Page 1

Instruction Sheet

®

B2000 Cyclone

RPS-0097 07/17 Effective for models with serial numbers beginning with “J”.

IMPORTANT RECEIVING INSTRUCTIONS

Visually inspect all components for shipping damage. If shipping damage is found, notify carrier at once. Shipping damage is

NOT covered by warranty. The carrier is responsible for all repair and replacement costs resulting from damage in shipment.

SAFETY ISSUES

IMPORTANT – USER SAFETY AND PROTECTION: In setting up systems to fit your operations, care must be taken to select the proper components

and design to insure appropriate that all safety measures have been taken to avoid the risk of personal injury and property damage from your

application or system.

GARDNER BENDER IS NOT RESPONSIBLE FOR DAMAGE OR INJURY CAUSED BY UNSAFE USE, MAINTENANCE OR THE APPLICATION OF

ITS PRODUCTS. Please contact Gardner Bender for guidance when you are in doubt as to the proper safety precautions to be taken in designing

and setting up your particular application

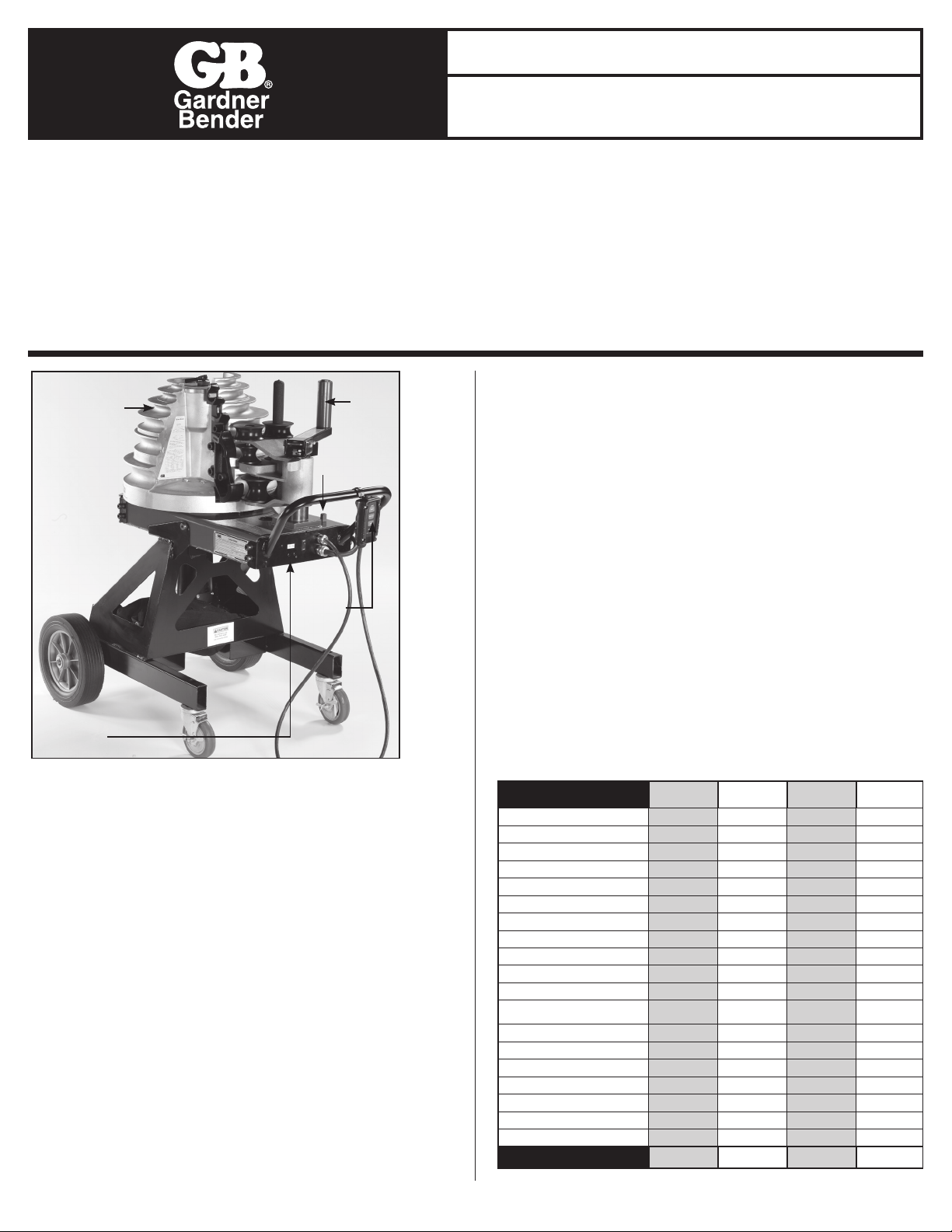

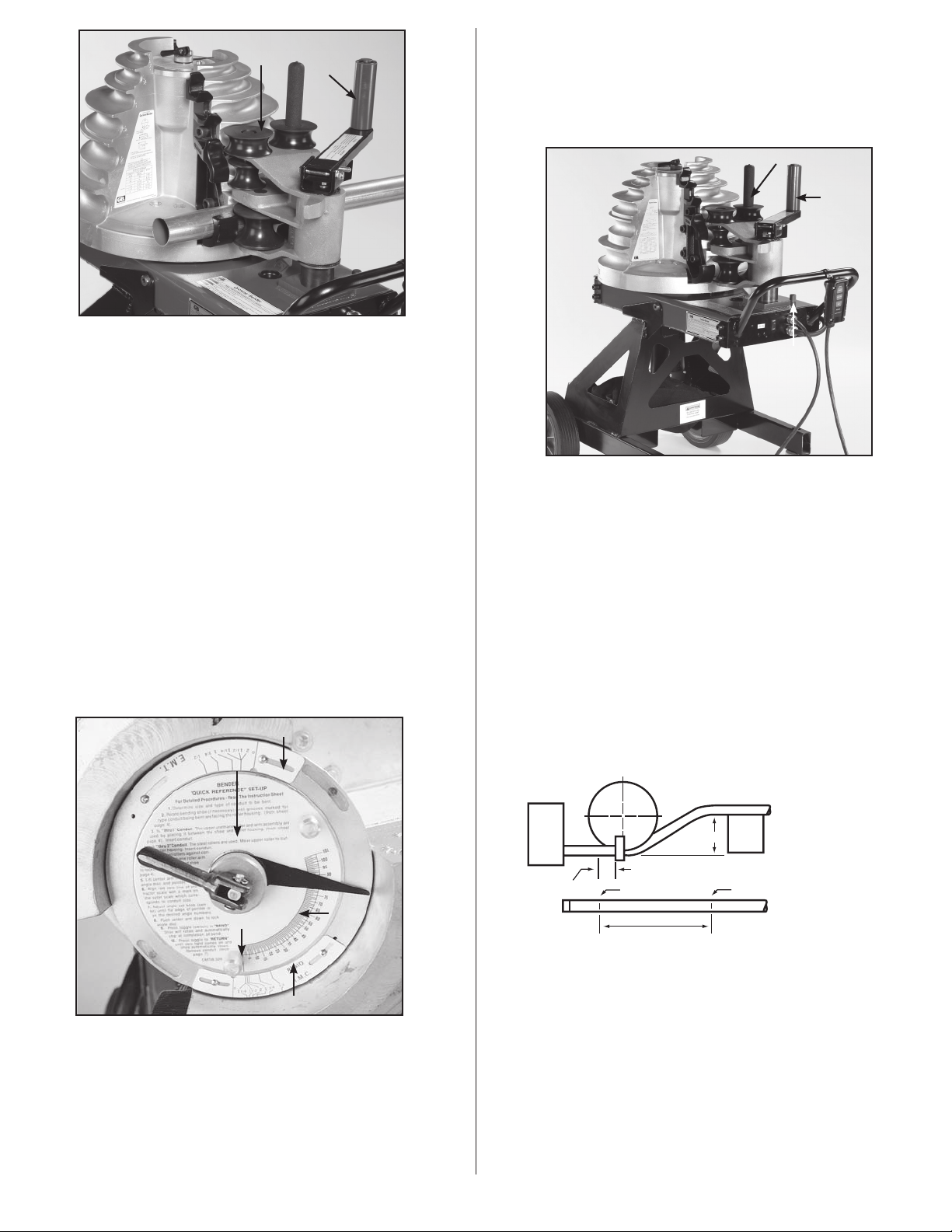

Bending Shoe

High/Low

Voltage

Indicator

Figure 1. B2000 Cyclone® Bender

1.0 DESCRIPTION

• Engineered to save time; bends 0.5 inch to 2 inch

Rigid, Rigid aluminum, EMT and IMC conduit with

a single shoe and no loose parts

• Easy dial settings create accurate bends every time

and make training time virtually non-existent

• Bends in both horizontal and vertical positions to create

accurate offset bends

• Quickly creates repeated bends at the same degree

• Strong legs offer increased jobsite durability (10x life test)

• Large tires/wheels - increase mobility

• Strong upright handle provides ease of use

• Easily lift and transport using the forklift tubes built into base

• Lift Hook for security (job-site) tethering

• Incorporates storage area for tools, etc. while in use

• Includes Weather-Resistant Cover

The Cyclone®, GB model B2000 production bender is used to bend

EMT, IMC, rigid steel or rigid aluminum conduit. A single bending

shoe accommodates sizes

The shoe is driven by a 115 V, 15 A motor. The roller housing

consists of a single urethane roller support arm, and three sets of

nylon rollers.

1

⁄2", 3⁄4", 1", 11⁄4", 11⁄2" and 2" conduit.

.

Pendant

Control

Upper

Roller

Frame Stop

The bender control pendant consists of a zero light, a green power

light, a jog push button, a push button for “Bend and Return”. An

8’ electrical cord connects the pendant to the bender frame. The

bender can be used in a horizontal or vertical position.

The end plate contains an ON-OFF switch which is also a circuit

breaker. When the switch is turned on, the two leds will flash red,

then green to indicate normal function.

To avoid damaging the bender control circuit, an input voltage

sensing system is built into the control circuit. If input voltage is less

than 92 VAC or higher than 132 VAC the bender will shut off. One of

the two LEDS located on the end plate will light to indicate whether

high or low voltage exists.

Re-set the bender by turning unit off then on again. If the incoming

current voltage has not been corrected, the bender will not operate.

The voltage range must be within 92 VAC to 132 VAC. Any situation

which causes a voltage drop or increase must be corrected before

using the B2000 Bender.

Voltage drops may be caused by:

• Extension cords that are too long.

• Extension cords made of light (16-18 gauge) wire.

• Multiple power tools on a single circuit.

• Other devices which require high amperes to operate.

Gardner Bender B2000 vs. Competitor Benders

SINGLE SHOE BENDING FOR:

EMT

Rigid

IMC

PVC coated rigid

Durable and repairable analog controls

Intuitive and easy to use

No loose or separate parts for use

Low/high voltage shut-off/protection

Resettable circuit breaker

Hoist/crane lift point

No changeover or adjustment for

conduit types or sizes

No leveling before use

No homing or initial setup before use

Horizontal and vertical bending

Operate on 15A circuit

Forklift capable leg assy

Weight (lbs)

Dimension (Inches)

PRICE GB PRICE +21% +39% +19%

B2000

1/2” - 2” 1/2” - 2” 3/4” - 2” 1/2” - 2”

1/2” - 2” 1/2” - 2” 3/4” - 2” 1/2” - 2”

1/2” - 2” 1/2” - 2” 3/4” - 2” 1/2 - 2”

1/2” - 1 1/2” accessory no accessory

47 x 33 x 43 46 x 30 x 33 38 x 30 x 50 45.5 x 32.5 x 44

1

Bender

GB

3 3

3 3

3

3

3

3 3 3

3 3

3 3

3 3

3 3 3 3

3

3 3 3 3

408 513 600 615

Green

Competitor

fuse fuse fuse

Brown

Competitor

Blue

Competitor

Page 2

2.0 WARNINGS

• This instruction manual contains warnings and safety rules

which must be observed by the user to ensure safe operation

of the instrument and retain it in safe condition.

• Read through and understand the instructions contained in

this manual before using the instrument.

• Keep the manual at hand to enable quick reference whenever

necessary.

• The instrument is to be used only in its intended applications.

• Understand and follow all the safety instructions contained in

the manual.

• It is essential that all safety instructions are adhered to.

• Failure to follow the safety instructions may cause injury,

instrument damage.

WARNING is reserved for conditions and actions

that can cause serious or fatal injury.

CAUTION is reserved for conditions and actions

that can cause injury or instrument damage.

WARNING:

• Do not operate the bender on damp or wet surfaces. Do not stand

on wet surfaces while operating the bender.

• To avoid possible injury, do not place fingers under the bottom edge

of the bending shoe. See Figure 2.

• Read and understand all instructions and warning information in this

manual before operating this machine.

• Do not use this machine in a hazardous environment. Hazards

include flammable liquids, gases, or other materials. Using this tool

in hazardous environments can result in a fire or explosion.

• Electric shock hazard. Inspect power cord before use. Repair or

replace if it is damaged. DO not modify the power cord or plug.

• Always use safety glasses. Everyday glasses are NOT safety glasses.

When using in dusty environment, use face or dust mask.

• Keep guards in place and in working order.

• Do not use extension cords that are longer than 30 m (100'). Do

not use damaged extension cords. Use only three-wire, 12 AWG

extension cords that have three-prong grounding-type plugs and

three-hole receptacles that accept the tool’s plug.

• Keep hands away from bending shoe, rollers, and conduit when

bender is in use.

• Reduce the risk of unintentional starting by making sure switch is

in off position before plugging in. Never leave machine unattended.

Turn power off and do not leave machine until it comes to a

complete stop.

• Keep working area of bender clear form any tools or other

equipment when using the bender.

• Never stand on tool. Serious injury could occur if tool is tipped. Do

not overreach. Keep proper footing and balance at all times.

• Adjust fork spacing to match fork tubes on

bender. Ensure front wheel brakes are engaged before inserting

forks into fork tubes.

• Unplug bender from any power source before disassembling,

reassembling, and repairing any parts.

• Operator must ALWAYS face the front of the bender with the bending

degree scale visible and maintain a minimum of 3 feet distance while

the conduit is being bent. All other personnel must remain out of the

area while the bender is in operation.

CAUTION:

• Conduit moves rapidly as it is bent. The path of the conduit must be

clear of obstructions.

• Wear proper apparel. Do not wear loose clothing, gloves, neckties,

rings, bracelets, or other jewelry which may get caught in moving

parts. Nonslip footwear is recommended. Wear protective hair

covering to contain long hair.

• Do not force rollers or alter machine. It will do the job better and

safer at the rate for which it was designed.

• Use for bending only. Do not force machine to do a job for which

it was not designed. Use this machine only for the manufacturer’s

intended purpose only. Use other than that which is instructed in this

manual can result in injury or property damage.

• Keep children away. All visitors should be kept safe distance from

work area.

• Make workshop kid proof with padlocks, master switches, or by

removing starter keys.

• Use recommended accessories. The use of improper accessories

may cause risk of injury to person

• Some bender parts and accessories are heavy and may require more

than one pesron to lift and assemble.

• Maintain tool with care. Keep tool clean for best and safest

performance. Follow maintenance and troubleshooting instructions

for lubricating and changing parts.

• Support conduit when unloading it from shoe. Conduit can become

loose once roller housing is pulled away from the shoe.

• Keep all decals on bender clean and legible at all times.

• Inspect for any damaged/malfunctioning parts before using the

bender. If any damaged/malfunctioning parts are found during

inspection, repair or replace parts.

NOTE: All operations referring to “toward the operator” are

viewed from the lifting handle end of the bender frame.

3.0 SPECIFICATIONS

Power Source ...................................... 120 V 60 cycle AC

Pendant Control Circuit ...................... 12 VDC

Motor ...................................................1 HP 100 V 60 cycle

Weight .................................................. 408 lbs.

Height...................................................38 inches

Width .................................................... 31 inches

Length .................................................. 45 inches

Circuit Breaker ....................................15 Amp

Bend Capability ................................... 1⁄2” - 2” IMC, EMT

Rigid Steel or

Rigid Aluminum

DC

CAUTION:

• During pipe bending, stand behind the frame handle. Keep hands,

clothing and control cord away from the bending shoe and rollers.

• To prevent damage to the bending shoe, do not allow the clamping

jaws to strike the upper roller support arm when the shoe is rotating.

Position the roller housing against the frame stop. See Figure 1.

• Select an operating area large enough to permit loading pipe section

and bending without striking objects or personnel.

• Do not attempt to bend conduit or pipe other than 1⁄2" through 2"

IMC, EMT, rigid steel or aluminum. Bending other materials will

damage the bender and void the warranty.

2

Page 3

4.0 OPERATION

Roller Support Arm

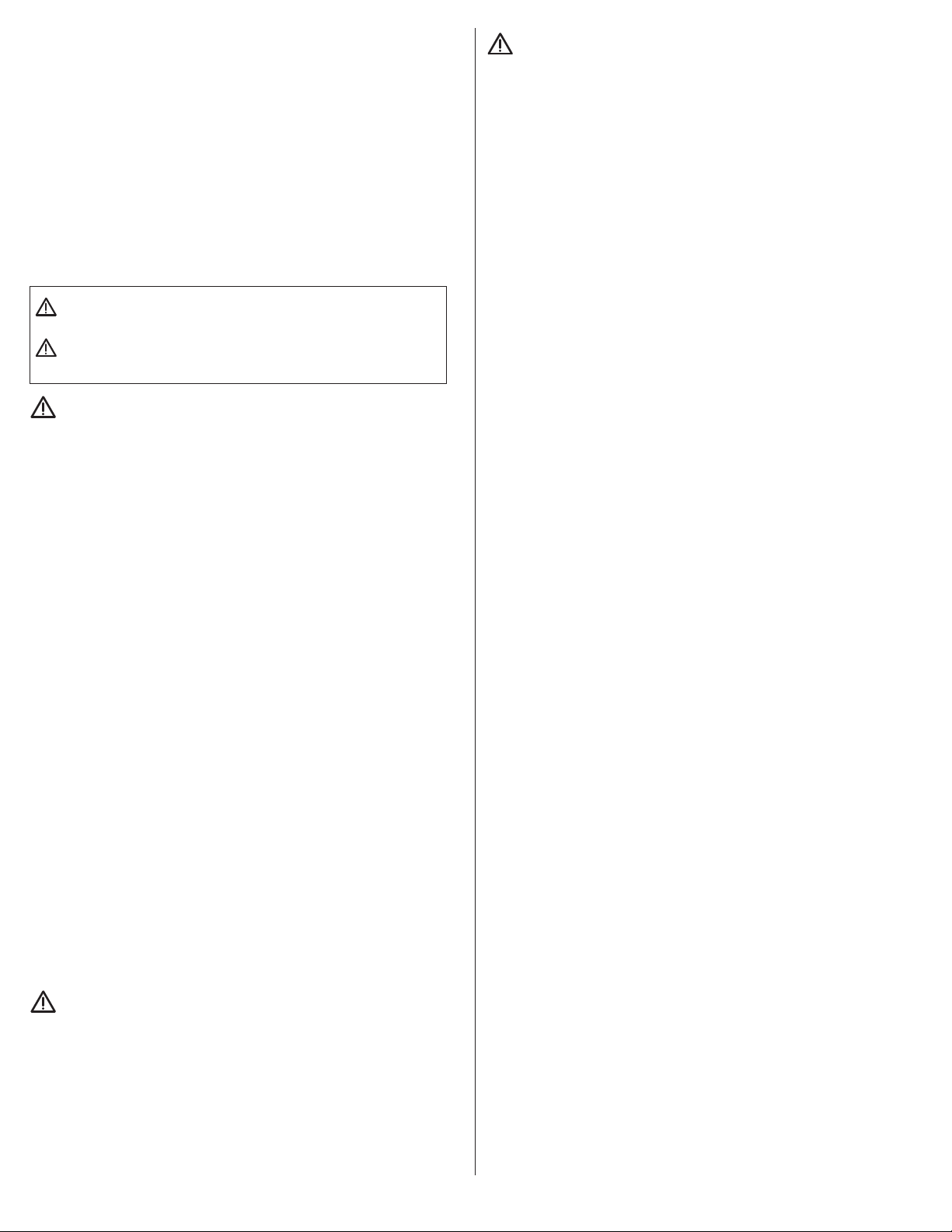

4.1 Bending 1⁄2", 3⁄4" and 1" IMC, EMT and

rigid conduit:

1. Position the bender in a level dry area large enough to permit

loading and unloading various lengths of conduit. Position the

frame, either horizontally or vertically, by pulling the spring

loaded pin on the side of the bender frame. See Figure 2.

4. Push the roller housing against the frame stop.

See Figure 2. Rotate the shoe to bring the required grooves

(EMT, IMC or Rigid) facing toward the operator. To activate

the shoe, hold the pendant toggle switch in “Return” and

press the jog button until the zero light goes out. The shoe

will rotate and stop in the load position. The zero light will

come on.

5. The upper urethane roller and support arm (See Figure 4)

is used for bending

1

⁄2" through 1" conduit. One of the

top three shoe grooves will be used, depending on

conduit size.

Positioning

Pin

Upper

Roller

Support

Arm

Figure 2. Vertical Position

2. Identify the type (IMC, EMT or Rigid) and size conduit

to be bent.

3. Locate the markings that indicate which grooves are used for

specific materials, and which grooves are used for specific

size conduit. See Figure 3.

Bend Groove

Jaw

Frame Stop

Upper Roller

Figure 4. Bending 1/2" - 1"

6. When bending

1

⁄2" - 1" conduit the upper roller and support

arm must be positioned between the shoe and the roller

housing. Position the urethane roller by moving the roller

housing against the frame stop and removing the pin.

7. Lift the roller support arm to clear the nylon rollers and swing

the arm (toward shoe) over the roller housing. Lower the arm

into the support bracket and insert the ring pin. See Figure 5.

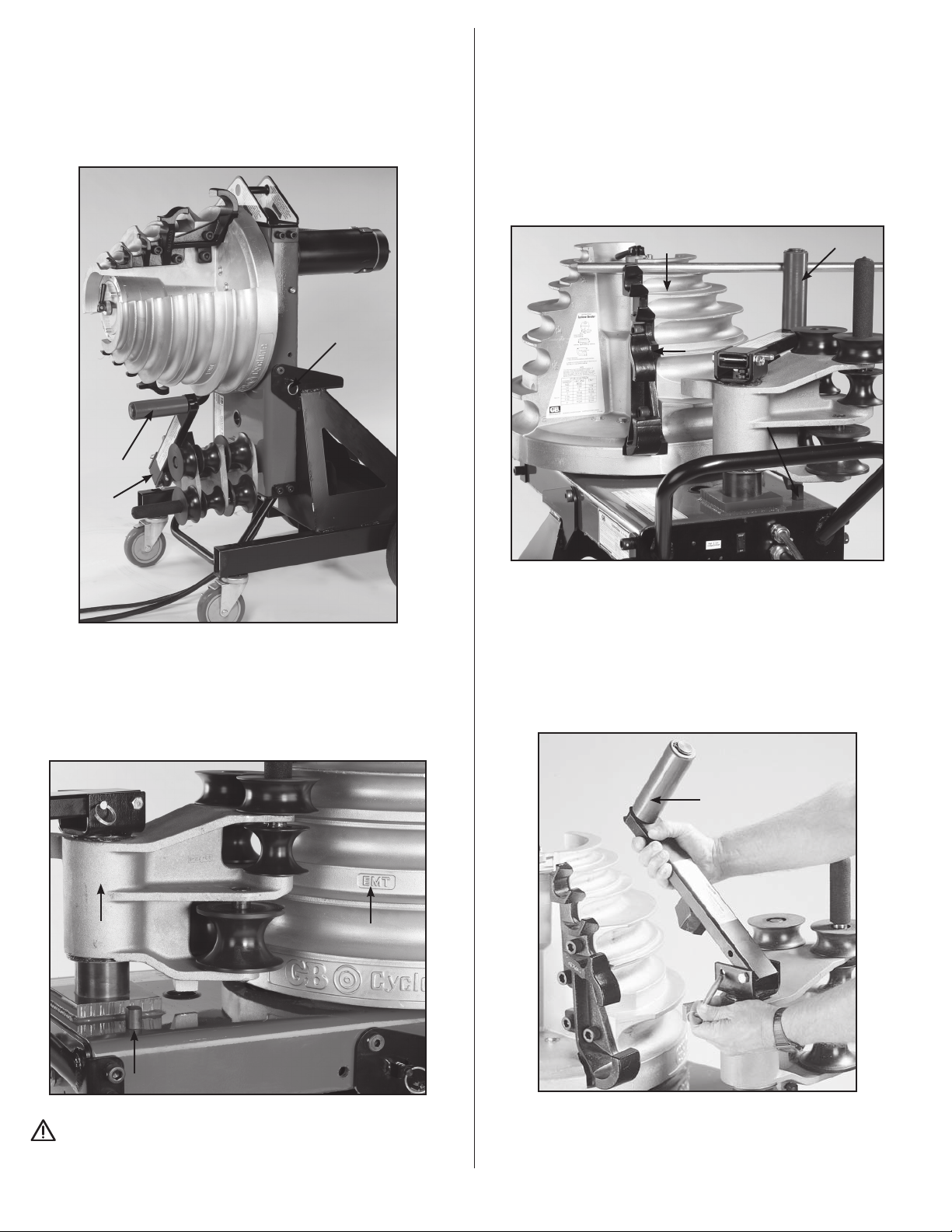

Roller Housing

Frame Stop

Material

Identifier

Figure 3. Set Up

CAUTION: To avoid damaging the rollers and roller

housing, always place the roller housing against the frame stop

prior to rotating the shoe.

Roller Support Arm

Figure 5. Position Roller Support

3

Page 4

8. Insert the conduit in the shoe groove marked with the number

Type Scale

Roller Support Arm

Locking Handle

Upper Urethane Roller

Roller Support Arm

Upper Urethane Roller

matching the size conduit being bent. The conduit must set in

the shoe and in the jaw. The end of the conduit must extend

a minimum of 2" beyond the jaw. See Figure 3. Refer to table

A or B on page 5 for bending data.

9. Each time a different size and type of conduit is being bent,

three facts must be determined and set into the bender

shoe control system. The required settings are: conduit size,

material and desired bend angle. Prior to setting, be sure the

desired size indicator scale is toward the operator and the

correct shoe grooves are also toward the operator.

a. Lift the locking handle. See Figure 6. Use the two small

pins to rotate the angle disc, clockwise, until the red zero

line is directly in line with the zero line on the size scale.

b. Set the bender for specific conduit size by turning the

angle disc until the red line is on the size indicator mark

which matches the size conduit being bent. Be sure the

correct size scale is being used (EMT, lMC, or Rigid).

c. Move the bend angle set knob (See Figure 6) until

the flat edge of the pointer is on a line indicating the

exact degree of bend desired. Lower the center arm to

lock the pointer and scale and to prevent inadvertent

movement during bending.

Locking Handle

Rotating Pins

Angle Set Knob

Upper Urethane Roller

Frame Handle

Nylon Rollers

Figure 7. Position Roller Support

CAUTION: To avoid damage to the bending shoe, always

place the roller housing against the frame stop, prior to

activating the bending shoe.

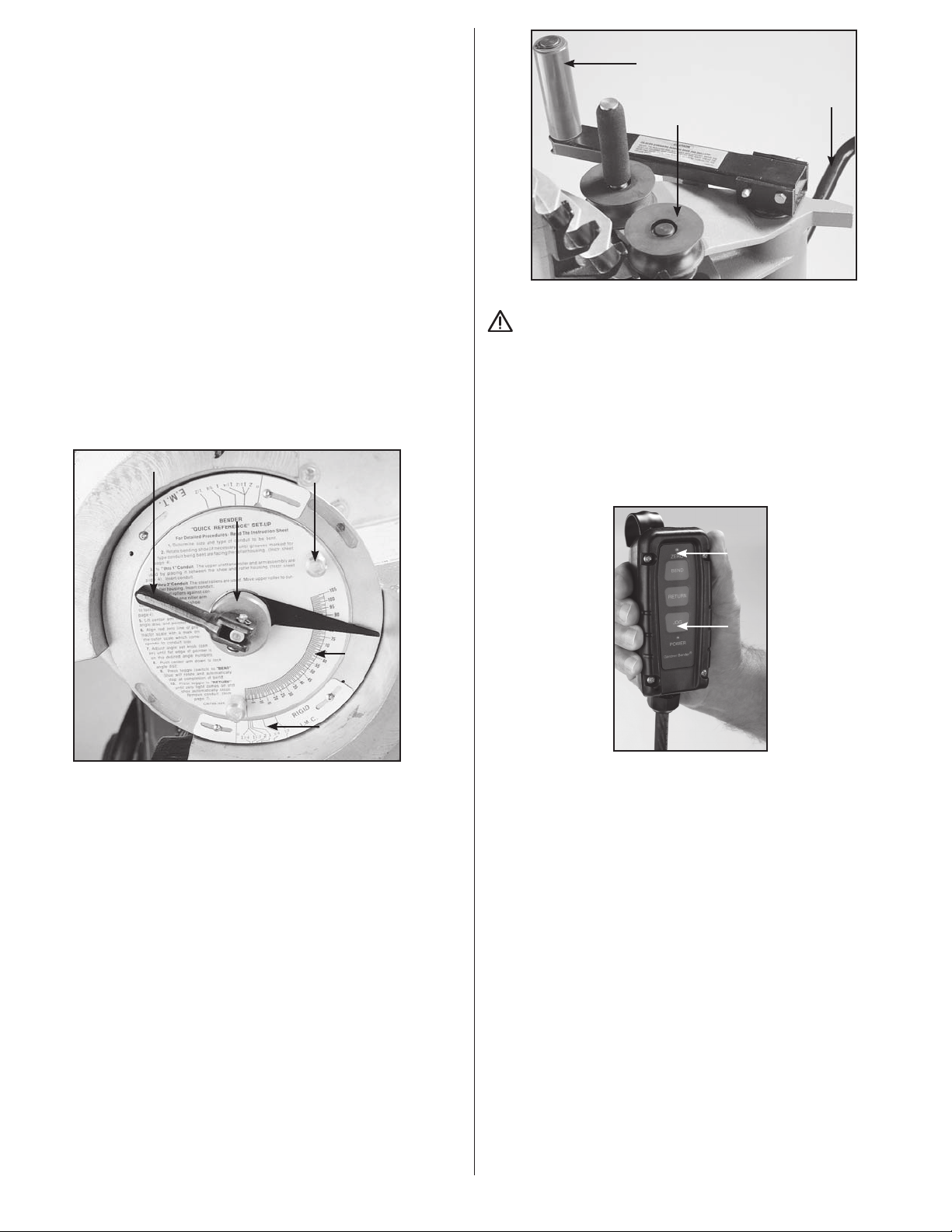

3. Check the bending shoe to be sure the correct grooves for

the conduit being bent are facing toward the operator. If the

shoe must be rotated, hold the pendant control Return button

and press the jog button until the zero light goes out. The

shoe will rotate 180° then stop in the load position. See Figure

8. The zero light will come on.

Angle

Disk

Size Scale

Figure 6. Set Angle Scale

10. Activate the bending shoe by holding the pendant control

Bend button. The shoe will rotate until the angle set on the

pointer is reached.

11. To remove the conduit, hold the “Return” button. The shoe

will return to the start position and stop automatically. The

zero set light will come on. Bending more conduit of the

same type and size is accomplished by loading conduit and

pressing the bend button.

4.2 Bending 11⁄4", 11⁄2" and 2" Conduit

NOTE: All operations referring to “toward the operator” are viewed

from the lifting handle end of the bender frame.

1. Bending 11⁄4" through 2" requires using one of the three sets

of nylon rollers and one of the grooves on the lower half of the

bending shoe.

2. Move the roller housing against the frame stop. See Figure

11. The upper urethane roller must be on the outside (toward

frame handle) of the roller housing. See Figure 7. If it’s not,

pull the ring pin. Lift the roller support arm, swing it over the

roller housing, lower the handle into the bracket and insert the

ring pin.

Zero

Light

Jog

Button

Figure 8. Pendant Control

4. When bending 11⁄4" - 2" conduit, position roller housing and

upper arm. Then push the conduit between the shoe groove

and the 2" nylon rollers until the bend mark on the conduit is

in line with the outside edge of the clamp jaw.

5. Grasp the upper urethane roller and move the support arm

counterclockwise until it contacts the roller housing. The two

nylon rollers should have moved against the conduit and

should firmly hold the conduit in the shoe. See Figure 9.

4

Page 5

Nylon

Type Scale

Roller Support Arm

Locking Handle

Upper Urethane Roller

EMT Size Scale

Rollers

Upper

Urethane

Roller

Figure 9. Locking in Roller Support

6. Each time a different size and type of conduit is being

bent, three facts must be determined and set into the

bender shoe control system. The required settings

are: conduit size, material and desired bend angle. Prior

to setting, be sure the pipe size scale is toward the

operator and the correct shoe grooves are also toward

the operator.

a. Lift the locking handle to release the angle set knob and

angle disc. Use the two small pins to rotate the angle disc,

b. Set the bender for specific conduit size by turning the

clockwise. See Figure 10.

angle disc until the red line is on an outer size scale mark

which matches the size conduit being bent. See Figure 10.

Be sure the correct size scale is being used (EMT, lMC, or

Rigid).

c. Move the angle set knob (See Figure 10) until the flat edge

of the pointer is on the line indicating the exact degree of

bend desired. Lower the center arm to lock the pointer,

angle disc and to prevent inadvertent movement during

bending.

EMT Size Scale

Angle Set Knob

8. To unload conduit, hold the Return button. The shoe will return

to the start position and stop automatically.

9. Grasp the upper urethane roller and move the support arm

clockwise until the rollers move away from the conduit. See

Figure 11. Push the roller housing against the frame stop.

Remove bent conduit.

10. To bend more conduit of the same material and at the same

angle, load and secure as described in steps 3 through 6. To

bend the same type conduit but at a different angle, load and

secure; turn angle set knob to the desired angle, then press the

bend button.

11. Bending different type and size conduit requires repeating

steps 2 through 10.

4.3 Offset Bending

1. Obtain distance “M” from table A, and measure this distance

from mark #1 and place mark #2.

2. Now place mark #1 in line with front edge of shoe clamp and

make first bend.

3. Next rotate conduit 180° level, place mark #2 in line with front

edge of shoe clamp and make second bend.

Roller Housing Handle

Upper

Urethane

Roller

Frame

Stop

Figure 11. Unload Conduit

Zero Point

Rigid/IMC Size Scale

Angle Disc

Figure 10. Set Angle Indicator

7. Use the control pendant. The zero light should be on. Hold

the Bend button. The shoe will rotate until the desired bend is

achieved, then stop automatically.

NOTE: If the zero light is not on, press the Return button until the

shoe stops and the zero light comes on.

Offset

Box

Min. 2"

Front Edge of Clamp

M

See Table A

Beam

Mark #2Mark #1

NOTE: When bending rigid aluminum, set bend angle indicator

approximately 4° short of desired angle, since aluminum does not

have spring-back of steel.

5

Page 6

Table A

Type Scale

Roller Support Arm

15° Bend 30° Bend 45° Bend

Offset Conduit Conduit Conduit

Required Max. Size M Max. Size M Max. Size M

2"

4" 1

6" 2" 23

8" 30

10" 38

12" 46

14" 54

16" 61

18" 67

20" 77

22" 85" 44” 31

To locate distance between centers of offset bending marks other than

listed in table A use the following multipliers:

15° bend - 3.9

30° bend - 2.0

45° bend - 1.4

3

⁄4" 73⁄4"

1

⁄2" 157⁄16"

3

3

⁄16" 1" 12" 1⁄2” 81⁄2"

5

⁄8" 11⁄2" 16" 1” 115⁄16"

5

⁄8" 2" 20" 11⁄4” 141⁄8"

3

⁄8" 24" 11⁄2” 1615⁄16"

1

⁄16" 28" 2" 1913⁄16"

13

⁄16" 32" 225⁄8"

7

⁄16" 36" 257⁄16"

1

⁄4" 40" 281⁄4"

⁄4" 8"

Table C

Conduit Stub-up Conduit Stub-up

Size Set-back Size Set-back

1⁄2" Rigid 73⁄4" 11⁄4" Rigid 123⁄4"

1

⁄2" IMC 73⁄4" 11⁄4" IMC 121⁄2"

1

⁄2" EMT 75⁄8" 11⁄4" EMT 13"

3

⁄4" Rigid 9" 11⁄2" Rigid 131⁄2"

3

⁄4" IMC 9" 11⁄2" IMC 131⁄2"

3

⁄4" EMT 81⁄2" 11⁄2" EMT 131⁄2"

1" Rigid 10

1" IMC 10

1" EMT 10

1

⁄8" 2" Rigid 153⁄4"

1

⁄8" 2" IMC 151⁄2"

3

⁄8" 2" EMT 151⁄2"

5.0 ANGLE ADJUSTMENT

1

⁄8"

Two different type scales are mounted on the shoe outer rim.

One for

1

⁄2" thru 2" IMC and Rigid, the other for EMT 1⁄2" thru 2"

See Figure 12.

Each scale indicator is adjustable to compensate for over long

or short bends which may be due to differences in conduit

characteristics or other variations.

4.4 Stub-up Bending

1. Table C shows minimum length (inches).

2. Mark #1 is stub length, deduct from this as per table C

and obtain mark #2.

Table B

BEND RADIUS

Conduit Radius Radius

Size Rigid / IMC EMT

1

⁄2" 331⁄32" 37⁄8"

3

⁄4" 425⁄32" 429⁄32"

1" 5

1

1

⁄4" 67⁄8" 73⁄32"

1

1

⁄2" 79⁄16" 71⁄2"

2" 8

Mark #2

Shoe

Front Edge of

Clamp Mark #2

Stub Length

Set Back

9

⁄16" 529⁄32"

9

⁄32" 89⁄16"

Min. 2"

Mark #1

Stub to Bottom

of Pipe

Bends which are too long: Loosen the size scale (for type material

being bent) mounting screws. Slide the scale clockwise as many

degrees as the overbend (if bend is 5° over, move indicator 5°

clockwise). The degree of movement is observed by watching one

of the size marks as it moves past the angle disc scale. Tighten

the mounting screws.

Bends which are too short: Loosen the size scale (for type material

being bent) mounting screws. Slide the scale counterclockwise

as many degrees as the bend is short (if bend is 5° short move

counterclockwise 5°). The degree movement is observed by watching

one of the size marks as it moves past the angle disc scale. Tighten

the mounting screws.

Type Scale

Type Scale

Note: Two

scales one

for rigid

and one

for IMC

Figure 12. Two Type Scales

6

Page 7

6.0 MAINTENANCE

Figure 1

B2000 Bender Assembly

Periodic general maintenance to the bender may be required to

reduce the risk of malfunctioning rollers, sprockets, gear teeth,

and/or chains. These parts can become dirty, worn, or damaged

over time and may need to be greased or cleaned. Pressurized

air can be used to clean any dust or residue inside the bender

housing. The bender should not make any uncommon noises such

as rattling during use. If this happens, turn off the bender and

perform an inspection on the machine.

A troubleshooting aid exists on the printed circuit board mounted

to the inside of the operating handle. If all systems are functional,

a white L.E.D. (pictured in Figure 13) will flash once every two

seconds while the machine is powered up.

Error codes consist of different light patterns.

1. Blink twice = the motor is over heated.

2. Blink three times = limit switch has failed.

3. Blink 4 times = pendant control malfunction.

In addition the L.E.D. will be steady on if the bend or return button

is being pressed.

7.2 Forklift Transportation

1. Rotate bender to the horizontal bending position.

a. Pull handle end of the bender to remove the preload applied

on the positioning pin of the bender (Figure 14, #14), and

pull locking pin.

b. While pulling positioning pin, carefully raise the handle end

of the bender until the sprocket housing (Figure 14, #4)

locks in the horizontal position.

2. From the back of the bender opposite to the handle, insert forks

into fork tubes. Refer to decals located on frame for detailed

instructions.

3. Move to the desired location.

7.3 Lift/Hoist Transportation

1. If nylon sling is being used, ensure sling is long enough to

avoid contact with the bender. Bender should be hoisted in the

vertical bending position only.

2. Confirm that the Roller Housing (Figure 14, #20) and Upper

Roller (Figure 14, #12) are in place and locked.

3. Loop the nylon sling through the End Plate Lift Hook

(Figure 14, #26). DO NOT HOIST BENDER USING THE HANDLE

(Figure 14, #38).

4. NOTE: End Plate Lift Hook can also be used for job site tethering

for added security.

White L.E.D.

Figure 13. L.E.D. Location

7.0 TRANSPORTATION

7.1 On ground Transportation

1. Rotate bender to the horizontal bending position.

a. Pull handle end of the bender to remove the preload

applied on the locking pin of the bender (Figure 14, #14),

and pull positioning pin.

b. While pulling positioning pin, carefully raise the handle end

of the bender until the sprocket housing (Figure 14, #4)

locks in the horizontal position.

2. Unlock wheels (if locked) (Figure 14, #13), and use handle

(Figure 14, #38) to push/pull bender to the desired location.

2

3

9

10

1

7

8

5

6

37

26

SEE INSERT A Page 3

& Fig. 6, (page 8)

11

9

10

20

36

4

34

35

35

34

Figure 14. Bender Transportation

23

24

17

14

18

19

21

12

21

22

15

16

13

38

27

35

(See Fig. 7)

34

25

7

Loading...

Loading...