Gamma X-6 Owner's Manual

OWNER'S MANUAL

Issue 4 - November 2012

X-6

STRINGING MACHINE

2

LIMITED WARRANTY

GAMMA Sports (GAMMA) warrants to the original purchaser that the X-STRINGER stringing machine ("EQUIPMENT")

purchased is free from defects in materials and workmanship for a period of fi ve (5) years from the date of original purchase

for mechanical parts (excluding any electrical parts and string clamps), and for a period of one (1) year from the date of

purchase for any electrical parts and string clamps. Should any defects develop under normal use within the specifi ed time

periods, GAMMA will at its option, repair or replace the defective EQUIPMENT provided it is returned to GAMMA prepaid

at the purchaser's expense. This warranty does not apply to any damage or defect caused by negligence, abuse, misuse,

unauthorized alteration, shipping, handling, or part wear and tear as a result of normal use.

Routine maintenance, adjustment, and cleaning required to ensure proper operation are the responsibility of the purchaser

and are not covered under the terms of this warranty. These include, but are not limited to: String Clamp adjustment, as

described on page 13, Turntable Bushing Adjustment, as described on page 13 and the Rotational String Gripper.

GAMMA's obligation under this warranty is limited to repair or replacement of defective EQUIPMENT , and no one is authorized

to promise any other liability. GAMMA shall in no event be liable for any incidental or consequential damages.

T o return defective EQUIPMENT , a return authorization (RA#) must be obtained from a GAMMA customer service representative. The RA# must be marked on the outside of the shipping carton being returned. All returns must be shipped prepaid by

the customer to GAMMA. Please retain the original shipping carton and packing materials for any future shipments. GAMMA

will not be responsible for machines which are not sent in the original undamaged packaging.

A GAMMA Care Service Plan is also available through GAMMA customer service, call 800.333.0337 for details.

X-6

MGX6-12 OWNER’S MANUAL

TABLE OF CONTENTS

WARRANTY ................................................................................................P AGE 2

FEATURES .................................................................................................PAGE 3

ASSEMBLY INSTRUCTIONS .....................................................................PAGE 4

MOUNTING THE FRAME ...........................................................................PAGE 6

STRINGING THE FRAME ..........................................................................PAGE 8

ADDITIONAL FEATURES ......................................................................... PAGE 11

PATHFINDER AWL ...................................................................................PAGE 12

MAINTENANCE & ADJUSTMENTS .........................................................PAGE 13

TROUBLESHOOTING TIPS .....................................................................P AGE 13

PARTS LIST ..............................................................................................PAGE 14

PARTS DRAWING ....................................................................................PAGE 15

3

MACHINE FEATURES

Drop Weight Tensioner with 8 to 90 lbs Tension Range and

Permanently Engraved Weight Scale

Professional Six Point “Quick Mount” Racquet Mounting

System- Accommodates All Racquets

Parallel Jaw Rotating Ratchet Gripper with Diamond Dust

Coated Gripping Surfaces

Two Composite Floating Clamps with Thumb Screw

Adjustment

High Strength Extruded Aluminum Base with Durable

Anodized Finish and Convenient Padded Tool Tray

Unique Internal Drawer System for Storing Tools and Adaptors

FEATURES

4

ASSEMBLY INSTRUCTIONS

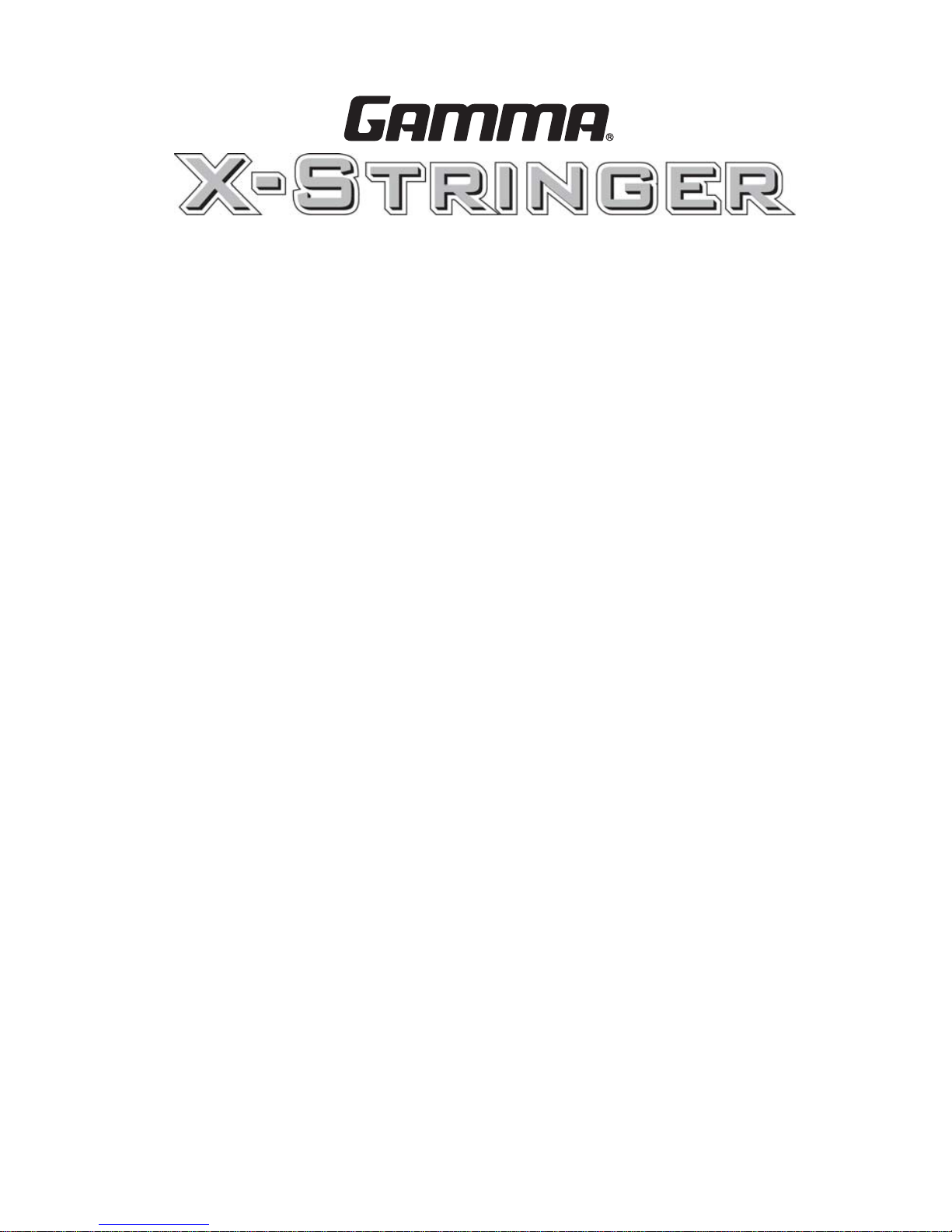

Engaging the Drop Weight Bar Stop

The stringing machine is shipped with the

drop weight bar in the horizontal position. T o

limit the rotation of the drop weight bar and

prevent racquet damage during stringing,

the bar stop must be engaged.

Hold the drop weight bar in the vertical position as shown while turning the 5mm stop

screw located on the back side of the winder

stand clockwise.

Winder Support Stand Installation

Remove the M5 bolts from the 2 brackets

located in the rear slots of the machine base

using the 5MM hex key. Slide the brackets

to the right end of the base and position the

winder stand over the brackets aligning the

holes in the base of the winder stand with the

holes in the brackets. Attach the winder support stand using the M5 bolts. Install all 4 bolts

loosely at fi rst and then tighten all securely.

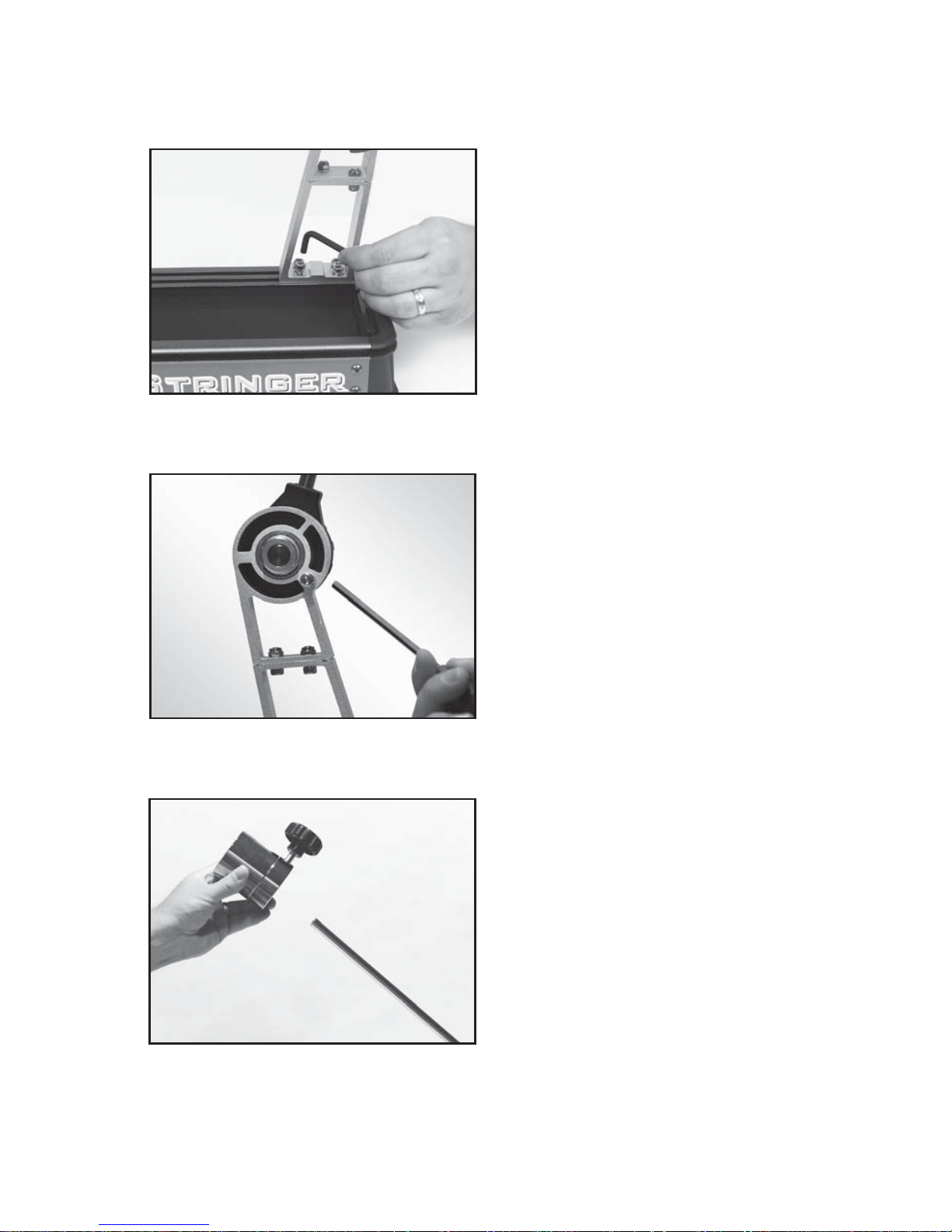

Installing the Drop Weight

Remove the end cap from the tension bar and

slide the drop weight onto the bar. The weight

should be oriented with the knob end closest

to the string winder. Replace the end cap.

5

ASSEMBLY INSTRUCTIONS

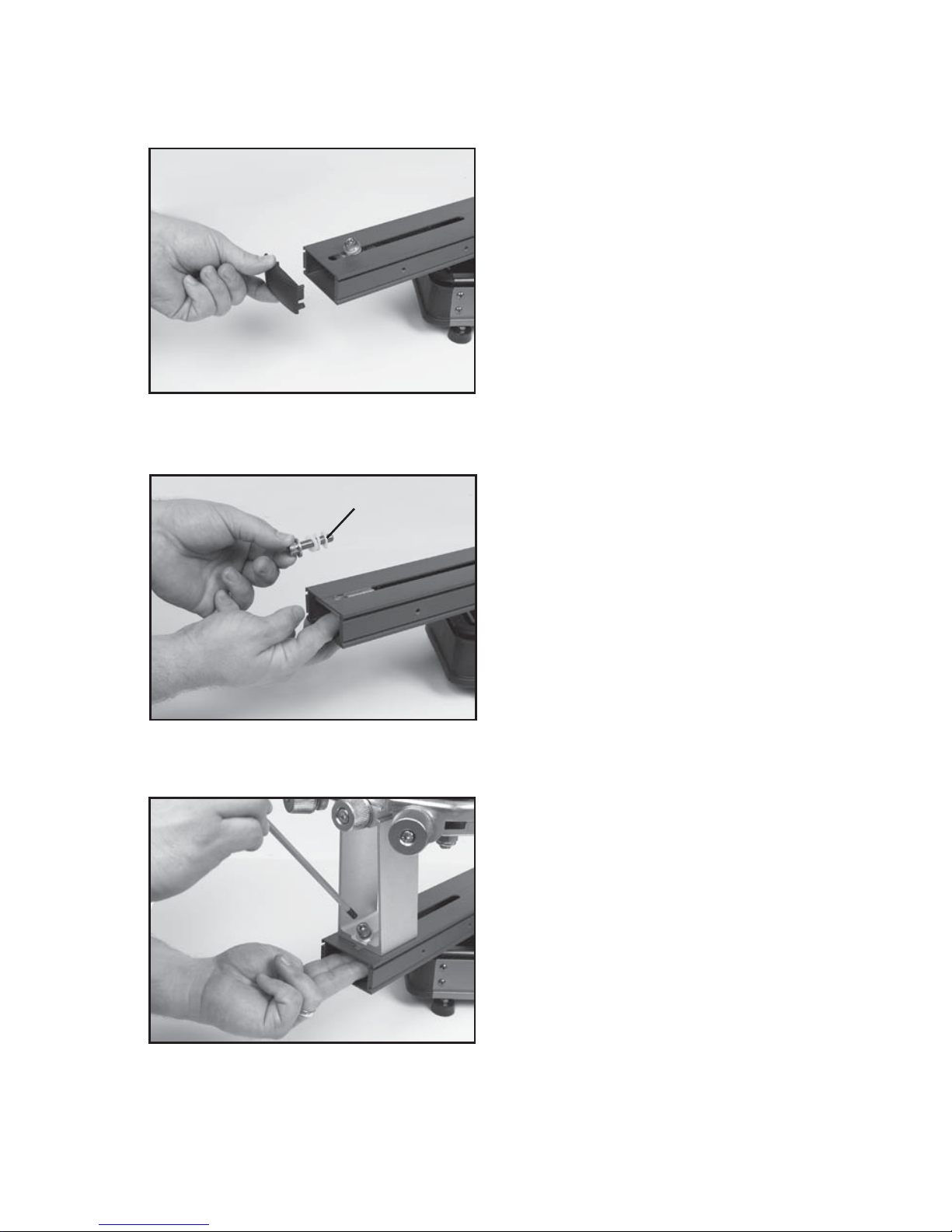

Installing the Frame Support Posts

Place the support post onto the central slot

of the turntable. While holding the mounting

plate against the inside top surface of the

turntable with your fi ngers, align the hole in

the support post with the hole in the mounting

plate. Install the mounting bolt through the

support post and into the plate by hand and

tighten with the 6 mm hex wrench. Re-install

the turntable end caps.

Repeat procedure on the opposite side of

the turntable

Remove Mounting Bolts

While holding the mounting plate on the

inside of the turntable remove the support

post mounting bolts.

Note: There are two Nylon washers that are

included for shipping purposes only. Remove

and discard the nylon washers.

Repeat procedure on the opposite side of

the turntable

Support Post Installation

To install the support posts you must fi rst

remove the turntable end cap by grasping

the sides of the end cap and removing it, to

gain access to the inside of the turntable.

Repeat procedure on the opposite side of

the turntable.

If end caps are tight, a fl at blade screw driver

may be used to pry the end caps off.

Nylon

Washers

Loading...

Loading...