Gamma 6500 Els Owner's Manual

OWNER'S MANUAL

Issue 1 - July 2006

STRINGING MACHINE

6500 Els

2 POINT MOUNTING

1

LIMITED WARRANTY

GAMMA SPORTS ("GAMMA") warrants to the original purchaser that the GAMMA stringing machine ("EQUIPMENT") purchased

is free from defects in materials and workmanship for a period of five (5) years from the date of original purchase for mechanical parts

(excluding electronic parts and string clamps), and for a period of one (1) year from the date of purchase for electronic parts and string

clamps. Should any defects develop under normal use within the specified time periods, GAMMA will at its option, repair or replace

the defective EQUIPMENT provided it is returned to GAMMA prepaid at the purchaser's expense. This warranty does not apply to

any damage or defect caused by negligence, abuse, misuse, unauthorized alteration, shipping, handling, or part wear and tear as a

result of normal use.

Routine maintenance, adjustment, and cleaning required to ensure proper operation are the responsibility of the purchaser and are

not covered under the terms of this warranty. These include, but are not limited to: String Clamp adjustment, as described on page

12, cleaning of String Clamps, as described on page 18, and cleaning of String Gripper, as described on page 18.

GAMMA's obligation under this warranty is limited to repair or replacement of defective EQUIPMENT, and no one is authorized to

promise any other liability. GAMMA shall in no event be liable for any incidental or consequential damages.

To return defective EQUIPMENT, a return authorization (RA#) must be obtained from a GAMMA customer service representative

by calling 1-800-333-0337. The RA# must be marked on the outside of the shipping carton being returned. All returns must be shipped

prepaid by the customer to GAMMA. Please retain the original shipping carton and packing materials for any future shipments.

6500 Els

OWNER’S MANUAL

TABLE OF CONTENTS

PAGE 1 ................................................................................................ WARRANTY

PAGE 2 ...................................................................................................FEATURES

PAGE 3 .....................................................................UNPACKING AND CONTENTS

PAGE 4 ....................................................................... ASSEMBLY INSTRUCTIONS

PAGE 9 ......................................................... POWER CONNECTIONS & CONTROL

PAGE 10 ......................................CONTROL PANEL FUNCTIONS AND FEATURES

PAGE 11 ...................................................... STRING LENGTH METER OPERATION

PAGE 12 ........................................................ QUICK ACTION CLAMP OPERATION

PAGE 13 ............................................STRING GRIPPER / TENSIONER OPERATION

PAGE 14 ............................................................................ MOUNTING THE FRAME

PAGE 15 ............................................................................STRINGING THE FRAME

PAGE 16 ................................................................PATHFINDER AWL OPERATION

PAGE 17 ....................................................................... TENSIONER CALIBRATION

PAGE 18 .............................................................................. CLEANING AND CARE

PAGE 19 ....................................................................... TROUBLE SHOOTING TIPS

PAGE 20 ................................................................. PART NUMBERS AND LISTING

2

6500 Els

KEY PRODUCT FEATURES

1. Electric Constant Pull String Tensioner w/ Diamond Coated String Gripper

(10-90 lbs tension range in 0.5 lbs increments)

2. Control Panel w/ Calibration, Lbs/Kgs, Pulling Speed & String Length Functions

3. String Reel Holder

4. Electronic String Length Meter

5. 2-Point Self-Centering Mounting System (4 point support)

6. Quick Action Swivel, String Clamps w/ Diamond Coating

7. Convenient Foot Actuated Tensioner Switch

8. Fiberglass Cover w/ Integrated Tool Trays (70 sq. in. of storage area)

9. Height Adjustable from 39” to 46” (can also be used on table top)

10. 110 V / 220 V Compatibility

9

5

10

8

7

4

2

1

6

3

3

6500 Els

UNPACKING INSTRUCTIONS & CONTENTS

Instructions for Unpacking and Preparing for Assembly

The 6500 Els is shipped in three cartons, a large carton for the stringing machine and

accessories, a medium carton with the turntable and mounting system and a smaller

carton for the post and base legs. Please save the cartons and packing materials

for possible shipments in the future. Gamma Sports cannot be responsible for

machines that are not returned, in their original, undamaged packaging. The tools you will

need to assemble the 6500 Els are provided with the machine. Due to the weight of the

tensioner unit, you may need the assistance of someone to help lift the tensioner unit out

of the carton.

Once the cartons are opened, remove all inner cartons and check to be sure that all parts

are present and accounted for.

Contents of Base & Leg Carton

(1) Lower Post

(1) Upper Post with Flange Plate

(4) Legs

(1) Locking Knob Screw

(4) M8 x 25 Flat Head Screws

(4) M8 x 30 Cap Screws

(1) String Reel Holder (M8 Threaded Pin), (1) Knob, (10) Spacers, & (2) M8 Washers

(1) Box Wrenches – 6 & 12 mm

Contents of Turntable & Mounting System Carton

(1) Turntable

(2) Mounting Stands w/ Frame Hold Downs

(2) S tring Clamp Heads

Contents of Large Master Carton (including accessory cartons packed inside)

(1) Stringer Assembly Unit w/ Tensioner Module

(1) Power Cord w/ Ground Pin

(4) Rubber Feet w/ Screws

(1) Foot Pedal Tensioner Switch

(1) Face Plate for String Length Meter & (2) Spare String Length Meter Clamp Pads

(1) Tool Kit (contains side cutter, bent nose pliers, needle nose pliers)

(1) Straight Stringers Awl & (1) Pathfinder Specialty Awl

(1) St arting Clamp

(2) Composite Badminton Floating Clamps

(1) 9 pc L-Hex Wrench Set

(1) 17mm socket

(1) Gripper/Clamp Cleaning Stone

4

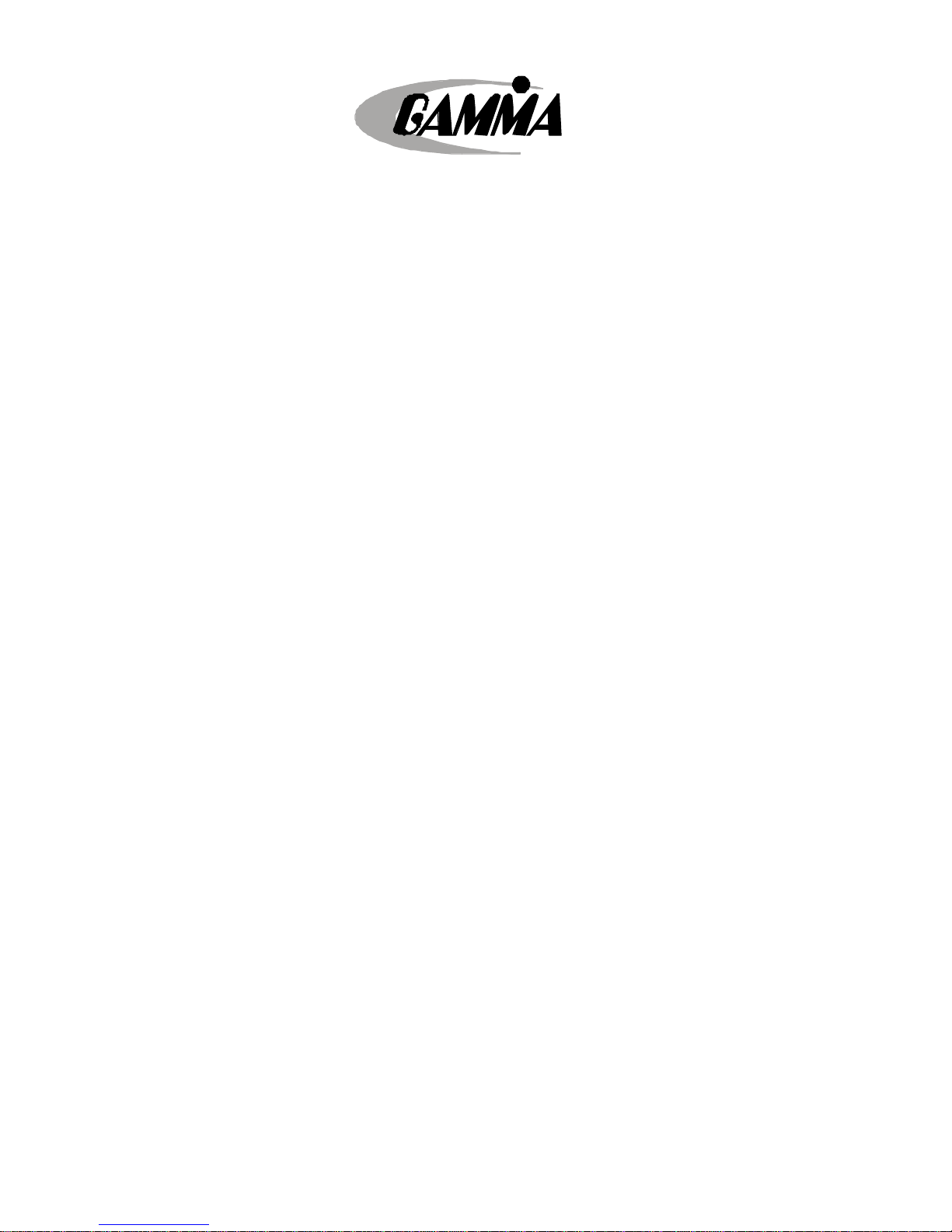

Base Leg Assembly

The stringing machine uses a four leg base

design. The legs must be assembled to the

support post before use. Remove the lower

column support, the upper column support,

four (4) legs, four (4) socket head cap screws

and four (4) flat head cap screws from the

small shipping carton.

Base Leg Assembly (Cont.)

Align the holes in the leg flange with the

matching holes in the lower column support

post. Secure the leg with one FLAT HEAD

cap screw through the upper hole, and one

SOCKET HEAD cap screw through the bottom hole. Repeat this procedure for the three

remaining legs.

ASSEMBLY INSTRUCTIONS

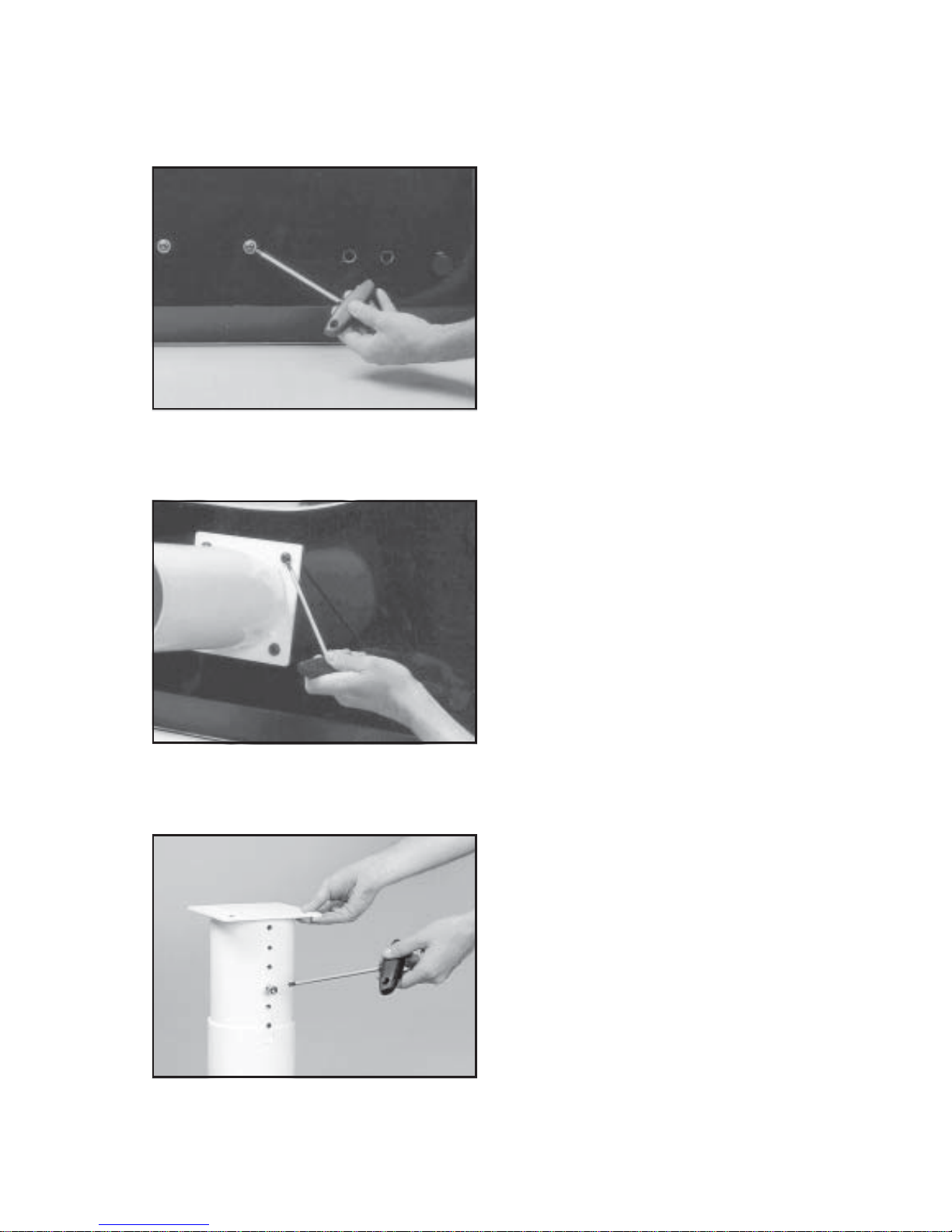

Base Leg Assembly (Cont.)

To complete the base stand, screw the height adjustment locking knob (“A”) into the side of the support

column. The locking knob should not protrude beyond

the inside of the support column at this time.

“A”

5

Stand Upper Post Installation

Remove the four (4) button head cap screws

from the base of the assembly.

ASSEMBLY INSTRUCTIONS

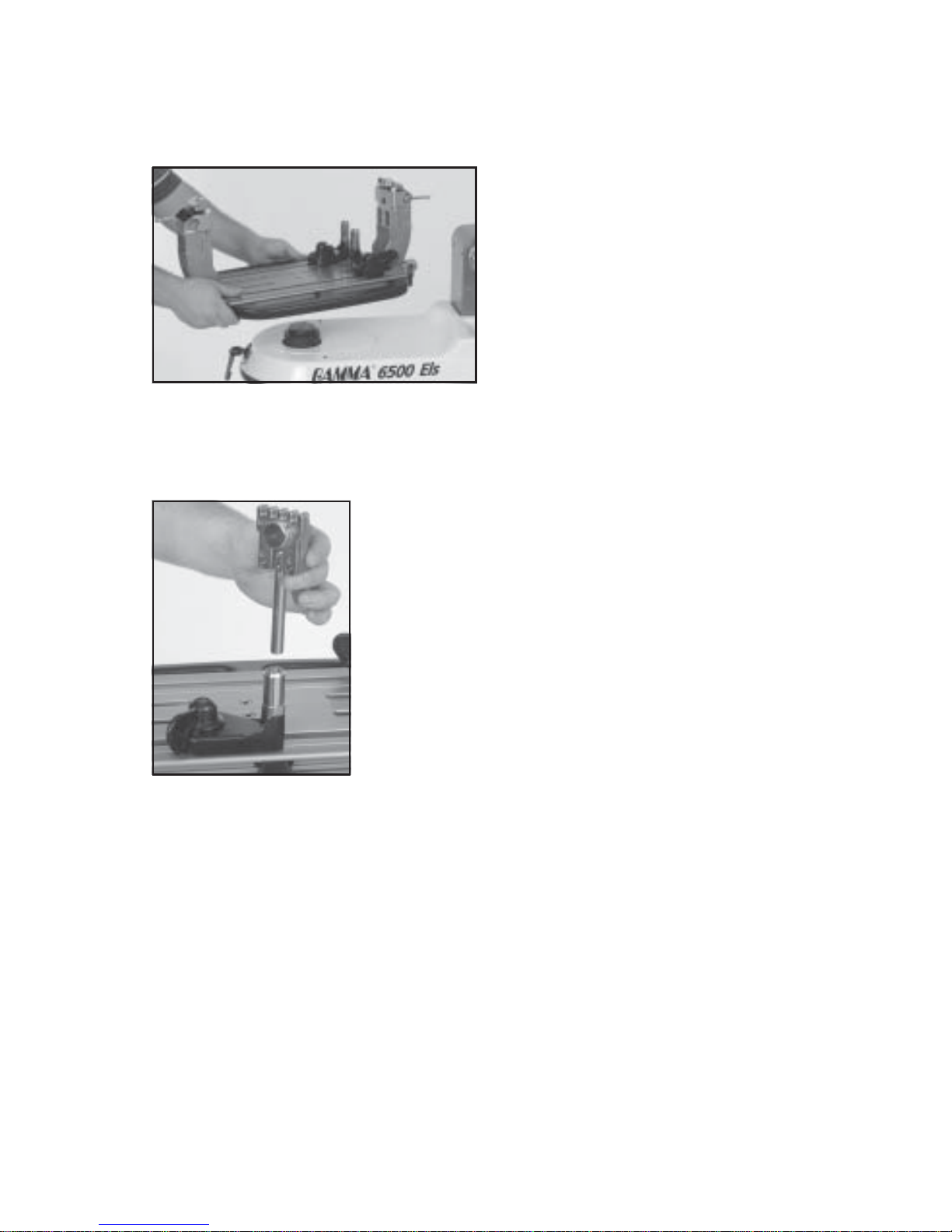

Stand Upper Post Installation (cont.)

With the height adjustment cap screw on the

upper post facing the left side of the tensioner,

align the four (4) holes in the upper post

flange with the holes in the tensioner base.

Secure the flange to the base with the four

cap screws.

Height Adjustment

The height of the machine is adjustable from

39” to 46”. To change the height, remove the

socket head cap screw from its current position and place it in the appropriate hole to set

the desired height of the machine.

6

Clamp Head Installation

The post of the string clamp head and the tube of the string

clamp base are treated with grease to provide protection

against corrosion during shipping. Remove any excessive

grease with a clean cloth prior to use. The post and tube may

also be cleaned with isopropyl alcohol. After this type of

thorough cleaning, the post and tube should be treated with a

light coating of machine oil to protect the surfaces against

corrosion and to ensure smooth operation.

Installing the Turntable

Remove the nuts from underneath of the

turntable and leave the screws in position.

Align the four (4) holes in the center of the

turntable with the four (4) holes on the

turntable pin. Tighten them securely with the

6mm allen wrench.

ASSEMBLY INSTRUCTIONS

Loading...

Loading...