Page 1

D Betriebsanleitung

Elektro-Kettensäge

GB Operating Instructions

Electric Chainsaw

F Mode dʼemploi

Tronçonneuse électrique

NL Instructies voor gebruik

Elektrische kettingzaag

S Bruksanvisning

Elektrisk motorsåg

DK Brugsanvisning

Elektrisk kædesav

N Bruksanvisning

Elektrisk kjedesag

FIN Käyttöohje

Sähkökäyttöinen moottorisaha

I Istruzioni per lʼuso

Elettrosega

E Manual de instrucciones

Motosierra eléctrica

P Instruções de utilização

Motosserra eléctrica

PL Instrukcja obsіugi

Piła łańcuchowa elektryczna

H Vevőtájékoztató

Elektromos láncfűrész

CZ Návod k obsluze

Elektrická řetězová pila

SK Návod na používanie

Elektrická reťazová píla

GR Oδηγíες χρήσεως

Ηλεκτρικό αλυσοπρίονο

RUS Инструкция по эксплуатации

Электрическая цепная пила

SLO Navodila za uporabo

Električna verižna žaga

HR Uputstva za upotrebu

Električna lančana pila

UA Інструкція з експлуатації

Електрична ручна ланцюгова пилка

RO Instrucţiuni de utilizare

Ferăstrău electric cu lanţ

TR Kullanma Talimatı

Elektrikli Testere

BG Инструкция за експлоатация

Електрическа моторна резачка

EST Kasutusjuhend

Elektriline kettsaag

LT Eksploatavimo instrukcija

Elektriniai grandininiai pjūklai

LV Lietošanas instrukcija

Elektriskais ķēdes zāģis

D

GBFNLSDKN

FIN

IEPPL

H

CZSKGRRUSSLOHR

UA

RO

TRBGESTLT

LV

CSI 4020-X Electric Chainsaw

Art. 8863

CST 3519-X Electric Chainsaw

Art. 8862

GARDENA

Æ

Page 2

D

WICHTIGE INFORMATION

Bitte vor dem Benutzen des Gerätes

durchlesen und gut aufbewahren

GB

IMPORTANT INFORMATION

Read before use and retain for future

reference

F

RENSEIGNEMENTS IMPORTANTS

A lire avant usage et à conserver pour

référence ultérieure

NL

BELANGRIJKE INFORMATIE

Leest u deze informatie voor het gebruik

en bewaar ze voor toekomstige

raadpleging

S

VIKTIG INFORMATION

Läs anvisningarna före användningen och

spara dem för framtida behov

N

VIKTIG INFORMASJON

Les bruksanvisningen nøye før bruk og

oppbevar den for senere bruk

FIN

VIGTIGE OPLYSNINGER

Du bør læse brugsanvisningen før brug og

gemme til senere henvisning

I

INFORMAZIONI IMPORTANTI

Leggere prima dellʼuso e conservare per

ulteriore consultazione

E

INFORMACIÓN IMPORTANTE

Léase antes de utilizar y consérvela como

referencia en el futuro

P

INFORMAÇÕES IMPORTANTES

Leia antes de utilizar e guarde para

consulta futura

VIGTIGE OPLYSNINGER

Du bør læse brugsanvisningen før brug og

gemme til senere henvisning

SK

GR

PL

H

CZ

DK

UWAGA Zapoznać się z treścią niniejszej

instrukcji przed użyciem i zachować ją do

dalszego użytkowania urządzenia

RUS

FONTOS INFORMÁCIÓ

Használat előtt olvassa el, és tartsa meg

későbbi felhasználásra

DŮLEŽITÁ INFORMACE

Než začnete stroj používat, přečtěte si

pozorně tento návod a uschovejte jej pro další

použití v budoucnu

DÔLEŽITÉ INFORMÁCIE

Pred použitím si prečítajte nasledovné

informácie a odložte si ich pre budúcu

potrebu

ΣΗΜΑΝΤΙΚΕΣ ΠΛΗΡΟΦΟΡΙΕΣ

∆ιαβάστε αυτό το φυλλάδιο πριν από τη

χρήση της συσκευής και φυλάξτε το για

µελλοντική αναφορά

ВАЖНАЯ ИНФОРМАЦИЯ

Прочитайте перед тем, как включить

триммер, и сохраните для дальнейшего

использования.

SLO

POMEMBNA INFORMACIJA

Preberite pred uporabo in shranite za

prihodnjo uporabo

HR

VAŽNE INFORMACIJE

Pročitati prije upotrebe i sačuvati za

buduće osvrte

UA

ВАЖЛИВА ІНФОРМАЦІЯ

Прочитайте перед початком роботи і

збережіть для подальшого

використання

RO

Manual de instrucţiuni

Inainte să folosiţi fierastraul pentru prima

oară, citiţi cu atenţie manualul de

instrucţiuni pentru a-i înţelege conţinutul.

TR

ÖNEMLİ BİLGİLER

Kullanmadan önce okuyunuz ve ileride

başvurmak üzere saklayınız.

BG

ВАЖНА ИНФОРМАЦИЯ

Прочетете преди употреба и запазете за

бъдещи справки

EST

OLULINE TEAVE

Enne seadme kasutuselevõtmist lugege

kasutusjuhend läbi ning säilitage see tuleviku

tarbeks.

LT

Operatoriaus instrukcijÅ rinkinys

Perskaitykite |¡ instrukcijÅ rinkin¡ labai

atidãiai, kad pilnai suprastum>te turin¡, prie|

prad>dami naudoti vejos/ ãol>s pjov>jƒ.

LV

ВАЖЛИВА ІНФОРМАЦІЯ

Прочитайте перед початком роботи і

збережіть для подальшого

використання

Page 3

25

26

23

24

27

28

8

A

5 19

7

2

3

4

1

6

16

12

17

10

20

13

18

15

14

11

9

21

22

29

5

4

7

8

2

3

1

6

12

10

13

11

9

29

30

31

32

G

A

R

D

E

NA

Æ

Page 4

B

C

b

b

2

2

3

14

1

1

3a

2

c

a

c

a

3b

4a 4b

5

6a

7a

6b

7b

Page 5

D

1a

1b

3

5a

6a

2a

2b

4

5b

6b

7a

7b

Page 6

E

G

2

F

1

2

3mm

3

4a

1

2

5

1

=

4b

6

7

8

Page 7

Page 8

G

12

13

10

11

9

A

B

0

60

14

0.5mm

300- 35

0

15

Page 9

H

1

2

3

4

Page 10

H

5

6

7

8

2

3

B

C

B

9

C

A

A

C

B

B

C

10

Page 11

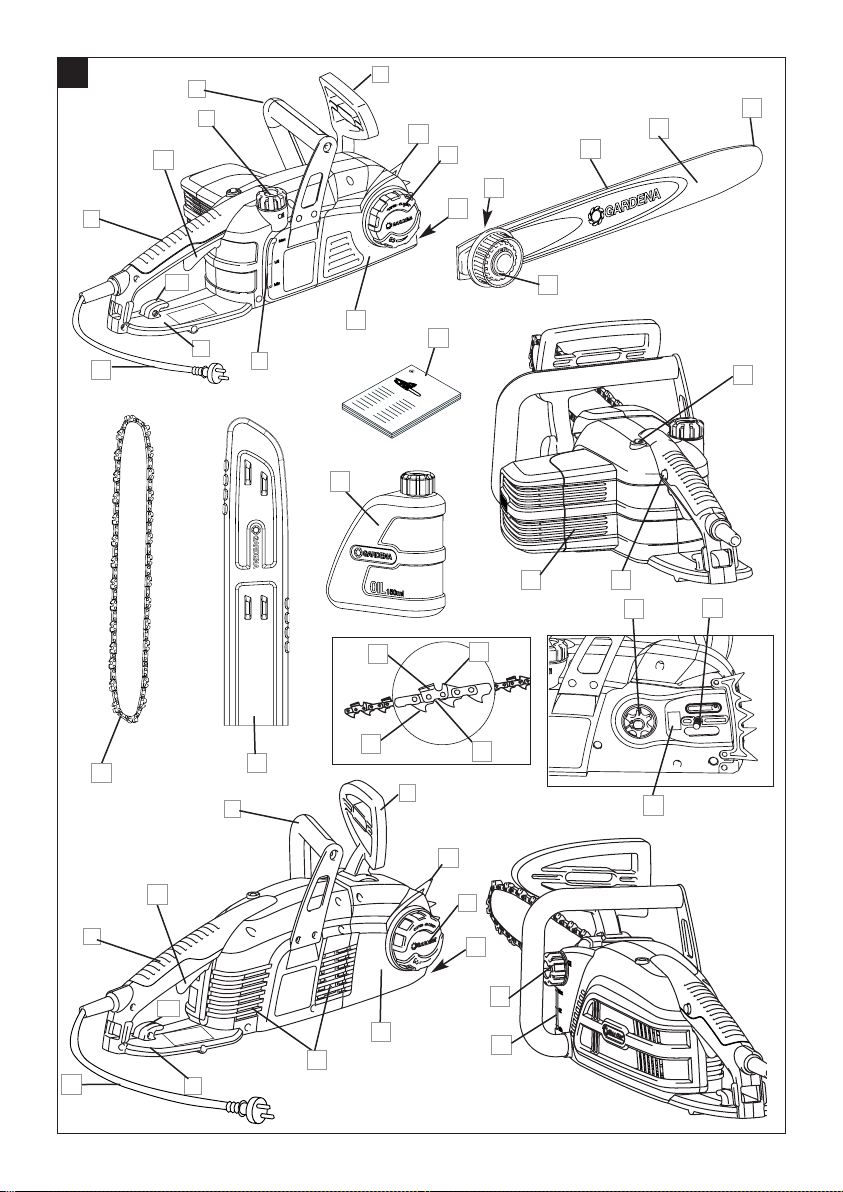

A. GENERAL DESCRIPTION

ENGLISH - 1

1) Guaranteed sound power

according to directive 2000/14/EC

2) Class II tool

3) CE marking of conformity

4) Rated frequency

5) Rated power

6) Alternating current

7) Rated voltage

8) Product code

9) Year of manufacture

10) Maximum length of guide bar

11) Manufacturerʼs name and address

12) Model

Example of identification label

1) Cable

2) Rear handle

3) Rear hand guard

4) Oil tank inspection gauge

5) Air vents

6) Switch

7) Oil tank cap

8) Front handle

9) Front hand guard/chain brake

lever

10) Spiked bumper

11) Chain tensioner knob

12) Chain catcher

13) Drive sprocket cover

14) Lubrication hole

15) Guide bar groove

16) Guide bar

17) Nose sprocket

18) Chain tensioning mechanism

19) Switch block

20) Guide bar cover

21) Chain

22) Manual

23) Cutting tooth

24) Cutting depth gauge

25) Drive tooth

26) Cutting link

27) Drive sprocket

28) Bar retaining screw

29) Cable strain relief

30) Magnet

31) Thermal Cut-Out

32) Oil Bottle

1

9

7

4

5

3

6

8

11

12

2

10

Page 12

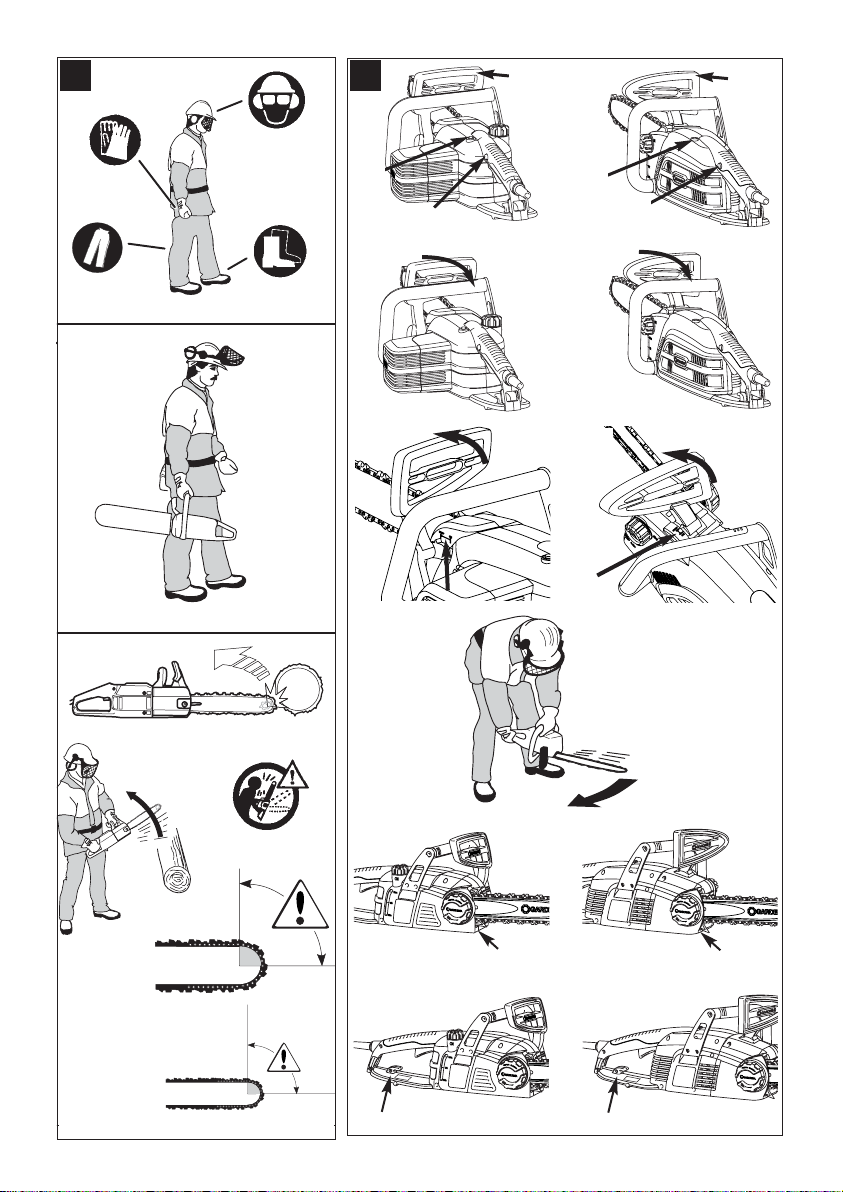

B. SAFETY PRECAUTIONS

10 m

MEANING OF SYMBOLS

Warning!

Read the instruction

manual carefully

Protective boots

Protective goggles or

visor, protective helmet

and hearing protection

Protective cut-proof

gloves

Protective long,

cut-proof trousers

Chain brake:

deactivated, activated

Remove plug from the

mains immediately if the

cable is damaged or cut

Correct direction of the

cutting teeth.

Always grip the machine

with two hands

Kickback danger

Do not expose to rain or

moisture.

Chain oil

Refrain from

Turn the machine off

Disconnect the plug

before adjusting or

cleaning.

10 m

General Power Tool Safety Warnings

WARNING Read all safety warnings and all

instructions.

and instructions may result in electric shock, fire

and/or serious injury.

Save all warnings and instructions for future

reference.

The term ʻ“power tool” in the warnings refers to your

mains-operated (corded) power tool .

1) Work area safety

a) Keep work area clean and well lit.

dark areas invite accidents.

b) Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases or dust.

create sparks which may ignite the dust

or fumes.

c) Keep children and bystanders away while

operating a power tool.

you to lose control.

Keep bystanders away

Failure to follow the warnings

Distractions can cause

Cluttered or

Power tools

Risk of electric shock

2) Electrical safety

a) Power tool plugs must match the outlet.

Never modify the plug in any way. Do not use

any adaptor plugs with earthed (grounded)

power tools.

outlets will reduce risk of electric shock.

b) Avoid body contact with earthed or grounded

surfaces such as pipes, radiators, ranges and

refrigerators.

electric shock if your body is earthed or grounded.

c) Do not expose power tools to rain or wet

conditions.

increase the risk electric shock.

d) Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges or

moving parts.

increase the risk of electric shock.

e) When operating a power tool outdoors, use an

extension cord suitable for outdoor use.

of a cord suitable for outdoor use reduces the risk

of electric shock.

Unmodified plugs and matching

There is an increased risk of

Water entering a power tool will

Damaged or entangled cords

ENGLISH - 2

Use

Page 13

f) If operating a power tool in a damp location is

unavoidable, use a residual current device

(RCD) protected supply.

Use of an RCD

reduces the risk of electric shock.

3) Personal safety

a) Stay alert, watch what you are doing and use

common sense when operating a power tool.

Do not use a power tool while you are tired or

under the influence of drugs, alcohol or

medication.

A moment of inattention while

operating power tools may result in serious

personal injury.

b) Use personal protective equipment. Always

wear eye protection.

Protective equipment such

as dust mask, non-skid safety shoes, hard hat, or

hearing protection used for appropriate conditions

will reduce personal injuries.

Obtainable from a

workwear supplier.

c) Prevent unintentional starting. Ensure the

switch is in the off-position before connecting

to power source and/or battery pack, picking

up or carrying the tool.

Carrying power tools

with your finger on the switch or energising power

tools that have the switch on invites accidents.

d) Do not overreach. Keep proper footing and

balance at all times.

This enables better control

of the power tool in unexpected situations.

e) Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and gloves

away from moving parts.

Loose clothes,

jewellery or long hair can be caught in moving

parts.

4) Power tool use and care

a) Do not force the power tool. Use the correct

power tool for your application.

The correct

power tool will do the job better and safer at the

rate for which it was designed.

b) Do not use the power tool if the switch does

not turn it on and off.

Any power tool that

cannot be controlled with the switch is dangerous

and must be repaired.

c) Disconnect the plug from the power source

before making any adjustments, changing

accessories, or storing power tools.

Such

preventive safety measures reduce the risk of

starting the power tool accidentally.

d) Store idle power tools out of the reach of

children and do not allow persons unfamiliar

with the power tool or these instructions to

operate the power tool.

Power tools are

dangerous in the hands of untrained users.

e) Maintain power tools. Check for

misalignment or binding of moving parts,

breakage of parts and any other condition that

may affect the power tool’s operation. If

damaged, have the power tool repaired before

use.

Many accidents are caused by poorly

maintained power tools.

f) Keep cutting tools sharp and clean.

Properly

maintained cutting tools with sharp cutting edges

are less likely to bind and are easier to control.

g) Use the power tool, accessories and tool bits

etc. in accordance with these instructions,

taking into account the working conditions

and the work to be performed.

Use of the

power tool for operations different from those

intended could result in a hazardous situation.

5. Service

a) Have your power tool serviced by a qualified

repair person using only identical

replacement parts.

This will ensure that the

safety of the power tool is maintained.

Chain saw safety warnings:

• Keep all parts of the body away from the saw

chain when the chain saw is operating.

Before you start the chain saw, make sure the

saw chain is not contacting anything.

A

moment of inattention while operating chain saws

may cause entanglement of your clothing or body

with the saw chain.

• Always hold the chain saw with your right

hand on the rear handle and your left hand on

the front handle.

Holding the chain saw with a

reversed hand configuration increases the risk of

personal injury and should never be done.

• Wear safety glasses and hearing protection.

Further protective equipment for head, hands,

legs and feet is recommended.

Adequate

protective clothing will reduce personal injury by

flying debris or accidental contact with the saw

chain.

Obtainable from a workwear supplier.

• Do not operate a chain saw in a tree.

Operation of chain saw while up a tree may result

in personal injury.

• Always keep proper footing and operate the

chain saw only when standing on fixed,

secure and level surface.

Slippery or unstable

surfaces such as ladders may cause a loss of

balance or control of the chain saw.

• When cutting a limb that is under tension be

alert for spring back.

When the tension in the

wood fibres is released the spring loaded limb

may strike the operator and/or throw the chain

saw out of control.

• Use extreme caution when cutting brush and

saplings.

The slender material may catch the

saw chain and be whipped forward toward you or

pull you off balance.

• Carry the chain saw by the front handle with the

chain saw switched off and away from your

body. When transporting or storing the chain

saw always fit the guide bar cover.

Proper

handling of the chain saw will reduce the likelihood

of accidental contact with the moving saw chain.

• Follow instructions for lubricating, chain

tensioning and changing accessories.

Improperly tensioned or lubricated chain may

either break or increase the chance for kickback.

• Keep handles dry, clean and free from oil and

grease.

Greasy, oily handles are slippery

causing loss of control.

• Cut wood only. Do not use chain saw for

purposes not intended. For example: do not

use chain saw for cutting plastic, masonry or

non-wood building materials.

Use of the chain

saw for operations different than intended could

result in a hazardous situation.

ENGLISH - 3

Page 14

Causes and operator prevention of kickback:

Kickback may occur when the nose or tip of the

guide bar touches an object (Fig B3), or when

the wood closes in and pinches the saw chain in

the cut.

Tip contact in some cases may cause a sudden

reverse reaction, kicking the guide bar up and

back towards the operator.

Pinching the saw chain along the top of the guide

bar may push the guide bar rapidly back towards

the operator.

Either of these reactions may cause you to lose

control of the saw which could result in serious

personal injury. Do not rely exclusively upon the

safety devices built into your saw. As a chain

saw user, you should take several steps to keep

your cutting jobs free from accident or injury.

Kickback is a result of tool misuse and/or

incorrect operating procedures or conditions and

can be avoided by taking proper precautions as

given below:

• Maintain a firm grip, with thumbs and fingers

encircling the chain saw handles, with both

hands on the saw and position your body and

arm to allow you to resist kickback forces.

Kickback forces can be controlled by the

operator, if proper precautions are taken. Do not

let go of the chain saw.

• Do not overreach and do not cut above

shoulder height.

tip contact and enables better control of the chain

saw in unexpected situations.

• Only use replacement bars and chains

specified by the manufacturer.

replacement bars and chains may cause chain

breakage and/or kickback.

• Follow the manufacturer’s sharpening and

maintenance instructions for the saw chain.

Decreasing the depth gauge height can lead to

increased kickback.

Additional Safety Recommendations

1. Manual use. All persons using this machine

must read the user manual completely with

extreme care. The user manual must be included

with the machine in the case of sale or loan to

another person.

2. Precautions prior to machine use. Never

permit this machine to be used by any persons

who are not perfectly familiar with the manual

instructions. Inexperienced persons must follow a

training period operating on a saw horse only.

3. Control checks. Check the machine with care

before use each time, especially if it has been

subject to strong impact, or if it shows any signs

of malfunction. Perform all operations described

in the chapter “Maintenance & Storage – Before

each use”.

4. Repairs and Maintenance. All the machine

parts that can be replaced personally, are clearly

explained in the “Assembly / disassembly”

instructions chapter. Where necessary, all other

machine parts must be replaced exclusively by an

Authorised Service Centre.

This helps prevent unintended

Incorrect

5. Clothing. (fig B1) When using this machine the

user must wear the following approved individual

protective clothing : close-fitting protective

clothing, safety boots with non-slip soles, crushproof toe protectors and cut-proof protection, cutproof vibration-proof gloves, protective goggles or

safety visor, ear protection muffs and helmet (if

there is any danger of falling objects). Obtainable

from a workwear supplier

6. Health precautions – Vibrations and Noise

levels. Please be aware of noise restrictions in

the immediate area. Prolonged machine use

exposes the user to vibrations that can generate

“white finger phenomenon” (Raynaudʼs

Phenomenon), carpal tunnel syndrome and

similar disturbances.

7. Health precautions – Chemical agents. Use oil

which is approved by the manufacturer.

8. Health precautions - Heat. During use, sprocket and

chain reach very high temperatures, take care not to

touch these parts while hot.

Transport and storage precautions.(fig B2) Each

time the work area is changed to another location,

disconnect the machine from the mains supply and

activate the chain brake lever. Mount the guide bar

cover guard each time before transporting or

storage. Always carry the machine by hand with the

bar facing backwards, or when transporting the

machine in a vehicle, always attach it securely to

prevent damage.

Kickback reaction. (fig B3) The kickback reaction

consists of a violent upwards-reverse action of the

bar towards the user. This generally occurs if the

upper part of the bar nose (called the “kickback

danger zone” ) (see red marking on the Guide Bar)

comes into contact with some object, or if the chain

is blocked in the wood. Kickback can make the user

loose control of the machine provoking dangerous

and even fatal accidents. The chain brake lever and

other safety devices are not sufficient to protect the

user against injury: the user must be well aware of

the conditions that can provoke the reaction, and

prevent them by paying very close attention

according to experience, together with prudent and

correct machine handling (for example: never cut

several branches at a time because this can cause

accidental impact on the “kickback danger zone”

Work area safety

1. Never allow children or people unfamiliar with

these instructions to use the product. Local

regulations may restrict the age of the operator.

2. Only use the product in the manner and for the

functions described in these instructions.

3. Check the whole work area carefully to check for any

danger source (e.g.: roads, paths, electric cables,

dangerous trees, etc)

4. Keep all bystanders and animals well clear of the

work area (where necessary, fence off the area and

use warning signs) at a minimum distance of 2.5 x

the trunk height; in any case no less than ten

metres.

5. The operator or user is responsible for accidents or

hazards occurring to other people or their property.

ENGLISH - 4

Page 15

Electrical safety

1. It is recommended that you use a Residual

Current Device (R.C.D.) with a tripping current of

not more than 30mA. Even with a R.C.D.

installed 100% safety cannot be guaranteed and

safe working practice must be followed at all

times. Check your R.C.D. every time you use it.

2. Before use, examine cable for damage, replace it

if there are signs of damage or ageing.

3. Do not use the product if the electric cables are

damaged or worn.

4. Immediately disconnect from the mains electricity

supply if the cable is cut, or the insulation is

damaged. Do not touch the electric cable until

the electrical supply has been disconnected. Do

not repair a cut or damaged cable. Take the

product to an Authorised Service Centre and

have the cable replaced.

5. Always make sure that the cable/ extension cord is

kept behind the user, ensuring that it does not

create a source of danger for the user or for other

persons, and check that it cannot be damaged (by

heat, sharp objects, sharp edges, oil, etc);

6. Position the cable so that it will not be caught on

branches and the like, during cutting.

7. Always switch off at the mains before

disconnecting any plug, cable connector or

extension cable.

8. Switch off, remove plug from mains and examine

electric supply cable for damage or ageing

before

winding cable for storage. Do not repair

a damaged cable. Take the product to an

Authorised Service Centre and have the cable

replaced.

9. Remove the plug from the mains before leaving

the product unattended for any period.

10.Always wind cable carefully, avoiding kinking.

11.Use only on AC mains supply voltage shown on

the product rating label.

12.The chainsaw is double insulated to EN60745-1

& 2-13.

Cables

1. Mains cables and extensions are available from

your local Approved service centre

2. Only use approved extension cables

3. Extension cables and leads should only be used

if they are designed for outdoor use and comply

with H07 RN-F or IEC 60245 designation 66.

Use only 1.0mm

2

size cable up to 40m in length

maximum

C. SAFETY EQUIPMENT DESCRIPTION

SWITCH BLOCK

Your machine is equipped with a device (fig.1a, 2a)

that when deactivated, stops the switch from being

pressed thus preventing accidental start-up.

CHAIN BRAKE ACTION ON SWITCH RELEASE

Your machine is equipped with a device that blocks

the chain immediately as soon as the switch is

released; If this device should not work at any time,

the machine must NOT be used and must be taken

to an Authorised Service Centre.

FRONT HAND GUARD / CHAIN BRAKE LEVER

The front hand guard (fig.1b, 2b) is designed to

prevent your left hand from coming into contact with

the chain (on condition that the machine is held

correctly according to instructions). The front hand

guard also acts as a chain brake, including a device

that stops the chain in less than 0.15 of a second in

the case of kickback. The chain brake is released

when the front hand guard is pulled backwards and

clicked in position (fig.3a, 3b). The chain brake is

activated when the front hand guard is pushed

forward and the chain is stopped (see ON-STOP

indication) (fig.4a, 4b). The chain brake can be

activated using the left wrist by pushing forwards, or

when the wrist comes into contact with the front

hand guard as a result of kickback.

When the machine is used with the bar in horizontal

position, for example during tree felling, the chain

brake offers less protection.(fig.5).

N.B.: When the chain brake is activated, a safety

switch cuts off all current to the motor.

Releasing the chain brake whilst the switch

is held will start the product.

CHAIN CATCHER

This machine is equipped with a chain catcher (fig.6a, 6b)

located under the sprocket. This mechanism is designed

to stop the backward chain movement in the case of

chain breaking or derailing. These situations can be

avoided by ensuring correct chain tension (Refer to

chapter “D. Assembly/disassembly”).

REAR HAND GUARD

This acts to protect (fig.7a, 7b) the hand in the case

of chain breaking or derailing.

THERMAL CUT-OUT

The Motor is protected by a Thermal Cut-Out Switch

(fig 1c, 2c) which is activated when the chain

becomes jammed or if the motor is overloaded.

When this occurs, stop and remove the plug from

the power supply, clear any obstruction and wait for

a few minutes for the product to cool down. Reset

by pushing back in the Thermal Cut-Out Switch.

Resetting the Thermal Cut-out Switch with the

chain brake released and the switch held will

start the product.

ENGLISH - 5

Page 16

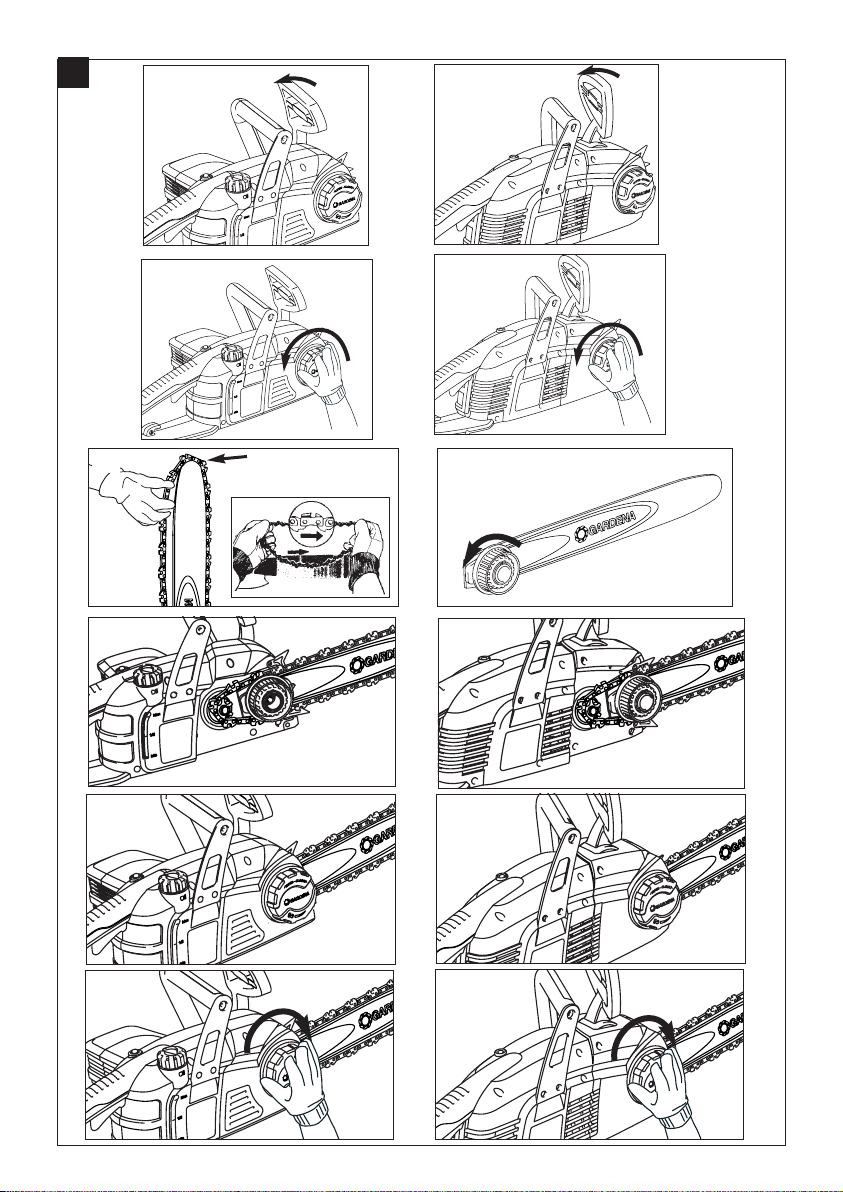

D. ASSEMBLY / DISASSEMBLY

BAR AND CHAIN ASSEMBLY

Take great care when assembling to ensure this is performed correctly.

Remove the plug from the power supply before working on the product.

1a & 1b. Check that the chain brake is not activated. If so, deactivate it.

2a & 2b. Unscrew the chain tensioning knob and rotate in an anti-clockwise direction to remove the drive

sprocket cover.

Wear Gloves.

3 Position the chain over the bar, starting at the nose sprocket, fitting it into the guide bar groove.

Ensure that the sharp side of the cutting teeth face in a forward direction on the upper part of the bar.(see

markings on the bar)

4. Rotate the chain tensioning mechanism anti-clockwise as far as possible.

5a & 5b. Mount the bar on the bar retaining screw and it will attach to the magnet. Position the chain over

the drive sprocket.

6a & 6b. Replace the drive sprocket cover, ensuring the drive teeth of the chain are engaged in the drive

sprocket and in the bar guide groove.

7a & b. To tension the chain, turn the chain tensioner knob in a clockwise direction until securely tightened.

The chain is now tensioned correctly for use.

Tensioning the chain too tightly will overload the motor and cause damage. Insufficient tension can provoke

chain derailing, whereas a chain tightened correctly provides the best cutting characteristics and prolonged

work life. Check the tension regularly because the chain length tends to stretch with use (especially when

the chain is new; after the first assembly, the chain tension must be checked after a few minutes machine

operation); in any case do not tighten the chain immediately after use, but wait until it cools down.

In cases where the loosened chain needs to be adjusted, always unscrew the chain tensioning knob 2 turns

and then securely tighten again leaving the chain tensioned for use.

Warning:- The chain and guide bar can become very hot

E. START-UP AND STOPPING

Start-up: grip both handles firmly, release the chain

brake lever whilst ensuring hand is still on front

handle, press and maintain the switch block (fig E1)

pressed in, then press the switch (fig E2) (at this

point the switch block can be released).

F. BAR AND CHAIN LUBRICATION

ATTENTION! Insufficient lubrication will provoke

chain breaking and can cause serious injury.

Refer to “Maintenance & Storage” for indications on

ensuring that the chain oil is sufficiently distributed.

Choice of chain oil

Use oil which is approved by the manufacturer.

We advise the use of bio chain oil which is

biologically degradable.

ENGLISH - 6

Stopping: The machine will stop whenever the

switch is released or by activating the chain brake.

Filling oil tank

Unscrew the oil tank cap, and fill the tank taking

care not to spill any oil (if this occurs clean the

machine carefully) and then screw the cap back on

tightly.

Page 17

(fig.1) When using the machine, prevent:

- cutting in conditions where the trunk could split during

cutting (wood under pressure, dry dead trees, etc):

sudden splitting can be very dangerous.

- the bar or the chain from becoming blocked in the

cutting notch: if this should occur, disconnect the

machine from the main electricity supply and try to raise

the trunk using an appropriate tool as a lever; do not

attempt to free the machine by shaking or pulling as this

could cause damage or injury.

- situations that can lead to kickback reactions.

- using the product above shoulder height

- cutting wood with foreign objects e.g. nails

Never use the machine in earth or stones, this leads to

immediate wear of the chain.

(fig.1) During machine use:

- When cutting on sloping ground, always work uphill of the

trunk to avoid being hit if the trunk should roll downhill.

- When felling trees, always finish the job: a partially cut tree

could break and fall.

- At the end of each cutting operation the user will notice a

considerable change in the strength necessary for controlling

the machine. Great care must be taken not to loose control.

Below is a description of two different types of cutting

operation:

Cutting action by pulling the chain (from top to bottom)

(fig.2) can lead to dangerous sudden movement of the

machine towards the trunk with consequential loss of

control. Where possible, use the spiked bumper during

cutting operations.

H. CUTTING TECHNIQUES

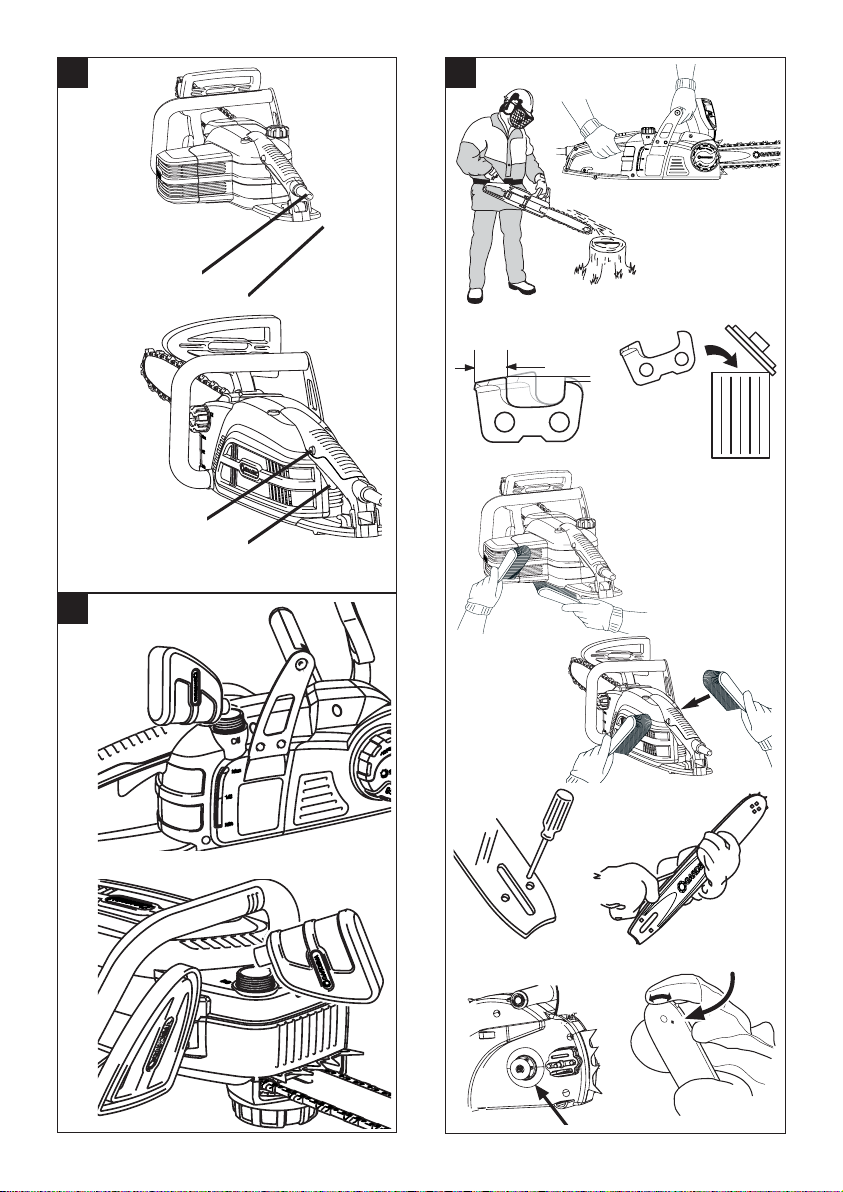

G. MAINTENANCE AND STORAGE

Before performing any maintenance or

cleaning, remove the plug from the mains.

ATTENTION! In cases where work

environments are particularly dirty or dusty, the

operations described must be performed more

frequently than mentioned in the instructions.

Before each use

Check that the chain oil pump functions correctly:

direct the bar towards a clear surface at a distance

of about 20 centimetres; after the machine has run

for about a minute, the surface should show clear

traces of oil (fig.1).

Check that excessive strength is not needed for

activating and deactivating the chain brake. Also

check that it is not activated too easily and that it is

not blocked. Then check chain brake function as

follows: release the chain brake, grip the machine

correctly and start up the machine, activate the

chain brake by pushing the front hand guard forward

with the left wrist or arm but without removing the

hand from the handle (fig.2). If the chain brake is

working correctly, the chain should be stopped

immediately.

Check that the chain is sharpened correctly, in good

working condition and that the tension is correct. If

the chain is irregularly worn, or if the cutting teeth

are only 3 mm long, the chain must be replaced

(fig.3).

Clean the air vents regularly to prevent motor

overheating (fig 4a, 4b).

Check that the switch and switch block function

correctly (to be performed with the chain brake

released): press the switch and the switch block and

ensure that they return to idle position as soon as

they are released; check that it is impossible to

press the switch without activating the switch block.

Check that the chain catcher and the right hand

guard are in correct condition without any visible

faults such as damaged material.

Every 2-3 hours of use

Check the bar condition, if necessary clean the lubrication

holes (fig.5) and the guide grooves (fig.6) carefully; If the

groove is worn or shows signs of deep notching, it must be

replaced. Clean the drive sprocket regularly and check

that it has not been subject to excess wear (fig.7).

Lubricate the nose sprocket with bearing grease through

the hole shown in the illustration (fig.8).

Chain sharpening

Contact an Authorised Service Centre regarding

any problems with sharpening the chain.

The chain needs to be correctly sharpened. A

wrongly sharpened chain can cause kickback

and a high risk of injury.

If the chain does not cut correctly, or requires hard bar

pressure against the wood, and if the sawdust is very

fine, this is a sign that it is not sharpened correctly. If

the cutting action produces no sawdust, this means the

cutting edge has been worn completely and the chain

is pulverising the wood during cutting. A wellsharpened chain crosses through the wood without

effort or pressure and produces large long wood

shavings.

The cutting side of the chain is composed of the cutting

link (fig.9) with a cutting tooth (fig.10) and a cutting limit

gauge (fig.11). The difference between these

determines the cutting depth; a file guide and a 4mm

diameter round file are needed to obtain good

sharpening results; Follow the instructions below:

Once the chain has been mounted and the tension is

correctly adjusted, and the chain brake is activated,

position the file guide perpendicular to the bar as

shown in the illustration (fig.12), filing the cutting teeth

at the angle shown (fig.13A, 13B), always working from

the interior towards the exterior, lessening the pressure

during the return stage (it is very important to follow the

instructions perfectly: excessive or insufficient

sharpening angles or an incorrect file diameter will

increase the risk of kickback.) To obtain higher

precision on side angles, it is advisable to position the

file so that it exceeds the upper cutter by about 0.5

mm. File all the teeth on one side first, then turn the

machine over and repeat the operation. Make sure

that after sharpening operations, all teeth are the same

length and that the height of the depth gauge is 0.6 mm

lower than the upper cutter: check the height using a

proper template and file (with a flat file) all protruding

parts, rounding off the front part of the depth gauge

(fig.14), paying attention to not file the kickback

protection tooth (fig.15)

Every 30 hours use.

Take the machine to the Authorised Service Centre

Storage/Transport

Allow the product to cool down and place the cover

over the bar and chain.

Store the product in a cool, dry, place and out of reach

of children. Do not store outdoors.

Ensure the oil does not leak out from the product.

ENGLISH - 7

Page 18

Cutting action pushing the chain (from bottom to top)

(fig.3) will lead to the danger of a sudden movement of

the machine in the direction of the user, with the risk of

hitting the user, or an impact of the “kickback danger

zone” on the trunk resulting in strong kickback; extreme

care must be taken when cutting in this manner.

The safest method for using the machine, is to block the

log on a sawhorse, cutting from top to bottom, on the

portion outside the sawhorse. (fig.4)

Spiked bumper use.

Where possible, use the spiked bumper to ensure safer

cutting action: plant it in the bark or surface of the trunk in

order to maintain more control over the machine.

Below are descriptions of typical cutting procedure to be

adopted for specific situations. However, these should be

assessed each time to calculate whether the method is

most suitable or not, In order to use a method with the

least possible risk.

Trunk on the ground. (Risk of touching the ground with

the chain once the bar has passed trough the trunk).

(fig.5)

Cut from top to bottom through the whole trunk. Towards

the end of the cut, proceed very carefully to prevent the

chain from hitting the ground. If it is possible, cut 2/3 of

the trunk, roll it over, and cut the remaining third from top

to bottom to limit the risk of the chain touching the

ground.

Trunk supported at one end only(Risk of trunk

breaking during cutting action). (fig.6)

Begin the cut from underneath for about 1/3 of the

diameter, and then finish the cutting action from the top to

meet the undercut.

Trunk supported at both ends.(Risk of pinching the

chain). (fig.7)

Begin the cut from above for about 1/3 of the diameter,

and then continue from underneath to meet the overcut.

Trunk laying on a slope. Always stand on the uphill side

of the log. When ʻcutting throughʼ, to maintain complete

control, release the cutting pressure near the end of the

cut without relaxing your grip on the chainsaw handles.

Do not let the chain contact the ground.

Tree felling.

ATTENTION!: Never attempt to fell a tree if you do not

have the necessary experience, and in any case never

fell trees that have trunks with a diameter larger than the

length of the bar! This operation is reserved for expert

machine users with adequate equipment.

When felling a tree, the aim is to have the tree fall in the

most convenient position for the following limbing and

bucking operations. (Avoid trees falling on top of other

trees: Felling trees that are entangled with other trees is

a very dangerous operation).

First of all decide which is the best direction for the tree to

fall by evaluating the following: objects or other plants

around the tree, the inclination, the curve, wind direction,

and greatest branch concentration. Take into account

dead or broken branches that may break off during felling

creating a further danger risk.

ATTENTION! During tree felling operations in critical

conditions, always remove ear protection immediately

after cutting operations to be able to listen for unusual

noises and any warning signals.

Preliminary cutting operations and identifying the

retreat path.

Eliminate any branches that interfere with the job (fig.8),

starting from top to bottom, and then, always keeping the

trunk between the user and the machine eliminate the

more difficult branches afterwards, piece by piece.

Eliminate all plants that interfere with work operations and

control the area for possible obstacles (rocks, roots,

ditches,etc.) when planning the retreat path (to follow

during tree fall); Refer to the illustration (fig.9) for the

directions to be maintained (A. predicted tree fall

direction. B. Retreat path. C. Danger zone).

FELLING CUTS (fig.10)

In order to ensure that the user has complete control over

the tree fall, the cutting instructions are as follows:

The cut that controls the fall direction of the tree is to be

executed first: First of all cut the UPPER PART of the

directional notch on the side the tree must fall. Remain

on the right hand side of the tree and cut using the chain

pull method; then cut the LOWER PART that must meet

the end of the upper part. The depth of the directional

notch must be

least 45° between upper and lower cut. The meeting

point between the two sides of the notch is called

“directional cut line” This line must be perfectly horizontal

at right angles (90°) to the felling direction.

The felling cut that provokes the tree fall, is performed at

3 to 5cm above the lower part of the directional felling cut

line, finishing at a distance of 1/10 of the trunk from the

notch. Remain on the left hand side of the tree and cut

using the chain pulling method and the spiked bumper.

Check that the tree does not move in a direction other

than that predicted for the fall. As soon as possible insert

a felling lever or wedge into the cut. The uncut part of the

trunk is called the “hinge”, as it is intended to guide the

tree as it falls; in cases where the cuts are not sufficient,

not straight, or have been cut through completely, the tree

fall cannot be controlled (extremely dangerous!). For this

reason the various cuts must be performed with great

precision.

When cutting operations are completed the tree will begin

to fall. Where necessary help tree fall using wedges or

felling levers.

1/

4

of the trunk diameter, with an angle of at

Limbing

Once the tree has been felled, the trunk must be limbed:

in other words, the branches are removed from the trunk.

Do not underestimate this operation because the large

majority of kickback accidents occur during this stage.

For this reason pay close attention to the position of the

bar nose during cutting operations and always work on

the left hand side of the trunk.

ENGLISH - 8

Page 19

Motor does Motor turns The machine Motor turns Braking

not start with difficulty starts but improperly or devices do

or loses does not cut at reduced not stop the

power properly speeds chain properly

Make sure the main

line is powered

Make sure the machine

is properly plugged in

Make sure your

cable/ext. cord is not

damaged

Make sure that chain

brake is not activated

Check that chain is

properly assembled

and tensioned

Check chain

lubrification as in

chapters F and G

Make sure that the

chain is sharp

Check Thermal cut-out

switch is activated

Contact your

authorised centre

•

•

•

•

•

••

•

•

••

TROUBLESHOOTING TABLE

•

ENGLISH - 9

ENVIRONMENTAL INFORMATION

This section contains information useful for maintaining the characteristic of ecocompatibility included in the

origin design of the machine, and as regards proper use and disposal of chain oil

USE OF THE MACHINE

The operations of filling the oil tank should be carried out in such a way as to avoid spilling oil and

contaminating the soil and the environment.

DISPOSAL

Do not dispose of the machine inappropriately when it is no longer usable. Deliver it to an authorized

organization for proper disposal in compliance with the regulation in force.

The symbol on the product or on its packaging indicates that this product may not be treated as

household waste. Instead it shall be handed over to the applicable collection point for the recycling of

electrical and electronic equipment. By ensuring this product is disposed of correctly, you will help prevent

potential negative consequences for the environment and human health, which could otherwise be caused

by inappropriate waste handling of this product. For more detailed information about recycling of this

product, please contact your local council office, your household waste disposal service or the shop where

you purchased the product.

•

•

The chain and chain guide are consumables and are not covered by the guarantee.

Page 20

EU Certificate of Conformity

The undersigned GARDENA Manufacturing GmbH, Hans-Lorenser-Str. 40, D-89079 Ulm, hereby certifies

that, when leaving our factory, the units indicated below are in accordance with the harmonised EU

guidelines, EU standards of safety and product specific standards. This certificate becomes void if the units

are modified without our approval.

Description of Unit......................Electric Chainsaw

Type(s) ......................................CST3519-X, CSI4020-X

Year of CE Marking....................2009

EU Directives:

98/37/EC, 2004/108/EC, 2000/14/EC

Harmonised EN:

EN60745-1, EN60745-2-13, EN50366, EN55014-1, EN61000-3-2, EN61000-3-11

Notified Body that carried out the EC type-examination

in accordance with article 8 section 2c....... MEEI Kft., 1007

Certificate no. ............................................. M3 2992559 (CST 3519-X)

Working area related emission characteristic Level L

Vibrations Value ah according to ISO 22868 given in the table.

WA

The Noise Level L

Conformity Assessment Procedure............ Annex V

Ulm 16/07/2009

Peter Lameli

Technical Dept. Manager

values according to 2000/14/EC are given in the table.

Type CST3519-XCSI4020-X

Dry Weight (Kg) 5.6 5.5

Power (kW) 1.9 2.0

Oil tank volume (cm

Chain pitch (inches) 3/8 3/8

Chain gauge (mm) 1.3 1.3

Maximum length of guide bar (mm) 350 400

Measured Sound Power L

Guaranteed Sound Power L

Sound pressure Level L

Value a

Uncertainty K of a

Mains-Impedance Z

Cutting Speed (m/s)

Váci út 48/a-b

1132 Budapest

Hungary

M3 2992560 (CST 4020-X)

h

(m/s2) 5.9 5.3

pA

according to ISO 22868 given in the table.

3

) 180 180

WA

(dB(A)) 106 106

WA

(dB(A)) 108 108

pa

(dB(A)) 95 95

h

(m/s2) 1.5 1.5

max (

Ω)

0.310 0.314

12 15

EN 61000-3-11 Compliance statement

Depending on the characteristics of the local electricity supply network, use of this product may result in

short voltage drops at the instant of switching on. This may influence other electrical equipment e.g a

momentary dimming of a lamp. If the Mains impedance Zmax of your electricity supply is less than the

value shown in the table (applicable to your model) then these effects will not occur. The value of the

network impedance may be determined by contacting your electricity supply authority

ENGLISH - 10

Page 21

Deutschland / Germany

GARDENA

Manufacturing GmbH

Central Service

Hans-Lorenser-Straße 40

D-89079 Ulm

Produktfragen:

(+49) 731 490-123

Reparaturen:

(+49) 731 490-290

service@gardena.com

Argentina

Husqvarna Argentina S.A.

Vera 745

(C1414AOO) Buenos Aires

Phone: (+54) 11 4858-5000

diego.poggi@ar.husqvarna.com

Australia

Husqvarna Australia Pty. Ltd.

8 Park Drive

Dandenong UIC 3175

Austria / Österreich

GARDENA

Österreich Ges.m.b.H.

Stettnerweg 11-15

2100 Korneuburg

Tel . : (+43) 22 62 7 45 45 36

kundendienst@gardena.at

Belgium

GARDENA Belgium NV/SA

Sterrebeekstraat 163

1930 Zaventem

Phone: (+32) 2 7 20 92 12

Mail: info@gardena.be

Brazil

Palash Comércio e

Importação Ltda.

Rua São João do Araguaia, 338

– Jardim Califórnia –

Barueri – SP - Brasil –

CEP 06409-060

Phone: (+55) 11 4198-9777

eduardo@palash.com.br

Bulgaria

Хускварна България ЕООД

1799 София

Бул.„Андрей Ляпчев” Nº 72

Тел.: (+359) 2 80 99 424

www.husqvarna.bg

Canada

GARDENA Canada Ltd.

100 Summerlea Road

Brampton, Ontario L6T 4X3

Phone: (+1) 905 792 93 30

info@gardenacanada.com

Chile

Antonio Martinic y Cia Ltda.

Cassillas 272

Centro de Cassillas

Santiago de Chile

Phone: (+56) 2 20 10 708

garfar_cl@yahoo.com

Costa Rica

Compania Exim

Euroiberoamericana S.A.

Los Colegios, Moravia,

200 metros al Sur del Colegi

Saint Francis - San José

Phone: (+506) 297 68 84

exim_euro@racsa.co.cr

Croatia

KLIS d.o.o.

Stanciceva 79

10419 Vukovina

Phone: (+385) 1 622 777 0

gardena@klis-trgovina.hr

Cyprus

FARMOKIPIKI LTD

P.O. Box 7098

74, Digeni Akrita Ave.

1641 Nicosia

Phone: (+357) 22 75 47 62

condam@spidernet.com.cy

Czech Republic

GARDENA spol. s r.o.

Tuřanka 115

627 00 Brno

Phone: (+420) 800 100 425

gardena@gardenabrno.cz

Denmark

GARDENA

Husqvarna Consumer Outdoor

Products

Salgsafdelning Danmark

Box 9003

S-200 39 Malmö

info@gardena.dk

Estonia

Husqvarna Eesti OÜ

Consumer Outdoor Products

Kesk tee 10, Aaviku küla

Rae vald, Harju maakond

75305

kontakt.etj@husqvarna.ee

Finland

Oy Husqvarna Ab

Consumer Outdoor Products

Lautatarhankatu 8 B / PL 3

00581 HELSINKI

info@gardena.fi

France

GARDENA

PARIS NORD 2

69, rue de la Belle Etoile

BP 57080

ROISSY EN FRANCE

95948 ROISSY CDG CEDEX

Tél. (+33) 0826 101 455

service.consommateurs@

gardena.fr

Great Britain

Husqvarna UK Ltd

Preston Road

Aycliffe Industrial Park

Newton Aycliffe

County Durham

DL5 6UP

info.gardena@

husqvarna.co.uk

Greece

Agrokip

Psomadopoulos S.A.

Ifaistou 33A

Industrial Area Koropi

194 00 Athens Greece

V.A.T. EL093474846

Phone: (+30) 210 66 20 225

service@agrokip.gr

Hungary

Husqvarna

Magyarország Kft.

Ezred u. 1- 3

1044 Budapest

Phone: (+36) 80 20 40 33

gardena@gardena.hu

Iceland

Ó. Johnson & Kaaber

Tunguhalsi 1

110 Reykjavik

ooj@ojk.is

Ireland

Michael McLoughlin & Sons

Hardware Limited

Long Mile Road

Dublin 12

Italy

GARDENA Italia S.p.A.

Via Donizetti 22

20020 Lainate (Mi)

Phone: (+39) 02.93.94.79.1

info@gardenaitalia.it

Japan

KAKUICHI Co. Ltd.

Sumitomo Realty &

Development Kojimachi

BLDG., 8F

5-1 Nibanncyo, Chiyoda-ku

Tokyo 102-0084

Phone: (+81) 33 264 4721

m_ishihara@kaku-ichi.co.jp

Latvia

SIA „Husqvarna Latvija”

Consumer Outdoor Products

B◊k·žu iela 6, Rœga, LV-1024

info@husqvarna.lv

Lithuania

UAB Husqvarna Lietuva

Consumer Outdoor Products

Ateities pl. 77C

LT-52104 Kaunas

centras@husqvarna.lt

Luxembourg

Magasins Jules Neuberg

39, rue Jacques Stas

Luxembourg-Gasperich 2549

Case Postale No. 12

Luxembourg 2010

Phone: (+352) 40 14 01

api@neuberg.lu

Netherlands

GARDENA Nederland B.V.

Postbus 50176

1305 AD ALMERE

Phone: (+31) 36 521 00 00

info@gardena.nl

Neth. Antilles

Jonka Enterprises N.V.

Sta. Rosa Weg 196

P.O. Box 8200, Curaçao

Phone: (+599) 9 767 66 55

pgm@jonka.com

New Zealand

Husqvarna NZ Ltd.

15 Earl Richardson Ave/

Manukau City

Auckland

Norway

GARDENA

Husqvarna Consumer Outdoor

Products

Salgskontor Norge

Kleverveien 6

1540 Vestby

info@gardena.no

Poland

GARDENA Polska Sp. z o.o.

Szymanów 9 d

05-532 Baniocha

Phone: (+48) 22 727 56 90

gardena@gardena.pl

Portugal

GARDENA Portugal Lda.

Sintra Business Park

Edifício 1, Fracção 0-G

2710-089 Sintra

Phone: (+351) 21 922 85 30

info@gardena.pt

Romania

MADEX INTERNATIONAL SRL

Soseaua Odaii 117-123,

Sector 1,

єti, RO 013603

Bucure

Phone: (+40) 21 352 76 03

madex@ines.ro

Russia / Россия

ООО ГАРДЕНА РУС

123007, г. Москва

Хорошевское шоссе, д. 32А

Тел.: (+7) 495 380 31 80

info@gardena-rus.ru

Singapore

Hy - Ray PRIVATE LIMITED

40 Jalan Pemimpin

#02-08 Tat Ann Building

Singapore 577185

Phone: (+65) 6253 2277

hyray@singnet.com.sg

Slovak Republic

GARDENA Slovensko, s.r.o.

Panónska cesta 17

851 04 Bratislava

Phone: (+421) 263 453 722

info@gardena.sk

Slovenia

GARDENA d.o.o.

Brodišče 15

1236 Trzin

Phone: (+386) 1 580 93 32

servis@gardena.si

South Africa

GARDENA

South Africa (Pty.) Ltd.

P.O. Box 11534

Vorna Valley 1686

Phone: (+27) 11 315 02 23

sales@gardena.co.za

Spain

GARDENA IBÉRICA S.L.U.

C/ Basauri, nº 6

La Florida

28023 Madrid

Phone: (+34) 91 708 05 00

atencioncliente@gardena.es

Sweden

GARDENA

Husqvarna Consumer Outdoor

Products

Försäljningskontor Sverige

Box 9003

200 39 Malmö

info@gardena.se

Switzerland / Schweiz

Consumer Products

Husqvarna Schweiz AG

Industriestrasse 10

5506 Mägenwil

Phone: (+ 41) (0) 848 800 464

info@gardena.ch

Turkey

GARDENA / Dost Di

Mümessillik A.

Çad. Adil Sokak No.1

Kartal - İstanbul

Phone: (+90) 216 38 93 939

info@gardena-dost.com.tr

Ukraine / Україна

ТОВ «ГАРДЕНА УКРАЇНА»

Васильківська, 34, 204-Г

03022, Київ

Тел. (+38 044) 498 39 02

info@gardena.ua

USA

Melnor Inc.

3085 Shawnee Drive

Winchester, VA 22604

Phone: (+1) 540 722-9080

service_us@melnor.com

8862-20.960.03/ 0709

© GARDENA

Manufacturing GmbH

D-89070 Ulm

http: //www.gardena.com

ş Tic aret

Ş. Sanayi

Loading...

Loading...