Page 1

GARDENA

®

D Gebrauchsanweisung

Hauswasserautomat

GB Operating Instructions

Pressure Tank Unit

F Mode d’emploi

Pompe d’arrosage automatique

NL Gebruiksaanwijzing

Pomp met hydrofoor

S Bruksanvisning

Pumpautomat

I Istruzioni per l’uso

Pompa ad intervento automatico per uso domestico

E Manual de instrucciones

Bomba doméstico

P Instruções de utilização

Bomba de Pressão

DK Brugsanvisning

Husvandværk

4000/4 electronic plus

Art. 1482

4000/5 electronic plus

Art. 1484

Page 2

E

B

3

G

5

C

4

2

13

D

C

9

0

A

D

D

E F

5

6D

7

F

8

B

3

13 a

A

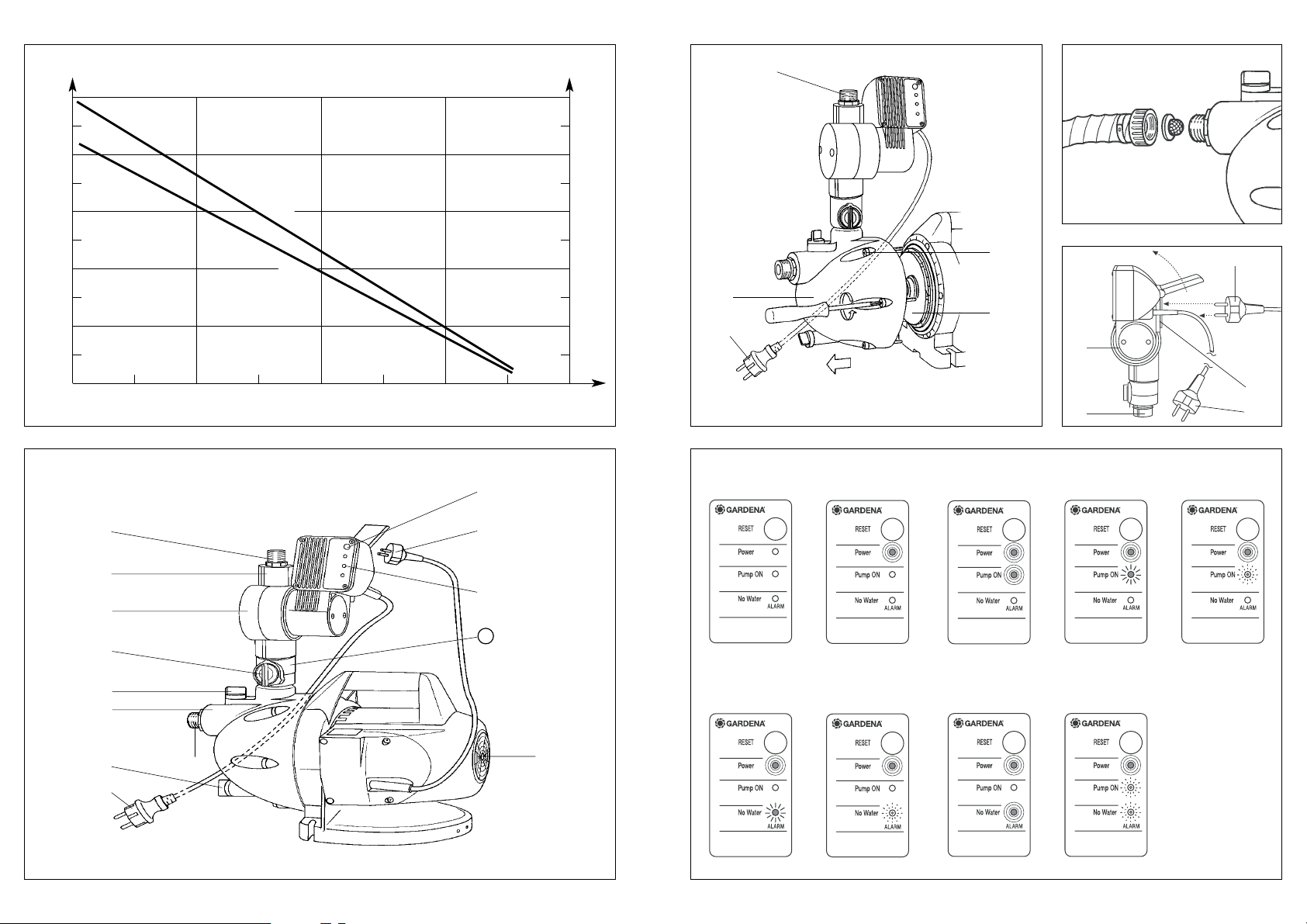

0 1000 2000 3000 4000 l/h

m

50

40

30

20

10

0

bar

5

4

3

2

1

4000/5 electronic plus

4000/4 electronic plus

F1

F6

F2

F7

F3

F8

F4

F9

F5

Page 3

4

D

Bitte lesen Sie diese

Gebrauchsanweisung vor

Montage und Inbetriebnahme Ihres

Gerätes sorgfältig. Beim Lesen

der Gebrauchsanweisung bitte

die Umschlagseite herausklappen.

Inhaltsverzeichnis Seite

1. Hinweise zur Gebrauchsanweisung 5

2. Ordnungsgemäßer Gebrauch 5

3. Technische Daten 5

4. Funktionsteile 6

5. Maßnahmen vor der

Inbetriebnahme 6

6. Inbetriebnahme 7

7. Sicherheitshinweise zur

Inbetriebnahme 7

8. Funktion und Display des

Elektronischen Druckschalters 8

9. Benutzungshinweise 9

10. Wartung, Pflege, Aufbewahrung 9

11. Empfehlenswertes Zubehör 10

12. Störungen 10

Garantie 74

G

Please read these operating

instructions carefully before

assembling and using the unit.

Unfold inside cover pages to read

the operating instructions.

Contents Page

1. Information concerning

the Operating Instructions 14

2. Product Use 14

3. Technical Data 14

4. Functional Parts 15

5. Preparations prior to Operation 15

6. Starting Operation 16

7. Safety Hints before Operation 16

8. Function and Display of the

Electronic Manometric Switch 17

9. Operation Hints 18

10. Maintenance, Care, Storage 18

11. Recommended Accessories 19

12. Trouble-Shooting 19

Guarantee 74

F

Nous vous remercions de bien

vouloir lire attentivement ce

mode d’emploi avant d’utiliser votre

pompe. Pour une meilleure compréhension, dépliez le 2ème volet

de la couverture de manière à faire

apparaître les schémas de montage.

Contenu Page

1. Informations sur le mode

d’emploi 22

2. Domaine d’utilisation 22

3. Caractéristiques techniques 22

4. Description du produit 23

5. Préparation de la mise en service 23

6. Mise en service 24

7. Précautions d’emploi 24

8. Fonctionnement et affichage

de l’interrupteur manométrique 25

9. Conseils d’utilisation 26

10. Entretien et rangement 27

11. Accessoires recommandés 27

12. Incidents 27

Garantie 74

N

Lees deze gebruiksaanwijzing

voor montage en ingebruikname van het apparaat zorgvuldig

door. Bij het lezen van de gebruiksaanwijzing de bladzijden met de afbeeldingen openslaan.

Inhoudsopgave Pagina

1. Aanwijzingen bij de

gebruiksaanwijzing 30

2. Juist gebruik 30

3. Technische gegevens 30

4. Bedieningsonderdelen 31

5. Maatregelen vóór de

ingebruikname 31

6. Ingebruikname 32

7. Veiligheidstips voor ingebruikname 32

8. Funktie en display van

de elektronische besturing 33

9. Gebruikstips 34

10. Verzorging, onderhoud, opslag 34

11. Aanbevolen accessoires 35

12. Storingen 35

Garantie 74

S

Läs igenom bruksanvsiningen

noggrant innan Du tar Din

pump i bruk. Ha omslaget utvikt när

Du läser bruksanvisningen.

Innehåll Sida

1. Information 38

2. Användningsområde 38

3. Tekniska data 38

4. Beskrivning 38

5. Åtgärder innan automaten

tas i bruk 39

6. Drift 40

7. Säkerhetsråd vid drift 40

8. Den elektroniska styrningens

funktion och display 40

9. Viktiga råd 42

10. Underhåll, skötsel och förvaring 42

11. Rekommenderade tillbehör 42

12. Felsökning 42

Garanti 75

I

Prima di mettere in uso la

nuova pompa, leggere attentamente le istruzioni tenendo aperto

il pieghevole per avere sott’occhio

i disegni esplicativi.

Indice pagina

1. Avvertenze 45

2. Uso corretto 45

3. Caratteristiche tecniche 45

4. Parti funzionali 45

5. Operazioni preliminari 46

6. Messa in uso 47

7. Norme di sicurezza 47

8. Pressostato elettronico 47

9. Norme operative 48

10. Manutenzione 49

11. Accessori 49

12. Anomalie di funzionamento 49

Garanzia 75

E

Antes del montaje y de la

puesta en marcha del aparato,

aconsejamos una atenta lectura del

presente manual de instrucciones.

Para facilitar la lectura, desdoble la

cubierta.

Índice Página

1. Indicaciones del manual

de instrucciones 52

2. Uso correcto 52

3. Datos técnicos de la bomba 52

4. Piezas funcionales 52

5. Operaciones antes de la puesta

en servicio 53

6. Puesta en servicio 54

7. Medidas de seguridad para

la puesta en funcionamiento 54

8. Función y display del interruptor

electrónico 54

9. Instrucciones de uso 56

10. Mantenimiento, cuidados,

almacenamiento 56

11. Accesorios recomendados 56

12. Averías 57

Garantía 75

P

Por favor leia atentamente

estas instruções de utilização

antes de utilizar esta bomba.

Desdobre as páginas na capa interior

para ler as instruções de utilização.

Conteúdo Página

1. Informações acerca das

instruções 59

2. Utilização do produto 59

3. Dados técnicos 59

4. Componentes funcionais 60

5. Providências a serem tomadas

antes da colocação em funcionamento 60

6. Colocação em funcionamento 61

7. Medidas de segurança antes

do funcionamento 61

8. Funcionamento e indicações

do display do interruptor

manométrico electrónico 62

9. Conselhos de utilização 63

10. Manutenção, conservação

e armazenagem 64

11. Acessórios recomendados 64

12. Falhas 65

Garantia 75

K

Læs denne brugsanvisning

omhyggeligt igennem før montering og igangsætning af apparatet.

Klap brugsanvisningens omslagsside

ud under læsningen.

Inhold Side

1. Henvisninger til brugsanvisningen 67

2. Korrekt anvendelse 67

3. Tekniske data 67

4. Funktionsdele 67

5. Foranstaltninger før igangsætning 68

6. Igangsætning 69

7. Sikkerhedshenvisninger

i forbindelse med igangsætning 69

8. Det elektroniske manometer

kontakts funktion og display 69

9. Anvendelseshenvisninger 71

10. Vedligeholdelse, pleje, opbevaring 71

11. Anbefalelsesværdigt tilbehør 71

12. Fejl 72

Garanti 75

Page 4

15

G

14

G

1

Water drain screw

2

Suction side

3

Pump fitting 33.3 mm (G1)

4

Filler cap with screw plug

5

Electronic Manometric Switch

6

Inlet, delivery side

7

RESET button

8

Light-emitting diodes

9

Screws for casing attachment

0

Casing cover

A

Turbine

B

Turbine axle

C

Rotary switch for non-return

valve

D

Mains connector for the

Manometric Switch

E

Connector socket for

pump connector plug

F

Mains plug for pump

G

Outlet, delivery side

4. Functional Parts (ill. B/C/E)

5.1 Mounting the Electronic

Manometric Switch

The Electronic Manometric Switch

5

is fitted with a 33.3 mm (G1)

outer thread at the inlet side6.

To mount the Electronic Manometric Switch proceed as follows:

1. Hold the top of the Electronic

Manometric Switch with one

hand and with the other, screw

the lower rotating part into the

inner thread of the pump.

Screw up to the limit.

Note: When the limit has been

reached, the non-return valve

(13a) can be turned in the

counter-clockwise direction

– a maximum of one turn

however – into any position

which is the most convenient

for you.The display can also be

turned into any desired position

before the connection on the

pressure side

3/ G

is tight-

ened up.

2. Plug the mains plug for the

pump Finto the connector

socket Eat the back of the

display for the Electronic

Manometric Switch (ill. E).

5.2 Location and Filling of

the Pump before Operation

1. Locate the pump at safe

distance of the liquid.

Take care that the site is firm

and solid, in order to ensure

safe location of the pump.

2. Before operation, fill the

pump either a) through the

filler cap, or b) through the

outlet nozzle of the Electronic Manometric Switch

with at least 2 I of the liquid

to be pumped:

a) To fill the pump through

the filler cap

4

: Undo the

screw plug at the filling

nozzle and tighten up again

after filling the pump (do

not use a wrench).

b) To fill the pump through the

outlet nozzle on the delivery

side

G

of the Electronic

Manometric Switch:

1. Set the rotary switch/ non-

return valve to position 2

(non-return valve open).

2. Open the screw plug

of the filler cap

4

(for

bleeding).

3. Fill the pump with liquid

through the outlet on the

delivery side

G

of the

Electronic Manometric

Switch until liquid exits

the pump on the suction

side

2

.

4. Tightly close the screw

plug again.

As well as the pump itself,

the suction hose with backflow preventer shall be filled

in order to ensure troublefree drawing (refer to the

section “Suction hose connection”).

5.3 Suction hose connection

Suction Side

2

1. Screw one of the two supplied

pump fittings 3onto the

suction side 2of the pump

and tighten it by hand until

the washer fits closely.

Note: For the suction side use

a vacuum-resistant suction

hose with back-flow preventer (e.g. GARDENA Suc

tion Unit, art.no. 1411). Only

this way, the suction hose can

be filled up before initial operation. Additionally, the liquid to

be pumped stays in the suction

hose, when the pump cuts

out. Thus easy priming is

made possible when starting

the pump again. For suction

heights exceeding 4 m, we

recommend to fix additionally

the suction hose, e.g. by fastening it to a wooden peg, thus

the pump is relieved of load.

2. Before connection, equip the

union nut of the suction hose

with the supplied dirt filter (ill.

D). First of all remove the flat

packing which may be in the

union nut.

Note: Alternatively, you can

also use the GARDENA Pump

Preliminary Filter, art. no.1730/

1731. It is especially recommended for use with highly

contaminated or with a very

sandy liquid. Filtration of water

is essential to prevent the Electronic Manometric Switch from

internal contamination, thus

avoiding malfunction of the unit.

3. In case of permanent, indoor

installation of the pump for

domestic water supply, in order

to reduce noise and to avoid

damages at the Manometric

Switch caused by vibration,

it is recommended to connect

the Pressure Tank Unit via

flexible suction lines, e.g.in

conjunction with the GARDENA

Bore Hole Suction Hose,

art.no. 1729, to the pipe network but not firmly via rigid

pipes.

5. Preparations prior to Operation

Please read these operating

instructions thoroughly. Follow

the information given. Use the

operating instructions to get

acquainted with the operating

parts and the proper use of

the Pressure Tank Unit.

A

For safety reasons,

people who are not

familiar with these operating

instructions should not use

this Pressure Tank Unit.

Following the operating instructions supplied by the manufacturer is a prerequisite for the

proper use of the pump.

The operating instructions include

all necessary instructions concerning operation, maintenance

and service.

GARDENA Pressure Tank Units

4000/4 electronic plus, 4000/ 5 electronic plus

1. Information concerning the Operating Instructions

GARDENA Pressure Tank Units

have been designed for private

use around house and garden.

Pressure Tank Units are predominantly used for operating

watering implements and systems

in private gardens.

Besides, the GARDENA Pressure Tank Units can be used for

domestic water supply, e.g. when

taking rainwater for domestic

use.

A

GARDENA Pressure Tank

Units are not designed for

continuous operation (e.g. industrial application, continuous

circulating operation).

Corrosive, easily combustible,

aggressive or explosive substances (e.g. petrol, petroleum,

nitro thinner) as well as food

must not be pumped.

The temperature of the liquid to

be pumped should not exceed

35 °C.

2. Product Use

4000/4e plus 4000/ 5e plus

Rated power 800 W 1,000 W

Max. delivery capacity 3,600 l /h 3,600 l / h

Max. delivery head 42 m 50 m

Max. pressure

(= cut-out pressure) 4.2 bar 5.0 bar

Cut-in pressure approx. 2.2 ± 0,2 bar 2.2 ± 0,2 bar

Max. suction head 9 m 9 m

Perm. internal pressure

(delivery side) 6 bar 6 bar

Voltage 230 V 230 V

Frequency 50 Hz 50 Hz

Noise level L

WA

1)

77 dB (A) 79 dB (A)

1) Measuring method according to directive 2000/ 14/EC

Performance Characteristics (ill. A)

Technical data of the above performance characteristics is measured at a suction height of 0.5 m,

using a 25 mm (1”) suction hose.

3.Technical Data

Page 5

17

G

16

G

The Electronic Manometric Switch

is equipped with an electronic

control unit with fixed programs.

The electronic control unit is activated by pulses from the manometric switch and the flow recognition of the dry-running safety

feature.

The manometric switch is set

at the factory to a switching

pressure of approx. 2.2 bar.

This setting cannot be changed.

The dry-running safety mechanism protects the pump

against damage and controls

the time the pump continues to

run against the closed delivery

side.

The LEDs (light emitting diodes)

display the operating status

(➔ see “Electronic Control Display”).

Explanation of Terms

..

Priming cycle

The pump attempts to restore

normal operation in 4 minutes.

..

Automatic self-priming mode

(➔➔yellow Alarm LED flashes)

After a fault, the pump’s electronic control unit makes three

automatic self-priming attempts

at different time intervals (after

1 hour, after 5 hours and after

20 hours) to restore normal

operation.

The priming cycle (see above)

is used for each of these attempts.

..

Re-plugging

(removing the mains plug

and then plugging it

back in the socket again)

Important ! Remove the plug

from the socket! Check the

unit and pump for any faults

(see section “Finding Faults”).

Rectify any faults and restart

the pump by plugging the

mains plug into a socket supplying 230 V AC.

Electronic Control Display

Operating Status

lit flashing flashing

quickly

..

RESET Button (ill. F 1)

The RESET button is used

to reset and restart the pump

after a fault.

..

Red Power LED is lit (ill. F2)

The pump is connected to

the mains power.

The pump functions in the

normal operating mode.

..

Green LED is lit (ill. F 3)

The pump is connected to the

mains and the pump is running.

Once the pump has reached

the max. pump pressure, the

pump switches off (the green

LED extinguishes) and the

pump functions in the normal

operating mode.

..

Green LED flashing slowly

(once a second) (ill. F 4)

➔ The flow rate on the deliv-

ery side is too low (below

90 l/h).

The pump continues to run

and then switches off. It

turns on again as soon as

the switching pressure of

approx. 2.2 bar has been

reached (e.g. in the case

of a leak).

➔ The pump must be switched

off just before you finish

draining water from the unit.

..

Green LED flashing quickly

(four times a second) (ill. F5)

➔ The flow rate on the inlet

side is too low (below

400 l/h).

The pump continues to

run for approx. 40 seconds.

If normal operation is not

achieved during this time,

the pump switches off and

the control unit changes

to the “automatic self-

priming mode”.

Not

e: The pump can be

switched on again at any

time by pressing the

RESET button.

..

Yellow LED flashing slowly

(once a second) (ill. F 6)

➔ The amount of water is

too low when restarting

the pump.

The pump runs through

the first “priming cycle”.

If the normal operating

mode is not achieved, the

pump switches off and

the control unit changes

to the “automatic self-

priming mode”.

Not

e: The pump can be

restarted at any time by

pressing the RESET button.

..

Yellow LED flashing quickly

(four times a second) (ill. F7)

➔ Alarm which indicates if the

amount of water is too low

when the pump is operating

in the normal mode. The

control unit changes to the

“automatic self-priming

mode”.

Not

e: The pump can be

restarted at any time by

pressing the RESET button.

..

Yellow LED is lit (ill. F 8)

➔ The “automatic self-

priming mode” is no longer

active and the unit is no

longer supplying water

(e.g. no water in the container or borse or the filter

is dirty).

Not

e: The pump can be

restarted at any time by

pressing the RESET button

or by “re-plugging”.

..

Green and yellow LEDs

flashing quickly and alternately

(four times a second) (ill. F9)

➔ Warning:There is a leak

in the pipe system.

8. Function and Display of the Electronic Manometric Switch

Important! Don’t use any hose

connection system fittings on

the suction side!

Delivery Side

G

4. Screw the second pump fitting

3

into the outlet nozzle of the

delivery side Gof Electronic

Manometric Switch, and tighten

up by hand. Take care that the

washer of the pump fitting fits

closely to the delivery side.

Note 1: The pump fitting is

equipped with a 33.3 mm (G 1)

thread to which 13 mm (1/2” ),

19 mm (3/ 4”) and 16 mm

(5/8”) hoses can be connected by using GARDENA hose

connection system fittings.

Note 2: Best results regarding

the delivery capacity of the

pump are achieved when connecting 19 mm (3/ 4”) hoses

in conjunction with GARDENA

“Profi ” Maxi-Flow System fittings (e.g. art.no.1752) or

when using 25 mm (1”) hoses

with fittings available from

your sanitary dealer.

When connecting simultane-

ously several hoses / watering

accessories, we recommend

application of our GARDENA

Twin-Tap Connector (art.no. 1210)

or Four Channel Water Distributor

(art.no. 1194) which can be

screwed directly onto the pump

fitting on the delivery side

G

.

Using the pump for the

first time

1.Set the switch of the backflow

valve to Position 2.

2.Slightly open the release

points in the delivery pipe (e.g.

spray lance, tap) ➔ air must

be allowed to escape during

the suction process.

3.Plug the mains plug

D

for the

Electronic Manometric Switch

into an outlet socket supplying

230 V alternating current.

Caution! The pump immediately starts to run!

4.As soon as the pump begins

to pump, turn the switch to

Position 1 (normal operation)

➔ ensures fault-free operation

of the pump.

6. Starting Operation

A

..

Caution: Pursuant to

DIN VDE 0100 -702 and

0100-738 use of the pump

nearby swimming pools and

garden ponds and other

similar places is only permissible, if the pump is operated

with a residual-current device with a residual-current

rating ≤≤30 mA. Please ask

your electrician for his advice.

..

The pump must be located

on solid, even ground, protected from flooding.Take

care that the pump cannot

fall into water.

..

Mains power cables should

not have a smaller crosssection than a rubber

sheathed cable of the designation H07 RNF. Extension

cables must meet the requirements of DIN VDE 0620.

..

In Austria, the electrical

connections must be made

according to ÖVE-EM 42,

T2 (2000)/ 1979 § 22 based

on § 2022.1. Pursuant to this

regulation it’s imperative to

operate pumps for swimming

pools and garden ponds

exclusively via an isolating

transformer. Please ask

your electrician.

..

In Switzerland mobile appliances which are used outdoors, must be connected

via a residual-current device.

..

When using the pump for

domestic water supply,

please adhere to the local

water and sewerage regulations. In addition observe

the regulations of DIN 1988.

If necessary, contact your

sanitary expert.

..

Children under the age of 16

are not allowed to operate

the pump. Keep them away

from the connected unit.

..

Protect the pump from rain.

Don’t use the pump in wet

or moist area.

..

Before operating the pump,

first make a visual check, if

there is any damage of the

pump (esp. regarding power

cable and plug). A damaged

pump must not be used. In

case of damage, please have

the pump checked by our

GARDENA Service Centre or

by an authorised electrician.

..

Check line voltage. Data

indicated on the type plate

must match technical data

of the mains supply.

7. Safety Hints before Operation

Page 6

19

G

A

Attention! Disconnect

the plug from the mains

before carrying out any work

on the pump!

A turbine clogged by contamination can be released by using

a screwdriver to turn over the

turbine axle

B

(observe the arrow

on the casing indicating the direction of rotation). If this is not possible any more, the turbine space

can be cleaned by opening the

screws

9

and removing the

casing cover0.

The turbine Acan be removed

if necessary, by using a screwdriver to hold the turbine axle

B

in place while loosening the

turbine Awith a ring spanner

at the same time.

When assembling, take care that

the parts are re-assembled corresponding to the sequence of

the disassembly.

Before the first frost sets in,

the pump should be drained

via the water drain screw

1

.

Store it protected from frost.

To empty the Electronic Mano-

metric Switch

5

put the rotary

switch Cin position 2 and

open the water drain screw 1.

10. Maintenance, Care, Storage (ill. B/C)

..

GARDENA Suction Hoses

Kink- and vacuum-resistant,

sold by the metre with 19 mm

(3/4”) or 25 mm (1” ) diameter

without fittings or in fixed

length, complete with fittings.

..

GARDENA Suction Hose

Fittings (art. no. 1723/1724)/

Suction Filter with Backflow

Preventer (art. no. 1726 /

1727/1728)

To equip suction hoses sold

by the metre.

..

GARDENA Pump

Preliminary Filter,

art. no. 1731

Recommended for pumping

sandy liquids.

art. no. 1730, recommended

for pumping sandy liquids

and higher water quantities.

..

GARDENA Bore Hole

Suction Hose, art. no. 1729

For vacuum-resistant connection of the pump to boreholes

or pipe networks. Length 0.5 m.

With 33.3 mm (G 1) female

thread at both ends.

11. Recommended Accessories

Problem Probable cause Remedy

Pump motor runs, Leaks at suction side. Eliminate leak.

Suction filter at the suction hose To adjust the flow rate of the

but delivery capacity is totally or partly sucked free. suction side to the delivery side,

or pressure suddenly reduce the flow rate at the pump’s

decreases. delivery side

G

. Observe min.

flow rate (see section 9).

Suction filter or backflow Clean filter or backflow preventer.

preventer clogged.

Turbine clogged. Unplug and clean the turbine

(see point 10).

Pump doesn’t deliver water. Leaks at suction side. Eliminate leak.

Pump switches on and off Dirt has collected on the 1. Remove manometric switch

continuously if liquid is impeller. from pump.

drawn at a rate greater than 2. Return valve set to position 2.

400 l/h. 3. Rinse manometric switch

Pump doesn’t start or No power. Check fuses and electric connec-

suddenly stops during tions.

operation.

Circuit breaker has cut out the Disconnect at the mains and clean

pump because of overloading. the turbine (refer to “Maintenance,

Care and Storage”). Observe

max. liquid temperature (35°C).

Electric failure. Send the pump to one of our

GARDENA Service Centres.

Electronic Manometric Switch First disconnect the plug

calcified.

A at the mains ! Then lower

the pressure, e. g. by opening

a consumer.

Decalcify the Electronic Manometric Switch. Unplug it, disconnect the pressure hose / pressure

12. Trouble-Shooting

18

G

..

Don’t use the power cable

for carrying the pump or for

plugging off. Protect the

power cable from heat, oil

and sharp edges.

..

Please unplug the pump

after operation and before

carrying out any maintenance works.

..

In order to avoid dry-running

of the pump, take care that

the end of the suction hose

is always submerged into

the liquid.

..

The temperature of the liquid

to be pumped must not exceed

35 °C.

..

Sand and other abrasive substances in the liquid cause

increased wear and reduce

the pump’s output.

..

The pump is not designed for

continuous operation (e.g.

industrial application, continuous circulating operation).

..

The minimum flow rate is

90 I/h (= 1.5 I/min).Watering

accessories with lower rate

must not be operated.

..

When using the pump for pressure intensification, the max.

permissible internal pressure

of 6 bar (on the delivery side)

must not be exceeded.

The to be increased delivery

pressure and the pump pressure sum up.

Example: pressure at the

water tap 1.5 bar, max.

pressure of the GARDENA

Pressure Tank Unit 4000 /4

electronic plus 4.2 bar,

total pressure 5.7 bar.

9. Operation Hints

The pump switches on and

off because of a leak. If the

pump switches on and off

more than 7 times within 2

minutes, the

control unit issues a warning

via flashing LEDs and the

motor switches itself off.

Not

e: The pump can only be

restarted by “re-plugging”.

Finding Faults

Important ! Unplug the pump.

Check the pump for possible

faults such as:

➔ Faulty or leaking back-flow

preventer at the end of the

suction hose

➔ Pump and suction hose

are not filled up with the

liquid to be pumped

➔ Backflow valve switch set

to position 2 and was not set

to position 1 once the pump

began pumping

➔ Suction hose end is not sub-

merged into the liquid

➔ Outlet too low

➔ Suction hose or connections

are not water-tight

➔ Suction filter clogged

➔ Air cannot escape on delivery

side since release points are

closed etc.

➔ Delivery pipe or consumer are

not water-tight

➔ The pump switches on and

off because of a leak. If the

pump switches on and off more

than 7 times within 2 minutes,

the control unit issues a warning via flashing LEDs and the

motor switches itself off.

Clear the fault. Plug in the pump

in order to start again operation

of the pump.

Shouldn’t the pump start priming, although you have repeatedly pressed the RESET button,

please contact one of our

GARDENA Service Centres

(addresses you will find on the

rear side).

Page 7

21

G

20

G

The undersigned

GARDENA Kress + Kastner GmbH · Hans-Lorenser-Str. 40 · D-89079 Ulm

hereby certifies that, when leaving our factory, the units indicated below are in accordance with the

harmonised EU guidelines, EU standards of safety and product specific standards.

This certificate becomes void if the units are modified without our approval.

EU Certificate of Conformity

If you have any problems with

your Pressure Tank Unit, please

contact our Service or return

the defective unit together with a

short description of the problem –

in case of guarantee, with a copy

of the receipt – postage paid to

one of the GARDENA Service

Centres listed on the back of this

leaflet.

Note: The pump can also be

operated without the Electronic

Manometric Switch 5by plugging the mains plug for the pump

F

into the mains socket. If the

fault is caused by the Electronic

Manometric Switch, then it is

sufficient to forward this to the

appropriate servicing office.

We expressly point out that,

in accordance with the product

liability law, we are not liable

for any damage caused by our

units if it is due to improper

repair or if parts exchanged are

not original GARDENA parts

or parts approved by us, and if

the repairs were not carried out

by a GARDENA Service Centre

or an authorised electrician.

The same applies to spare

parts and accessories.

line and fill antiliming agent or a

mixture of water and vinegar into

the pump using the delivery outlet

6

. Afterwards rinse thoroughly.

Pump constantly cuts in Leak on the pressure side. Check the pressure line and

and out without drawing connected consumers for leaks.

water. The non-return valve shall be at

position 1 when localising faults.

Note: Even the smallest leak

(loss of a few mls) can cause the

pressure in the pump to drop.

The cause of this is often small

leaks at taps and toilet flushing

cisterns.

There being deposits of dirt in Loosen the Electronic Manoin Electronic Manometric Switch. metric Switch from the pump.

Turn the non-return valve

C

to

position 2.

Clean the non-return valve, e.g.

by flushing in the direction of flow.

Pump does not cut out. Rotary switch / non-return Set the rotary switch to posi-

valve is set to position 2. tion 1.

Non-return valve of the Electronic Clean the non-return valve, e.g.

Manometric Switch is blocked. by flushing in the direction of flow.

Larger leaks on the pressure side. Rectify leaks.

Pump doesn’t start Outlet end (e.g. water accessory) Open the outlet end.

working. is closed. There is sufficient water

pressure in the pressure line.

Description of the units:

Pressure Tank Unit

Types:

4000/4 electronic plus

4000/5 electronic plus

Art. nos.:

1482 / 1484

EU directives:

Machinery Directive 98/37/ EC

Electromagnetic Compatibility

89/336/EC

Low Voltage Directive 73/ 23/ EC

Directive 93/68 /EC

Directive 2000/14/EC

Harmonised

European standards:

EN 292-1

EN 292-2

EN 60335-1

EN 60335-2-41

Noise level:

measured / guaranteed

1482 77 / 78 dB(A)

1484 79 / 80 dB(A)

Year of CE marking:

1996

Ulm, 21.02.2002

Thomas Heinl

Technical Dept. Manager

Page 8

74

D

Garantie

GARDENA gewährt für dieses

Produkt die gesetzliche Garantie

(ab Kaufdatum). Diese Garantieleistung bezieht sich auf alle

wesentlichen Mängel des Gerätes, die nachweislich auf Materialoder Fabrikationsfehler zurückzuführen sind. Sie erfolgt durch

die Ersatzlieferung eines einwandfreien Gerätes oder durch

die kostenlose Reparatur des eingesandten Gerätes nach unserer

Wahl, wenn folgende Voraussetzungen gewährleistet sind:

.Das Gerät wurde sachgemäß

und laut den Empfehlungen

in der Gebrauchsanweisung

behandelt.

.Es wurde weder vom Käufer

noch von einem Dritten versucht, das Gerät zu reparieren.

Die Verschleißteile Turbine und

Filter sind von der Garantie ausgeschlossen.

Diese Hersteller-Garantie berührt

die gegenüber dem Händler/

Verkäufer bestehenden Gewährleistungsansprüche nicht.

G

Guarantee

GARDENA honours the guarantee legally required for this product (starting from the date of

purchase). This guarantee covers

all serious defects of the unit

that can be proved to be material

or manufacturing faults. Under

guarantee we will either replace

the unit or repair it free of charge

if following conditions apply:

.The unit must have been

handled properly and in keeping with the requirements of

the operating instructions.

.Neither the purchaser or a

non-authorised third party

have attempted to repair

the unit.

The turbine and the filter are

wearing parts and are not covered by the guarantee.

This manufacturer’s guarantee

does not affect the user’s

existing warranty claims against

the dealer/seller.

F

Garantie

GARDENA accorde pour cet

appareil la garantie légale à

compter du jour de l’achat. Elle

comprend le remplacement gratuit des pièces défectueuses

ou de l’appareil, le choix en étant

laissé à la libre initiative de

GARDENA. En tout état de cause

s’applique la garantie légale couvrant toutes les conséquences

des défauts ou vices cachés

(article 1641 et suivants du Code

Civil).

Pour que ces garanties soient

valables, les conditions suivantes

doivent être remplies :

.L’appareil a été manipulé de

manière adéquate, suivant les

instructions du mode d’emploi.

.Il n’y a eu aucun essai de

réparation, ni par le client, ni

par un tiers.

La turbine et le filtre sont des

pièces d’usure et sont par conséquent exclus de la garantie.

Une intervention sous garantie

ne prolonge pas la durée initiale

de la garantie contractuelle.

Toutes les revendications dépassant le contenu de ce texte

ne sont pas couvertes par la

garantie, quel que soit le motif

de droit.

Pendant la période de garantie,

le Service Après-Vente effectuera, à titre payant, les réparations nécessaires par suite

de manipulations erronées.

N

Garantie

GARDENA geeft op dit product

de wettelijke garantie (vanaf de

aankoopdatum). Deze garantie

heeft betrekking op alle wezenlijke defecten aan het toestel,

die aanwijsbaar op materiaal- of

fabricagefouten berusten.

Garantie vindt plaats door de levering van een vervangend apparaat of door de gratis reparatie

van het ingestuurde apparaat,

naar onze keuze, indien aan de

volgende voorwaarden is voldaan:

.Het apparaat werd vakkundig

en volgens de adviezen in

de gebruiksaanwijzing behandeld.

.Noch de koper, noch een

derde persoon heeft getracht

het apparaat te repareren.

De aan slijtage onderhevige turbine en het filter vallen niet onder

de garantie.

Deze garantie van de producent

heeft geen betrekking op de ten

aanzien van de handelaar/ verkoper bestaande aansprakelijkheid.

S

Garanti

GARDENA lämnar garanti enligt

gällande lag för denna produkt

(gällande från inköpsdatum).

Denna garanti täcker alla allvarliga defekter på maskinen som

kan bevisas vara materiella

fel eller tillverkningsfel. Under

garantitiden repareras eller utbytes enheten utan kostnad

under följande förutsättningar:

.Enheten måste ha skötts och

använts i enlighet med bruksanvisningen.

.Varken köparen eller en icke

auktoriserad tredje part får

ha försökt reparera enheten.

Page 9

Deutschland

GARDENA Kress + Kastner GmbH

GARDENA Service

Hans-Lorenser-Straße 40

D-89079 Ulm

Produktfragen: (07 31) 490-123

Reparaturen: (07 31) 490-290

Argentina

Argensem S.A.

Venezuela 1075

(1618) El Talar - Buenos Aires

Australia

NYLEX Corporation Ltd.

25-29 Nepean Highway

P.O. Box 68

Mentone, Victoria 3194

Austria

GARDENA Österreich Ges. m.b.H.

Stettnerweg 11-15

2100 Korneuburg

Belgium

MARKT (Belgium) NV/SA

Sterrebeekstraat 163

1930 Zaventem

Brazil

M. Cassab

Av. das Nações Unidas, 20.882

Santo Amaro, CEP 04795-000

São Paulo - S.P.

Bulgaria / България

ДЕНЕКС ООД

Бул. ”Г.М.Димитров” 16 ет.4

София 1797

Canada

GARDENA Canada Ltd.

100, Summerlea Road

Brampton, Ontario

Canada L6T 4X3

Chile

Antonio Martinic Y CIA. LTDA.

Gilberto Fuenzalida 185 Loc.

Las Condes - Santiago de Chile

Costa Rica

Compania Exim

Euroiberoamericana S.A.

350 Sur del Automercado

Los Yoses

San Pedro

Cyprus

FARMOKIPIKI LTD

P.O. Box 7098

74, Digeni Akrita Ave.

1641 Nicosia

Czech Republic

GARDENA spol. s.r.o.

Řípská 20

62700 Brno

Denmark

GARDENA Danmark A/S

Naverland 8

2600 Glostrup

Finland

Habitec Oy

Martinkyläntie 52

01720 Vantaa

France

GARDENA France

Service Après-Vente

BP 50080

95948 ROISSY CDG Cedex

Great Britain

GARDENA UK Ltd.

27- 28 Brenkley Way

Blezard Business Park

Seaton Burn

Newcastle upon Tyne

NE13 6DS

Greece

Agrokip G. Psomadopoulos & Co.

20, Lykourgou str.

Kallithea - Athens

Hungary

GARDENA Magyarország Kft.

Késmárk utca 22

1158 Budapest

Iceland

Heimilistaeki hf

Saetun 8

P.O. Box 5340

125 Reykjavik

Republic of Ireland

Michael McLoughlin & Sons

Hardware Limited

Long Mile Road

Dublin 12

Italy

GARDENA Italia S.r.l.

Via Donizetti 22

20020 Lainate (Mi)

Japan

KAKUDAI Mfg. Co. Ltd.

1-4- 4, Itachibori Nishi-ku

Osaka 550

Luxembourg

Magasins Jules Neuberg

Grand Rue 30

Case Postale No. 12

Luxembourg 2010

Netherlands

GARDENA Nederland B.V.

Postbus 50176

1305 AD ALMERE

Neth. Antilles

Jonka Enterprises N.V.

Sta. Rosa Weg 196

P.O. Box 8200

Curaçao

New Zealand

NYLEX New Zealand Limited

Private Bag 94001

South Auckland Mail Centre

10 Offenhauser Drive

East Tamaki, Manukau

Norway

GARDENA Norge A/S

Postboks 214

2013 Skjetten

Poland

GARDENA Polska Sp.z o.o.

Szymanów 9 d

05-532 Baniocha

Portugal

MARKT (Portugal), Lda.

Recta da Granja do Marquês

Edif. GARDENA

Algueirão

2725-596 Mem Martins

Russia / Россия

АО АМИДА ТТЦ

ул. Моcфилмовcкая 66

117330 Моcква

Singapore

Variware

Holland Road Shopping Centre

227-A 1st Fl., Unit 29

Holland Avenue

Singapore 1027

Slowenia / Croatia

Silk d.o.o. Trgovina

Brodišče 15

1236 Trzin

South Africa

GARDENA South Africa (Pty.) Ltd.

P.O. Box 11534

Vorna Valley 1686

Spain

ANMI Andreu y Miriam S.A.

Calle Pere IV, 111

08018 Barcelona

Sweden

GARDENA Svenska AB

Box 9003

20039 Malmö

Switzerland

GARDENA Kress + Kastner AG

Bitziberg 1

8184 Bachenbülach

Ukraine / Украина

АОЗТ АЛЬЦЕСТ

ул. Гайдара 50

г. Киев 01033

Turkey

Dost Diþ Ticaret Mümessillik A.Þ.

Yeþilbaðlar Mah. Baþkent

Cad. No. 26

Pendik - Ýstanbul

USA

GARDENA

3085 Shawnee Drive

Winchester, VA 22604

1482- 20.960. 08/ 0021

GARDENA Kress + Kastner GmbH

Postfach 2747, D- 89070 Ulm

http: //www.gardena.com

Loading...

Loading...