GS-EVB-HB-66508B-RN Technical Manual

DANGER!

handling the product.

_____________________________________________________________________________________________________________________

GS-EVB-HB-66508B-RN

Technical Manual

Visit www.gansystems.com

for the latest version of this technical manual.

This evaluation kit is designed for engineering evaluation in a controlled

lab environment and should be handled by qualified personnel ONLY.

High voltage will be exposed on the board during the test and even brief

contact during operation may result in severe injury or death.

Never leave the board operating unattended. After it is de-energized,

always wait until all capacitors are discharged before touching the board.

CAUTION:

This product contains parts that are susceptible to damage by electrostatic

discharge (ESD). Always follow ESD prevention procedures when

GS-EVB-HB-66508B-RN Rev. 210118 © 2021 GaN Systems Inc. www.gansystems.com 1

Please refer to the Evaluation Board/Kit Important Notice on page 26

GS-EVB-HB-66508B-RN Technical Manual

Part Number

GaN E-HEMT P/N:

Description

RAA226110 gate driver, 0V turn off voltage

GS665MB-EVB

Universal 650V Mother Board

_____________________________________________________________________________________________________________________

Overview

The GS-EVB-HB-66508B-RN is a RTK226110DE0010BU RAA226110

https://www.renesas.com/products/raa226110

daughter board style. This evaluation kit consists of two GaN Systems 650V GaN Enhancement-mode

HEMTs (E-HEMTs) and all necessary circuits including half bridge gate drivers, isolated power supplies

and optional heatsink to form a functional half bridge power stage. It allows users to easily evaluate the

GaN E-HEMT performance in any half bridge-based topology, either with the universal mother board

(P/N: GS665MB-EVB) or users’ own system design. The GS-EVB-HB-66508B-RN demo board provides 0V

turn-off voltage solution. 0V turn-off solution is normally used in low power application. 0V turn-off

solution is easy to implement as there is no need a negative power supply rail. And the reverse

conduction voltage drop of GaN is lower. For E-mode GaN device the Vgs threshold voltage is low (typ:

1.7V). 0V turn-off has the risk of false turn-on when the GaN device is in off state. Also, the switching-off

loss will be higher than negative turn-off voltage. The 0V turn-off solution is normally used in the low

power applications.

Features:

• Serves as a reference design and evaluation tool as well as deployment-ready solution for easy in-

system evaluation.

• Vertical mount style with height of 35mm, which fits in majority of 1U design and allows

evaluation of GaN E-HEMT in traditional through-hole type power supply board.

• Current shunt position for switching characterization testing

• Universal form factor and footprint for all products

• 0V turn off voltage

The daughter board and universal mother board ordering part numbers are below:

gate drive demo board following GS665XXX-EVBDB

Table 1 Ordering part numbers

GS-EVB-HB-66508B-RN GS66508B

GaN E-HEMT 650V/30A, 50mΩ With

Control and Power I/Os:

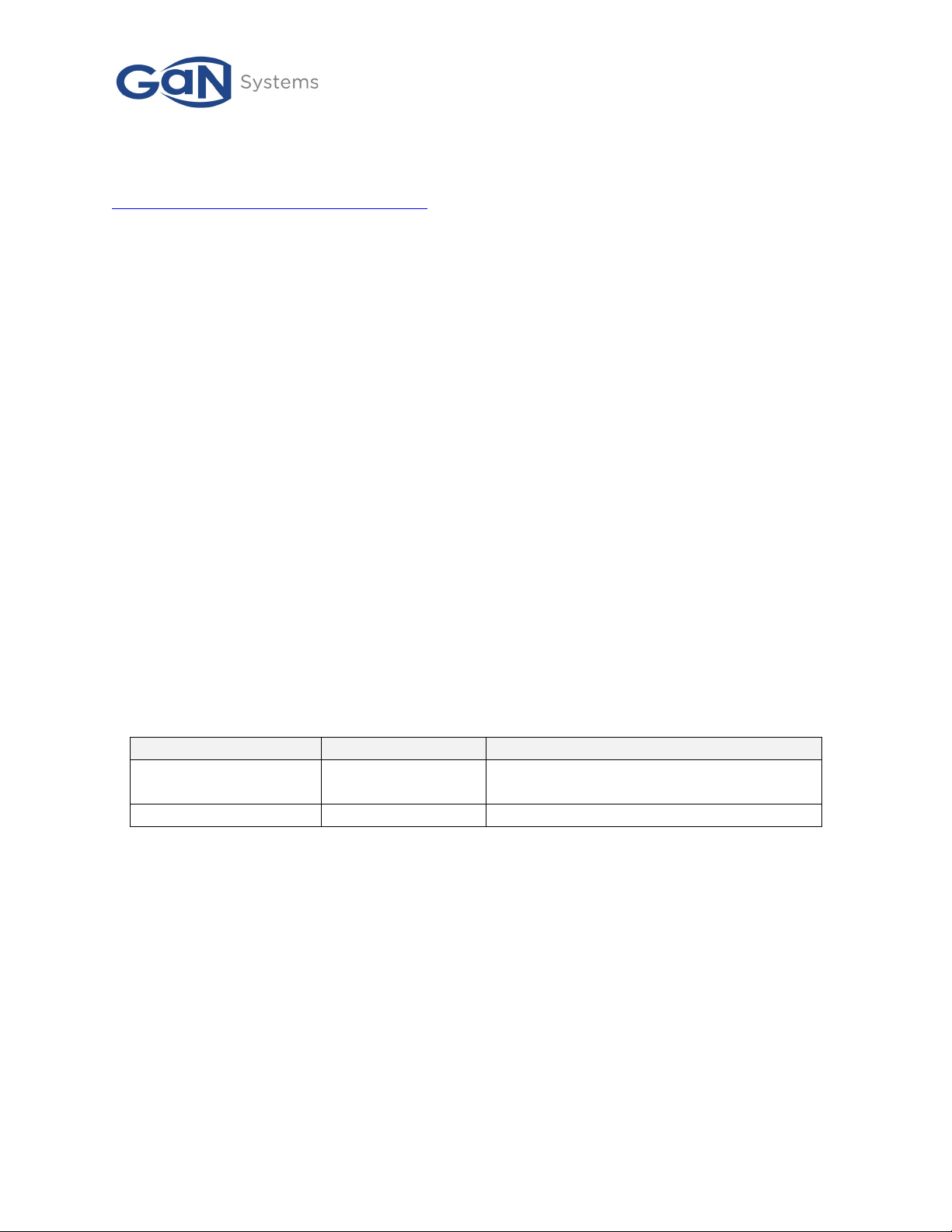

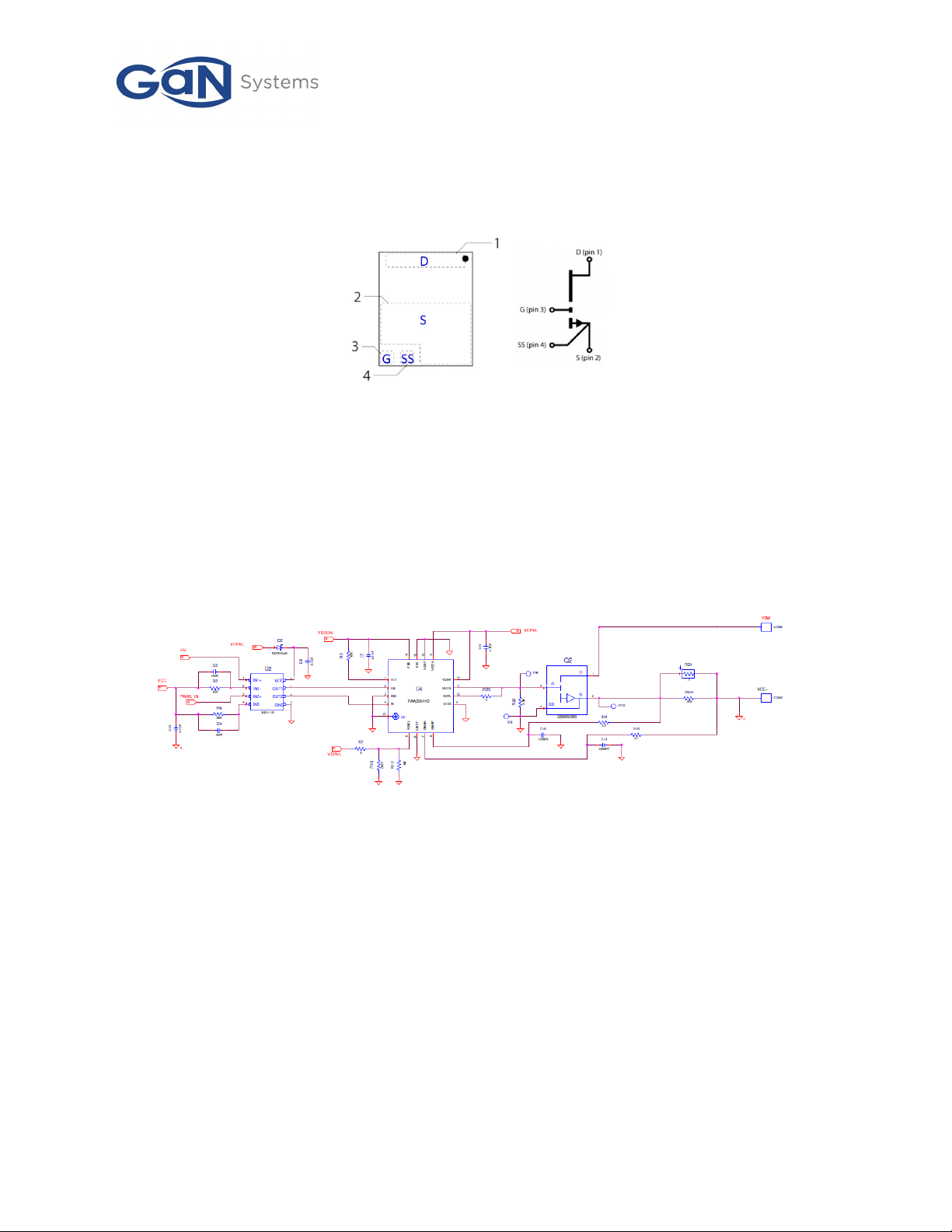

The daughter board GS-EVB-HB-66508B-RN circuit diagram is shown in Figure 1. The control logic

inputs on 2x3 pin header J1 are listed below:

GS-EVB-HB-66508B-RN Rev. 210118 © 2021 GaN Systems Inc. www.gansystems.com 2

Please refer to the Evaluation Board/Kit Important Notice on page 26

GS-EVB-HB-66508B-RN Technical Manual

Pin

Descriptipon

drive outputs.

switches.

VDRV

Not used. VDRV can be connected to VCC though R43. R43 is DNP by default.

PWMH_IN

High side PWM logic input for top switch Q1. It is compatible wth 3.3V and 5V

PWML_IN

Low side PWM logic input for bottom switch Q2. It is compatible wth 3.3V and 5V

0V

Logic inputs and gate drive power supply ground return.

IL611-1E

Q 1 Q

2

Iso

.

DC / DC

Iso

.

DC / DC

VDC

+

VSW

VDC

-

VCC

ENABLE

shunt

C 4 -

10

PWMH

PWML

Gate Driver

RAA226110

Gate Driver

IL611-1E

RAA226110

_____________________________________________________________________________________________________________________

Table 2 Control pins

ENABLE Enable input. It is internally pulled up to VCC, a low logic disables all the PWM gate

+5V +5V auxillary power supply input for logic circuit and gate driver. On the daughter

board there are 2 isolated 5V to 9V DC/DC power supplies for top and bottom

The 3 power pins are:

• VDC+: Input DC Bus voltage

• VSW: Switching node output

• VDC-: Input DC bus voltage ground return. Note that control ground 0V is isolated from VDC-

Isolator

Isolator

Figure 1 GS-EVB-HB-66508B-RN Evaluation Board Block Diagram

GS-EVB-HB-66508B-RN Rev. 210118 © 2021 GaN Systems Inc. www.gansystems.com 3

Please refer to the Evaluation Board/Kit Important Notice on page 26

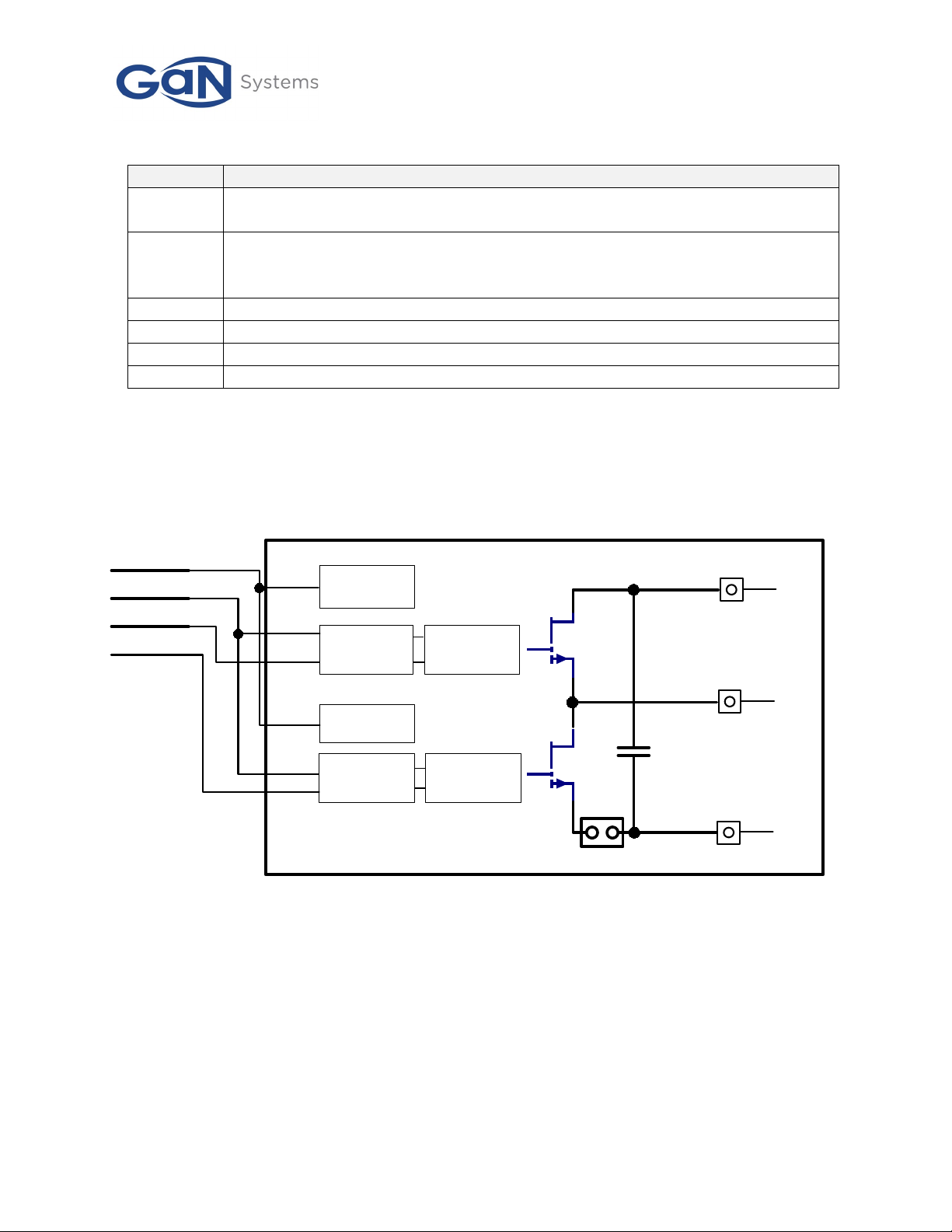

GS-EVB-HB-66508B-RN Technical Manual

C

D

F

E

A

B

G

Heat sink location

_____________________________________________________________________________________________________________________

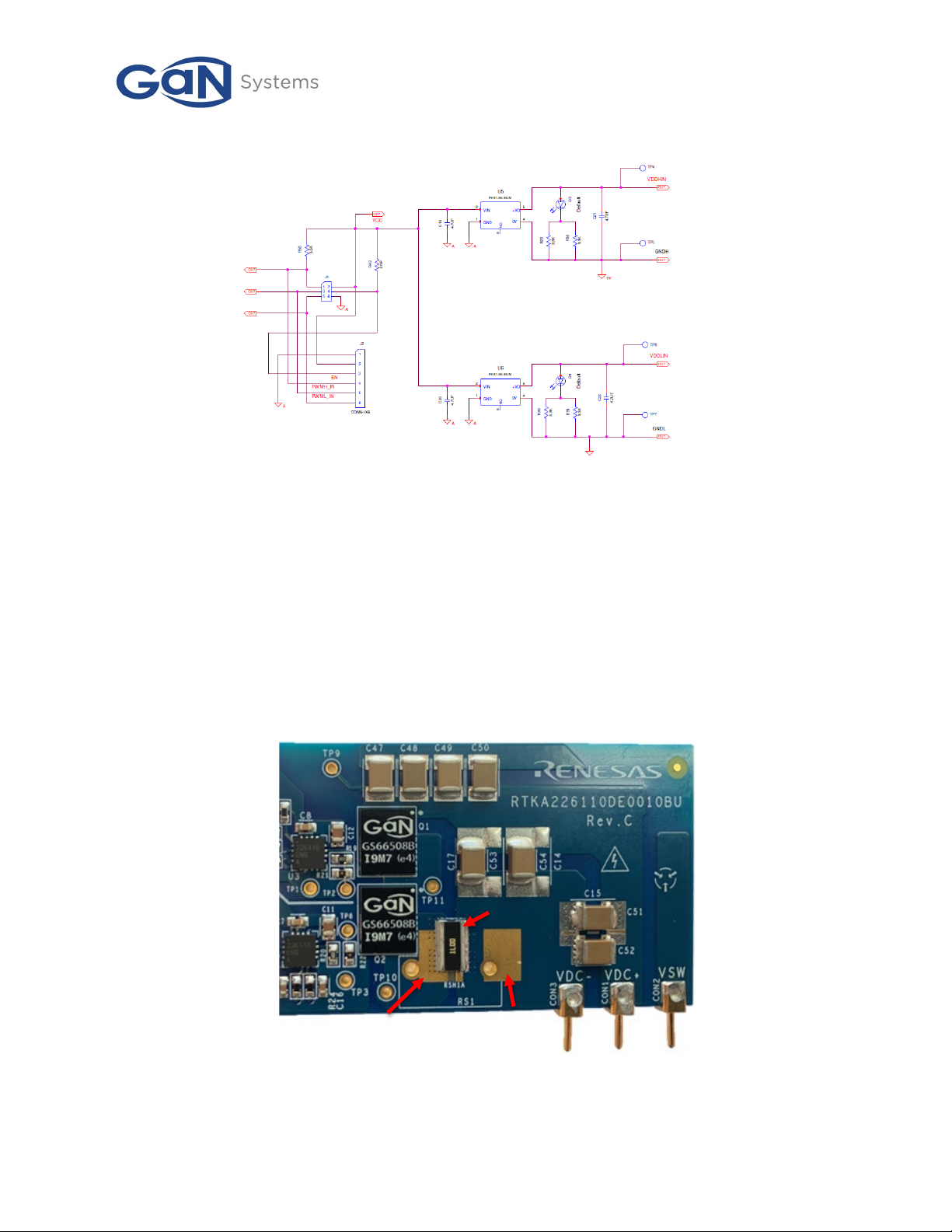

GS-EVB-HB-66508B-RN half bridge daughter board

Figure 2 GS-EVB-HB-66508B-RN top side

Figure 3 GS-EVB-HB-66508B-RN bottom side

A. 2x GaN Systems 650V E-HEMT GS66508B, 30A/50mΩ.

B. Decoupling capacitors C14-C17 and C47-C54.

C. Signal isolator IL611-1E.

D. GaN driver RAA226110.

E. OCP shunt.

F. TP8(gate) and TP3(source) test points for bottom Q2 V

G. 5V-9V isolated DC/DC gate drive power supply

GS.

GS-EVB-HB-66508B-RN Rev. 210118 © 2021 GaN Systems Inc. www.gansystems.com 4

Please refer to the Evaluation Board/Kit Important Notice on page 26

GS-EVB-HB-66508B-RN Technical Manual

_____________________________________________________________________________________________________________________

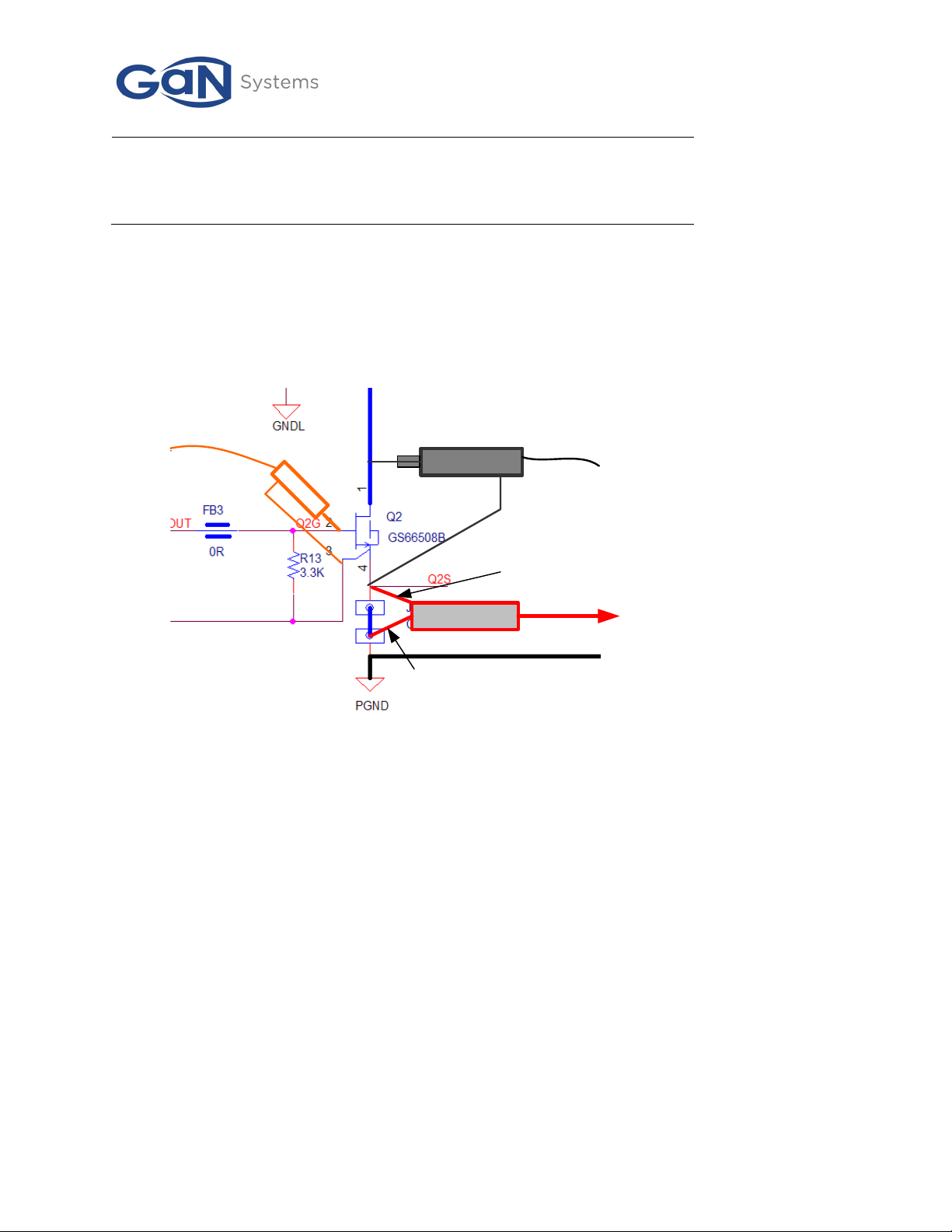

GaN E-HEMTs:

• This daughter board includes two GaN Systems E-HEMT GS66508B (650V/30A, 50mΩ) in a

GaNPx™ B type package. The large S pad serves as source connection and thermal pad. The pin

4 is the kelvin source connection for gate drive return.

Figure 4 Package outline of GS66508B

Gate driver circuit:

• Renesas RAA226110 low-side gate driver is chosen for this design. This driver provides 5.8V gate

drive with 3.8V UVLO. It supports the 5.8V turn on and -3V/0V turn off. It has separated source

and sink drive outputs which eliminates the need for additional diode. OCP is also integrated in

the driver.

• RAA226110 provides configurable source current(0.3A/0.75A/2A) to adjust the slew rate of

GS66508B without gate resistor to minimize the gate loop. The turn off speed can be directly

controlled by the gate resistor Rg_off (R19/R20).

Figure 5 Gate driver circuit

Gate drive power supply:

• 5V-9V isolated DC/DC converters are used for gate drive. The RAA226110 accpets 4.5V to 18V

VDD input voltage. DC/DC conterter 9V output is directly connected to RAA226110.

GS-EVB-HB-66508B-RN Rev. 210118 © 2021 GaN Systems Inc. www.gansystems.com 5

Please refer to the Evaluation Board/Kit Important Notice on page 26

GS-EVB-HB-66508B-RN Technical Manual

Q2 source

Shunt

_____________________________________________________________________________________________________________________

Figure 6 Gate drive power supply

Current shunt:

• The board provides an optional current shunt position E(figure2) between the source of Q2 and

power ground return. This allows drain current measurement for switching characterization test

such as Eon/Eoff measurement.

• The current shunt is also used to provide the OCP signal for the RAA226110 to trigger OCP. The

OCP threchold voltage 40mV/80mV/120mV can be configured through the IDSET pin of

RAA226110.

• If current shunt is not used position E must be shorted.

Figure 7 Current shunt position E

GS-EVB-HB-66508B-RN Rev. 210118 © 2021 GaN Systems Inc. www.gansystems.com 6

Please refer to the Evaluation Board/Kit Important Notice on page 26

GS-EVB-HB-66508B-RN Technical Manual

CAUTION:

before powering up.

VGL

VSL

VSW

BNC case

To oscilloscope

probe input (use

50Ω termination)

BNC tip

V

DS

V

GS

I

D

_____________________________________________________________________________________________________________________

Measurement with current shunt:

1. When measuring VSW with current shunt, ensure all channel probe grounds and current shunt

2. The output of coaxial current shunt can be connected to oscilloscope via 50Ω termination

3. The measured current is inverted and can be scaled by using: Id=Vid/Rshunt.

Check the shunt position E before the first time use. To complete the circuit

position E needs to be either shorted or a current shunt must be inserted

BNC output case are all referenced to the source end of Q2 before the current shunt. The

recommended setup of probes is shown as below.

impedance to reduce the ringing.

Figure 8 Recommended probe connection with current shunt

Thermal design:

1. GS66508B has a thermal pad at the bottom side for heat dissipation. The heat is transferred to the

bottom side of PCB using thermal vias and copper plane.

2. A heatsink (35x35mm size) can be attached to the bottom side of board for optimum cooling.

Thermal Interface Material (TIM) is needed to provide electrical insulation and conformance to

the PCB surface. The daughter board evaluation kit supplies with a sample 35x35mm fin heatsink

(not installed), although other heatsinks can also be used to fit users’ system design.

®

3. A thermal tape type TIM (Berguist

heatsink has the thermal tape pre-applied so simply peel off the protective film and attach the

heatsink to the back of board as marked in Figure 3.

4. Two optional mounting holes as shown in Figure 9 are provided for mounting customized

heatsink using screws.

5. Using the supplied heatsink and TIM, the overall junction to ambient thermal resistance R

~9°C/W with 500LFM airflow.

6. Forced air cooling is recommended for power testing.

GS-EVB-HB-66508B-RN Rev. 210118 © 2021 GaN Systems Inc. www.gansystems.com 7

Please refer to the Evaluation Board/Kit Important Notice on page 26

Bond-Ply 100) is chosen for its easy assembly. The supplied

thJ-A is

GS-EVB-HB-66508B-RN Technical Manual

temperature exceeding T

J_MAX

(150°C)

12

V INPUT

(+)

5V Power Supply

CIN

VSW

PWM control & dead

time circuit

Daughter Board

Probing point for VSW

For Ext.

12VDC Fan

Airflow direction

Optional Cout

VDC-

VOUT

VDC-

VDC+

_____________________________________________________________________________________________________________________

Figure 9 The daughter board with heatsink attached

CAUTION:

Using GS-EVB-HB-66508B-RN with universal mother board GS665MB-EVB

There is no on-board over-temperature protection. Device temperature must

be closely monitored during the test. Never operate the board with device

GS-EVB-HB-66508B-RN Rev. 210118 © 2021 GaN Systems Inc. www.gansystems.com 8

Figure 10 650V universal mother board GS665MB-EVB

Please refer to the Evaluation Board/Kit Important Notice on page 26

GS-EVB-HB-66508B-RN Technical Manual

0V

D1 PMEG2005EB

SOD523

R6

1K00

TR12K

C11

100pF

0V

R5

1K00

C10

1uF

C9

0.1uF

+5V

J7

112538

1

2

3

4

5

R4

100R

R1206

R2

100R

R1206

U2A

74VHC132

3

1

2

14

7

0V

R1

49R9

0V

D2 PMEG2005EB

SOD523

TR22K

C12

100pF

0V

U2B

74VHC132

4

5

6

U2C

74VHC132

9

10

8

U2D

74VHC132

12

13

11

TP7

TP8

DNP

DNP

PWM

OUTPUT

INVERTED

PW M OUTPUT

R3

49R9

DNP

DNP

R7

49R9

_____________________________________________________________________________________________________________________

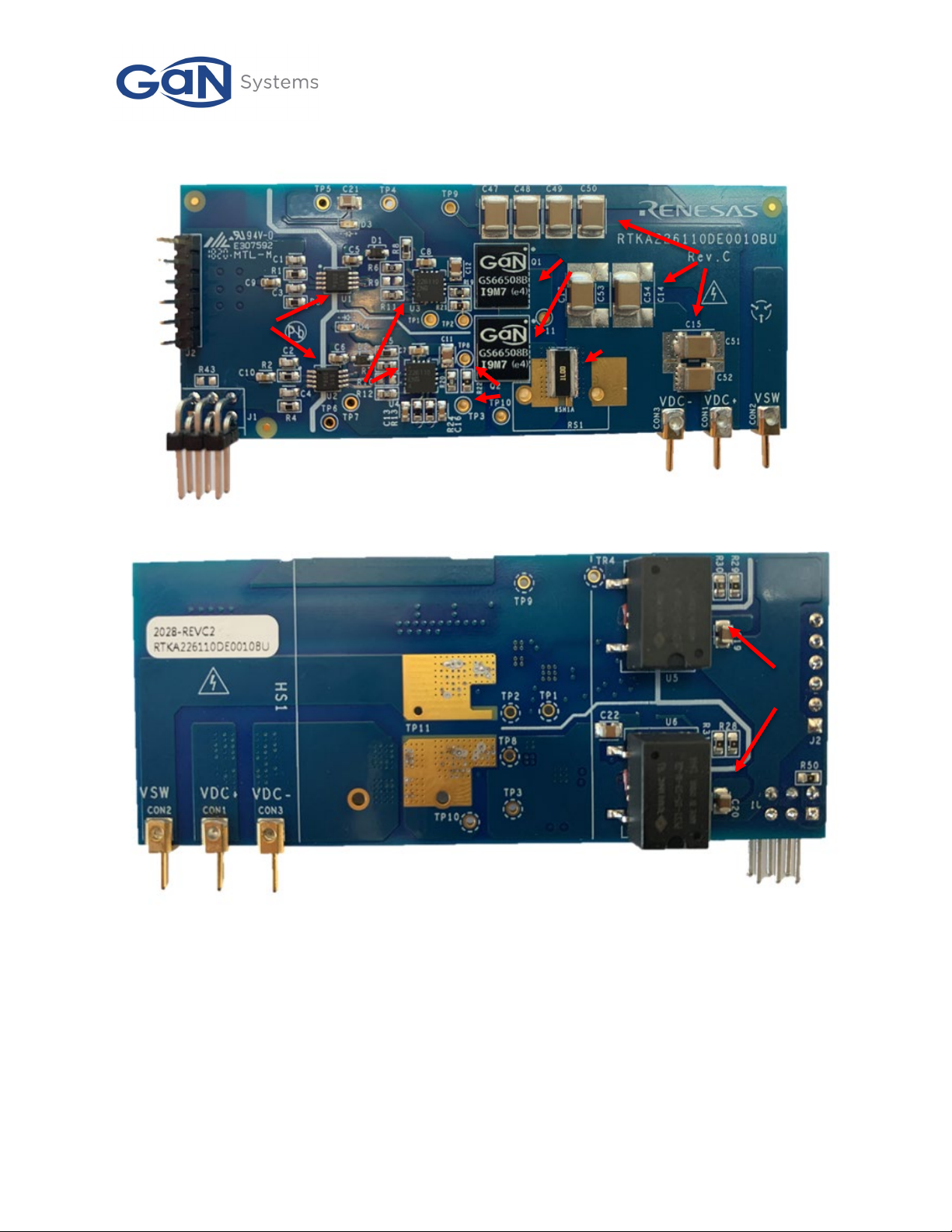

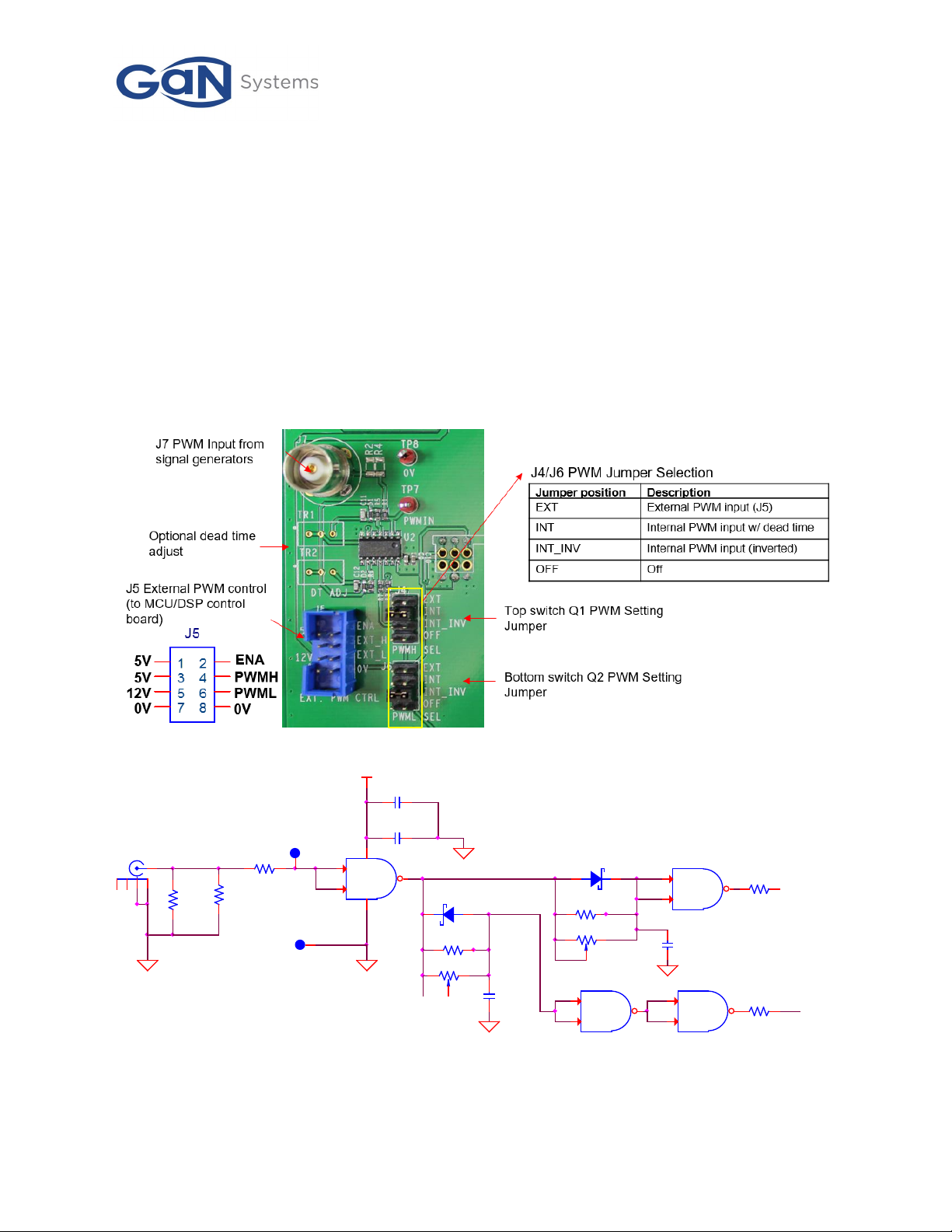

GaN Systems provides a universal 650V mother board (ordering part number: GS665MB-EVB, sold

separately) that can be used as the basic evaluation platform for all the daughter boards.

The universal 650V mother board evaluation kit includes following items:

1. Mother board GS665MB-EVB

2. 12VDC Fan

12V input:

The board can be powered by 9-12V on J1. On-board voltage regulator creates to 5V for daughter board

and control logic circuits. J3 is used for external 12VDC fan.

PWM control circuit:

Figure 11 PWM control input and dead time circuit

Please refer to the Evaluation Board/Kit Important Notice on page 26

Figure 12 On board dead time generatrion circuit

The top and bottom switches PWM inputs can be individually controlled by two jumpers J4 and J6. Users

can choose between a pair of complementary on-board internal PWM signals (non-inverted and inverted,

GS-EVB-HB-66508B-RN Rev. 210118 © 2021 GaN Systems Inc. www.gansystems.com 9

Loading...

Loading...