Page 1

PRO 100

STRINGING MACHINE

OO

WNER'S MANUWNER'S MANU

O

WNER'S MANU

OO

WNER'S MANUWNER'S MANU

Issue 3 - September 22, 1998Issue 3 - September 22, 1998

Issue 3 - September 22, 1998

Issue 3 - September 22, 1998Issue 3 - September 22, 1998

Copyright 1998 GAMMA Sports - All Rights Reserved

ALAL

AL

ALAL

Page 2

PRO 100

OWNER'S MANUAL

TABLE OF CONTENTSTABLE OF CONTENTS

TABLE OF CONTENTS

TABLE OF CONTENTSTABLE OF CONTENTS

PAGE 1 ............................................................................................WARRANTY

PAGE 2 .....................................................................ASSEMBLY INSTRUCTIONS

PAGE 5 ..................................................................... MOUNTING THE RACQUET

PAGE 6 ..........................................................................STRINGING THE FRAME

PAGE 9 ............................................................................................PARTS LIST

PAGE 10 ....................................................................... EXPLODED PARTS VIEW

LIMITED WARRANTYLIMITED WARRANTY

LIMITED WARRANTY

LIMITED WARRANTYLIMITED WARRANTY

GAMMA SPORTS ("GAMMA") warrants to the original purchaser that the GAMMA PROGRESSION stringing machine

("EQUIPMENT") purchased is free from defects in materials and workmanship for a period of five (5) years from the date of

original purchase for mechanical parts (excluding electrical parts and string clamps), and for a period of one (1) year from

the date of purchase for all electrical parts and string clamps. Should any defects develop under normal use within the

specified time periods, GAMMA will at its option, repair or replace the defective EQUIPMENT provided it is returned to GAMMA

prepaid at the purchaser's expense. This warranty does not apply to any damage or defect caused by negligence, abuse,

misuse, unauthorized alteration, shipping, handling, or part wear and tear as a result of normal use.

GAMMA's obligation under this warranty is limited to repair or replacement of defective EQUIPMENT, and no one is authorized

to promise any other liability. GAMMA shall in no event be liable for any incidental or consequential damages.

To return defective EQUIPMENT, a return authorization (RA#) must be obtained from a GAMMA customer service

representative by calling 1-800-333-0337. The RA# must be marked on the outside of the shipping carton being returned. All

returns must be shipped prepaid by the customer to GAMMA. Please retain the original shipping carton and packing materials

for any future shipments. GAMMA will not be responsible for machines which are not sent in the original undamaged

packaging.

1

Page 3

ASSEMBLY INSTRUCTIONS

Installing the Base Legs

A

The PRO 100 is shipped with the legs separate from the base and requires assembly

before use.

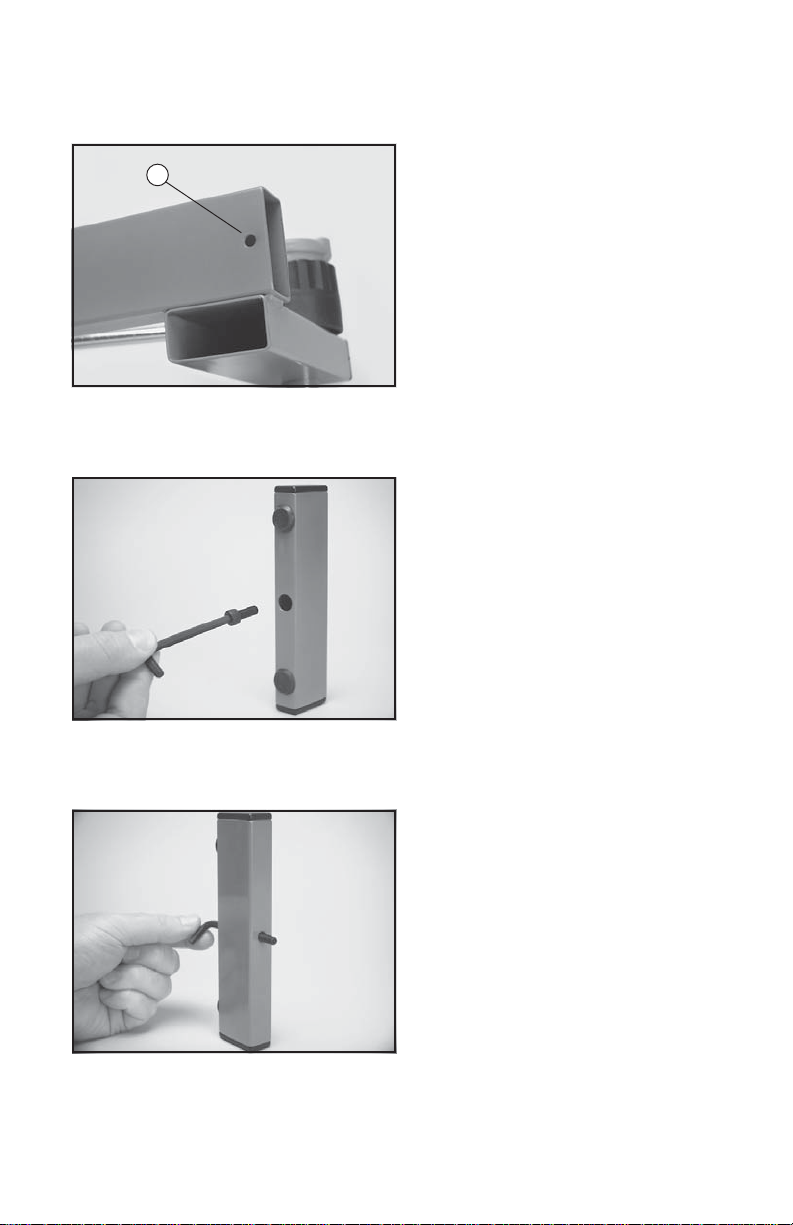

Hole (A) in the machine base is the attaching

point for the base leg.

Place one screw onto the end of the 4mm

hex wrench. Carefully insert the screw

through the large hole in the bottom of the leg

and continue through the small hole at the

top of the leg.

While holding the leg, screw and wrench as

one unit, place the exposed end of the screw

through hole (A) in the machine base.

Place one washer over the exposed screw

end inside of the machine base. Thread one

locking nut onto the screw end.

2

Page 4

ASSEMBLY INSTRUCTIONS

Installing the Base Legs ( cont. )

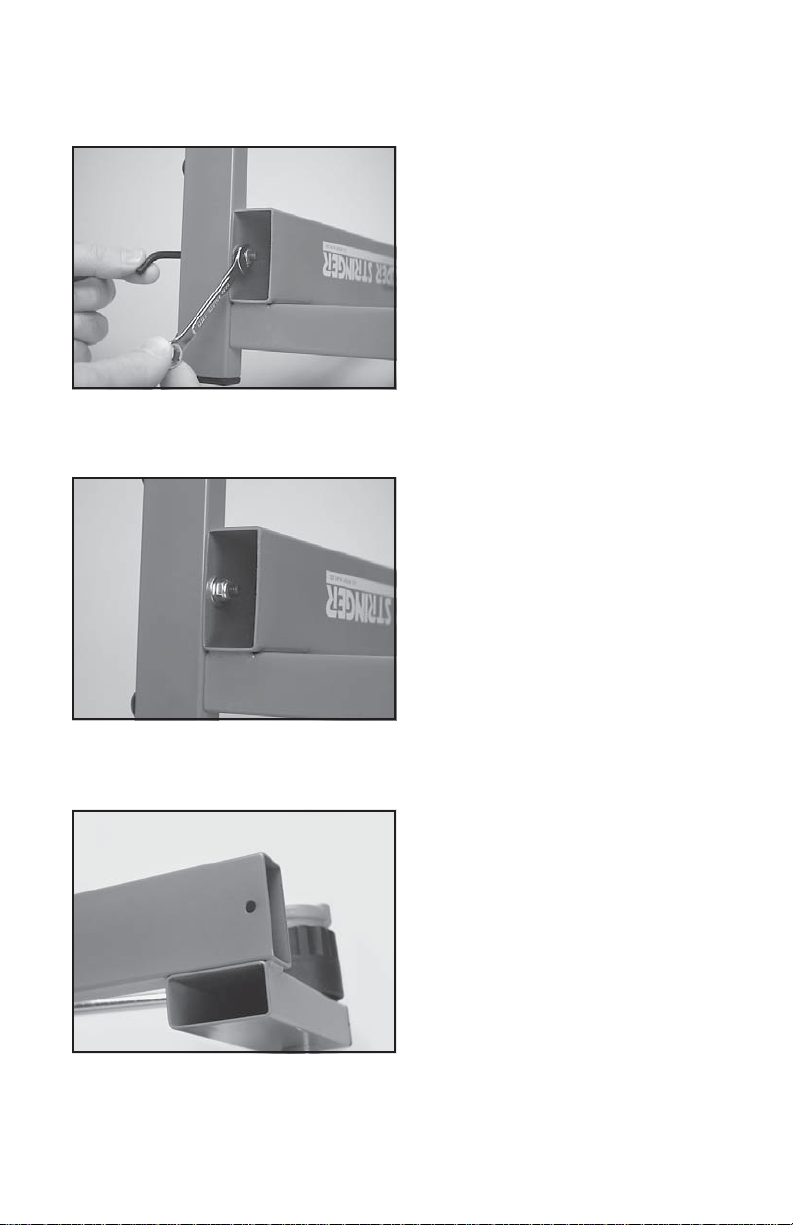

Using the included 10mm box wrench, securely tighten the locking nut.

The completed leg / base assembly.

Replace the base endcap making sure the

notched side of the endcap is aligned with

the leg attachment screw.

3

Page 5

ASSEMBLY INSTRUCTIONS

Installing the Turntable

Insert the turntable center post into the bushing assembly of the machine base.

Installing the Support posts

Slide each support post onto the end of the

turntable bar. The posts should be oriented

so as to angle away from the turntable center

post.

Installing the Drop Weight

Remove the endcap from the tension bar

and slide the drop weight onto the bar. The

weight should be oriented with the knob end

closest to the string winder. Replace the

endcap.

4

Page 6

MOUNTING THE RACQUET

Installing the Racquet Support Adapters

The PRO 100 is supplied with two styles of

Racquet Support Adapters. A thick profile

adapter for widebody racquets and a thin

profile adapter for conventional racquet

frames. The Adapters are also tapered, use

the highest side of the adapter that does not

interfere with the string grommet holes.

Adjusting the Frame Support Posts

Place the racquet frame over the center

posts and onto the frame support posts.

Loosen the locking screws on one support

post and slide the post in the appropriate

direction until the plastic adapter contacts

the frame. Securely tighten the locking

screws. Adjust the opposite post in the same

manner.

It is extremely important both plastic adapters are in contact with the frame to prevent

racquet damage.

Securing the Racquet

With the frame support posts properly adjusted, place the frame hold down plates

over the center screws and tighten the clamp

bar knobs securely. Do not overtighten the

knobs as frame damage may occur.

Note: Inverted throat racquet frames may

require the throat clamp plate to be rotated

180 degrees to match the frame.

5

Page 7

STRINGING THE FRAME

Starting the Main Strings

To begin stringing the main strings, count

the number of holes at the throat of the

frame, which will determine the starting point.

For racquets with 4 or 8 holes at the throat,

the main strings will begin at the head. For

racquets with 2 or 6 holes at the throat, the

main strings will begin at the throat.

Thread the two ends of the string through the

two center grommet holes at the head or

throat as determined in the previous step.

Route the strings through the opposite center

holes.

Clamping the First Main String

Thread one end of the string through the

adjacent grommet hole and pull excess by

hand. Clamp both the center and the adjacent string to each other on the inside of the

frame.

Pulling Tension

While holding the tension bar slightly above

horizontal, wrap the free string clockwise

around the gripper drum once and position

between the gripper jaw.

Gently turn the gripper clockwise while

squeezing the jaws together until all slack in

the string is removed.

Note: For proper operation, the string gripper

jaw must be in the position shown. The

tension in the string provides the clamping

force to the jaws.

6

Page 8

STRINGING THE FRAME

Pulling Tension

While holding the string gripper drum with

your hand, lift the tension bar to approx. 45

degree angle and let fall. If the tension bar

drops below horizontal, repeat the above

action until the bar comes to rest parallel to

the racquet. The set tension will be reached

when the bar rests horizontal.

If the bar comes to rest above horizontal,

release the string and re-pull tension.

Manually forcing the bar into the horizontal

position will greatly increase string tension

and may result in racquet damage.

Clamping the String

Clamp the tensioned string to the next adjacent string using the secong string clamp.

Release the tensioned string by raising the

tension arm.

Repeat the procedure for all of the remaining

main strings and tie off following the racquet

manufacturers recommendations.

Starting the Cross Strings

Follow the manufacturer's recommended

stringing pattern for one or two piece stringing. This will determine the starting point for

the cross strings. Weave the first two cross

strings and pull tension as per Step 3. Clamp

the cross strings as per Step 4.

7

Page 9

STRINGING THE FRAME

Finishing the String Job

Weave and tension the remaining cross

strings and tie off at the specified grommet

hole.

Remove the strung racquet from the Super

Stringer in the reverse order of mounting.

8

Page 10

PARTS LIST

PART #

4

24

25A

26

27

28

29

30A

31

32B

33B

34

36

37

42

43

44

45

46

47

48

49

50

51

DESCRIPTION

TURTABLE BUSHING

KNOB

SET SCREW

TENSION BAR CAP

DROP WEIGHT KNOB

FRONT WEIGHT

BACK WEIGHT

SET SCREW

STRING GRIPPER DRUM

UPPER GRIPPER JAW

LOWER GRIPPER JAW

RATCHET TEETH

GRIPPER JAW SPRING

CAP SCREW

FLOATING CLAMP ASMBLY

LEVER JAW

INNER JAW

KNOB JAW

LEVER

KNOB

SWING BOLT

RETURN SPRING

PIVOT PIN

RETAINING RING

PART #

78

79

82

82A

83

84

85

86A

87

88

89

92

93

94

95

161

162

163

69

70

72

73

98

DESCRIPTION

CLAMP PLATE

CLAMP PLATE PAD

FRM SUPP ADPTR - SHORT

FRM SUPP ADPTR - TALL

BASE

LEG

LEG CAP

WINDER STAND ENDCAP

RUBBER FEET

CAP SCREW

WASHER

TURNTABLE

SUPPORT POST

SUPPORT PIN

SUPPORT POST PAD

WINDER BEARING

GRIPPER PIVOT PIN - BS

PIVOT PIN RET. COLLAR

( NOT SHOWN )

HEX WRENCH / 3MM

T - HEX WRENCH / 5MM

PATHFINDER AWL

STRINGERS AWL

BOX WRENCH / 10MM

9

Page 11

EXPLODED PARTS VIEW

10

Loading...

Loading...