TDC5™ Temperature Controller

Operator’s Manual

Copyright © 2019 Gamry Instruments, Inc. All rights reserved. Printed in the USA.

Revision 1

January 21, 2019

Part # 988-00072

i

ii

1

Limited Warranty

Gamry Instruments, Inc. warrants to the original user of this product that it shall be free of defects resulting

from faulty manufacture of the product or its components for a period of two years from the date of

shipment.

Gamry Instruments, Inc. makes no warranties regarding either the satisfactory performance of the TDC5

Temperature Controller including the software used with this product or the fitness of TDC5-based systems

for any particular purpose. The remedy for breach of this Limited Warranty shall be limited solely to repair

or by replacement, as determined by Gamry Instruments, Inc., and shall not include other damages.

Gamry Instruments, Inc. reserves the right to make revisions to the TDC5 at any time without incurring any

obligation to install same on TDC5s previously purchased. All system specifications are subject to change

without notice.

There are no warranties which extend beyond the description herein. This warranty is in lieu of, and

excludes any and all other warranties or representations, expressed, implied or statutory, including

merchantability and fitness, as well as any and all other obligations or liabilities of Gamry

Instruments, Inc., including but not limited to, special or consequential damages.

This limited warranty gives you specific legal rights and you may have others which vary from state to state.

Some states do not allow for the exclusion of incidental or consequential damages.

No person, firm or corporation is authorized to assume for Gamry Instruments, Inc. any additional

obligation or liability not expressly provided herein except in writing duly executed by an officer of Gamry

Instruments, Inc.

2

If You Have Problems

Contact us at your earliest convenience. We can be contacted via:

Telephone (215) 682-9330 9:00 AM–5:00 PM US Eastern Standard Time

(877) 367-4267 Toll-free US & Canada Only

Fax (215) 682-9331

E-mail techsupport@gamry.com

Mail Gamry Instruments, Inc.

734 Louis Drive

Warminster, PA 18974

USA

If you write to us about a problem, provide as much information as possible.

If you are having problems in installation or use of this TDC5 Temperature Controller, please call from a

telephone next to the instrument, where you can change instrument settings while talking to us.

We are happy to provide a reasonable level of free support for TDC5 purchasers. Reasonable support

includes telephone assistance covering the normal installation, use, and simple tuning of the TDC5.

3

Disclaimers

Gamry Instruments, Inc. cannot guarantee that the TDC5 will work with all computer systems, heaters,

cooling devices, or cells.

The information in this manual has been carefully checked and is believed to be accurate as of the time of

printing. However, Gamry Instruments, Inc. assumes no responsibility for errors that might appear.

Copyrights and Trademarks

Gamry Framework™ Software Copyright © 1989–2019 Gamry Instruments, Inc.

CPT Software Copyright © 1992–2019 Gamry Instruments, Inc.

Explain Computer Language Copyright © 1989–2019 Gamry Instruments, Inc.

Gamry, Explain, Gamry Framework, CPT, and TDC5 are trademarks of Gamry Instruments, Inc.

Windows and Excel® are registered trademarks of Microsoft Corporation. OMEGA® is a registered

trademark of OMEGA ENGINEERING, INC.

No part of this document may be copied or reproduced in any form without the prior written consent of

Gamry Instruments, Inc.

4

5

Table of Contents

Limited Warranty ........................................................................................................................... 1

If You Have Problems .................................................................................................................... 2

Disclaimers .................................................................................................................................... 3

Copyrights and Trademarks ............................................................................................................ 3

Chapter 1: Safety Considerations .................................................................................................... 7

Introduction ...................................................................................................................... 7

Inspection ......................................................................................................................... 7

Line Voltages .................................................................................................................... 8

Switched AC Outlet Fuses ................................................................................................. 8

TDC5 Electrical Outlet Safety ............................................................................................ 8

Heater Safety .................................................................................................................... 9

RFI Warning...................................................................................................................... 9

Electrical Transient Sensitivity ............................................................................................ 9

Chapter 2: Installation ................................................................................................................... 11

Initial Visual Inspection ..................................................................................................... 11

Unpacking Your TDC5 ...................................................................................................... 11

Physical Location .............................................................................................................. 11

Differences Between an Omega CS8DPT and a TDC5 ....................................................... 12

Power-up Check ............................................................................................................... 13

USB Cable ........................................................................................................................ 14

Using Device Manager to Install TDC5 .............................................................................. 14

Connecting the TDC5 to a Heater or Cooler ...................................................................... 16

Connecting the TDC5 to an RTD Probe ............................................................................. 17

Cell Cables from the Potentiostat ....................................................................................... 17

Setting up the TDC5 Operating Modes .............................................................................. 17

Checking TDC5 Operation ................................................................................................ 18

Chapter 3: Use ............................................................................................................................. 19

Using Framework Scripts to Set Up and Control Your TDC5 ............................................... 19

Thermal Design of Your Experiment .................................................................................. 19

Tuning the TDC5 Temperature Controller: Overview ......................................................... 20

When to Tune .................................................................................................................. 20

Restoring Factory Settings .................................................................................................. 21

Automatic versus Manual Tuning ....................................................................................... 22

Auto Tuning the TDC5 ...................................................................................................... 22

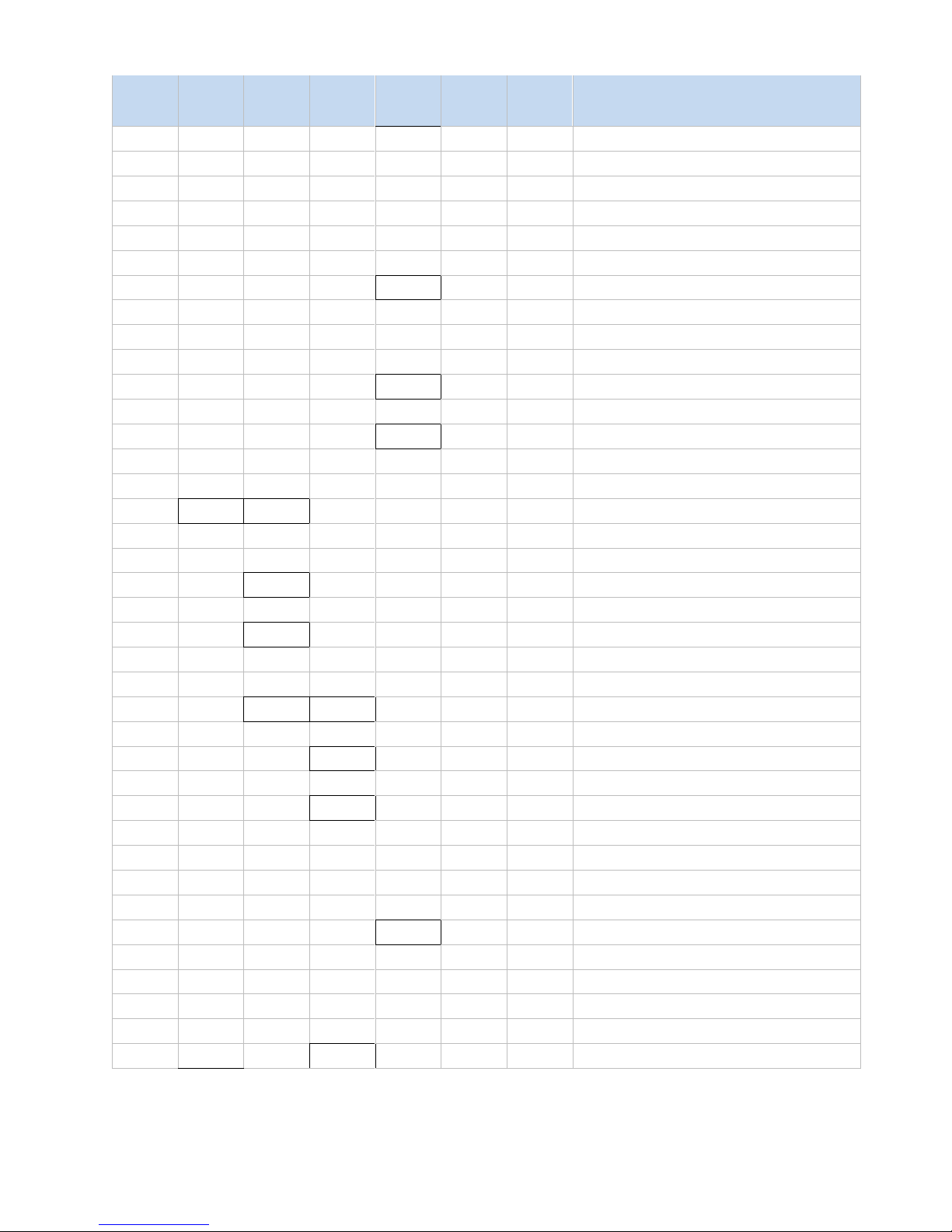

Appendix A: Default Controller Configuration ................................................................................. 23

Initialization Mode Menu .................................................................................................. 23

Programming Mode Menu ................................................................................................ 27

Changes that Gamry Instruments Has Made to Default Settings .......................................... 31

Index ............................................................................................................................................. 33

6

Chapter 1: Safety Considerations

7

Chapter 1: Safety Considerations

Introduction

The Gamry Instruments TDC5 is based on a standard temperature controller, the Omega Engineering Inc.

Model CS8DPT. Gamry Instruments has performed slight modifications of this unit to allow easier incorporation

of it into an electrochemical test system.

Omega provides a User’s Guide that covers safety issues in detail. In most cases, the Omega information is not

duplicated here. If you do not have a copy of this document, contact Omega at http://www.omega.com.

Your TDC5 Temperature Controller has been supplied in a safe condition. Consult the Omega User’s Guide to

ensure continued safe operation of this device.

Inspection

When you receive your TDC5 Temperature Controller, inspect it for evidence of shipping damage. If you note

any damage, please notify Gamry Instruments Inc. and the shipping carrier immediately. Save the shipping

container for possible inspection by the carrier.

As defined in IEC Publication 348, Safety Requirements for Electronic Measuring Apparatus, the TDC5 is a Class

I apparatus. Class I apparatus is only safe from electrical shock hazards if the case of the apparatus is connected

to a protective earth ground.

In the TDC5 this protective ground connection is made via the ground prong in the AC line cord. When you

use the TDC5 with an approved line cord, the connection to the protective earth ground is automatically made

prior to making any power connections.

The TDC5 is supplied with a line cord suitable for use in the United States. In other countries, you may have to

replace the line cord with one suitable for your electrical outlet type. You must always use a line cord with a

Warning: If the protective ground is not properly connected, it creates a safety hazard,

which could result in personnel injury or death. Do not negate the protection of this earth ground by any

means. Do not use the TDC5 with a 2 wire extension cord, with an adapter that does not provide for

protective grounding, or with an electrical outlet that is not properly wired with a protective earth ground.

Warning: A TDC5 Temperature Controller damaged in shipment can be a safety hazard.

The protective grounding can be rendered ineffective if the TDC5 is damaged in shipment. Do not operate

damaged apparatus until a qualified service technician has verified its safety. Tag a damaged TDC5 to

indicate that it could be a safety hazard.

Chapter 1: Safety Considerations

8

CEE 22 Standard V female connector on the instrument end of the cable. This is the same connector used on

the US standard line cord supplied with your TDC5. Omega Engineering (http://www.omega.com) is one source

for international line cords, as described in their User’s Guide.

The wiring polarity of a properly wired connector is shown in the Table 1-1 for both US line cords and

European line cords that follow the “harmonized” wiring convention.

Table 1-1

Line Cord Polarities and Colors

If you have any doubts about the line cord for use with your TDC5, please contact a qualified electrician or

instrument service technician for assistance. The qualified person can perform a simple continuity check that

can verify the connection of the TDC5 chassis to earth and thereby check the safety of your TDC5 installation.

Line Voltages

The TDC5 is designed to operate at AC line voltages between 90 and 240 VAC, 50 or 60 Hz. No modification

of the TDC5 is required when switching between US and international AC line voltages.

Switched AC Outlet Fuses

Both of the switched outlets on the back of the TDC5 have fuses above and to the left of the outputs. In

accordance with international safety standards, both the line and neutral connections are fused. For Output 1,

the maximum allowed fuse rating is 3 A; for Output 2, the maximum allowed fuse is 5A.

The TDC5 is provided with 3 A and 5 A, fast-blow, 5 × 20 mm fuses in the switched outlets.

You may wish to tailor the fuses in each outlet for the expected load. For example, if you are using a 200 W

cartridge heater with a 120 VAC power line, the nominal current is a bit less than 2 A. You may want to use a

2.5 A or 3 A fuse in the switched outlet to the heater. Keeping the fuse rating just above the rated power can

prevent or minimize damage to an improperly operated heater.

TDC5 Electrical Outlet Safety

The TDC5 has two switched electrical outlets on the rear panel of its enclosure. These outlets are under the

control of the TDC5’s controller module or a remote computer. For safety considerations, whenever the TDC5

is powered, you must treat these outlets as being on.

Line

Neutral

Earth Ground

US

Black

White

Green

European

Brown

Light Blue

Green/Yellow

Warning: If you replace the line cord, you must use a line cord rated to carry at least 15 A

of AC current. If you replace the line cord you must use a line cord with the same polarity as that supplied

with the TDC5. An improper line cord can create a safety hazard, which could result in injury or death.

Chapter 1: Safety Considerations

9

In most cases, the TDC5 will power one or both of these outlets when it is first powered up.

Heater Safety

The TDC5 Temperature Controller is often used to control an electrical heating apparatus that is located on or

very near to an electrochemical cell filled with electrolyte. This can represent a significant safety hazard unless

care is taken to insure that the heater has no exposed wires or contacts.

RFI Warning

Your TDC5 Temperature Controller generates, uses, and can radiate radio-frequency energy. The radiated

levels are low enough that the TDC5 should present no interference problem in most industrial laboratory

environments. The TDC5 may cause radio-frequency interference if operated in a residential environment.

Electrical Transient Sensitivity

Your TDC5 Temperature Controller was designed to offer reasonable immunity from electrical transients.

However, in severe cases, the TDC5 could malfunction or even suffer damage from electrical transients. If you

are having problems in this regard, the following steps may help:

If the problem is static electricity (sparks are apparent when you touch the TDC5:

Placing your TDC5 on a static control work surface may help. Static-control work surfaces are now generally

available from computer supply houses and electronics tool suppliers. An antistatic floor mat may also help,

particularly if a carpet is involved in generating the static electricity.

Air ionizers or even simple air humidifiers can reduce the voltage available in static discharges.

Warning: An AC-powered heater connected to a cell containing electrolyte can represent a

significant electrical-shock hazard. Make sure that there are no exposed wires or connections in your heater

circuit. Even cracked insulation can be a real hazard when salt water is spilled on a wire.

Warning: The switched electrical outlets on the TDC5 rear panel must always be treated as

on whenever the TDC5 is powered. Remove the TDC5 line cord if you must work with a wire in contact

with these outlets. Do not trust that the control signals for these outlets, when off, remains off. Do not

touch any wire connected to these outlets unless the TDC5 line cord has been disconnected.

Chapter 1: Safety Considerations

10

If the problem is AC power-line transients (often from large electrical motors near the TDC5):

Try plugging your TDC5 into a different AC-power branch circuit.

Plug your TDC5 into a power-line surge suppressor. Inexpensive surge suppressors are now generally available

because of their use with computer equipment.

Contact Gamry Instruments, Inc. if these measures do not solve the problem.

Chapter 2: Installation

11

Chapter 2: Installation

This chapter covers normal installation of the TDC5 Temperature Controller. The TDC5 was designed to run the

experiments in the Gamry Instruments CPT Critical Pitting Test System, but it is also useful for other purposes.

The TDC5 is an Omega Engineering Inc., Model CS8DPT Temperature Controller. Please review the Omega

User’s Guide to familiarize yourself with the operation of the temperature controller.

Initial Visual Inspection

After you remove your TDC5 from its shipping carton, check it for any signs of shipping damage. If any damage

is noted, please notify Gamry Instruments, Inc. and the shipping carrier immediately. Save the shipping

container for possible inspection by the carrier.

Unpacking Your TDC5

The following list of items should be supplied with your TDC5:

Qty Gamry P/N Omega P/N Description

1 990-00491 Gamry TDC5 (modified Omega CS8DPT)

1 988-00072 Gamry TDC5 Operator’s Manual (this document)

1 720-00078 Main Power Cord, USA version

1 985-00192 USB 3.0 type A male/male cable, 6 ft.

1 M4640 Omega User’s Guide

1 990-00055 RTD Probe

1 720-00016 TDC5 Adapter for RTD cable

Contact your local Gamry Instruments representative if you cannot find any of these items in your shipping

containers.

Physical Location

You can place your TDC5 on a normal workbench surface. You will need access to the rear of the instrument

because power connections are made from the rear. The TDC5 is not restricted to operation in a flat position.

You can operate it on its side, or even upside-down.

Warning: The protective grounding can be rendered ineffective if the TDC5 is damaged

in shipment. Do not operate damaged apparatus until its safety has been verified by a qualified service

technician. Tag a damaged TDC5 to indicate that it could be a safety hazard.

Chapter 2: Installation

12

Differences Between an Omega CS8DPT and a TDC5

Hardware Differences

A Gamry Instruments TDC5 has one

addition compared to an unmodified

Omega CS8DPT: A new connector is

added to the front panel. It is a

three-pin connector used for a threewire 100 Ω platinum RTD. The RTD

connector is wired in parallel with

the input terminal strip on the

Omega CS8DPT. You can still make

use of the full range of input

connections.

Firmware Differences

The firmware configuration settings for the PID (proportional, integrating and derivative) controller in the TDC5

are changed from the Omega defaults. See Appendix A for details. Basically, Gamry Instruments’ controller

setup includes:

Configuration for operation with a three-wire 100 Ω platinum RTD as the temperature sensor,

PID tuning values appropriate for a Gamry Instruments Flexcell™ with a 300 W heating jacket and active

cooling through the Flexcell’s heating coil.

AC Line Connection

The TDC5 is designed to operate at AC line voltages between 90 and 240 VAC, 50 or 60 Hz. You must use a

suitable AC power cord to connect the TDC5 to your AC power

source (mains).

Your TDC5 was shipped with a USA-type AC power input cord. If you

need a different power cord, you may obtain one locally or contact

Omega Engineering Inc. (http://www.omega.com).

The power cord using with the TDC5 must terminate with a CEE 22

Standard V female connector on the instrument end of the cable and

If you make other input connections:

• Be careful to avoid connecting two input devices, one to the 3-pin Gamry connector and one to

the terminal strip. Unplug the RTD from its connector if you connect any sensor to the input

terminal strip.

• You must reconfigure the controller for the alternate input. Consult the Omega manual for

additional details.

must be rated for 10 A service.

Make sure that a newly installed TDC5 has no connection to its switched OUTPUT outlets

when it is first powered. You want to verify that the TDC5 powers up correctly before you add the

complexity of external devices.

Warning: If you replace the line cord you must use a line cord rated to carry at least 10

A of AC current. An improper line cord can create a safety hazard, which could result in injury or death.

Power-up Check

After the TDC5 is

connected to an

appropriate AC voltage

source, you can turn it on

to verify its basic operation.

The power switch is a large

rocker switch on the left

side of the rear panel.

Chapter 2: Installation

When the TDC5 is powered up, the temperature controller should light up and display a couple of status

messages. Each message will be displayed for a few seconds.

If you connected an RTD to the unit, the upper display should show the current temperature at the probe (the

units are degrees Celsius). If you do not have a probe installed, the upper display should show a line containing

the characters oPER, as shown below:

Once the unit has powered up correctly, turn it off before making the remaining system connections.

13

Chapter 2: Installation

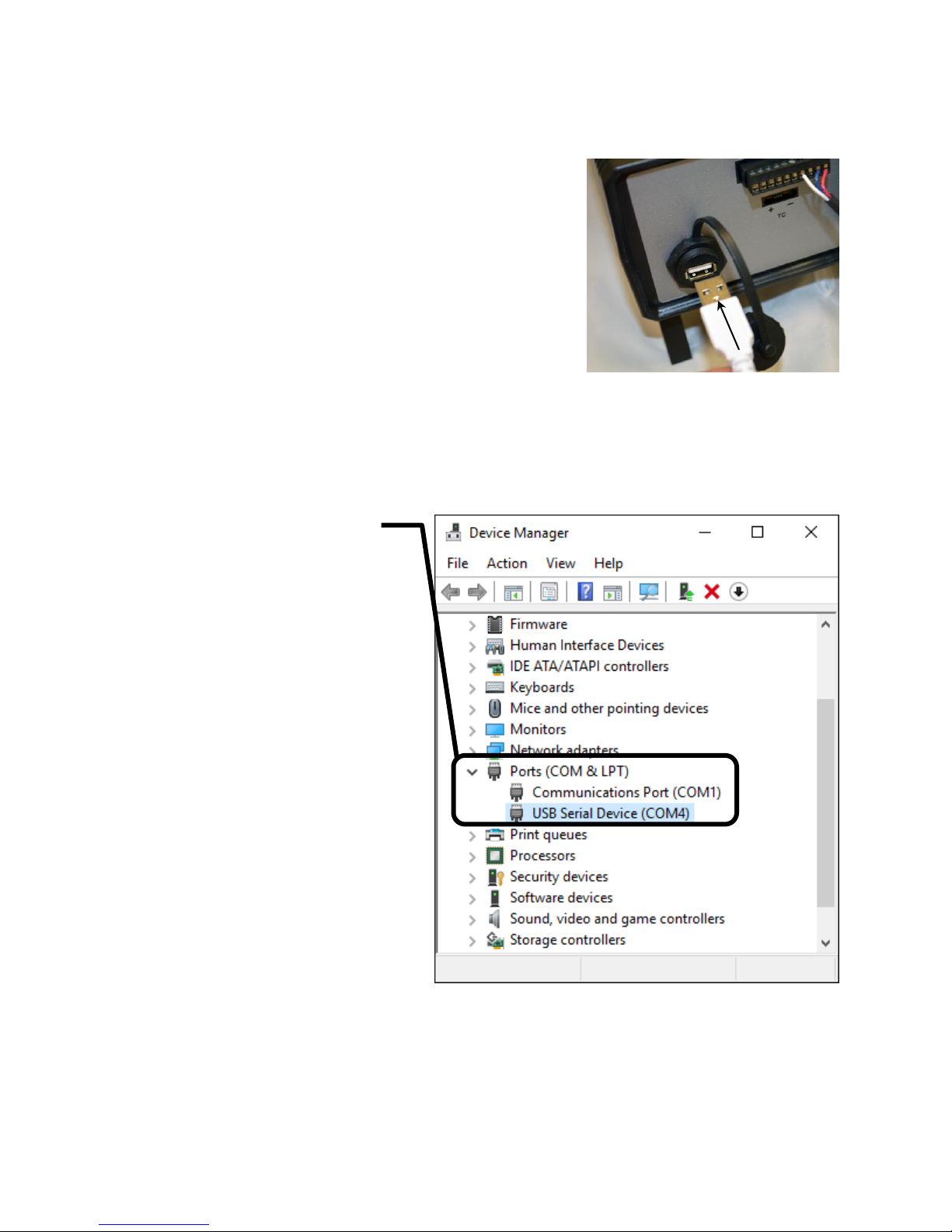

USB Cable

Connect the USB cable between the USB Type-A port on the front

panel of the TDC5 and a USB Type-A port on your host computer.

The supplied cable for this connection is a dual-ended USB Type-A

cable. Type A is a rectangular connector. (Type B is an almost square

USB connector.)

Using Device Manager to Install TDC5

1. After the TDC5 is plugged into an available USB port on the host computer, turn on the host computer.

2. Log into your user account.

3. Run Device Manager on the host computer.

In Windows® 7, you can find Device Manager in the Control Panel. In Windows® 10, you can find it by

searching in the Windows® search box.

4. Expand the Ports section in Device

Manager as shown.

5. Turn on the TDC5 and look for a new

entry that suddenly appears under Ports.

This entry will tell you the COM number

associated with the TDC5. Take note of

this for use during installation of the

Gamry Instruments software.

6. If the COM port is higher than number 8,

decide on a port number less than 8.

7. Right-click on the new USB Serial Device

that suddenly appeared, and select

Properties.

A USB Serial Device Properties window

like the one shown on the next page

appears.

14

8. Select the Port Settings tab.

9. Click the Advanced… button.

The Advanced Settings for COMx dialog box

appears as shown below. (Here x stands for the

particular port number you have chosen.)

Chapter 2: Installation

10. Select a new COM Port Number from the drop-down menu.

Select a number of 8 or less. You do not

need to change any other settings. After

you have made a selection, remember

this number to use during the Gamry

Software Installation.

11. Click the OK buttons on the two open

dialog boxes to close them.

12. Close the Device Manager by clicking on

the X in the upper right-hand corner.

13. Proceed with the Gamry Software

Installation.

14. Make sure to select Temperature

Controllers in the Select Features dialog

box during installation:

15

15. During installation, be sure

Warning: An AC-powered heater connected to a cell containing electrolyte can

represent a significant electrical-shock hazard. Make sure that there are no exposed wires or connections in

your heater circuit. Even cracked insulation can be a hazard when salt water is spilled on a wire.

to choose the TDC5 in the

Temperature Controller

Configurations Type drop-

down menu. Choose the

correct COM port that you

noted down earlier.

Chapter 2: Installation

Connecting the TDC5 to a Heater or Cooler

There are many ways to heat an electrochemical cell. These include an immersible heater in the electrolyte,

heating tape surrounding the cell, or a heating mantle. The TDC5 can be used with all these types of heaters, as

long as they are AC-powered.

The AC power for the heater is drawn from Output 1 on the rear panel of the TDC5. This output is a IEC Type

B female connector (common in the USA and Canada). Electrical cords with the corresponding male connector

are available worldwide.

Please check that the fuse on Output 1 is appropriate for use with your heater. The TDC5 is shipped with a 3 A

Output 1 fuse already installed.

In addition to controlling a heater, the TDC5 can control a cooling device. The AC power for the cooler is

drawn from the outlet labeled Output 2 on the rear of the TDC5.

The cooling device can be as simple as a solenoid valve in a cold-water line leading to a water jacket

surrounding the cell. Another common cooling device is the compressor in a refrigeration unit.

Before connecting a cooling device to the TDC5, verify that the Output 2 fuse is the correct value for your

cooling device. The TDC5 is shipped with a 5 A Output 2 fuse already installed.

16

Chapter 2: Installation

Please refer to the Omega documentation supplied with your TDC5 for information about

the various controller parameters. Do not change a parameter without some knowledge of that parameter’s

effect on the controller.

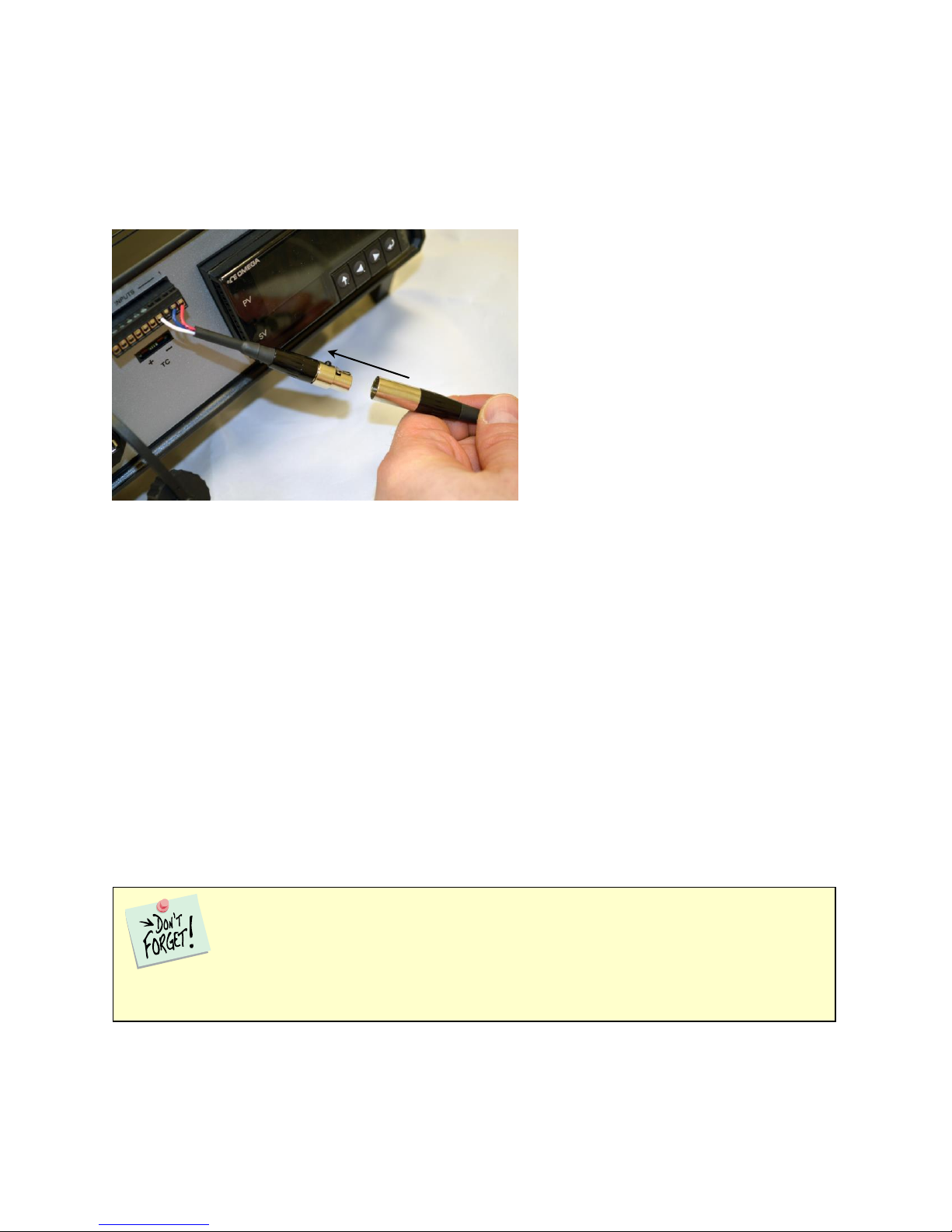

Connecting the TDC5 to an RTD Probe

The TDC5 must be able to measure the temperature before it can control it. The TDC5 uses a platinum RTD to

measure the cell temperature. A suitable RTD is supplied with the TDC5. This sensor plugs into adapter cable

supplied with your TDC5:

Contact Gamry Instruments, Inc. at our US facility if you need to substitute a third-party RTD into a CPT

system.

Place the active end of the RTD as close as possible to the working electrode in your cell. This minimizes the

effect of thermal gradients on the control accuracy.

Cell Cables from the Potentiostat

A TDC5 in your system does not affect the cell cable connections. These connections are made directly from

the potentiostat to the cell. Please read the your potentiostat’s Operator’s Manual for cell cable instructions.

Setting up the TDC5 Operating Modes

The PID controller built into the TDC5 has a number of different operating modes, each of which is configured

by means of user-entered parameters.

The TDC5 is shipped with default settings appropriate for heating and cooling a Gamry Instruments FlexCell

using a 300 W heating jacket and a solenoid-controlled cold-water flow for cooling.

Appendix A lists the factory TDC5 settings.

17

Chapter 2: Installation

18

Checking TDC5 Operation

To test the operation of the TDC5, run a simple check-out script provided with the CPT Critical Pitting Test

System. The name of this script is CHECK110.EXP. Use the procedure in the CPT Installation Manual to

perform this checkout.

Chapter 3: Use

19

Chapter 3: Use

This chapter covers normal use of the TDC5 Temperature Controller. The TDC5 is intended primarily for use in

the Gamry Instruments CPT Critical Pitting Test System. It should also prove useful in other applications.

The TDC5 is based on the Omega CS8DPT temperature controller. Please read the Omega documentation to

familiarize yourself with the operation of this apparatus.

Using Framework Scripts to Set Up and Control Your TDC5

For your convenience, the Gamry Instruments Framework™ software includes a number of Explain™ scripts that

simplify setup and tuning of the TDC5. These scripts include:

TDC5 Start Auto Tune.exp

Used to start the controller auto-tune process

TDC5 Initialize Settings.exp

Restores the TDC5 to the factory default settings

There is one downside to using these scripts. They only run on a computer that has a Gamry Instruments

potentiostat installed in the system and currently connected. If you do not have a potentiostat in the system, the

script will show an error message and terminate before it outputs anything to the TDC5.

Thermal Design of Your Experiment

The TDC5 is used to control the temperature of a electrochemical cell. It does so by turning on and off a heat

source that transfers heat to the cell. Optionally, a cooler can be used to remove heat from the cell. In either

case, the TDC5 switches AC power to the heater or cooler to control the direction of any transfer of heat.

The TDC5 is a closed-loop system. It measures the temperature of the cell and uses feedback to control the

heater and cooler.

Two major thermal problems are present to some degree in all system designs:

The first problem is temperature gradients in the cell. They are invariably present. However, they can be

minimized by proper cell design.

You cannot run any TDC5 script on a computer that does not include a Gamry Instruments

potentiostat.

Tuning the TDC5 so that it works optimally on your experimental setup is very difficult using

the front-panel controls of the TDC5. We strongly recommend that you use the scripts listed above to tune

your TDC5.

Chapter 3: Use

Stirring the electrolyte helps a great deal.

The heater should have a large area of contact with the cell. Water jackets are good in this regard. Cartridge

type heaters are poor.

Insulation surrounding the cell may minimize inhomogeneities by slowing the loss of heat through the walls of

the cell. This is especially true near the working electrode, which may represent the major pathway of escaping

heat. It is not unusual to find the electrolyte temperature near the working electrode 5–20C lower than that of

the bulk of the electrolyte.

If you cannot prevent thermal inhomogenieties, you can at least minimize their effects. One important design

consideration is the placement of the RTD used to sense the cell temperature. Place the RTD as close as

possible to the working electrode. This minimizes the error between the actual temperature at the working

electrode and the temperature setting.

A second problem concerns the rate of temperature change. You would like to have the rate of heat transfer to

the cell’s contents high, so that changes in the cell’s temperature can be made quickly. A more subtle point is

that the rate of heat loss from the cell should also be high. If it is not, the controller risks gross overshoots of the

set point temperature when it raises the cell temperature. Ideally, the system actively cools the cell as well as

heats it. Active cooling can consist of a system as simple as tap water flowing through a cooling coil and a

solenoid valve. Temperature control via an external heater such as a heating mantle is moderately slow. An

internal heater, such as a cartridge heater is often quicker.

Tuning the TDC5 Temperature Controller: Overview

Closed-loop control systems such as the TDC5 must be tuned for optimal performance. A poorly tuned system

suffers from slow response, overshoot, and poor accuracy. The tuning parameters depend greatly on the

characteristics of the system being controlled.

The temperature controller in the TDC5 can be used in an ON/OFF mode or a PID (Proportional, Integral,

Derivative) mode. The ON/OFF mode uses hysteresis parameters to control its switching. The PID mode uses

tuning parameters. The controller in PID mode reaches the set-point temperature quickly without much

overshoot and maintains that temperature within a closer tolerance than the ON/OFF mode.

When to Tune

The TDC5 is normally operated in PID (proportional, integrating, derivative) mode. This is a standard method

for process-control equipment that allows for rapid changes in the set parameter. In this mode the TDC5 must

be tuned to match it to the thermal characteristics of the system that it is controlling.

The TDC5 is shipped in a default for PID-control mode configuration. You must explicitly change it to operate

in any other control mode.

The TDC5 is initially configured with parameters appropriate for a Gamry Instruments FlexCell™ heated with a

300 W jacket and cooled using solenoid-valve controlling water-flow through a cooling coil. The tuning settings

are described below:

20

Chapter 3: Use

21

FACTORY-SET TUNING PARAMETERS

Retune your TDC5 with your cell system before you use it to run any real tests. Retune whenever you make

major changes in the thermal behavior of your system. Typical changes that may require retuning include:

Changing to a different cell,

Addition of thermal insulation to the cell,

Addition of a cooling coil,

Changing the position or power of the heater, or

Changing from an aqueous electrolyte to an organic electrolyte.

In general you do not have to retune when switching from one aqueous electrolyte to another. Tuning is

therefore only an issue when you first set up your system. After the controller has been tuned for your system,

you may ignore tuning as long as your experimental setup remains relatively constant.

Restoring Factory Settings

The TDC5 is configured using many settings (fully listed in Appendix A) which can be entered by a complicated

user interface using the four buttons on the front of the TDC5. We anticipate that anyone using this interface is

likely to scramble the TDC5 settings at least once. Various “automatic” TDC5 operations could also result in

incorrect settings, especially if they are interrupted in mid-operation.

Re-entering all the default settings manually would be time-consuming and error-prone. For this reason, Gamry

Instruments has provided an Explain script that resets all TDC5 settings to the default settings:

Start the Gamry Instruments Framework™ software.

Select Experiment > Named Script… > TDC5 Initialize Settings.exp from the Framework menu. (The

Framework script that resets the TDC5 is TDC5 Initialize Settings.exp).

When this script runs, it displays a TDC5 Quality Check window similar to that in Figure 3-1.

Figure 3-1. Initial Dialog Box Displayed by a TDC5 Script

When you click the OK button, the script sends configuration data to the TDC5.

Parameter (Symbol)

Setting

Proportional Band 1

9C

Reset 1

685 s

Rate 1

109 s

Cycle Time 1

1 s

Dead Band

14 db

Chapter 3: Use

Parameter (Symbol)

Setting

Proportional Band 1

9C

Reset 1

685 s

Rate 1

109 s

Cycle Time 1

1 s

Dead Band (db)

14

This process should take less than one minute. At the end of the transfer process, a second dialog box, similar to

Figure 3-2, appears.

Figure 3-2. Final Dialog Box Displayed by a TDC5 Script

Click the OK button to end the reset process.

Automatic versus Manual Tuning

Tune your TDC5 automatically whenever possible.

Unfortunately, the system response with many electrochemical cells is too slow for auto tuning. You cannot

auto tune if a 5C increase or decrease in the system temperature takes more than ten minutes. In most cases,

auto tune on an electrochemical cell will fail unless the system is actively cooled.

A full description of the manual tuning of PID controllers is beyond the scope of this manual. However, a later

section of this chapter does give a relatively simple step-by-step procedure for manually tuning the TDC5.

The following table contains the tuning parameters for a Gamry Instruments Flex Cell used with a 300 W

heating mantle and switched cooling using water flow though the standard cooling coil. The solution was stirred.

Auto Tuning the TDC5

We strongly recommend that you auto-tune the TDC5 as explained in the Omega® User’s Guide, section 4.6.2.

22

Appendix A: Default Controller Configuration

Level

2

Level

3

Level

4

Level

5

Level

6

Level

7

Level

8

Notes

INPt

t.C.

k

Type K thermocouple

J

Type J thermocouple

t

Type T thermocouple

E

Type E thermocouple

N

Type N thermocouple

R

Type R thermocouple

S

Type S thermocouple

b

Type B thermocouple

C

Type C thermocouple

Rtd

N.wIR

3 wI

3-wire RTD

4 wI

4-wire RTD

2 wI

2-wire RTD

A.CRV

385.1

385 calibration curve, 100 Ω

385.5

385 calibration curve, 500 Ω

385.t

385 calibration curve, 1000 Ω

392

392 calibration curve, 100 Ω

391.6

391.6 calibration curve, 100 Ω

tHRM

2.25k

2250 Ω thermistor

5k

5000 Ω thermistor

10k

10,000 Ω thermistor

PRoC

4–20

Process input range: 4 to 20 mA

Note: This Manual and Live Scaling submenu is the same for all PRoC

ranges.

MANL

Rd.1

Low display reading

IN.1

Manual input for Rd.1

Rd.2

High display reading

IN.2

Manual input for Rd.2

LIVE

Rd.1

Low display reading

IN.1

Live Rd.1 input, ENTER for current

Rd.2

High display reading

IN.2

Live Rd.2 input, ENTER for current

0–24

Process input range: 0 to 24 mA

+-10

Process input range: -10 to +10 V

Note: +- 1.0 and +-0.1 support SNGL, dIFF and RtIO tYPE

+-1

tYPE

SNGL

Process input range: -1 to +1 V

Appendix A: Default Controller Configuration

Initialization Mode Menu

23

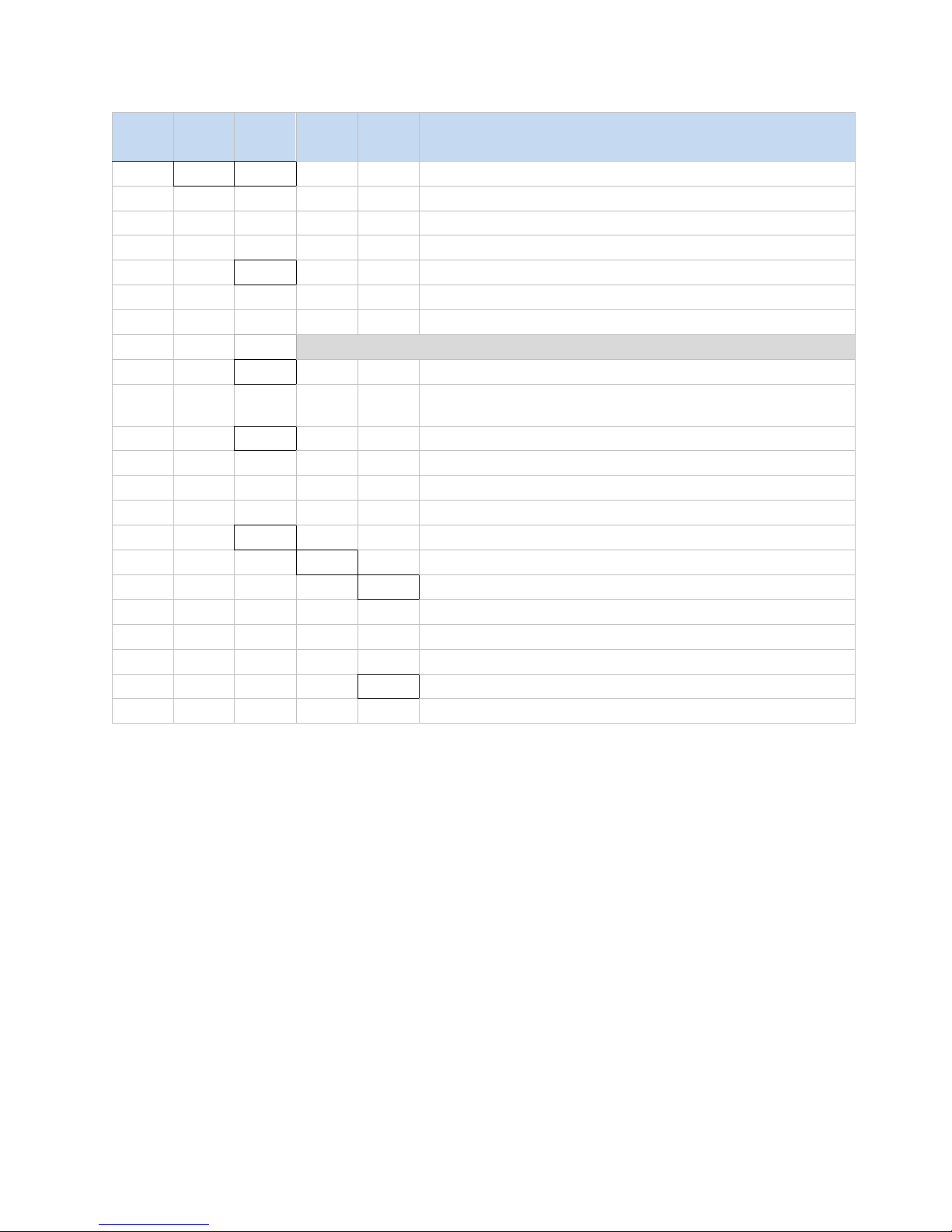

Appendix A: Default Controller Configuration

Level

2

Level

3

Level

4

Level

5

Level

6

Level

7

Level

8

Notes

dIFF

Differential between AIN+ and AIN-

RtLO

Ratiometric between AIN+ and AIN-

+-0.1

Process input range: -0.1 to +0.1 V

Note: The +- 0.05 input supports dIFF and RtIO tYPE

+-.05

tYPE

dIFF

Differential between AIN+ and AIN-

RtLO

Ratiometric between AIN+ and AIN-

Process input range: -0.05 to +0.05 V

tARE

dSbL

Disable tARE feature

ENbL

Enable tARE on oPER menu

RMt

Enable tARE on oPER and Digital Input

LINR

N.PNt

Specifies the number of points to use

Note: The Manual / Live inputs repeat from 1..10, represented by n

MANL

Rd.n

Low display reading

IN.n

Manual input for Rd.n

LIVE

Rd.n

Low display reading

IN.n

Live Rd.n input, ENTER for current

RdG

dEC.P

FFF.F

Reading format -999.9 to +999.9

FFFF

Reading format -9999 to +9999

FF.FF

Reading format -99.99 to +99.99

F.FFF

Reading format -9.999 to +9.999

°F°C

°C

Degrees Celsius annunciator

°F

Degrees Fahrenheit annunciator

NoNE

Turns off for non-temperature units

d.RNd

Display Rounding

FLtR

8

Readings per displayed value: 8

16

16

32

32

64

64

128

128

1 2 2

3

4

4

Note: Four digit displays offer 2 annunciators, Six digit displays offer 6

ANN.n

ALM.1

Alarm 1 status mapped to “1”

ALM.2

Alarm 2 status mapped to “1”

oUt#

Output state selections by name

NCLR

GRN

Default display color: Green

REd

Red

24

Appendix A: Default Controller Configuration

Level

2

Level

3

Level

4

Level

5

Level

6

Level

7

Level

8

Notes

AMbR

Amber

bRGt

HIGH

High display brightness

MEd

Medium display brightness

Low

Low display brightness

ECtN

5 V

Excitation voltage: 5 V

10 V

10 V

12 V

12 V

24 V

24 V

0 V

Excitation off

CoMM

USb

Configure the USB port

Note: This PRot submenu is the same for USB, Ethernet, and Serial ports.

PRot

oMEG

ModE

CMd

Waits for commands from other end

CoNt

Transmit continuously every ###.#

sec

dAt.F

StAt

No

yES

Includes Alarm status bytes

RdNG

yES

Includes process reading

No

PEAk

No

yES

Includes highest process reading

VALy

No

yES

Includes lowest process reading

UNIt

No

yES

Send unit with value (F, C, V, mV, mA)

_LF_

No

yES

Appends line feed after each send

ECHo

yES

Retransmits received commands

No

SEPR

_CR_

Carriage Return separator in CoNt

SPCE

Space separator in CoNt Mode

M.bUS

RtU

Standard Modbus protocol

ASCI

Omega ASCII protocol

AddR

USB requires Address

EtHN

PRot

Ethernet port configuration

AddR

Ethernet “Telnet” requires Address

SER

PRot

Serial port configuration

C.PAR

bUS.F

232C

Single device Serial Comm Mode

485

Multiple devices Serial Comm Mode

bAUd

19.2

Baud rate: 19,200 Bd

25

Appendix A: Default Controller Configuration

Level

2

Level

3

Level

4

Level

5

Level

6

Level

7

Level

8

Notes

9600

9,600 Bd

4800

4,800 Bd

2400

2,400 Bd

1200

1,200 Bd

57.6

57,600 Bd

115.2

115,200 Bd

PRty

odd

Odd parity check used

EVEN

Even parity check used

NoNE

No parity bit is used

oFF

Parity bit is fixed as a zero

dAtA

8bIt

8 bit data format

7bIt

7 bit data format

StoP

1bIt

1 stop bit

2bIt

2 stop bits gives a “force 1” parity bit

AddR

Address for 485, placeholder for 232

SFty

PwoN

RSM

RUN on power up if not previously faulted

wAIt

Power on: oPER Mode, ENTER to run

RUN

RUN’s automatically on power up

RUN.M

dSbL

ENTER in Stby, PAUS, StoP runs

ENbL

ENTER in modes above displays RUN

SP.LM

SP.Lo

Low Setpoint limit

SP.HI

High Setpoint limit

SEN.M

Sensor Monitor

LPbk

dSbL

Loop break timeout disabled

ENbL

Loop break timeout value (MM.SS)

o.CRk

ENbl

Open Input circuit detection enabled

dSbL

Open Input circuit detection disabled

E.LAt

ENbl

Latch sensor error enabled

dSbL

Latch sensor error disabled

OUT.M

Output Monitor

oUt1

oUt1 is replaced by output type

o.bRk

Output break detection

dSbL

Output break detection disabled

ENbl

P.dEV

Output break process deviation

P.tME

Output break time deviation

oUt2

oUt2 is replaced by output type

oUt3

oUt3 is replaced by output type

E.LAt

ENbl

Latch output error enabled

26

Appendix A: Default Controller Configuration

Level

2

Level

3

Level

4

Level

5

Level

6

Notes

SP1

Process goal for PID, default goal for oN.oF

SP2

ASbo

Setpoint 2 value can track SP1, SP2 is an absolute value

dEVI

SP2 is a deviation value

ALM.1

Note: This submenu is the same for all other Alarm configurations.

tyPE

oFF

ALM.1 is not used for display or outputs

AboV

Alarm: process value above Alarm trigger

bELo

Alarm: process value below Alarm trigger

HI.Lo.

Alarm: process value outside Alarm triggers

bANd

Alarm: process value between Alarm triggers

Ab.dV

AbSo

Absolute Mode; use ALR.H and ALR.L as triggers

d.SP1

Deviation Mode; triggers are deviations from SP1

d.SP2

Deviation Mode; triggers are deviations from SP2

CN.SP

Tracks the Ramp & Soak instantaneous setpoint

ALR.H

Alarm high parameter for trigger calculations

ALR.L

Alarm low parameter for trigger calculations

A.CLR

REd

Red display when Alarm is active

AMbR

Amber display when Alarm is active

dEFt

Color does not change for Alarm

HI.HI

oFF

High High / Low Low Alarm Mode turned off

Level 2

Level 3

Level 4

Level 5

Level 6

Level 7

Level 8

Notes

dSbL

Latch output error disabled

t.CAL

NoNE

Manual temperature calibration

1.PNt

Set offset, default = 0

2.PNt

R.Lo

Set range low point, default = 0

R.HI

Set range high point, default = 999.9

ICE.P

ok?

Reset 32°F/0°C reference value

dSbL

Clears the ICE.P offset value

SAVE

_____

Download current settings to USB

LoAd

_____

Upload settings from USB stick

VER.N

1.00.0

Displays firmware revision number

VER.U

ok?

ENTER downloads firmware update

F.dFt

ok?

ENTER resets to factory defaults

I.Pwd

No

No required password for INIt Mode

yES

_____

Set password for INIt Mode

P.Pwd

No

No password for PRoG Mode

yES

_____

Set password for PRoG Mode

Programming Mode Menu

27

Appendix A: Default Controller Configuration

Level

2

Level

3

Level

4

Level

5

Level

6

Notes

GRN

Green display when Alarm is active

oN

Offset value for active High High / Low Low Mode

LtCH

No

Alarm does not latch

yES

Alarm latches until cleared via front panel

botH

Alarm latches, cleared via front panel or digital input

RMt

Alarm latches until cleared via digital input

CtCL

N.o.

Output activated with Alarm

N.C.

Output deactivated with Alarm

A.P.oN

yES

Alarm active at power on

No

Alarm inactive at power on

dE.oN

Delay turning off Alarm (sec), default = 1.0

dE.oF

Delay turning off Alarm (sec), default = 0.0

ALM.2

Alarm 2

oUt1

oUt1 is replaced by output type

Note: This submenu is the same for all other outputs.

ModE

oFF

Output does nothing

PId

PID Control Mode

ACtN

RVRS

Reverse acting control (heating)

dRCt

Direct acting control (cooling)

RV.DR

Reverse/Direct acting control (heating/cooling)

PId.2

PID 2 Control Mode

ACtN

RVRS

Reverse acting control (heating)

dRCt

Direct acting control (cooling)

RV.DR

Reverse/Direct acting control (heating/cooling)

oN.oF

ACtN

RVRS

Off when > SP1, on when < SP1

dRCt

Off when < SP1, on when > SP1

dEAd

Deadband value, default = 5

S.PNt

SP1

Either Setpoint can be used of on/off, default is SP1

SP2

Specifying SP2 allows two outputs to be set for heat/cool

ALM.1

Output is an Alarm using ALM.1 configuration

ALM.2

Output is an Alarm using ALM.2 configuration

RtRN

Rd1

Process value for oUt1

oUt1

Output value for Rd1

Rd2

Process value for oUt2

RE.oN

Activate during Ramp events

SE.oN

Activate during Soak events

SEN.E

Activate if any sensor error is detected

OPL.E

Activate if any output is open loop

CyCL

PWM pulse width in seconds

RNGE

0-10

Analog Output Range: 0–10 Volts

oUt2

Output value for Rd2

28

Appendix A: Default Controller Configuration

Level

2

Level

3

Level

4

Level

5

Level

6

Notes

0-5

0–5 Volts

0-20

0–20 mA

4-20

4–20 mA

0-24

0–24 mA

oUt2

oUt2 is replaced by output type

oUt3

oUt3 is replaced by output type (1/8 DIN can have up to

6)

PId

ACtN

RVRS

Increase to SP1 (i.e., heating)

dRCt

Decrease to SP1 (i.e., cooling)

RV.DR

Increase or Decrease to SP1 (i.e., heating/cooling)

A.to

Set timeout time for autotune

tUNE

StRt

Initiates autotune after StRt confirmation

GAIN

_P_

Manual Proportional Band setting

_I_

Manual Integral Factor setting

_d_

Manual Derivative Factor setting

rCg

Relative Cool Gain (heating/cooling mode)

oFst

Control Offset

dEAd

Control Dead band/Overlap band (in process unit)

%Lo

Low clamping limit for Pulse, Analog Outputs

%HI

High clamping limit for Pulse, Analog Outputs

AdPt

ENbL

Enable fuzzy logic adaptive tuning

dSbL

Disable fuzzy logic adaptive tuning

PId.2

Note: This menu is the same for PID menu.

RM.SP

oFF

Use SP1, not remote Setpoint

oN

4–20

Remote analog Input sets SP1; range: 4–20 mA

Note: This submenu is the same for all RM.SP ranges.

RS.Lo

Min Setpoint for scaled range

IN.Lo

Input value for RS.Lo

RS.HI

Max Setpoint for scaled range

IN.HI

Input value for RS.HI

0–24

0–24 mA

0–10

0–10 V

M.RMP

R.CtL

No

Multi-Ramp/Soak Mode off

yES

Multi-Ramp/Soak Mode on

RMt

M.RMP on, start with digital input

S.PRG

Select program (number for M.RMP program), options 1–

99

M.tRk

RAMP

Guaranteed Ramp: soak SP must be reached in ramp time

0–1

0–1 V

29

Appendix A: Default Controller Configuration

Level

2

Level

3

Level

4

Level

5

Level

6

Notes

SoAk

Guaranteed Soak: soak time always preserved

CYCL

Guaranteed Cycle: ramp can extend but cycle time can’t

Note: tIM.F does not appear for 6 digit display that use a HH:MM:SS format

tIM.F

MM:SS

“Minutes : Seconds” default time format for R/S programs

HH:M

M

“Hours : Minutes” default time format for R/S programs

E.ACt

StOP

Stop running at the end of the program

HOLd

Continue to hold at the last soak setpoint at program end

LINk

Start the specified ramp & soak program at program end

N.SEG

1 to 8 Ramp/Soak segments (8 each, 16 total)

S.SEG

Select segment number to edit, entry replaces # below

MRt.#

Time for Ramp number, default = 10

MRE.#

oFF

Ramp events on for this segment

oN

Ramp events off for this segment

MSP.#

Setpoint value for Soak number

MSt.#

Time for Soak number, default = 10

MSE.#

oFF

Soak events off for this segment

oN

Soak events on for this segment

Changes that Gamry Instruments Has Made to Default Settings

Set Omega Protocol, Command Mode, No Line Feed, No Echo, Use <CR>

Set Input Configuration, RTD 3 Wire, 100 ohms, 385 Curve

Set Output 1 to PID Mode

Set Output 2 to On/Off Mode

Set Output 1 On/Off Configuration to Reverse, Dead Band 14

Set Output 2 On/Off Configuration to Direct, Dead Band 14

Set Display to FFF.F degrees C, Green Color

Set Point 1 = 35 degrees C

31

Set Point 2 = 35 degrees C

Set Proportional Band to 9C

Set Integral factor to 685 s

Set Derivative factor Rate to 109 s

Set Cycle time to 1 s

Appendix A: Default Controller Configuration

32

Index

AC line cord, 7

AC Outlet Fuses, 8

Advanced Settings for COMx dialog box, 15

Advanced… button, 15

auto tuning, 22

Index

potentiostat, 17, 19

power cord, 11

power line transient, 10

power switch, 13

Programming Mode Menu, 30

Properties, 14

RFI, 9

RTD, 11, 12, 13, 17, 20

cable, 8, 12, 17

CEE 22, 8, 12

Cell Cables, 17

CHECK110.EXP, 18

COM port, 14

COM Port Number, 15

Control Panel, 14

cooler, 16

cooling device, 16

CPT Critical Pitting Test System, 11, 18, 19

CS8DPT, 7, 11, 12, 19

Default Controller Configuration, 25

Device Manager, 14, 15

electrical transients, 9

Explain™ scripts, 19

Flexcell™, 12, 17, 20

Framework™ software, 19, 21

fuse

cooler, 16

heater, 16

safety, 7

Select Features dialog box, 15

shipping damage, 7

static electricity, 9

TDC5

Cell Connections, 16

Checkout, 18

Operating Modes, 17

Tuning, 20

TDC5 adapter for RTD, 11

TDC5 Initialize Settings.exp, 19, 21

TDC5 Start Auto Tune.exp, 19

Temperature Controller Configurations, 16

Temperature Controllers, 15

Thermal Design, 19

Type drop-down menu, 16

USB cable, 11, 14

USB Serial Device, 14

USB Serial Device Properties window, 14

Use

TDC5, 19

Gamry Software Installation, 2-15

heater, 8, 9, 16, 19, 20, 21

host computer, 14

Initialization Mode Menu, 25

line voltages, 8, 12

oPER, 13

Output 1, 16

Output 2, 16

Parameters

Operating, 21

PID, 12, 17, 20, 22

Port Settings tab, 15

Ports, 14

Visual Inspection, 11

33

Redefining Electrochemical Measurement

Part #: 988-00067

734 Louis Drive

Warminster, PA 18974

Tel: (215) 682-9330

www.gamry.com

Loading...

Loading...