Troubleshooting Guide

B2000 Cyclone® Bender

GAR_TL_045_0717

SERVICE INSTRUCTIONS

These Service instructions are intended for use by a qualified personal at Authorized Gardner Bender Service

Centers. Users of Gardner Bender equipment should see the bender instruction sheet for installation, operation and

maintenance information.

SAFETY ISSUES

WARNING is reserved for conditions and actions that can cause serious or fatal injury.

CAUTION is reserved for conditions and actions that can cause injury or instrument damage.

WARNING:

• Do not locate the bender on damp or wet surfaces. Do not stand on damp or wet surfaces when repairing

or operating the bender.

• To avoid electrical shock, always unplug the bender power cord before removing end plates, motor or any electrical wiring.

CAUTION:

• To avoid physical injury, use two people to remove and install the bending shoe or to move it from place to place.

• Keep hands, clothing and electrical power cords away from moving rollers, bending shoe and exposed gears.

• Prior to installation: apply a coat of molycoat or equivalent to all shafts. When installing shafts,

use soft head mallets to seat in position.

REQUIRE TOOLS AND TEST EQUIPMENT

• Torque Wrench

• Allen Wrench

• Open Wrench ½" and 9/16"

• Sockets

• Lithium Grease

• Soft Head Mallet

TABLE OF CONTENTS

1.0 Troubleshooting Guide .........................................2-6

2.0 Pendant Troubleshooting ........................................ 6

3.0 Disassemble Instructions ....................................... 7

Limit Switch ..................................................... 7

Roller Housing ................................................. 7

Bender Shoe .................................................... 7

Circuit Board .................................................... 7

Electric Motor .................................................. 7

Drive Sprocket Assembly ................................ 8

4.0 Reassembly Instructions ........................................ 8

Drive Belt and Sprockets ................................ 8

Motor Assembly .............................................. 9

Shoe Shaft ....................................................... 9

Roller Housing ................................................. 9

Prinited Circuit Board ...................................... 9

Limit Switch Assem/Wiring ............................. 9

• 2" EMT and Rigid Conduit

• Silicone sealant

• Multimeter

• Strap Wrench

• Repair Parts Sheet

• Instructions Manual

5.0 Zero Adjustment .................................................... 10

6.0 Parts Breakdown ................................................... 11

B2000 Bender ................................................ 11

Bottom of Electric Motor .............................. 12

Shoe ............................................................... 13

Limit Switch ................................................... 14

Roller Housing ............................................... 15

Upper Roller / Handle ................................... 16

Sprocket Housing .......................................... 17

Handle / Control Circuit ................................18

7.0 Wiring Schematic .................................................. 19

8.0 Limit Switch Wiring Diagram ................................ 20

9.0 Maintenance .......................................................... 21

10.0 Interchangeable Part Compatibility ..............21-23

1

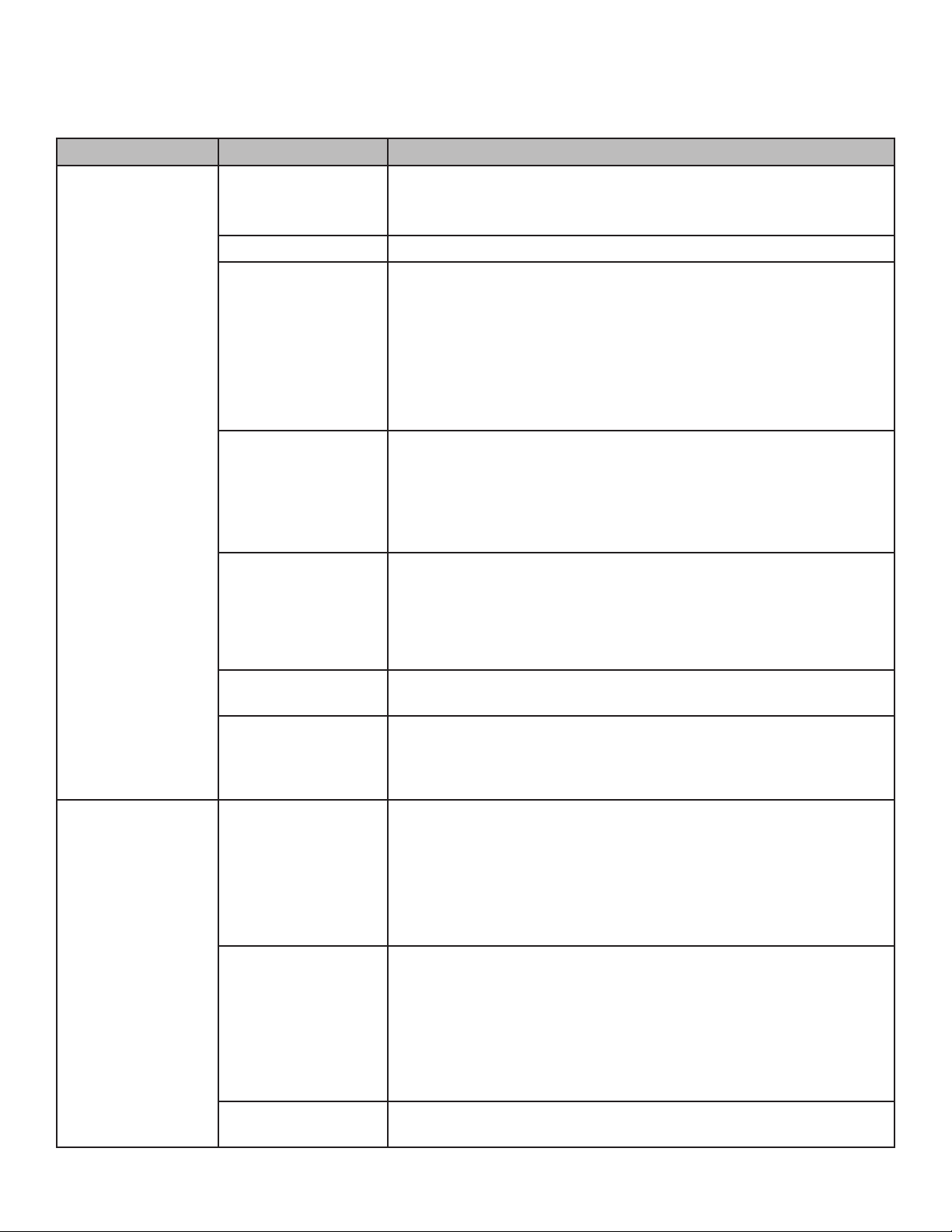

1.0 TROUBLESHOTTING GUIDE

*Note: Troubleshooting or maintenance that requires the B2000 to be disassembled in any way should be done by a

professional indicated by Gardner Bender to avoid permanent damage to the machine. Contact nearest Gardner Bender

Service Center for guidance.

PROBLEM POSSIBLE CAUSE ACTION

Bending shoe does not

move when switch is in

bend or return position.

Roller Housing and

Upper Roller do not

properly lock the

conduit into place.

Circuit break / power

switch in the off position.

No power to bender. Check for voltage at power source. Use 110 VAC, 15 amp outlet.

Blown Fuse.* *THIS PROBLEM WILL NOT OCCUR ON MODELS B2000-5 THROUGH

12V DC power supply

failed.

Remote pendant

wiring harness is

malfunctioning.

Power circuit on P.C.

board is malfunctioning.

Motor overload or/

overheated.

Upper Roller pivot is in

incorrect position.

Incorrect rollers used. If the Roller Housing (Part Number – CU295900K) has been disassembled in

Rollers are damaged Replace damaged rollers.

Check that power switch (Part Number – CB25) is in the “ON” position. When

the bender is ON, the two LEDs on the Rear Handle End Plate (Part Number –

HC12) will flash red, then green to indicate normal function. The green power

light on the control pendant (Part Number – PO5C) should be lit.

B2000-7 (SERIAL NUMBERS BEGINNING WITH LETTERS “F” - “K” OR

BENDERS MANUFACTURED BETWEEN 2001 AND 2007). THESE MODELS

DO NOT HAVE A FUSE.

Inspect 15 amp fuse and perform continuity check for a short.

If no continuity, replace fuse with new 15 amp, 125 volt fuse.

Fuse located behind handle mounting plate in the left corner of the

control panel. Refer to “Circuit Board” in “DISASSEMBLY” section (page 7)

for instructions.

Unplug bender power cord. On P.C. board, remove cover on plug.

Connect positive meter lead on black wire and negative lead on green wire.

Plug in the power cord.

Meter should indicate 12V DC.

If not, replace P.C. board, Part Number- EC2006 or HC12

Refer to “Circuit Board” in “DISASSEMBLY” section (page 7) for instructions.

Remote pendant wiring in the harness may be pinched or cut in a way that

causes bending to malfunction despite the indicator LEDs on Rear Handle

End Plate and Remote Pendant illuminating.

Replace wire harness. (Refer to Repair Parts List for illustration and

additional part numbers).

Refer to “Circuit Board” in “DISASSEMBLY” section (page 7) for instructions.

Control circuit is not activating bender.

Replace P.C. board, Part Number- EC2006 or HC12

Allow time for motor to cool. Activate bender.

If motor will not run, perform continuity check. If there is continuity, motor

is damaged and must be replaced, Part Number – CL43259

Refer to “Electric Motor” in “DISASSEMBLY” section (page 7) for instructions.

If the Upper Roller has been disassembled in the past, the pivot may be in the

wrong position.

While facing the B2000 push handles, remove the Upper Roller (Part Number –

CK994900) and look down the bearing shaft. There will be an off-center hole

at the bottom of the bearing. If the Upper Roller is correctly installed facing to

the right, this hole should be closer to you to ensure that the pivot is in

the right position.

Refer to “Roller Housing” in “DISASSEMBLY” section (page 7) for instructions.

the past, the rollers may have been incorrectly reassembled. The middle set of

1½" nylon rollers (Part Numbers – CU299281 and CU319281) must be placed

in the correct position and are not interchangeable. The upper set of 1¼"

rollers (Part Number – CU300281) can be swapped and the lower set of

2" rollers (Part Number – CU298281) can be swapped.

Refer to “Roller Housing” in “DISASSEMBLY” section (page 7) and “Roller

Housing” in “RE-ASSEMBLY” section (page 9) for instructions on assembling

the rollers.

Refer to “Roller Housing” in “DISASSEMBLY” section (page 7) for instructions.

2

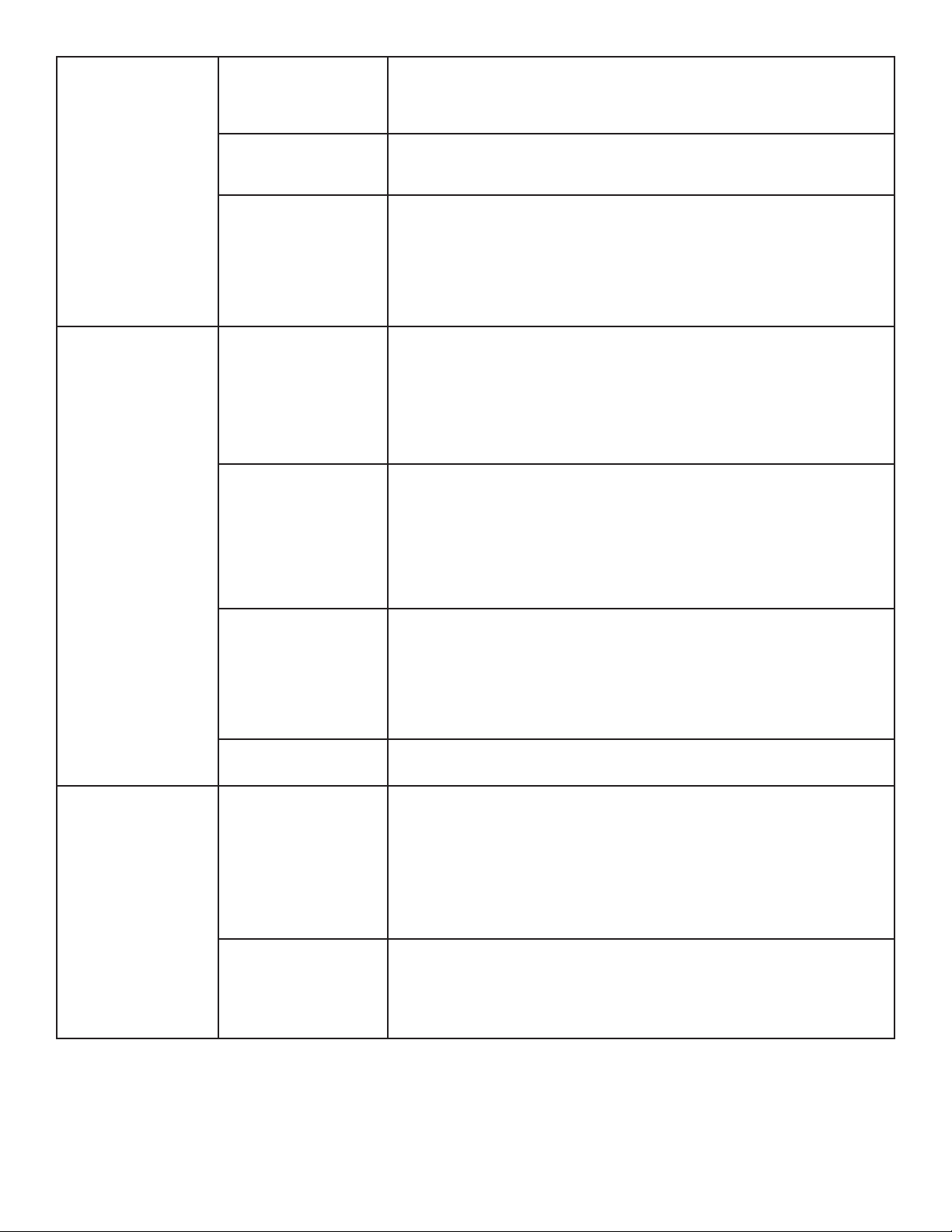

Drive belt tensioning

seems loose.

Bend switch does not

function, return switch

functions.

Bend function works,

return switch does not.

Belt is worn out. Belt may be worn or damaged and must be replaced,

Part Number – CL310014.

Refer to “Drive Sprocket Assembly” in “DISASSEMBLY” section (page 8)

for instructions.

Tensioner failure. Tensioner may be damaged and must be replaced, Part Number – CL306900.

The motor must be removed in order to remove the tensioner. Refer to

“Electric Motor” in “DISASSEMBLY” section (page 5) for instructions.

Motor pulley is lose. If the motor has been disassembled in the past, thread-locking fluid may

not have applied to the containing screw of the motor pulley (Part Number –

CL311019) when reassembling the motor assembly (Part Number – CL43259).

Apply thread-locking fluid on containing screw and assemble it to the

motor pulley.

Refer to “Electric Motor” in “DISASSEMBLY” section (pages 7 & 8)

for instructions.

Remote pendant

bend switch or wiring

inoperative.

Unplug bender power cord, test for continuity at hard¬ness to pendant. Attach

leads to black and white wires. Press bend switch. If no continuity, check

switch under pendant cover. Place ohm meter on leads for black wire and

white wire. Depress bend switch.

If continuity exists, replace switch, Part Number - DA9687372.

If no continuity, wire harness is faulty.

Refer to “Limit Switch” in “DISASSEMBLY” section (page 7) for instructions.

Bend limit switch or

harness to limit switch

is malfunctioning.

Unplug bender power cord. Perform continuity check on green and orange

wires. Press bend limit switch actu¬ator tab.

If continuity exists, replace switch, Part Number - DA9687372.

If no continuity, check wiring harness. (Refer to Repair Parts List for

illustration and additional part numbers).

If no continuity exists on wire harness, it must be replaced.

Refer to “Limit Switch” in “DISASSEMBLY” section (page 7) for instructions

Plunger on bend limit

switch is not being

tripped by the shoe post.

Remove shoe indicator plate (Part Number – CM801950). Observe the shoe

post as it passes the bend limit switch (Part Number - DA9687372). The shoe

post should trip the plunger on the bend limit switch as it passes over the limit

switch.

If the shoe post is not tripping the plunger, replace the limit switch, Part

Number- DA9687372.

Refer to “Limit Switch” in “DISASSEMBLY” section (page 7) for instructions.

Printed circuit board

malfunctioning.

Pendant return switch is

malfunctioning.

Replace P.C. board, Part Number- EC2006 or HC12

Refer to “Circuit Board” in “DISASSEMBLY” section (page 7) for instructions.

Unplug bender power cord. Perform continuity check on pendant return

switch. Attach leads to black wire and white wire, depress return switch.

*The colors described here are not present on the model B2000-7 and B20008 pendant harness (B2000 SERIAL NUMBERS BEGINNING WITH LETTERS

“J” - “N” OR BENDERS MANUFACTURED AFTER 2007). However, the same

troubleshooting actions should be taken.

If continuity exists, replace switch, Part Number - DA9687372.

Refer to “Limit Switch” in “DISASSEMBLY” section (page 7) for instructions.

Wiring is malfunctioning. If no continuity, check wire harness. Attach ohm meter leads to orange

and blue wires. Depress return switch.

If no continuity; replace wire harness, Part Number – CL¬712647SR.

Refer to “Drive Sprocket Assembly” in “DISASSEMBLY” section (page 8)

for instructions.

3

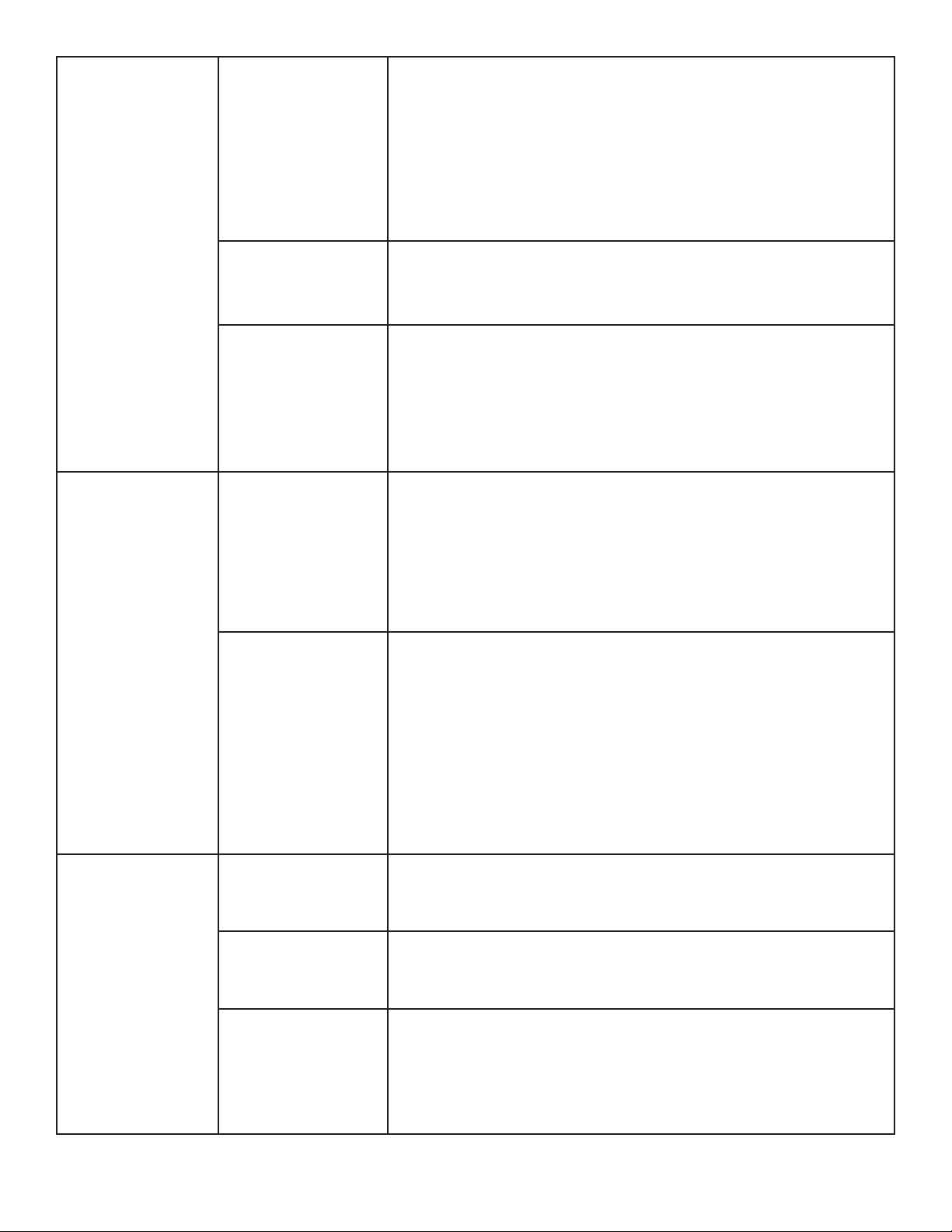

Bender shoe will not

return when pressing

return and jog button.

Bender shoe

successfully returns to

zero, indicator light on

top of Pendant Control

malfunctions and does

not light.

Bender consistently

develops over bends.

Jog button

malfunctioning.

Wire harness to pendant

damaged.

Pendant damaged or

malfunctioning.

Zero limit switch is

malfunctioning and is

not receiving voltage.

Harness to switch is

malfunctioning and is

not receiving voltage.

Bend angle is not

correctly indicated.

Bender zero adjustments

are necessary.

Bender angle

adjustments are

necessary.

Unplug bender power cord. Perform continuity check on wire harness.

Attach leads to red and green wires, Depress override (jog) button.

*The colors described here are not present on the model B2000-7 and

B2000-8 pendant harness (B2000 SERIAL NUMBERS BEGINNING WITH

LETTERS “J” - “N” OR BENDERS MANUFACTURED AFTER 2007).

However, the same troubleshooting actions should be taken.

If continuity exists, check jog switch in pendant control, (Parts Not Available).

Remove cover, place leads on red and green wires at switch. Depress jog

switch. If there is continuity, replace switch (Parts Not Available).

Refer to “Circuit Board” in “DISASSEMBLY” section (page 8) for instructions

If no continuity exists, fault lies in wire harness.

Replace wire harness. (Refer to Repair Parts List for illustration and

additional part numbers).

Refer to “Circuit Board” in “DISASSEMBLY” section (page 7) for instructions.

Replace pendant switch, Part Number – PO5C

If model B2000-4 or older (SERIAL NUMBERS BEGINNING WITH LETTERS

“A” - “E” OR BENDERS MANUFACTURED BEFORE 2001), customer may

need to upgrade to current model B2000. Older model pendant switch is no

longer available.

For models B2000-5 and B2000-6 (SERIAL NUMBERS BEGINNING WITH

LETTERS “F” - “H” OR BENDERS MANUFACTURED BETWEEN 2001 AND

2004), customer may be able to adapt new pendant (P05C) to older models.

Unplug bender power cord. Perform continuity check on harness from pendant

control. Attach leads to black and red wires.

Refer to “Circuit Board” in “DISASSEMBLY” section (page 5) for instructions.

If continuity exists, check the zero limit switch (see illustration in Repair Parts

List).

Attach the leads to black and red wires at the limit switch. Depress limit switch

actuator tab. If continuity exists, replace switch, Part Number- DA9687372.

Refer to “Limit Switch” in “DISASSEMBLY” section (page 7) for instructions.

Unplug bender power cord. Perform continuity check on wire harness

from limit switch.

If no continuity exists, the wire harness is malfunctioning.

Remove and strip wire harness wire ends, crimp on female terminals

(Part Number – 21-161F), and reconnect terminals to limit switches.

If problem continues, replace wire harness.

In order to replace the limit switch wire harness, the following components

need to be disassembled: bender shoe (item #1), sprocket (item #8),

end plate (item #26), and handle (item #38). Please refer to Figure 1 to

identify listed parts.

Refer to “Bender Shoe”, “Drive Sprocket”, and “Limit Switch” in

“DISASSEMBLY” section (pages 7 & 8) for instructions.

Ensure that the flat edge of the pointer (Part Number – 802950N) is on a line

indicating the exact degree of bend desired, not the angled edge. Failure to do

this will lead to inaccurate bends.

Refer to Instruction Sheet for operation instructions.

Ensure bender zero adjustment has been performed. This is required

after every re-assembly.

Refer to “ZERO SET ADJUSTMENT” section (page 10) for mechanical

adjustment instructions.

Differences in conduit characteristics and other variations can lead to incorrect

scale indications. Loosen the size scale (for type material being bent) mounting

screws. Slide the scale clockwise as many degrees as the over bend (if bend is

5° over, move indicator 5° clockwise). The degree of movement is observed by

watching one of the size marks as it moves past the angle disc scale. Tighten

the mounting screws.

Refer to Instruction Sheet for more Angle Adjustment instructions.

4

Bender consistently

develops over bends

Bender does not stop

at selected bend angle.

During return function,

bender shoe does not

stop at zero point.

Bender shoe does not

stop rotating in both

the return and bend

directions.

Braking resistor on P.C.

board is malfunctioning.

P.C. board circuit is

malfunctioning.

Bender is incorrectly

set up.

Bend limit switch is not

being actuated by shoe

post.

Bend limit switch is

malfunctioning.

Braking resistor is

malfunctioning.

Brake circuit (P.C. board)

is malfunctioning.

Plunger on return

limit switch is not

being tripped by the

trip ring tab.

Bend limit switch is

malfunctioning.

Return limit switch is

malfunctioning.

Brake resistors are

malfunctioning.

Limit switches

assembled incorrectly

on the switch arm.

Unplug bender power cord. Perform resistance measurements on braking

resistor. Remove chassis from rear of bender. Attach ohm meter across to

brown and gray wires.

If meter reads above 11 ohms, replace resistor.

Refer to “Circuit Board” in “DISASSEMBLY” section (page 7) for instructions.

Remove and replace P.C. Board, Part Number- EC2006 or HC12.

Refer to “Circuit Board” in “DISASSEMBLY” section (page 7) for instructions.

Ensure bender angle adjustment and zero adjustment has been performed.

This is required after every re-assembly.

Refer to “ZERO SET ADJUSTMENT” section (page 10) for mechanical

adjustment instructions. Refer to Instruction Sheet for Angle Adjustment

instructions and correct set up instructions.

Remove shoe indicator plate. Observe the tabs as they pass the bend limit

switch.

Adjust switch until tabs correctly contact the posts.

Refer to “Limit Switch” in “DISASSEMBLY” section (page 7) for instructions.

Unplug the bender power cord. Attach leads to orange and green wires at the

switch. Continuity should exist. Push the actuator tab (on the switch).

Continuity should be broken. If not, replace the switch.

Refer to “Limit Switch” in “DISASSEMBLY” section (page 7) for instructions.

Unplug the bender power cord. Perform resistance measurement on braking

resistor. Attach leads across terminals.

A 9-11 ohms (+ 1 ohm) resistance is normal. Other readings are unacceptable.

Replace braking resistor, Part Number – RA19.

Refer to “Circuit Board” in “DISASSEMBLY” section (page 7) for instructions.

If all other tests are positive, replace P.C. board, Part Number– EC2006

or HC12.

Refer to “Circuit Board” in “DISASSEMBLY” section (page 7) for instructions.

Remove limit switch assembly. Observe tab to return limit switch contact.

If switch is not contacting tab, adjust switch position.

Refer to “Limit Switch” in “DISASSEMBLY” section (page 7) for instructions.

If post to switch is correct, perform bend limit switch continuity check. Attach

leads to orange and green wires. Press limit switch tab.

Continuity should result. If not, replace switch.

Refer to “Limit Switch” in “DISASSEMBLY” section (page 7) for instructions.

Unplug the bender power cord. Perform return limit switch continuity check.

Attach leads to white and blue wires.

Continuity should be broken. If not, replace return limit switch.

Refer to “Limit Switch” in “DISASSEMBLY” section (page 7) for instructions.

Unplug the bender power cord. Perform resistance measurement on each

resistor. Place ohm meter leads on gray and brown wires.

Meter should read 9-11 ohms. If reading is over 11 ohms, replace resistor.

Refer to “Circuit Board” in “DISASSEMBLY” section (page 7) for instructions.

If the Limit Switch has been disassembled in the past, the switches may have

been reassembled incorrectly on the switch arm. The switch arm must have

two limit switches (blue face, facing away from arm) on the long side of the

arm, and one limit switch (black face, facing away from arm) on the short side

of the arm.

Refer to “Limit Switch” in “DISASSEMBLY” section (page 7) for instructions.

5

Bend function works,

Wiring Schematic

return function results

in bending direction.

Return function works,

bend function results in

shoe moving in return

Direction circuit on P.C.

board is malfunctioning.

Brake circuit on P.C.

board is malfunctioning.

Replace P.C. board.

Refer to “Circuit Board” in “DISASSEMBLY” section (page 7) for instructions.

If all other tests are positive, replace P.C. board.

Refer to “Circuit Board” in “DISASSEMBLY” section (page 7) for instructions.

direction.

Return function works.

Depressing bend

switch, shoe moves

Direction circuit on P.C.

board is malfunctioning.

Replace P.C. board.

Refer to “Circuit Board” in “DISASSEMBLY” section (page 7) for instructions.

in return.

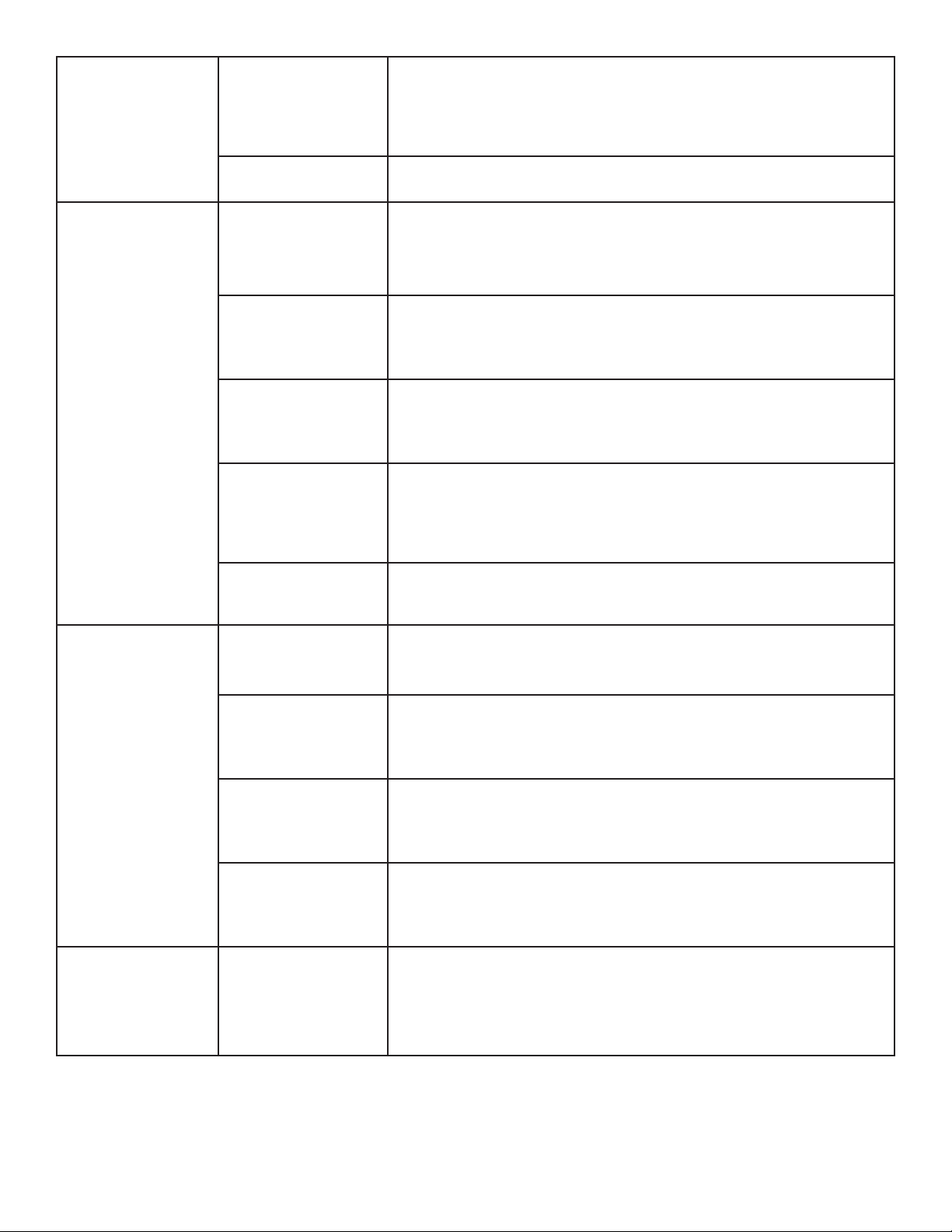

2.0 PENDANT (P05C) TROUBLESHOOTING

1. Verify continuity for both wires traveling from the zero limit switch down to the wire harness.

GREEN

(OPEN)

ORANGE

BEND LIMIT SWITCH

BLOCK MOUNTING

(OPEN)

BLACK

RED

ZERO STOP SWITCH

WHITE

(OPEN)

BLUE

K

RETURN LIMIT SWITCH Typical Switch Contacts

COMMON

NORMALLY OPEN

NORMALLY CLOSED

2. Verify that the black wire goes to the pin on the limit switch that is separate from the other two, and that the red wire

is connected to the middle pin.

3. Test Zero Light - Take a multimeter and set it to the diode (

) function and place the red lead on the orange wire

in the harness and the black lead to the red (pink) wire in the harness. This should illuminate the green Zero LED

4. Test Power LED - Take a multimeter and set it to the diode (

) function and place the red lead on the orange wire

and black lead on the yellow wire. This should illuminate the red Power LED.

5. Test Bend Button - Set a multimeter to the continuity or ohms function. Place one meter lead to the pin of the Black

wire in the pendant wire harness, and place the other lead on the pin for the Blue with Black strip wire. While the

probe tips are making contact with the pins in the harness, press the bend button. When the button is pressed, 0

Ohms and/or the continuity buzzer should go off.

6. Test Return Button - Set a multimeter to continuity or ohms function. Place one meter lead on the pin of the Black

wire in the pendant wire harness. Place the other meter lead to the pin of the Blue wire in the harness. With the

probes still making contact with the pins, press the Return button. When the button is pressed, 0 Ohms and/or the

continuity buzzer should go off.

7. Test Jog Button - Set a multimeter to the continuity or Ohms function. Place one meter lead to the pin of the Black

wire in the pendant wire harness, and place the other lead on the pin for the Brown wire. While the probe tips are

making contact with the pins in the harness, press the bend button. When the button is pressed, 0 Ohms and/or the

continuity buzzer should go off.

6

3.0 DISASSEMBLY INSTRUCTIONS

IMPORTANT: To avoid unnecessary service, the bender

should be tested prior to any service work. Please refer

to the maintenance section in the instructions manual and

Troubleshooting section.

Limit Switch (Figure 3)

1. Prior to removing components of the limit switch

and angle adjustments, the bending shoe, trip ring

and sprocket housing must be marked to aid in

re-assembly.

2. Position the bending shoe to the zero point by

pressing the pendant in “RETURN. Continue holding

the switch until the shoe stops and the zero light

comes on.

3. Unplug the bender power cord.

4. Scribe a mark on the side of the trip ring (Figure 1)

and a matching mark on the bending shoe.

5. Scribe a mark on the lower portion of the bending

shoe and on the sprocket housing (Figure 1).

6. Remove the silicone packing from the trip ring

mounting screws (Figure 3). Remove the mounting

screws and the top plate assembly (Figure 3), the size

indicator plates must not be removed.

7. Remove and tag the wires attached to the limit

switches (Figure 3). Leave the switches (Figure 3)

attached unless they require replacement.

8. Remove the springs and the three screws from the

plate assembly (Figure 3).

9. Leave actuator and clamp attached to upper plate

assembly unless damaged.

10. Examine all components for signs of wear or damage.

Use troubleshooting procedures to electrically check

switches. Repair or replace items that are worn,

damaged or non-functional.

11. Refer to “RE-ASSEMBLY” section of this manual.

Roller Housing (Figure 4 & 5)

1. Remove the pin (Figure 5 Item #6) securing the upper

roller arm (#5). Remove the nut (Figure 5 Item #10)

and remove the cap screw (Figure 5 #9) securing the

arm in the Cam Shaft (Figure 5 Item #7).

2. Remove the cap screw (Figure 5 Item #12) and the

washer (Figure 5 Item #13). Lift the roller housing

(Figure 4 Item #1) from the shaft. Remove the thrust

washers (Figure 1 Item #21) and the shims (Figure 1

Item #22).

3. Inspect all rollers, the housing and shaft for wear and

damage. Replace worn or damaged items.

4. All nylon rollers should be secured in the housing by

retaining rings around the roller shafts (Figure 4). Be

sure that the correct rollers are reassembled in the

exact location they were in originally. All new rollers

contain factory installed bearing.

Bender Shoe (Figure 1 & 2)

1. Prior to removing the bending shoe, the limit switch

assembly must be removed. Refer to “LIMIT SWITCH”

in the disassembly procedures.

2. Remove the four bolts (Figure 1 Item #9) and washers

(Figure 1 Item #10) located on the flat portion of each

side of the shoe (Figure 2 Item # 1).

3. Two people are required to lift the bending shoe. Lift

at two places (180° apart) and pull the shoe straight

up until it clears the shoe shaft.

4. Inspect the shoe for worn grooves, cracks or other

damage. Each conduit groove should be checked for

wear by placing a piece of conduit (of correct size and

material) into the groove. It should fit easily without

excessive gaps above, below or behind it.

5. If shoe damage is suspected, a dye penetrate may be

required to locate cracks in the casting.

6. Refer to Re-Assembly procedures.

Circuit Board (Figures 7 / Insert B)

1. The printed circuit board is mounted inside of the

sprocket housing. Access is gained by removing the

handle assembly.

WARNING: To avoid electrical shock, unplug the

bender power cord prior to removing the handle and

access plate.

2. Remove the four screws and washers (Figure 7 Items

#13 & 17).

3. Remove the handle assembly (Figure 1 Item# 38)

NOTE: Hold the handle to prevent it from falling and

causing damage to electrical connectors inside the

sprocket housing.

4. Lower the handle and plate assembly. Unplug the

power cord receptacle (Figure 7 Item #3) from the

P.C. board plug. Unplug the pendant receptacle (Fig.

7 Item #7) from the P.C. board plug.

5. Conduct testing procedures described in the

“Troubleshooting” section. See Insert B for wiring

diagram.

Electric Motor (Figure 6)

WARNING: Unplug bender power cord prior to removing

motor or wiring.

1. Remove acorn nuts securing the motor bottom cover.

2. Remove electrical wires from bottom of motor. Refer

to (Page 14 Insert A).

3. Remove bolt and washer (Figure 6 Item #26 & 27)

which secures the locking plate (Figure 6 Item #37)

to the bottom of the sprocket housing. Remove bolt

(Figure 6 Item #38), lock washer (Figure 6 Item #39)

and washer (Figure 6 Item #40) which secures the

sprocket shaft in the locking place.

4. Rotate the sprocket shaft by placing the locking plate

over the shaft flats. Turn the shaft until the sprocket

belts and chains are loose.

5. Remove the conduit nut (Figure 6 Item #15) from the

motor connection. Slide the flexible conduit out of the

7

elbow and pull the wires out.

6. Remove the rear access plate by removing 4 cap

screws and washers.

7. Remove the four cap screws and washers (Figure 6

Item #18 & 19) securing the motor to the sprocket

housing, Remove the motor, unhook the drive belt

from the motor shaft.

8. Remove the belt tensioner (Figure 6 Item #2) by

removing nut and washer. The tensioner shaft is

spring loaded. Remove the tensioner assembly

spring and shaft from inside the sprocket housing.

Drive Sprocket Assembly (Figure 6)

1. Separate the drive chain (Figure 1 Item #8) by

removing the master link.

NOTE: The master link is assembled with clip on top

– it must be reassembled the same way.

2. Remove drive sprocket (Figure 1 Item #7) from shoe

shaft (Figure 6 Item # 31), Remove spacer (Figure 1

Item #5) and DU Washer (Figure 1 Item #6).

3. Remove dust cap (Figure 1 Item #36) from sprocket

housing.

4. Remove cap screw (Figure 6 Item #22) and washer

(Figure 6 Item #47 / 23). Lightly tap bottom of roller

housing shaft (Figure 6 Item #11) to remove it from

the sprocket housing.

NOTE: Use brass drift pin or leather mallet to remove

shafts.

5. Rotate sprocket (Figure 6 Item # 34) until the master

link for chain (Figure 6 Item #28) appears in the

access opening.

6. Remove the master link and remove the chain from

the sprocket housing.

7. Remove the cap screw (Figure 1 Item #22) and

washer (Figure 1 Item #23 / 47). Carefully remove

shoe shaft (Figure 6 Item #31) by holding the limit

switch wires inside the sprocket housing and lifting

the shaft out of the housing. Remove bearing (Figure

6 Item# 21).

8. While removing the sprocket shaft (Figure 6 Item

#33), hold the sprocket down, tap the shaft (from the

bottom) and remove it from the sprocket housing.

9. Remove sprocket assemblies (#8) and (#9) from the

housing and remove thrust washer (#10).

10. Remove sprocket assembly (#11) and thrust washer

(#12) from the housing.

11. Clean the sprocket housing (inside), wipe away

grease and dirt. Use lower pressure air hose to

remove any accumulation of debris.

12. Clean all sprockets, gear teeth and chains. Check

for worn gear teeth and worn or damaged bearings.

Check chains and drive belt for wear and/or damage.

Replace damaged or worn items.

4.0 RE-ASSEMBLY INSTRUCTIONS

Drive Belt And Sprockets (Figure 6)

1. Position drive belt sprocket (Figure 6 Item #24) and

shoe sprocket (Figure 6 Item #29) on a flat surface.

Connect 3/8” chain (Figure 6 Item #10) to drive belt

sprocket (upper gear) and to shoe bracket (large

lower gear). Insert master link (pin up).

2. Lift the belt sprocket, slip the belt (Figure 6 Item # 1)

under the sprockets and position it in the sprocket

grooves. Lift the shoe sprocket, position the belt so it

is around sprocket shaft boss (Figure 6).

3. Pull the belt tight around the belt sprocket. Fasten

the loose end together with a rubber band to keep

the belt snug on the sprocket.

4. Insert drive sprocket (Figure 6 Item #34) into the

housing (large gear up) and position the gear through

the hole (under bracket). Place small blocks between

the gear and the housing to hold the sprocket against

the inside of the housing.

5. Position shoe sprocket (Figure 6 Item #29) and belt

sprocket into the housing, from the motor end. The

belt sprocket is aligned under the drive sprocket and

the shoe sprocket is positioned under the shoe shaft

hole. The loose belt end belongs toward the motor

end of the housing. Position thrust washer (Figure

6 Item #20) between the belt sprocket and drive

sprocket, bearing surface facing up.

6. Place the thrust washer (Figure 6 Item #20) under the

shoe sprocket.

7. Align drive sprocket (Figure 6 Item #34) and belt

sprocket (Figure 6 Item #24) with the center hold

(under bracket on housing). Place bearing (Figure 6

Item #35) on top of sprocket. Remove blocks.

8. Mark high point on end of sprocket shaft (Figure 6

Item #33). Lubricate shaft with light coat of general

purpose grease. Insert shaft (flats first) through the

sprockets. Drive flush with the top sprocket.

9. Insert cap screw (Figure 6 Item #27) through washer

(Figure 6 #26) and locking plate (Figure 6 Item

#37). Torque to 28 – 32 ft. lb. Install cap screw into

sprocket shaft under housing. Install cap screw

(Figure 6 Item #38) and washer (Figure 6 Item #39

/40) in hole aligned with lock plate slot. Torque to 19

– 21 ft. lb.

10. Mark the middle link of chain (Figure 6 Item #28).

Put the chain over the small (upper) gear teeth of

sprocket (Figure 6 Item #29). Place chain around

large gear of sprocket (Figure 6 Item #34).

11. Install master link through the access hole in the

housing (pins up).

12. Install tensioner assembly by inserting shaft (Figure 6

Item #1) through the inside of the sprocket housing

(threads outward). Assemble the lock washer (Figure

6 Item #2) and nut and tighten.

13. From inside the sprocket housing slide the spring

over the shaft, then slide the tension roller over the

shaft (roller toward drive belt). Place something under

the tension bracket to wedge it in place away from

the drive belt.

8

Motor Assembly (Figure 6 / Insert A)

1. Remove restraint from drive belt.

2. Place gasket (#1) on motor flange. Insert motor into

the sprocket housing. Install one mounting screws

and washers into mounting hole closer to the belt

3. Position the drive belt over the motor pulley. Align the

belt to ride at the same height on the motor pulley

and grooved sprocket.

4. Using a strap tool put it around the motor to help

align the mounting holes with the motor. Install the 3

mounting screws and washers.

5. Remove the wedge from beneath the tension bracket.

The roller should engage the belt.

6. Connect wiring to base of motor. (Figure 1 Insert B).

Shoe Shaft (Figure 6)

1. Position the shoe shaft (Figure 6 Item #31) in the

sprocket housing (Figure 6 Item #32) with the hole for

the wiring facing the hole in the housing.

2. Insert the D.U. bearing (Figure 6 Item #21) between

the shoe sprocket and the sprocket housing (Figure 6

Item #32).

3. Push the shoe sprocket (Figure 1 Item #7) into the

sprocket until it rests on the housing. Install two

washers (Figure 6 Item #23 / 47) and cap screw (#22)

through bottom of housing and tighten to secure

shoe shaft. Torque 68-82 ft. lbs.

4. Install connector into bottom of sprocket housing and

tighten. Install bushing in wire hole (housing) near the

shoe shaft.

5. Install limit switch wires (Figure 1 Item #3) from inside

sprocket housing, through the bushing and into the

side of the shoe shaft. Push the wires up and through

the top of the shaft. Pull at least six inches out of the

shaft.

6. Position shoe drive sprocket (Figure 1 Item #7) over

the shoe shaft. Install the drive chain around the shoe

sprocket and the drive sprocket (Figure 1 Item #8)

(under housing bracket).

7. Install master link, pins down. Support the sprocket

with blocks to level the chain and fasten the master

link.

8. Place the thrust washer (Figure 1 Item #6) and washer

(#5) on the shoe shaft. Place the bending shoe over

the shaft and align the mounting holes with the

sprocket holes. Use alignment marks placed during

removal, to position the shoe on the shaft. Install four

cap screws (Figure 1 Item #9) and washers (#10) to

secure the shoe and sprocket. Torque to 68-92 ft. lbs.

Roller Housing (Figure 4 & 5)

1. Insert roller housing shaft (Figure 6 Item #11) into

sprocket housing until it seats in bottom of the

housing.

2. Secure the shaft with washer (Figure 6 Item #23) and

cap screw (Figure 6 Item #22) from the bottom of the

sprocket housing.

3. Place shim (Figure 1 Item #22) and washers (Figure 1

#21) over the shaft. Install the complete roller housing

on the shaft. Secure with cap screw (Figure 5 Item

#12) and washer (Figure 5 #13).

4. Before securing cam shaft (Figure 5 Item #7) to shaft

(Figure 6 Item #11), notice that the hole located on

bracket is off center. Make sure that the hole is closer

to the handle of the bender and secure cam shaft

with cap screw (Figure 5 Item #12) and washer (#13).

5. Position the upper roller arm (Figure 4 Item #11) in the

bracket and install mounting bolt (Figure 5 Item #9),

washer (#10), nut washer (#11) and pin (#6).

Printed Circuit Board (Figures 7 / Insert B)

1. Connect the sprocket harness receptacle to the

board plug. Connect motor wire receptacle to the

board plug.

2. Connect the pendant receptacle to the P.C. board

plug. Connect power cord receptacle to P.C. board

plug. Be sure the harness ground wires are attached

to the end plate.

3. Position the handle assembly against the sprocket

housing and attach with 4 washers and screws.

Limit Switch Assembly & Wiring (Figure 3 / Insert B)

1. Insert the four wires from the main harness into

the conduit connecter, through the conduit and

connecter (Figure 6 #16 / 17).

2. Attach wires to motor. See Insert A for wire colors

and terminal locations. Install motor cap using cap

nuts.

3. Pull any excess wire into the sprocket housing. Be

sure main harness is fastened to the housing with the

(J) clip.

4. Insert the limit switch wires through the plate assembly

(Figure 3 Item #9). Position the thrust washer and

plate into the bending shoe and fasten with lock

washers (Figure 3 Item #9) and cap screws (included).

5. Install the return limit switch and zero stop switch,

secure with screws to the switch arm (Figure 3 #7 / 8

/ 9).

6. Install the Bend limit switch and secure to switch arm

with screws (Figure 3 Insert B).

7. Connect wires to switches as shown in Insert B and

set the switch arm onto the plate assembly (#9).

8. Insert clamp assembly (#1) through the trip ring

assembly (#5) and secure the actuator (#6).

9. Place the trip ring (#5) on the shoe and align the

marks scribed, during disassembly, on the trip ring

and bending shoe. Secure trip ring with screws.

9

5.0 ZERO SET ADJUSTMENT

TO ENSURE ACCURATE BENDS, THE BENDER ZERO ADJUSTMENT MUST BE ACCOMPLISHED

AFTER RE-ASSEMBLY.

1. Plugs bend power cord into 110/115V outlet. Push upper roller assembly against the stop on the sprocket housing

(Figure 19).

2. Press and hold “ADVANCE” on pendant switch until RIGID side of shoe is facing the upper roller housing.

3. Place a straight edge against the shoe (clamp surface) and toward the upper roller shaft.

4. Jog the bender until 2 ½ inches exists between the straight edge and the shoe clamp (See Figure 4).

5. Loosen the trip ring mounting screws (See Figure 5). Rotate the trip ring until the zero light, on the pendant, is on

(Figure 6). Tighten the mounting screws and cover screws and cover screw slot with a clear silicone sealant.

Figure 4

Figure 5

Figure 6

10

Figure 1

Figure 1

B2000 Bender Assembly

B2000 Bender Assembly

9

2

3

9

23

10

24

10

1

21

22

7

8

5

6

34

35

37

26

20

36

4

35

17

34

35

12

38

27

(See Fig. 7)

34

25

SEE INSERT A Page 3

& Fig. 6, (page 8)

11

11

18

21

19

14

15

16

13

INSERT A

28

31

29

30

30

33

32

31

B2000 Bender Assembly

Item # Part # # Req’d Description

1 Figure 2, pg. 4 1 Shoe Sub Assm

2 Figure 3, pg. 5 1 Limit Switch Assm

3 CL712647SR 1 Cable, Limit and Switch

4 SHM115 1 Sprocket Housing

5 CL157108 1 Washer, Shoe

6 CL221108 1 Washer, Thrust

7 CL170228 1 Shoe Sprocket

8 CL333066 1 Chain

9 Common Repl. 4

Part Hex Cap Screw

10 Common Repl. 4

Part

11 LA205 1 Leg Assembly (incl. 13, 19 & 21)

12 CK994900 1 Upper Roller and Handle (Figure 5)

13 CB208 2 Casters Assm (Hardware incl.)

14 CL185061 1 Locking Pin

15 CL183110 1 Spring

16 F57044 1 Ring

17 M00084 2 Screw, Shoulder

18 WB207 2 Wheel Assm (incl. 19 & 21)

19 Common Repl. 2

Part

3

⁄8"-24 x 2-1⁄2 Grade 5 Zinc Plated

3

⁄4” plu SAE Flat Washer

3

⁄32" x 1-1⁄4" Zinc plated cotter pin

B2000 Bender Assembly, cont.

Item # Part # # Req’d Description

20 CU295900K 1 Roller Housing Assm (Figure 4)

21 CK696108 1 Washer

22 CL229248 4 Shim

23 Common Repl. 1

Part Head Cap Screw Zinc plated

24 Common Repl. 1

Part

25 EC2006 1 Relay Control Assm (Figure 9)

26 LP204 1 End Plate (incl. 34 & 35)

27 HC12 1 Handle & Ctrl Ckt Assm (Figure 7)

28 call tech support 1 Wire Assembly (See Above)

29 call tech support 1 Wire Assembly (See Above)

30 E1001104 2 Push-on Connector (See Above)

31 E1001021 2 Ring-Tongue Connector (See Above)

32 call tech support 1 Wire Assembly (See Above)

33 call tech support 1 Wire Assembly (See Above)

34 Common Repl. 8

Part Head Cap Screw

35 Common Repl. 8

Part Lock Washer

36 CM129006 1 Seal

37 LK15 2 Decal Kit

38 H905 1 Rear Handle

3

⁄8" -16 x 1" g. Low Carbon Hex

5

⁄16" Zinc plated USS Flat Washer

1

⁄2"-13 x 7⁄8" Alloy Plain Finish Socket

1

⁄2" Plain Finish High Collar

12

Figure 2

Shoe Subassembly

8

10

11

9

3

GB

2

4

1

4

Shoe Subassembly

Item # Part # # Req’d Description

1 CL199809K 1 Shoe Bending (Incl. items 7, 8, 9 and 10)

2 CN542005 1 Clamp, IMC (Incl. items 4, 5, 6)

3 CN541005 1 Clamp, EMT (Incl. items 4, 5, 6)

4 Common 6 5⁄8" -18 x 21⁄4" Plain Alloy Socket Head

Replaceable Part Cap Screw

5 Common 6 5⁄8" Plain Finish Medium Split Lock

Replaceable Part Washer

6 Common 6 5⁄8" -18 Low Carbon Plain Finish

Replaceable Part Finished Hex Nut

6

5

7 7

8

Shoe Subassembly, cont.

Item # Part # # Req’d Description

7 CK691061 2 Pin

8 CL61107 2 Bearing (includes 2)

9 CM126026 1 Instruction Decal - Stub-Up

10 CM127026 1 Instruction Decal - Offset

11 CM627028 2 Insert, Shoe

13

1

2

3

5

6

9

8 8

8

7

1

1

B2000CK

Clamp kit

2

CM802950N

Knob Sub Assembly Kit

3

CM767108

Washer

4

CM801950

Upper Plate Assembly

5

B2000-TRK

Trip Ring Assembly Kit

6

CM803950N

Actuator Kit

7

B2000LSK

Limit Switch Kit

8

DA9687372

Limit Switch (3-Pack)

10

CM593026

Pipe size decal EMT

11

CM594026

Pipe size decal Rigid/IMC

12

ZCF679220

Plate Assembly Kit

12

11

10

4

(Incl. #10

& #11)

Figure 3

Limit Switch Assembly

Limit Switch Assembly

Item # Part # Description

1 B2000HCK Clamp Kit

ZCM793055N Thread Locker (for #1) not pictured

2 CM802950N Knob Sub Assembly Kit

3 CM767108 Washer

4 CM801950 Upper Plate Assembly

5 B2000-TRK Trip Ring Assembly Kit (Incl. #10 & #11)

6 CM803950N Actuator Kit

7 B2000-LSK Limit Switch Kit

8 DA9687372 Limit Switching (3-Pack)

9 CM797950KW Plate Assembly Kit

10 CM593026 Pipe size decal EMT

11 CM594026 Pipe size decal Rigid/IMC

12 ZCF679220 Springs

14

Figure 4

7

7

7

10

10

8

5

3

9

2

6

7

3

9

11

2

1

4

5

13

12

Roller Housing Assembly – CU295900K

NOTE: Item 11 is a separate

assembly not included with the

roller housing (Figure 5).

Roller Housing Assembly-CU295900K

Item # Part # # Req’d Description

1 CU296037K 1 Housing, Roller

2 CL61107 2 Bearing

3 Common Repl.

Part

4 CU299281 1 11⁄2" Roller

5 CU298281 2 2” Roller (Set of 2)

6 CN452104K 1 Shaft, Roller

7 Common Repl. 4

Part

8 CU319281 1 11⁄2" Roller

*

*When the housing is ordered, the bearings will be pre-installed.

7

⁄8" External Retaining Ring

7

⁄8" Carbon Spring Steel E-Clip

Roller Housing Assembly-CU295900, cont.

Item # Part # # Req’d Description

9 CU300281 2 11⁄4" Roller (Set of 2)

10 CU297104 2 Shaft, Roller

11 CK994900 1 Upper Roller Assm

(see Figure 5)

12 DC694104 1 Axle

13 CL343550 1 Grip, Handle

B2000-RK Kit includes:

Roller and Ring Kit

11⁄2" Roller

Qty

1

2

1

2

2

4

Part#

#4

#5 2" Roller (Set of 2)

#8 11⁄2" Roller

#9 11⁄4" Roller (Set of 2)

#3 7⁄8" External Retaining Ring

#7 7⁄8" Carbon Spring Steel E-Clip

15

Figure 5

Upper Roller and Handle Assembly – CK994900

4

1

2

3

4

10

11

9

5

Upper Roller and Handle Assembly-CK994900

Item # Part # # Req’d Description

1 Common Repl. 1 1" External Retaining Ring

Part

2 CK569108 1 Washer

3 CK575281K 1 1⁄2"-1" Roller

4 CK295107 2 Bearing (Set of 2)

5 CL30900 1 Roller Axle Assembly

6 Common Repl. 1 3⁄8" x 3" Zinc Coherless Hitch Pin

Part

7 CL662950KW 1 Cam Shaft

8 CK693107 2 Bearing (Set of 2)

9 Common Repl. 1 3⁄8" -16 x 3" A307A Low Carbon

Part Zinc Plated Hex Bolt

10 Common Repl. 1 3⁄8" - 16" Lock Nut- Nylon

Part

11 Order Kit LK15 1 Decal, Caution

12 Common Repl. 1 3⁄8" - 16 x 1" 1g. Low Carbon Hex

Part Head Cap Screw, Zinc Plated

13 Common Repl. Part 1 5⁄16" Zinc Plated USS Flat Washer

*

*

12

13

6

7

8

8

*These items come with bearings installed.

16

17

Figure 6

Sprocket Housing

Assembly - DA7058900

31

33

11

36

32

18

19

14

2

12

41

19

21

16

13

46

15

48

47

23

26

22

27

38

47

39

37

40

22

10

23

30

24

42

43

44

45

35

34

28

20

29

25

1

20

Sprocket Housing Assembly - DA7058900

Item # Part # # Req’d Description

1 CL310014 1 Drive Belt

2 CL306900 Includes:

1 Tensioner Assembly

1 Snap Ring

1 Roller

1 Bearing

1 Washer, Thrust

1 Tensioner Weldment

1 Spring

1 Shaft Tensioner

1 Nut, .375-16

10 CL335066 1 Chain, .375 Pitch

11 CW172104 1 Shaft, Roller Housing

12 C550357 1 Gasket, Motor

13 Common Repl. 1 Screw (10-32)

Part

14 CL43259 1 Motor Assembly

15 CL674096 1 Connector

16 CL673228 1 Conduit, Flexible

17 CL675096 1 Connector

18 Common Repl. 4 3⁄8" - 24 x 1" Grade S Plain Finish

Part Hex Cap Screw

19 Common Repl. 5 3⁄8” Plain Finish Medium Split

Part Lock Washer

20 CL54108 2 Washer, Thrust

21 CL656108 1 Bearing

22 Common Repl. 2 1⁄2" - 30 x 3" Grade 5 Plain Finish

Part Hex Cap Screw

23 Common Repl. 4 1⁄2" Belleville Washer

Part

*

24 CU541950W 1 Sprocket Assembly w/ Bearings

*

Sprocket Housing Assembly - DA7058900, cont.

Item # Part # # Req’d Description

25 CL53107 2 Bearing

26 CL12108 1 Washer

27 Common Repl. 1 3⁄8" - 16 x 2" Grade 5 Zinc Plated

Part Hex Cap Screw

28 CL334066 1 Chain, .625 Pitch

29 CU542950K 1 Sprocket Assembly w/ Bearings

30 CL670107 2 Bearing

*

31 CU674104 1 Shaft, Shoe

32 SHM115 1 Housing, Sprocket

33 CL309104 1 Shaft, Sprocket

34 CL667950KW 1 Sprocket Assembly w/ Bearings

*

35 CL53107 2 Bearing

36 CL224028 1 Stop Screw

37 CL669101 1 Locking Plate

38 Common Repl. 1 5⁄16" - 24 x 1⁄2" LG Grade 5 Med.

Part Carbon Stl. Zinc Plated

39 Common Repl. 1 5⁄16" Zinc Plated USS Flat Washer

Part

40 Common Repl. 1 1⁄4" Plain Finish USS Flat Washer

Part

41 CL311019 1 Pulley, 10 Groove

42 DA6153006 1 Connector (Body 40) - limit switch

43 CM26006 8 Terminal, Female - limit switch

44 CM33006 1 Connector (M-1) - motor

45 CM28006 2 Terminal, Female - motor

46 Common Repl. 1 #10 -32 x 3⁄32" LG.

Part

47 CU675108 2 Washer

48 Common Repl. 1 CAP

Part

*These items come with bearings installed.

17

Figure 7

Handle

Faceplate

White Wire

Note: Numbers molded

onto switch by the terminal

verify these before

attaching wires

Black Wire

to Circuit Board

Black Wire from

Power Plug

1

2

3

Handle and Control Circuit Assembly – HC12

7, 8

6

6

19

1

10

9

18

11

13

16

17

3, 4

12

HC12 Contents

Item # Part # # Req’d Description

1 CJ458885 1 Locknut

2 CM178647SR 1 Plug Assembly

3 CM32006 1 Receptacle, Power Cord

4 CM25061 2 Pin, Cord Receptacle

5 PO5C 1 Pendant Station Assm

6 Common Repl. 3 #6 -32 X

Part Cap Screw

7 DA6152006 1 Receptacle, Pendant

8 CM27061 8 Pin, Receptacle

9 LK15 1 Decal, Kit

10 LK15 1 Decal, Kit

11 EC2006 1 Circuit Board

12 H905 1 Handle Assembly

13 Common Repl. 4 1⁄2" - 13 x 7⁄8" Alloy Plain Finish

Part Socket Head Cap Screw

14 DA7046900 1 Wire, Jumper

15 F1550 1 Grip, Cord

16 Common Repl. 1 #10 Hi-Collar Helical Spring

Part Lock Washer

17 Common Repl. 4

Part Lock Washer

18 CB25 1 Switch

19 RA19 1 Braking Resistor

Item 3 is packed with item 4 loose.

Item 7 is packed with item 8 loose.

Instructions provided for assembling loose connectors.

DA 7070900 Limit Switch Jumper (not shown) (for older units)

1

⁄2" Plain Finish High Collar

3

⁄8" LG. Button Hd.

18

14

15

15

2

5

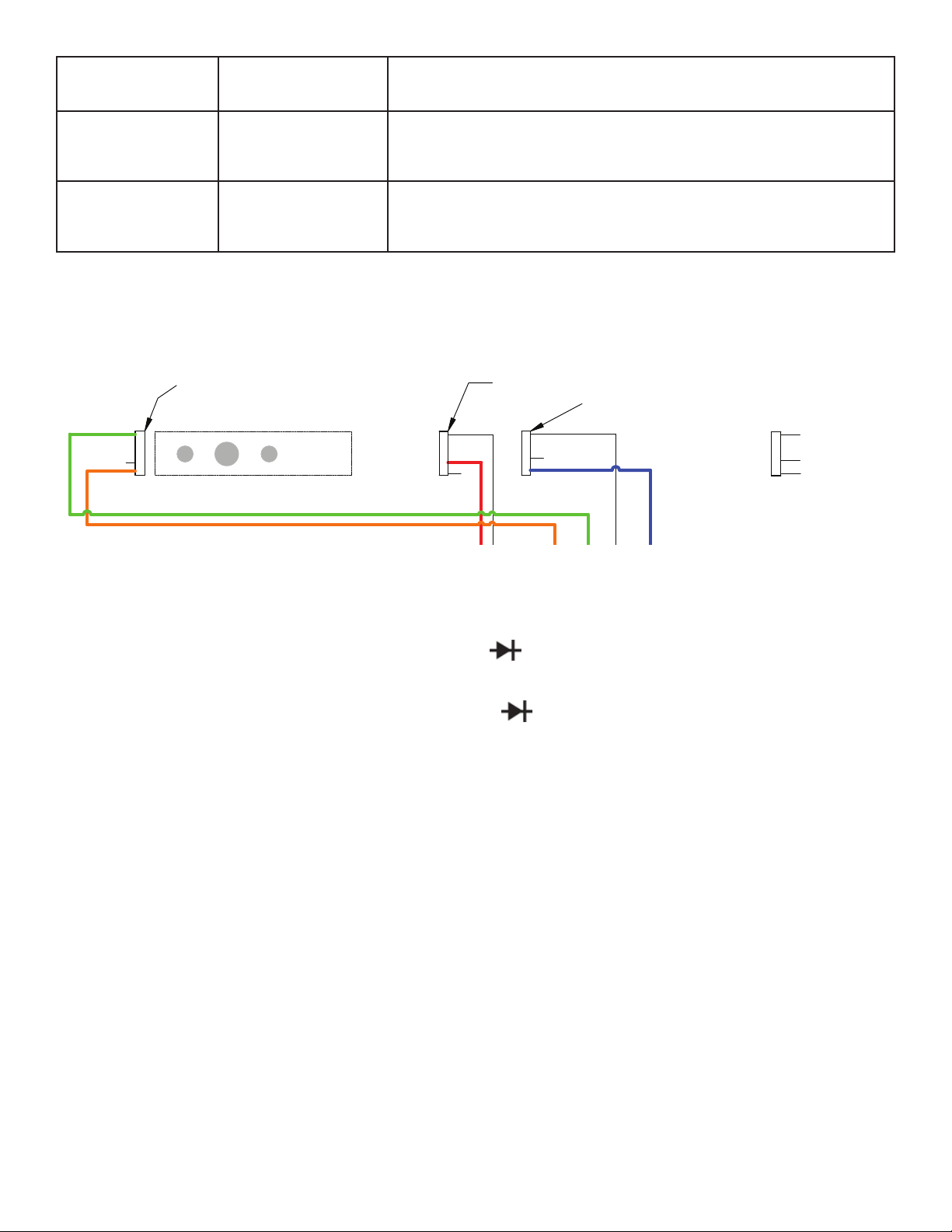

Wiring Diagram

for BMK3 Switch

BEND LIMIT SWITCH

Wiring Schematic

GREEN

(OPEN)

ORANGE

NOTE: 2-LONG STUDS FOR COVER MOUNTING ONLY

AZ

BLACK

BLOCK MOUNTING

BOTTOM OF MOTOR

YELLOW

GREY

ZERO STOP SWITCH

BLACK

RED

(OPEN)

BLACK

ORANGE GREEN

WHITE

(42)

(43)

(46)

RED

BLACK

(45)

YELLOW

(48)

RETURN LIMIT SWITCH Typical Switch Contacts

WHITE

(OPEN)

BLUE

(41)

BLUE

(44)

GREY

(47)

COMMON

NORMALLY OPEN

NORMALLY CLOSED

CONNECTOR TO CIRUIT BOARD

RED

MALE CONNECTOR

POWER CORD

FEMALE CONNECTOR

RED

BLACK

RED

BLACK

CIRCUIT BOARD

P5

P7

P8

P6

WHITE

WHITE

FEMALE CONNECTOR

BLACK

WHITE

BLACK

BMK3 SWITCH

BLACK

BLACK

WHITE

BLACK

MALE CONNECTOR

WHITE

19

Limit Switch Wiring Diagram:

Rear view

(insert terminals)

(face connects to PC board)

x

Yellow Grey

BlackRed Blue

OrangeWhite Green

Yellow – from motor Grey – from motor

Red – from zero stop switch Black – from zero stop switch Blue – from return limit switch

White – from return limit switch Orange – from bend limit switch Green – from bend limit switch

Front view

x

YellowGrey

BlackBlue Red

OrangeGreen White

20

9.0 MAINTENANCE

A troubleshooting aid exists on the printed circuit board mounted to the inside of the operating handle. If all systems are functional, a

white L.E.D. (pictured in Figure 13) will flash once every two seconds while the machine is powered up.

Error codes consist of different light patterns.

1. Blink twice = the motor is over heated.

2. Blink 3 times = limit switch has failed.

3. Blink 4 times = pendant control malfunction.

In addition the L.E.D. will be steady on if the bend or return button is being pressed.

White L.E.D.

Figure 13. L.E.D. Location

10.0 INTERCHANGEABLE PART COMPATIBILITY

The part descriptions listed in the table below have variations between models of the B2000 and may not be compatible with every

model. Part Numbers listed as “Interchangeable” are compatible with the B2000-8 and have the same Part Number. Part Numbers

listed as “N/A” are not used on that Model. If the part description is not listed in the table below, that part is interchangeable between

all models unless otherwise noted.

Model B2000-8

Serial Number

Beginning With

Approximate

Manufacturing

Date

SHOE SUBASSEMBLY

Shoe Insert

IMC/Rigid Clamp

EMT Clamp

Washer

LIMIT SWITCH SUBASSEMBLY

Clamp Kit

Knob Sub

Assembly Kit

Upper Plate

Assembly

Actuator Kit

(CURRENT)

N J

03/2014 07/2007 10/2004 03/2001 07/1997 05/1986 08/1984 01/1983 02/1982

1

CM627028 Interchangeable Interchangeable

CN542005 Interchangeable Interchangeable Interchangeable Interchangeable Interchangeable Interchangeable

CN541005 Interchangeable Interchangeable Interchangeable Interchangeable Interchangeable Interchangeable

N/A N/A N/A N/A N/A N/A N/A N/A B1040108

B2000HCK B2000-BCK B2000-BCK B2000-BCK B2000-BCK B2000-BCK B2000-BCK B2000-BCK B2000-BCK

CM802950N CM802950 CM802950 CM802950 CM802951 CM802952 CM802953 CM802954 CM802955

CM801950 CM801950KW CM801950KW CM801950KW CM801950KW CM801950KW CM801950KW CM801950KW CM801950KW

CM803950N CM803950KW CM803950KW CM803950KW CM803950KW CM803950KW CM803950KW CM803950KW CM803950KW

B2000-7 B2000-6 B2000-5 B2000-4 B2000-3 B2000-2 B2000-1 B2000

K

2

H F

(CM627028)

G

N/A N/A N/A N/A N/A N/A

E D C B A

(CN542005)

(CN541005)

CL214005 CL214005

CL215005 CL215005

(ORIGINAL)

21

Model B2000-8

Serial Number

Beginning With

Approximate

Manufacturing

Date

(CURRENT)

N J

03/2014 07/2007 10/2004 03/2001 07/1997 05/1986 08/1984 01/1983 02/1982

LIMIT SWITCH SUBASSEMBLY

Limit Switch Kit

Spring –

Middle Shaft

Shaft

Bushing

Plate Guide

Spring –

Supporting Shaft

Cap Screw

B2000LSK Interchangeable Interchangeable Interchangeable Interchangeable

N/A CF679110 CF679110 CF679110 CF679110 CF679110 CF679110 CF679110 N/A

N/A CM772104 CM772104 CM772104 CM772104 CM772104 CM772104 CM772104 N/A

N/A CM782039 CM782039 CM782039 CM782039 CM782039 CM782039 CM782039 N/A

CM770071N CM803950KW CM803950KW CM803950KW CM803950KW CM803950KW CM803950KW CM803950KW N/A

CF679220 N/A N/A N/A N/A N/A N/A N/A N/A

N/A CM474028 CM474028 CM474028 CM474028 CM474028 CM474028 CM474028 N/A

ROLLER HOUSING SUBASSEMBLY

Handle Grip

Axle

CK575281 Interchangeable Interchangeable Interchangeable Interchangeable

DC694104 Interchangeable Interchangeable Interchangeable Interchangeable

B2000-7 B2000-6 B2000-5 B2000-4 B2000-3 B2000-2 B2000-1 B2000

K

2

3

UPPER ROLLER AND HANDLE SUBASSEMBLY

Hex Head

Cap Screw

Flat Washer

Lock Nut

Lock Washer

Lock Pin

Hex Bolt

DU Bearing

B1077046 Interchangeable Interchangeable Interchangeable

CL944108 Interchangeable Interchangeable Interchangeable

CU438055 Interchangeable Interchangeable Interchangeable Interchangeable Interchangeable

N/A N/A N/A N/A N/A N/A C432108 C432108 N/A

CK218061 Interchangeable Interchangeable Interchangeable Interchangeable Interchangeable Interchangeable Interchangeable

CH400028 Interchangeable Interchangeable Interchangeable Interchangeable Interchangeable Interchangeable Interchangeable

CK295107 Interchangeable Interchangeable Interchangeable Interchangeable Interchangeable Interchangeable Interchangeable

SPROCKET HOUSING SUBASSEMBLY

Housing

Bushing/CAP

Sprocket

Belt Sprocket

SHM115 Interchangeable Interchangeable

CL714980 Interchangeable Interchangeable Interchangeable Interchangeable

CU542950 Interchangeable Interchangeable Interchangeable Interchangeable Interchangeable

CU541950 Interchangeable Interchangeable Interchangeable Interchangeable

HANDLE AND CONTROL CIRCUIT SUBASSEMBLY

Pendant + Cord

Assembly

Voltage Decal

(High & Low)

Circuit Board

Handle

Switch

Bolts

Screw

Bracket

Lock Washer

GnD. Screw

GnD. Washer

P05C Interchangeable

LK15 Interchangeable

(P05C)

(LK15)

EC2006 EC2006 BH201 BH201 BH201 CN985900 CN985900 CN985900 CN985900

H905 H905 LP204 LP204 LP204 CL723070 CL723070 CL723070 CL723070

CB25 CB25 N/A N/A N/A N/A N/A N/A N/A

M00085 Interchangeable Interchangeable

N/A N/A N/A B1487046 B1487046 B1487046 B1487046 N/A N/A

N/A N/A N/A CM16950W CM16950W CM16950W CM16950W N/A N/A

B36 Interchangeable Interchangeable

CH307028 Interchangeable Interchangeable Interchangeable Interchangeable

CW401028 Interchangeable Interchangeable Interchangeable Interchangeable

(ORIGINAL)

H F

G

(B1077046)

(CL944108)

(SHM115)

4

CL323001 CL323001 CL323001 CL323001 CL323001 CL323001

E D C B A

(B2000LSK)

(CK575281)

(DC694104)

CL789103

CL254372

N/A N/A N/A N/A

N/A N/A N/A N/A

CL789103

CL254372

CL789103

CL254373

CL789103

CL254374

N/A N/A N/A N/A N/A

N/A N/A N/A N/A N/A

C425120 C425120 N/A

(CK218061)

(CH400028)

(CK295107)

ZCK218061

N/A

CK693107

CL329950K CL329950K CL329950K

(CL714980)

(CU541950)

(CU438055)

N/A N/A N/A N/A

(CU542950)

ZCU543950 CL308950K CL308950K CL308950K

CN982900W CN982900W CN982900W CN982900 CN982900 CL718950 CL718950

DA6987026 DA6987026 DA6987026 N/A N/A N/A N/A

(M00085)

(B36)

N/A N/A N/A N/A N/A N/A

N/A N/A N/A N/A N/A N/A

(CH307028)

(CW401028)

CK478028 CK478028 CK478028 CK478028

M2231108 M2231108 M2231108 M2231108

22

Loading...

Loading...