Page 1

8500 Els

STRINGING MACHINE

OWNER'S MANUAL

Issue 1 - May 24, 2001

Copyright 2001 GAMMA Sports - All Rights Reserved

Page 2

8500 Els

Owner’s Manual

TABLE OF CONTENTS

INSIDE FRONT COVER .....................................................................WARRANTY

PAGE 1................................................................................................. FEATURES

PAGE 2................................................................ CONTENTS AND UNPACKING

PAGE 3..................................................................... ASSEMBLY INSTRUCTIONS

PAGE 9.................................................... POWER CONNECTIONS & CONTROL

PAGE 10................................ CONTROL PANEL FUNCTIONS AND FEATURES

PAGE 11................................................. STRING LENGTH METER OPERATION

PAGE 12........................................................... CAM-LOCK CLAMP OPERATION

PAGE 13.................................... STRING GRIPPER / TENSIONER OPERATION

PAGE 14......................................................................... MOUNTING THE FRAME

PAGE 15........................................................................ STRINGING THE FRAME

PAGE 16 ............................................................ PATHFINDER AWL OPERATION

PAGE 17................................................... MAINTENANCE AND ADJUSTMENTS

PAGE 18........................................ CARE AND CLEANING / BUZZER CONTROL

PAGE 19.................................................................... TROUBLE SHOOTING TIPS

PAGE 20.............................................................. PART NUMBERS AND LISTING

GAMMA SPORTS ("GAMMA") warrants to the original purchaser that the GAMMA stringing machine ("EQUIPMENT") purchased is free from

LIMITED WARRANTY

defects in materials and workmanship for a period of five (5) years from the date of original purchase for mechanical parts (excluding electronic

parts and string clamps), and for a period of one (1) year from the date of purchase for electronic parts and string clamps. Should any defects

develop under normal use within the specified time periods, GAMMA will at its option, repair or replace the defective EQUIPMENT provided it is

returned to GAMMA prepaid at the purchaser's expense. This warranty does not apply to any damage or defect caused by negligence, abuse,

misuse, unauthorized alteration, shipping, handling, or part wear and tear as a result of normal use.

Routine maintenance, adjustment, and cleaning required to ensure proper operation are the responsibility of the purchaser and are not covered

under the terms of this warranty. These include, but are not limited to: String Clamp adjustment, as described on page 12, Linear Gripper Plate

adjustment, as described on page 13, Cam-Lock Base adjustment, as described on page 17, Linear String Gripper adjustment, as described on

page 18, and cleaning of String Clamps, as described on page 18.

GAMMA's obligation under this warranty is limited to repair or replacement of defective EQUIPMENT, and no one is authorized to promise any

other liability. GAMMA shall in no event be liable for any incidental or consequential damages.

To return defective EQUIPMENT, a return authorization (RA#) must be obtained from a GAMMA customer service representative by calling 1-800333-0337. The RA# must be marked on the outside of the shipping carton being returned. All returns must be shipped prepaid by the customer

to GAMMA. Please retain the original shipping carton and packing materials for any future shipments.

Page 3

8500 Els

Key Product Features

5

6

9

1

2

8

10

4

3

1. Electric Constant Linear Pull String Tensioner w/ Diamond Coated String Gripper

(10-90 lbs tension range in 0.10 lbs increments)

2. Electronic Control Panel w/ Keypad, Knot, Prestretch, & String Length Functions

3. String Reel Holder

4. Electronic String Length Meter

5. 6 Point “Suspension” Mounting System (10 point support)

6. Dual Action, CAM-Lock, Swivel, String Clamps w/ Diamond Coating

7. Convenient Foot Actuated Tensioner Switch

8. Full Fiberglass Cover w/ Integrated Tool Trays (60 sq in of storage area)

9. Height Adjustable from 39” to 46” (can also be used on table top)

10. 110 V / 220 V Compatibility

1

7

Page 4

8500 Els

Unpacking Instructions & Contents

Instructions for Unpacking and Preparing for Assembly

The 8500 Els is shipped in two cartons, a large carton for the stringing machine and accessories and a smaller

carton for the post and base legs. Please save the cartons and packing materials for possible shipments in

the future. Gamma Sports cannot be responsible for machines that are not returned, shipped in their original,

undamaged packaging. The tools you will need to assemble the 8500 Els are provided with the machine. Due to

the weight of the tensioner unit, you may need the assistance of someone to help lift the tensioner unit out of the

carton.

Once the cartons are opened, remove all inner cartons and check to be sure that all parts are present and

accounted for.

Contents of Base & Leg Carton

(1) Lower Post

(2) Upper Post with Flange Plate

(4) Legs

(1) Locking Knob Screw

(4) M8 x 25 Flat Head Screws

(4) M8 x 30 Cap Screws

(1) String Reel Holder (M8 Threaded Pin), (1) Knob, (8) Spacers, & (2) M8 Washers

Contents of Large Master Carton (including accessory cartons packed inside)

(1) Stringer Assembly Unit w/ Tensioner Module and Turntable

(1) Power Cord w/ Ground Pin

(2) Suspension Mounting Stands w/ Frame Support Slide, Side Supports, and Adapters

(2) Mounting Stand Locking Levers w/ Washers

(2) String Clamp Heads

(2) Badminton Frame Support Slides Fitted w/ Plastic Adapter

(1) Package of Spare plastic adapters for mounting system supports (contains 16 pcs)

(1) Face Plate for String Length Meter & (4) Spare String Length Meter Clamp Pads

(4) Rubber Feet w/ Screws

(1) Foot Pedal Tensioner Switch

(1) Tool Kit (contains side cutter, bent nose pliers, needle nose pliers)

(1) Straight Stringers Awl & (1) Pathfinder Specialty Awl

(1) Starting Clamp

(2) Composite Badminton Floating Clamps

(1) 6 mm “T” Handle Hex Wrench

(1) 5 mm “T” Handle Hex Wrench

(1) 10 pc L-Hex Wrench Set

(2) Support Post Screws (M10)

(1) Open End Wrench – 6 mm

2

Page 5

Assembly Instructions

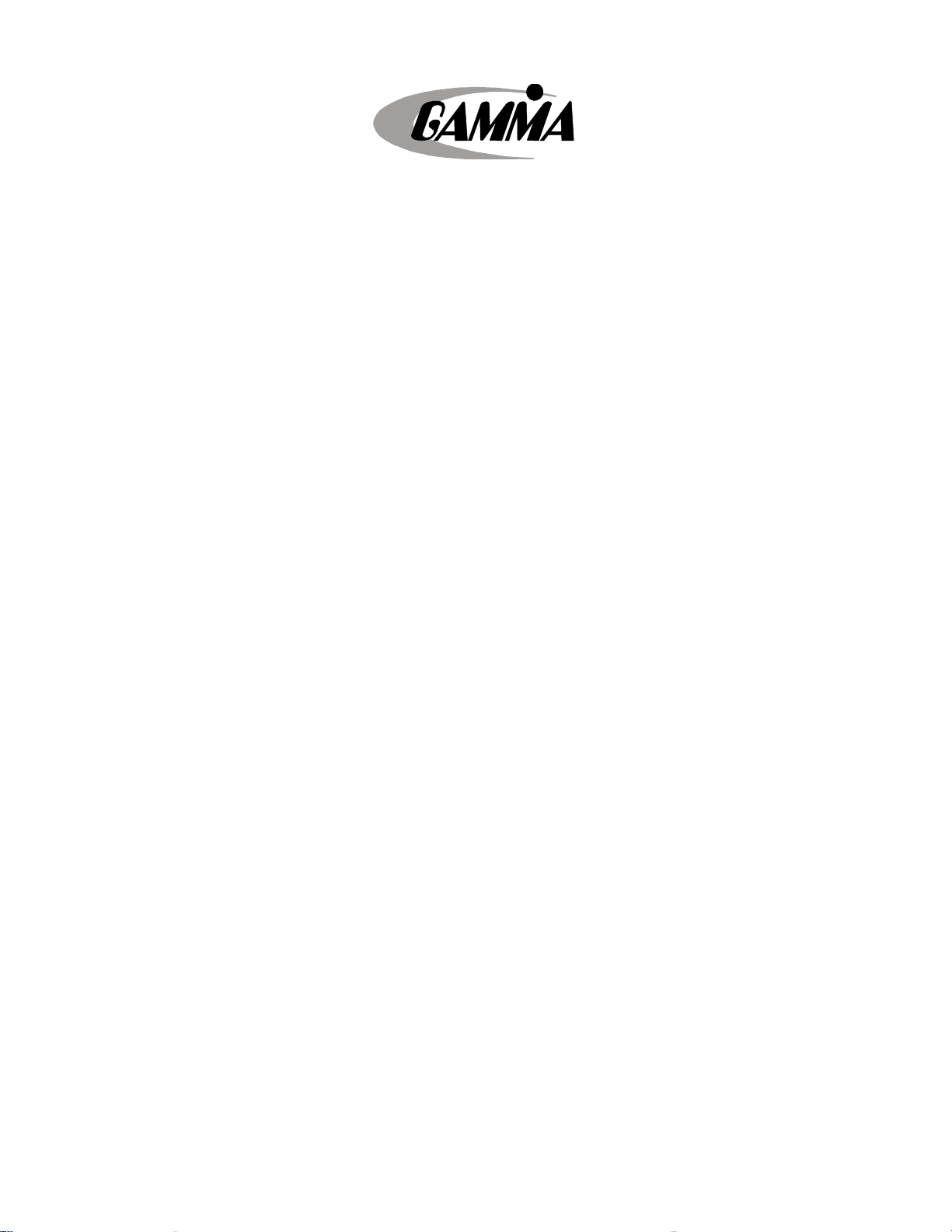

Base Leg Assembly

The stringing machine uses a four leg base design. The

legs must be assembled to the support post before use.

Remove the lower column support, the upper column

support, four (4) legs, four (4) socket head cap screws

and four (4) flat head cap screws from the small shipping

carton.

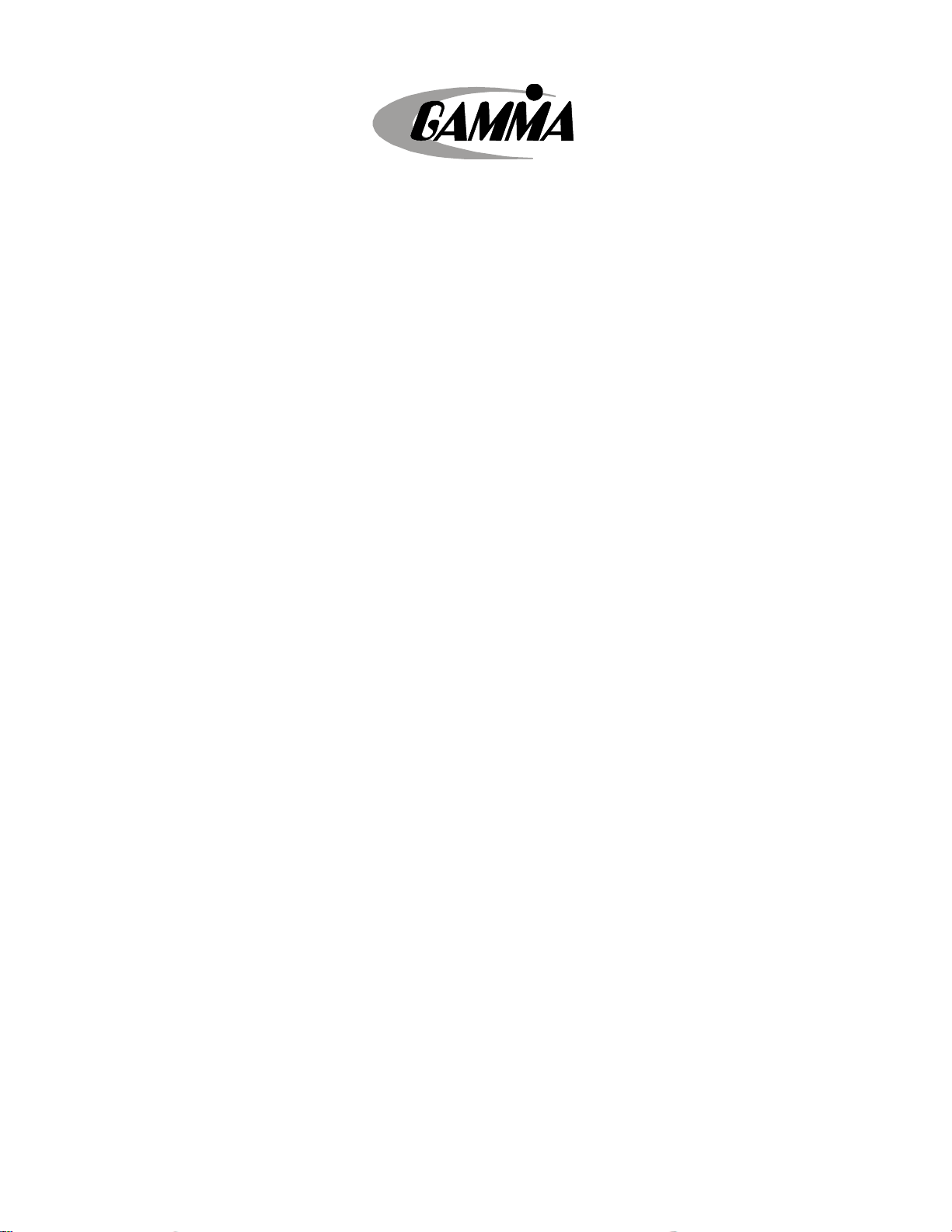

Base Leg Assembly (Cont.)

Align the holes in the leg flange with the matching holes

in the lower column support post. Secure the leg with one

FLAT HEAD cap screw through the upper hole, and one

SOCKET HEAD cap screw through the bottom hole.

Repeat this procedure for the three remaining legs.

“A”

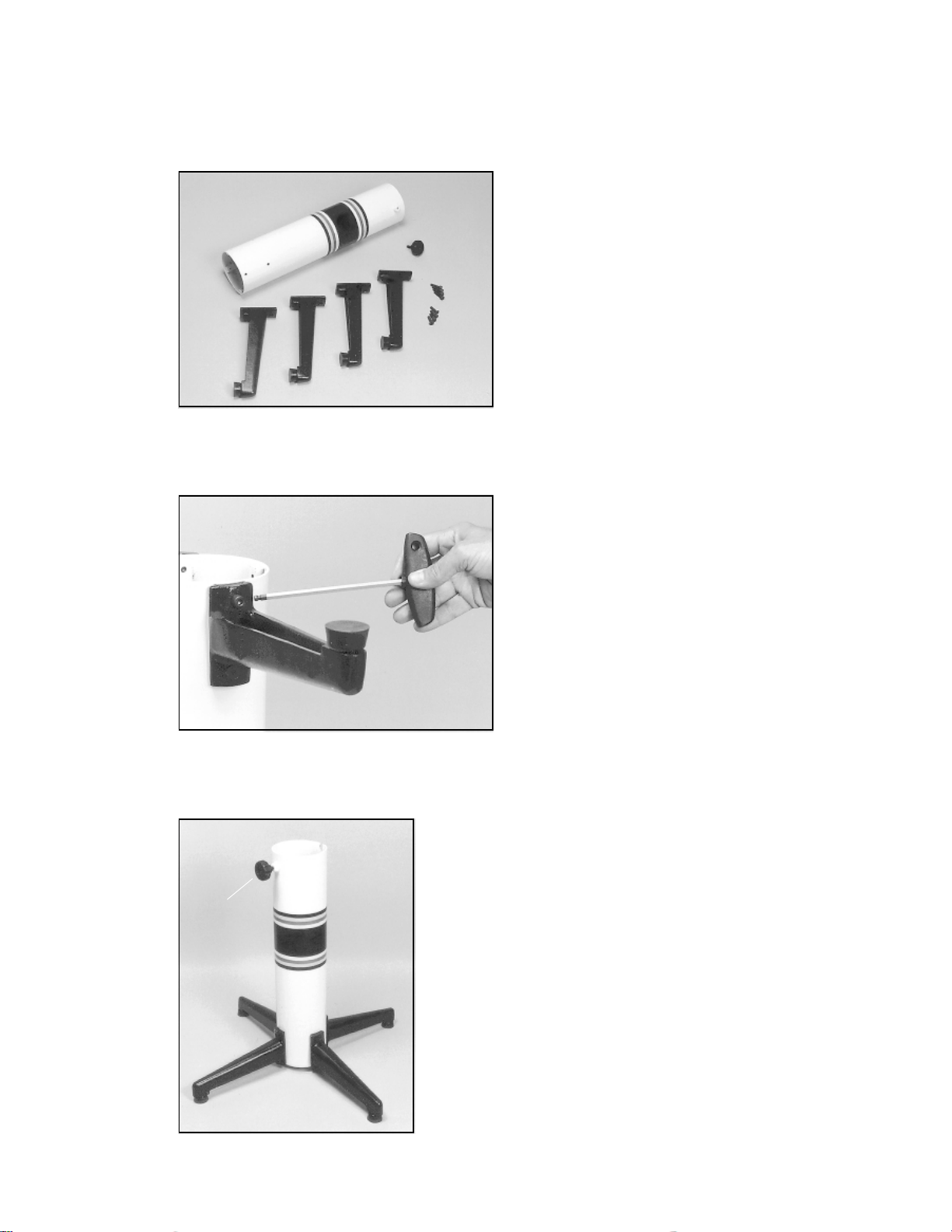

Base Leg Assembly (Cont.)

To complete the base stand, screw the height adjustment locking knob

(“A”) into the side of the support column. The locking knob should not

protrude beyond the inside of the support column at this time.

3

Page 6

Assembly Instructions

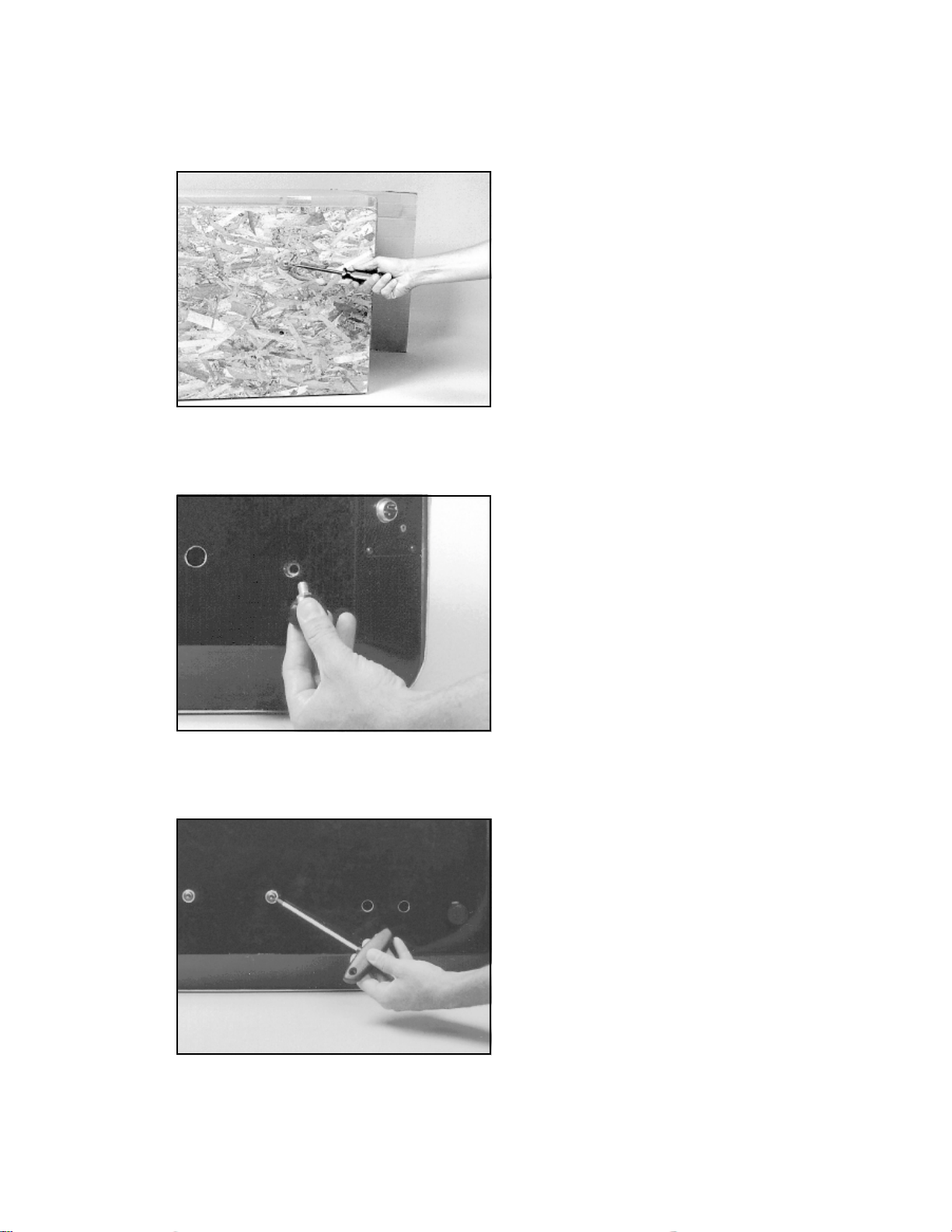

Unpacking the Tensioner Assembly

The tensioner assembly is packed inside the inner

carton and is bolted to a sheet of wood with four (4) bolts

to prevent damage during shipment. Another sheet of

wood is bolted to the underside of the inner carton

through the first piece of wood. First locate the nuts

attached to the bolts that secure the outer piece of wood

to the inner piece of wood. Remove the nuts and with

assistance carefully lift the tensioner assembly from the

inner carton and lay it floor. To remove the inner piece of

wood from the base of the machine, raise each end and

remove the four (4) shipping bolts from the underside of

the wooden sheet. Note: Please retain the bolts, wood

and cartons for future shipment.

Foot Installation

CAUTION ! To maintain the alignment between the

fiberglass covers and the frame, it is very important

that the feet be installed before removing the four

center screws that attach the tensioner assembly to

the upper post flange.

To install the feet, tilt the tensioner back on its side and

screw the four feet into the holes at the corners of the

base.

Stand Upper Post Installation

After installing the four corner feet, remove the four (4)

button head cap screws from the base of the assembly.

4

Page 7

Assembly Instructions

Stand Upper Post Installation (cont.)

With the height adjustment cap screw on the upper post

facing the right side of the tensioner, align the four (4)

holes in the upper post flange with the holes in the

tensioner base. Secure the flange to the base with the

four cap screws.

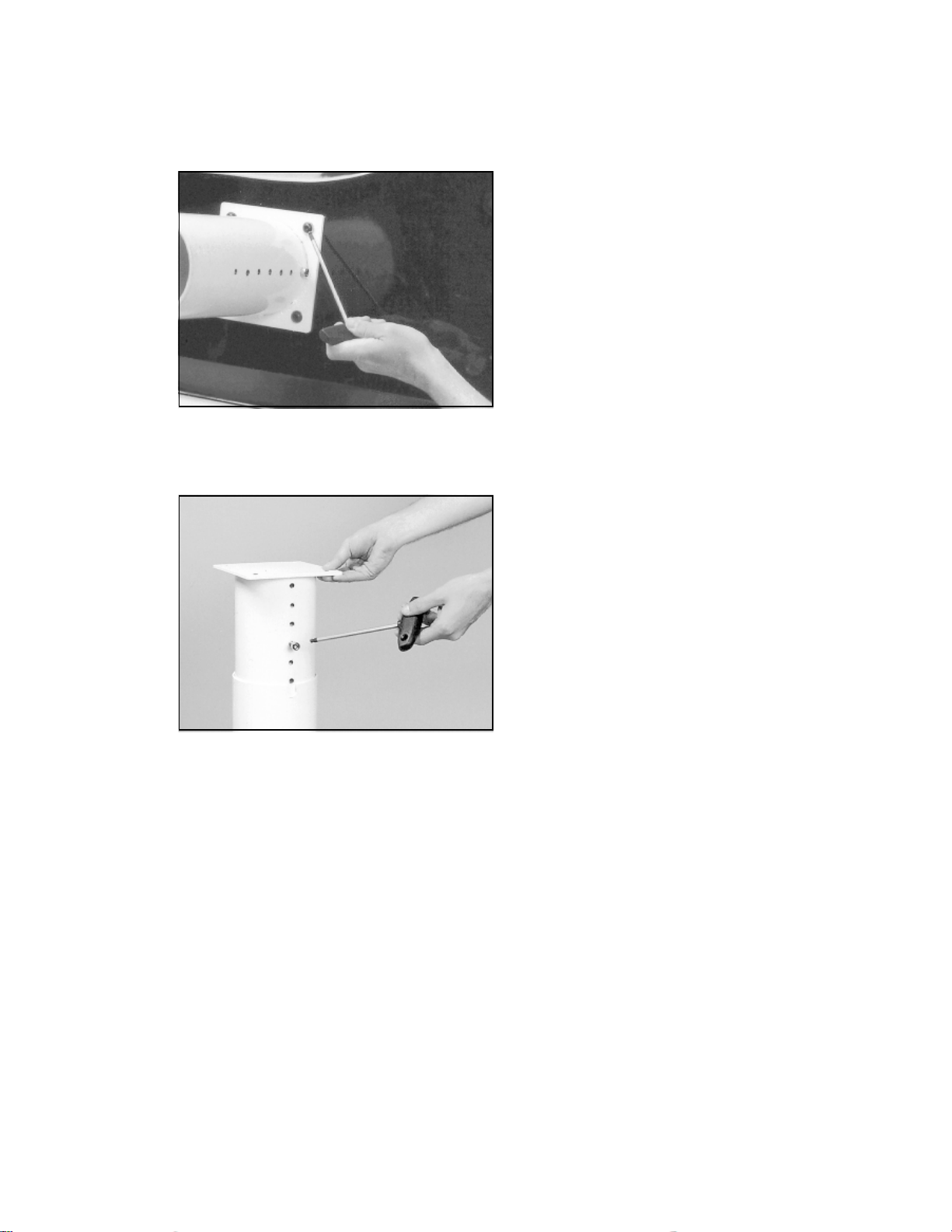

Height Adjustment

The height of the machine is adjustable from 39” to 46”.

To change the height, remove the socket head cap

screw from its current position and place it in the

appropriate hole to set the desired height of the machine.

5

Page 8

Assembly Instructions

Installing the Racquet Mounting System

Align the threaded hole in the bottom of the frame

support post with the slot in the turntable. Screw the lever

lock bolt with washer into the center hole located in the

bottom of the support post and loosely tighten. Position

the washer with the rounded edge toward the turntable.

Repeat procedure for the support post on the opposite

side of the turntable.

There are two guide pins located in the bottom of the

support post. The outer guide pin may be removed if

needed to provide additional separation space between

the mounting arms for mounting super oversize racquets.

Clamp Head Installation

The post of the string clamp head and the tube of the

string clamp base are treated with grease to provide

protection against corrosion during shipping. Remove

any excessive grease with a clean cloth prior to use. The

post and tube may also be cleaned with isopropyl

alcohol. After this type of thorough cleaning, the post

and tube should be treated with a light coating of

machine oil to protect the surfaces against corrosion and

to ensure smooth operation.

6

Page 9

String Reel Holder Installation

The string reel holder pin is an 8 mm rod with threads on

both ends, and flat surfaces machined on one end.

Thread the end of the pin without the flat surfaces into the

threaded boss on the right side of the lower column

support. Using the M6 open end wrench positioned on

the flat surfaces, securely tighten the pin to the lower

column support.

The string reel holder can hold up to 5 reels of string

(depending on the size of the string reel). Before placing

the first reel on the pin, slide two M8 washers over the pin

and slide them to the boss on the lower column support.

After the first reel is placed onto the pin, place two

spacers between each reel to provide enough space

between reels and allow them to turn freely without

rubbing against one another. (To provide a smooth feed

to the String Length Meter, place the reels on the pin so

the string spools off the reel from the underside of the

reel.)

After the last reel is installed, place the remaining

spacer(s) on the pin and attach the threaded knob to the

end of the pin.

7

Page 10

SLM Face Plate Installation

Remove the tape covering the opening on the front side

of the bottom cover to expose the string length meter.

Position the face plate assembly over the opening in the

bottom cover, and align the two countersunk end holes

of the face plate with the threaded attachment holes in

the front of the string length meter. With the two flat head

machine screws, secure the face plate assembly to the

string length meter.

To check for proper alignment, lift the top clamp of the

face plate assembly and insert a section of racquet

string at least 12 inches long into the entrance hole of the

face plate. Continue feeding the string section into the

string length meter, until it appears through the exit hole.

If the entrance or exit holes appear to be blocked, loosen

the attachment screws and adjust the position of the

face plate assembly until the section of string exits the

face plate. After the face plate is properly aligned,

tighten the flat head screws.

8

Page 11

Power Connection & Controls

Instructions for Power Connection (Refer to Figure 1)

CAUTION ! Before connecting to the power supply, check the voltage supply switch setting located on the

side panel as shown in Figure 1. To change from 110 volts service to 220 volt service simply slide the

switch fully to the top or to the bottom until “110V” or “220V” appears on the switch plate.

The acceptable range of input voltages for the “110 V” setting is between 110 V and 120 V @ 60 Hz and for

the “220 V” setting, between 220 V and 240 V @ 50 to 60 Hz. If you have any question regarding the input

voltage supply for your area, please ask your electric utility company.

To install the power cord, insert the female end of the power cord into the Power Cord Socket located on the side

panel and plug the male end into a grounded power outlet.

When using extension cords, use grounded heavy duty extension cords rated for 15 AMP service. To connect the

foot pedal switch, insert the 2 pin male connector located at the end of the foot pedal switch cord, into the two pin

receptacle located in the side panel. Tighten the connector with the sleeve nut located on the foot pedal switch

connector.

After checking to be certain that the machine is set for the correct input voltage, switch on the machine by

pressing the Lighted On-Off Power Switch on the side panel. At start-up, the LED will display a countdown from

“9.0” to “0.0” while the machine performs a self diagnostics check at start-up. The machine should be permitted

to warm-up for 10 minutes prior to stringing. After ten minutes, it is recommended that the “TEST” button be

pressed to self calibrate after warm-up.

“E” “A”

“F”

“G”

“B” “D”

“C”

Figure 1 - Side Panel Features

“A” - Lighted On-Off Power Switch

“B” - Power Cord Socket

“C” - Sliding Fuse Holder w/ Spare Fuse

“D” - 110V / 220V Switch

110

“E” - 2 Pin Foot Pedal Switch Socket

Figure 2 - Front Panel Features

“I”

“H”

“F” - Parallel Plate String Gripper

“G” - Tensioning Button Switch

“H” - Control Panel

“I” - LED Display

9

Page 12

Control Panel Functions and Features

Keypad - Used to enter

tension settings

Tension Index Buttons - Changes tension setting

in +/- 1.0 or 0.1 Lb or Kg increments. Holding the

button down will scroll the tension setting values

up or down. Tension settings entered with the

tension index buttons are placed into temporary

memory setting “0”.

Single Digit (0-4)

Memory LED Display

Three Digit (XX.X) Tension Settings or String

Length LED Display

Release Button - Returns gripper to starting

position and releases tension

Memory Button - Indexes from 4 preset tension

settings that can be stored in memory. Settings are

retained even if machine is turned off. Each press of

the button indexes to the next memory setting.

Memory settings 1-4 must be entered using the

keypad followed by pressing the “ENT” button.

Clear Button - Clears display to enter a new

tension

Test Function - Performs internal calibration

check. Press and hold for 5 seconds until the

winder reverses and performs an internal

diagnostic check, such as the one performed at

start-up.

Lbs/Kgs Button - Changes tension

display from Lbs to Kgs. Each press of the button

toggles back and forth between Lbs and Kgs

Pre-Stretch Function - Pulls string 10% or 20%

over the tension setting (up to 90 lbs / 40.8 kgs),

releases the string, and repulls to the tension

setting. Each press of the button toggles between

10%, 20% or no pre-stretch.

Enter Button - Confirms tension setting when entered

on keypad (display flashes when tensions are keyed

in with the keypad until this button is pressed)

Knot Function - Increases pulling tension by 10%

over the setting value (max 90 lbs / 40.8 kgs) for one

pull. During pull the Memory LED flashes to indicate

that the Knot function is enabled.

Speed Button - Changes pulling speed of winder

from Fast to Slow. Slow speed is recommended

for low stretch strings, such as Kevlar. Each press

of the button toggles back and forth between Fast

and Slow speed.

String Length Meter Button - Enables string

length meter function. Each press of the button

toggles back and forth between Meters and Feet

measurement. To switch back to tensioning

function, press the “Lbs/Kgs” button.

10

Page 13

String Length Meter Operation

To enable the String Length Meter (SLM) function, press

the String Length function key on the keypad. When the

String Length button is pressed, one of the Red LED

indicators below “M” or “FT” will light up to indicate that

the SLM function is enabled. Pressing the String Length

button will toggle between “M” and “FT” to set the

measurement units for either Meters (“M”) or Feet (“FT”).

Measurements are displayed in 0.1 increments.

To measure out a length of string from a reel (sets can

also be measured) insert one end of the string through

the string guide grommet (from the backside). While

lifting the clamp pad, insert the string through the

entrance hole of the face plate until it appears at the exit

hole and release the clamp pad. (The clamp pads will

prevent debris from entering the SLM.)

When the end of the string appears out of the exit hole,

press the “C” button on the keypad to “Zero” the SLM,

and the length of string measured will be measured from

the point on the string located at the edge of the exit

hole. Pull the end of the string in a slow steady fashion

and the SLM will begin measuring the length of string

pulled and indicate the measurement on the LED display. When the desired length of string is measured, cut

the string at the exit hole.

NOTE : When reaching the end of a length of string,

pull the string through very slowly to avoid inaccurate string measurement. The string length meter was

designed to measure strings between 1.10 mm (18 ga)

and 1.45 mm (15 ga) at an accuracy of +/- 0.3% of the

indicated value and +/- 2 inches (50 mm) absolute.

When measuring strings smaller than 1.10 mm (such

indicated value (up to 6” short in 40 ft) and +/- 2 inches (50 mm) absolute.

as badminton strings) the error will be -2.5% of the

11

Page 14

Cam-Lock Clamp Operation

Clamp Head Operation

To clamp a string, lift the clamp head and place the string

between the jaws and depress the clamp head lever to

secure the string. The clamping pressure applied to the

string should be adjusted to provide sufficient pressure

to secure the string when subjected to the desired pulling

tension. The diamond coated gripper plates provide for

increased friction between the clamps and the string to

allow for reduced clamping pressure while securing and

holding the string under tension.

CAM-LOCK Clamp Base Operation

Rotate the Base Locking Lever clockwise to secure the

clamp base to the turntable.

Reverse the clamping procedure to unlock the string

clamp. The Locking Lever is spring loaded to assist the

unlocking of the clamp base.

The Locking Lever should be tightened enough to prevent clamp base slippage on the turntable, when the

desired tension is placed on the string. To go from the

loose position to the clamped position and back, generally requires the travel permitted by the clamp base. If

the travel is not sufficient to allow smooth operation of,

adjust the Clamp Base as outlined in the Clamp Base

Adjustment section.

Clamp Head Adjustment

The clamp heads will need minor adjustments according to what string type, construction, and gauge you are

using.

To adjust the gap (clamping pressure) between the

clamp jaws, insert the string through the racquet as if

you were beginning the main strings. Clamp the strings

and pull tension. If the string slips through the jaws of the

clamp, tighten the clamp by compressing the clamp

jaws together by hand while turning the Adjustment

Adjustment

Knob

Note: The string clamps supplied with your stringing machine can accomodate tight string patterns such as

badminton. Depending on the string pattern, the clamp may spread the strings slightly which will not compromise the

quality of the string job.

Knob, in the clockwise direction. If the clamp leaves

impressions or damages the string, it may be excessively tight and should be adjusted by turning the hex

screw counter clockwise to open the gap between the

jaws. The clamp jaws must be cleaned periodically to be

free from dirt and any residue for them to grip properly.

12

Page 15

String Gripper Operation

String Gripper Operation

To insert a string into the linear string gripper, wrap the

free end of the string clockwise around the roller guide

and insert the string between the diamond dust coated

string gripper plates. Excessive slack in the string

should be removed before applying tension. Pull the

string perpendicular to the gripper plates and begin

tensioning. As tension is applied, the grippers will

engage to hold the string. For adjustment of the parallel

plates, see “Setting the Gripper Plate Spacing” on page

18.

CAUTION ! CHILDREN SHOULD NEVER BE PERMITTED TO OPERATE THIS MACHINE WITHOUT

ADULT SUPERVISION.

Tensioner Operation

Tensioning

Button

Setting the String Tension

String tensions may be entered using the keypad and

storing the settings into one of four memory storage

settings (See section on Control panel Functions and

features) or by using the tension index buttons. While the

tension setting is entered, the value displayed will be

flashing until the “ENT” button is pressed, indicating that

the tension setting is accepted.

Tensioning a String

After the string in inserted into the parallel plate

grippers, press the tensioning button switch on the

front panel of the machine, or press the foot pedal

switch to activate the tensioner. The using the fast

pulling speed (see section on Control Panel Functions

and features) the tensioner will start pulling at full

speed and then slow down as the tension in the string

approaches the tension setting. When the tension in

the string reaches the tension setting, the LED display

will begin to flash, and the string will be ready to clamp

off. In the event that the tensioner reaches the end of

its travel and the string is not yet at tension, the buzzer

will sound. Clamp off the string and repeat the tensioning

process. If one of the keys on the control panel are

accidently pressed while tensioning a string, the

tensioner will automatically reverse and release the

string being tensioned.

13

Page 16

Mounting the Frame

Adjusting the Frame Support Posts

Place the racquet frame over the center support slide

and onto the frame support. Loosen the lever lock bolt on

one support post. Slide the post outward until the center

support of the racquet support slide is positioned near

the inside surface of the racquet frame. Securely tighten

the lever lock bolt.

Adjust the opposite post using the same procedure.

Caution: To avoid racquet damage, the support slide

should not contact the racquet prior to fixing the support

posts.

Shoulder Support Adjustment

The shoulder supports are adjustable to provide support

to the racquet frame. Loosen the knurled knob at the

bottom of the shoulder support and swivel the support so

that the pads will contact the frame squarely when the

arms are closed against the racquet. Should the shoulder supports block string holes, adjust the position of the

racquet between the arms until the shoulder supports

contact the racquet between grommet holes.

Securing the Shoulder Supports

Secure the racquet frame with the shoulder supports by

rotating the large adjustment knobs on the outside of the

support post assemblies clockwise. Adjust the supports

until firm contact is made between the shoulder supports

and the frame.

The tear drop shaped holes towards the back of the

shoulder supports are handy for holding the loose

end of the string while pulling the string through the

racquet. Simply insert the loose end into the tear

drop shaped holes and slide the string into the point

of the hole.

14

Page 17

Mounting the Frame

Support Slide Adjustment

Once the frame support posts are secured, lightly tighten

the support slides by turning the knobs on the outside of

the slides clockwise. Adjust the slides in equal increments until slight resistance is felt.

Apply a final adjustment to all racquet support points

until the racquet is firmly secured in the mounting

system.

Should the frame supports lose contact with the frame

while stringing, they should be adjusted, as needed, to

maintain contact with the frame.

Stringing the Frame

Installing the Main Strings

To begin stringing the main strings, insert the two ends

of the string through the two center holes at the appropriate end of the frame and continue through the center

holes on the opposite end of the racquet.

Secure one of the strings using a string clamp and insert

the free end into the string gripper.

When tension is applied to the string, clamp off the

tensioned section of string, release string from tensioner,

and proceed to thread string into next sets of holes. After

the last main strings are pulled, tie-off the strings at the

appropriate hole specified by the racquet manufacturer.

Installing the Cross Strings

Weave the cross strings over and under the main strings

being careful to alternate the weave direction of each

consecutive cross string so as to be opposite of the

previously installed cross string.

Once the final cross string is tensioned and clamped, tie

off at the appropriate hole specified by the racquet

manufacturer.

Remove the strung racquet by loosening the shoulder

supports and support slides in small increments until the

racquet is free from the mounting system.

15

Page 18

Pathfinder Awl Operation

The machine includes the new Pathfinder stringing awl

which creates a pathway between or around strings to

make inserting a string through tight grommets easier

and quicker.

Insert the awl through the grommet hole in the same

manner as for traditional awls. The Pathfinder awl must

be in the closed position before insertion.

Once the awl is inserted, pull the handle of the awl

outward while holding the tip section in place, leaving

the outer sheath in the grommet hole.

Insert the end of the string into the center of the sheath.

While holding pressure on the string, slowly pull the

sheath out of the grommet hole to leave the end of the

string exposed.

16

Page 19

Tensioner Calibration

Each stringing machine has been checked and calibrated at the factory using accurate load sensing devices to

ensure that the machine pulls at the correct tension. The tension is then controlled by the pre-set factory settings

of the electronics. However, if you suspect that your machine is not pulling at the correct tension, or if you would

like to check the pulling tension using a tension calibration device, you may do so.

Most tension calibrators (such as a Gamma Tension Calibrator) function by inserting a string from the end of the

calibrator into a string clamp, and pulling on the string located on the opposite end of the calibrator. The tension

measured by the calibration device will then display the tension being applied to the calibrator by the machine.

With the machine set for the fast pulling speed, and the tension set at 20 lbs., place the string from one end of the

calibrator (preferrably equipped with synthetic string) into a string clamp. Place the opposite end into the string

gripper and apply tension. If the tension indicated on the calibrator does not match the tension setting, release the

string and remove it from the gripper.

Press and hold the “Test” button on the control panel for 5 seconds and release it when the tension display

starts its countdown and the machine performs its own self diagnostic test. After the display returns to

the preset value, recheck the pulling tension using the tension calibrator at both 20 and 60 lbs.

can be externally calibrated by up to +/- 5 lbs from the factory settings. If the difference between the measurement

from the calibrator and the tension setting is more than 5 lbs. call the machine service department of GAMMA Sports

at 1-800-333-0337 for assistance.

In the event that the measurement from the calibrator does not match the tension setting, the machine

To calibrate the machine externally, set the machine for a pulling tension of 40 lbs. With the

calibrator attached, press and hold the “TEST” button until a flashing “9” appears on the display.

Press the “+0.1” or “-0.1” buttons, to match the display value to the calibrator value. Press “ENT”

to save the calibration settings.

Cam-Lock Clamp Base Adjustment

If the bases of the Cam-Lock clamps slip on the glide bars, the base

locking levers may need adjustment.

Remove the plastic cap by pulling straight up on the edges of the cap.

Line up the large hole in the clamp base with the smaller hole in the

locking cone as shown.

Insert the 3mm hex wrench through the holes and into the screw located

in the base. Rotate the wrench clockwise to tighten the clamp and

decrease the base locking lever travel. Rotate the wrench counterclockwise to loosen the clamp and increase the base locking lever travel.

17

Page 20

Setting the Gripper Plate Spacing

The parallel plates of the string gripper are adjustable to

accomodate varying string gauges and types of string. If

the string slips through the gripper plates while pulling

tension, rotate the gripper adjustment screw counterclockwise. If the string is damaged while pulling tension,

rotate the gripper adjustment screw clockwise. The

gripper is properly adjusted when there is enough pressure to securely grip the string without causing damage

to the string.

Gripper Adjustment

Screw

Cleaning Instructions for String Clamps

To thoroughly clean the diamond coated surfaces of the

clamp heads, remove the adjustment knob screw, lever

plate, and compression spring to expose the inside

surfaces of the clamps. Using the cleaning stone provided with your machine (you can also use a small tooth

brush or a sharpening stone for knives), scrub the

diamond coated plates until all debris is removed. Clean

any dust or residue with a damp cloth and re-assemble

the clamp head.

Buzzer Control

The stringing machine is equipped with a buzzer function that sounds when any key or button is pressed; it also sounds

an intermittent warning when the tensioner has pulled a string to the end of its travel and is not yet at tension, or if there

is an internal error in the machine. The buzzer can, however, be disabled for normal key / button presses. To toggle

between buzzer enabled / buzzer disabled modes:

Turn the machine on; while the display is counting down from 9 to 0, press the clear (C) and enter

(ENT) keys together. The machine will switch modes, and the changes will remain in effect until

the user toggles modes again.

NOTE: In disabled mode, the buzzer will still sound if the tensioner has pulled a string to the end of its travel and is

not yet at tension, or if there is an internal error in the machine. This is meant to alert the user of a problem, and should

never be disabled.

18

Page 21

T roubleshooting Tips

PROBLEM SOLUTION

String slips in clamps

String slips in gripper • Adjust gripper adjustment screw

String clamp slips on base • Adjust base locking lever

String Length Meter measures inconsistently • Contact Gamma Sports Machine Service

Electrical system does not function

To check fuse, remove the power cord and pull the fuse holder straight out. Remove the fuse from the clips

and examine it. If it is burned out, replace it with the spare fuse located in the holder and replace the fuse

holder in its socket. Supply power to the machine and check for proper operation. If problems persist, contact

Gamma Sports Customer Service at 1-800-333-0337.

• Adjust gap between jaws

• Clean clamp jaws

• Clean base of clamp and turntable glide bars

Department for SLM Cleaning Procedure

• Check power source / voltage setting

• Check power cord connection

• Check fuse

• Call Gamma Sports customer service

Self Diagnostics

The electronics of the machine are designed to provide self diagnostic trouble shooting information, if parts of

the machine do not function normally. When this occurs, error codes will appear on the display. A summary of

the error codes and corrective actions that should be taken are provided below.

Code Corrective Action

C01

C02

C06 • Call GAMMA Sports for assistance

C07 • Check for loose power connection at AC socket or wall outlet

C09 • Check that voltage setting for machine is correct

To reset the machine after an error code appears, press the Clear (“C”) button on the control panel. If the error

code disappears, resume stringing as normal. If the error code re-appears, corrective action needs to be taken.

For assistance, call the machine repair department of GAMMA Sports at 1-800-333-0337.

• Check wiring to return microswitch on motor and PC board

• Check return microswitch on motor shaft

• Call GAMMA Sports for assistance

• Check that string is still not engaged in gripper after gripper returns

• Call GAMMA Sports for assistance

• Call GAMMA Sports for assistance

19

Page 22

8500 Els

Parts Summary

173

199

195

194

178

204

205

209

Inside Cover

248

218

Inside Cover

203

217

219

115

127

106

221

223

180

222

249

208

211

210

212

247

250

101

102

103

128

22A

21B

134

133

23A

114

132

21A

135

122A

14

20

6B

139

9

13

136

121

22A

131

22B 23A

23B

Page 23

8500 Els

Parts List

Part # Description

6B Cap Screw - M8 x 30

9 Washer - M8

13 Locking Lever

14 Washer - M10

21A Frame Support Slide SM Tennis

21B Frame Support Slide SM Badminton

22A Badminton/Squash Throat Adapter

22B Badminton Head Adapter

23A Tennis/Squash/Racquetball

Standard Adapter

23B Tennis Fan/Tapered Pattern Adapter

101 AC Power Cord

102 Fuse Holder Cap

103 Fuse

106 Locking Knob Screw

114 Short Leg

115 Flat Head Cap Screw -M8 x 25

121 Leveling Foot

122A Shoulder Support Pads - Black

127 Flanged Upper Support Column

128 FRP Base Foot

131 Foot Pedal Switch

132 Mounting Arm Adj. Knob SM

133 Support Slide Adj. Screw SM

134 Suspension Mounting Arms

135 Shoulder Support Adj. Knob SM

136 Shoulder Support SM

139 Shoulder Support Bushing

173 Turntable Glide Bar/12.5mm

178 Glide Bar SST

180 Comp Fixed Clamp Thin

194 TT Brake Pad

195 TT Brake Pad Flat Head Screw

199 Flanged TT Pin

203 Flanged TT Pin Cap Screw

204 Cam Lock Base/Glide Bar Assy

205 Cam Lock Clamp Base

208 Lower Column (w/RH Reel Hold)

209 TT Brake Lever

210 Reel Holder Bolt

211 Reel Holder Spacer

212 Reel Holder Knob

Part # Description

217 8500 Lower Cover

218 8500 Frame Assy

219 8500 Transformer Set (117/230)

221 String Length Meter Cover

222 String Length Meter Clamp Pads

223 String Length Meter

247 8500 Els Tensioner Module

248 8500 Top Cover

249 8500 Upper Tray Pad

250 8500 Lower Tray Pad

SP ARE PARTS & TOOLS

Part # Description

72 Pathfinder Guiding Awl

73 Stringer’s Awl

109 Needle Nose Pliers

110 Bent Nose Pliers

169 Bad. Flying Clamp Set

170 M10x35 Cap Screw for SM

171 Cutting Pliers

194 TT Brake Pad

206 13 mm Open End Wrench

221 String Length Meter Clamp Pads

224 6 mm Open End Wrench

230 Gripper/Clamp Cleaning Stone

251 Long Hex Wrench Set (9 pcs)

21

Loading...

Loading...