Page 1

Instruction Manual

Mobile Bend-MateTM

Ultra EegorTM Bending Table

IMPORTANT — USER SAFETY AND PROTECTION: In setting up systems to fit your operations, take care to

select the proper components and design to insure appropriate integration with your operations and existing

equipment. Observe safety measures to avoid the risk of personal injury and property damage from your application

or system.

GARDNER BENDER CANNOT BE RESPONSIBLE FOR DAMAGE OR INJURY CAUSED BY UNSAFE USE,

MAINTENANCE OR APPLICATION OF ITS PRODUCTS. Please contact Gardner Bender for guidance when you are

in doubt as to the proper safety precautions to be taken in designing and setting up your particular application.

1

Page 2

Mobile Bend-MateTM

Ultra EegorTM Bending Table

Contents

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Identification ...................................3-4

Hydraulic Hose Runs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Mounting Bender to Table Top ......................5

Securing Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-6

Mobility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Replacement Parts ...............................7

2

Page 3

Description

The Gardner Bender Mobile Bend-MateTM Table is designed to

be used with the Ultra EegorTM hydraulic conduit bender. Due to

its overall compact size and locking swivel casters, mobility has

significantly increased. Additionally, due to components being

centrally stored, provides minimal setup time.

Overview

This manual is to provide a general summary of the Mobile Bend-

TM

Mate

Table. For information on conduit bending, please refer to

instruction sheet ZRPS-0023 for the proper use and maintenance

of the Ultra EegorTM conduit bender.

Safety

The instruction manual and labels applied to the product provide

information for avoiding injury or death from unsafe practices

related to setting up and operating this machine. It is critical that

all personnel involved with the use of this machine understand

these hazards and unsafe practices. The three levels (Danger,

Warning, and Caution) define the severity of the hazard.

DANGER: Immediate hazards that if not avoided WILL

result in severe injury or death.

WARNING: Serious injury or death COULD occur if proper

attention is not observed.

CAUTION: Injury or property damage MAY occur if proper

attention is not observed.

Unpacking

Prior to unpacking, place unit on a flat surface. Remove crate

framework and banding from unit.

WARNING: When removing unit from pallet, use only a

forklift.

WARNING: Do not attempt to remove unit by hand!

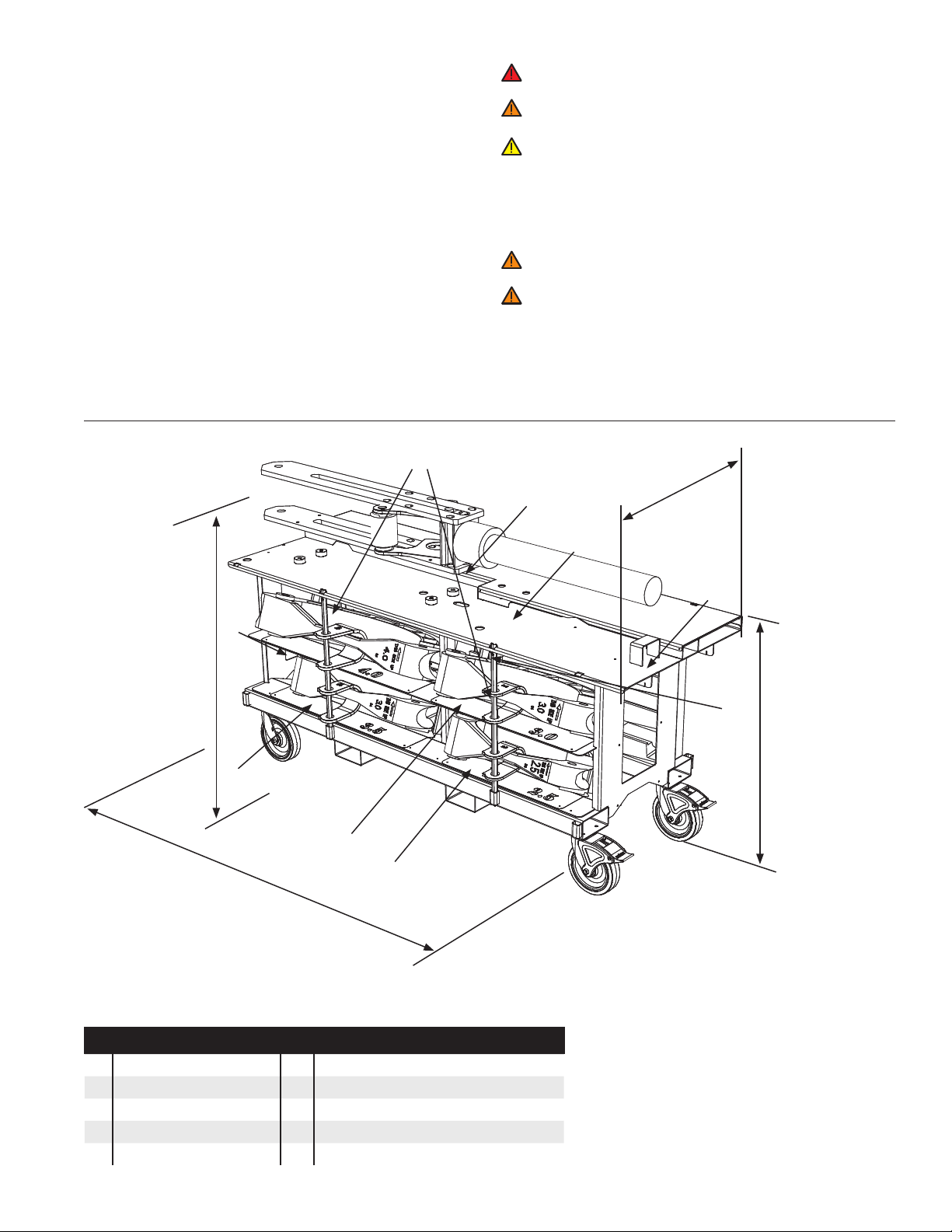

43 1/2"

5

28"

6

7

8

4

9

36"

3

2

1

79"

IDENTIFICATION

1

2.5" Shoe Storage

2

3.0" Shoe Storage

3

3.5" Shoe Storage

4

4.0" Shoe Storage

5

Security Bars: Shoes

6

Ultra EegorTM Long Stroke Bender

7

Anchor Pin Storage Area

8

Cylinder Support

9

U-Strap Pin Storage

Unit weight with accessories: 1178 lbs

3

Page 4

8

4

3

2

1

7

6

IDENTIFICATION

1

2.5" Follow Bar Storage

2

3.0" Follow Bar Storage

3

3.5" Follow Bar Storage

4

4.0" Follow Bar Storage

Pump Hose Routing

5

Hydraulic Pump Storage

6

Pivot Pin Storage

7

Security Bar: Follow Bar

8

Work/Bending Area

5

For pump hose connection instructions, refer to provided ZU4

Pump Series Instruction Sheet RPS-0152.

4

For cylinder hose connection instructions, refer to provided

Hydraulic Bender instruction sheet ZRPS-0023.

Page 5

Mounting Bender to Table Top

WARNING: Body parts are in danger of being crushed by

moving or movable parts.

Bender Load Plate

Table Stand-off

Carefully align Ultra EegorTM Long Stroke bender mounting holes

with mounting pads found on table top.

From underneath of table, securely install hex bolts through table

standoff and bender load plate.

Make sure hex bolts are fully seated

through table top & standoff and tightly

fastened to bender load plate.

Conduit Bending Shoes

To properly secure bending shoes within unit, place corresponding

sized U-Strap between shoe and feed security bar through the

U-Strap holes as shown below.

Place lock (not included) on security bar to firmly secure.

Follow Bars

To properly secure follow bars, install security bar through table top

until fully seated.

Place lock (not included) on security bar to firmly secure.

5

Page 6

Bender

If desired, the Mobile Bend-Mate

a cable lock to be threaded through a tabletop opening and

around the Bender for security while not in use.

Tabletop opening located underneath Bender

TM

Table will accommodate

P408S Z-ClassTM Hydraulic Pump

Specifications

Motor Size

Type

Reservoir Capacity

Pump Type

Pressure Rating

1st stage (psi) 100

2nd stage (psi) 10,000

Output Flow Rate

1st stage (in3/min) 700

2nd stage (in3/min) 60

Valve Type

Current Draw (max) (Amps) 20

Motor Voltage (VAC) 115

Sound (dba) 85-90

Weight (lbs) 85

Relief Valve Adj. Range (psi) 2,000-10,000

1.7hp

Z-Class™

2 gallon

double-acting

4 way/3 pos.

Pump Security

The hydraulic pump can be secured similarly by

threading a cable lock between pump handle and

around table chassis.

WARNING: Remove RED shipping plug before

use & install Reservoir Breather Cap to prevent

damage or bodily harm.

COMPONENTS

Part #

ZCM645 Cable Strap

ZB00001 Bracket Bridge

Included Breather

Description

Qty

1

1

1

Mobility

The Mobile Bend-MateTM is extremely maneuverable due to

incorporating 8” front swivel casters with footbrake and 8” rear

swivel locking casters.

FrontSwivelCasterwithFootbrake

Pump is secured to the

table using the bracket

and table strap.

RearSwivelLockingCaster

6

Page 7

Replacement Parts

3

1

IDENTIFICATION

Item

1

2

3

Part #

ZB00020 Shoe/Follow Bar Security Bar

ZCP00107 Front: Swivel Caster with Brake

ZB00107 Rear: Swivel Locking Caster

REPAIR AND SERVICE INSTRUCTIONS: For repair service and parts contact your nearest Gardner Bender Service

Center. The Service Center will provide complete and prompt service on all Gardner Bender products.

Description

Qty

2

3

2

2

PARTS AND SERVICE: For quality workmanship and

genuine Gardner Bender parts, select an Authorized

Gardner Bender Service Center for your repair

needs. Only repairs performed by an Authorized

Service Center displaying the official Gardner Bender

Authorized sign are backed with full factory warranty.

Contact Gardner Bender for the name of the nearest

Gardner Bender Authorized Service Center.

WARRANTY: Gardner Bender warrants its products

against defects in workmanship and materials for

3 year from date of delivery to user. Warranty does

not cover ordinary wear and tear, abuse, misuse,

overloading or altered products.

WARRANTY RETURN PROCEDURE: When question

of warranty claim arises, send the unit to the nearest

Gardner Bender Authorized Service Center for

inspection, transportation prepaid. Furnish evidence

of purchase date. If the claim comes under the terms

of our warranty the Authorized Service Center will

REPAIR OR REPLACE PARTS AFFECTED and return

the unit prepaid.

7

Loading...

Loading...