Gantner Electronic GEA1150001A Users manual

Installation, Configuration, Operation

Document Version 3.3

GAT NET.Lock 7000 System

Electronic RFID Locker Locks

www.gantner.com

HB_GAT-NETLOCK7000--US_33

1

GAT NET.Lock 7000 System

2

HB_GAT-NETLOCK7000--US_33

www.gantner.com

GAT NET.Lock 7000 System

!

Copyright 2014-2015, GANTNER Electronic GmbH, Schruns (Austria).

General warning and safety instructions

Dear customer,

We congratulate you on having selected a product (appliance or software) from GANTNER Electronic GmbH. Our aim is to ensure

that our product operates with safety and to your complete satisfaction. To achieve this aim we take this opportunity to familiarise

you with the following guidelines:

1. Installation, commissioning, operation and maintenance of the purchased product must be carried out in accordance with the

instructions, i.e., in accordance with the technical conditions of operation as described in the corresponding product documentation.

2. Before installation, commissioning, operation or maintenance it is therefore essential that you read the corresponding chapter

of this manual and observe its instructions.

3. If there are still some points on which you are not entirely clear, please do not take a chance. All queries can be clarified by

your Gantner company representative, or by ringing the GANTNER Electronic GmbH hotline.

4. Where not otherwise specifically documented, the appropriate installation, commissioning, operation and maintenance of the

product is the customer’s responsibility.

5. Directly on receipt of the goods, inspect both the packaging and the product itself for any signs of damage. Also check that

the delivery is complete and includes all accessories, documentation, auxiliary devices, etc.

6. If the packaging or product has been damaged in transport, or should you suspect that it may have a fault, the product must

not be put into service. In this case, contact your Gantner company representative. They will make every effort to resolve the

problem as quickly as possible.

7. Installation, commissioning and servicing of our appliances must only be carried out by suitably trained personnel. In particular, electrical connections must only be made by correspondingly qualified specialists. Here, the appropriate installation provisions in accordance with the relevant national Electrical Engineers construction regulations (e.g., ÖVE, [Austrian] VDE, [German]...) must be observed.

8. Where not otherwise stated, installation and maintenance work on our appliances must be carried out when disconnected

from the power supply. This applies in particular to appliances which are normally supplied by low-voltage current.

9. It is prohibited to make alterations to the appliances or to remove protective shields and covers.

10. Do not attempt yourself to repair an appliance after a defect, failure or damage, or to put it back into operation again. In such

cases, it is essential you contact either your Gantner company representative or the GANTNER Electronic GmbH hotline.

11. GANTNER Electronic GmbH accepts no responsibility for any injuries or damage caused as a result of improper use.

12. Although every care is taken and we are continuously aiming for improvement, we cannot completely exclude the possibility

of errors appearing in our documentation. GANTNER Electronic GmbH therefore accepts no responsibility for the completeness or the accuracy of this manual. The right is reserved to make alterations, and we may carry out alterations at any time

without giving prior notice.

13. Should you discover any fault with the product or in its accompanying documentation, or have any suggestions for improvement, you may confidently approach either your Gantner company representative or GANTNER Electronic GmbH directly.

www.gantner.com

HB_GAT-NETLOCK7000--US_33

3

GAT NET.Lock 7000 System

14. However, even if you just want to tell us that everything has functioned perfectly, we still look forward to hearing from you.

We wish you a successful application of our product and look forward to welcoming you again as a customer soon.

Contact address / manufacturer:

GANTNER Electronic GmbH

Montafonerstrasse 8

A - 6780 Schruns/Austria

Tel.: +43 5556 73784 - 442

Fax: +43 5556 73784 - 8020

Email: info.leisure@gantner.com

Website: www.gantner.com

4

HB_GAT-NETLOCK7000--US_33

www.gantner.com

GAT NET.Lock 7000 System

Table of Contents

TABLE OF CONTENTS

1. INTRODUCTION ............................................................................................................................................ 7

1.1 About this Manual ................................................................................................................................... 7

1.2 Contact & Inquiries .................................................................................................................................. 7

2. General Information ..................................................................................................................................... 8

2.1 System Parts ........................................................................................................................................... 8

2.2 Ordering Guide ........................................................................................................................................ 9

2.3 Basic Function of the GAT NET.Lock 7000 System ............................................................................. 11

2.4 Term Definitions .................................................................................................................................... 11

2.5 RFID Technology .................................................................................................................................. 12

3. Mounting ..................................................................................................................................................... 13

3.1 Definition of the Door Hinge (Right or Left Door) .................................................................................. 13

3.2 Metallic and Non-Metallic Doors ........................................................................................................... 14

3.3 Dimension Diagrams for Mounting ........................................................................................................ 14

3.3.1 Door Width ..................................................................................................................................... 14

3.3.2 Basic Dimensions of GAT NET.Lock 7000 and the GAT NET.Lock Bolt Sets .............................. 15

3.4 Door Status Contact .............................................................................................................................. 16

3.5 Mounting in Lockers with Non-Metallic Doors ....................................................................................... 17

3.5.1 Important Measures when Mounting the GAT NET.Lock 7000 and Bolt Set (Non-Metal Doors) . 17

3.5.2 Steps for Mounting of the GAT NET.Lock 7000 at Non-Metallic Doors ........................................ 18

3.6 Mounting in Lockers with Metallic Doors ............................................................................................... 20

3.6.1 Cut-Outs in the Locker Door .......................................................................................................... 21

3.6.2 Important Measurements when Mounting the GAT NET.Lock 7000 and Bolt Set (Metal Doors) . 21

3.6.3 Steps for Mounting the GAT NET.Lock 7000 onto Metallic Doors ................................................ 22

3.7 Points to be observed during Installation .............................................................................................. 23

3.8 Test Installation ..................................................................................................................................... 24

3.9 Replacement after a Burglary Attempt .................................................................................................. 24

3.10 Installation of the GAT NET.Controller M/S 7000 ............................................................................. 24

3.10.1 Instructions for Mounting the GAT NET.Controller M 7000 und S 7000: ...................................... 25

4. Electrical Connection ................................................................................................................................. 27

4.1 System Structure ................................................................................................................................... 27

4.2 Cable Connection of the GAT NET.Lock 7000 ..................................................................................... 28

4.2.1 Connection Cable .......................................................................................................................... 28

4.2.2 Cable Outlets ................................................................................................................................. 28

4.2.3 Power Supply ................................................................................................................................. 28

4.3 Connections at the Slave Controller GAT NET.Controller S 7000........................................................ 29

4.3.1 GAT NET.Lock 7000 Connection .................................................................................................. 29

4.3.2 Network Connection ....................................................................................................................... 29

4.3.3 Power Supply ................................................................................................................................. 31

4.3.4 LED Signals and Buttons ............................................................................................................... 32

4.4 Connections on the GAT NET.Controller M 7000 Master Controller .................................................... 33

4.4.1 Connecting the GAT NET.Controller S 7000 Slave Controllers to the Master Controller ............. 33

4.4.2 Ethernet Connection ...................................................................................................................... 33

4.4.3 Connection of the Power Supply ................................................................................................... 34

4.4.4 LED Signals and Buttons ............................................................................................................... 34

5. Configuration And Operation .................................................................................................................... 35

5.1 Antenna Adjustment of the GAT NET.Lock 7000 ................................................................................. 35

5.2 Locker Operation by the Visitor ............................................................................................................. 35

5.2.1 Lock a Locker ................................................................................................................................. 35

5.2.2 Unlock and Open a Locker ............................................................................................................ 35

5.3 Restart a Controller GAT NET.Controller S 7000 or GAT NET.Controller M 7000 .............................. 36

5.4 Delete Configuration Parameters of a Controller (= Reset to Default Settings) ................................... 36

5.5 Status Information for the GAT NET.Controller S 7000 and GAT NET.Controller M 7000 .................. 37

www.gantner.com

HB_GAT-NETLOCK7000--US_33

5

GAT NET.Lock 7000 System

Table of Contents

5.5.1 Slave Controller ............................................................................................................................. 37

5.5.2 Master Controller ........................................................................................................................... 37

5.6 GAT Relaxx - Operation Software for GAT NET.Lock 7000 System ................................................... 38

5.6.3 User Interface ................................................................................................................................ 38

6. Technical Data ........................................................................................................................................... 41

6.1 GAT NET.Lock 7000 ............................................................................................................................ 41

6.2 GAT NET.Controller S 7000 ................................................................................................................. 41

6.3 GAT NET.Controller M 7000 ................................................................................................................ 42

6

HB_GAT-NETLOCK7000--US_33

www.gantner.com

GAT NET.Lock 7000 System

Introduction

1. INTRODUCTION

1.1 About this Manual

This manual contains all the necessary information required to install GAT NET.Lock 7000 RFID locks into lockers/depots. Operating instructions for the end user are also fully explained. In order to use GAT NET.Lock 7000

locks, a GAT NET.Controller S 7000 slave controller, a GAT NET.Controller M 7000 master controller with their associated network and power cabling are required. In addition to these hardware requirements, PC software (e.g.

GAT Relaxx) is required to firstly configure the installation then used to control and monitor the locker system and

the RFID data carriers used to operate the locks. The installation and operation of these system parts are also described in this manual. For the GAT Relaxx configuration software there is also a separate installation manual as

well as a help function which is integrated into the software.

In chapter 2 "General Information", general information about the GAT NET.Lock 7000 system as well as an overview of the various system parts with order information can be found.

Chapter 3 "Mounting" includes instructions on how the GAT NET.Lock 7000 locks are mounted in the lockers. Here

the mounting procedure of the locks and bolt sets is described in addition to all important measurements and instal-

lation information. Because there are many different types of lockers available, the mounting procedure is described

generally and is not for a certain type of locker.

The chapter 4 "Electrical Connection" describes how the GAT NET.Lock 7000 locks and controllers are connected

to each other and connected to their power supplies. Also found here is information about the requirements and in-

stallation of the network connection cables.

Chapter 5 "Configuration And Operation" describes the operation of the GAT NET.Lock 7000 by a user/visitor within

a facility. Instructions for antenna adjustment and the resetting and deleting of configuration parameters in the con-

trollers are also explained. The LED display signals and acoustic signals on the controllers are also described here.

A brief overview of the GAT Relaxx configuration software is also included in this chapter.

Chapter 6 "Technical Data" contains the necessary technical information for the GAT NET.Lock 7000 locks and the

GAT NET.Controller S 7000 and M 7000 controllers.

1.2 Contact & Inquiries

For all inquiries concerning the GAT NET.Lock 7000 system and associated devices please get in touch with your

representative / distributor or directly with one of the GANTNER Technology branch offices. The addresses, phone

and fax numbers are listed on the inner side of the cover.

www.gantner.com

HB_GAT-NETLOCK7000--US_33

7

GAT NET.Lock 7000 System

13. Ethernet Patch Cable

4. GAT NET.Controller S 7000

(Slave Controller)

12. GAT NET.Lock Connector

Coupling for cable connection

6. GAT NET.Power Supply 100-240V

Power Supply Unit

8. GAT NET.Power Plug

5. GAT NET.Controller M 7000

(Master Controller)

1. GAT NET.Lock 7000

2. GAT NET.Lock BoltSet 7100

(For non-metallic doors)

+

11. GAT NET.Lock Cable 4m

(4m connection cable)

3. GAT NET.Lock BoltSet 7200

(For metallic doors. Includes label carrier)

10. GAT NET.Lock Label GEA right

GAT NET.Lock Label GEA NUM right

GAT NET.Lock Label GEA left

GAT NET.Lock Label GEA NUM left

(Front labels in different designs)

9. GAT NET.Lock Tool 7000

(Centre punch gauge for bolt mounting)

14. GAT NET.Lock Basic Set F

GAT NET.Lock Basic Set ISO

(Five master cards and an assumption

of liability sheet)

7. GAT NET.Power Cord US

(US power cable for GAT

NET.Power Supply 100-240 V)

General Information

2. GENERAL INFORMATION

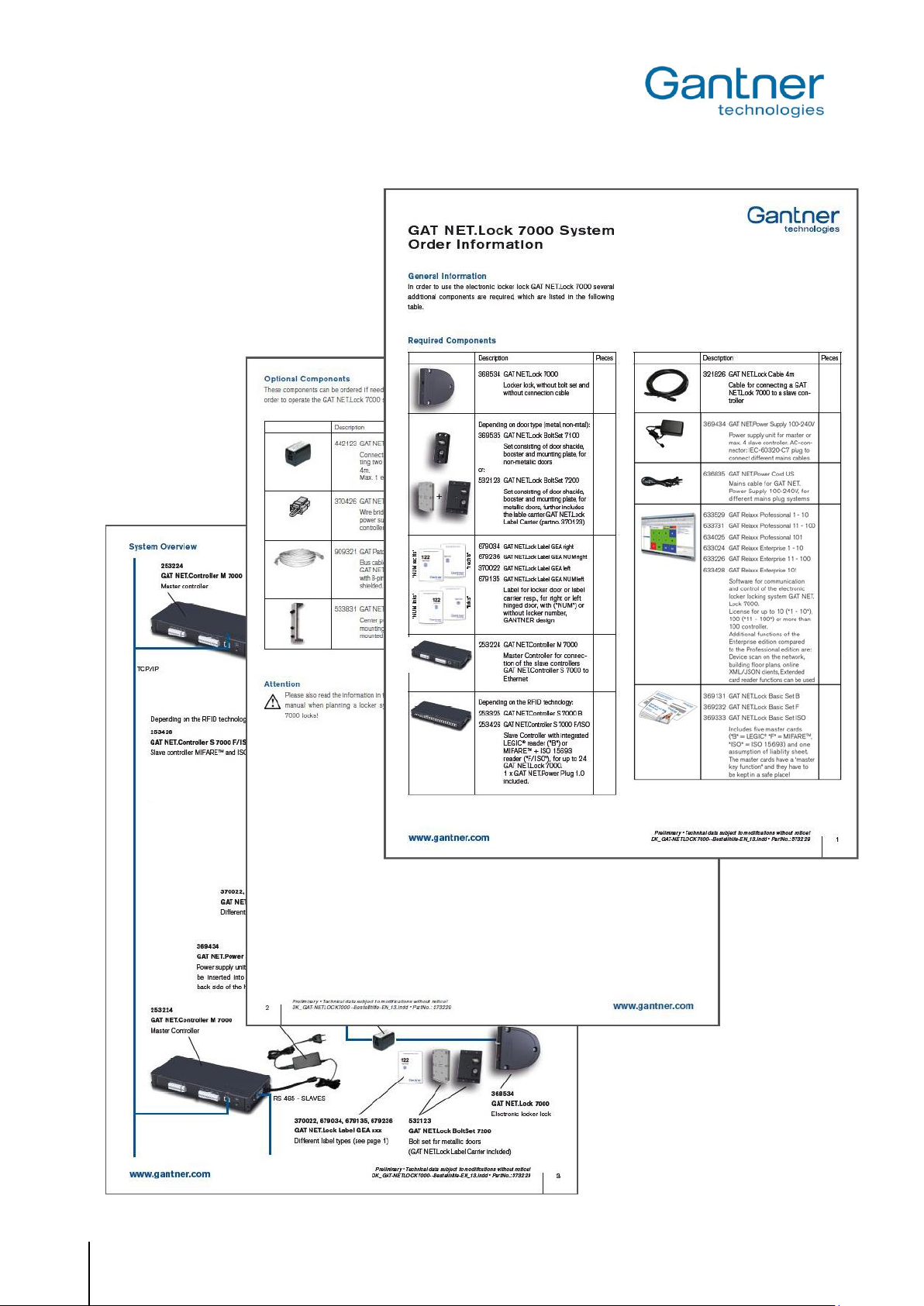

2.1 System Parts

The GAT NET.Lock 7000 system consists of the following system parts:

Figure 2.1 - System parts of the GAT NET.Lock 7000 system

8

HB_GAT-NETLOCK7000--US_33

www.gantner.com

GAT NET.Lock 7000 System

General Information

1. GAT NET.Lock 7000

Electronic RFID locker lock without connection cable and without bolt set.

2. GAT NET.Lock BoltSet 7100

Bolt set with door shackle and booster. Used for non-metallic doors. The bolt set is mounted on the inside of

the locker door.

3. GAT NET.Lock BoltSet 7200

Bolt set with door shackle and booster. Used for metallic doors. The bolt set is installed into locker door. The

label carrier is also included in the set.

4. GAT NET.Controller S 7000

The slave controller is a control unit to connect up to 24 GAT NET.Lock 7000 locks. There are two different

types of slave controllers available which differ in the type of RFID technology they can read.

5. GAT NET.Controller M 7000

The master controller is a control unit to connect up to 8 GAT NET.Controller S 7000 slave controllers. The

master controller is used to connect the slave controller(s) to a server / PC.

6. GAT NET.Power Supply 100-240V

Power supply unit for the slave and master controller.

7. GAT NET.Power Cord US

Power cable for connection of GAT NET.Power Supply 100-240 V to the US mains power sockets.

8. GAT NET.Power Plug

Plug to supply multiple controllers with a single power supply (see "4.3. Connections at the Slave Controller

GAT NET.Controller S 7000").

9. GAT NET.Lock Tool 7000

Centre punch gauge for bolt mounting in the locker doors. With this gauge drill holes for the bolt installation can

be easily marked on the locker door.

10. GAT NET.Lock Label 7000 GEA xxx

Different locker door labels in GANTNER design. The labels are available for right and left doors and with or

without printed locker numbers. On metallic doors the labels are stuck onto the label carrier. On non-metallic

doors the labels can be stuck directly onto the doors.

11. GAT NET.Lock Cable 4m

4-pin connection cable (4 metres) to connect a GAT NET.Lock 7000 to a slave controller. MOLEX plug on both

ends.

12. GAT NET.Lock Connector

Connection socket to connect two GAT NET.Lock Cable 4m.

13. Ethernet Patch Cable

Standard network cable (min. CAT5) to connect the slave controller to the master controller.

14. GAT NET.Lock Basic Set xxx

Set consisting of five master cards and an assumption of liability sheet. The master cards have master key

functionality and can be used to open all lockers in a GAT NET.Lock 7000 locker system (e.g. used for serviceand cleaning personnel). Available for different RFID technologies ("F" for MIFARE® and "ISO" for ISO 15693

systems).

2.2 Ordering Guide

For the planning and ordering of the GAT NET.Lock 7000 system components, an ordering guide is available in a

separate document ("DK_GAT-NETLOCK7000--Bestellhilfe-EN").

www.gantner.com

HB_GAT-NETLOCK7000--US_33

9

GAT NET.Lock 7000 System

General Information

10

HB_GAT-NETLOCK7000--US_33

www.gantner.com

GAT NET.Lock 7000 System

General Information

2.3 Basic Function of the GAT NET.Lock 7000 System

The GAT NET.Lock 7000 lock is the ideal solution for the convenient electronic locking of wardrobe lockers in fitness clubs, baths, golf resorts, hotels and other individual company applications. Operation of the GAT NET.Lock

7000 is carried out using contactless RFID data carriers (Radio Frequency Identification).

The GAT NET.Lock 7000 is suitable for any type of locker material (e.g. sheet metal, wood, HPL, solid plastic) and

can be used for left- and right-hinged doors alike. The various operating modes enable the flexible use of these

locks.

The GAT NET.Lock 7000 is installed on the inner side of the locker body. A bolt set is mounted on the inside of the

locker door. This bolt set holds the door shackle which inserts into the GAT NET.Lock 7000 and locks the door. The

bolt set also includes a passive booster in order to amplify the RFID reading field.

The GAT NET.Lock 7000 locks are controlled by the GAT NET.Controller S 7000 slave controllers. The slave controllers support the RFID technologies MIFARETM and ISO 15693. Up to 24 GAT NET.Lock 7000 locks can be connected to one slave controller. The slave controllers are connected to master controllers which then communicate

over Ethernet with a software application (e.g. GAT Relaxx software from GANTNER Electronic GmbH) on a host

computer/server.

Using a locker

The facility user closes the door of a free locker and whilst holding the door shut puts their data carrier next to the

reading centre on the locker door (the reading centre is indicated by the LED inside the lock). The GAT NET.Lock

7000 reads the data carrier information then communicates with the host software (via the slave and master controllers) to determine if the user is allowed to use the locker (depending on their authorisation). If the user is authorised

to use the locker, a command is sent to the GAT NET.Lock 7000 to lock the locker door.

To unlock a locker door the user again holds their data carrier next to the reading centre of their previously locked

locker door. The GAT NET.Lock 7000 communicates with the controllers and host software to confirm or deny if the

user has valid authorisation to unlock the locker door. The locker door automatically opens after a valid command

has been sent to the GAT NET.Lock 7000.

2.4 Term Definitions

Several terms are used often in this manual and are defined below.

Locker:

The term "locker" is used to generally describe all possible locker applications, for example, a changing locker, a

depot or a private box. All these locker possibilities are locked by the GAT NET.Lock 7000.

Lock:

General term for the GAT NET.Lock 7000.

RFID (Radio-Frequency Identification):

Identification from a short distance using radio frequency. An RFID data carrier is used as identification media.

Data Carrier:

A data carrier in this manual is an identification media which is used by the persons/visitors of a facility for identification at the GAT NET.Lock 7000 locker locks. Data carriers are available in many different forms such as plastic

wristbands or chip cards. Data carriers are available in different technologies (MIFARETM, ISO 15693).

www.gantner.com

HB_GAT-NETLOCK7000--US_33

11

GAT NET.Lock 7000 System

General Information

FID (Company ID) and Site Key:

LEGIC systems use an FID number. In MIFARE systems a site key is used which is a combination of the FID and

the read and write keys. The FID and site keys are unique numbers for every leisure facility installation. These

numbers are encoded in every data carrier and device and with this number it can be guaranteed that data carriers

of one installation are not used in other installations.

Slave Controller:

The GAT NET.Controller S 7000 slave controller is a device to which all GAT NET.Lock 7000 locks are connected

to (up to 24 locks per slave controller). The slave controller receives control signals via the serial RS 485 network

and operates the connected electronic locks accordingly.

Master Controller:

The GAT NET.Controller M 7000 master controller is used to connect the slave controllers via Ethernet to a higherranking PC/server running locker system control software (e.g. GAT Relaxx).

Booster:

Electronic component for amplifying the RFID reading field of the GAT NET.Lock 7000. A booster is often used to

extend the RIFD reading range of the GAT NET.Lock 7000, e.g., on metallic or thick doors or small data carriers.

The bolt sets for the GAT NET.Lock 7000 already include boosters - 1 in the GAT NET.Lock BoltSet 7100 for nonmetallic doors and 2 in the GAT NET.Lock BoltSet 7200 for metallic doors.

GAT Relaxx:

PC software which is installed on a server/host computer and which is used to configure and control the connected

controllers and locks. A separate installation manual and integrated help is available for this software.

User / Visitor:

The general terms "user" and "visitor" describe the people that use the lockers and the GAT NET.Lock 7000.

2.5 RFID Technology

Identification of users at the GAT NET.Lock 7000 is done via RFID (radio-frequency identification) using a frequency

of 13.56 MHz. There are two different technologies supported. Different letter/letters are added to GANTNER product model identifiers to notify of the technology which the device supports:

- "F": MIFARETM

- "ISO": ISO 15693

The GAT NET.Lock 7000 and the GAT NET.Controller M 7000 master controller can work with all of these technologies. The slave controller GAT NET.Controller S 7000 F/ISO supports also both of these technologies.

Therefore, it is necessary that all data carriers in a facility are of the same technology. The information in this manual is written in general for all RFID types. If there is special information only valid for a certain type of technology it

will be noted.

12

HB_GAT-NETLOCK7000--US_33

www.gantner.com

GAT NET.Lock 7000 System

Mounting

3. MOUNTING

This mounting instruction describes how to install the GAT NET.Lock 7000 locker locks. Please read this

instruction carefully and follow it prior to working on the lockers or installing the locks.

As there is a wide variety of applications and locker types, a test installation including a functional testing

must always be performed prior to the serial production of the lockers and the installation of the locks (see

chapter "3.8. Test Installation").

Please also read the most important points for installation summarized in chapter "3.7. Points to be observed during Installation".

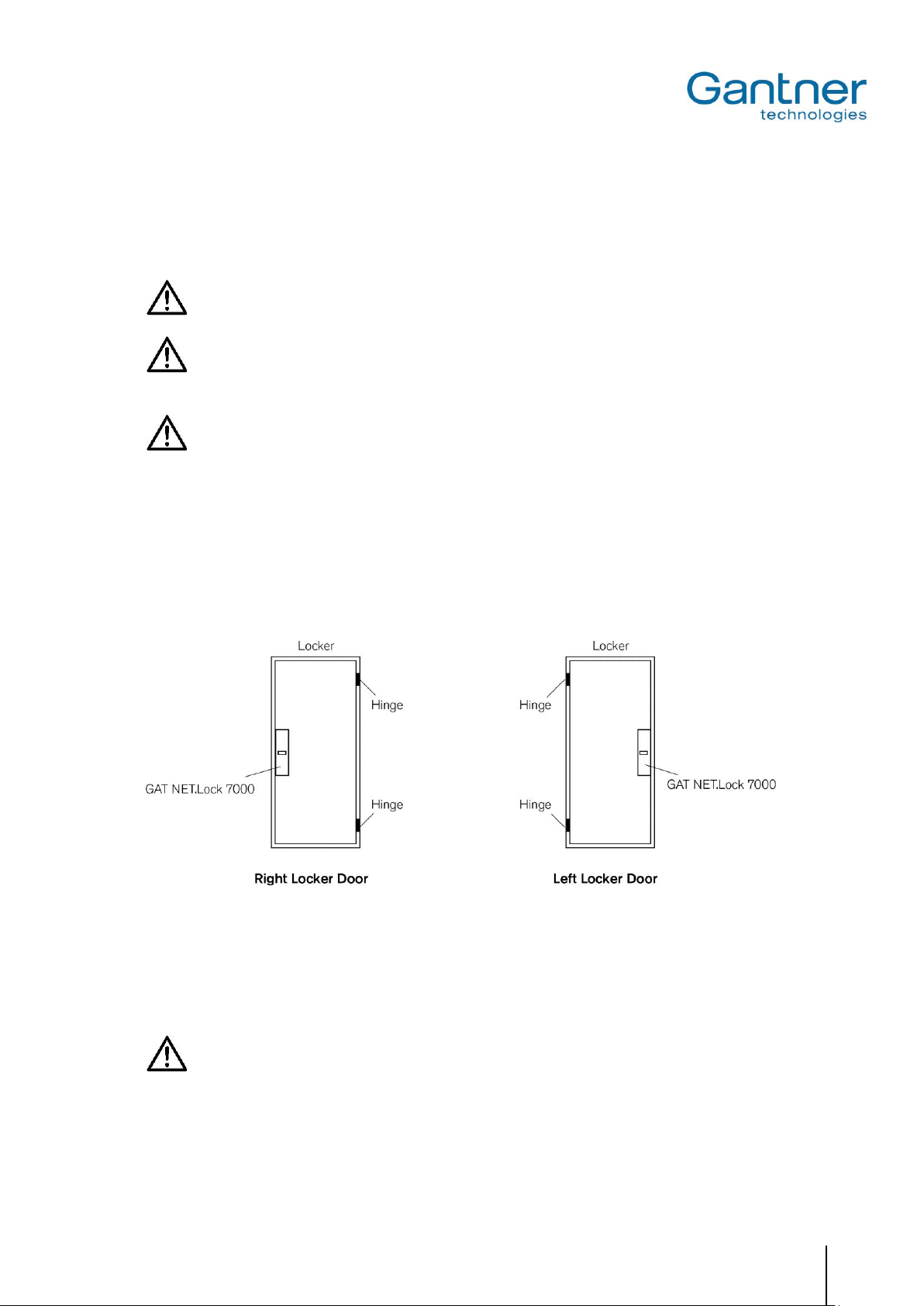

3.1 Definition of the Door Hinge (Right or Left Door)

For the mounting, it is important to determine whether the door is hinged to the left or the right. This is defined as

follows:

Figure 3.1 - Definition of the opening direction of lockers (left/right)

In the following pages the mounting for right-hinged doors is described. The installation process for left locker doors

is in principle the same as for right locker doors, only with reversed lock and door orientation.

The hinges must not be equipped with retaining springs or other elements which keep the locker door shut!

The locker door must release and open without resistance by itself when it is unlocked by the GAT

NET.Lock 7000.

www.gantner.com

HB_GAT-NETLOCK7000-- US_33

13

GAT NET.Lock 7000 System

Mounting

3.2 Metallic and Non-Metallic Doors

Because the RFID field of the GAT NET.Lock 7000 is distorted or blocked by metal (e.g. with metallic locker doors),

a cut-out has to be made in metallic locker doors into which the GAT NET.Lock Bolt Set 7200 and the label carrier

can be installed. A specific cut-out for non-metallic doors is not necessary, only a drill hole for the LED field is required.

Since the reading range of the GAT NET.Lock 7000 is limited, the locker door of non-metallic lockers must not be

too thick. The maximum door thickness of non-metallic doors depends on the RFID technology and data carriers

used.

3.3 Dimension Diagrams for Mounting

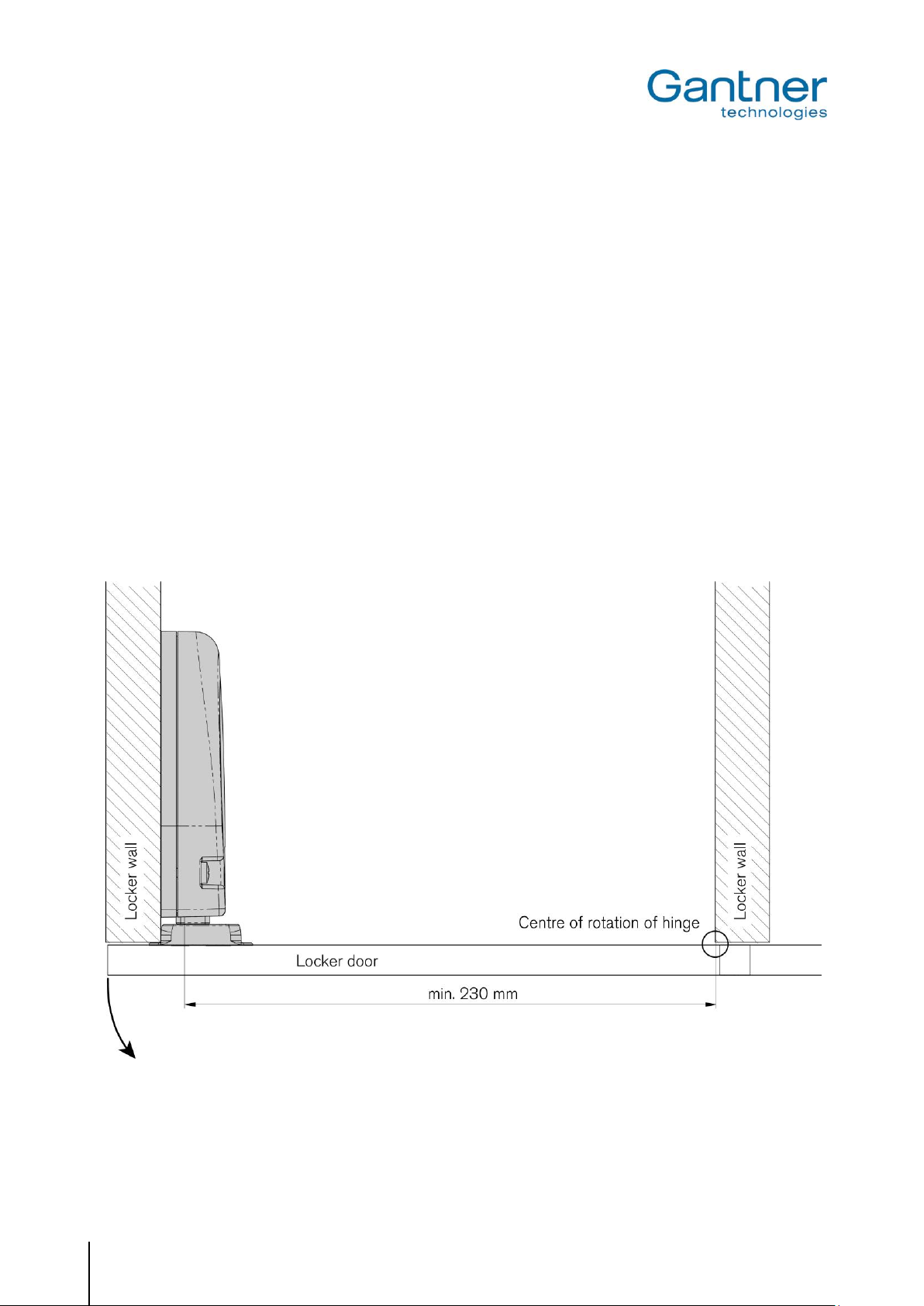

3.3.1 Door Width

The minimum door width allowed (measured from the door shackle to the hinge) is 230 mm. If the door is narrower,

the door shackle would hit the locker when the door is being closed.

Figure 3.2 - Minimal door width

14

HB_GAT-NETLOCK7000--US_33

www.gantner.com

Loading...

Loading...