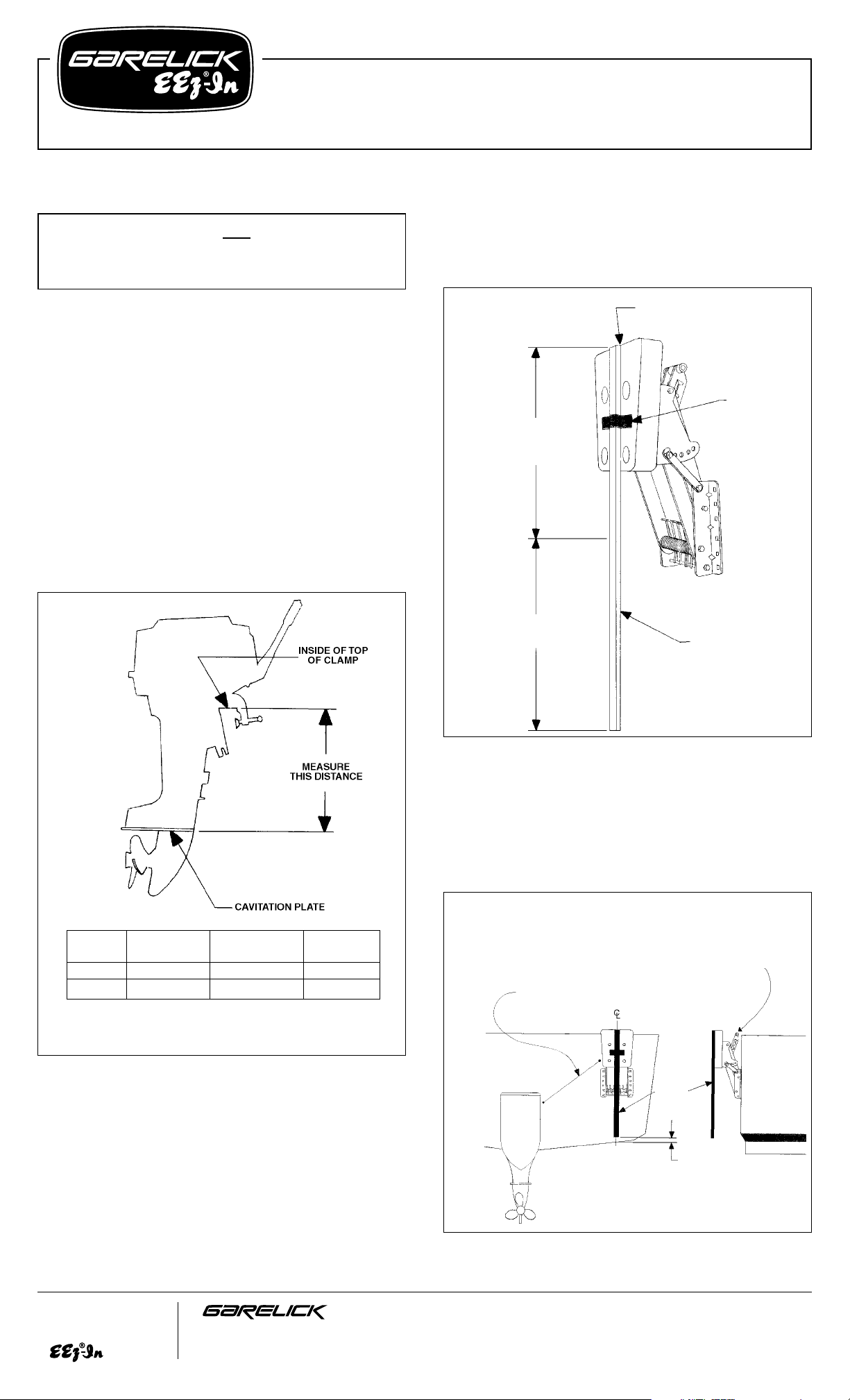

Refer to Fig. 1

Measure the distance on your outboard motor between the

cavitation plate and the upper inside edge of the mounting

clamp. Subtract 2" from this length. Then add the total travel

distance of your model outboard motor bracket from the table

below to the distance measured on your motor.

Refer to Fig. 2

Mark this total length on a stick and tape it so that the top is

flush with the top of the mounting board of the motor bracket.

Choose the most appropriate side of your transom for mounting

the bracket. Position your bracket so it will not interfere with the

turning operation of your main motor or rudder.

Refer to Fig. 3

For Powerboat Installation: Take your outboard motor bracket

with the stick taped on and place the mounting flanges on your

transom. Position the bracket so the bottom of the stick is one

inch above the boat’s bottom at the centerline of the outboard

motor bracket.

FIG. 3

Write for

a Complete

Catalog

Phone: 651-459-9795

PO Box 8, 644 2nd Street E-mail: mail@garelick.com

St. Paul Park, Minnesota 55071 On the Web: www.garelick.com

10-08

FIG. 1

MOTOR

WEIGHT NOT VERTICAL

MODEL H.P. RATING TO EXCEED TRAVEL

71090 7

1

⁄2 TO 30 169 LBS. 91⁄2"

71091 7

1

⁄2 TO 25 175 LBS. 151⁄2"

FIG. 2

DISTANCE FROM CLAMP

TO CAVITATION PLATE

LESS 2"

TRAVEL DISTANCE

FROM TABLE

TAPE

STICK

TOP OF STICK IS EVEN WITH

TOP OF MOUNTING BOARD

IF THE BRACKET RELEASE HANDLE IS AT OR

BELOW THE RUB RAIL OR THE TOP OF THE

TRANSOM, ADD A 1" SHIM OF SUITABLE MATERIAL

BETWEEN THE TRANSOM AND THE BRACKET TO

ALLOW FULL AFT MOTION OF RELEASE HANDLE.

BRACKET AND MOTOR DO NOT INTERFERE WITH

OPERATION OF MAIN MOTOR UNIT.

STICK

1"

BRACKET IS POSITIONED SO THE BOTTOM OF THE

STICK IS 1" ABOVE THE BOAT’S BOTTOM AT THE

CENTERLINE OF THE MOTOR BRACKET

(over)

NOTE: Vertical travel is based on installation that is

perpendicular to waterline.

Transom Mounting Hardware NOT Supplied Due to Various

Transom Thicknesses.

Recommend 5/16" Stainless Steel Fasteners

Mounting and Operating Instructions –

Heavy Duty Outboard Motor Bracket Models 71090 and 71091

Form 12.295

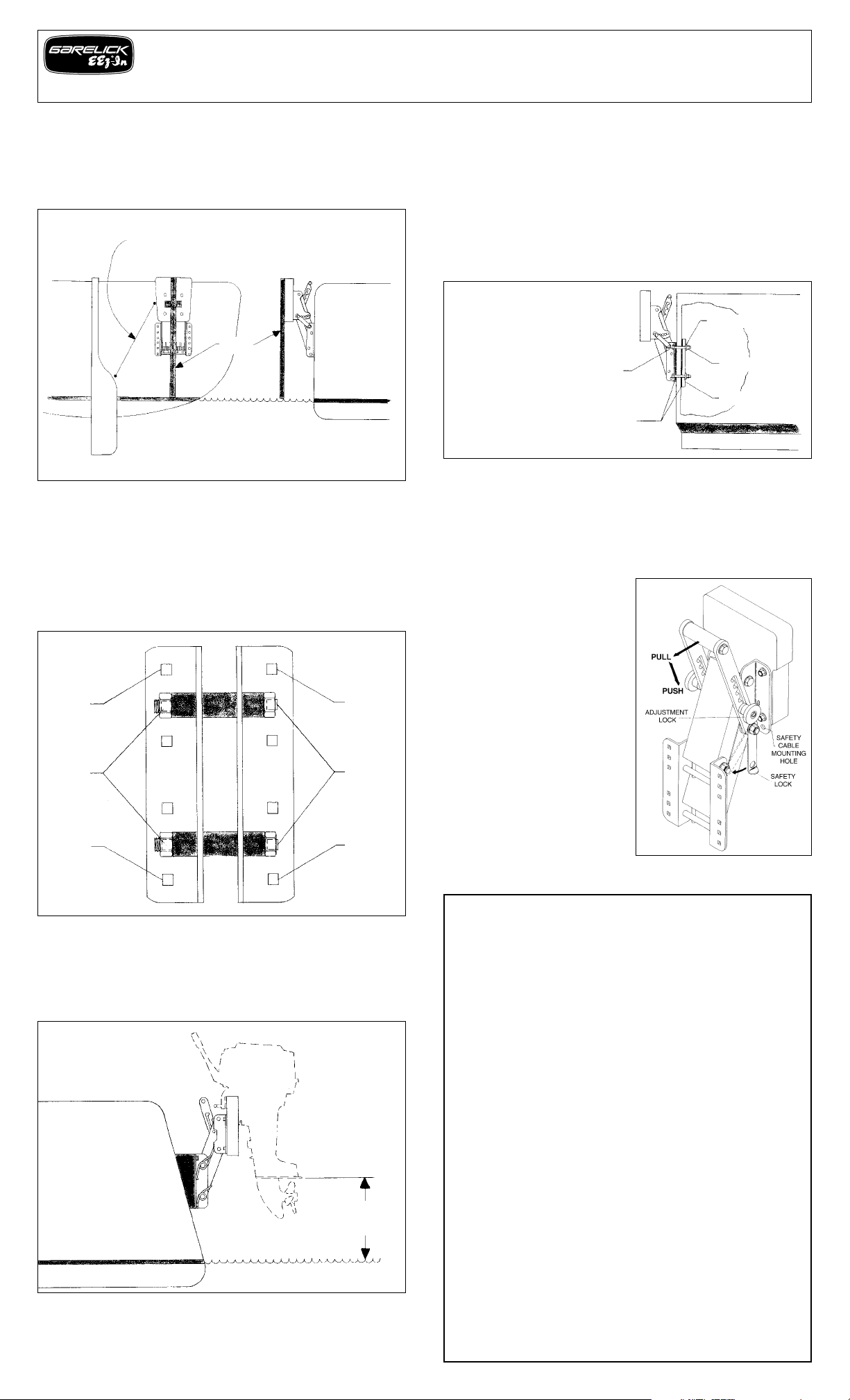

Refer to Fig. 4

For Sailboat Installation: Take your outboard motor bracket

with the stick taped on and place the mounting flanges on your

transom. Position the bracket so the bottom of the stick is even

with the boat’s actual waterline.

Refer to Fig. 5

After the bracket has been properly positioned, mark the four

outside hole locations using the bracket as a template on your

transom (See Fig. 5). NOTE: If it is necessary to use the center

holes on the bracket, you must reverse the mounting bolts so

their heads will be on the inside of the transom. Drill the four

marked 3/8" holes, making sure to hold the drill at right angles

to the transom when drilling.

Refer to Fig. 6

Check the angle of the transom on your boat and determine if

the motor to be used can be trimmed so the cavitation plate is

parallel to the waterline. If not make a wedge out of suitable

material to do so.

Refer to Fig. 7

It is recommended that a backing plate be made and mounted

on the inside of the transom for needed rigidity. Attach your

motor bracket to the transom by coating the inside surfaces of

the mounting flanges and backing plate with a marine

adhesive/sealant compound and then squeeze a small amount

into each bolt hole on both sides of the transom. Secure the

bracket to the transom as illustrated. The bracket is now ready

for motor mounting.

OPERATING INSTRUCTIONS

Refer to Fig. 8

To Lower Motor: Loosen safety lock by counter rotating red

knobs. Rotate right knob toward boat; left knob away from

boat. Pull lever handle toward boat to disengage lock pin. Push

down through length of handle to adjust to desired height.

Tighten safety lock by counter

rotating red knobs. Rotate

right knob away from boat.

Rotate left knob toward boat.

To Raise Motor: Loosen safety

lock. Pull lever handle toward

boat and lift to desired height.

Tighten safety lock.

NOTE: Always tighten safety

lock after adjusting bracket

height.

NOTE: The bracket springs

counter most of the motor’s

weight; however, a push or lift

through the length of the

handle may be needed.

FIG. 7

FIG. 4

FIG. 8

FIG. 6

AUXILIARY OUTBOARD MOTOR BRACKET

IMPORTANT CAUTION GUIDELINES

Failure to observe these points could result in personal

injury or damage to Bracket, Motor or Boat.

1. Install motor bracket only in “up” position with safety

lock in “locked” position.

2. Always remove your motor from the bracket when

trailering. Failure to do so could result in damage to

boat, motor and bracket.

3. Do not exceed the stated H.P. rating or weight.

4. Make sure the motor clamps are tight before use.

5. Use a safety cable when operating your motor.

6. Operate motor at low speed.

7. Avoid turning motor at full throttle, refrain from sharp

turns.

8. Do Not raise or lower bracket when motor is running.

9. Operate motor in lowest position possible for best performance.

10. Always raise motor when not in use. It may be

necessary to turn motor prior to tilting to avoid

interference.

11. Avoid contact with moving parts.

12. Keep pivoting bolts greased to insure smooth

operation.

BRACKET AND MOTOR DO NOT INTERFERE

WITH OPERATION OF RUDDER

STICK

BRACKET IS POSITIONED SO THE BOTTOM OF THE

STICK IS EVEN WITH THE BOAT’S ACTUAL WATERLINE

FIG. 5

1

CENTER

HOLES

CENTER

HOLES

3

2

4

CAVITATION PLATE

IS PARALLEL TO

WATERLINE

IF TRANSOM IS SUCH

THAT THE MOTOR

CANNOT BE

PROPERLY TRIMMED,

MAKE A WEDGE TO

PLACE MOTOR IN

CORRECT OPERATING

POSITION.

DRILL BOLT HOLES AT RIGHT

ANGLE (90°) TO TRANSOM

BOLT

LOCK WASHER

HEX NUT

BACKING PLATE

MARINE ADHESIVE

Loading...

Loading...