Gardiner technology 580 User Manual

GGGGAAAARRRRDDDDTTTTEEEECC

CC

5555 0000 0000 SSSS EEEE RRRR IIII EEEE SS

GARDTEC

Installation Instructions

580

SS

GARDTEC

580

Contents

Introduction 1

Planning the Control Panel Location 2

Installation 2

Cable Entries 3

Mains Supply Connection 4

Terminal Block Connections 5

Output Terminal Descriptions 6

Remote Keypad 8

Digigard Communicator Interface 8

Initial Power Up 9

Reset to Default Modes 9

System Programming 10

Programming Charts 12

Sample programming Session 15

Engineer Modes 19

Setting the System 20

Removing Zones 21

Testing the System 22

Viewing the Log 23

Setting Chime On/Off 24

Changing Engineer Codes 25

ENGINEERS MANUAL

Resetting After an Alarm 26

Programmable Options Description 27

Display Messages

System 30

Status 30

Log 31

Fault Finder 32

Specification 34

Zone Type Terminology 35

GARDTEC

580

ENGINEERS MANUAL

Introduction

The Gardtec 580 Control Panel is a seven zone microprocessor based unit that has

been designed to be suitable for domestic and small commercial installations. All

zones are fully programmable by the engineer.

Upon completion of the installation the engineer may, if need be, re-program several

factory set options so as to tailor the Control Panel to suit the requirements of the system.

It should be noted that if a new four digit engineer code starts with a 9 it will be

locked into the system and may only be changed by using the code again

(default to factory settings will have no effect). This gives you the ability to protect your service revenue.

The Control Panel is supplied complete with an onboard keypad. Upto four remote keypads may be fitted if required. If remote keypads are used one extra entry / exit zone

may be used from the terminals within one of the keypads

All detection and output wiring is taken directly to the Control Panel, which also incorporates a 220/240V a.c connection. A transformer and adequate space for a rechargeable lead acid battery upto 7 ampere/hour is also provided.

Display of the system status is given via a twin seven segment L.E.D display on the

Control Panel. This display is also echoed on all remote keypads that are fitted. The

twin seven segment display has the ability to give more logical information to the user.

Keypress tamper is factory set to 24 digits (without a valid code number) before the

tamper is activated. During unset conditions this will cause an internal alarm and during a set condition it will cause a full alarm.

We recommend that this engineers manual and the user manual are read and fully

understood before any installation of the system is carried out. You will find that a little

time spent now understanding the product will be a great time saver for the future.

Page 1

GARDTEC

580

ENGINEERS MANUAL

Planning the Control Panel Location

Consideration in locating the fixing position of the Control Panel should be given to:

The underside position of the lid securing screw with relation to the cover

fitting and removal.

Access for the routing of cables for the system from detection devices,

sounders (internal and external), remote keypads, mains, etc.

The fixing of a 3 amp unswitched fused spur.

Operation of the onboard keypad.

Readability of the display.

Installation

Slacken the cover screw located on the lower edge of the Control Panel but do not

remove completely.

Pull the lower edge of the cover forward and upwards in one movement. Store cover in

a safe place.

Although the main P.C.B (Printed Circuit Board) is protected by the plastic moulding

we would recommend that it is removed until the rear portion of the Control Panel is

fixed to the wall.

To do this remove the speaker wires from the terminal block. Unclip the P.C.B from

one of the side clips and lift clear of the other side clip with a sidewards motion. Unplug

the a.c/battery connection from the underside of the P.C.B. Store the P.C.B in a safe

place.

Mark the fixing position on the wall (one upper hanger and two fixing holes) using the

Control Panel backplate as a template. Under no circumstances should you drill whilst

holding the backplate in position.

Fix to the wall using appropriate wall plugs and No.8 screws at least 30mm long. Do

not tighten the screws at this stage, wait until all your wiring is in place.

Page 2

GARDTEC

580

ENGINEERS MANUAL

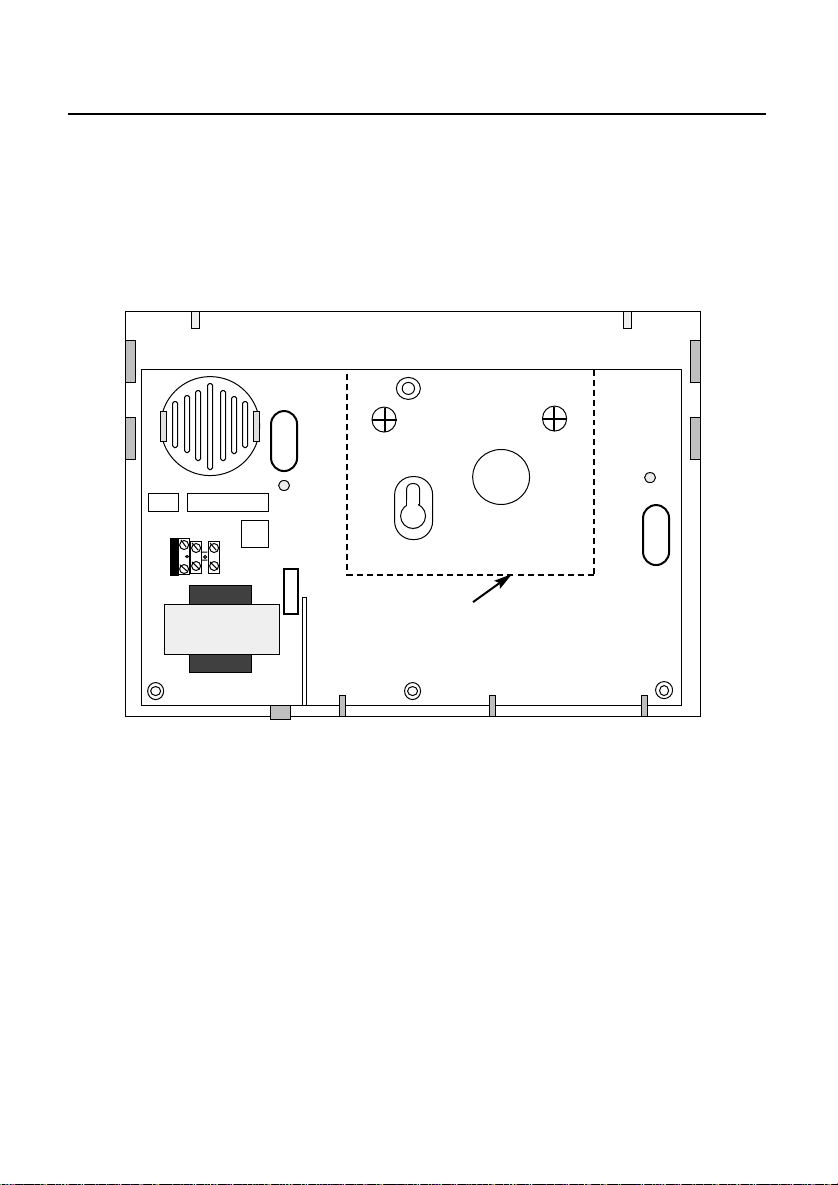

Cable Entries

The cable entries can be seen in Fig 1. below. It should be noted that when the larger

of the two cable entry slots below the speaker housing is used the cables will tend to

lie flat and side by side. This will make the task of tightening the fixing screws and getting the panel to 'lie flat' to the wall easier.

Fig 1. GARDTEC 580 Backplate.

KEY:

D

L

AB

C

E

A = Mains entry H = Cover fixing screw

B = Low voltage cable entry x4 J = Speaker enclosure

C = Mains connector K = Transformer

D = P.C.B Supports x4 L = P.C.B Retaining clips

J

B

D

M

P

K

H

GGG

E

N

F

Digigard Position

E

B

D

L

N

D

B

E

E = Fixing screw holes x4 M = Rear tamper switch position

F = Fixing screw hanger N =Digigard retaining lugs x2

G = Battery Retaining Lugs P = Spare fuse holder

Page 3

GARDTEC

580

ENGINEERS MANUAL

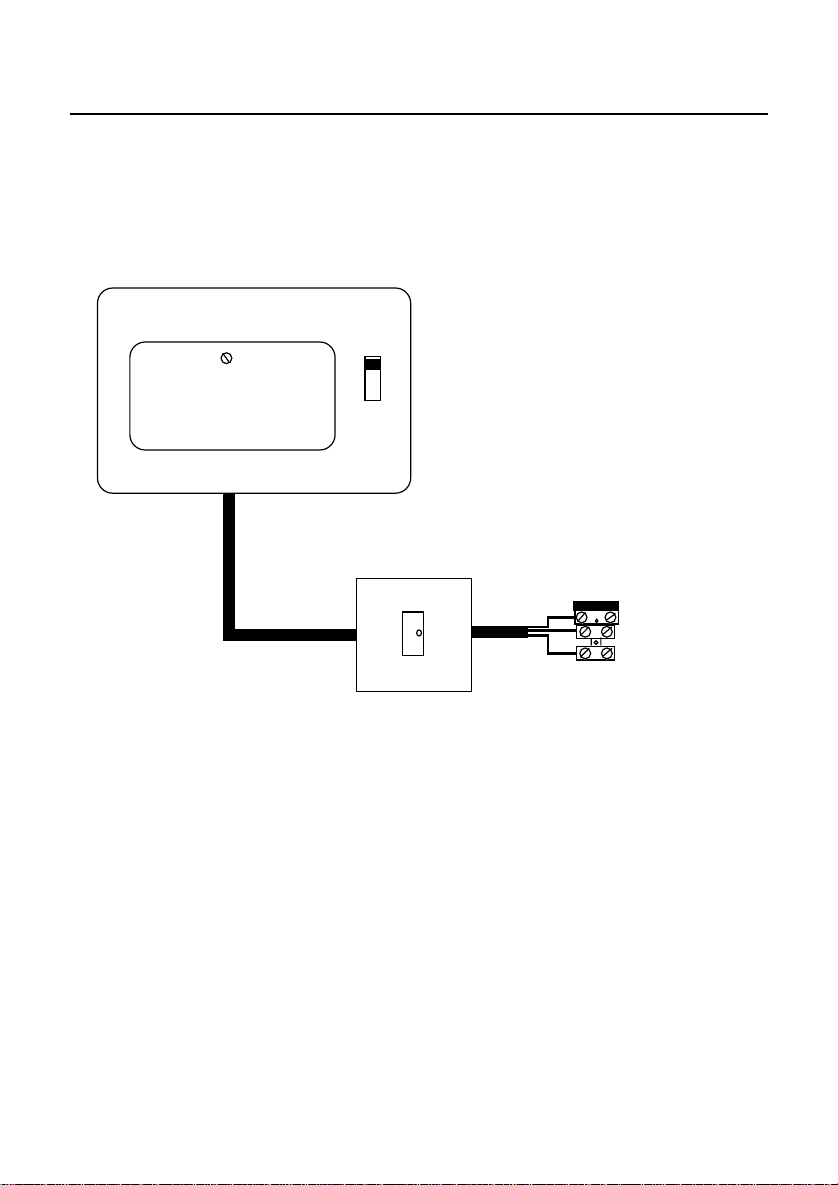

Mains Supply Connection

A 220/240V a.c supply should be taken directly from the consumer unit. In order to

comply with the requirements of B.S 4737 this should be via a 3 Amp unswitched fused

spur. This is shown in Fig 2. below.

Fig 2. Mains Supply Connection

Consumer Unit

Off

On

3A Unswitched

Spur

Connections:

Live = Red

Earth = Green/Yellow

Neutral = Black

L

E

N

Page 4

GARDTEC

580

Terminal Block Connections

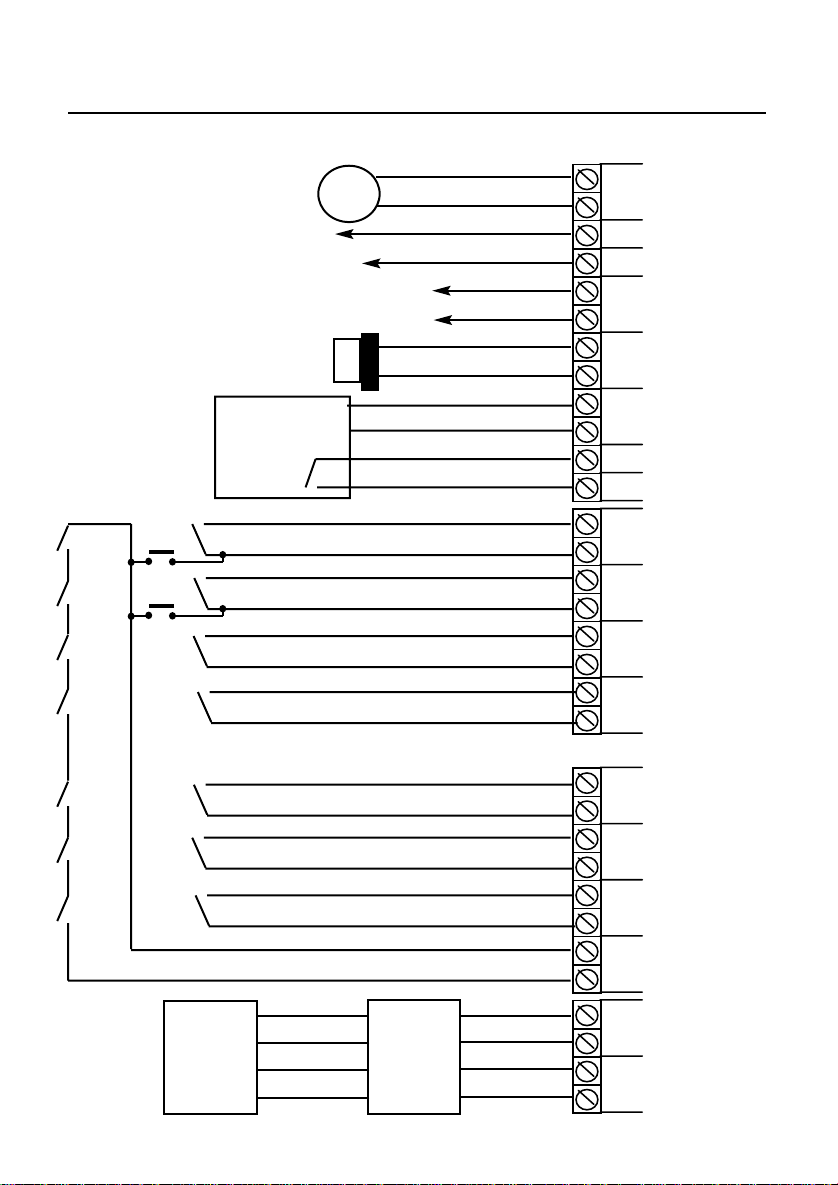

Fig 3. below shows the connections for a typical system.

PROGRAMMABLE SW+ TO LATCH TERMINALS ON GARDSCANS, SHOCKGARDS ETC

PROGRAMMABLE OUTPUT TO DETECTORS

REQUIRING + REMOVE TO RESET

N/O DEVICE

N/O DEVICE

SPEAKER

STROBE

LIGHT

S.A.B

MODULE

N/C DEVICES

N/C DEVICES

N/C DEVICES

N/C DEVICES

12V

DETECTOR

SUPPLY

ENGINEERS MANUAL

+

SPKR

PGM1

PGM2

+

AUX 12V

+

STROBE

+

BELL

BELL HOLD SAB TAMP

+

AZ1

+

AZ2

+

AZ3

+

AZ4

-

N/C DEVICES

N/C DEVICES

N/C DEVICES

N/C TAMPER LOOP

REMOTE

D OUT

KEYPAD

4 wire

(MAX 4)

D IN

12V

+

AZ5

+

AZ6

+

AZ7

+

TAMP

-

D IN

REMOTE

D OUT

KEYPAD

4 wire

0V

12V

0V

IN

DATA

OUT

+

AUX 12V

-

Page 5

GARDTEC

580

ENGINEERS MANUAL

Output Terminal Descriptions

Speaker Terminals

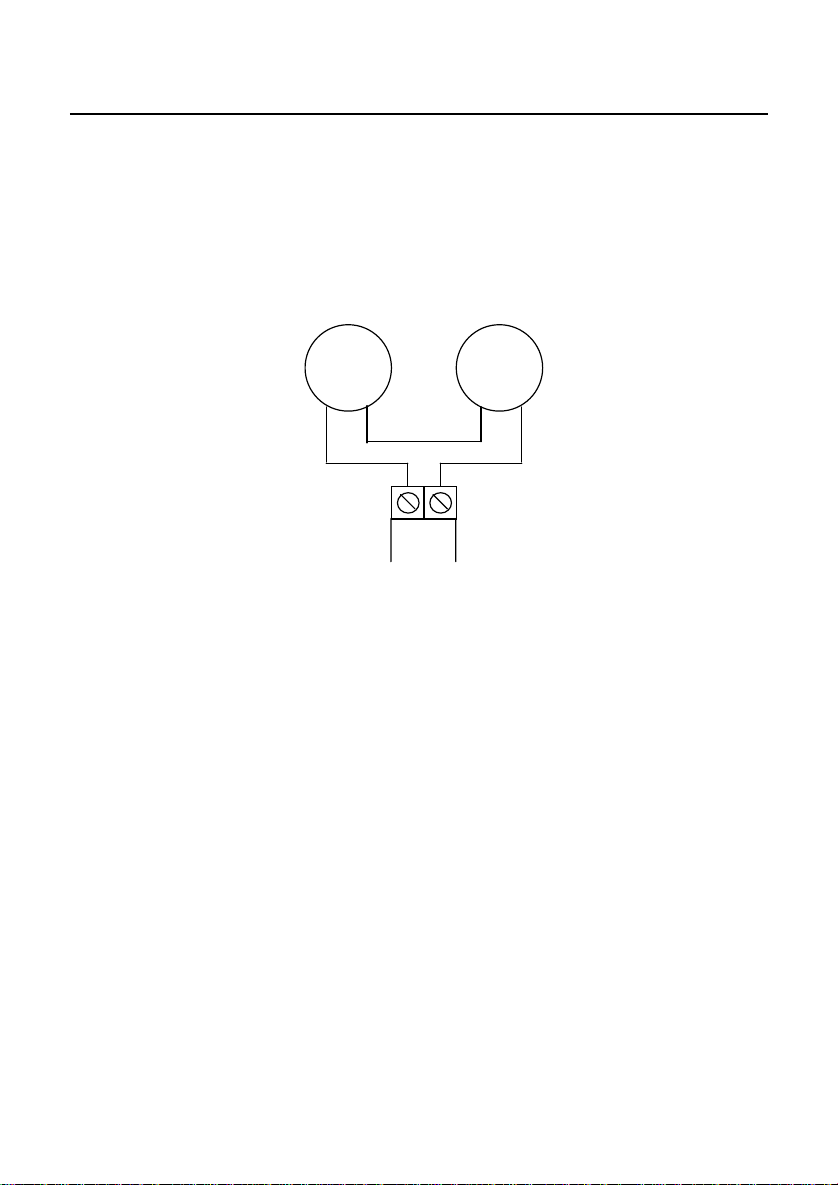

One speaker is fitted as standard to the GARDTEC

each keypad. If an extension speaker is required it should have a minimum impedance

of 16 . Both of the speakers should be wired in series format as shown in Fig 4.

Fig 4. 2 x Speakers

580

and a speaker is supplied in

Coarse adjustment

of the low volume

tones is achieved

through adjustment

Speaker 1

(Panel)

Speaker 2

16

(Extension)

of the onboard

potentiometer situated to the right of

fuse F2 on the PCB

edge. Fine adjustment is via the software option

- +

SPKR

'Sounder Levels'

PGM 1 Terminal

This terminal provides the switch +ve (or set +ve) required by most types of latching

detectors. The terminal is an open collector output held at 12V through an integral 1k

resistor. Max current sink into this terminal is 50mA. This terminal is programmable for

other uses (as shown in PGM2) if required.

PGM 2 Terminal

This terminal provides a switched 12V output and is programmable by the engineer

from the list below. The terminal would normally be used with latching detectors that

require the power to be removed to reset. Max current source from this terminal is

50mA

PGM Options

Pulse On Switch +ve Pulse Off

(set +ve)

Bell Strobe Exit / Entry

Test Int Alarm

A more detailed description is given in the programmable options description.

Page 6

GARDTEC

580

ENGINEERS MANUAL

Output Terminal Descriptions (cont)

Power Supply Rating

It should be noted that the Gardtec 580 has 1 Amp available for the full system.

Sounders, detectors and other auxiliary items should be included when calculating current drawn by the system. Any damage caused through overloading the

Control Panel will not be covered by the warranty.

AUX 12V Terminals

This pair of terminals supply the + and - supply for detectors such as Gardscan P.I.Rs,

Shockgard vibration sensors, etc. 1 Amp is available from these terminals (see power

supply rating above).

Strobe Terminals

This pair of terminals are the output for the strobe light. The negative terminal is

switched during an alarm period. It should be noted that after an alarm, the strobe will

overrun after the bell has reset until the system is unset. A maximum of 500mA may be

drawn from these terminals (see power supply rating above).

Bell Terminals

This pair of terminals are the output for the Bell or external sounder. The negative terminal is switched during an alarm period. A maximum of 1 Amp may be drawn from

these terminals (see power supply rating above).

Page 7

GARDTEC

580

Remote Keypads

ENGINEERS MANUAL

Upto four remote keypads may be fitted to the GARDTEC

GARDTEC

integral speaker.

One extra Entry / Exit zone may be used from any one of the RKPs increasing the

number of available zones to eight. Terminals to facilitate both the extra zone and

associated tamper are included within the remote keypad.

A four core connection will be required between the control panel data port and remote

keypad(s), we would advise that all keypads are in a 'daisy chain' format.

Full instructions for connection are included with the RKPs.

580

LED RKP has a twin seven segment display, backlit keypad and an

580

control panel. The

ProDigi Communicator

The ProDigi communicator may be fitted to the GARDTEC

core connection will be required to the control panel data port. The ProDigi must be the

first device in the 'daisy chain' line between the control panel and any other remote

devices.

The ProDigi will require programming from a GARDTEC

ProDigi programmer. A ProDigi programmer is available at all Gardiner Technology

branches for customer use.

580

Series control. A four

800 Series

control panel or a

Page 8

GARDTEC

580

ENGINEERS MANUAL

Initial Power Up

When the Control Panel is initially powered up it will be either set or unset dependent

on the state of the Control Panel when it was powered down. The factory default state

will be unset.

As power is applied segments of the twin seven segment display will be lit for approx

six seconds. During this period press 4 6 YES NO to ensure that the Control Panel is

at factory settings. The display will then show set or unset.

Reset to Default Modes

Two methods may be used to reset the Control Panel back to factory defaults.

Method 1

Remove the cover from the Control Panel (this will cause a tamper Cb on display and

sounder).

Remove the link marked LK1 on the edge of the P.C.B module (this will give temporary

access to the default codes 5678 for user and 1234 for engineer)

Enter the factory default user code 5678 to stop the sounder.

If you wish to re-program the user code, enter this code again to enter user mode

and follow the user instructions for changing user codes. You must replace LK1

before you enter the new code.

Or if you wish to re-program an engineer option, enter the factory default engineer

code (1234) and press YES to gain access. Then replace LK1 and follow the engineer

programming instructions.

Method 2

Apply power to the panel and press 00 within the first 5 seconds.

Down power the again and leave for at least 10 seconds.

Re-apply either the mains or battery supply.

Press 4 6 YES NO within the first 5 seconds.

The Control Panel is now back to factory defaults.

Note: The two methods shown above will have no effect on the engineer code if

it started with a '9'. If this is the case, only re-use of the programmed engineer

code will allow it to be changed.

Page 9

GARDTEC

580

ENGINEERS MANUAL

System Programming

The system may be programmed by the engineer by use of the engineer code (1234

factory default). Other functions are also available to the engineer, these are as follows.

Set

The engineer may fully set the system or partset the system.

Unset

The engineer may only unset the system using the engineer code if it has previously

been set using the engineer code.

Remove

The engineer may remove individual zones when setting the system.

Test

The engineer may use this function to test the system.

Log

Using this function the engineer may read the log. The log will be shown on a last

event first basis.

Chime

Using this function the engineer may turn the chime function on and off. It should be

noted that chime zones must first be programmed from the engineer zone option.

The above options will be dealt with in the section Engineer Modes

Fig 6. shows the flow chart to be used when programming the GARDTEC

Page 10

580

Loading...

Loading...