L-BV

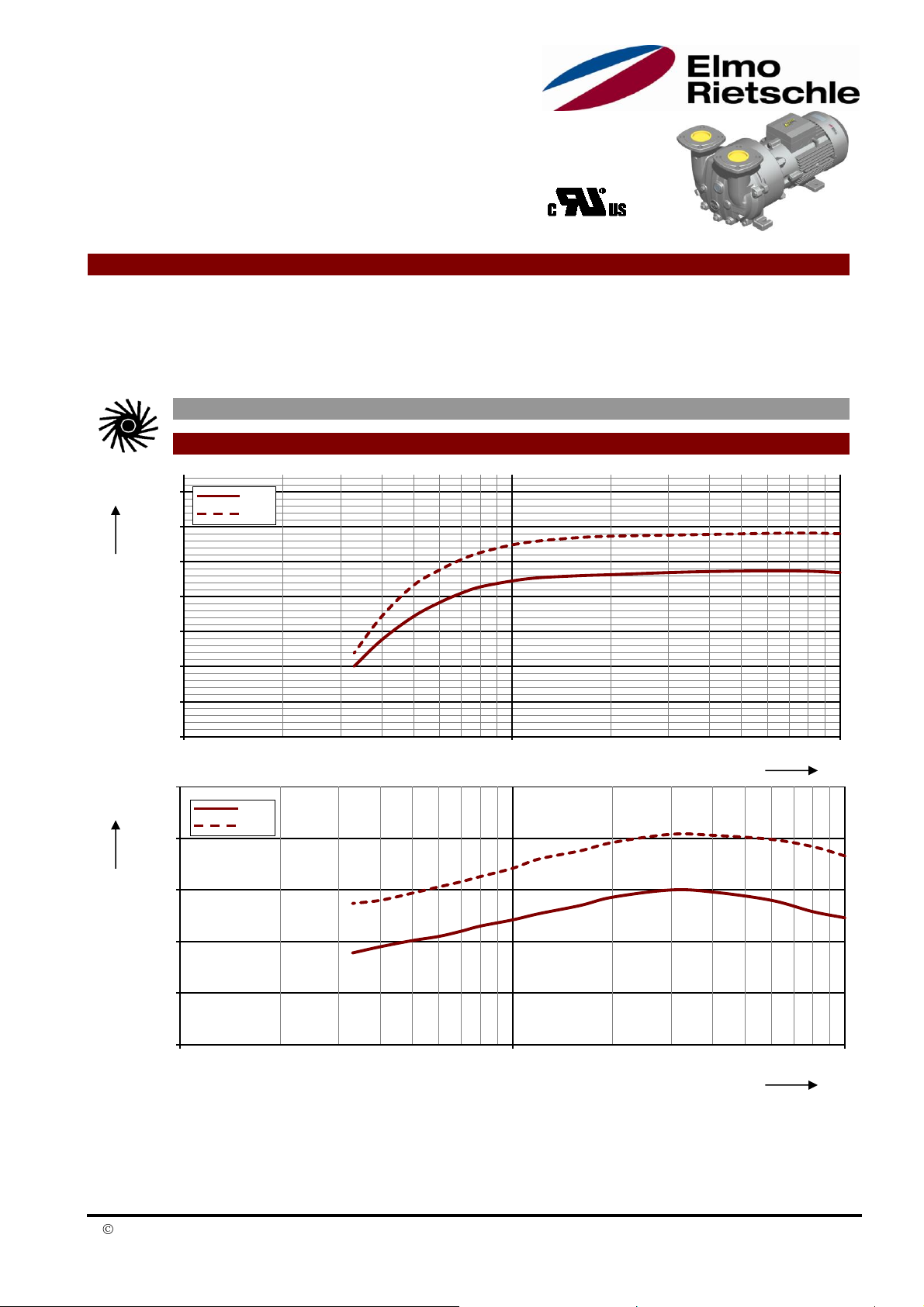

Suction capacity V [m³/h]

Inlet pressure p [mbar abs.]

Power consumption P

at pump shaft [kW]

Inlet pressure p [mbar abs.]

Gardner Denver Deutschland GmbH Page 1 Technical data sheet - Edition 09/2013

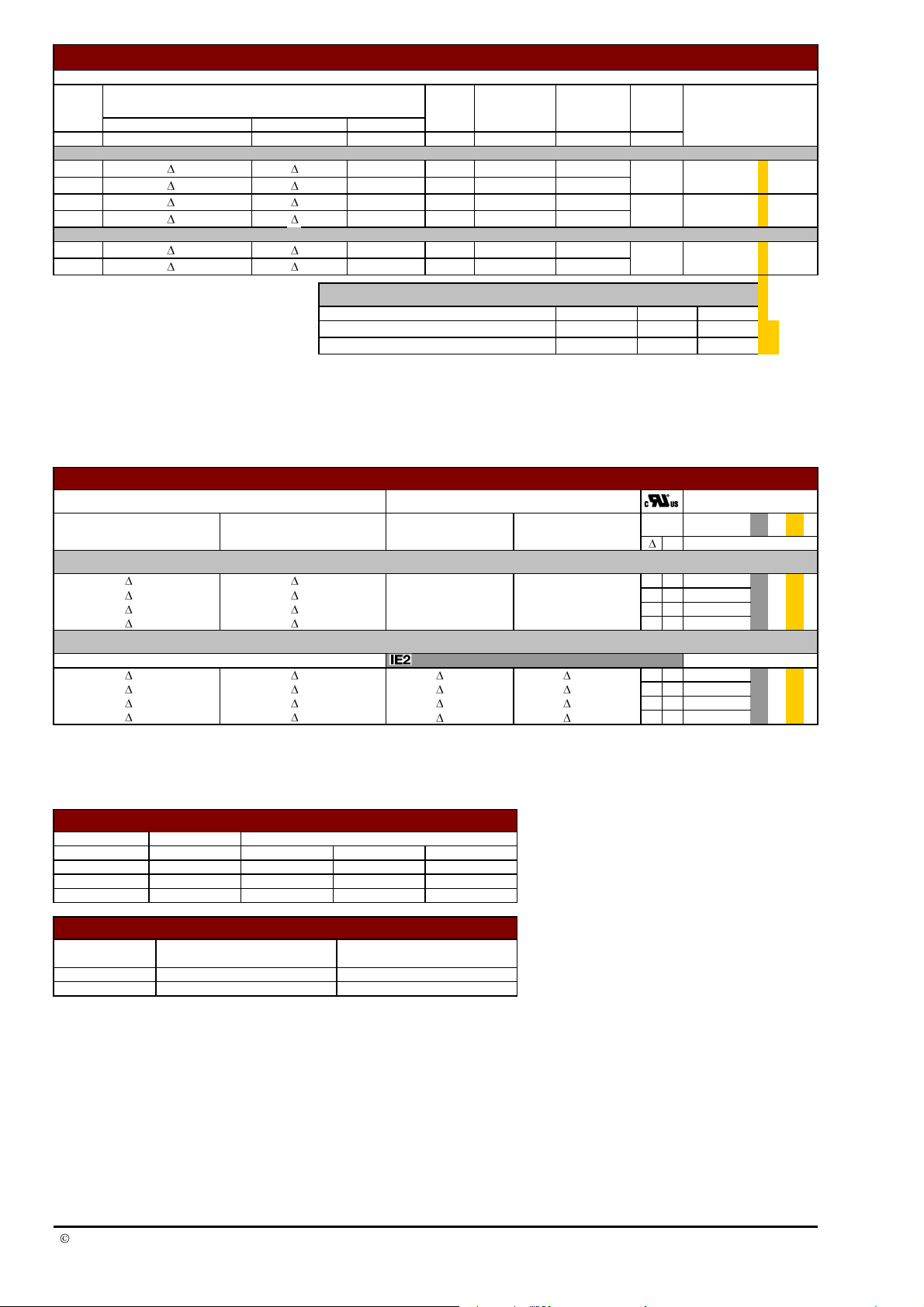

Data sheet 2BV2 061

Liquid ring vacuum pump

The motors are supplied as standard for the input voltage ranges of 50 and 60 Hz

and for the protection category IP55 as well as approbated for UL and CSA.

Vacuum ATEX-pumps with 2006/42 EG for category 2G are available, too.

Performance curves

General information

Elmo Rietschle vacuum pumps of the model range L-BV2 are suitable for

evacuating gases and wet vapours down to inlet pressures of 33 mbar abs. (97 %

vacuum). All these vacuum pumps are equipped with built-in cavitation protection.

They work cavitation free down to 80 mbar abs. For operation at lower inlet

pressures the integrated cavitation protection should be connected for protecting

the vacuum pump (no external pipes necessary).

The vacuum pumps are particularly space-saving, reliable and robust in their

monoblock design. The reinforced stainless steel shaft, the permanently

lubricated bearings and the ceramic internal coating of the pump housings

prevent wear, corrosion and calcification.

The characteristic curves are based on the evacuation of 100 % saturated air and

an intake temperature of 20 °C. At a suction pressure of 1013 mbar abs. and a

temperature of the operating liquid of 15 °C (water as operating liquid) the

characteristic curves will be achieved. The tolerance is ± 10 %.

Vacuum operation

0

10

20

30

40

50

60

70

10 100 1000

50 Hz

60 Hz

…

0.0

0.5

1.0

1.5

2.0

2.5

10 100 1000

50 Hz

60 Hz

-

1)

The quantities of operating liquid apply for fresh water operation without discharge liquid separator.

N

2)

Measuring surface sound pressure level acc. to EN ISO 3744, measured with an equivalent unit at a distance of 1 m. The pump is throttled to an average suction pressure, with

piping connected, but no relief valves fitted, tolerance ±3 dB (A).

M**-

Bronze

Ceramic

Casing

Cast iron (internal surface with ceramic coating)

CrNi steel

Port plate

□

H03-5S

Lantern

Ceramic

*

CrNi steel

26*29**65

2.00

1.10

0.23

4.6

4.55050060575

085H7

2BV2061-0

□

H

H03-8S

3~ 50/60 Hz, IP55, Insulation material class F, UL 507 and CSA 22.2 No 113 (certificate number E225239)

7.8705.9

/ 4.5 Y

0.23

0.23

2.00

1.10

/ 3.4 Y

1.45

500 VH575 V

•

230 V

460 V

•••••

3 Phase

P6350 - 450 V

/ 610 - 725 V Y

400 - 500 V

P

7

•

/ 690 V Y

/ 460 V Y•265 V

1

200 - 260 V

/ 350 - 450 V Y

230 - 290 V

450 - 550 V

P

5•P

575 V

•

/ 600 - 720 V Y

380 - 480 V

•

3 Phase

H

180 - 240 V

/ 310 - 415 V Y

200 - 275 V

200 V

Fixed voltage

•

/ 400 V Y

230 V

/ 345 V Y

Other voltages

Voltage range

S

50 Hz

V

2BV2 061-..

..-

□

Gardner Denver Deutschland GmbH

345 - 415 V

High efficiency motors (IE2) available on request. Please refer to corresponding data sheets.

/ 380 - 480 V Y

0.15 / 0.17

200 - 500

/ 660 - 720 V Y

mbar abs.

15 °C

Technical data sheet - Edition 09/2013

220 - 275 V

Operation liquid quantity for 50 Hz / 60 Hz [m³/h]

12 °C

> 500

0.1 / 0.12

0.12 / 0.14

0.23 / 0.23

60

0.58

Page 2

1200

Max. additional water carry over / Back pressure

Frequency

[Hz]

Water carry-over

[m³/h]

Back pressure

[mbar] atm.

0.1 / 0.12

520 - 600 V

All L-BV fulfil the 2006/42/EC (machinery) and 2006/95/EC (low voltage) directives and the EN 60034-1 norm “Rotating electrical machines”. The motors comply with EN 60 034-1 / -2 / -30

(IEC 60034) and thermalclass F. For three phase motors tolerances are +/-10% for fixed voltage motors and +/-5% for voltage range motors. Singlephase machines are designed with a +/5% tolerance. The frequency tolerance is +/- 2 % maximum.

3)

8 °C

10 °C

For partial recirculation operation the quantity of the fresh applied

refrigerant can be reduced by circulation of the operating liquid in a

circuit (with discharge liqiud separator and internal recirculation of the

operating liquid, available as accessories). Complete circuit systems LSV available on request.

p1

Fresh water

Partial recirculation

0.15 / 0.17

/ 345 - 480 V Y

/ 400 V Y

0.23 / 0.23

0.15 / 0.17

/ 690 - 725 V Y

0.12 / 0.14

400 V

500 V

< 200

/ 345 - 440 V Y

/ 345 - 415 V Y

60 Hz

200 - 240 V

dB(A)

50

0.58

1200

0.23 / 0.23

0.1 / 0.12

0.12 / 0.14

An inlet pressure of 10 mbar abs. can be achieved by connecting a

gas ejector (see accessories). The gas ejector can be mounted

directly onto the vacuum pump.

Selection and ordering data

3)

Sound

pressure

level

2)

Weight

Approx.

345 - 415

3.4

/ 600 - 720 Y

185 - 220 V

50 Hz

60 Hz

60 Hz

SF

1.45

0.23

70

Impeller

1.21

m³/h

/ 400 - 500 V Y

Hz

V

/ 320 - 380 V Y

200 - 254 V

3 Phase

□

Typ 2BV2 061

Frequency

Rated

Service

factor

Operation

liquid

quantity

1)

Current

kg

Order No.

Voltage

1.10

0.23

3~ 50/60 Hz, IP55, Insulation material class F, UL 507 and CSA 22.2 No 113 (certificate number E225239)

PowerA kW

60

H03-7S

70

0.23652.00

**

2BV2061-0

□

50

200 - 240

/ 345 - 415 Y

1.45

/ 1.96 Y

4.550380 - 480

1.21

26*29

1.21

26*65

29

**

The cast iron machines are completely painted in standard color RAL 9006.

All cast parts of the stainless steel version are pickled and passivated, the motor is standardly painted in RAL 9006.

60

220 - 275

/ 380 - 480 Y

2BV2061-0

Materials

Chrome-nickel-molybdenum steel

(X6CrNiMoTi 17-12-2 / 1.4571)

EN 10088 - 3

Chrome-nickel steel

X10CrNiS 18-9 / 1.4305 / EN 10088 - 3

Changes in particular of the quoted performance curve, data and weights may occur without prior notice. The data given do not constitute an obligation from our side to deliver as shown.

Carbon / Ceramic / Viton (FPM) /

Chrome-nickel steel

(EN 12756 - BVVGG)

Cast chrome-nickel-molybdenum steel

(G-X6CrNiMo 18-10 / 1.4408)

EN 10213-4

Chrome-nickel-molybdenum steel

(X6CrNiMoTi 17-12-2 / 1.4571)

EN 10088 - 3

Chrome-nickel-molybdenum steel

(X6CrNiMoTi 17-12-2 / 1.4571)

EN 10088 - 3

SIC / Carbon / Viton (FPM) /

Teflon (PTFE) sheated /

Chrome-nickel-molybdenum steel

(EN 12756 - Q1BM1GG)

Chrome-nickel steel

(X12CrNi 17-7 / 1.4310)

EN 10088 - 2

Chrome-nickel-molybdenum steel

(X5CrNiMo 17-12-2 / 1.4401)

EN 10088 - 2

Materials

Part

No.

CrNi steel / ceramic / CrNi steel

005

Pump shaft

Chrome steel

(X20Cr13 / 1.4021)

EN 10088 - 3

Chrome steel

(X20Cr13 / 1.4021)

EN 10088 - 3

002

SIC / Carbon / Viton (FPM) /

Teflon (PTFE) sheated /

Chrome-nickel-molybdenum steel

(EN 12756 - Q1BM1GG)

Cast chrome-nickel-molybdenum steel

(G-X6CrNiMo 18-10 / 1.4408)

EN 10213-4

Chrome-nickel-molybdenum steel

(X6CrNiMoTi 17-12-2 / 1.4571)

EN 10088 - 3

Feather key

Chrome-nickel-molybdenum steel

(X6CrNiMoTi 17-12-2 / 1.4571)

EN 10088 - 3

Casing

Cast iron - internal surface with

ceramic coating against corrosion

and abrasion

EN-GJL HB 195 / EN-JL2030)

EN 1561

Cast chrome-nickel-molybdenum steel

(G-X6CrNiMo 18-10 / 1.4408)

EN 10213-4

Chrome-nickel-molybdenum steel

(X6CrNiMoTi 17-12-2 / 1.4571)

EN 10088 - 3

037

Washer

Chrome-nickel steel

X10CrNiS 18-9 / 1.4305 / EN 10088 - 3

006

Mechanical seal

Carbon / Ceramic / Viton (FPM) /

Chrome-nickel steel

(EN 12756 - BVVGG)

035

047

Impeller

Cast aluminium bronze

(G-CuAl10Fe5Ni5 / CC33G-GS)

EN 1982

Chrome-nickel steel

X10CrNiS 18-9 / 1.4305 / EN 10088 - 3

Chrome-nickel steel

X10CrNiS 18-9 / 1.4305 / EN 10088 - 3

Cast chrome-nickel-molybdenum steel

(G-X6CrNiMo 18-10 / 1.4408)

EN 10213-4

Cast chrome-nickel-molybdenum steel

(G-X6CrNiMo 18-10 / 1.4408)

EN 10213-4

036

Set screw

Chrome-nickel-molybdenum steel

(X5CrNiMo 17-12-2 / 1.4401)

EN 10088 - 2

not applicable

Tolerance ring

for impeller

Chrome-nickel steel

(X12CrNi 17-7 / 1.4310)

EN 10088 - 2

Chrome-nickel steel

(X12CrNi 17-7 / 1.4310)

EN 10088 - 2

Cast chrome-nickel-molybdenum steel

(G-X6CrNiMo 18-10 / 1.4408)

EN 10284

Chrome-nickel-molybdenum steel

(X5CrNiMo 17-12-2 / 1.4401)

EN 10088 - 2

048

Cast chrome-nickel-molybdenum steel

(G-X6CrNiMo 18-10 / 1.44.08)

EN 10213-4

049

Valve plate

Teflon (PTFE)

Teflon (PTFE)

050

Port plate

Ceramic - C221

EN 60672 - 1

Chrome-nickel steel

(X12CrNi 17-7 / 1.4310)

EN 10088 - 2

Chrome-nickel-molybdenum steel

(X10CrNiMoTi 18-10 / 1.4571)

EN 10088 - 2

051

Intercepting plate

Chrome-nickel-molybdenum steel

(X10CrNiMoTi 18-10 / 1.4571)

EN 10088 - 2

Ceramic - C221

EN 60672 - 1

Ceramic - C221

EN 60672 - 1

Chrome-nickel-molybdenum steel

(X10CrNiMoTi 18-10 / 1.4571)

EN 10088 - 2

Chrome-nickel-molybdenum steel

(X10CrNiMoTi 18-10 / 1.4571)

EN 10088 - 2

063

Cover

Cast iron

(EN-GJL HB 195 / EN-JL2030)

EN1561

Viton (FPM)

flat gasket: Teflon (PTFE) and

O-ring: silicone-caotchouc /

Teflon (PTFE) sheathed

Teflon (PTFE)

Teflon (PTFE)

Gasket for cover

Nitrile-butadiene-caotchouc (NBR)

ISO 1629

Viton (FPM)

Cast chrome-nickel-molybdenum steel

(G-X6CrNiMo 18-10 / 1.4408)

EN 10213-4

Cast chrome-nickel-molybdenum steel

(G-X6CrNiMo 18-10 / 1.4408)

EN 10213-4

Chrome-nickel-molybdenum steel

(X10CrNiMoTi 18-10 / 1.4571)

EN 10088 - 3

Chrome-nickel-molybdenum steel

(X10CrNiMoTi 18-10 / 1.4571)

EN 10088 - 3

057

Cast chrome-nickel-molybdenum steel

(G-X6CrNiMo 18-10 / 1.4408)

EN 10213-4

061

Screw

Steel (DIN ISO 8992)

Steel (DIN ISO 8992)

Sealing ring

Teflon (PTFE)

Teflon (PTFE)

Chrome-nickel-molybdenum steel

(X10CrNiMoTi 18-10 / 1.4571)

EN 10088 - 3

068

Plug screw

Machining steel, lead alloyed

(11SMnPb30 / 1.0718)

EN 10087

FPM (flour rubber)

Chrome-nickel-molybdenum steel

(X10CrNiMoTi 18-10 / 1.4571)

EN 10088 - 3

Chrome-nickel-molybdenum steel

(X10CrNiMoTi 18-10 / 1.4571)

EN 10088 - 3

Teflon (PTFE)

Teflon (PTFE)

Steel (DIN ISO 8992)

Steel (DIN ISO 8992)

Chrome-nickel-molybdenum steel

(X5CrNiMo 17-12-2 / 1.4401)

EN 10088 - 3

Washer for

cavitation

protection

Chrome-nickel steel

(X5CrNi 18-10 / 1.4301)

EN 10088 - 3

Chrome-nickel steel

(X5CrNi 18-10 / 1.4301)

EN 10088 - 3

Chrome-nickel steel

(X5CrNi 18-10 / 1.4301)

EN 10088 - 3

Plug screw

Machining steel, lead alloyed

(11SMnPb30 / 1.0718)

EN 10087

Chrome-nickel-molybdenum steel

(X5CrNiMo 17-12-2 / 1.4401)

EN 10088 - 3

CrNi steel / CrNi steel / CrNi steel

Chrome-nickel steel

(X5CrNi 18-10 / 1.4301)

EN 10088 - 3

072

FPM (flour rubber)

FEP (Perfluorethylenpropylen) & Silicon

071

Pipe of cavitation

protection

069

Chrome-nickel-molybdenum steel

(X10CrNiMoTi 18-10 / 1.4571)

EN 10088 - 3

Chrome-nickel-molybdenum steel

(X10CrNiMoTi 18-10 / 1.4571)

EN 10088 - 3

Sealing ring

Teflon (PTFE)

Teflon (PTFE)

Cast iron / ceramic / bronze

079

CrNi steel / ceramic / CrNi steel

Chrome-nickel-molybdenum steel

(X5CrNiMo 17-12-2 / 1.4401)

EN 10088 - 3

070

O-Ring

FPM (flour rubber)

Tel.: +49 9771 6888-0

Tel.: +49 7622 392-0

Fax: +49 9771 6888-4000

Fax: +49 7622 392-300

Materials

Teflon (PTFE)

Teflon (PTFE)

080

Your Ultimate Source for Vacuum and Pressure

www.gd-elmorietschle.com

▪

er.de@gardnerdenver.com

Elmo Rietschle is a brand of Gardner Denver

Gardner Denver Deutschland GmbH

Gardner Denver Schopfheim GmbH

Industriestraße 26

97616 Bad Neustadt - Germany

Roggenbachstraße 58

79650 Schopfheim - Germany

Loading...

Loading...