Page 1

Instructions for Use

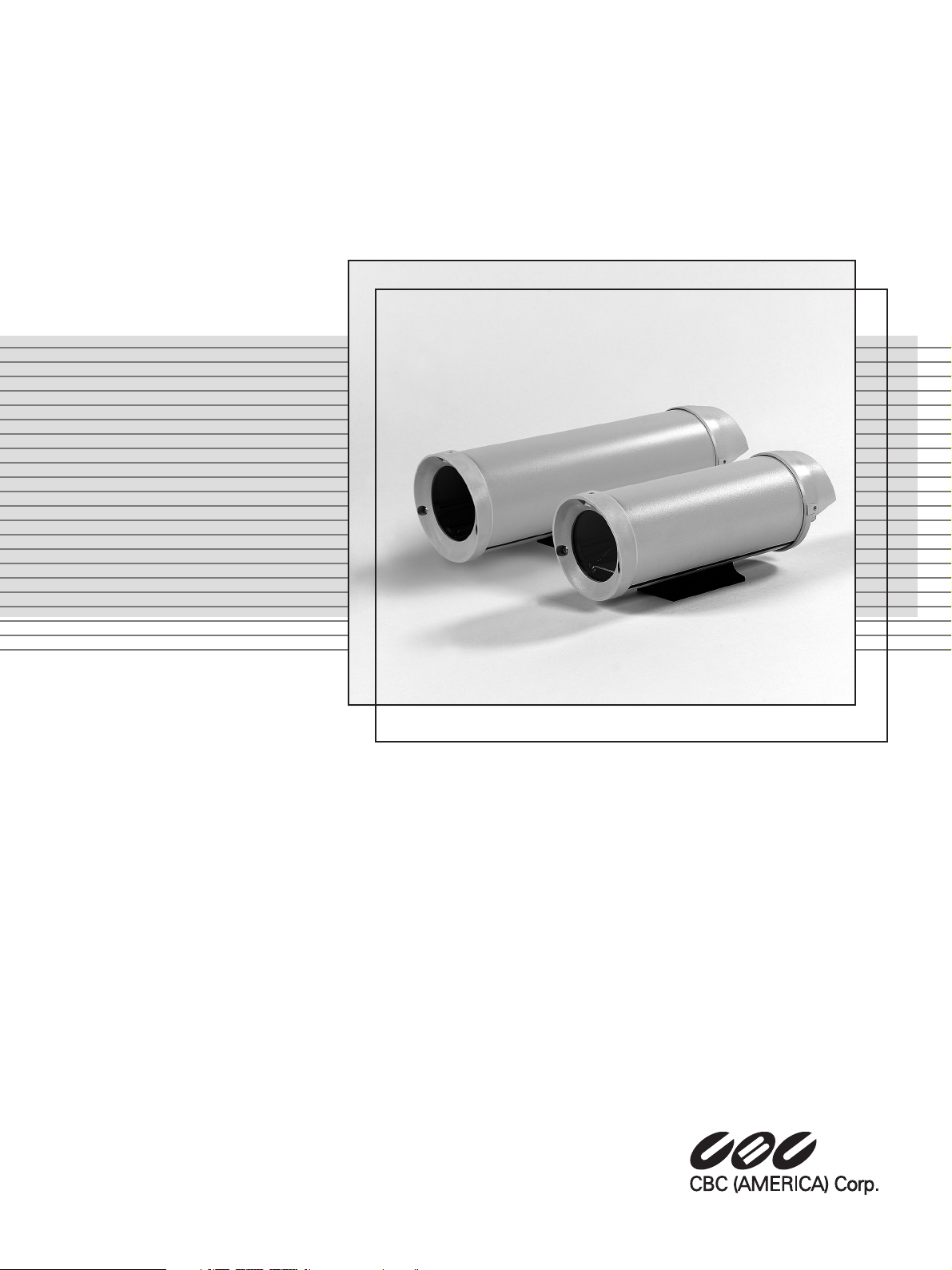

H Series Housings

Page 2

2

IMPORTANT SAFEGUARDS

1. Read Instructions - All the safety and operating instructions should be read

before the unit is operated.

2. Retain Instructions - The safety and operating instructions should be

retained for future reference.

3. Heed Warnings - All warnings on the unit and in the operating instructions

should be adhered to.

4. Follow Instructions - All operating and use instructions should be followed.

5. Cleaning - Unplug the unit from the outlet before cleaning. Do not use

liquid cleaners or aerosol cleaners. Use a damp cloth for cleaning.

6. Attachments - Do not use attachments not recommended by the product

manufacturer as they may cause hazards.

7. Accessories - Do not place this unit on an unstable stand, tripod, bracket,

or mount. The unit may fall, causing serious injury to a person and serious

damage to the unit. Use only with a stand, tripod, bracket, or mount

recommended by the manufacturer or sold with the product. Any

mounting of the unit should follow the manufacturer's instructions and

should use a mounting accessory recommended by the manufacturer.

An appliance and cart combination should be moved with care. Quick

stops, excessive force, and uneven surfaces may cause the appliance and cart

combination to overturn.

8. Ventilation - Openings in the enclosure, if any, are provided for ventilation,

to ensure reliable operation of the unit, and to protect it from overheating.

These openings must not be blocked or covered. This unit should not be

placed in a built-in installation unless proper ventilation is provided or the

manufacturer's instructions have been adhered to.

9. Power Sources - This unit should be operated only from the type of power

source indicated on the marking label. If you are not sure of the type of

power supply you plan to use, consult your appliance dealer or local power

company. For units intended to operate from battery power or other

sources, refer to the operating instructions.

10. Grounding or Polarization - This unit may be equipped with a polarized

alternating-current line plug (a plug having one blade wider than the other).

This plug will fit into the power outlet only one way. This is a safety

feature. If you are unable to insert the plug fully into the outlet, try

reversing the plug. If the plug should still fail to fit, contact your electrician

to replace your obsolete outlet. Do not defeat the safety purpose of the

polarized plug.

Alternately, this unit may be equipped with a 3-wire grounding-type plug, a

plug having a third (grounding) pin. This plug will only fit into a

grounding-type power outlet. This is a safety feature. If you are unable to

insert the plug into the outlet, contact your electrician to replace your

obsolete outlet. Do not defeat the safety purpose of the grounding-type

plug.

11. Power Cord Protection - Power supply cords should be routed so that they

are not likely to be walked on or pinched by items placed upon or against

them, paying particular attention to cords and plugs, convenience

receptacles, and the point where they exit from the appliance.

12. Power Lines - An outdoor system should not be located in the vicinity of

overhead power lines or other electric light or power circuits or where it can

fall into such power lines or circuits. When installing an outdoor system,

extreme care should be taken to keep from touching such power lines or

circuits as contact with them might be fatal. U.S.A. models only - refer to the

National Electrical Code Article 820 regarding installation of CATV systems.

13. Overloading - Do not overload outlets and extension cords as this can result

in a risk of fire or electric shock.

14. Object and Liquid Entry - Never push objects of any kind into this unit

through openings, as they may touch dangerous voltage points or short out

parts that could result in a fire or electric shock. Never spill liquid of any

kind on the unit.

15. Servicing - Do not attempt to service this unit yourself as opening or

removing covers may expose you to dangerous voltage or other hazards.

Refer all servicing to qualified service personnel.

16. Damage Requiring Service - Unplug the unit from the outlet and refer

servicing to qualified service personnel under the following conditions:

a. When the power supply cord or plug is damaged.

b. If liquid has been spilled or objects have fallen into the unit.

c. If the unit has been exposed to rain or water.

d. If the unit does not operate normally by following the operating

instructions. Adjust only those controls that are covered by the

operating instructions, as an improper adjustment of other controls

may result in damage and will often require extensive work by a

qualified technician to restore the unit to its normal operation.

e. If the unit has been dropped or the cabinet has been damaged.

f. When the unit exhibits a distinct change in performance--this indicates

a need for service.

17. Replacement Parts - When replacement parts are required, be sure the

service technician has used replacement parts specified by the manufacturer

or have the same characteristics as the original part. Unauthorized

substitutions may result in fire, electric shock, or other hazards.

18. Safety Check - Upon completion of any service or repairs to this unit, ask

the service technician to perform safety checks to determine that the unit is

in proper operating condition.

19. Coax Grounding - If an outside cable system is connected to the unit, be

sure the cable system is grounded. U.S.A. models only--Section 810 of the

National Electrical Code, ANSI/NFPA No.70-1981, provides information

with respect to proper grounding of the mount and supporting structure,

grounding of the coax to a discharge unit, size of grounding conductors,

location of discharge unit, connection to grounding electrodes, and

requirements for the grounding electrode.

20. Lightning - For added protection of this unit during a lightning storm, or

when it is left unattended and unused for long periods of time, unplug it

from the wall outlet and disconnect the cable system. This will prevent

damage to the unit due to lightning and power line surges.

Page 3

3

SAFETY PRECAUTIONS

This label may appear on the bottom of the unit due to space

limitations.

The lightning flash with an arrowhead symbol

within an equilateral triangle is intended to alert

the user to the presence of uninsulated

"dangerous voltage" within the product's

enclosure that may be of sufficient magnitude to

constitute a risk of electric shock to persons.

The exclamation point within an equilateral

triangle is intended to alert the user to presence

of important operating and maintenance

(servicing) instructions in the literature

accompanying the appliance.

SECURITE

En raison de limitation de place, cette étiquette peut être placée

sur le dessous de l'appareil.

L'éclair fléché dans un triangle équilatéral, avertit

l'utilisateur de la présence d'une "tension

dangereuse" non isolée à l'intérieur de l'appareil et

d'une valeur suffisante pour constituer un risque

d'électrocution.

Le point d'exclamation contenu dans un triangle

équilatéral, avertit l'utilisateur de la présence, dans

la documentation qui accompagne l'appareil, de

consignes d'utilisation et de maintenance

importantes.

SICHERHEITSVORKEHRUNGEN

Aus Platzgründen kann diese Warnung auf der Unterseite des

Gerätes angebracht sein.

Das Blitzsymbol im gleichseitigen Dreieck soll

den Benutzer auf nicht isolierte "Hochspannung"

im Gehäuse aufmerksam machen, die eventuell

stark genug ist, um einen elektrischen Schlag zu

verursachen.

Das Ausrufezeichen im gleichseitigen Dreieck soll

den Benutzer auf wichtige Bedienungs- und

Wartungsanleitungen in der dem Gerät

beigefügten Literatur aufmerksam machen.

PRECAUCIONES DE SEGURIDAD

Debido a limitaciones de espacio, esta etiqueta puede aparecer

en la parte inferior de la unidad.

El símbolo representado por un relámpago con

punta de flecha dentro de un triángulo equilátero,

se muestra con el objetivo de alertar al usuario que

existen "voltages peligrosos" sin aislamiento,

dentro de la cubierta de la unidad. Dichos

voltages pueden ser de tal magnitud que

constituyen un riesgo de choque eléctrico a

personas.

El símbolo de exclamación dentro de un triángulo

equilátero, se muestra con el objetivo de alertar al

ususario de que instrucciones de operación y

mantenimiento importantes acompañan al equipo.

CAUTION: TO REDUCE THE RISK OF

ELECTRICAL SHOCK, DO NOT OPEN COVERS.

NO USER SERVICEABLE PARTS INSIDE. REFER

SERVICING TO QUALIFIED SERVICE

PERSONNEL.

DANGER: POUR ÉVITER TOUT RISQUE

D'ÉLECTROCUTION, NE PAS OUVRIR LE

BOÎTIER. IL N'Y A PAS DE PIÈCES

REMPLAÇABLES À L'INTÉRIEUR. POUR

TOUTE RÉVISION, S'ADRESSER À UN

TECHNICIEN SPÉCIALISÉ.

VORSICHT: UM EINEN ELEKTRISCHEN

SCHLAG ZU VERMEIDEN, ABDECKUNG

NICHT ENTFERNEN. WARTUNGEN ALLER

ART QUALIFIZIERTEM PERSONAL

ÜBERLASSEN.

PRECAUCION: PARA REDUCIR EL RIESGO DE

CHOQUE ELÉCTRICO, FAVOR NO ABRIR LA

CUBIERTA. ESTE EQUIPO NO CONSTA DE

PIEZAS O PARTES QUE REQUIEREN SERVICIO

O MANTENIMIENTO. PARA REPARACIONES

FAVOR REFERIRSE A UN TÉCNICO

CALIFICADO.

Page 4

4

CONTENTS

1 UNPACKING . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

2 ACCESSORIES . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

2.1 Sunshields . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

2.2 Tamper Proof Kit . . . . . . . . . . . . . . . . . . . . . . . . . . .4

3 SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

4 CARE AND MAINTENANCE . . . . . . . . . . . . . . .4

5 DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . .4

6 INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . .4

6.1 Model Designation . . . . . . . . . . . . . . . . . . . . . . . . . .4

6.2 Maximum Camera/Lens Size . . . . . . . . . . . . . . . . . .4

6.3 Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

6.4 Cable Requirements . . . . . . . . . . . . . . . . . . . . . . . . .5

6.5 Housing Mounting . . . . . . . . . . . . . . . . . . . . . . . . . .5

6.6 Cover Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

6.7 Camera/Lens Installation . . . . . . . . . . . . . . . . . . . . .5

6.8 Camera/Lens Wiring . . . . . . . . . . . . . . . . . . . . . . . .6

6.9 Video Coax Connection . . . . . . . . . . . . . . . . . . . . . .7

6.10 Lens Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

6.11 Camera/Lens Adjustment . . . . . . . . . . . . . . . . . . . . .7

6.12 Final Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

6.13 Fuse Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . .8

7 EXPLODED VIEW . . . . . . . . . . . . . . . . . . . . . . . . .8

7.1 Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

1 UNPACKING

Unpack carefully. This is mechanical equipment and should be

handled with care.

Check for the following:

n Housing (with correct model number).

n Hardware Kit - H-1 & H-2 Models:

1 1/4-20 x 3/8-in Button Head Screw.

2 1/4-20 x 1/2-in Button Head Screw.

2 1/4-in Spring Washers.

1 5/16-in Flat Washer.

2 Fittings, 3/8-in NPT.

2 Rubber Plug, 1/2-in NPT.

1 Nut, 3/8-in NPT.

2 Fittings, 1/2-in NPT.

2 Nut, 1/2-in NPT.

1 Spacer Block.

If an item appears to have been damaged in shipment, replace it

properly in its carton and notify the shipper. If any items are

missing, contact the company from which the unit was purchased.

The shipping carton is the safest container in which the unit

may be transported. Save it for possible future use.

2ACCESSORIES (Optional)

2.1 Sunshields

Provides protection from the direct rays of sun and promotes

cooling to reduce internal housing temperatures. Strongly

recommended for housing to be used outdoors.

SS1: For H-1 & H-2 Series Housings.

2.2 Tamperproof Kit

Contains tamper resistant screws and bit key to tamperproof up

to five housings.

TPK 1: For all H Series Housings.

3 SERVICE

If the unit ever needs repair service or parts, the customer

should contact the company from which the unit was purchased

for authorization to return and shipping instructions.

4 CARE AND MAINTENANCE

Regularly scheduled maintenance will help prolong the

operation life of this unit. Clean the viewing window as needed

with a mild, nonabrasive detergent in water and a soft cloth.

5 DESCRIPTION

The H Series Housings are smart stylized housings for indoor

and outdoor use. These housings meet customers' demands for

an attractive housing that is both cost competitive and easy to

install.

6 INSTALLATION

This installation should be made by qualified service personnel

and conform to the National Electrical Code and applicable

local codes.

6.1 Model Designation

Model Description Voltage Use with Camera

No. Models with These

Voltage Ranges

H-1 Housing ----- 24 VAC or 12 VDC

H-2 Housing with heater

1

24/23 24 VAC

H-3 Housing w/heater/blower 24/25 24 VAC

1. The heater operates at 24 VAC, 50/60 Hz and requires 15 W of power.

Do Not Exceed 30 VAC Input on 24 VAC models. Operation

above 30 VAC violates low voltage operation (Class 2

Specifications). Normal operation is 24 VAC.

TUV Approved 24 VAC Models

Caution: Use an approved power supply incorporating

reinforced insulation from primary to secondary to isolate unit

from Mains.

6.2 Maximum Camera/Lens Size

H-1: 68 W x 54 H x 197 L mm (2.68 x 2.1 x 7.75 in)

H-2: 68 W x 54 H x 197 L mm (2.68 x 2.1 x 7.75 in)

H-3: 71 W x 71 H x 229 L mm (2.8 x 2.8 x 9)

6.3 Tools Required

- Small flat blade screwdriver.

- Phillips screwdriver (P2).

- Adjustable wrench.

- Wire cutter/stripper/crimper tool.

- 5/32-in (or 4 mm) hex wrench.

Page 5

5

6.4 Cable Requirements

Video Transmission (Coaxial)

Cable Type: RG-59/U for runs < 300 m (1000 ft).

RG-11/U for runs < 600 m (2000 ft).

Cable Size: Outside diameter between

4.6 mm (0.181-in) - 7.9 mm (0.312-in).

Cable Shape: Round.

Shield: > 93% Braided Copper Shield.

Center Conductor: Stranded Copper Center.

DC Resistance: < 15 Ohms/1000 (RG-59/U).

< 6 Ohms/1000 (RG-11/U).

Cable Impedence: 75 Ohm.

Agency Rating: UL.

Environmental: Outdoor rated.

Temperature Rating: > 80 °C.

Sources: Belden 9259.

Belden 9238.

Input Power Cord - North American

Cable Type: SJTOW-A rated.

Cable Size: Outside diameter between

4.3 mm (0.170 in) - 11.9 mm (0.470 in).

Cable Shape: Round.

Conductors: 3 conductor version and

2 conductor version.

Agency Rating: UL/C.S.A., UL VW-1.

Environmental: Outdoor rated.

Temperature Rating: 105 °C.

Voltage Rating: 300 V.

Sources: Belden 19506.

Belden 19509.

Northwire 573939.

Input Power Cord - European

Cable Type: H05RN-F3G0.75 and

H05RN-F3G1.00.

Cable Size: Outside diameter between

4.3 mm (0.170 in) - 11.9 mm (0.470 in).

Cable Shape: Round.

Conductors: 3 conductor version and

2 conductor version.

Agency Rating: VDE.

Environmental: Outdoor rated.

Sources: Olflex 1600252.

Olflex 1600253.

Lens Control Cable

Cable Type: Jacketed Multiconductor Cable.

Cable Size: Outside diameter between

4.3 mm (0.170 in) - 11.9 mm (0.470 in).

Cable Shape: Round.

Shield: Overall shielding.

Conductors: Stranded 20 to 16 AWG wire.

No. of Conductors: 4 and 8.

Conductor

Insulation: Color coded.

Sources: Belden 9552.

Belden 9554.

6.5 Housing Mounting

1. Use the two 1/4-20 x 0.50-inch screws and 1/4-in spring

washers provided in the hardware kit to mount the housing

to a mount or a pan/tilt. The spring washers must be used

for the screws to thread properly.

2. The outer most set of 1/4-20 threaded holes are for

mounting to feed-through mounts and the inner most 1/420 holes are for mounting to all other mounts and pan/tilts.

6.6 Cover Removal

1. Loosen the top two screws on the rear of the housing. These

screws are captive and will not come out all the way. Do not

remove the bottom two screws. See Figure 1.

Figure 1: Loosening Captive Screws

2. Grasp the housing's front cap and pull forward. Do not

squeeze the cover itself. This will make it difficult to slide off

the cover. See Figure 2.

Figure 2: Removing the Cover

3. The cover is attached to the base. Allow the cover to dangle

from the base.

6.7 Camera/Lens Installation

1. Loosen the two screws holding the camera bracket to the

base. It is not necessary to remove them completely. See

Figure 3.

Loosen These Screws

Do Not Remove

Grasp Here

Page 6

6

Figure 3: Removing the Camera Bracket

2. Remove the camera bracket from the base. If you are using

the feed-through feature, refer to section 6.8.3 at this time.

Mounting fixed lens cameras in H Series Housings

3a. Attach the lens to the camera.

3b. Use the 1/4-20 x 3/8-inch screw to mount the camera to the

camera bracket. The lens should extend approximately 6

mm (0.25-in) from the front of the camera bracket. See

Figure 4.

Figure 4: Attaching the Camera

6.8 Camera/Lens Wiring

WARNING: Only use the cables specified under

"INSTALLATION, Cable Requirements" for wiring

of all cameras and lenses.

6.8.1 Fittings

1. The two large 1/2-in NPT fittings accept round cable with

diameters from 4.3 mm (0.17-in) to 11.9 mm (0.47-in). The

small fittings will accept cables with diameters from 4.6 mm

(0.181-in) to 7.9 mm (0.312-in).

Be sure to securely tighten all fittings to ensure a

liquid-tight seal. Failure to do so could allow water to

enter the housing and damage the camera and lens.

If a sealant is to be used, be sure it is a neutral cure type.

Sealants that release acetic acid may harm camera electronics.

Use of "drip loops" is recommended on the wiring

outside of the rear end cap.

6.8.2 Conduit

These housings are designed to allow conduit to be directly

connected.

1. Remove the rear fittings and attach the conduit and conduit

fittings directly to the housing rearcap. The holes accept

1/2-in conduit fittings and PG 13.5 conduit fittings. Any

unused holes can be covered using the plugs provided in the

hardware kit.

6.8.3 Feed-through Wiring

These housings have the capability of having the cabling feed

through the foot of the housing. This requires the use of feedthrough mounts like the WB-1, WB-2, & JB-1.

1. Prior to mounting the camera. Remove the two dome plugs

located inside the housing. See Figure 5.

Figure 5: Feed-through Wiring

2. Screw the two 3/8-in NPT fittings into the foot of the

housing.

3. Pull the cabling through the fittings and into the housing.

Tighten the fitting to 4.0 N-m to 4.5 N-m (35 in-lb to

40 in-lb). This torque rating is approximately 1 to 1 1/2

turns past the point the fitting starts to grip the wire. Failure

to do so will result in water damage to all electronic parts.

4. Attach top bracket of the mount to the foot of the housing.

5. Cover the holes in the rear cap with the rubber plugs

provided. Push in until flush and then release.

Camera

Bracket

Loosen These

Screws

1/4-20 ¥ 3/8 Screw

6.4 mm

0.25 in

Camera Bracket

Camera

Remove These

Dome Plugs

3/8-inch

NPT Fitting

Foot

1/2-inch

Rubber Plugs

Rear Cap

Page 7

7

6.8.4 Power Connections

Power connection into the housings is to be supplied through a

minimum type UL Standard "SJ" cord acceptable for outdoor

use. Installation must conform to acceptable NEC and local

codes. For 24 volt cameras, use the chart below for selecting the

proper wire size.

Recommended Maximum Cable Lengths for Housings

Equipped with 24 Volt Cameras, Heaters, and Blowers

Wire Size Housing Distance

mm2AWG meters feet

0,5 20 28.6 94

118 45.7 150

1,5 16 70.1 230

2,5 14 115.5 379

412 183.8 603

610 292.6 960

10 8 464.2 1523

Note: The use of wire sizes larger than 1,5 mm2(14 AWG) will require a

splice in order to accomodate the terminal block.

1. Install one of the large 1/2-in NPT fittings into one of the

holes in the rear cap. The terminal block side is preferable. If

you are using the feed-through option, ignore this step.

2. Route the power cable through the fitting in the rear cap or

one of the feed-through fittings in the foot.

3. The terminal block provided on H-1 & H-2 units accepts

wire ranging from 20 to 14AWG or 1.5 mm2. The terminal

block provided on /H-3 units accepts wire ranging from 18

to 12AWG or 2.5 mm2. When using larger wire sizes, splice

to a smaller size wire at the terminal block end. The splice

may need to be enclosed in a junction box if it does not pass

through the fittings.

4. On heater and heater/blower units, make sure the heater and

fan wires stay connected to the terminal.

5. A screw/terminal lug is provided for securing a safety

ground. To attach the safety grounding wire (green 115 volt,

green/yellow 230 volt), first unscrew the terminal lug and

strip and crimp the grounding wire into the lug. Attach the

terminal lug to the bracket using the M4 x 10 screw

provided (H-1 & H-2 models use an M4 Nut to screw the

lug to the base). See Figure 6.

Be sure to securley tighten all fitting s to ensure a liquid-tight

seal. Failure to do so could allow water to enter the housing

and damage the camera and lens.

6.9 Video Coax Connection

WARNING: Only use the cables specified under

"INSTALLATION, Cable Requirements" for wiring of

the video coax connection.

1. Install a 1/2-in NPT fitting into the remaining hole in the

rear cap.

2. Route the video coax cable through one of the fittings

installed in step 1 or one of the feed-through fittings in the

base.

3. Attach BNC connector to the coax and connect it to the

camera. Pull excess wire out of the housing and tighten the

fitting to 8.5 N-m to 9.0 N-m (75 in-lb to 80 in-lb). This

torgue rating is approximately1 to 1 1/2 turns past the point

the fittings starts to grip the wire. Failure to do so will

result in water damage to the electronic parts.

Be sure to securley tighten all fitting s to ensure a liquid-tight

seal. Failure to do so could allow water to enter the housing

and damage the camera and lens.

Use of “drip loops” is recommended on the wiring outside of

the rear end cap.

6.10 Lens Wiring

WARNING: Only use the cables specified under

"INSTALLATION, Cable Requirements" for wiring of

the lens.

Use of "drip loops" is recommended on the wiring outside of

the rear end cap.

1. Install the last 1/2-inch NPT fitting into the remaining hole

in the rear cap. Zoom lenses can only be installed into

H-3 housings.

Ground

Neutral

Line

Terminal Lug

Screw

Fuseholder

Figure 7: Power Connections - Fan Units

Neutral

Neutral

Terminal Lug

Terminal Lug

M4 Nut

M4 Nut

Line

Line

Figure 6: Power Connections - Nonfan units

Page 8

2. If installing a zoom lens, insert the lens control cable

through the last fitting at the rear of the housing. Attach the

lens wiring to the lens mating connector and connect it to

the lens. If mating connector is not available, connect

directly to the lens cable. Pull any excess wire out of the

housing and tighten the fitting to 8.5 N.m to 9.0 N.m

(75 in.lb to 80 in.lb). This torque rating is approximately 1

to 1-1/2 turns past the point where the fitting starts to grip

the wire. Failure to do so will result in water damage to all

electronic parts.

NOTE: See specification on lens cord for correct plug

connection.

Be sure to securely tighten all fittings to ensure a

liquid-tight seal. Failure to do so could allow water to

enter the housing and damage the camera and lens.

Use of "drip loops" is recommended on the wiring

outside of the rear end cap.

6.11 Camera/Lens Adjustment

1. Verify camera and lens operation before final assembly of

the cradle into the housing. Adjust the camera focus and

iris as necessary. See individual camera instructions.

6.12 Final Assembly

1. Use the plugs or fittings provided to plug any remaining

holes in the rear cap.

2. Reinstall the cover. Align the bottom of the cover ribs with the top of

the base. Slide the cover onto the base. Make sure the seal is not

folded over or torn. Use silicone grease to lubricate the seals if

necessary. See Figure 8.

3. As the cover nears the rear cap, make sure the captive screws

in the back are not blocking the cover from engaging into the

rear cap.

4. Screw the two rear captive screws into the housing.

6.13 Fuse Replacement

1. To replace a fuse, take a flat blade screw driver and twist

the top of the fuseholder counter clockwise about a ⁄ of a turn.

The fuse is spring loaded so it will eject.

2. Replace the fuse with a fuse that has the same current rating.

The fuse is a 5x20 mm slow blow cartridge type fuse.

Recommend using Littelfuse series 218.

See Detail

Detail Scale 2 : 1

Scale 3 : 1

Cover Rib

To p of Base

Seal

Figure 8: Reinstalling the Cover

6

5

4

3

2

1

7

7 EXPLODED VIEW

7.1 Parts List

Ref Drawing

No. Number Part Description

1 LTC 9480/20HTR 24VAC Heater Kit

2 315 3142 001 Camera Bracket Kit

3 315 3143 001 Foot Kit

6 315 3146 002 Rearcap Kit

7 315 3147 001 Base Kit

8 315 3148 004 Cover Kit

9 315 3149 001 Frontcap Kit

- 315 3062 001 Hardware Kit

©2002 CBC (America) Corp.

New York: 55 Mall Drive, Commack, NY 11725 Tel: 800 422 6707 or 631 864 9700 Fax: 631 543 5426

California: 20521 Earl Street, Torrance, CA 90503 Tel: 800 888 0131 or 310 793 1500 Fax: 310 793 1506

www.cbcamerica.com

Data subject to change without notice

100_0058_002 CBC

Printed in USA

8

Page 9

WB-1, JB-1, PMA-1

Feed-through Mounts

& Accessories

Instructions for Use

Page 10

SAFETY PRECAUTIONS

The exclamation point within an equilateral triangle is

intended to alert the user to presence of important operating and maintenance (servicing) instructions in the literature accompanying the appliance.

SECURITE

Le point d'exclamation à l'intérieur d'un triangle équilatéral avertit

l'utilisateur de la présence

d'instructions importantes d'utilisation et de

maintenance dans la documentation accompagnant

l'appareil.

SICHERHEITSVORKENHRUNGEN

Das Ausrufezeichen in dem gleichseitigen Dreieck ist dazu da, den

Benutzer auf wich-tige

Inbetriebnahme- und Instandhaltungs-vorschriften

hinzuweisen, die dem Gerät in Form einer Broschüre

beigelegt sind.

PRECAUCIONES DE SEGURIDAD

El símbolo de exclamación dentro de un triángulo equilátero, se muestra con el objetivo de alertar al ususario

de que instrucciones de operación y

mantenimiento importantes acompañan al equipo.

1UNPACKING

Unpack carefully. This is mechanical equipment and should be handled with care.

Check for the following items:

n Verify the unit model number.

n Instructions for Use.

If an item appears to have been damaged in shipment, replace it properly in its carton and notify the shipper. If any items are missing, contact the company from which the unit was purchased.

The shipping carton is the safest container in which the unit may be

transported. Save it for possible future use.

2SERVICE

If the unit ever needs repair service, the customer should

contact the company from which the unit was purchased for authorization to return and shipping instructions.

3DESCRIPTION

WB1 18-cm (7-in) and JB1 40-cm (15-in) Feed-through Mounts.

This indoor/outdoor mounting equipment is designed for fixed camera or camera housing installations up to 9 kg (20 lb) rated load.

These models are made of lightweight aluminum and feature welded

construction, providing an extremely rigid camera mount. These

brackets have been specifically designed for the H1 & H2 series

housings. All mounts come fully assembled.

4INSTALLATION

4.1 WB-1, JB-1

1. Determine a secure wall mounting location.

2

WARNING: All mounts are deisgned to support a load only

in a vertical direction. Mounts MUST be positioned as

shown under SPECIFICATIONS.

2.

Cautions:

a. For a secure installation, use four 8-mm (5/16-in) diameter

fasteners (not included). Use stainless steel or zinc plated

fasteners.

b. If bolts are used, they should extend through the mounting

surface and be secured with flat washers, lock washers, and

nuts on the opposite side. Each bolt must have a

minimum pull-out strength of 200 kg (450 lb).

c. If studs are used, they should be anchored in concrete or

welded to a steel backer plate. Each stud must have a minimum pull out strength of 200 kg (450 lb).

d. If the wall mount is attached to wood or to a blind

structure (with no access to the rear), each fastener

must have a minimum pull-out strength of at least 200 kg

(450 lb).

3. Locate the four holes or stud locations using the flange as a

template (four holes equally spaced on a 69.9-mm (2-3/4-in bolt

circle).

4. Feed wires through the large hole in the flange or through the

slot on the surface where the camera housing mounts.

5. Install the mount using bolts or studs at least 8-mm (5/16-in) in

diameter.

6. To mount the camera or camera housing:

a. Mount camera with a 1/4-20 bolt and lock washer (not

furnished) in the center hole of the adjustable head.

b. Mount housings with three 1/4-20 bolts and lock

washers (not furnished).

c. Lock mount head in position by using the supplied

1/8-inch long-arm hex wrench to tighten screws.

4.2 PMA-1 Pole mount Adapter

1. Tools required

8mm Hex Wrench

Banding Tool (PMA-1 recommended)

2. Mounting

1. Attach the bracket to the pole at the desired height using the

two straps and two buckles provided.

2. Tension the straps according to the instructions for the banding

tool. BAND-IT, Banding tool is recommended and may be purchased seperately. A BAND-IT Tool Instruction Chart is provided with each pole mount. Figure 1. shows how the ends of the

bands are bent around the buckle.

Figure 1: Banding Method

Tension and

Bend Back Bands

Bend Buckle

Tab Over Bands

Page 11

3

5SPECIFICATIONS

5.1 WB1 18-cm (7-in) Indoor/Outdoor

Feed-through Mount

Maximum Load: 9 kg (20 lb).

Mounting Head: Adjustable. 360° pan, 180° tilt.

Finish: Dark mushroom.

Approx. Weight: 0.3 kg (0.7 lb).

WARNING: All mounts must be mounted as shown.

WARNING: All mounts must be mounted as shown.

5.2 JB1 40-cm (15-in) Indoor/Outdoor

Feed-through J-mount

Maximum Load: 9 kg (20 lb).

Mounting Head: Adjustable. 360° pan, 180° tilt.

Finish: Dark mushroom.

Approx. Weight: 0.55 kg (1.2 lb).

WARNING: All mounts must be mounted as shown.

5.3 PMA-1 pole Mount Adapter

Maximum Load: 9kg (20lb)

Finish: Formed Aluminum Plate

Approximate Weight: 0.5kg (1lb)

3. Secure the wall mount to the pole mount using the four (4) 8mm

screws and lock washers provided.

WB-1 uses 8mm screws

Figure 2: Securing Model PMA-1

WB-1 Feed-through Mount

JB1 Feed-through J-mount

Pole Mount

0.31

12.7

0.50

7.9

23.9

0.94

88.9

3.50

73.2

2.88

25.4

1.00

37.3

1.47

74.7

2.94

6.9

0.27

Wall Mount

Buckle

Lock Washer

Screw

Band

8.9

0.35

391

15.4

179.8

7.08

88.9

3.50

157

6.2

234

9.2

mm

in

138.3

5.45

mm

in

Page 12

©2002 CBC (America) Corp.

New York: 55 Mall Drive, Commack, NY 11725 Tel: 800 422 6707 or 631 864 9700 Fax: 631 543 5426

California: 20521 Earl Street, Torrance, CA 90503 Tel: 800 888 0131 or 310 793 1500 Fax: 310 793 1506

www.cbcamerica.com

Data subject to change without notice

100_0059_002 CBC

Printed in U.S.A.

Loading...

Loading...