Installation and

User’s Guide

GLED-600

(Sagittal)

GLED-800

(Crosshair)

Table of Contents

Introduction and Intended Use ....................................................................... 3

Definitions ....................................................................................................... 4

Safety Information .......................................................................................... 4

Storage and Transportation ........................................................................... 4

Environmental Limits ...................................................................................... 4

Location of Labels .......................................................................................... 5

Operator Controls .......................................................................................... 6

Pre-Installation ...........................................................................................7-11

Installation Requirements .............................................................................. 8

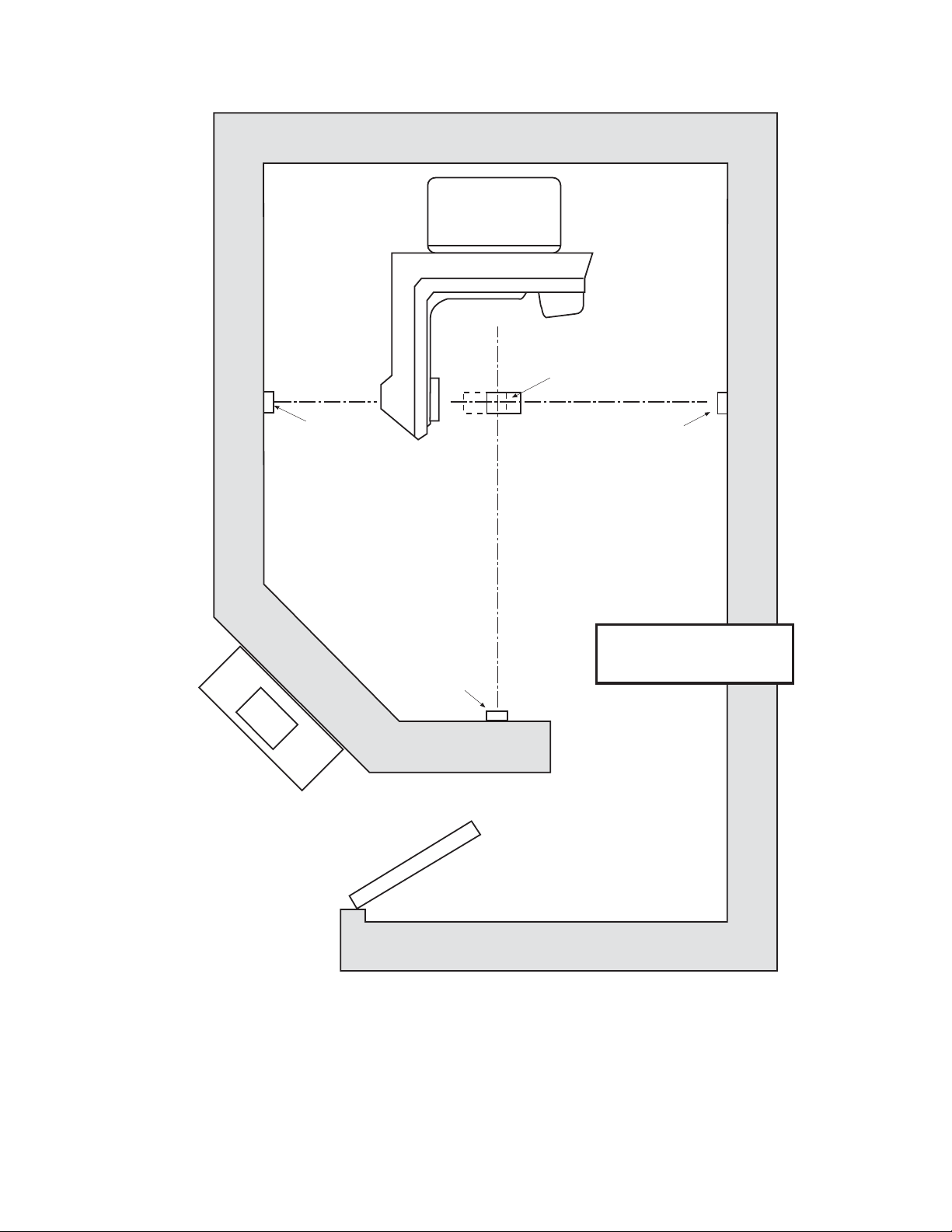

Typical Room Layout ......................................................................................9

Room Preparation .........................................................................................10

Installation ............................................................................................... 13-18

Side Optical Aligner Installation................................................................13-14

Second Side Aligner Installation .................................................................. 16

Installation on Angled Walls ......................................................................... 17

Ceiling Aligner Installation ............................................................................ 18

Sagittal Aligner Installation ........................................................................... 20

Remote Control ........................................................................................21-29

Optical Aligner Adjustments .................................................................... 30-32

Maintenance & Cleaning................................................................................32

Troubleshooting .......................................................................................33-34

Repair and Parts Information .................................................................. 35-37

Replacing the LED ....................................................................................... 35

Dismantling and Disposal ............................................................................ 36

Parts List ...................................................................................................... 37

Specifications ................................................................................................38

Technical Support ........................................................................................ 40

Product Warranty ......................................................................................... 40

NOTE: Installation Template was shipped with your patient positioning unit. For replacement

template, please use Gammex part number: 007882

3

Dear Valued Customer

Congratulations on your recent purchase of a Gammex Optical Alignment System!

This optical alignment system product is the result of over 40 years of continuous

quality improvement of alignment technologies. If, after carefully reading this

manual, you have any questions, please contact our Sales and Service Department

at 1-800-Gammex 1 or 1-800-426-6391.

Introduction

This Installation and User’s Guide includes the information you will need to safely

and efficiently install, operate and maintain your medical alignment system. This

guide is only intended for use with Gammex AccuChrom 3 models GLED-800

(Crosshair) and GLED–600 (Sagittal).

Intended Use

These optical alignment products are intended to be used for aligning patients to

medical diagnostic imaging and radiation therapy equipment which utilizes ionizing

radiation. They are intended to be used in medical clinic or hospital settings by

trained medical staff. The optical alignment products are not designed to be used

around flammable anesthetics, which present a risk of explosion or fire. The optical

alignment products are not intended to be used in a sterile or corrosive

environment. No other uses are intended nor implied.

4

Storage and Transportation

• Do not drop

• Non-corrosive environment

• Storage Temperature: -20 to +40° C (-4 to +104° F)

• Storage Humidity: 0 to 85% relative humidity (no dew nor condensation)

Environmental Limits:

• Operating Temperature: +5 to +35° C (+41 to +95° F)

• Operating Humidity: 0 to 85 % relative humidity (no dew nor condensation)

• No flammable anesthetics

• No corrosives

General Safety

Signal words are used according to international standards. The meanings of these

signal words are:

DANGER

- Indicates an imminently hazardous situation which, if not avoided,

will result in death or serious injury. This signal word is to be limited to the

most extreme situations.

WARNING

- Indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury.

CAUTION

- Indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury. It may also be used to alert against

unsafe practices. Permitted for property damage only accidents.

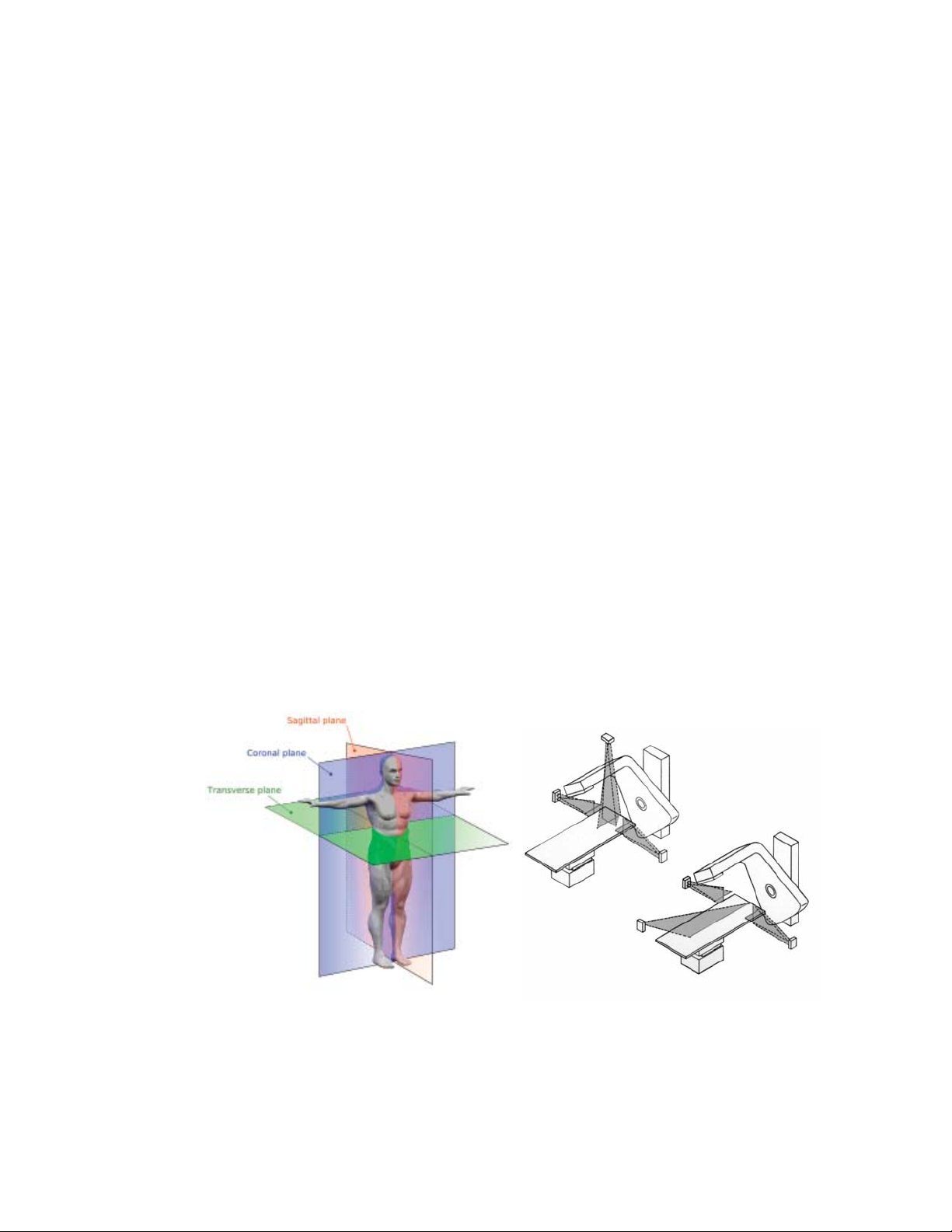

Sagittal - Single vertical line projecting

Crosshair - Crossed line projecting

Iso-center - Center point where the X, Y and Z planes coincide.

Indicates user to consult accompanying document

This symbol indicates that when the end-user wishes to

discard this product, it must be sent to a separate collection

facility for recovery and recycling.

Caution - Optical Radiation Risk of eye damage. Do not stare

directly at light source.

5

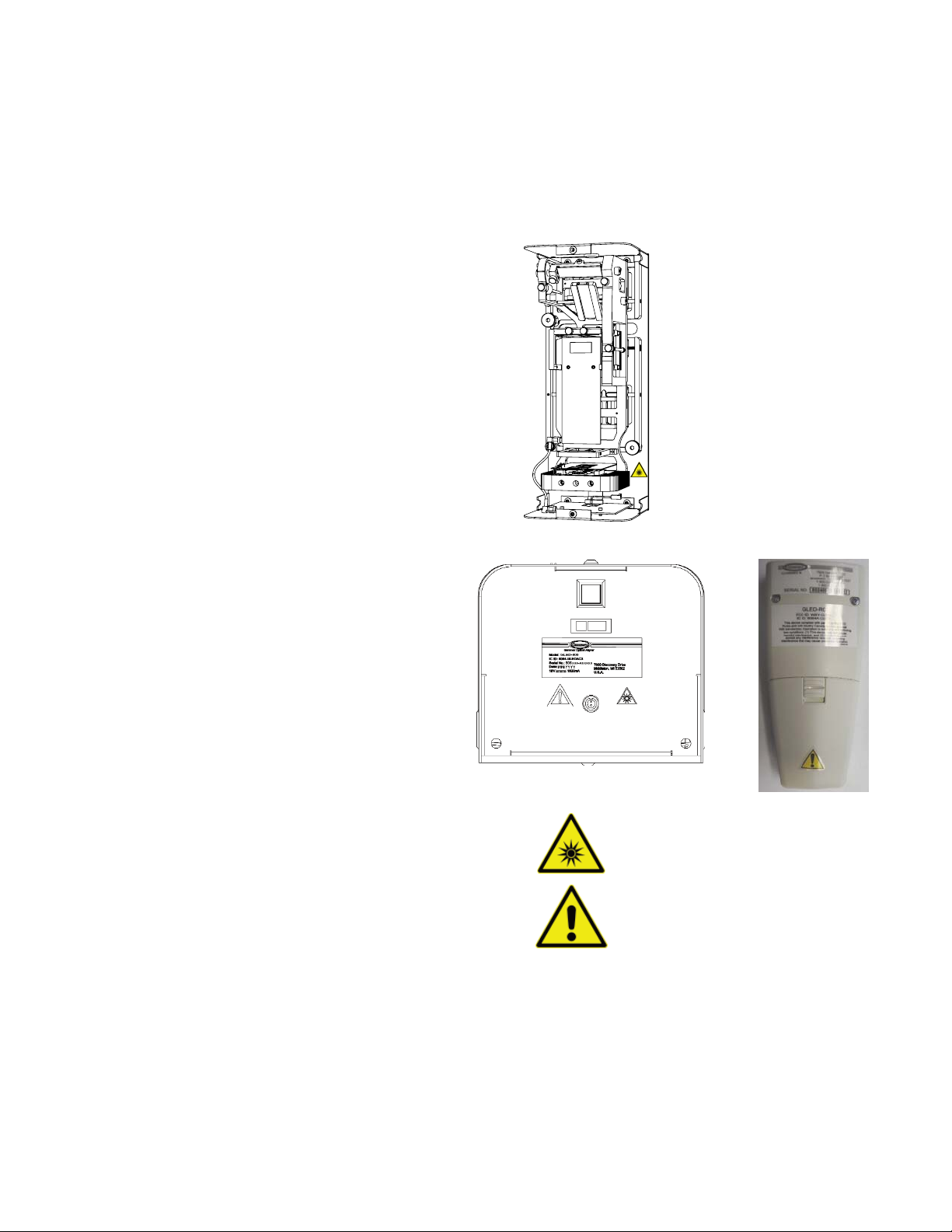

Location of labels

Safety labels are located in two places on the Optical Aligner:

1) On the Optical Aligner back plate

2) Bottom outside of housing

3) Back of remote control

Labels

Optical Radiation

Caution/Read Accompanying Material

6

Operator Controls

A - Cover

B - Dust cover

C - Bayonet Lock Power Plug

D - ON/OFF Power Button (Push on/push

off) Lighted when on.

E - DIP Switches

• To turn the optical aligner on: push the

ON/OFF button (D). The button (D) will

glow green and you will see the beam of the

optical aligner through the dust cover (B).

• To turn the optical aligner off: push the

ON/OFF button (D). The button goes dark.

NOTE:

• Some medical facilities power all the optical aligners from one wall switch so all units

in the system can be turned on and off from

a convenient location.

• Some facilities connect the optical aligners

to a timer so they are automatically turned

off.

*Consult your local electrical codes for

specific requirements.

D

C

A

B

E

Bottom View

7

Pre-Installation

GENERAL

All Gammex AccuChrom 3 Optical Alignment Systems provide an optical aid for

rapid and accurate patient positioning and repositioning for therapy and simulator

machines.

TECHNICAL DESCRIPTION

For the purpose of this manual, a single optical aligner will be referred to as a

unit and a set of related aligners will be referred to as a system.

Various combinations of the GLED-800 crosshair AccuChrom 3 and the GLED600 sagittal (straight line) AccuChrom 3 are used with different systems. The

GLED-800 optical aligners, mounted on each side, project crosshairs along the

X-axis. A GLED-800 optical aligner mounted on the ceiling projects a crosshair

vertically along the Z-axis. The Sagittal GLED-600 optical aligner projects a

straight line in the Z-Y plane.

X

X

X

Y

Z-Y

Plane

X-Z

X-Y

Z-Y

8

Installation Requirements

ELECTRICAL

Each optical aligner is provided with a universal power supply (transformer) with an

input of 100 to 240 volts AC at 50 to 60 Hz. The universal power supply plugs into a

wall outlet using one of four (4) interchangeable “snap-in” plugs that fit most outlets.

A 1.83 meter (6 foot) power cord supplies 18 Volt DC power to the optical aligner

with a bayonet type locking power plug.

TOOLS NEEDED

In addition to some basic tools, such as screwdrivers, a hammer and a ladder; you

will need an electric hammer drill, plumb bob, water level, masking tape and 15M

(50 feet) of string. The mounting hardware, a 1/4-20 tap, 2 drill bits (#7 and 3/8”),

1/4” anchor and a 3/16” hex (allen) wrench, are included with the optical alignment

systems. A spinning laser may be used as an alternative to a water level. Contact

us for more information.

CAUTION: The location of each optical aligner is determined in relation to the

therapy machine’s crosshair and isocenter. Before installing an optical alignment

system, ask the physicist to verify that the field light aligns with the therapy

machine’s isocenter. See Figure 1 on page 9.

During commissioning/validation of a linear accelerator, please power off all

AccuChrom 3 positioning units (to prevent damage caused by high levels of

radiation). They may be powered back on immediately after commissioning/

validation.

9

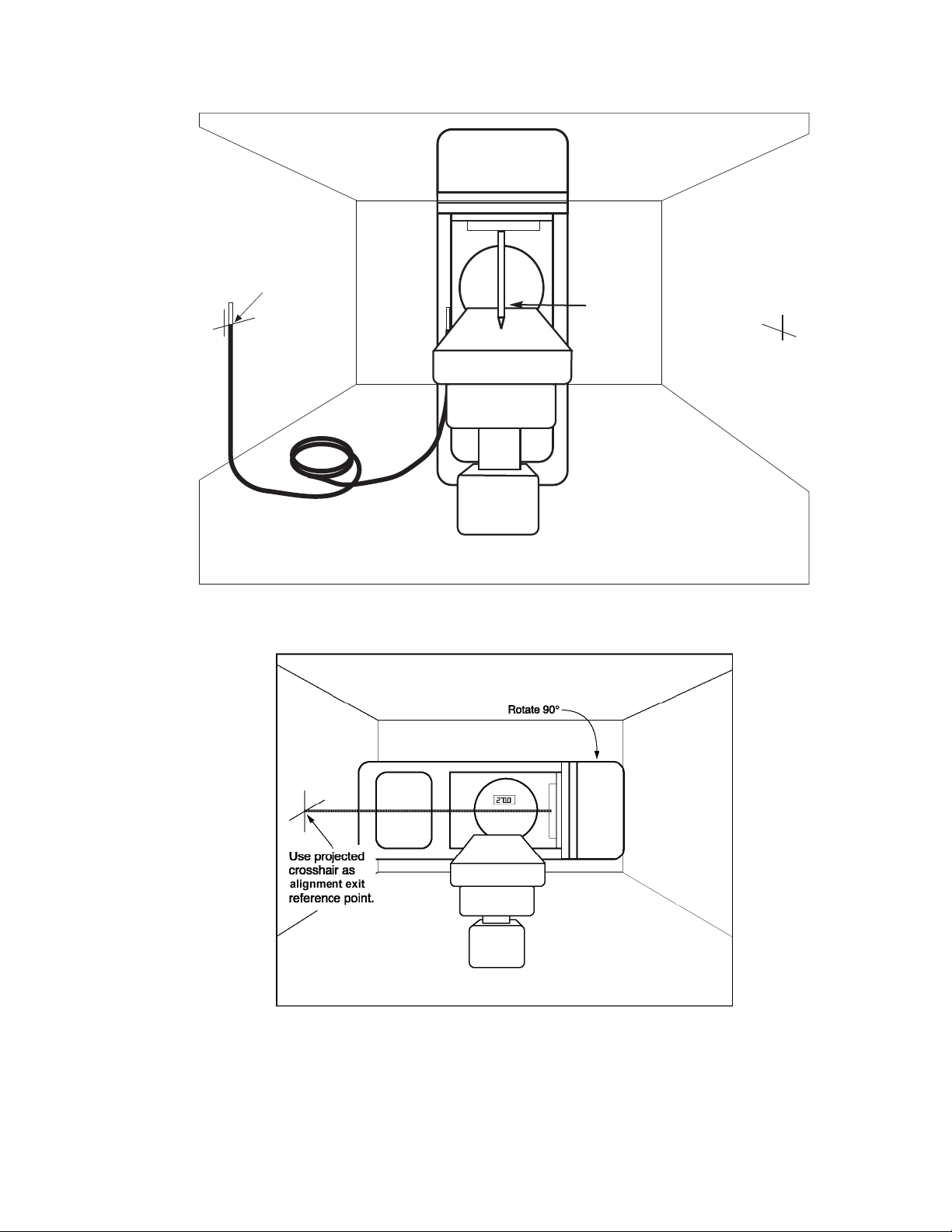

Gantry rotated 90 °

Figure 1

Room Layout

Overhead aligner

(crosshair)

Side aligner

(crosshair)

Sagittal

aligner

Side aligner

(crosshair)

AccuChrom 3

Alignment Systems

10

Pre-Installation

Use a water level to line up the optical aligner’s exit reference point at the height of

isocenter. See Figure 2 on page 10.

PREPARING THE ROOM

1. Unpack each optical alignment unit and remove shipping stability screws according

to the pre-installation guide included with the unit.

2. Turn the linear accelerator lamp on.

3. Set gantry and collimator to 0º and level the collimator.

4. Lower the table as far as possible.

COLLIMATOR CROSSHAIR ACCURACY

The collimator projected crosshair is used as a reference when determining the optical

aligners locations. The light field should coincide with isocenter, the gantry should be

level, and if collimator crosshair displacement exists, it should be compensated for.

1. Project a collimator crosshair onto a piece of paper taped to the table and mark the

center with a dot.

2. Rotate through 360° and mark the center again.

3. If there is a difference between the two dots, review this finding with site physicist.

The physicist will make the final determination as to where to place the crosshair if

a difference in dot location is observed.

USING THE LEVEL

Use a level to determine the height of the optical aligner exit reference point when

installing optical alignment systems in a simulator room or in a room with angled walls.

In standard treatment rooms, the level should also be used to verify the optical alignment system location. See

Figure 2 on page 10.

1. Raise the table to the front pointer (isocenter).

2. Remove caps on ends of level and remove air bubbles.

3. Line up with the table edge and with the wall.

4. The line on the wall indicates the horizontal axis of the optical aligner exit

reference point.

11

Horizontal line

Figure 2

Use a water level to line up the alignment exit reference point at the height of

isocenter.

Figure 3

Rotate the gantry 90º and project a crosshair onto the wall.

Front

Pointer

Showing the

Height of the

laser exit

reference point.

12

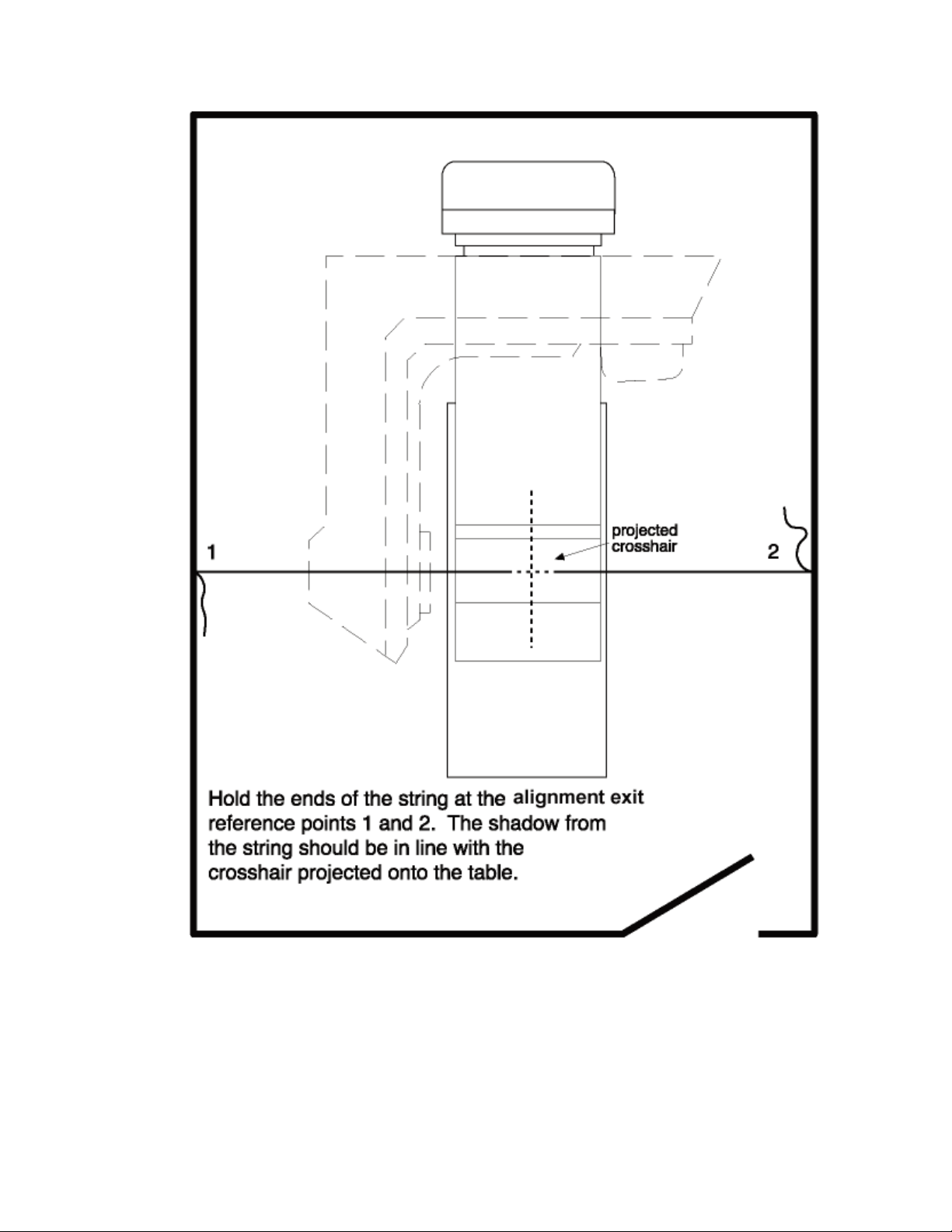

Figure 4

Use a string to verify the location of the units.

13

Installing Optical Alignment Systems

SIDE OPTICAL ALIGNER INSTALLATION

For all GLED-800 installations.

For angled walls, refer to page 17.

1. Rotate the gantry 90° to the 270° position and project a crosshair onto the wall.

See

Figure 3 on page 11.

2. Use a pencil and straight rule to trace the crosshair onto the wall.

3. Line up the template provided, so that the projected crosshair lines up with the

optical aligner exit point on the template. Use a level to line up the template.

4. Mark the outer edge of the template and also mark the mounting holes.

5. Rotate the gantry 180° to the 90° position and repeat steps 2-4 on the opposite

wall.

6. Return the gantry to 0°.

7. Tape a blank 8 X 10 piece of paper to the table.

8. Project the collimator crosshair onto the paper, keep the field as wide as

possible.

9. Hold the ends of a string on each wall at the center of the crosshair traced in

step 2. The string shadow should be in line with projected crosshair. See

Figure 4 on page 12.

10. Drill the mounting holes. Tap threads or install anchors as necessary.

11. Remove the AccuChrom 3 from its packaging

and remove shipping stability

screws according to the pre-installation guide included with the unit

. Remove

two screws from the front cover using a 1/8” hex (allen) wrench. Slide the cover

straight off towards the front.