Gamma 9900 Els Owner's Manual

9900 Els

STRINGING MACHINE

2 PT SC MOUNTING

OWNER’S MANUAL

Issue 1 - June 2015

9900 Els

OWNER’S MANUAL

TABLE OF CONTENTS

WARRANTY ................................................................................................PAGE 2

FEA TURES .................................................................................................PAGE 3

UNPACKING & ASSEMBLY INSTRUCTIONS ............................................PAGE 4

POWER CONNECTION & CONTROLS.....................................................PAGE 11

CONTROL PANEL FUNCTIONS AND FEATURES....................................PAGE 12

DISPLAY SCREEN.....................................................................................PAGE 13

MACHINE FUNCTIONS..... ......................................................................PAGE 14

STRING GRIPPER OPERATION .............................................................PAGE 19

MOUNTING THE FRAME ........................................................................ PAGE 20

STRINGING THE FRAME ........................................................................PAGE 21

STRING LENGTH METER .......................................................................PAGE 25

ADDITIONAL FEATURES..........................................................................PAGE 26

P A THFINDER A WL....................................................................................P AGE 27

MAINTENANCE & ADJUSTMENTS .........................................................PAGE 28

TROUBLESHOOTING TIPS .....................................................................PAGE 30

PARTS LIST ............................................................................................. PAGE 32

PARTS DRAWING ....................................................................................PAGE 33

LIMITED WARRANTY

GAMMA SPORTS warrants to the original purchaser that the 9900 Els stringing machine (“EQUIPMENT”) purchased is free

from defects in materials and workmanship for a period of fi ve (5) years from the date of original purchase for mechanical

parts (excluding electrical parts and string clamps), and for a period of one (1) year from the date of purchase for all electrical

parts and string clamps. Should any defects develop under normal use within the specifi ed time periods, GAMMA will at its

option, repair or replace the defective EQUIPMENT provided it is returned to GAMMA prepaid at the purchaser’s expense.

This warranty does not apply to any damage or defect caused by negligence, abuse, misuse, unauthorized alteration, shipping, handling, or part wear and tear as a result of normal use.

Routine maintenance, adjustment, and cleaning required to ensure proper operation are the responsibility of the purchaser

and are not covered under the terms of this warranty. These include, but are not limited to: String Clamp adjustment, as

described on page 28, Clamp Base adjustment, as described on page 28, and the cleaning procedures listed on page 29.

GAMMA’ s obligation under this warranty is limited to repair or replacement of defective EQUIPMENT , and no one is authorized

to promise any other liability. GAMMA shall in no event be liable for any incidental or consequential damages.

T o return defective EQUIPMENT , a return authorization (RA#) must be obtained from a GAMMA customer service representative. The RA# must be marked on the outside of the shipping carton being returned. All returns must be shipped prepaid by

the customer to GAMMA. Please retain the original shipping carton and packing materials for any future shipments. GAMMA

will not be responsible for machines which are not sent in the original undamaged packaging.

A GAMMA Care Service Plan is also available through GAMMA customer service, call 800.333.0337 for details.

2

MACHINE FEATURES

MACHINE FEATURES

Electric Constant Pull Tensioner with 11.0 to 90.0 lbs Tension

Range

Digital Tension Setting with LCD Display

Auto Start Quick Closing Linear String Gripper

Professional Two Point Self Centering Racquet Mounting

System- Accommodates All Racquets

Auto-Release Cam-Lock Swivel Base Clamps

4 Tooth Universal String Clamps

High Strength Extruded Aluminum Frame with Durable FRP

Finish and Convenient Deep Padded Tool Tray

Unique Turntable Clutch to Customize Rotation Friction

Convenient Foot Actuated Tensioner Switch

String Length Meter

3

9900 Els

Unpacking Instructions & Contents

Instructions for Unpacking and Preparing for Assembly

The stringing machine is shipped in three cartons, a large master carton for the stringing

machine base with tensioner module and accessories, a medium carton for the turntable

and mounting system and a smaller carton for the fl oor stand post and base legs. Please

save the cartons and packing materials for possible shipments in the future. Gamma

Sports cannot be responsible for machines that are not returned, shipped in their original,

undamaged packaging. The tools you will need to assemble the machine are provided

with the machine. Due to the weight of the tensioner unit, you may need the assistance of

someone to help lift the tensioner unit out of the carton.

Once the cartons are opened, remove all inner cartons and check to be sure that all parts

are present and accounted for.

Contents of Electric Floor Stand (MMU3-20)

(1) Column Assembly

(4) Legs

(4) Leveling Feet

(4) M8 x 30 Flat Head Screws

(4) M8 x 35 Cap Screws

(4) M6 x 20 Cap Screws

(1) String Reel Holder (M8 Threaded Pin), (1) Knob, (8) Spacers, & (2) M8 Washers

Contents of Mounting System Carton (MMU3-28)

(1) Turntable Assembly w/ String Clamp Base and Mounting Stands w/ Frame Support

Slide, Side Supports, and Adapters

(2) String Clamps

(1) Package of spare plastic adapters for frame and mounting system supports

Contents of Machine Base Carton (MMU3-18)

(1) Stringer Assembly Unit w/ Tensioner Module

(1) Power Cord

(1) AC Adaptor

(1) Foot Pedal Tensioner Switch

(4) Rubber Feet for Table Top Use

(1) Wiring Harness for Electric Floor Stand Connection

(1) Stringing Tool Set - Includes 1 ea Diagonal Cutter, Bent Nose Pliers, Straight Nose

Pliers, Starting Clamp, Straight Awl & Pathfi nder Specialty A wl

(1) Tools for assembly and maintenance

4

ASSEMBLY INSTRUCTIONS

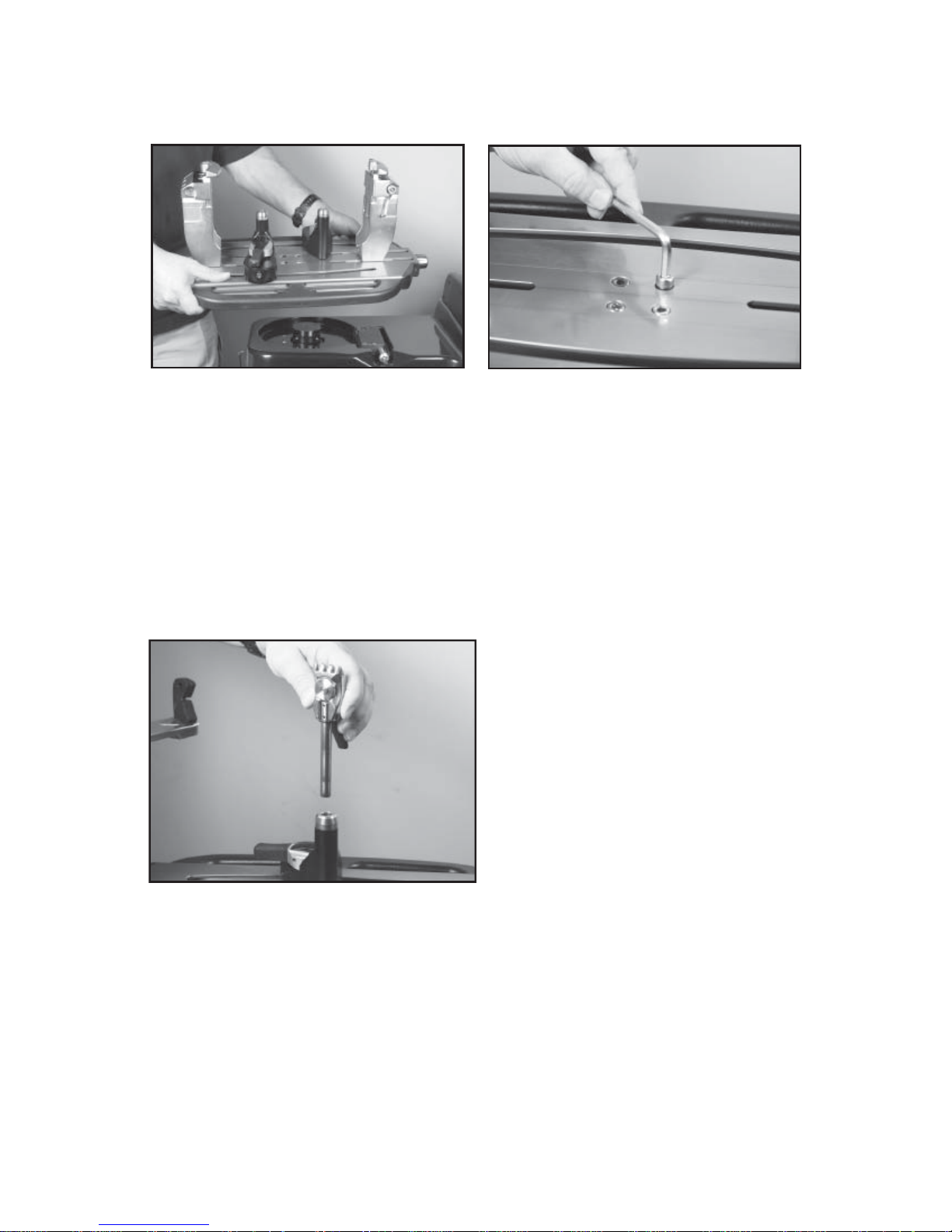

Floor Stand Leg Assembly

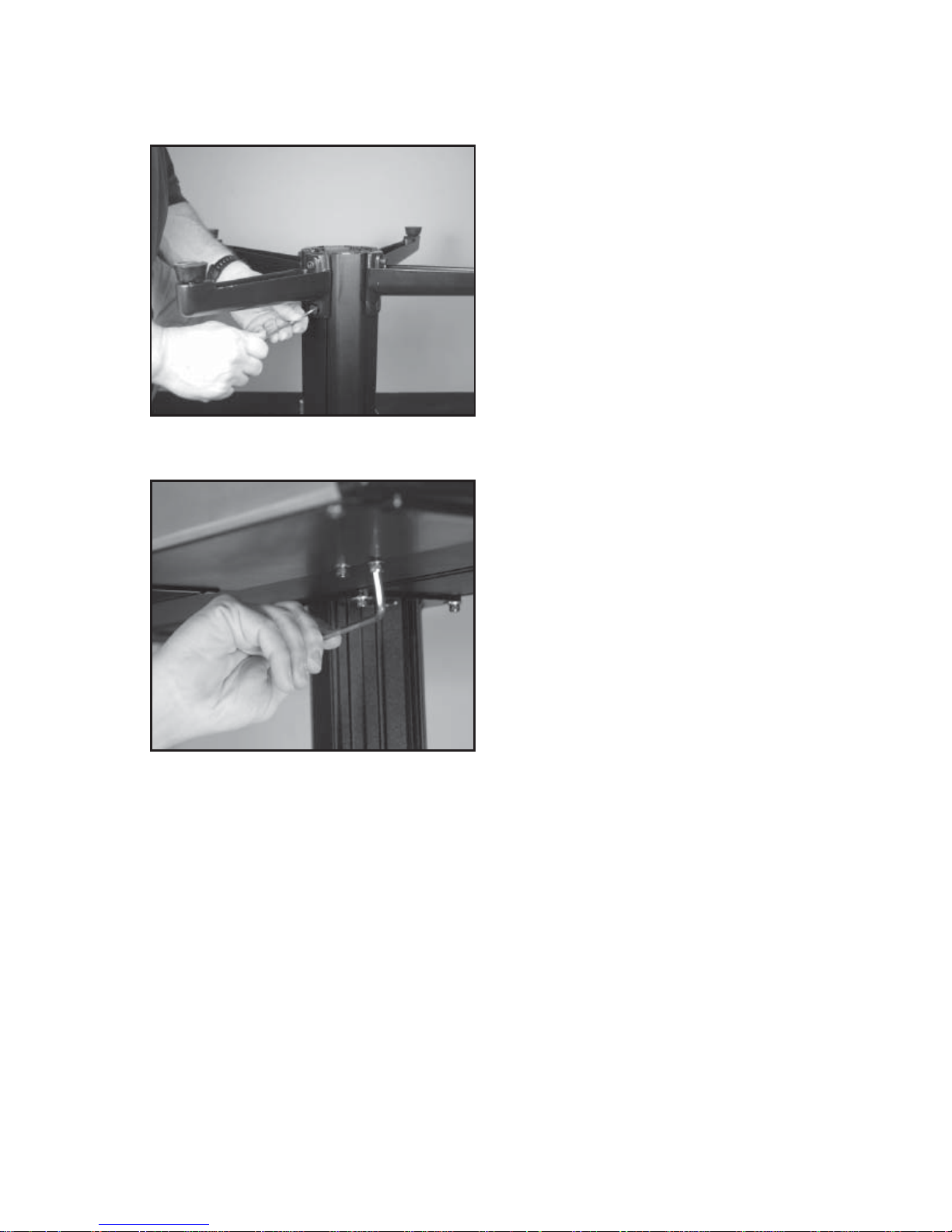

The stringing machine uses a four leg fl oor

stand design. The legs must be assembled

to the Lower Column before use. Remove

all parts from the shipping carton to confi rm

that contents match the parts list.

Align the holes in the Leg Flange with the

matching holes in the Lower Column. Secure the leg with one M8x30 fl at head screw

through the upper hole, and one M8x35

socket head cap screw through the bottom

hole. Repeat this procedure for the three

remaining legs.

Mounting the Floor Stand to the

Machine Base

The Floor Stand can be mounted to the machine base by laying the machine on the fl oor

to align the 4 holes in the fl ange plate to the

machine base or by setting the machine on top

of the upright Floor Stand. Note: If mounting

the machine base to the top of the upright

Floor Stand use the help of an assistant to

balance the machine base while aligning

and tightening the four cap bolts. Orient the

fl oor stand to the machine so that the boss

for the string reel will be on the left side of

the machine base and the fl oor stand power

switch is at the rear side of the machine base.

CAUTION: To prevent damage to the string gripper, never lift or

move the machine by the string gripper.

5

ASSEMBLY INSTRUCTIONS

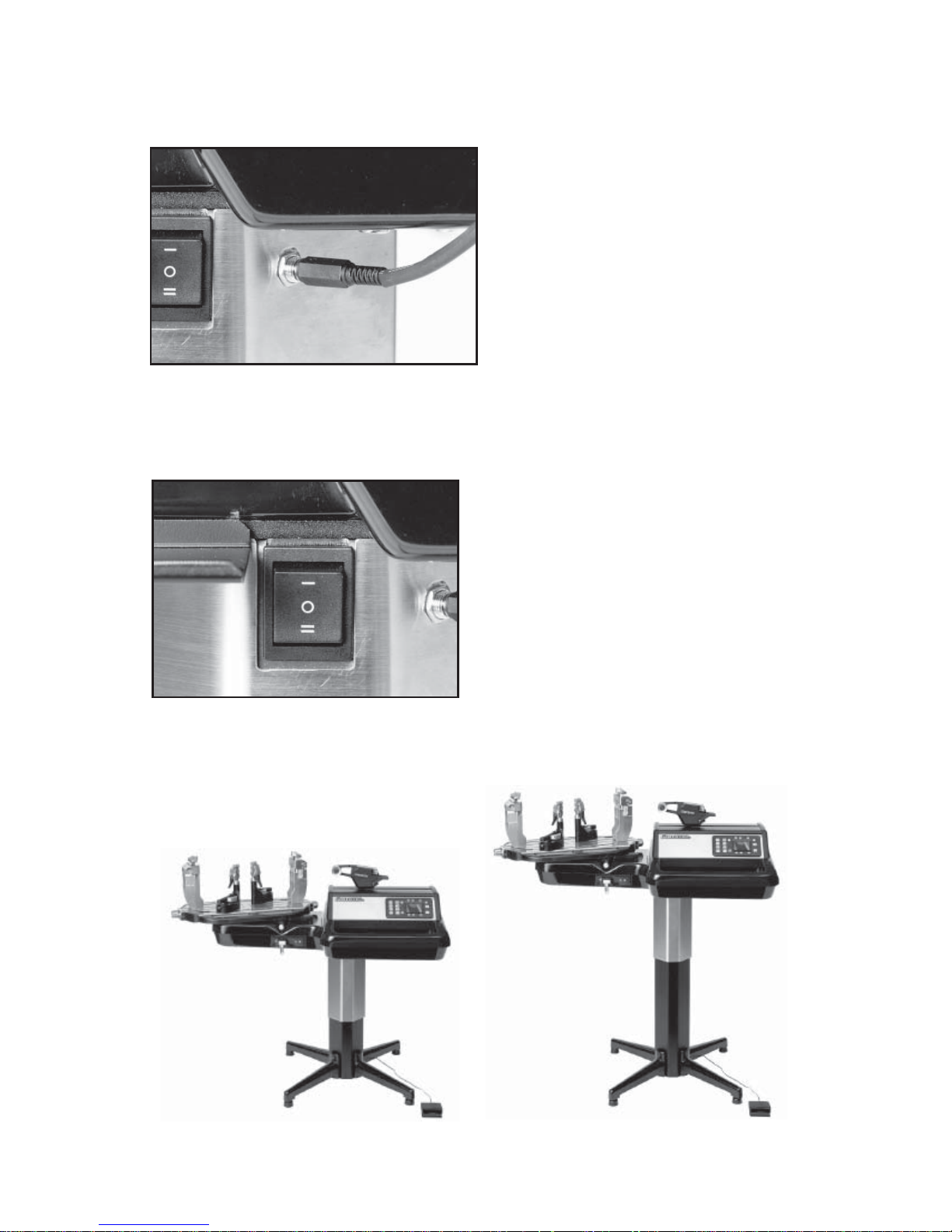

Floor Stand Power Connection

Plug the Floor Stand power cord from bottom

left side of the tensioner housing into the

socket on the Floor Stand column.

Floor Stand Height Adjustment

The electric fl oor stand permits height adjust-

ments from 39” to 49”. The machine height

can be raised or lowered by depressing the

rocker switch Up or Down. When the desired

height is reached set the rocker switch to the

neutral position.

6

ASSEMBLY INSTRUCTIONS

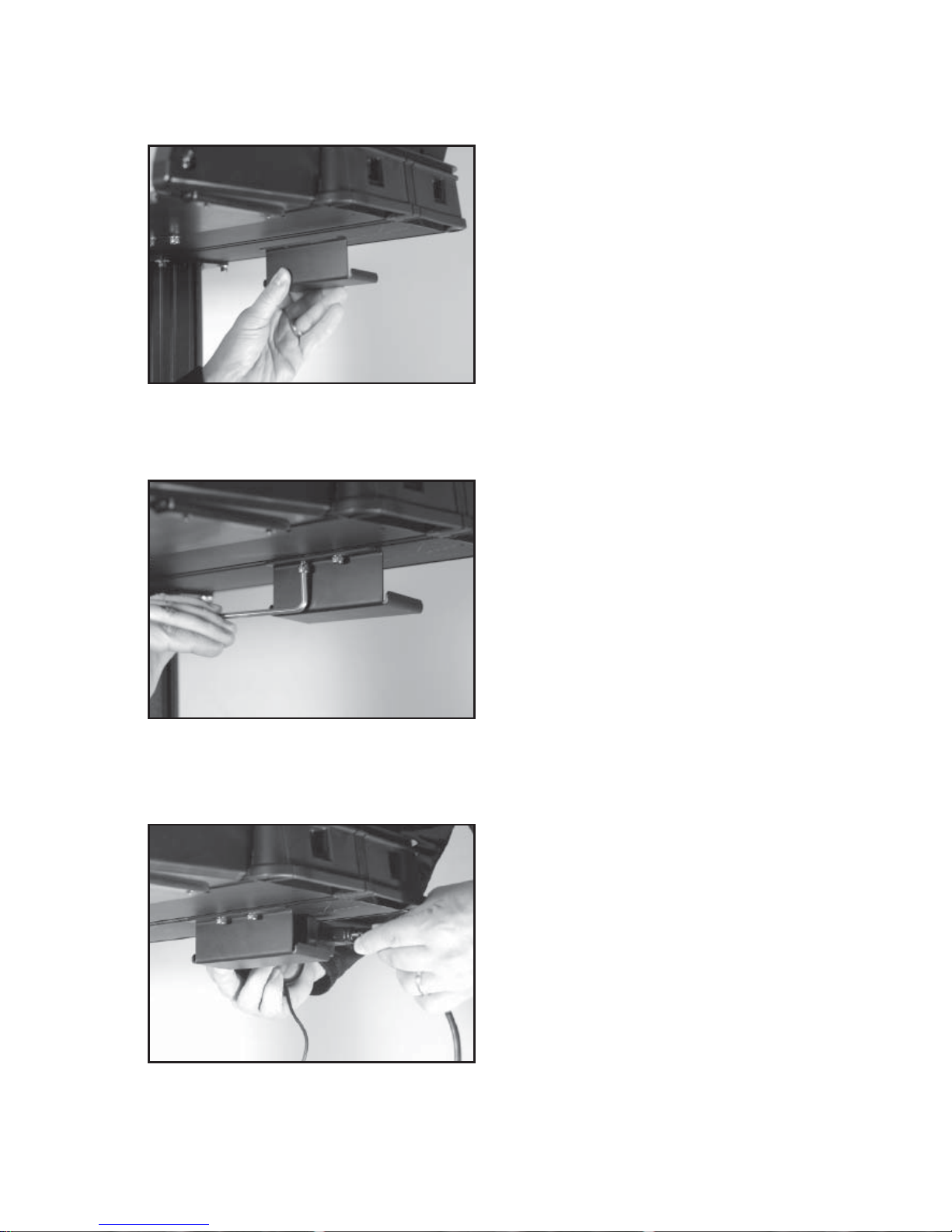

AC Power Adapter Storage Shelf

The AC Power Adapter Storage Shelf provides a means to secure and protect the

power adapter by storing it safely under the

machine base. This will reduce a potential

tripping hazard as well as eliminate potential

damage to the AC Power Supply if laying

on the fl oor.

AC Power Adapter Storage Shelf

T o mount the Storage Shelf to the underside

of the base, align the holes in the storage

shelf bracket with the holes in the base. Use

a 6 mm hex wrench to tighten the two hex

head cap screws.

NOTE: T o avoid risk of damaging the threads

in the base, DO NOT OVERTIGHTEN.

AC Power Adapter Storage Shelf

Place the AC Power Adapter into the Storage

Shelf. Coil the pin connector cable and tuck

it between the top of the AC Power Adapter

and the machine base.

7

ASSEMBLY INSTRUCTIONS

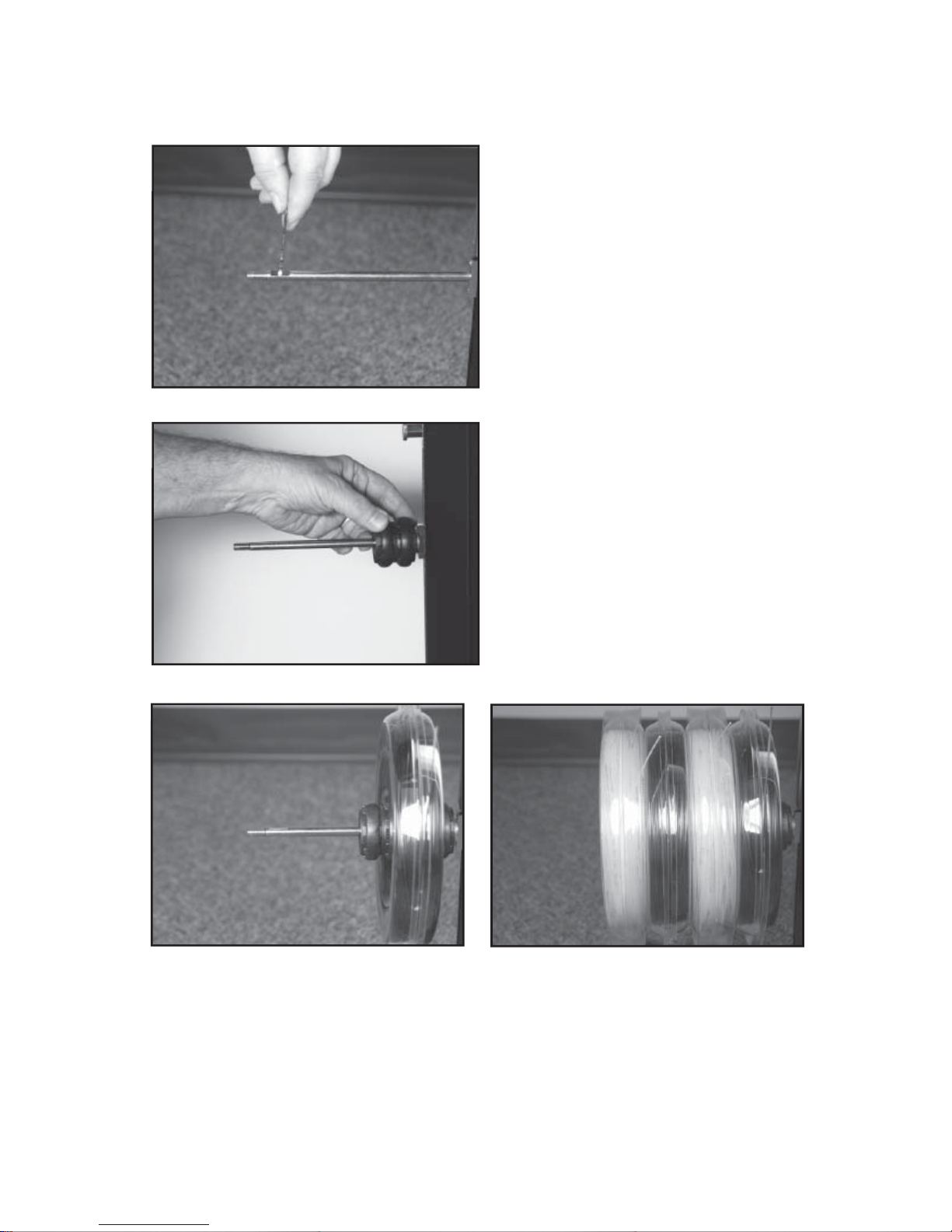

String Reel Installation

The String Reel Holder pin is an 8 mm rod

with threads on both ends and fl at surfaces

machined on one end. Thread the end of the

pin without the fl at surfaces into the threaded

boss on the right side of the Lower Column.

Using the M6 open end wrench positioned

on the fl at surfaces, securely tighten the pin

to the Lower Column.

The String Reel Holder can hold up to 4 reels

of string (depending on the size of the string

reel). Before placing the fi rst reel on the rod,

slide two spacers over the pin and slide them

to the connector on the Lower Column.

After the fi rst reel is placed onto the rod, place two spacers between each reel to provide

enough space between reels to allow them to turn freely without rubbing against one another.

(To provide a smooth feed to the String Length Meter , place the reels on the rod so the string

spools off the reel from the underside of the reel).

After the last reel is installed, place the two M8 washers on the pin and attach the threaded

knob to the end of the rod.

8

ASSEMBLY INSTRUCTIONS

Turntable and Mounting System Installation

To install the T urntable position the T urntable over the turntable pin and align the holes in the

turntable with the holes in the turntable pin. Insert the bolts through the holes in the turntable

and turntable pin and tighten with an M6 hex wrench.

STRING CLAMP INSTALLATION

String Clamp Installation

The post of the String Clamp and tube of

the String Clamp Base may be treated with

grease to provide protection against corrosion during shipping and while in storage.

Remove any excessive grease with a clean

cloth prior to use. The post and tube may

also be cleaned with isopropyl alcohol. After

this type of thorough cleaning, the post and

tube should be treated with a light coating of

machine oil to protect the surfaces against

corrosion and to ensure smooth operation.

9

POWER CONNECTION & CONTROLS

A

B

C

Front Panel Features

A - String Gripper

B - Tension Lever Switch

C - Control Panel with LCD Display

Back Panel Features

D - Power Switch

E - A/C Power Cord Socket

F - Foot Pedal Switch Socket

G - Floor Stand Power Socket

D

E

F

G

Instructions for Power Connection and Controls

CAUTION ! Before connecting to the power supply, check the voltage source that the

machine is being connected to. The acceptable range of input voltages for this machine is between 100 V and 240 V @ 50 to 60 Hz. If you have any questions regarding

the input voltage supply for your area, please ask your electric utility company.

To install the power cord, insert the female end of the power cord into the AC Adapter and

then insert the female end of the cord from the AC Adapter into the A/C Power Cord Socket

“E” located on the back side below the tensioner. Plug the male end of the power cord into

a grounded power outlet. When using extension cords, use grounded heavy duty extension

cords rated for 15 AMP service.

Insert one end of fl oor stand power cord into the Floor Stand Power Socket “F” and the

other end into the power socket next to the rocker switch on the top column of the fl oor

stand.

Connect the Foot Pedal Switch by inserting the male pin at the end of the Foot Pedal

Switch cord into the Foot Pedal Switch Socket “G” located on the back panel of the Tensioner.

Switch on the machine by pressing the On-Off Power Switch “D”. At start-up, the machine

will perform a self diagnostics check.

WARNING! FOR INDOOR USE ONLY.

NEVER OPEN UNIT WITH POWER CONNECTED.

CHILDREN SHOULD NEVER BE PERMITTED TO OPERATE THIS MACHINE

WITHOUT ADUL T SUPERVISION.

10

Loading...

Loading...