Page 1

1.0 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

2.0 Safety Symbol Definitions . . . . . . . . . . . . . . . . . .2

3.0 Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

4.0 Grounding Instructions . . . . . . . . . . . . . . . . . . . . .3

5.0 Technical Specifications . . . . . . . . . . . . . . . . . . .3

6.0 Product Description . . . . . . . . . . . . . . . . . . . . . . .3

7.0 Use and Operation . . . . . . . . . . . . . . . . . . . . . . . .4

7.1 Blowing Line in Conduit . . . . . . . . . . . . . . . . .4

7.2 Preparation . . . . . . . . . . . . . . . . . . . . . . . . . .4

7.3 Selecting the Pull Lines . . . . . . . . . . . . . . . . .4

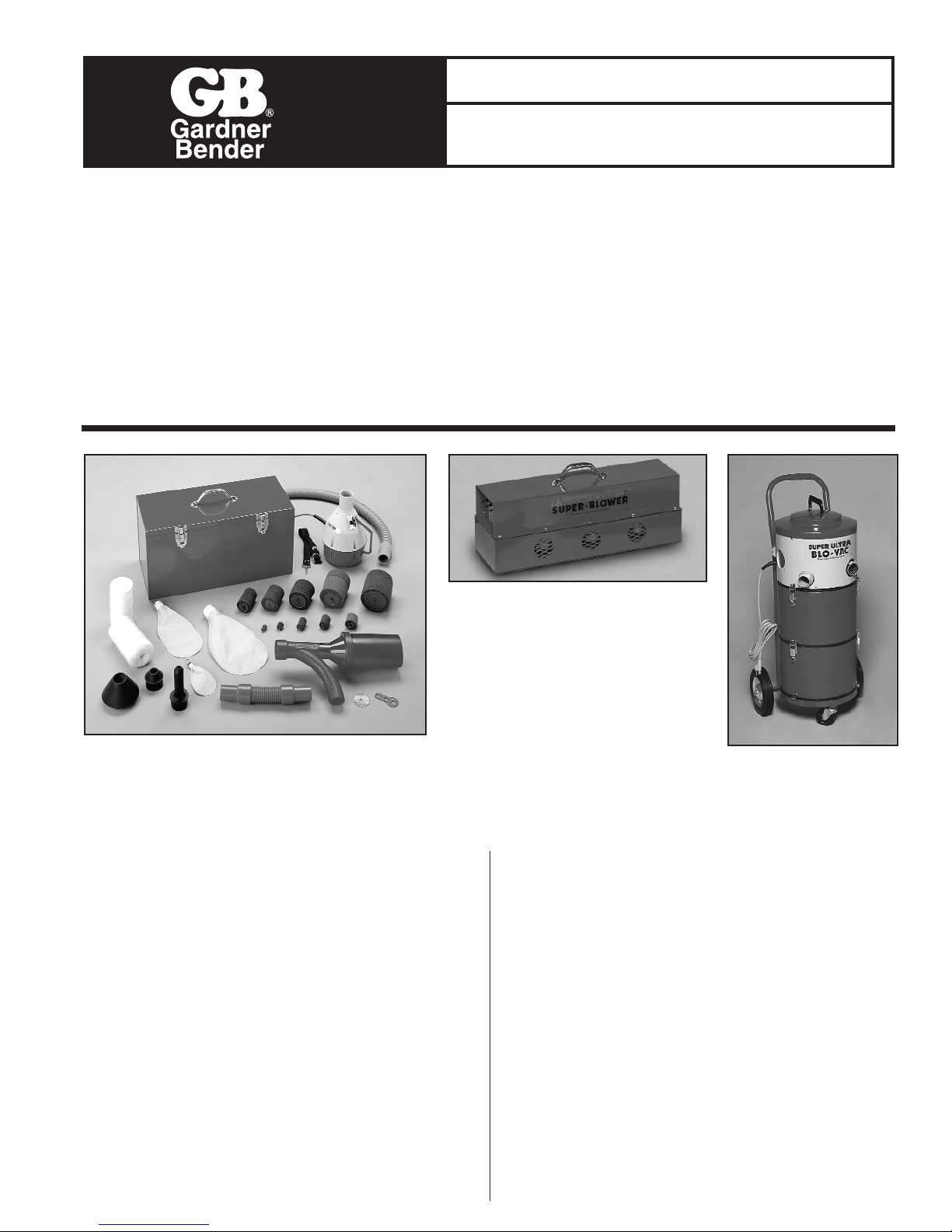

B3000 Blower for B60

B4500K Blower Kit

RPS-0106 01/02

Instruction Sheet

B4500K, B60, BV208DA

IMPORTANT RECEIVING INSTRUCTIONS

Visually inspect all components for shipping damage. If shipping damage is found, notify carrier at once. Shipping damage is NOT

covered by warranty. The carrier is responsible for all repair and replacement costs resulting from damage in shipment.

SAFETY ISSUES

IMPORTANT – USER SAFETY AND PROTECTION: In setting up systems to fit your operations, care must be taken to select the

proper components and design to insure appropriate that all safety measures have been taken to avoid the risk of personal injury

and property damage from your application or system.

GARDNER BENDER IS NOT RESPONSIBLE FOR DAMAGE OR INJURY CAUSED BY UNSAFE USE, MAINTENANCE OR THE

APPLICATION OF ITS PRODUCTS. Please contact Gardner Bender for guidance when you are in doubt as to the proper safety

precautions to be taken in designing and setting up your particular application.

7.4 Power Saver™ Line Packages . . . . . . . . . . .5

7.5 Tag-Along™ Line Packages . . . . . . . . . . . . .5

7.6 PL Series Pull Line . . . . . . . . . . . . . . . . . . . .5

7.7 Seal-Offs . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

7.8 Line Carriers . . . . . . . . . . . . . . . . . . . . . . . . .7

7.9 Blowing or Vacuuming Thru Conduit . . . . . . .8

8.0 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . .10

9.0 Jetline

®

Systems . . . . . . . . . . . . . . . . . . . . . . . .10

9.1 B4500K Line Shooter™ Blowing System . .11

9.2 B60 Super Blower™ System . . . . . . . . . . . .12

BV208DA Blo-Vac

™

Page 2

2

1.0 DESCRIPTION

The GB/JetLine®Blower and Blo-Vac™ Systems are low

pressure tools that deliver high volume air stream, which is

used to place pull line in most conduit from 1⁄2" to 6" diameter.

Blow-Vac™ systems are intended for commercial use only.

The systems are convenient to use in new and existing

construction. They require a 120 V, 60 Hz grounded power

source. See 5.0 Technical Specifications, GB/JetLine

®

Blowers Table and GB/JetLine®Blo-Vac™ Table.

The Blower or Blo-Vac™ System consists of four basic

components:

• The Power Unit – a high volume air or vacuum source.

• Hose and Seal-Off – to channel the air into the conduit and

form a seal at the conduit entrance.

• A Line Carrier – to serve as a movable object that supplies

the pulling force to install pull line in conduit.

• Pull Line – for pulling wire through the conduit, to pull rope

or cable for large or difficult runs.

A thorough understanding of all components and their

functions and operating precautions is essential for safe and

efficient use of the system.

Read and understand all the instructions before attempting to

use the system or blow line into conduit.

2.0 SAFETY SYMBOL DEFINITIONS

The symbol below is used to call your attention to instructions

concerning your personal safety. Watch for these symbols.

They point out important safety precautions. They mean

“ATTENTION! Become alert. Your personal safety is

involved.” Read the message that follows and be alert to the

possibility of personal injury or death.

DANGER: Indicates a high probability that death,

severe bodily injury or major property damage could result.

WARNING: Is serious but less inevitable. There is

some probability that death, severe bodily injury or

major property damage could result.

CAUTION: Is less serious but still demands

attention. Indicates a hazard which may result in minor

injury or property damage.

3.0 WARNINGS

This section contains information for your protection,

safety and quick reference. When using an electrical

appliance basic precautions should always be followed,

including the following.

Read all Instructions before using the Blo-Vac

™

System.

CAUTION: Do not leave the Blo-Vac™ when plugged

in. Unplug from outlet when not in use and

before servicing.

CAUTION: To reduce the risk of electrical shock: Do

not expose to rain. Store indoors.

CAUTION: Use only as described in this manual.

Use only manufacturer’s recommended attachments.

WARNING: Do not use with damaged cord or plug. If

the Blo-Vac™ is not working as it should, has been

dropped, damaged, or dropped in water, return it to a

service center.

CAUTION: Do not pull or carry by cord, use cord as

a handle, close a door on cord, or pull around sharp

edges or corners. Do not run the Blo-Vac

™

over cord.

Keep cord away from heated surfaces.

WARNING: Do not unplug by pulling on cord. To

unplug, grasp the plug, not the cord.

CAUTION: Do not handle plug or Blo-Vac

™

with

wet hands.

CAUTION: Do not put any object into openings. Do

not use with any opening blocked: keep free of dust, lint

and anything that may reduce air flow.

WARNING: Keep hair, loose clothing, fingers and all

parts of body away from openings and moving parts.

WARNING: Do not pick up anything that is burning

or smoking, such as cigarettes, matches, or hot ashes.

CAUTION: When used for vacuum clean-up, do not

use without filter bag in place.

CAUTION: Turn off switch before unplugging.

DANGER: Do not use to pick up flammable or

combustible liquids such as gasoline. Do not use in

areas where they are present.

WARNING: Use extra caution when working on a

ladder, elevated platforms, stairs, etc.

WARNING: Do not use the power unit in a manhole

— keep the power unit above ground.

DANGER: All GB/JetLine

®

conduit fishing Blo-Vac

™

systems are designed to force loose debris of all types

out of the conduit by means of a pressurized force.

Serious or critical injury may result to anyone struck by

high velocity debris or the line carrier. Warn all personnel

to stand clear of the conduit exit prior to pressurization

procedures or blowing line into the conduit.

CAUTION: GB/JetLine

®

Blo-Vac™Systems have

been designed specifically for fishing conduit. The

system, under certain field conditions, may be used to

remove debris or water from the conduit. The electric

motor is protected from liquid entering the fan area by a

float ball. If liquid is discharged, the float ball has been

defeated. Immediately unplug unit from power source

and check to make sure the float ball is functioning

properly and the sealing area is free of foreign matter.

DANGER: Failure to observe these instructions or

misuse of equipment could result in serious injury or

possible death.

Page 3

4.0. GROUNDING INSTRUCTIONS

The GB/JetLine®blowers and Blo-Vac™ systems require a

120 V, 60 Hz, 15 A circuit; with the exception of the B3000

power unit which requires a 120 V, 60 Hz, 30 A circuit; and

must be grounded. If the power unit should malfunction or

breakdown, grounding provides a path of least resistance for

the electrical current to reduce the risk of electrical shock.

These power units are equipped with a cord that has a

grounding conductor and grounding plug. The plug must be

inserted into an outlet that is properly grounded in

accordance with all codes and ordinances. See Figure 1.

CAUTION: Improper connection of the equipment

grounding conductor can result in a risk of electrical

shock. Check with a qualified electrician or service

person if you are in doubt as to whether the outlet is

properly grounded. Do not modify the plug provided with

the Blo-Vac™. If it will not fit the outlet, have the correct

outlet installed by a qualified electrician.

5.0 TECHNICAL SPECIFICATIONS

6.0 PRODUCT DESCRIPTION

GB/JetLine®Blowers and Blo-Vac™systems are designed to

provide a convenient means of installing pull line in a “sealed”

conduit. “Sealed” conduit for this purpose is considered EMT

conduit with compression type couplings, rigid conduit with

threaded joints, or PVC conduit with adhesive bonded joints.

Conduit with set screw type couplings does not effectively

seal joints and substantial air or vacuum loss occurs making it

difficult to maintain pressure or vacuum to place a line in

the conduit.

Blower Systems

GB/JetLine

®

supplies two blower systems; the B4500K Line

Shooter™ (for fishing from

1

⁄

2" through 4" trade size conduit)

and the B60 Super Blower™ for heavy duty work in conduit

from 21⁄2" through 6". See Figures 2 and 3.

B4500K Line Shooter

™

The B4500K Line Shooter™ conduit fishing kit is equipped

with a light weight 1261 Power Unit, three foot hose, shoulder

strap, power saver line packages, foam line carriers,

inflatables and accessories for fishing conduit from 1⁄2" through

4". Bulk pull line is not included with the kit.

3

Grounding Pin

Grounded

Outlet Box

Adapter

Metal

Screw

Tab for

Grounding Screw

Grounding

Blade

Figure 1. Grounding Methods

125 V

30 A

NEMA

L5-30R

GB/JetLine®Blowers

B4500K B60

Power Unit 1261 B3000

Voltage 120 120

Frequency 60 Hz 60 Hz

AMPS 7.50 23

In. Water Lift (sealed) 85-92 85-92

P.S.I. 3.31 3.31

CFM 90 270

No. of Motors 1 3

Impeller Stages (Fans) 2 2

Thermal Overload Yes Yes

Motor Type (Cooling) Flow Through Flow Through

Handling Portable Portable

Weight 7.5 lb 35 lb

Hose Dia. (Inch) 11⁄2 21⁄2

Length (Feet) 3 25

GB/JetLine®Blo-Vac™

BV208DA

Power Unit 1523

Voltage 120

Frequency 60 Hz

AMPS 13.8

Inches Water Lift (sealed)* 130-135

P.S.I.* 4.86

CFM 92

No. of Motors 1

Impeller Stages (Fans) 3

Thermal Overload No

Motor Type (Cooling) By-Pass

Handling Cart

Recovery Cap. (Gals) 9**

Height with Cart (Inch) 41

Motor Brush Life (Hours) 750

Weight 50 lb

Hose Dia. (Inch) 11⁄2

Length (Feet) 8

* Will vary with voltage and atmospheric conditions.

** When using recovery compartment and tool storage

compartment together.

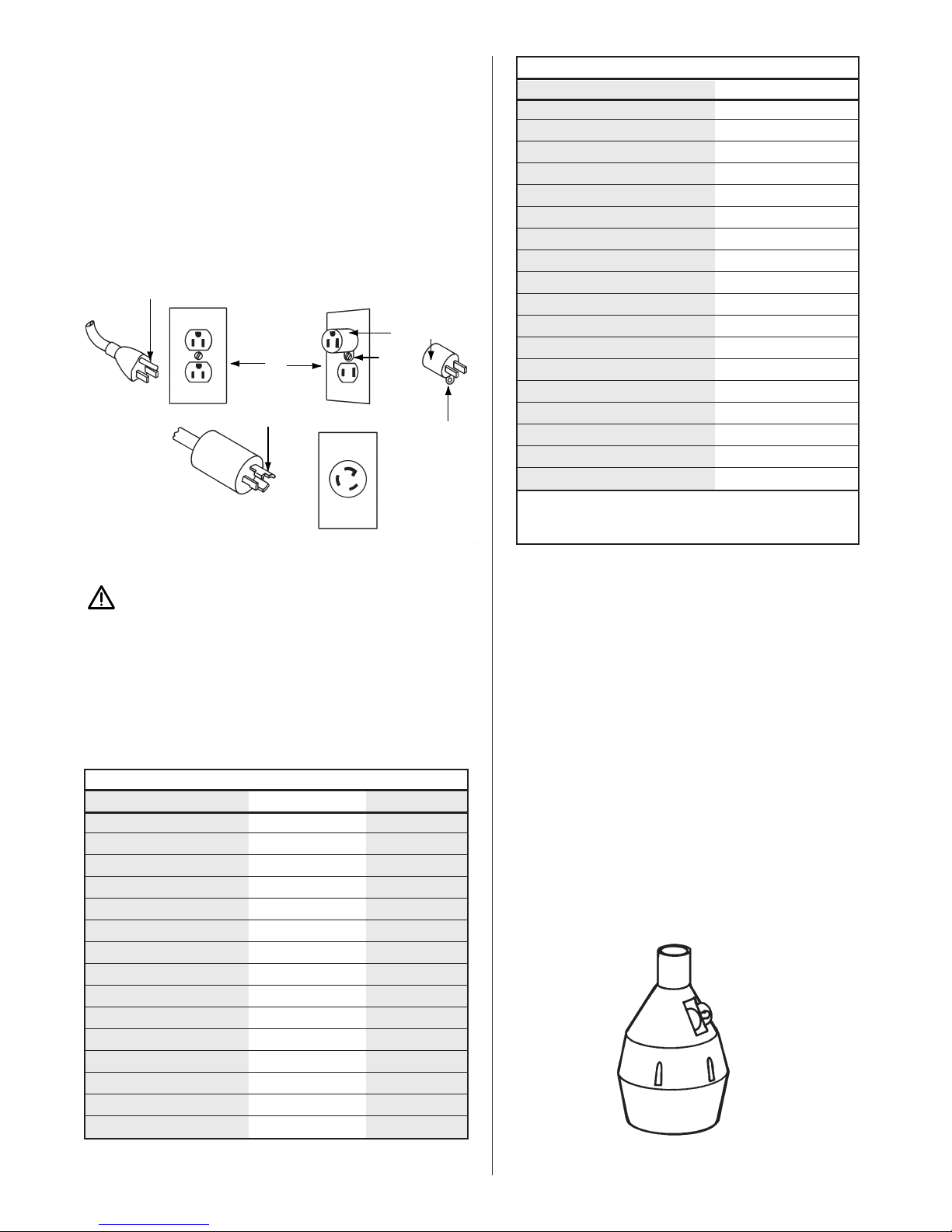

Figure 2. 1261 Blower

Page 4

B60 Super Blower™

The B60 Super Blower™ was designed for use in long

underground single bore conduit from 2

1

⁄2" through 6". The

B3000 Power Unit must remain above ground for safety

reasons, and the 21⁄2" diameter x 25' long hose and seal-off

are used in the manhole. The portable triple motor power unit

provides a high volume of air to blow a line in large bore

conduit whether above ground or below ground.

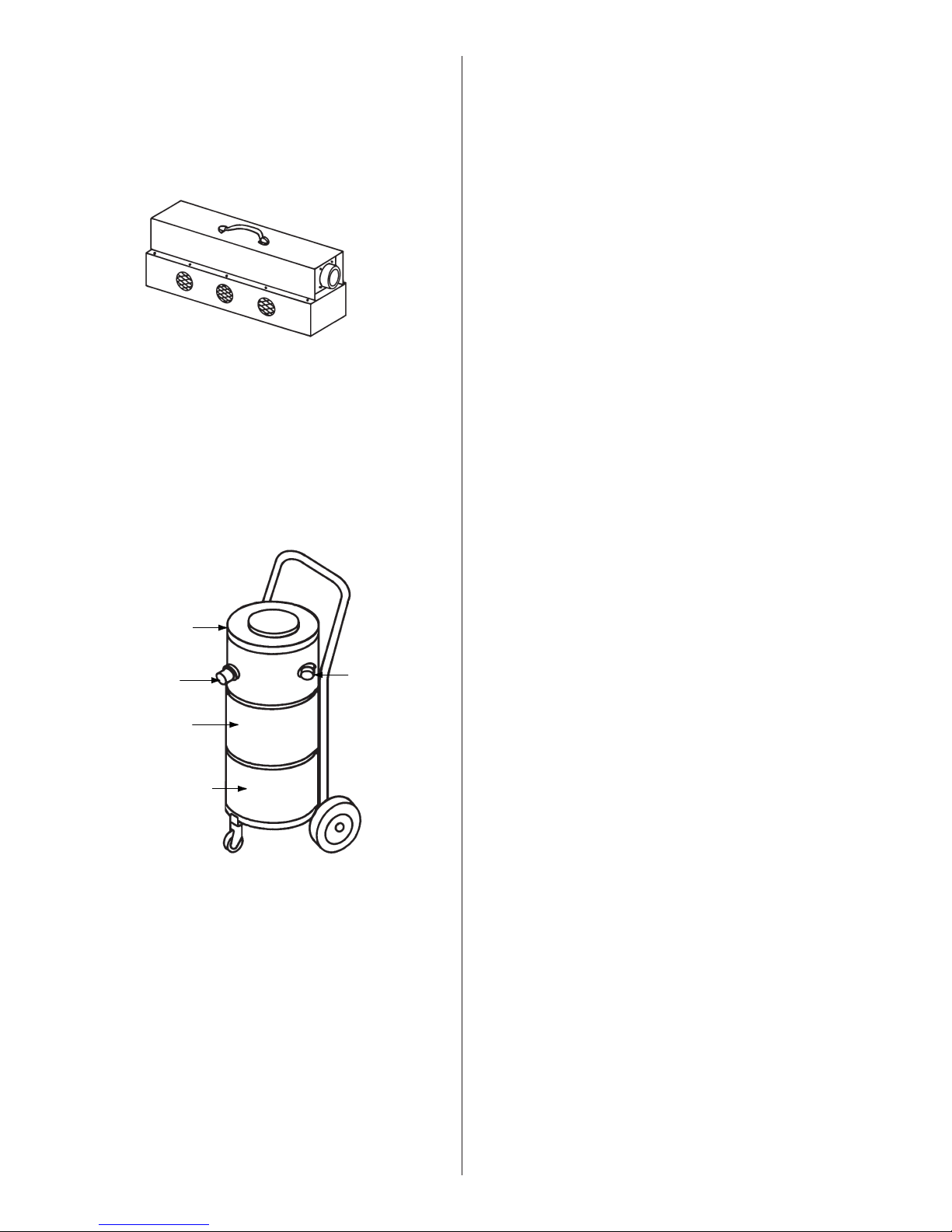

Blo-Vac™ Systems

GB/JetLine

®

Blo-Vac™ Systems: BV208DA Super-Ultra

Blo-Vac™ provides blowing or vacuuming capabilities

for conduit fishing of

1

⁄2" through 6". These systems provide a

higher output pressure for more difficult runs. The water lift

capabilities of the Blo-Vac™ is the same for blowing or

vacuuming. See 5.0 Technical Specifications, GB/JetLine

®

Blo-Vac™Table.

Each Blo-Vac™ system is cart mounted for easy transporting

around the job site. Each Blo-Vac™ unit has three

compartments which are easily separated. The top section is

the power unit, the center section is the recovery

compartment, and the bottom section is storage for

accessories. See Figure 4. The power unit and the recovery

compartment may be unlatched from the tool storage

compartment and used as a portable blower vacuum system.

All Blo-Vac™ systems are equipped with a 1

1

⁄2" diameter x 8'

long hose and seal-offs to fit

1

⁄2" through 6" conduit.

The BV208DA Super Ultra Blo-Vac™ has a powerful threestage motor fan section. The recovery capacity is 41⁄

2 gallons

expandable to 9 gallons by using the tool storage

compartment above the recovery compartment after

removing the false bottom. Housings are made of high

impact polypropylene.

7.0 USE AND OPERATION

The primary purpose of the GB/JetLine®Conduit Fishing

System is to place a pull line in the conduit by the quickest

and easiest means available. The GB/JetLine®Blower and

Blo-Vac™ systems are low pressure, high volume machines

that are easy and convenient to use.

7.1 Blowing Line in the Conduit

The GB/JetLine®Blower and Blo-Vac™ systems are

designed to blow line in a “sealed” conduit such as EMT

conduit with compression type couplings, rigid conduit with

threaded joints, or PVC conduit with adhesive bonded joints.

These types of conduit require very little effort to install a pull

line with the Blower or Blo-Vac™ system.

There are some conduit runs that will be difficult or impossible

to blow a line in, such as:

• Conduit containing hard packed sand, silt, debris

or concrete.

• Conduit containing water with a head greater than the

maximum water lift of the Blower or Blo-Vac™ system.

• Conduit with leaking or separated joints.

• Conduit with two sizes of duct connected by a reducer.

• Conduit with unsealed set screw couplings.

• Small diameter conduit of several hundred feet with

multiple bends.

Let Gravity Help

When blowing line in conduit of tall buildings or underground

duct, start at the highest elevation of the conduit entrance. In

underground duct; water may have accumulated in low points

of the run, and the blower may not be able to force it out.

Start at the highest point.

7.2 Preparation

It is helpful to know the purpose for which the line is to be

used once it has been blown into the conduit.This will aid the

user in selecting the appropriate line for the job.

Knowing the approximate length of the conduit run will

prevent selecting a line too short for the run. For example, if

lightweight pull line is being placed in

3

⁄4" conduit with a

estimated length of 195' to 200', select a 300'. Power Saver™

line package for the run. An alternate solution would be to

use a

3

⁄4" foam line carrier pulling bulk nylon line. Either

selection would insure an adequate length of line.

7.3 Selecting the Pull Line

It is not possible to foresee all conduit situations that may be

encountered, therefore, the following is presented as a guide

in selecting pull line. Determine which best fits the situation;

whether the line is to be used for conduit identification, pulling

in a larger line or rope, pulling in wire or for wire pulls at a

later date.

1. Identification of a conduit termination where multiple

conduit runs originate from a single location.

Recommended line: Power Saver™ Line Packages or

Bulk Nylon Line.

2. Placing a line in the conduit for use at a later date.

Recommended line: Small conduit

1

⁄2", 3⁄4" and 1" — Power

Saver™ Line Packages, Bulk Nylon Line or PL232 Pull

Line. Larger conduit 11⁄4" through 6" — Tag-Along™ Line

Packages, PL232 or PL235.

3. Pulling in larger line, rope or steel winch cable.

Recommended line: Small conduit — same as above.

Larger conduit PL232, PL235 or Poly Rope.

4. Pulling wire in conduit. Recommended line: PL232,

PL235 or Poly Rope.

4

Blower Outlet

Power Unit

Vacuum Inlet

Recovery Compartment

Tool Storage Compartment

Figure 4. Blo-Vac™

Figure 3. B3000 Super Blower

Page 5

7.4 Power Saver™ Line Packages

The Power Saver™ line package is the easiest and

most versatile line that can be installed in conduit. The selfcontained (no line carrier needed) 17 lb. breaking strength

nylon line package comes in different lengths sized for

1

⁄2", 3⁄4"

and 1" conduit. It dispenses a line as the package is blown or

vacuumed through the conduit. The line may be used for

identification of the conduit exit, pulling in a heavier pull line

(PL series pull line or small rope).

7.5 Tag-Along™ Line Packages

The Tag-Along™ line package must be used with a line

carrier (foam or inflatable) in 11⁄4" or larger conduit. The

increased package diameter and length prevents the package

from passing freely through or around bends in conduit less

than 1

1

⁄4". Once attached to the line carrier, the Tag-Along™

line package function and operation is similar to that of the

Power Saver™ package. Breaking strengths are 22 lbs.

Bulk Nylon Line

JetLine

®

bulk nylon line is fed into the conduit through the

seal-off feed through port. However, unlike the Power

Saver™ and Tag-Along™ package, bulk line packages

remain at the conduit entrance. Line is pulled into the conduit

by one of the JetLine

®

line carriers. Bulk nylon line is supplied

in 22 lb., 30 lb. and 100 lb. breaking strengths.

7.6 PL Series Pull Line

JetLine®linear stranded PL series pull lines are designed

specifically for conduit fishing. These lines are made of strong

polyolefin plastic that will not rust, rot or mildew. The coreless

wound roll of knot free pull line makes center dispensing from

the carton a convenient feature when feeding the pull line

directly into the conduit through the seal-off.

The PL Series are oval in shape and tend to flatten out in

bends. The flattened edges reduce the abrasive and cutting

effect in PVC conduit.

PL102 Pull Line - The 6500' roll of 190 lb. breaking strength

pull line is fiberlated polyolefin line (approx.

1

⁄8" in diameter).

PL232 Pull Line - The 6500' roll of 200 lb. breaking strength

pull line is oval in shape (approx. 3⁄32" x 5⁄32") will pass through

the feed through port of all JetLine®seal-offs.

PL235 Pull Line - The 2200' roll of 500 lb. breaking strength

pull line is oval in shape (approx. 1⁄8" x 5⁄16") will feed through

the port of Catalog No. B26 large Dial-A-Line™ seal-off body.

Figure 5. Power Saver™ Line Packages

Power Saver™ Line Packages

Part # Conduit Size Length

LP2150

1

⁄2" 150'

LP3200

3

⁄4" 200'

LP3300

3

⁄4" 300'

LP3450

3

⁄4" 450'

LP4200 1" 200'

LP4300 1" 300'

LP4450 1" 450'

Figure 6. Tag Along™ Line Packages

Tag-Along™ Line Packages

Part # Length Strength

LP2206T 400' 22 lbs

LP2208T 600' 22 lbs

LP2207T 800' 22 lbs

Figure 7. Bulk Nylon Line

Bulk Nylon Line

Part # Length Strength

LP1701 1000' 100 lbs

LP1702 2000' 30 lbs

LP1703 1400' 22 lbs

LP1707* 1350' 100 lbs

LP1722 2200' 90 lbs

* Wound on cardboard tube, not center dispensing.

Figure 8. Dispensing Carton and Bucket

PL-series Pull Line

Part # Length Strength

PL231 1000' 100 lbs

PL102 6500' 190 lbs

PL232 6500' 210 lbs

PL235 2200' 500 lbs

5

Page 6

Conduit Measuring Tape

JetLine

®

TT31 True Tape™ and ST40 Super True Tape™

provide an accurate means of measuring the length of

conduit runs already in place. Both are marked in

1' increments.

When measuring for wire length, measure from terminal to

terminal, not from end of conduit. See Conduit Measuring

Tape Table for allowances to be made for 90° bends, 45°

offsets, and panel boxes.

7.7 Seal-Offs

The GB/JetLine®seal-offs are the final connection between

the blower or Blo-Vac

™

hose and the conduit. Seal-offs

attach to the JV07 or B26 Dial-A-Line™ body. The tapered

seal-off cone (five sizes to fit 1⁄2" through 6" conduit) must be

held firmly in the conduit when blowing or vacuuming line

in conduit.

JV07 Dial-A-Line™ Body

The small JV07 Dial-A-Line™ body is used in conjunction

with the BV12 Hose Adapter, accepts the JV08 Short SealOff, JV09 Long Seal-Off or the JV12 Seal-Off. The perforated

dial plate on the JV07 is adjusted to feed pull line up to

1

⁄8"

diameter or for feeding TT31 True Tape™. Close off the feed

port when Power Saver™ or Tag-Along™ line packages are

used or when vacuuming.

JV08 Short Seal-Off

The JV08 Seal-Off is used in close quarters such as 2' x 4'

electrical boxes, etc. It may be used on

1

⁄2" through

11⁄4" conduit.

JV09 Long Seal-Off

The JV09 Seal-Off is similar to the JV08, except for length,

and is used to reach conduit in deep electrical boxes.

JV12 Seal-Off

The JV12 Seal-Off fits conduit sizes 1

1

⁄4" through 21⁄2".

B26 Dial-A-Line™ Body

The B26 is a large seal-off body that can be coupled directly

to either the 1

1

⁄2" or 21⁄2" hose assembly. It is used with the

BV23 and BV24 seal-offs. The dial plate has a small hole for

feeding pull line up to 1⁄8" diameter. The large hole is for larger

pull line and rope up to

1

⁄2" diameter. The slot is for feeding

TT31 True Tape™ or the feed port may be closed off when

using a Tag-Along™ line package with line carrier or

when vacuuming.

6

Figure 9. Conduit Measuring Tape

Conduit Measuring Tape

Part # Description Length

TT31 True Tape™ 3000' roll

ST40 Super True Tape™ 2750' roll

Figure 10. Dial-A-Line™ Seal-Off Body

and Hose Adapter

Figure 11. JV08 Short Seal-Off

Figure 12. JV09 Long Seal-Off

Figure 13. JV12 Seal-Off

Figure 14. Dial-A-Line™ Seal-Off Body

Page 7

BV23 and BV24 Seal-Off

The larger internal diameter of BV23 and BV24 seal-offs

allows more efficient flow of air when used with high volume

blowers and Blo-Vac™ systems. The BV23 and BV24

seal-offs are used in 1

1

⁄4" through 21⁄2" and 21⁄2" through 6"

conduit respectively.

7.8 Line Carriers

The line carrier is the movable “piston” that supplies the force

necessary to pull the line through the conduit when propelled

by the blower or Blo-Vac™ system. They are constructed of

durable material and is reusable.

Foam Line Carriers

GB/JetLine

®

foam line carriers are manufactured in 12 sizes

for use in conduit 1⁄2" through 6". The foam line carrier, as it

travels through the conduit, will clean out water and loose

debris providing the head of water is not greater than the

maximum water lift of the blower or Blo-Vac™ power unit.

Sizes for 1

1

⁄4" through 6" conduit are provided with a pulling

eye on one end and a hook on the other end. The hook

provides a convenient means of attaching the Tag-Along™

line package. If pull line is used, it should be attached to the

pulling eye.

The Inflatables®Line Carrier

The Inflatables

®

line carrier has less friction in the conduit and

is faster running than the foam line carrier. The flexible nature

of the line carrier allows it to inflate to the conduit diameter

and pass over local obstructions that would stop a foam

line carrier.

In large conduit 4", 5" and 6", the Inflatables

®

may lie against

the conduit wall. It may be necessary to point the seal-off

nozzle toward the inflatable sleeve to achieve initial inflation.

This is accomplished by tilting the seal-off nozzle in the

conduit entrance.

When vacuuming an inflatable in the conduit it may be

necessary to fluff it out and shake it to achieve inflation.

Plastic Line Carriers

The GB/JetLine

®

slotted double skirted plastic line carriers

were developed for the Blo-Vac™ conduit fishing systems for

use in long, single bore underground ducts. The low friction

properties of the plastic makes it a fast running line carrier. If

the line carrier encounters a blockage where it cannot get

through, the slotted skirt allows the line carrier to be pulled

out past joints or steps in the duct. A hard tug on the pull

line will cause the petals to turn inside out allowing for

easy withdrawal.

Figure 15. BV23 Short Seal-Off

Figure 16. BV24 Seal-Off

Plastic Line Carriers

Part # Conduit Size Part # Conduit Size

M2000 2" M4000 4"

M2500 21⁄2" M5000 5"

M3000 3" M6000 6"

M3500 3

1

⁄2"

Figure 17. Foam Line Carriers

Foam Line Carriers

Part # Conduit Size Part # Conduit Size

FC1

1

⁄2" FC7 21⁄2"

FC2

3

⁄4" FC8 3"

FC3 1" FC9 31⁄2"

FC4 11⁄4" FC10 4"

FC5 11⁄2" FC11 5"

FC6 2" FC12 6"

Figure 18. The Inflatables®Line Carrier

The Inflatables®Line Carriers

Part # Conduit Size

F125

3

⁄4", 1" and 11⁄4"

F250 11⁄2", 2" and 21⁄2"

F400 3", 31⁄2" and 4"

F600 5" and 6"

Figure 19. Missile Line Carrier

7

Page 8

7.9 Blowing or Vacuuming Through Conduit

Select the Power Saver™ line package for size and length of

line to fit the conduit. It is recommended that you flex the

package back and forth two or three times to loosen it. This

will make the line easier to dispense.

Blowing a line in the conduit

1. Insert the hose in the blower side of the Blo-Vac™

power unit.

2. Insert the BV12 hose adapter in the other end of the

hose. Screw the handle end of the JV07 Dial-A-Line™

body into the hose adapter. Select either the JV08 or

JV09 seal-off and screw it into the JV07. See Figures 20,

21 and 22.

3. Pull out approximately 2' of line and hold on to trailing end.

4. Insert the line package in the conduit — foam tip first.

5. Hold the seal-off cone firmly in the conduit entrance

and turn on the blower. Blow the line package through

the conduit.

6. It is recommended that the ends of the line be tied off, to

prevent it from being accidentally pulled into the conduit.

Vacuuming a line in the conduit

1. Insert the hose in the vacuum side on the Blo-Vac™

power unit.

2. Assemble the hose and seal-off as in Item 2 above.

3. At the far end of the conduit run, pull out approximately 2'

of line and tie off the trailing end of the line.

4. Insert the line package in the conduit — foam tip first.

5. Return to the other end of the conduit and power unit.

6. Hold the seal-off cone in the conduit and turn on the

power unit and vacuum the line package through

the conduit.

Tag-Along™ Line Package

Tag-Along™ line packages perform the same function

as Power Saver™ line packages except they are used

in 1

1

⁄4" diameter and larger conduit. Tag-Along™ package

must be used with a line carrier to supply the pulling force.

Select the Tag-Along™ line package and a line carrier either

foam or inflatable that fits the conduit diameter and proceed

as follows:

If a foam line carrier is selected—

1. Attach the Tag-Along™ line package plastic eye to hook.

Pull out approximately 2' of line. Tie off the ends of the

line to prevent it from being accidentally pulled into

the conduit.

2. Insert the foam line carrier and Tag-Along™ package in

the conduit.

3. Select the seal-off that best fits the conduit — JV07 DialA-Line™ body with the JV12 seal-off or the B26 Dial-ALine™ body with the BV23 or BV24 seal-off.

4. Hold the seal-off rubber cone firmly in the conduit and

turn on the power unit. The run time will be longer than

that for the Power Saver™ line package because of the

larger conduit and greater volume of air required.

However, the run time in 3" and 4" conduit 200' to 300'

long should be complete in 10 to 15 seconds.

Figure 20. Blowing a line in the conduit

JV08 Seal-Off

JV07 Dial-A-Line™ Body

BV12 Hose Adapter

Hose Assembly

Conduit

Power Saver™ Line Package

JV08 Seal-Off

JV07 Dial-A-Line™ Body

Figure 21. Blowing a line in the conduit

JV07 Dial-A-Line™ Body

Conduit

Power Saver™ Line Package

JV08 Seal-Off

Figure 22. Blowing a line in the conduit

Foam Line Carrier

Tag-Along™

BV23 Seal-Off

Trailing End of Line

B26 Dial-A-Line™ Body

12568 Hose Assembly

Figure 23. Blowing a Tag-Along™ line in the conduit

8

Page 9

If The Inflatables®line carrier is used—

1. Select The Inflatable

®

line carrier and attach the

Tag-Along™ line package to the wire. Pull out

approximately 2' of line and hold on to the trailing end.

2. Unfurl The Inflatables

®

line carrier and place it in the

conduit — bag portion first. See Figure 24.

3. In large conduit: (4", 5" and 6" diameter), it may be

necessary to point the seal-off nozzle at the plastic

sleeve of the Inflatable

®

to achieve initial inflation. This is

accomplished by tilting the seal-off in the conduit

entrance. Otherwise, the Inflatable®in its collapsed state

may allow the stream of air to blow past it.

Blowing Pull Line in the Conduit

All GB/JetLine

®

systems may be used to blow pull line or

nylon line in the conduit. Position Blo-Vac™ systems in a

location that allows good access to the conduit entrance. See

Figure 25.

Set-up as follows:

1. Insert the hose in the power unit blower port.

2. Select the JV07 Small Dial-A-Line™ body that accepts

the JV08, JV09 or JV12 Seal-off for conduit sizes

1

⁄2"

through 2

1

⁄2" or the B26 Large Dial-A-Line™ body that

accepts the BV23 or BV24 Seal-off for conduit sizes 11⁄4"

through 6".

3. Connect the hose to the Dial-A-Line™ body and thread

the pull line through the feed port. See Figures 26, 27

and 28.

4. Select the appropriate size line carrier and tie the pull

line securely to the line carrier to prevent loss of the line

in the conduit.

5. Insert the line carrier in the conduit and hold the seal-off

firmly in the conduit entrance and turn on the blower.

Vacuuming Pull Line in the Conduit

1. Insert the hose in the vacuum port.

2. Select the JV07 small Dial-A-Line™ body that accepts

the JV08, JV09 or JV12 Seal-off for conduit sizes

1

⁄2"

through 2

1

⁄

2" or the B26 Large Dial-A-Line™ body that

accepts the BV23 or BV24 Seal-off for conduit sizes 1

1

⁄4"

through 6".

3. Connect the hose to the Dial-A-Line™ body.

4. Place the pull line at the far end of the conduit.

5. Select the appropriate line carrier and tie the pull line

securely to the line carrier.

6. Insert the line carrier in the conduit and turn on the

power unit.

9

Conduit

B26 Dial-A-Line™ Body

BV24 Seal-Off

Inflatable

®

Tag-Along™ Line Package

Trailing End of Line

Hose Assembly

Figure 24: Blowing a Tag-Along Line Package

in conduit with the Inflatables

®

BV24 Seal-Off and

B26 Dial-A-Line Body

Figure 25: Blowing Pull Line in the Conduit

12568 - 8' Hose Assembly

BV208DA Super Ultra Blo-Vac™

Figure 27. Blowing line in conduit with the

Missile Line Carrier

®

B26 Dial-A-Line™ Body

Conduit

BV24 Seal-Off

Inflatable

®

Figure 26. Blowing line in conduit with the Inflatables

®

Pull Line

Pull Line

B26 Dial-A-Line™ Body

BV24 Seal-Off

Hose Assembly

Conduit

Missile Line Carrier

Figure 28. Blowing line in conduit with the

Foam Line Carrier

®

Foam Line Carrier

Conduit

JV08 Seal-Off

12568 Hose Assembly

BV12 Hose Adapter

JV07 Dial-A-Line™ Body

Pull Line

2x4

Box

Hose Assembly

Page 10

8.0 Maintenance

The Blowers and Blo-Vac™ systems should require very little

maintenance. If the unit should require service, see

instructions below.

Blower overheating occurs when attempting to blow line in

blocked conduit or a duct filled with water having a head

greater than the water lift capability of the blower. See 5.0

Technical Specifications, GB/JetLine

®

Blowers Table.

The 1261 and B3000 Blowers have an automatic thermal

overload switch built into the motor. If overheating occurs, the

switch will turn the motor off. After a cool-down period of 15 to

30 minutes, the motor will automatically re-set. The motor can

be restarted.

Blo-Vac™ power units are equipped with a perforated filter

screen, located on the under side of the motor compartment.

Occasionally the screen becomes clogged with lint and dust

and it should be cleaned to maintain maximum air flow.

Vacuuming Dirt and Water — Each Blo-Vac™ comes with a

cloth filter bag that must be used when vacuuming dirt and

water. Use as follows:

1. Release the latches securing the top and center together.

2. Remove the filter bag from the bottom tool storage

section. Slide the filter bag onto the intake canister

located on the bottom of the motor. The filter bag

prevents dust from entering the motor. Dust and dirt will

damage the motor and cause premature failure.

3. After use, clean the filter bag by shaking off the excess

dirt and store the clean bag in the lower compartment.

4. The Blo-Vac™ is equipped with a ball float to prevent

water from entering the motor. If the ball float seals the

motor inlet, the motor will sound different from usual.

Immediately turn the unit off. Empty the recovery section

and check the inlet screen for lint and dirt. Clean and

reassemble the Blo-Vac™ sections.

9.0 Jetline®Systems

9.1 B4500K Line Shooter™ Blowing System

Handles conduit 1⁄2" to 6".

• Includes lightweight Line Shooter™ hand-held blowgun and

flexible coupling extension for hard-to-reach conduit

openings.

• Compact #1261 blower unit delivers a powerful punch, yet

carries hands-free with shoulder strap. Durable high-impact

housing stands up to job site abuse.

• Exclusive line drag key controls line tension to prevent

overblowing and line pile-up.

• Includes 1,000' of 100 lb-test Poly-Pull™ line.

• Handy tool box holds entire system.

• Line Keeper™ slotted disc securely retains line in housing;

prevents lost lines.

• Specifications: 3.25 max. psi; 90 cfm; 1.2 hp motor.

• 115 V AC; 7 A.

B26 Dial-A-Line™ Body

BV24 Seal-Off

Conduit

Pull Line

Inflatable

®

12568 Hose Assembly

Figure 29. Vacuuming Line in Conduit

with the Inflatables

®

Blower Application

Blo-Vac™ Application

1

⁄2"

3

⁄4"

1"

11⁄4"

1 1⁄2"

2"

21⁄2"

3"

3

1

⁄2"

4"

5"

6"

B4500K

B60

BV208DA

0 200 400 600 800 1000 1200

0 200 400 600 800 1000 1200

Distance

Size Conduit

Distance

1

⁄2"

3

⁄4"

1"

11⁄4"

1 1⁄2"

2"

2

1

⁄2"

3"

3

1

⁄2"

4"

5"

6"

Size Conduit

Figure 30. Blowing Line in Conduit

with the Line Shooter™ Blower System

10

Page 11

9.2 B60 Jetline®Super Blower™ System

The most powerful blower system in the market.

• Blower unit delivers 275 cfm at 3 psi – more than enough to

blow 1⁄2" Poly-Pull™ rope 1000' or more through conduit up

to 6" diameter.

• Lightweight (35 lbs) and compact (24" x 7

1

⁄2" x 81⁄4") power

unit can be hand-carried right up to the work area.

• Extra-long 25' hose allows power unit to be located outside

the manhole or vault.

• All work is done from one end of the conduit, permitting oneperson operation. Works on 115 V AC power.

• System includes patented Dial-A-Line™ Seal-Off System;

eliminates extra steps by allowing simple “dial” selection of

feed-thru opening size for up to

1

⁄2" pull rope.

• May use pull rope and True Tape™ conduit measuring

tape simultaneously.

• 115 V AC, 23 A; Power Consumption 2.65 kw.

• Specifications: 4 max. psi; 150 cfm; 3 motors (1

1

⁄2 hp each).

9

8

3

4

5

6

7

23

21

22

10

11

12

13

14

19

18

17

16

15

1

2

24

20

Line Shooter™ Blowing System

Part # Description Weight ID #

1261 Power Unit 9 lbs 1

BR-1503 3' x 11⁄2" Heavy-duty Hose 1.6 lbs 2

BR-1549 Canister & Handle Assembly 1.8 lbs 3

BR-1060 1' Heavy-duty Hose (11⁄2" dia) .9 lb 4

BR-1003 Long Seal-off for 1⁄2" - 1" conduit .4 lb 5

BR-1004 Seal-off for 11⁄4" - 11⁄2" conduit 1.3 lbs 6

BR-1005 Seal-off for 2" - 4" conduit 1.2 lbs 7

BR-1650 Line Keeper™ Disc .2 lb 8

BR-1651 Line Drag Key .2 lb 9

FC1 Foam Line Carrier for 1⁄2" conduit .1 lb 10

FC2 Foam Line Carrier for 3⁄4" conduit .1 lb 11

FC3 Foam Line Carrier for 1" conduit .1 lb 12

FC4 Foam Line Carrier for 11⁄4" conduit .1 lb 13

FC5 Foam Line Carrier for 11⁄2" conduit .1 lb 14

FC6 Foam Line Carrier for 2" conduit .1 lb 15

FC7 Foam Line Carrier for 21⁄2" conduit .1 lb 16

FC8 Foam Line Carrier for 3" conduit .1 lb 17

FC9 Foam Line Carrier for 31⁄2" conduit .1 lb 18

FC10 Foam Line Carrier for 4" conduit .1 lb 19

F125 Line Carrier for 3⁄4", 1" & 11⁄4" conduit .1 lb 20

F250 Line Carrier for 11⁄2", 2" & 21⁄2" conduit .1 lb 21

F400 Line Carrier for 3", 31⁄

2" & 4" conduit .1 lb 22

PL231 Poly-Pull™ Line, 1,000' (100 lb test) 1.3 lbs 23

106 Carrying Case 15.7 lbs 24

Optional Accessories

Part # Description Weight

BR-1006 Seal Adapter for 5" & 6" conduit 1.1 lbs

BR-1500AC Air Compressor Valve Assembly 1.8 lbs

LP-1722 Nylon Bulk Line, 2,200' (90 lb test) 1.3 lbs

Figure 31. Line Shooter™ Blowing System

Figure 32. Blowing Line in Conduit

with the Jetline

®

Super Blower™ System

11

Page 12

Gardner

Bender

RPS-0106 01/02

PO Box 3241 • Milwaukee, WI 53201-3241 • 414-352-4160 • Fax 414-352-2377

6615 Ordan Drive • Mississauga, Ontario L5T 1X2 • 905-564-5749 • Fax 905-564-0305

WARRANTY: Gardner Bender warrants its product

against defects in workmanship and materials for 1

year from date of delivery to user. Chain is not

warranted. Warranty does not cover ordinary wear

and tear, abuse, misuse, overloading, altered products

or use of improper fluid.

WARRANTY RETURN PROCEDURE: When question

of warranty claim arises, send the unit to the nearest GB

Authorized Service Center for inspection, transportation

prepaid. Furnish evidence of purchase date. If the claim

comes under the terms of our warranty the Authorized

Service Center will REPAIR OR REPLACE PARTS

AFFECTED and return the unit prepaid.

PARTS AND SERVICE: For quality workmanship and

genuine Gardner Bender parts, select an Authorized

GB Service Center for your repair needs. Only

repairs performed by an Authorized Service Center

displaying the official GB Authorized sign are backed

with full factory warranty. Contact Gardner Bender

(414)352-4160 for the name of the nearest GB

Authorized Service Center.

REPAIR AND SERVICE INSTRUCTIONS: For repair service and parts contact your nearest Gardner Bender

Service Center. The Gardner Bender Service Center will provide complete and prompt service on all Gardner

Bender products.

Figure 33. Jetline®Super Blower™ System

1

4

5

6

7

3

2

Jetline®Super Blower System

Part # Description Weight ID #

B3000 Power Unit 34 lbs 1

126025 25' x 21⁄2" Heavy-duty Hose 12 lbs 2

B26 Large Dial-A-Line™ Seal-Off Body .7 lb 3

BV24 Seal-Off for 21⁄2" - 6" conduit 3.3 lbs 4

F400B Line Carrier for 3", 31⁄2", 4" conduit .1 lb 5

M5000 5" Plastic Line Carrier .4 lb 6

M6000 6" Plastic Line Carrier .5 lb 7

Loading...

Loading...