Page 1

User Manual

Copyright © 2010 Gammill, Inc. All Rights Reserved

Page 2

Gammill Vision™ User Manual

Copyright © 2010 Gammill, Inc. All Rights Reserved

Publish Date: February 2010

All rights reserved. No parts of this work may be reproduced in any form or by

any means – graphic, electronic, or mechanical, including photocopying,

recording, taping, or information storage and retrieval systems – without the

written permission of the publisher.

Products that are referred to in this document may be either trademarks and/or

registered trademarks of the respective owners. The publisher and the author

make no claim to these trademarks.

While every precaution has been taken in the preparation of this document, the

publisher and the author assume no responsibility for errors or omissions, or for

damages resulting from the use of information contained in this document or

from the use of programs and source code that may accompany it. In no event

shall the publisher and the author be liable for any loss of profit or any other

commercial damage caused or alleged to have been caused directly or indirectly

by this document.

Our thanks to Pat Barry for writing this manual, and Alan Barry for many of the pictures.

__________________________________

IMPORTANT MACHINE INFORMATION

It is our goal to ensure that Customers have information on the tools and accessories

(standard and optional), that are available for use with Gammill® quilting machines.

Some of the tools and accessories detailed in this Manual may be optional equipment.

We recommend that you consult with your Authorized Gammill Dealer or Sales

Representative for the most current list of standard and optional equipment. Standard

equipment, optional equipment, and pricing are subject to change without notice.

Page 3

Table of Contents

Section 1 - Tour your Gammill Vision™......................................................................................................... 6

Gammill Vision™ - Front View ....................................................................................................................... 6

Gammill Vision™ - Right SideView ................................................................................................................ 7

Gammill Vision™ - Left Side View ................................................................................................................. 8

Gammill Vision™ - Back View ....................................................................................................................... 9

Gammill Vision™ - Top View ....................................................................................................................... 10

Gammill Vision™ - Bottom Crosstrack (aka Carriage)................................................................................. 11

Tour Your Table ........................................................................................................................................... 12

GS-1PA Table.......................................................................................................................................... 12

Home-Pro Table ...................................................................................................................................... 13

Section 2 – Getting Ready to Quilt ............................................................................................................... 13

About the manual ................................................................................................................................ 13

About the instructions.......................................................................................................................... 13

Threading the Machines .............................................................................................................................. 13

Back Section............................................................................................................................................ 14

Middle Section ......................................................................................................................................... 15

Front Section ........................................................................................................................................... 16

Threading the Gammill Vision™ 18-8 ...................................................................................................... 17

Using the On-board Bobbin Winder ............................................................................................................. 17

Winding bobbins while quilting................................................................................................................. 18

Winding bobbins before quilting............................................................................................................... 18

Using a Stand-alone Bobbin Winder ............................................................................................................ 19

About the Bobbin Case ................................................................................................................................ 19

Inserting the Bobbin Case ....................................................................................................................... 20

Setting the Tensions .................................................................................................................................... 20

Set the Intermittent Tension..................................................................................................................... 20

Set the Rotary Tension ............................................................................................................................ 21

Set the Bobbin Case Tension .................................................................................................................. 21

Checking the Top Thread Tension ...................................................................................................... 21

Changing the Top Thread Tension...................................................................................................... 22

Section 3 - Navigating The Screens ............................................................................................................. 23

Turning on (and off) the machine ................................................................................................................. 23

Initialization:......................................................................................................................................... 23

Main Screen - Carousel of Patented Applications ....................................................................................... 24

Stitcher Modes......................................................................................................................................... 24

About the Stitch-regulator - ................................................................................................................. 24

Channel Locks ......................................................................................................................................... 25

Stitch Monitor ...................................................................................................................................... 26

FM Tuner ................................................................................................................................................. 28

Tools / Diagnostics .................................................................................................................................. 29

Settings / Preferences ............................................................................................................................. 30

Main Screen - Settings................................................................................................................................. 30

Main Screen - Setting Changes............................................................................................................... 30

Main Screen - Status Information ................................................................................................................ 32

Stitcher Status Button .............................................................................................................................. 32

Needle Positioner .................................................................................................................................... 33

Page 4

Laser Light ............................................................................................................................................... 33

Automatic Tie-offs .................................................................................................................................... 34

Stitch Counters ........................................................................................................................................ 34

Bobbin Factor Icon .............................................................................................................................. 35

Bobbin Fill Gauge ................................................................................................................................ 35

Stitch Counter Icon .............................................................................................................................. 36

Run-time Clock Icon. ........................................................................................................................... 37

Section 4 - Let’s Quilt ! .................................................................................................................................. 38

Standard Procedures ................................................................................................................................... 38

Pull up the bobbin .................................................................................................................................... 38

Tie-off Stitches to Begin........................................................................................................................... 39

Continuous Line Designs......................................................................................................................... 39

Tie-off to End ........................................................................................................................................... 39

Trim.......................................................................................................................................................... 39

Explore Stitching Modes ................................................................................................................................. 40

Regulate ................................................................................................................................................. 40

Coast Regulate ....................................................................................................................................... 40

Constant ................................................................................................................................................. 41

Baste ...................................................................................................................................................... 41

Explore the Settings / System Preferences ................................................................................................. 42

Laser Light ................................................................................................................................................42

Response..................................................................................................................................................42

Coast Spread............................................................................................................................................42

Coast Threshold .......................................................................................................................................42

The 4

th

scale .............................................................................................................................................43

System Alarms......................................................................................................................................... 43

Thread Break Alarm ............................................................................................................................ 43

Too Fast Alarm .................................................................................................................................... 43

Bobbin Empty Alarm............................................................................................................................ 43

Turning Off Alarms .............................................................................................................................. 44

Needle Positioner .................................................................................................................................... 44

System Volume........................................................................................................................................ 45

Calibration................................................................................................................................................ 45

Section 5 - Quilting Techniques.................................................................................................................... 47

How To Relocate the Screen ....................................................................................................................... 47

How To Start and Stop (a line of stitching) .................................................................................................. 48

How To Restart (a line of stitching) .............................................................................................................. 48

How To Test the Tension ............................................................................................................................. 49

Adjust the bobbin tension .................................................................................................................... 49

Adjust the top thread tension............................................................................................................... 50

Page 5

Congratulations on the purchase of your new Gammill Vision™ Quilting System.

Gammill has added high tech electronics to its ‘Best of Class’ stitching mechanism,

giving you an exceptional quilting experience!

The new features incorporated into the Gammill Vision™ are a result of suggestions from

current customers plus Gammill’s dedication to providing the best quilting system possible to

meet your needs. The Gammill Vision™ is complete with options that enable you to adjust the

stitching to suit your style.

The first and most obvious improvement is the touch screen, which displays the color icons for

all of the features. Operating instructions are easier to find and understand using the new

icons. What isn’t as obvious are the technological improvements behind these features. The

new technology enables you to easily learn, use, and maintain your new quilting partner. It

also allows you to update your system as new and exciting features are added in the future.

There is a new ‘Coast’ mode that combines the stitch-regulator with constant speed for

efficient transition to micro-stitching. The stitch-regulator operates at higher speeds, but the

machine automatically switches into constant speed when the machine speed drops below the

adjustable Coast threshold. This enables you to stitch motifs using the regulator, and

automatically switch to constant speed to micro-stipple the background.

We still offer the ‘Regulated’ mode but now you can adjust it to fit your speed. High-speed

quilters are prone to getting the occasional long stitch at take-off points. Slow-speed quilters

may see extra stitches in the points. Regardless of your speed preference, you can now easily

set the regulated mode response to adjust the stitching to suit your speed.

Another step toward trouble-free quilting is the optional digital video camera. Turn on your

camera and see the stitch quality on the underside of the quilt. No more flashlights and mirrors!

There are other self-diagnostic checks occurring while you are stitching. They are happening in

the background so they don’t disrupt your stitching unless a warning is needed. The early

warning system is a true time saver.

Thank you for choosing the Gammill Vision™ – we are sure you will enjoy it!

Please read this manual before operating your new machine, even if you have used a Gammill

Quilting System before. There is some new information that will make your quilting experience

easier, and you don’t want to miss it.

Page 6

Section 1 - Tour your Gammill Vision™

This chapter is dedicated to introducing the Gammill Vision™, and some new terminology.

Some terms will be familiar and some will be new, but if you understand the terms, the

explanations included later in this manual will make more sense. Consider this section an

overview; complete instructions are in later sections.

Gammill Vision™ - Front View

Here is a picture of your state-of-the-art Gammill Vision™.

1. Main Module – displays all the instructions and icons. The Main Module is actually a separate

module that fits into a docking station that is attached to the machine. There is a docking station at the front

and at the back of the machine, so the module can be moved to the back of the machine when doing

pantographs.

Caution: Be sure to have the power off when moving the module from one end to the other.

2. Handles – there are two handles in the front and in the back, and they function the same

way. In the left handle is the Single Stitch button that controls the single stitch and needle position functions. In

the right handle is the Run button that controls the starting and stopping of the stitching. Often the right button

is red and is called the Red button.

3. Light Bar – there is a long thin light fixture attached to the handles. The light switch is on the right

side, hidden by the black guard. Flip the switch away from you to get natural light (LED). Flip it toward you to

turn on the black light (UV) which is very helpful when using glow-pencil markers or when quilting with white

thread on white fabric.

4. Needle Area – The needle bar holds the needle in place.

The hopping foot is a circular guard that surrounds the

needle. The hopping foot is more than just a safety guard. It is

instrumental in creating a good stitch, and it also allows the use of

templates and rulers. The shape makes it safe to guide the machine

along the edge of a template or ruler for a perfect stitch line or design.

The camera also helps insure a good stitch.

Needle area in front

1. Main Module

with antenna

Front Docking Station

Laser Light Plug

2. Handles:

Left handle button

is Single Stitch

Right handle button

is the ‘Run’ button to

Start/Stop stitching

3. Light Bar

Light Bar switch is underneath

on the right. (UV, off, LED)

4. Needle Area

with optional

Camera

Page 7

Gammill Vision™ - Right SideView

The right side of the Gammill Vision™ has the threading path and tension devices.

1. Thread Path – Threading the machine can seem complicated but it is actually easy because

the thread guides clearly mark the path. In this example, thread comes off the cone, going straight up

into the first guide called the thread lead-off. There are two more guides that take it into the intermittent tension

assembly, and it is wrapped around the silver cylinder (which is a thread break sensor wheel) and then to

another guide and to the rotary tension assembly. Two ‘L’ shaped guides help keep the thread in the check

spring. From there it goes to the take up lever, through more guides and finally through the eye of the needle.

Detailed threading instructions are given in the following pages.

2. Bobbin Area – is the open area below the needle. The bobbin

and bobbin case are larger than most domestic sewing

machines so they hold more thread, and run out less often.

The sewing hook (also known as hook race or hook) spins around the

bobbin, catching the thread and making the stitch. Be sure nothing ever

obstructs this motion. This area will look familiar very soon since you will

clean the bobbin area with a small brush every time the bobbin is

changed. .

3. Crosstrack – Also known as the carriage, is a platform that holds the machine. It has two

tracks so the machine can roll front-to-back. It sits on two tracks on the table which allow it to roll left to right.

The crosstrack has the vertical channel lock attached as well as one of the encoders for the stitch-regulator.

4. “T” Bar is a bracket shaped like a ‘T’ that is screwed into the side of the machine. The bracket

can hold the stylus vertically when it is being used to align the machine with a mechanical template like the

WorkStation or the Design Center. The bracket can also hold the stylus horizontally for attaching the adjustable

laser clamp when it is being used to hold the laser light while stitching pantographs.

5. Laser Light – is being held in a special clamp that allows it to be turned so it points in

virtually any direction. When attached to the ‘T’ bracket, as shown here, the laser light is used to follow

pantographs which are stitched from the back of the machine. When using the laser light at the back, plug it

into the Power Enclosure on the left side at the back of the machine. It only fits in one place on the Power

Enclosure.

The laser light and clamp can also be moved to the front for use when working at the front of the

machine, as shown in the next paragraphs.

2. Bobbin Area, 3. Crosstrack, 4. “T” bracket, 5. Laser light, 6. Pickup roller

Take-up Lever

(behind guard)

Rotary Tension

(the check spring is

inside)

Thread Guides

Needle Area

Thread Break Sensor

Intermittent Tension

Thread Lead-off

Thread Guide

Cone thread

Page 8

6. Pick Up Roller – will hold the quilt layers after they are quilted. It must be located inside the throat

space to ensure the machine can move freely. It starts out small – taking just a few inches but as the quilt

nears completion, the size increases and this reduces the amount of quilting space left free for stitching.

Gammill Vision™ - Left Side View

The left side of the Gammill Vision™ has an on-board bobbin winder.

1. Bobbin Winder – How convenient it is to wind bobbins while you stitch so they will be

ready when you need the next one! The bobbin winder has a thread path, which travels from the

cone of thread, up through the guides, through the tension assembly and over to the bobbin. The bobbin

sits on a post that will spin when the machine is stitching. The bobbin winder lever is lowered into the

bobbin. As the bobbin fills, the lever is pushed up and will eventually pop up, stopping the bobbin winder

from turning

.

2. Laser Light – has been moved from the back of the machine to the front. It is still being

held by the adjustable laser clamp that allows easy adjustments, but now it is attached to a post on the

top of the machine. In this position, it is easy to follow stencils and block patterns. The light plugs into the

bottom side of the front Docking Station and the wire is held by the white clips, preventing it from touching

the front hand wheel.

This close-up picture shows the

Camera bracket (attached)

and

Camera assembly (plugged in).

Plug in H Channel lock. 5. Vertical Channel lock

4. Horizontal Channel lock. and its plug

3. Encoder for stitch-regulator 6.Camera connection

2. Laser Light with

adjustable laser clamp

Front hand wheel

Laser light front plug

Clips (to hold laser light wire

away from the hand wheel.)

1. Bobbin Winder

Tension Assembly

Thread Lead-off

Bobbin Winder Lever

Bobbin

Power Enclosure

Thread Cone

Page 9

3. Encoder – The stitch-regulator has two encoders that

‘ride’ the wheels and measure how fast the machine

is moving and in which direction, so it knows when to

make the next stitch. The encoder riding the wheel on the

machine monitors the Vertical movement (front to back). There is

another encoder that is located on the underside of the

crosstrack that monitors the horizontal movement (side to side).

Between these two encoders, the stitch-regulator can determine

when to stitch.

4. Horizontal Channel Lock – is a magnet attached to the side of the machine that locks

onto the crosstrack preventing it from moving forward and backward, hence the

Horizontal lock. The channel lock is set on and/or off by touching the icon on the screen.

The lock plugs into the adjacent electrical plug on the side.

5. Vertical Channel Lock – is a magnet attached to the front of the crosstrack that locks

onto the table preventing it from moving side to side, hence the Vertical lock. The

channel lock is set on and/or off by touching the icon on the screen. The lock plugs into

a wire connection at the front of the crosstrack. This cable at the back of the crosstrack

plugs into the right side of the Power Enclosure.

6. Camera connection – The larger of the two electrical plugs is for the camera connection.

Each plug has a unique shape so it can only fit in one place.

Camera Assembly

The camera assembly is held in place by a bracket that screws into the side of the

machine. It takes a video image of the under side of the quilt so you can examine the stitch

quality on the back. The camera also has both LED (white) lights and UV (black) lights to

help you see the stitches on the back of the quilt. The bracket looks like it is touching the

crosstrack, but it is not.

Gammill Vision™ - Back View

The machine can be operated from either the front or the back. All handle buttons remain active

regardless of the Main Module’s location.

1. Main Module and the rear

Docking Station. The screen can

be moved to the back dock very

easily, as shown. Lightly pull it straight

up to remove and reverse to install.

Camera assembly is plugged in, and the

lights are on.

The camera lens is in the middle.

The image will be displayed on the screen.

Encoders:

Vertical

Horizontal

Page 10

2. Handles on the back operate

just like the handles on the

front; The Single Stitch button is in

the left handle and the Run button is

in the right handle.

3. Vertical Spool Holder Extension

– is 4" long, and is located on top

the regular spool holder. It is used for

small spools or cones of cross-wound

thread.

4. Power Enclosure, cords, and

connectors - Each of the cords can

connect in only one spot, so getting

the machine plugged in is easy.

Gammill Vision™ - Top View

The top of the machine contains the power switches and more.

1. Motor - is mounted toward the

back of the machine. The motor

turns a belt which has a black plastic

covering for safety.

2.

Power and Motor Switches are

mounted in the middle. They can

easily be reached when standing in the

front or the back of the machine. Turn

power on first, then motor.

3.

Post - In front of the switches is the

post for the laser light. This is where

the laser is attached when working at the

front of the machine.

3. Post for laser mount

1. Motor

2. Power and Motor

switches

1. Main Module

(at rear)

Rear Docking Station

2. Handles & buttons

Left is single stitch

Right is Run

4. Power Enclosure

cords and connectors

3. Vertical Spool Holder

Extension

The Vision™ uses standard household current (110, grounded).

A high quality surge protector is recommended to protect your

investment.

Page 11

Gammill Vision™ - Bottom Crosstrack (aka Carriage)

Each machine has a special platform called a crosstrack or carriage, which allows the

machine to move freely around the table. The crosstrack has channel locks which use

magnets to stop the machine from moving. It also has encoders that detect and measure

motion which is an important element of the stitch size regulation. The machine’s wheels fit

into tracks on the crosstrack, enabling the machine to move front to back. The crosstrack’s

wheels fit into tracks on the table, enabling it to move side to side.

Tracks (also called rails) are specially designed to allow the wheels to move smoothly. There

are two tracks on the crosstrack (for the machine’s wheels) and two tracks on the table (for the crosstrack’s

wheels).

3. “H” and “V”

Channel locks

(See Page 9)

2. “X” and “Y”

Encoders

(See Page 9)

1. Tracks

Page 12

Tour Your Table

The Gammill Vision™ is available in three sizes; V18-8, V26-10, V30-12. The first number is

the distance in inches from the needle to the back of the throat area, and the second number

is the height of this space. The tables used for the Gammill Vision™ are the same as the

tables used for the same size Plus (stitch regulated) or Standard (non-stitch regulated)

machines.

The V18-8 is paired with the Home-Pro table, which is available in 10’ and 12’ lengths. The

V26-10 and the V30-12 require the GS1 table. The standard size for the GS1 table is 12’ but

custom lengths are available.

GS-1PA Table

This close-up picture shows the right side of the table, with many of the parts labeled.

1. The PA Assembly is incredibly useful! It can be released (just pull out the pivot pin) so it

can pivot the top roller up, exposing the batting and backing layers. This is very useful for

removing stray threads and smoothing the batting layer.

2. It has two fixed positions; Quilt and Load. When in Quilt position, the PA assembly is

slanted back, making it comfortable to sit while quilting. The picture shows the quilt position. In

load position, the PA assembly is vertical, not slanted, which makes the quilt layers easier to load. To

switch from one to the other, remove the pivot pin, reposition the PA assembly and re-insert the pin.

Leaders are strips of canvas that are attached to

three rollers; Pickup roller, Backing roller and the

Top roller.

The layers of the quilt will be attached to the canvas

leaders using pins, zippers, hook & loop tape, or even

plastic staples!

When fabric is loaded, these three rollers hold it

taut using locking levers (dogs) that fit into the

gear shaped end of each roller, near the hand

wheel.

This picture shows the right side of the table from a

different perspective.

1. The Pivotal Access (PA) Assembly consists of the

metal bar holding the three rollers

Top roller (with the hand wheel)

Stabilizer bar

Carrier bar (or belly bar).

2. Also shown is the pivot pin, and the two pivot

pin holes which control the angle of the assembly.

Quilt Position

Load Position

GS1 Table Parts

Page 13

Home-Pro Table

• Instructions are either numbered or listed as bullet points.

• Each set of instructions might be prefaced with a paragraph of ‘Prep Steps’ so you know

what needs to be done before you start the process.

• Often the instructions have some tips or suggestions that are printed in a smaller font.

• ‘Your Turn’ means you should take a few minutes and try the exercise.

• Many instruction sets are followed by a paragraph entitled ‘Beyond the Basics’ which

introduce alternative methods or techniques that you might want to try in the future.

As you grow in experience and exposure, you are sure to find different methods of performing

basic quilting techniques. There are certainly many ways to do these techniques and the ones

described here are (hopefully) simple and clear.

Threading the Machines

Now that you have taken a quick tour of your new quilting system, it is time to thread the

machine. There may still be some new terminology, but the text and pictures should help

define them.

The Home-Pro table is perfect for home use

and has a very sturdy metal frame. The

rollers, leaders, table top and crosstrack all

function in the same way as the GS-1PA table.

Section 2 – Getting Ready to Quilt

Now that you have been introduced to your new Gammill Vision™ quilting system, it is time to

get ready to quilt. The previous section defined many new terms – most of them were names

for the various parts of your quilting system. There will be more new terms, but since you know

the names of the machine parts, the new terms will make more sense.

About the instructions

The following sections provide step-by-step instructions and lots of good tips.

Page 14

The Gammill Vision™ 26-10 and 30-12 have the same thread path. The V18-8 is a little bit

different as we will see later in this section. Complete details are given by area, beginning with

the cone of thread at the back of the machine and working forward. Enlarged areas are often

photographed from a different perspective so the details will be shown more clearly.

Back Section

1. Draw some thread off the cone. Take it

straight up and into the first thread guide called

the thread lead-off.

Thread is wound onto a cone in a crisscross

method and needs to have it drawn off by

pulling the thread straight up so it does not twist.

2. Follow the twist of the metal and put the

thread through the second eyelet in the guide,

from the back to the front. See the enlarged

diagram.

3. The thread goes through another guide a few

inches forward.

Looking at the thread

lead-off from

behind shows it has

two eyelets.

Front Middle Back

Page 15

Middle Section

4. Bring the thread forward and through the thread

guide that is attached to the intermittent tension. If

this assembly were a clock, the thread guide

would be positioned at about 3:00.

When the stitcher is running, the intermittent

tension actually moves in and out about 1/32”.

This action is intended to add tension at just the

right time to aid in pulling the thread up from the

bottom of the quilt. This action makes it harder to

pull thread from the thread spool and easier to pull

thread from below the quilt, preventing loops. This

is a patented feature on the Gammill Vision™ 2610 and the Gammill Vision™ 30-12 (the Gammill

Vision™ 18-8 does not have this stroking feature

on the intermittent tension).

5. Wrap the thread clockwise around the tension

assembly once (which is really about 80% of the

way). The thread should fit inside the two blue gray tension disks.

Be sure the thread always stays between these

two disks because when it slips out, the under side

of the quilt will have poor tension. If the tension is

too tight, the thread will quickly work its way out of

the disks.

6. Bring the thread back to the thread break sensor and wrap it counterclockwise 1 ¾

turns. The thread will sit inside a “V” shaped track. This sensor turns when the machine is

stitching. If it stops turning for 50 stitches,

the Thread Break Alarm will sound.

.

Sometimes the Thread Break Alarm will

sound even if the top thread has not

broken. Stiff or slippery thread can slip out

of the track. Running out of bobbin thread

can also cause the alarm to sound.

7. Pull the thread forward to the next thread guide, bringing it down through the first hole and

up through the third hole.

5. Looking at the intermittent tension from

behind shows the thread guide, adjustment

knob, tension spring and the thread nestled

inside the two blue / gray tension disks.

Note: The Intermittent Tension Baseline setting

is when the adjustment knob is flush with the

inside threaded shaft.

Adjustment Knob

Tension spring

Tension disks

4. Thread guide

7. From guide toward

Rotary Tension.

6. Around Thread Break

Sensor 1 ¾ times

Page 16

Front Section

8. Bring the thread down, over the Top (right angled) bracket.

9. Wrap the thread around the rotary tension assembly 1 3/4 in a

clockwise direction, making sure the thread stays in the “V” shaped

track. The thread path is not quite two full rotations.

11. Bring the thread back down and under the Bottom (angled) bracket. As you pull on the

thread, the check spring will move from about 10:30 to 9:00 position, and back.

12. The thread then goes through the eyelet in the take-up lever (hidden behind the guard)

from back to front.

13. Bring the thread down, through the remaining thread guides.

14. Thread the needle, from front to back.

Bey ond the Ba sics -

Tip for easy thread changes – When you need to change the thread, don’t pull the current

thread out and rethread using the new color. Instead, go to the back of the machine and cut

the thread even with the top of the cone. Remove the original cone and replace it with the new

color. Draw off some thread from the new cone, and securely tie the ends of the two colors

together. Now, go the front of the machine, take the thread out of the needle, and pull on the

thread until the new color is in place. Cut off the knot and rethread the needle.

Important! Check that the new color thread is still securely tucked into the intermittent tension

disks and that it is still in the track around the thread break sensor, and rotary tension

assembly.

Top bracket

Check spring

Bottom bracket.

“V” Thread track

Tension spring

Adjustment knob

Threaded Shaft

Looking at the rotary tension from above shows the

brackets, guides and check spring.

10. Guide the thread up far enough so it catches the wire of

the check spring. The check spring has a ‘U’ shape, and it moves a

bit. Gently move the check spring down and forward to make it easier

to get the thread into the ‘U’ shape.

Note: The Rotary Tension Baseline setting is when the adjustment

knob is flush with the inside threaded shaft.

Page 17

Threading the Gammill Vision™ 18-8

Threading the smaller, V18-8 machine is virtually the same.

Using the On-board Bobbin Winder

This feature allows you to wind bobbins either

while you are quilting, or not. The bobbin

winder uses its own cone (or small cone) of

thread, so if you have two cones of the same

color, you can wind bobbins while you quilt. If

you don’t have two cones of the same color,

you can wind bobbins before you begin to

quilt.

1. Draw some thread off the cone on the left side of the

machine. Just like before, take it straight up and into the first

thread lead-off guide.

2. Follow the twist of the metal and put the thread through

the second eyelet in the lead-off guide, from the back to the

front.

3. The thread goes through another guide a few inches

forward.

4. The thread must go under the tension disk and through the guide on the other side. Don’t

wrap the thread around the tension disk. Keep the thread in the lower half only. Sometimes it

Go ahead and thread the machine. Pay special attention to how the thread fits

into the tension assemblies. Rotate both tension knobs until they are flush with

the screw they surround. This is the normal ‘Start’ position for all tension

adjustments. Pull on the top thread, and notice the resistance – that is good!

You r

Tur n

There is one extra thread guide in the front, however.

Page 18

is easiest to thread the first tension disk guide, then the second, and pull a loop around to the

bottom of the tension disks, and then pull on the thread from both sides to get the thread to

pass between the tension disks.

5. Bring the thread forward through the next thread guide and

up to the on-board bobbin winder.

Winding bobbins while quilting

1. Place an empty bobbin on the bobbin winder spindle. There

is a little wire spring on the end of this spindle that will hold the

bobbin in place. If you look closely at an empty bobbin, you will

see a small notch on the inside edge.

2. Don’t try to align the wire with the notch. Just push the bobbin onto the spindle and then turn

the bobbin until it clicks into place.

3. Wrap the thread clockwise around the center of the bobbin 6-8 times, securing the end.

4. Push the bobbin winder arm down. It will slide to the inside of the bobbin. Now, bring it back

up about ¼”, so it is not touching the center of the bobbin.

5. Now, when you begin to quilt, the bobbin will wind. When the bobbin is full, the arm will pop

up and the bobbin will stop revolving.

The bobbin should not be soft and mushy, but it also should not be so tight that you can’t feel a

little give when pressing on the thread with your fingernail.

Winding bobbins before quilting

If you need to wind bobbins before you begin to quilt, you will be running the machine from the

Diagnostics screen.

Detailed instructions for using the Diagnostics are in the next section, so don’t worry if you

don’t understand the following steps yet – You will!

1. Load an empty bobbin as described above.

2. Be sure the bobbin case is not in the machine.

3. Remove the thread from the needle and take-up lever.

Wrap it around the foam covering of one of the handles. This prevents tangling.

4. Choose Diagnostics from the Initial Screen carousel.

5. Change the speed setting to about 30-50%.

6. Start by pressing the red button in the Upper Left Corner of the screen.

7. When the bobbin is full, it will stop winding automatically.

8. Turn the machine off.

9. Remove the bobbin.

Bey ond the Ba sics – If you are familiar with the previous stitch regulated machine called

the ‘Plus’, you may wonder if Constant speed can still be used to wind bobbins. The answer is

‘yes’ but it is easier to use the Diagnostics screen – and – you won’t be adding to the stitch

counter like you would if you were using the Constant Stitch mode.

Page 19

Using a Stand-alone Bobbin Winder

One of the Gammill available accessories is a stand-alone

bobbin winder. Just like the on-board bobbin winder, the

stand-alone winder has a cone thread holder, a tension

assembly, bobbin post and a bobbin-fill lever and arm. In

addition, this winder has a foot pedal, motor and electrical

cord.

Batting was placed behind various parts to help display the details.

The bobbin post, fill lever and arm are shown below.

* When in the ‘Open’ position, the fill lever is straight up, and

the fill arm is angled down so there is enough room for the

empty bobbin to be pushed onto the bobbin post.

* When in the ‘Closed’ position, the fill lever is angled forward and the fill arm moves up into

the bobbin, without touching either side.

Batting was placed behind various parts to help display the details

1. Cone thread is mounted on the holder and the thread is drawn straight up and around the

thread guide, then down to the tension assembly.

2. The thread goes through the eyelet, around and between the tension disks, clockwise.

3. Draw the thread back toward the empty bobbin and wrap it around 6-8 times, clockwise.

4. Step on the foot pedal to start the motor and fill the bobbin.

5. When the bobbin is full, the Bobbin Fill Lever will pop to the Open position and the bobbin

winder will stop winding.

About the Bobbin Case

Once the bobbin is wound, it can be inserted into the bobbin

case. The bobbin case is similar to those used with domestic

sewing machines, but larger (size M), so it holds more thread.

Exactly how much more depends on the thickness of the

thread. Our bobbin case also has a thin metal piece inside

called an anti-backlash spring. This prevents the bobbin

Follow the steps (1-5) above to wind a bobbin.

* Adjust the tension knob if needed. Right to tighten, Left to loosen.

Remember, the bobbin should not be soft and mushy, but it also should

not be so tight that you can’t feel a little give when pressing on the thread

with your fingernail.

* If the thread pops out from between the tension disks, it is too tight.

You r

Tur n

Bobbin post and Fill Lever

Cone thread holder

Tension assembly

Motor Foot pedal

Electric Cord

Tension Assembly

Closed

Open

Bobbin Post

Bobbin on post

Bobbin Fill lever

Bobbin Fill arm

Tension Bar,

Thread slot

Tension screw

Page 20

thread from over-spinning when the machine comes to a

sudden stop.

A bobbin fits easily into the bobbin case, and should spin freely, in a clockwise direction. The

case has a thin metal tension strip with two screws. The smaller one is holding it on to the

case, and the larger one adjusts the tension – right to tighten and left to loosen. When making

adjustments, turn the screw about 5 -10 minutes of a revolution at a time.

Inserting the Bo bb in C as e

There is a spring loaded handle on the outside of the bobbin

case and part of this sticks out about 1/8”. When inserting the

bobbin case, align this bump to the notch in the rotary hook

assembly (about 4:00 position). Push in the case and listen for

the click to verify that it is properly inserted.

Hint: Use the spring loaded handle to remove the bobbin, but

don’t use it to insert the bobbin because it often prevents the

‘click’, which is your assurance that the bobbin case is in

properly.

Setting the Tensions

The following text contains concepts that a novice quilter may not know yet, but don’t worry.

Tension setting concepts are explained here, and reviewed again in the Techniques Section which includes exercises on checking the tension. By then you will have learned how to load a

quilt and run the machine. The concepts are reviewed again in the Care Section - which

includes troubleshooting suggestions for poor stitch quality.

A good stitch is a balanced stitch. This means little or no thread from one side shows up on the

other side. Factors other than tension may make the stitch look imperfect. If the batting is very

thin, or the threads are very thick, or the two thread colors are very different it will be almost

impossible to not see the thread from the other side.

Start with a thread made specifically for longarm quilting machines. A&E’s PermaCore 30 wt

thread is a great choice for the beginning quilter. This has a poly core that gives it strength,

and durability. Once you have bonded with your machine you can try other brands / types /

weights.

Set the Interm it te nt T en sion

• The In termittent Tension B aseline setting is when the adjustment knob is flush

with the inside threaded shaft, so start there.

• Intermittent tension adjustments might be needed on every quilt combination you do

because the thread, fabric, batting and backing all affect the stitch quality. Turn the

thumb screw to the right (clockwise) to tighten and the left to loosen. When adjusting

the tension, always turn the intermittent tension knob at least ½ turn at a time. It's a

coarse adjustment and less than ½ turn will not appreciably change the tension.

• If the tension is too tight, the thread will quickly work its way out of the disks.

Rotary hook shaft and notch

Page 21

• Be sure the thread stays nestled between the two tension disks. If it slips out, the

quilt will have poor tension.

Set the Rota ry T en si on

• The Rotary Tension Baseline setting is when the adjustment knob is flush with the

inside threaded shaft, so start there.

• The Rotary Tension should remain loose – just tighten it enough so the wheel rotates

when stitching. Turn the thumb screw to the right (clockwise) to tighten and the left to

loosen. Once this is set, it rarely needs to be changed.

Set the Bobb in C as e Te nsion

The ‘Bo bbin Basel ine’ for tension is determined like this:

1. Put a full bobbin into the bobbin case, place it in your hand

flat, so the bobbin can be seen. Pull on the thread and

make sure the bobbin is rotating clockwise.

2. Slide the thread through the slot and under the tension strip,

until it is coming out of the small space in the side.

The first time you use a new thread type, size or brand:

1. Tighten the tension screw on the bobbin case first (so the bobbin and case lifts off your

hand when you pull on the thread slowly).

2. Loosen gradually (loosen the tension screw 10 minutes at a time until the bobbin case

remains in your hand when you pull the thread slowly).

3. Adjust if needed (tighten the tension screw 5 minutes to make sure you didn’t overloosen the bobbin).

When refilling the bobbin:

• After inserting a full bobbin, try to pick the bobbin case up by the thread. The tension should

be tight enough to turn the bobbin case onto its side. And, it should be on the verge of

coming off your hand but should not lift off your hand. Adjust as needed.

Checking the Top Thread Tension

1. Start with a properly tensioned bobbin case.

2. Attach a test piece.

3. Pull up the bobbin, tie-off and stitch at a normal

speed. Include some soft curves, tight spirals,

straight lines (horizontal and vertical) and sharp

points. Look closely at the stitch quality.

4. Remove the pins and check the underneath too.

Properly loaded bobbin &

case turns on its side but does

not lift up off the surface.

Attach a test piece.

Page 22

Changing the Top Thread Tension

• If the tension is poor on the back of the quilt - top thread loops, bobbin thread laying

flat, eyelashes or stitches not embedding in the fabric - then tighten top tension ½

turn at a time to "pull" the stitch (the bobbin and top thread connection) into the

middle of the quilt.

• If tension is poor on top then check the bobbin case first. If it seems OK, loosen the

intermittent tension ½ turn at a time until stitch balance is achieved.

Check the stitch

quality

on the back also.

Stitch:

soft curves

tight spirals

straight lines

sharp points

Page 23

Section 3 - Navigating The Screens

Turning on (and off) the machine

If the machine is not turned on yet, do it now. Plug in the power cord using an extension if

needed. Please use a high quality surge protector! Locate the two switches on the top of

your machine. Always turn the Power on first, and the Motor on second. (O is OFF, and I is

ON). Reverse this order when turning the machine off. Each switch is labeled, using the

universal symbols for ‘Power’ and ‘Motor’. These universal symbols may not be familiar to you,

so it might be good to label your machine with the words instead of the icons. It really is

important to do this in the correct sequence.

The machine will take about 10 seconds to load the firmware. Firmware is a new term, which

means the Gammill Vision™ system isn’t just hardware, and it isn’t all software, it is a

combination of both – consider it a really smart quilting machine.

Initialization:

During the Initialization process, the Gammill Vision™ will perform some internal diagnostic

checks. The progress bar shows it is loading. Be patient – it may take a minute.

When it is done, it will display the Main Screen which is a touch screen which means you don’t

need a mouse or keyboard to initiate any of the features, you just touch the icon on the screen.

There are three important areas of the Main Screen:

1. Carousel of Icons - for all the features.

2. Settings – for current activity.

3. Status Information – for quick review.

The stitching feature icons are displayed in a circular

fashion, called a carousel. The icon at the front of the

carousel is the active icon. It is the only carousel icon

that can be initiated. Touching any of the background

icons in the carousel will do nothing.

Main Screen

2. Settings

ON : 1st the Power 2nd the Motor

These icons are the

universal symbols for :

Power

Motor

OFF : 1st the Motor 2nd the Power

Page 24

The green arrows are used to rotate the carousel, until the desired icon is at the front. The left

green arrow will rotate the carousel clockwise and the right rotates it counterclockwise.

Often times touching an icon will bring up a secondary screen, which presents more options for

you to choose. You don’t have to make a choice – you can return to the primary

screen just by pressing the Exit Icon (that looks like a door).

Main Screen - Carousel of Patented Applications

Touch the screen and get the icons to revolve. It may feel awkward at first, but you will soon

appreciate the fact that you don’t have to memorize any codes or key sequences. The icons

are all in front of you! Here is a list of icons, and what they do.

Stitcher Modes

About the Stitch-regulator -

There is one position on the carousel for the stitch-regulator, but four modes within the stitch

regulation software. Pressing the ‘Regulate’ Icon will rotate through the choices.

Regulate – means every stitch will be the same length – or as close as

possible. The encoders measure the speed and direction of the wheels and

feed the information back to the software, which calculates when to take the

next stitch. The target is to have every stitch exactly the same.

Coast – means the stitch-regulator is used at higher speeds but not at the

lower speeds. This allows the quilter to stitch motifs using the stitch-regulator,

and then slow down to do micro-stitching without the regulator (constant

speed). This eliminates the need to stop and turn off the regulator when

moving from the designs to the backgrounds or detail work.

You r

Tur n

Coast

Press Regulate

to change to

Constan

Press Coast

to change to

Press Constant

to change to

Baste

Regulate

Press Baste

to return to

Main Screen

The Main Screen starts with the Regulate icon in front.

The icon in the front determines how the stitcher will respond.

• To change the mode, press the icon once, and the next

stitch mode will be presented.

• Repeat until the desired mode appears.

Go ahead and try turning the carousel.

Touch the green arrow to move the

carousel counterclockwise as you read

the following section.

You r

Tur n

Page 25

Constant – means the stitcher is stitching at a constant pace, without regard

for the movement of the machine (aka sewing head). The encoders are not

sending movement information to the software. The stitch length will vary,

depending on how fast the operator moves the machine.

Baste – means to take very large stitches, similar to doing a sequence of

single stitch. These are measured in inches per stitch instead of stitches per

inch.

When using any of these stitching choices, the machine won’t begin to quilt until the stitcher

is started. Use the buttons in the handles or press the Stitch Button. When the stitcher is

running, the color of the Stitch Button changes.

Channel Locks

Bey ond the Ba sics: When both the horizontal and vertical channel locks are locked, the

machine will not move. This is very convenient when replacing the bobbins.

The Horizontal Channel Lock icon is next. It looks like an

open padlock with the letter “H”. That means the channel

lock is ‘off’. A closed padlock indicates the lock is ‘on’.

You r

Tur n

Press the icon to lock

the machine so it only

moves side-to-side.

Press the icon

again to unlock

The Vertical Channel Lock icon is next. It looks like an

open padlock with the letter “V”. That means the channel

lock is ‘off’. A closed padlock indicates the lock is ‘on’.

You r

Tur n

Press the icon to lock

the machine so it only

moves front-to-back.

Press the icon

again to unlock

Stitch Button (red) shows the stitcher is off.

Stitch Button (green) shows it is on.

Thanks to the stitch-regulator, even when

the stitcher is ‘on’ it won’t stitch until you

move the machine.

Page 26

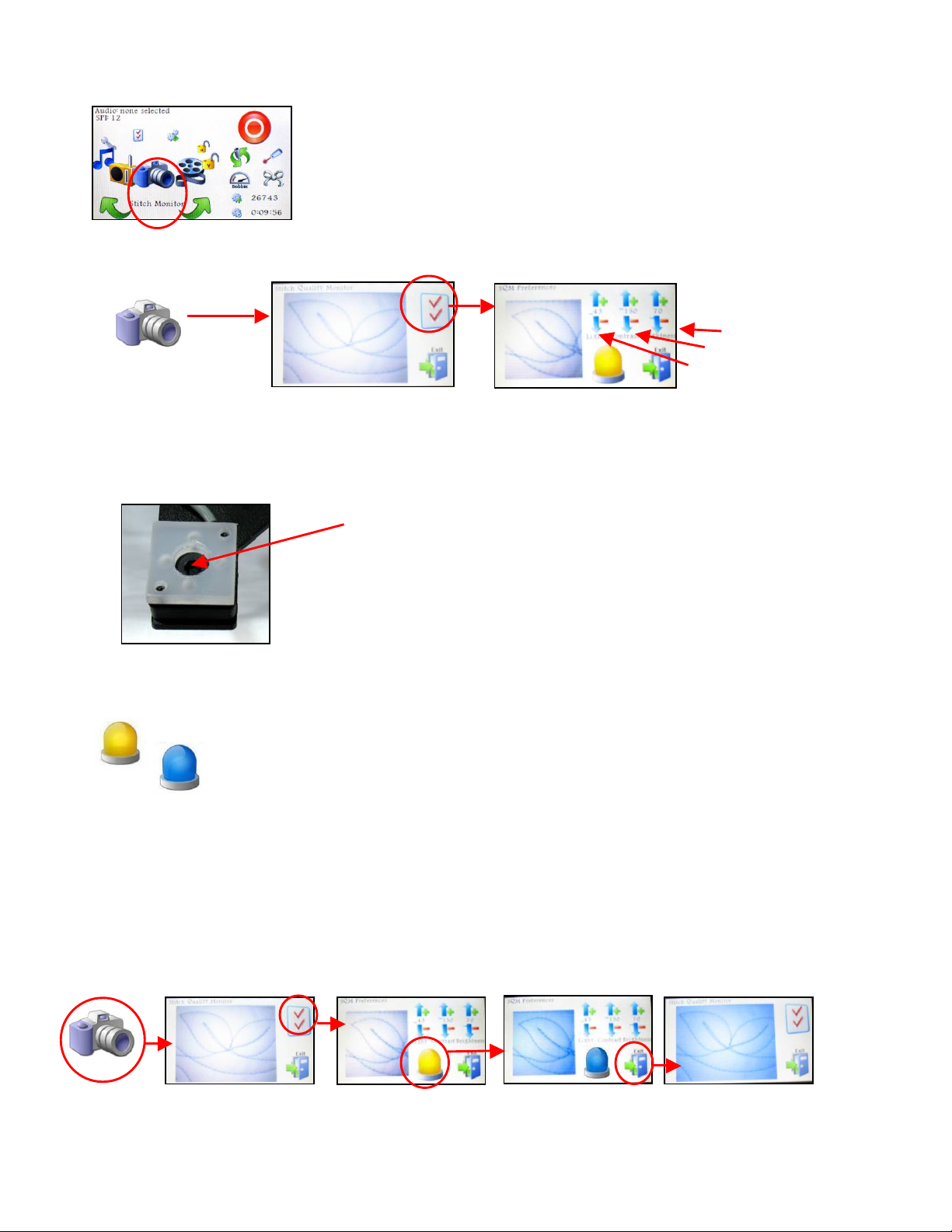

Stitch Monitor

Press the Settings Icon to adjust the camera settings if desired.

One of the camera settings is a light icon.

Try both types of lighting and choose the one with the clearest image.

1. Press the Camera Icon, and wait a few seconds for the image to appear.

(be sure the machine and camera lens are over/under the quilt).

2. Press the Camera Settings Icon.

3. Press the Camera Light Icon (yellow to blue or blue to yellow).

4. Press Exit to see a larger screen image.

The Stitch Monitor icon is next. The monitor uses a digital

video camera to view the stitch quality, and displays the

image right on the screen.

The Camera eye is in the middle of the white collar.

LED (white) lights are on each side.

UV (black) lights are on the top and bottom.

Camera Closeup

The Yellow refers to the daylight, or white LED light.

The Blue refers to ultraviolet lighting, or black UV light.

The following series of screen shots shows the effect of changing the lighting.

Adjust if needed.

Brightness.

Contrast

Light,

Page 27

The color of the thread and fabric impact the image clarity too. Try changing the Light intensity,

contrast and/or brightness to get the clearest image.

1. Press the Camera Settings Icon again to adjust other camera settings.

2. Change the Light intensity, Contrast and/or Brightness by touching the scales.

Touch the up arrow to increase, and the down arrow to decrease.

The adjustments take effect immediately, so fine tuning the picture is fast and easy.

3. Press Exit when done to see the larger image

4. Press Exit again to return to the stitching.

Bey ond the Ba sics: When working at the front of the

machine, put the laser light on the front mount, and point the

laser at the camera lens. This helps to identify the exact

placement of the camera image.

Press the Camera icon to show the image on the screen. (It takes a few seconds)

Position the machine over some quilted area of the quilt.

Look at the screen image of the underside.

Change the light choices (LED to UV and back)

Press up / down arrows to adjust the image quality if desired.

Press Exit to return to the monitor screen.

Press Exit to return to the Main Screen.

You r

Tur n

Camera eye is 3 ½” to

the left of the needle.

Page 28

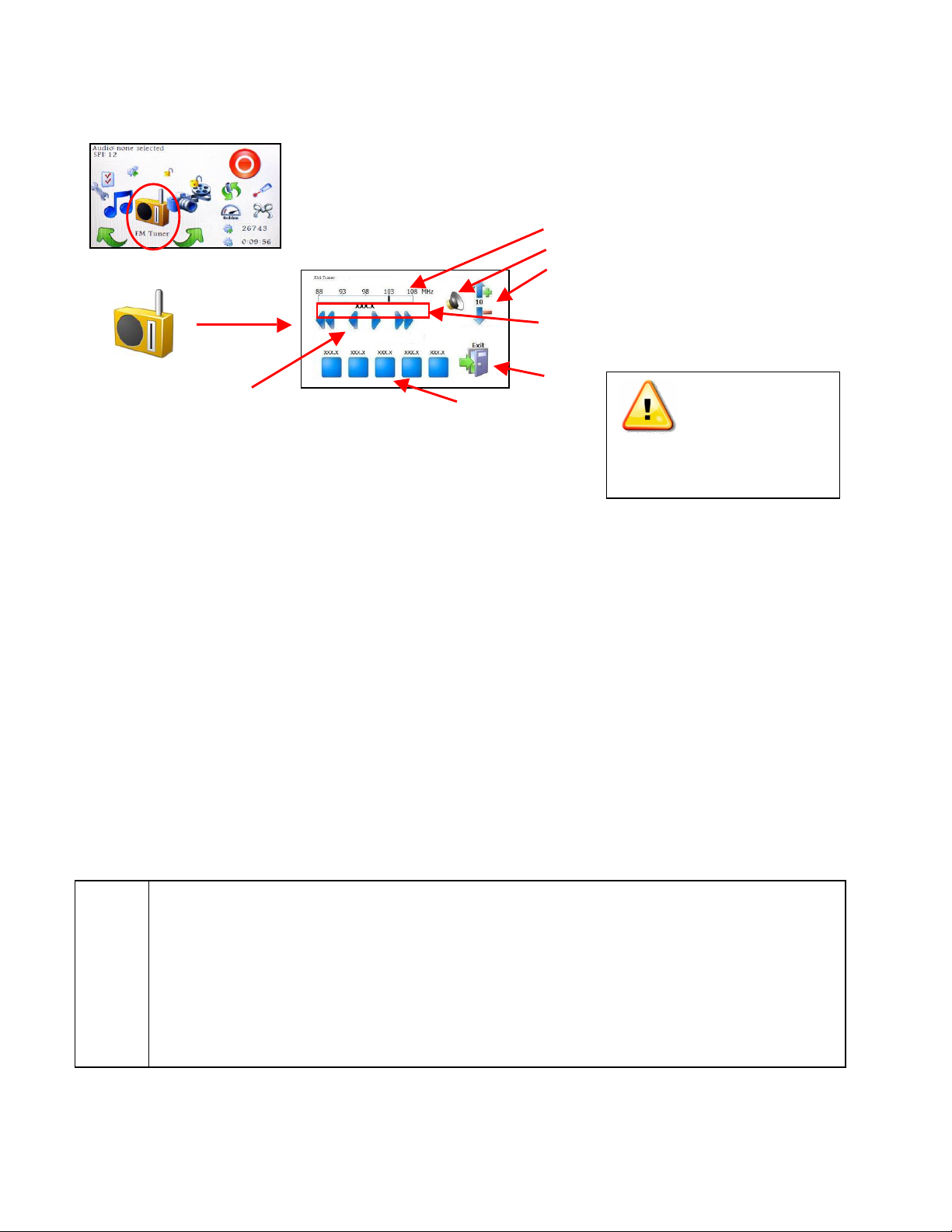

FM Tuner

To turn the radio On,

1. Press the FM Tuner Icon to display the radio dials.

2. Press the Speaker Icon to turn on the speaker.

3. Use the scan buttons to look for a station on the FM band.

• Scan Forward and Scan Reverse go to the next station.

• Step Forward or Step Reverse change the setting 0.1 MHz at a time.

• If the signal strength is > 30%, the call numbers will appear on the screen

(if the radio station transmits that information).

4. To Set one of the radio buttons, press it firmly and hold (just like a car radio)

5. Press the up / down arrows on the Volume scale to raise/lower the volume.

6. Press Exit to return to the Main Screen.

Note: Some radio stations can broadcast the song name and artist.

If your radio station has this capability, it will appear just above the FM band.

To turn the radio Off,

1. Press the FM Tuner Icon to display the radio dials.

2. Press the Speaker Icon to turn the speaker off.

3. Press Exit to return to the Main Screen.

Find your favorite radio station, and set one of the five buttons.

Press the FM Tuner icon to display the radio dials.

Press the speaker icon to turn it on, Use the Scan buttons to find a station.

Press and hold one of the Preset Buttons until you hear the bell.

Press Exit to close the screen.

To turn off the radio, Press the FM Tuner icon again,

Press the speaker icon again to turn it off, and then Press Exit.

You r

Tur n

The FM Tuner works just like an FM radio. This is a great option

for people who enjoy listening to the radio while they quilt.

Scan buttons

(Scan Reverse, Step Reverse, Step Forward, Scan Forward)

FM Radio Band

Speaker (on / off selector)

Volume Scale

Your chosen station frequency

call number and sometimes the

song title and artist appear.

Exit

Turn Power Off

before raising antenna

Or removing the module.

Page 29

Tools / Diagnostics

From this screen you (and your technician) will be able to check the operation of your machine.

These checks are explained in detail in the maintenance section of this manual – just an

overview is given here:

1. Stitcher On/Off button

2. Motor Power setting-to adjust to desired speed during maintenance and bobbin winding.

3. Virtual Position - shows machine head movement testing the x, y encoder sensors.

When the machine head is moved, this dot will move also.

4. Needle Position sensors –

The red dot on the top – turns green when the needle is at its highest point.

The red dot on the bottom – turns green when the needle is at its lowest point.

5. Exit – return to the Main Screen.

6. Handle Button Sensors – verify that the machine is acknowledging the pressing / and

releasing of the buttons in the handles.

7. Motor Diagnostics – are tests “For dealer/technician use only”

8. Motor Direction – Clockwise arrow shows forward, counter-clockwise shows reverse.

In Section 2, you learned how to wind bobbins before you begin to stitch. Review the details in

that section if needed because here is your chance to try it!

The Tools / Diagnostics icon is next. Diagnostics are tests that

check the operation of your machine and stitcher.

1. Stitcher On/Off button

2. Motor Power Setting

3. Virtual Position

4. Needle Position Sensors

5. Exit

6. Handle Button Sensors

7. Motor Diagnostics – for Dealers and Technicians only

8. Motor Direction

Wind a bobbin using the On-board winder (review the details given in Section 2).

1. Load an empty bobbin.

2. Remove the bobbin case.

3. Remove the thread from the needle & take up lever.

Wrap it around the foam covering of one of the handles. This prevents tangling.

4. Choose Diagnostics from the Main Screen carousel.

5. Change the motor speed setting to about 30-50%.

6. Make sure the motor is in forward position.

7. Press Start

8. When the bobbin is full, it will stop automatically.

9. Turn off the motor

10. Remove the bobbin.

You r

Tur n

Page 30

Settings / Preference

s

Main Screen - Settings

The upper left corner of the Main Screen displays the

settings for features currently active.

This example shows us that there is no audio active,

and that the current stitch size is 12 SPI.

It also shows the current stitch mode is ‘Regulated’.

If the current stitch mode was Coast, SPI would be displayed, just like Regulated mode.

If the current stitch mode was Constant, the Speed would be displayed in the Settings area.

If the current stitch mode was Baste, the IPS (Inches Per Stitch) size would be displayed.

Main Screen - Se tt in g Ch anges

From the Main Screen, you can change the stitch size setting for any current stitch mode.

• Touch the screen in the upper left corner area and

another dialog box appears.

• Touch the up arrows on the scale

to increase or decrease the setting.

• Press Exit to return to the Main Screen.

Go ahead and look at the System Preferences.

Most of these values are new to you, so please don’t change them yet.

Press Exit to return to the Main Screen.

You r

Tur n

The Settings / Preferences icon is next. This is where you set

your preferences as defaults. It is a good idea to learn how the

features work first, and then determine your preferred settings.

Some of the settings are explained as you learn each feature.

The rest are explained in detail, at the end of the next section.

Main Screen

Regulated Stitch Mode

Page 31

Regulated and Coast Regulated both use SPI (Stitches Per Inch) as the setting displayed on

the Main Screen. Any changes to the Coast Speed or Coast Threshold need to be done using

the Carousel Settings Icon.

Coast Regulated Stitch Mode

The range for Regulated is 8-24

SPI.

Constant Stitch Mode

The range is 1-100% motor power.

Baste Stitch Mode

The Baste Range is ½ to 4 IPS

(Inches Per Stitch) in ½”

Page 32

Main Screen - Status Information

Now that you have been introduced to all of the icons on the carousel, it is time to look at the

status information on the right side of the Main Screen.

Each of these icons displays the status of a frequently used piece of information so they need

to be easily accessible. The most important status icon is the Stitcher Status Button which is

also the most prominent and the most commonly used.

Several of the other icons represent counters that can be reset. Touching the lower right

corner of this screen will display a parameter screen that allows us to reset these counters

when needed. All of this will be explained in detail on the following pages.

Stitcher Status Button

The icons are color coded like a stop light, but also contain a symbol to

differentiate them for people who are color blind. The red button has a

‘0’ (or a circle) in it and the green button has a ‘1’ (or a line) in it. These

are the Universal symbols for On and Off, respectively.

The Stitcher Status Button in the upper right corner

shows when the stitcher is Off or On.

This is important since the stitcher is so quiet.

Remember, the stitcher does not stitch unless it is

being moved, so it could be ‘on’ even though it is

not actively stitching.

As a safety feature, stitcher will turn itself off if it

has not been moved in 3 seconds.

On

Off

To change the Stitcher Status, press the Stitcher Status Button on the

screen -OR- press the right handle button. Press it again to turn the stitcher

off.

You r

Tur n

Main Screen

Parameter Screen

Stitcher is Off

Page 33

Needle Positioner

This icon looks like the left machine handle. That is because the

needle positioner determines how the button in the left machine

handle operates. To turn the needle positioner on, you can touch

the "Needle Positioner" Icon on the main screen.

Two green arrows mean the needle positioner is off, so the left handle button makes

a complete stitch every time it is pressed.

One green and one red arrow mean the positioner is on so the left handle button

button makes a half stitch every time it is pressed. If the needle is in the ‘up’ position,

pressing the button once makes it go down, and stay there, in the fabric. Press it

again, and the needle returns to the ‘up’ position. This is helpful when quilting because it

holds the machine in place, not allowing it to move (and draw off extra thread).

If the needle is in the ‘down’ position when starting a continuous line of stitching, it will return to

the ‘down’ position when the stitching is stopped. This is especially useful with templates

because it prevents the machine from moving when you need to reposition the template or

adjust your grip.

Laser Light

The laser light can be used when working at the back of the machine or in the

front. When working in the back doing pantographs, the laser light is held by a

clamp attached to the “T” bracket on the side of the machine. When in this

position, the light plugs into the black plastic Power Enclosure casing in the

back.

When working in the front of the machine doing free motion work, the laser

light clamp attaches to the post at the top of the machine, near the front. When

in this position, the light plugs into the front docking station.

Touch the needle positioner icon on the main screen. Note the color change.

Press the left handle button to see how the needle responds when the positioner

is on and off.

You r

Tur n

Back mount

Front mount

Touch the laser icon on

the Main Screen to turn

the light on and off.

You r

Tur n

Laser is On

Laser is Off

Regardless of where the light is positioned,

it is turned off or on by touching the icon.

Page 34

Automatic Tie-offs

A truly unique feature of the Gammill Vision™ is the ability to do perfect tieoffs. This minimizes the size of the tie-off knot and makes it practically

invisible. And, it is so easy!

Press the Tie-off Icon on the Main Screen and the countdown window appears.

Press the Stitcher status button to begin. The status button turns green, but you must move

the machine just a bit to start the tie-offs. It will take 6 stitches at 30 stitches per inch and stop

stitching. When ready, you can continue your quilting, using any of the stitcher modes.

Stitch Counters

The last three icons in the lower right corner are all numeric counters of some kind. There is a

Bobbin Fill Gauge which is an estimate of when the bobbin thread is likely to run out, a Stitch

Counter that accumulates the number of stitches taken and a Run Time Clock which counts

the minutes spent stitching. Each of these numeric counters can be reset so you can collect

metrics on each quilt you do.

Touch the screen in the vicinity of the numeric counters and a parameter screen appears. It is

this parameter screen that allows you to reset any/all of the counters and begin the counts

anew. It also contains another scale “Bobbin Factor” that helps estimate when the bobbin will

Main Screen

Bobbin Fill Gauge

Stitch Counter

Run Time Clock

Parameter Screen

Main Screen

Practice doing tie-offs at the beginning and ending of a quilted design.

• Move the machine into position and pull up the Bobbin thread.

• Touch the Tie-off icon to start the beginning tie-off knot.

• Touch the Stitcher Status button.

• Move the machine just a little and the tie-off stitches will begin.

• When it stops, cut the threads.

• Choose any stitching mode, stitch a design, and stop.

• Touch the Tie-off icon to start the ending tie-off knot.

• Touch the Stitcher Status button.

• Move the machine just a little and the tie-off stitches will begin.

• Pull up the Bobbin thread and trim the threads.

You r

Tur n

Page 35

run out. Since threads vary in size or thickness, the amount of thread on a bobbin can vary

also. The Gammill Vision™ estimates the amount of thread on the bobbin, using the bobbin

factor that you set.

The Bobbin Factor scale ranges from 1 to 50.

Press the top arrow to increase (more thread) and the bottom arrow to decrease (less thread).

Bobbin Factor Icon

Change the Bobbin Factor every time you change the bobbin thread weight.

To do this:

1. Press the Bobbin Icon to display the Parameter Screen.

2. Press the Up or Down arrows to adjust the scale.

3. Press the Exit when done.

Bobbin Fill Gauge

Bey ond the Ba sics: Use the Bobbin Factor settings to adjust for partial bobbins. If you are

using a thread with a factor of 40, you have run out of bobbin, and you only have a half-full

bobbin left, go ahead and use it, but change the factor to 20. Doing this will enable you to use

the bobbin tracking capabilities even with partial bobbins.

Bobbin Fill Gauge

Every time a full bobbin is used, be sure to reset the Bobbin Fill Gauge.

To do this:

* Press the Bobbin Icon on the Main Screen to display the Parameter screen.

* Press the Bobbin Icon on the Parameter Screen to reset the counter.

* Answer the question:

“Do you really want to reset the parameter?”

Yes if you are sure (press green circle)

No if you are not (press red circle)

* Press Exit when done to return to the Main Screen.

Parameter Screen

Set the Bobbin Factor to your favorite thread size.

• Press the bobbin Icon to display the Parameter screen.

• Press the up and down arrows to change the setting.

The default of 40 works well for most standard longarm quilting machine threads.

• Press Exit when done.

You r

Tur n

Reset Stitch Counter

Reset Bobbin Fill Gauge

Reset Run Time clock

Bobbin Factor

Parameter Screen

Page 36

Any time you reset any counter, the machine will ask : “Are You Sure?” Instead of showing the

words ‘Yes’ or ‘No’, it will display two status dots. Green means ‘Yes’ and red means ‘No’. Just

press the dot that conveys your answer.

Stitch Counter Icon

People are often interested in the number of stitches taken on their quilt. By

resetting the counter before every quilt, you can provide this information.

To Reset the Stitch Counter:

• Press the Stitch Counter Icon on the Main Screen to display the Parameters.

• Press the Stitch Counter Reset Icon to reset the counter.

• Answer the question: “Do you really want to reset the parameter?”

If you answer ‘Yes’ the Parameter Screen will show a Stitch Count of zero.

• Press Exit when done to return to the Main Screen.

Press the bobbin Icon to display the Parameter screen. Press the bobbin

reset icon to reset the counter. Press the green button to confirm that you

really do want to reset the bobbin counter. Press Exit when done.

You r

Tur n

• Press the stitch counter to display the Parameter screen.

• Press the stitch counter reset icon to reset the counter.

• Press the green button to confirm you do want to reset the counter,

or the red button if you don’t.

• Press Exit when done.

You r

Tur n

Red is always a negative answer (Ex: Off, No, Stop, Cancel)

Green is always a positive answer (Ex: On, Yes, Go, OK)

Main Screen

Parameter Screen

Main Screen

Parameter Screen

Page 37

Run-time Clock Icon.

It is possible to track the total amount of time spent stitching a quilt. The run-time

clock only records the time when the machine is stitching. This is a really good

method for tracking time and measuring productivity and for the maintenance of

your machine. Be sure to reset the counter before beginning and record the time

when done.

To Reset the Run-time Clock:

• Press the Run-time Clock Icon on the Main Screen to display the Parameters.