Garelick 22000 User Manual

Installation and Operating Instructions for

Model 20000/20001/21000/

21001/22000 Seat Slide System

Form 12.331

Write for

a Complete

Catalog

Phone: 651-459-9795

PO Box 8, 644 2nd Street E-mail: mail@garelick.com

St. Paul Park, Minnesota 55071 On the Web: www.garelick.com

1/03

INSTALLATION

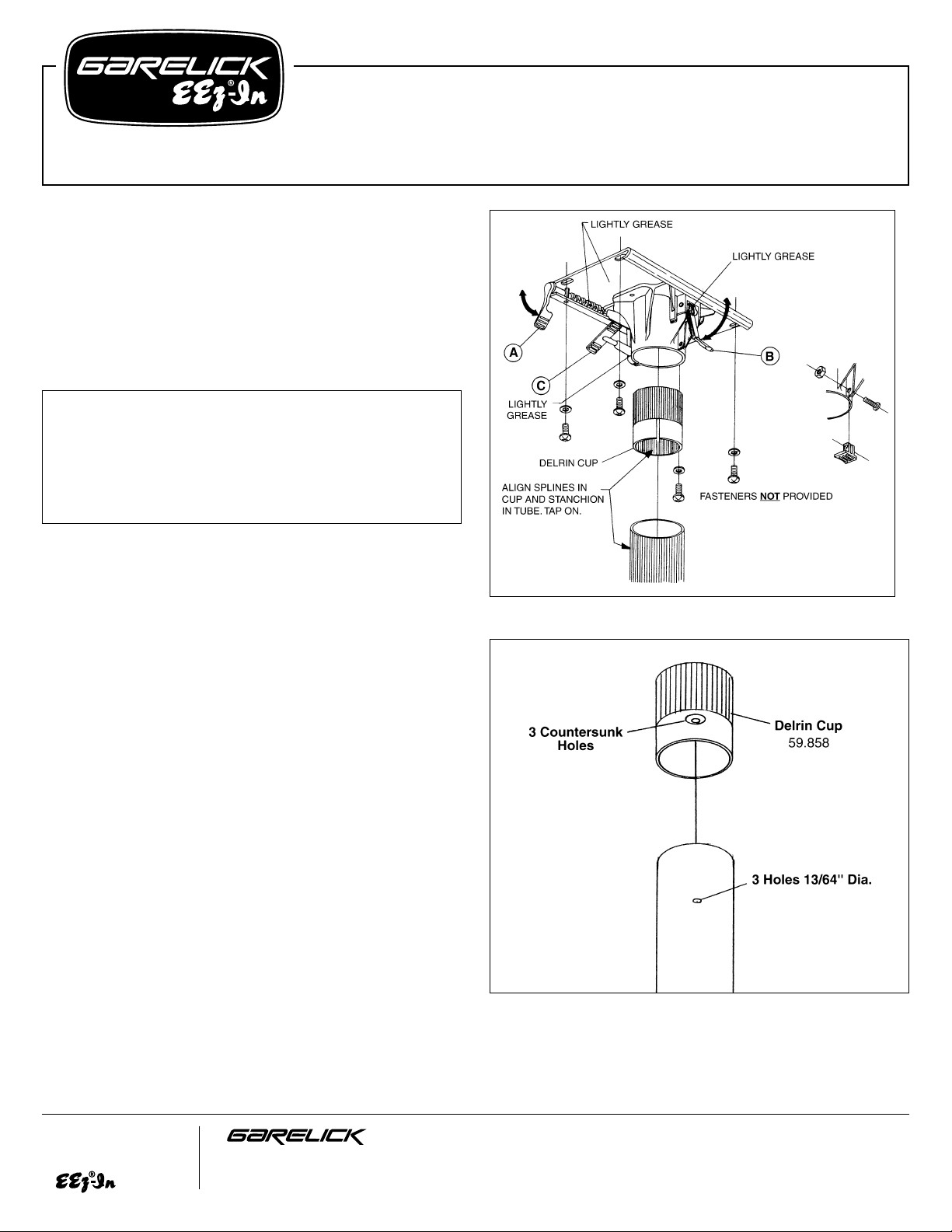

Read instructions completely before installing. Refer to Fig. 1.

1. Position Seat Slide on seat bottom and align 4 mounting

holes.

2. Secure Seat Slide with appropriate hardware.

NOTE: Fasteners are not provided due to the wide variety

of installations.

NOTE: All EEz-In seats use 1/4"-20 threaded T-nuts.

SPECIAL NOTE: for rotational molded EEz-In seats:

A. Remove the reinforcement brackets from the seat bottom

prior to installation.

B. Make certain that the portion of the screw entering the

seat shell’s T-Nut does not exceed 3/8". Seat shell T-nuts

are 1/4"-20 thread, use only 1/4"-20 machine screws.

3. Remove black delrin cup from swivel casting. Align

splines in cup with splines on seat pedestal and tap on

with a soft hammer, if necessary.

4. Slip seat with slide onto pedestal.

SMOOTH TUBE INSTALLATION

Read instructions completely before installing. Refer to Fig. 2.

1. Slide Delrin Cup (59.858) over stanchion tube. Align

one of three countersunk holes to front of the tube. This

will index casting so seat will lock in the forward facing

position. Push down until rim of cup contacts top of tube.

Center punch tube at locations of three countersunk

holes.

2. Drill three holes 13/64" diameter through tube. File or

scrape clean the burrs left from drilling.

3. Fasten cup in place using three flathead screws (03.547)

and locknuts (03.027).

99301 INSTALLATION INSTRUCTIONS

Read instructions completely before installing. Refer to Fig. 1.

1. Mount the seat and slide assembly on the pedestal. Slip

06.045 cup catch over rib in the casting directly under

the cam handle. Secure with 10-24 x 3/4" screw and

locknut.

(continued on back)

FIG. 1

FIG. 2

(continued)

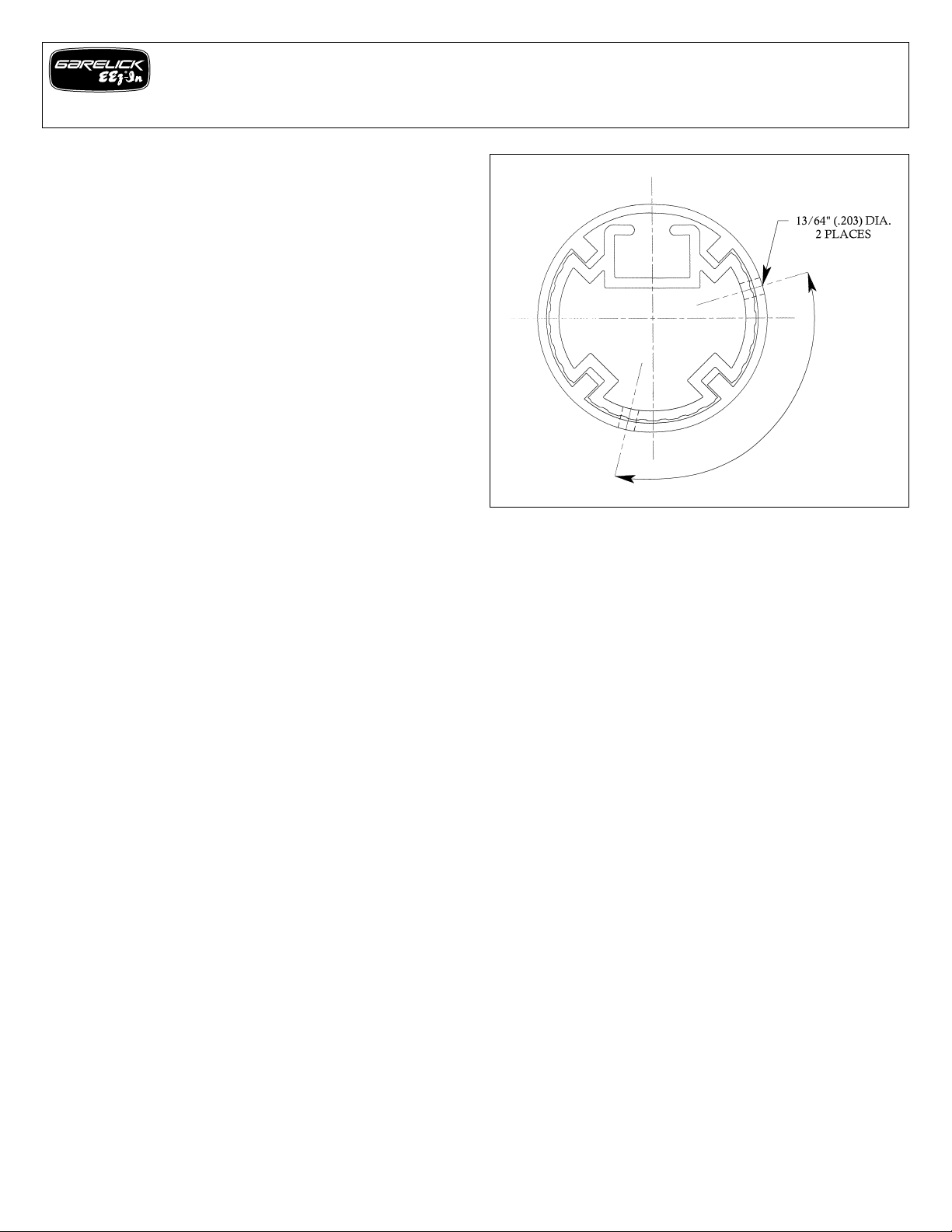

SMOOTH DELRIN CUP INSTALLATION FOR ADJUSTABLE

HEIGHT SEAT BASES MODELS 75436/75437

Refer to Fig. 3.

1. Align 2 of the 3 countersunk holes in the Delrin cup

(59.858) as shown in figure 3. This will allow clearance of

the screws and nuts with the ribs on the inside wall of the

stanchion. Mark the 2 locations and remove the cup.

2. Center punch the 2 marks. With a 13/64" bit, drill 2 holes

through.

3. Fasten cup in place using 2 flat head screws (03.547) and

2 locknuts (03.027).

NOTE: After assembly and installation of the seat is

complete, check to see if the seat will lock in the forward

facing position. If the seat locks slightly left or right of

perfectly forward, it may be necessary to rotate the base

slightly to achieve the ability to lock your seat straight

forward.

TO OPERATE

1. To adjust fore and aft seat position, pull up on Handle “A”,

slide seat to desired position and release handle. Slide will

lock into position.

2. To rotate seat and adjust the drag control feature for

rotation, pull Handle “B” up to the horizontal position and

release. The handle will maintain the horizontal position.

The seat is now free to rotate 360 degrees. To increase the

drag on rotation, turn Handle “C” clockwise to desired

resistance. To decrease drag, turn Handle “C” counterclockwise.

3. To positive lock the rotational feature, push Handle

“B”down and the Positive Quick Lock feature hunts for the

next available locking spline.

NOTE: Always use positive lock feature when boat is

underway.

MAINTENANCE

Keep a light film of grease on:

– Slide plate surface that the casting slides on

– The multiple cam surfaces that the casting locks into

– The Cam Surface on the Bottom of Handle “B” that is

exposed when in the horizontal position

– The Stainless Steel bolt that Handle “C” is threaded onto

Periodically check and tighten the mounting screws between the

seat slide and the seat bottom.

Installation and Operating Instructions –

Model 20000/20001/21000/21001/22000 Seat Slide System

Form 12.331

FIG. 3

Loading...

Loading...